NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 381 of 1767

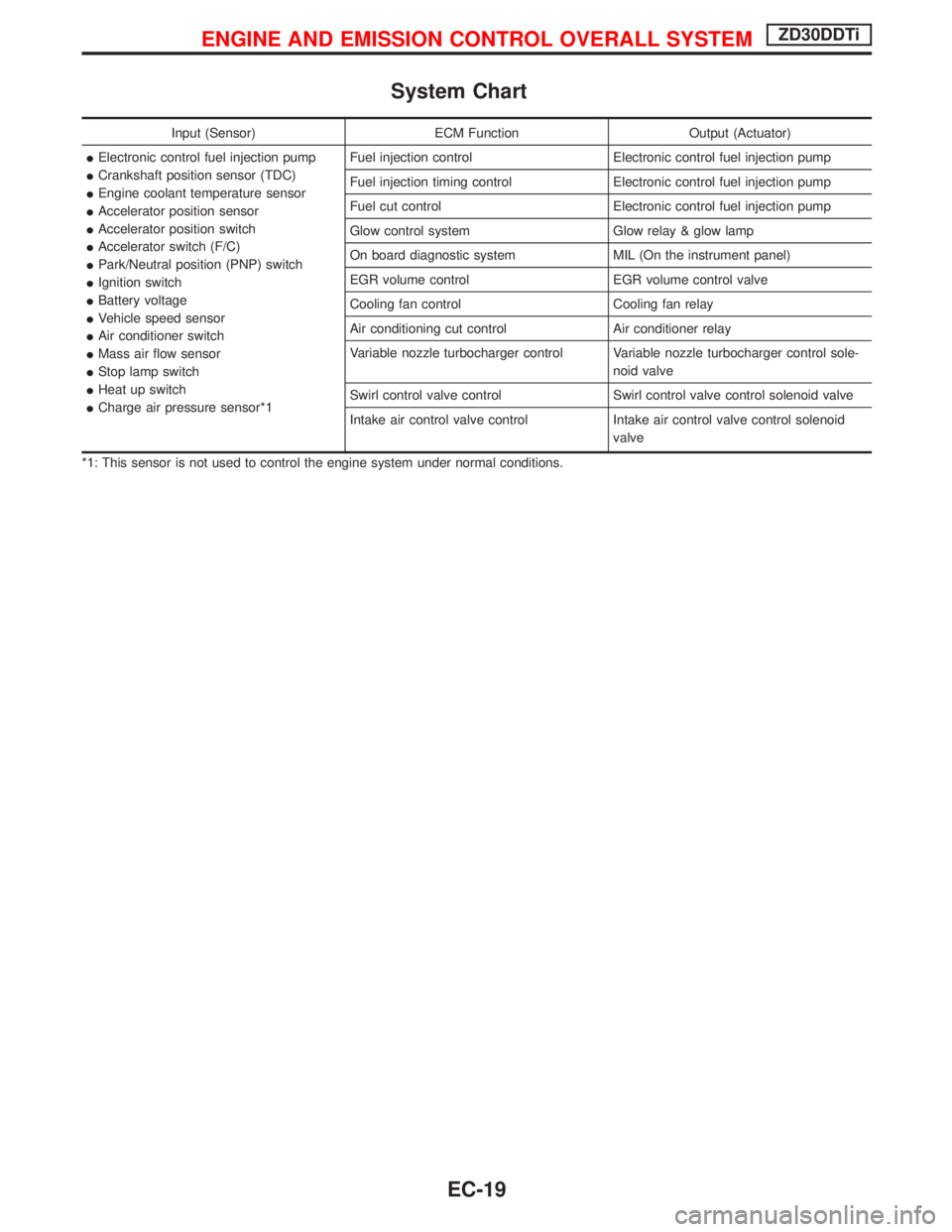

System Chart

Input (Sensor) ECM Function Output (Actuator)

IElectronic control fuel injection pump

ICrankshaft position sensor (TDC)

IEngine coolant temperature sensor

IAccelerator position sensor

IAccelerator position switch

IAccelerator switch (F/C)

IPark/Neutral position (PNP) switch

IIgnition switch

IBattery voltage

IVehicle speed sensor

IAir conditioner switch

IMass air flow sensor

IStop lamp switch

IHeat up switch

ICharge air pressure sensor*1Fuel injection control Electronic control fuel injection pump

Fuel injection timing control Electronic control fuel injection pump

Fuel cut control Electronic control fuel injection pump

Glow control system Glow relay & glow lamp

On board diagnostic system MIL (On the instrument panel)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Variable nozzle turbocharger control Variable nozzle turbocharger control sole-

noid valve

Swirl control valve control Swirl control valve control solenoid valve

Intake air control valve control Intake air control valve control solenoid

valve

*1: This sensor is not used to control the engine system under normal conditions.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-19

Page 382 of 1767

Fuel Injection Control System

DESCRIPTION

System description

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is compensated to improve engine performance.

Pulse signals are exchanged between ECM and electronic control fuel injection pump (control unit is built-in).

The fuel injection pump control unit performs duty control on the spill valve (built into the fuel injection pump)

according to the input signals to compensate the amount of fuel injected to the preset value.

Start control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (start control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Ignition switch Start signal

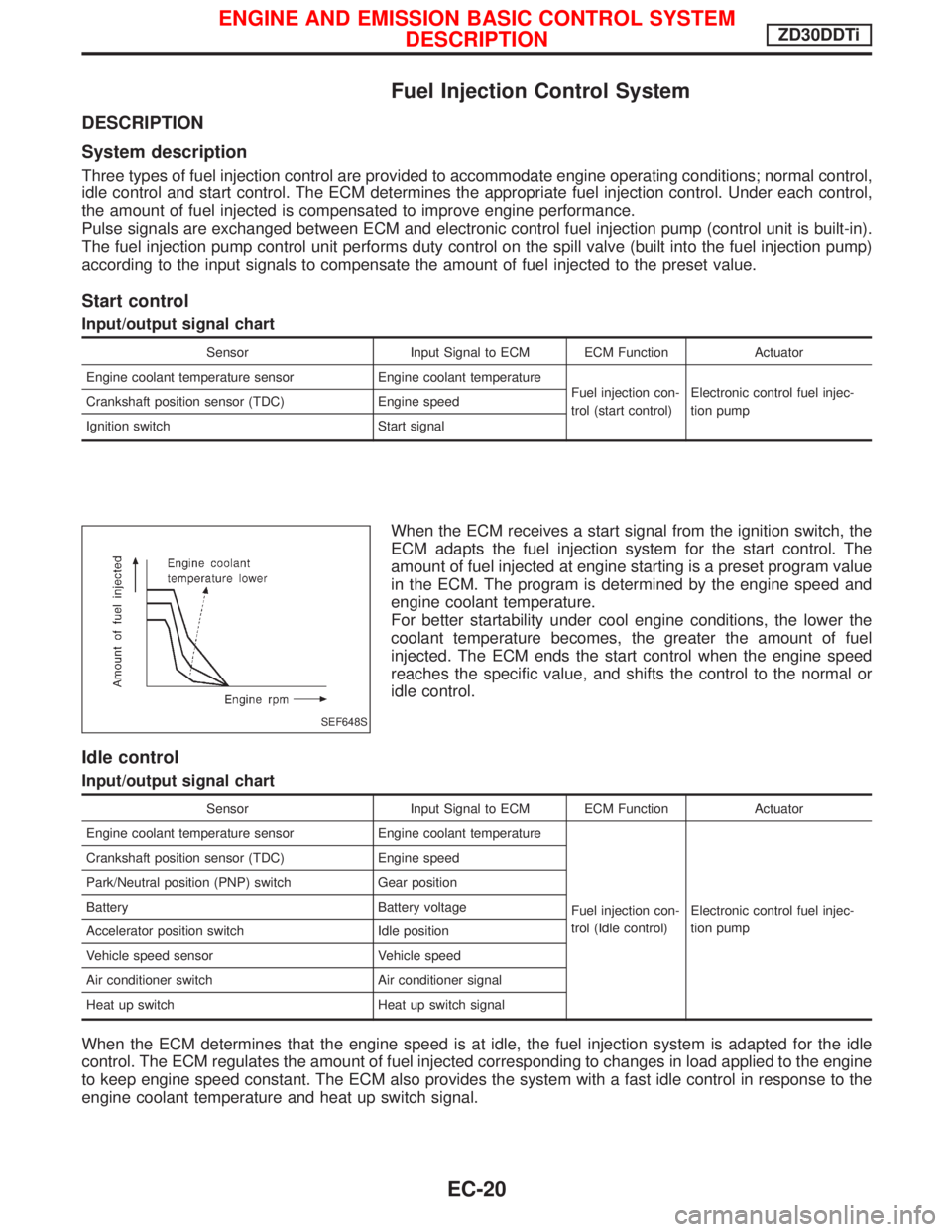

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed and

engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal or

idle control.

Idle control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (Idle control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Park/Neutral position (PNP) switch Gear position

Battery Battery voltage

Accelerator position switch Idle position

Vehicle speed sensor Vehicle speed

Air conditioner switch Air conditioner signal

Heat up switch Heat up switch signal

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the engine

to keep engine speed constant. The ECM also provides the system with a fast idle control in response to the

engine coolant temperature and heat up switch signal.

SEF648S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-20

Page 383 of 1767

Normal control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (TDC) Engine speed

Fuel injection con-

trol (Normal con-

trol)Electronic control fuel injec-

tion pump Accelerator position sensor Accelerator position

Vehicle speed sensor Vehicle speed

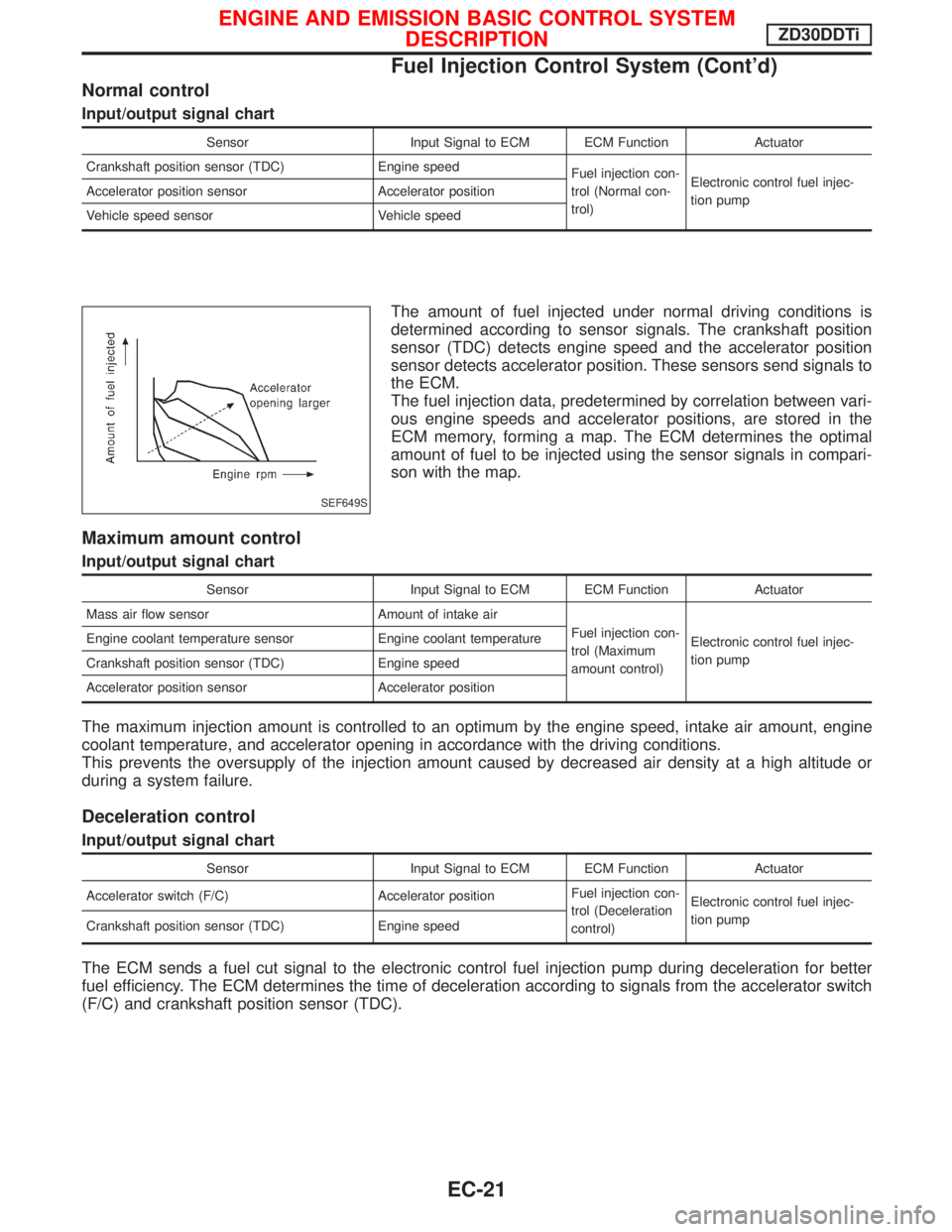

The amount of fuel injected under normal driving conditions is

determined according to sensor signals. The crankshaft position

sensor (TDC) detects engine speed and the accelerator position

sensor detects accelerator position. These sensors send signals to

the ECM.

The fuel injection data, predetermined by correlation between vari-

ous engine speeds and accelerator positions, are stored in the

ECM memory, forming a map. The ECM determines the optimal

amount of fuel to be injected using the sensor signals in compari-

son with the map.

Maximum amount control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Mass air flow sensor Amount of intake air

Fuel injection con-

trol (Maximum

amount control)Electronic control fuel injec-

tion pump Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

Accelerator position sensor Accelerator position

The maximum injection amount is controlled to an optimum by the engine speed, intake air amount, engine

coolant temperature, and accelerator opening in accordance with the driving conditions.

This prevents the oversupply of the injection amount caused by decreased air density at a high altitude or

during a system failure.

Deceleration control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Accelerator switch (F/C) Accelerator positionFuel injection con-

trol (Deceleration

control)Electronic control fuel injec-

tion pump

Crankshaft position sensor (TDC) Engine speed

The ECM sends a fuel cut signal to the electronic control fuel injection pump during deceleration for better

fuel efficiency. The ECM determines the time of deceleration according to signals from the accelerator switch

(F/C) and crankshaft position sensor (TDC).

SEF649S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

Fuel Injection Control System (Cont'd)

EC-21

Page 384 of 1767

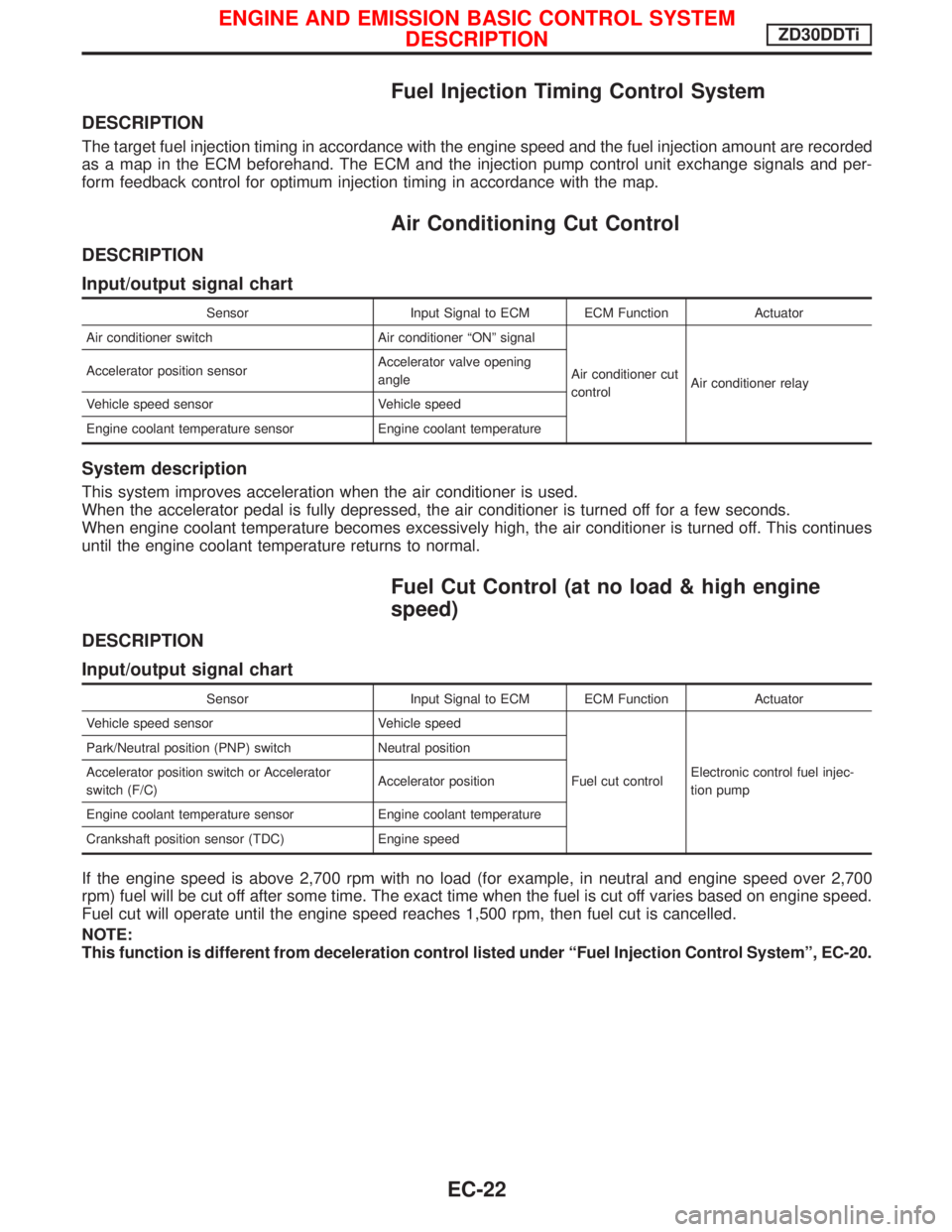

Fuel Injection Timing Control System

DESCRIPTION

The target fuel injection timing in accordance with the engine speed and the fuel injection amount are recorded

as a map in the ECM beforehand. The ECM and the injection pump control unit exchange signals and per-

form feedback control for optimum injection timing in accordance with the map.

Air Conditioning Cut Control

DESCRIPTION

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Air conditioner switch Air conditioner ªONº signal

Air conditioner cut

controlAir conditioner relay Accelerator position sensorAccelerator valve opening

angle

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

System description

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds.

When engine coolant temperature becomes excessively high, the air conditioner is turned off. This continues

until the engine coolant temperature returns to normal.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTION

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Vehicle speed sensor Vehicle speed

Fuel cut controlElectronic control fuel injec-

tion pump Park/Neutral position (PNP) switch Neutral position

Accelerator position switch or Accelerator

switch (F/C)Accelerator position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

If the engine speed is above 2,700 rpm with no load (for example, in neutral and engine speed over 2,700

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªFuel Injection Control Systemº, EC-20.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-22

Page 385 of 1767

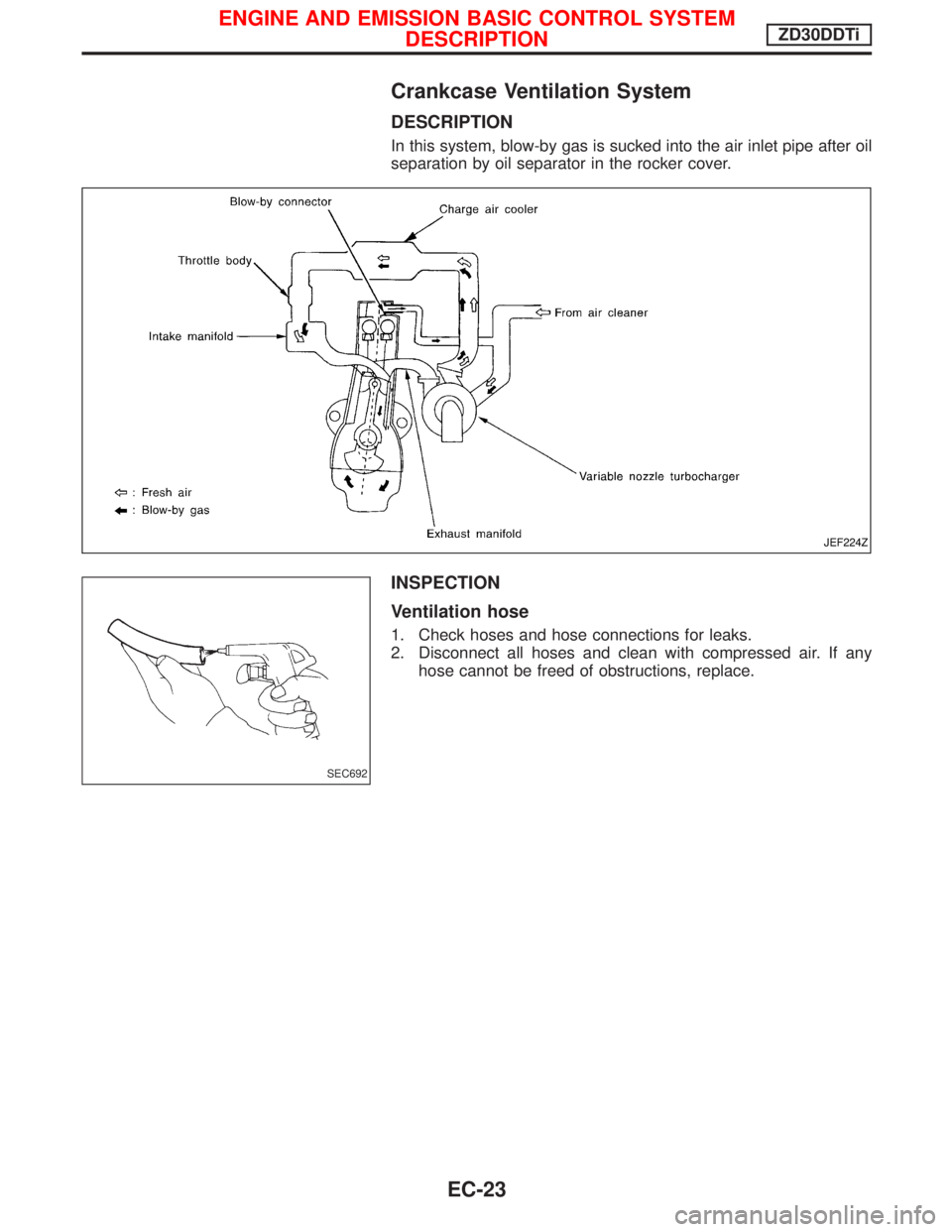

Crankcase Ventilation System

DESCRIPTION

In this system, blow-by gas is sucked into the air inlet pipe after oil

separation by oil separator in the rocker cover.

INSPECTION

Ventilation hose

1. Check hoses and hose connections for leaks.

2. Disconnect all hoses and clean with compressed air. If any

hose cannot be freed of obstructions, replace.

JEF224Z

SEC692

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-23

Page 386 of 1767

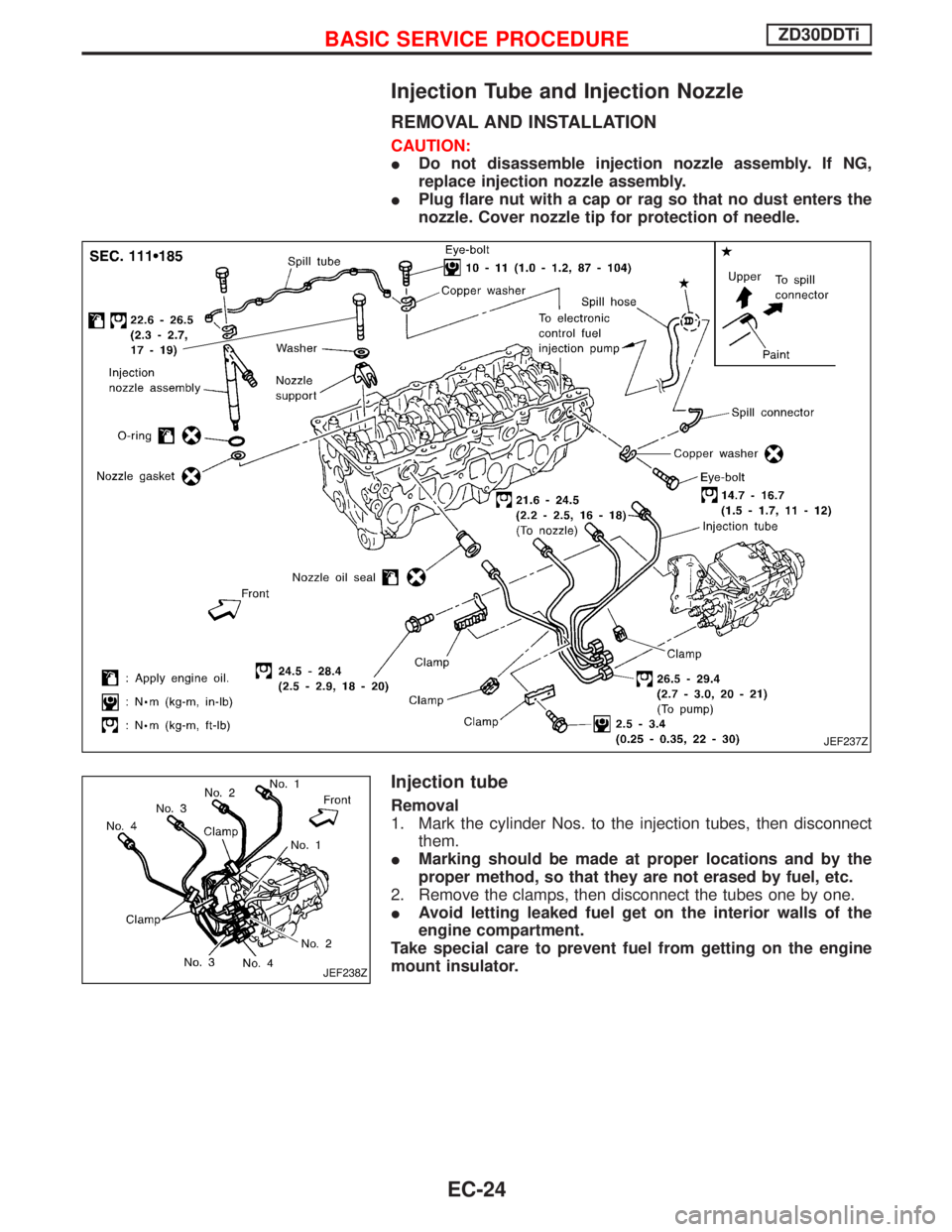

Injection Tube and Injection Nozzle

REMOVAL AND INSTALLATION

CAUTION:

IDo not disassemble injection nozzle assembly. If NG,

replace injection nozzle assembly.

IPlug flare nut with a cap or rag so that no dust enters the

nozzle. Cover nozzle tip for protection of needle.

Injection tube

Removal

1. Mark the cylinder Nos. to the injection tubes, then disconnect

them.

IMarking should be made at proper locations and by the

proper method, so that they are not erased by fuel, etc.

2. Remove the clamps, then disconnect the tubes one by one.

IAvoid letting leaked fuel get on the interior walls of the

engine compartment.

Take special care to prevent fuel from getting on the engine

mount insulator.

JEF237Z

JEF238Z

BASIC SERVICE PROCEDUREZD30DDTi

EC-24

Page 387 of 1767

Installation

IInstall the injection tubes, referring to the markings made dur-

ing removal.

IInstall the injection tubes in the order of No. 3, No. 4, No. 1, and

No. 2.

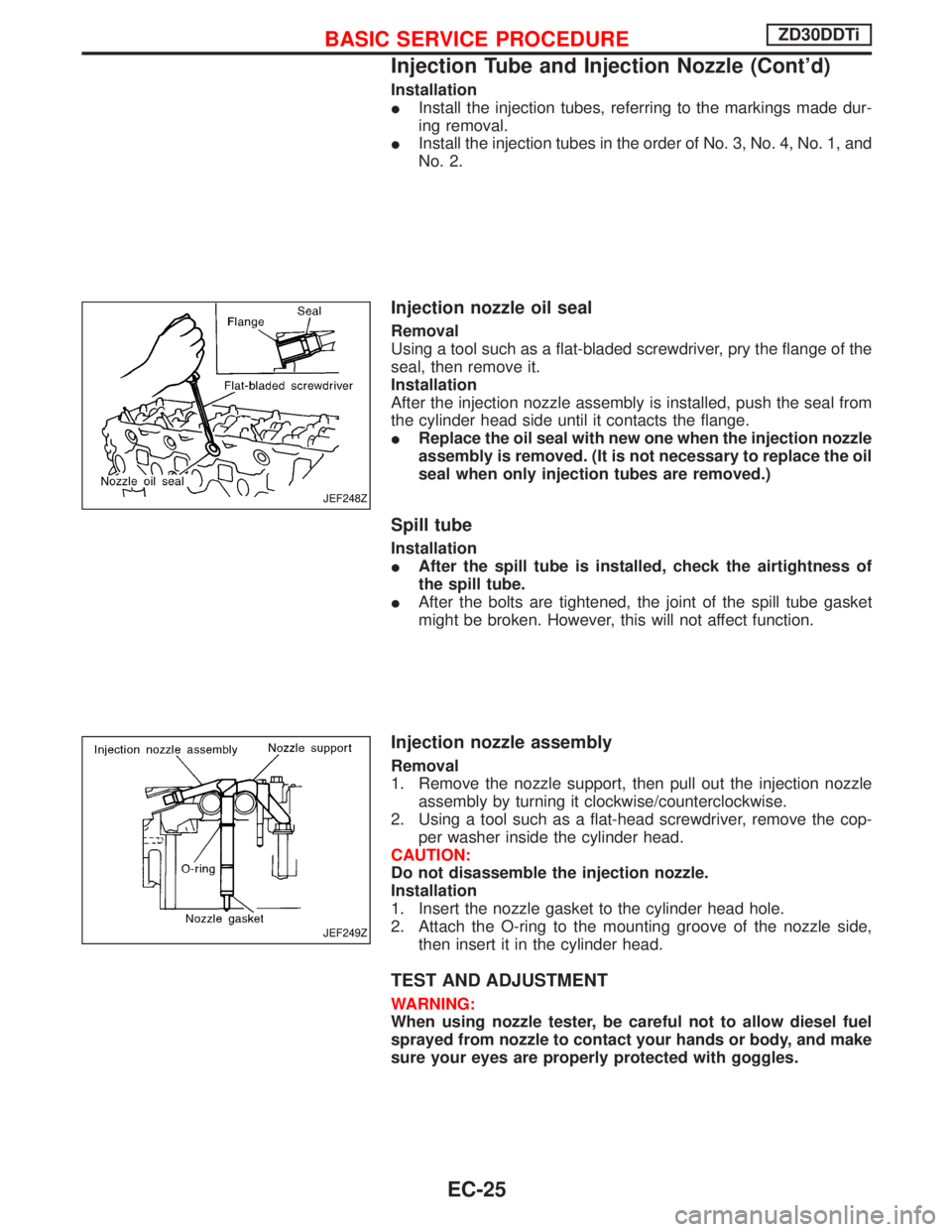

Injection nozzle oil seal

Removal

Using a tool such as a flat-bladed screwdriver, pry the flange of the

seal, then remove it.

Installation

After the injection nozzle assembly is installed, push the seal from

the cylinder head side until it contacts the flange.

IReplace the oil seal with new one when the injection nozzle

assembly is removed. (It is not necessary to replace the oil

seal when only injection tubes are removed.)

Spill tube

Installation

IAfter the spill tube is installed, check the airtightness of

the spill tube.

IAfter the bolts are tightened, the joint of the spill tube gasket

might be broken. However, this will not affect function.

Injection nozzle assembly

Removal

1. Remove the nozzle support, then pull out the injection nozzle

assembly by turning it clockwise/counterclockwise.

2. Using a tool such as a flat-head screwdriver, remove the cop-

per washer inside the cylinder head.

CAUTION:

Do not disassemble the injection nozzle.

Installation

1. Insert the nozzle gasket to the cylinder head hole.

2. Attach the O-ring to the mounting groove of the nozzle side,

then insert it in the cylinder head.

TEST AND ADJUSTMENT

WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to contact your hands or body, and make

sure your eyes are properly protected with goggles.

JEF248Z

JEF249Z

BASIC SERVICE PROCEDUREZD30DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-25

Page 388 of 1767

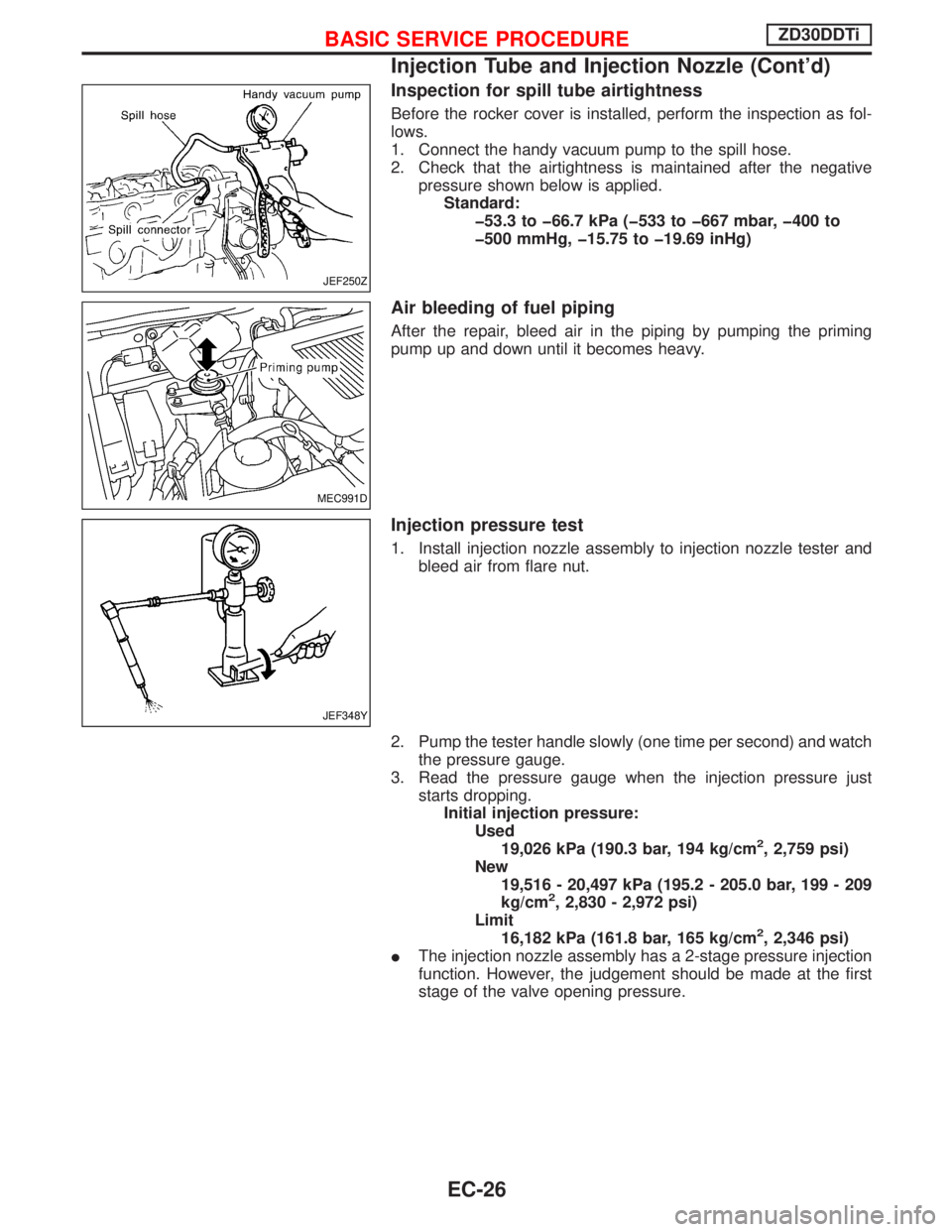

Inspection for spill tube airtightness

Before the rocker cover is installed, perform the inspection as fol-

lows.

1. Connect the handy vacuum pump to the spill hose.

2. Check that the airtightness is maintained after the negative

pressure shown below is applied.

Standard:

þ53.3 to þ66.7 kPa (þ533 to þ667 mbar, þ400 to

þ500 mmHg, þ15.75 to þ19.69 inHg)

Air bleeding of fuel piping

After the repair, bleed air in the piping by pumping the priming

pump up and down until it becomes heavy.

Injection pressure test

1. Install injection nozzle assembly to injection nozzle tester and

bleed air from flare nut.

2. Pump the tester handle slowly (one time per second) and watch

the pressure gauge.

3. Read the pressure gauge when the injection pressure just

starts dropping.

Initial injection pressure:

Used

19,026 kPa (190.3 bar, 194 kg/cm

2, 2,759 psi)

New

19,516 - 20,497 kPa (195.2 - 205.0 bar, 199 - 209

kg/cm

2, 2,830 - 2,972 psi)

Limit

16,182 kPa (161.8 bar, 165 kg/cm

2, 2,346 psi)

IThe injection nozzle assembly has a 2-stage pressure injection

function. However, the judgement should be made at the first

stage of the valve opening pressure.

JEF250Z

MEC991D

JEF348Y

BASIC SERVICE PROCEDUREZD30DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-26

Page 389 of 1767

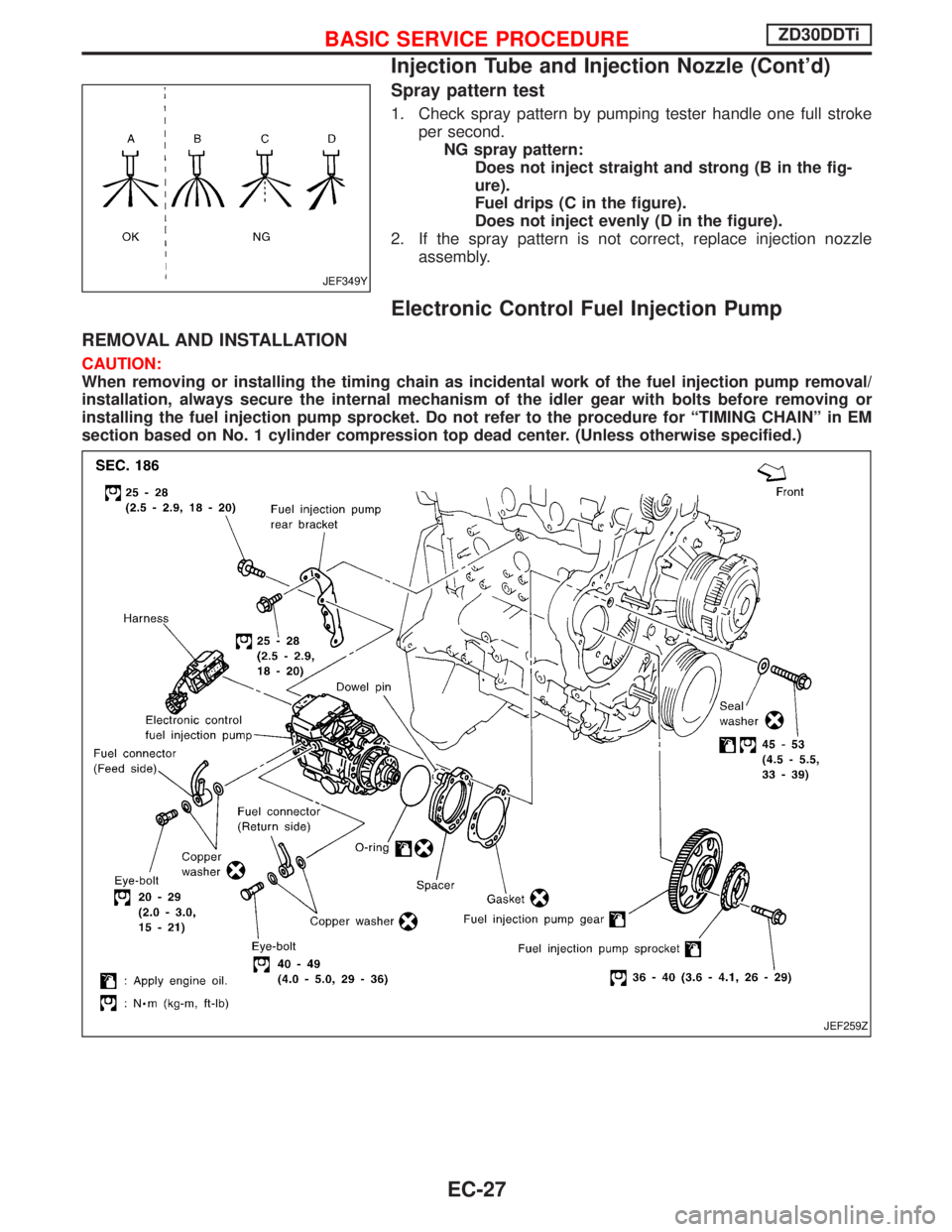

Spray pattern test

1. Check spray pattern by pumping tester handle one full stroke

per second.

NG spray pattern:

Does not inject straight and strong (B in the fig-

ure).

Fuel drips (C in the figure).

Does not inject evenly (D in the figure).

2. If the spray pattern is not correct, replace injection nozzle

assembly.

Electronic Control Fuel Injection Pump

REMOVAL AND INSTALLATION

CAUTION:

When removing or installing the timing chain as incidental work of the fuel injection pump removal/

installation, always secure the internal mechanism of the idler gear with bolts before removing or

installing the fuel injection pump sprocket. Do not refer to the procedure for ªTIMING CHAINº in EM

section based on No. 1 cylinder compression top dead center. (Unless otherwise specified.)

JEF349Y

JEF259Z

BASIC SERVICE PROCEDUREZD30DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-27

Page 390 of 1767

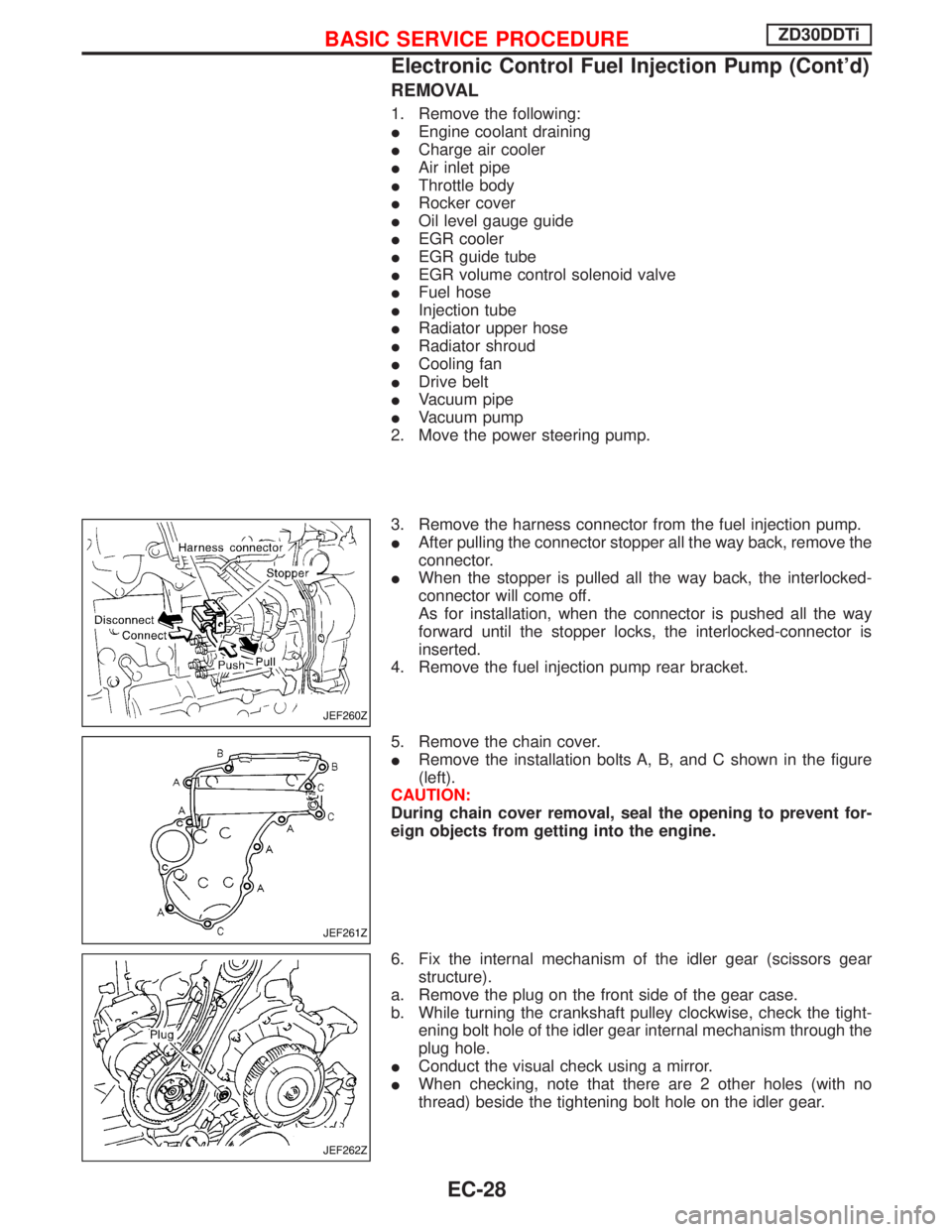

REMOVAL

1. Remove the following:

IEngine coolant draining

ICharge air cooler

IAir inlet pipe

IThrottle body

IRocker cover

IOil level gauge guide

IEGR cooler

IEGR guide tube

IEGR volume control solenoid valve

IFuel hose

IInjection tube

IRadiator upper hose

IRadiator shroud

ICooling fan

IDrive belt

IVacuum pipe

IVacuum pump

2. Move the power steering pump.

3. Remove the harness connector from the fuel injection pump.

IAfter pulling the connector stopper all the way back, remove the

connector.

IWhen the stopper is pulled all the way back, the interlocked-

connector will come off.

As for installation, when the connector is pushed all the way

forward until the stopper locks, the interlocked-connector is

inserted.

4. Remove the fuel injection pump rear bracket.

5. Remove the chain cover.

IRemove the installation bolts A, B, and C shown in the figure

(left).

CAUTION:

During chain cover removal, seal the opening to prevent for-

eign objects from getting into the engine.

6. Fix the internal mechanism of the idler gear (scissors gear

structure).

a. Remove the plug on the front side of the gear case.

b. While turning the crankshaft pulley clockwise, check the tight-

ening bolt hole of the idler gear internal mechanism through the

plug hole.

IConduct the visual check using a mirror.

IWhen checking, note that there are 2 other holes (with no

thread) beside the tightening bolt hole on the idler gear.

JEF260Z

JEF261Z

JEF262Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-28