NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: AUX, alternator replacement, heating, key battery, fuel consumption, coolant reservoir, automatic transmission

Page 371 of 1767

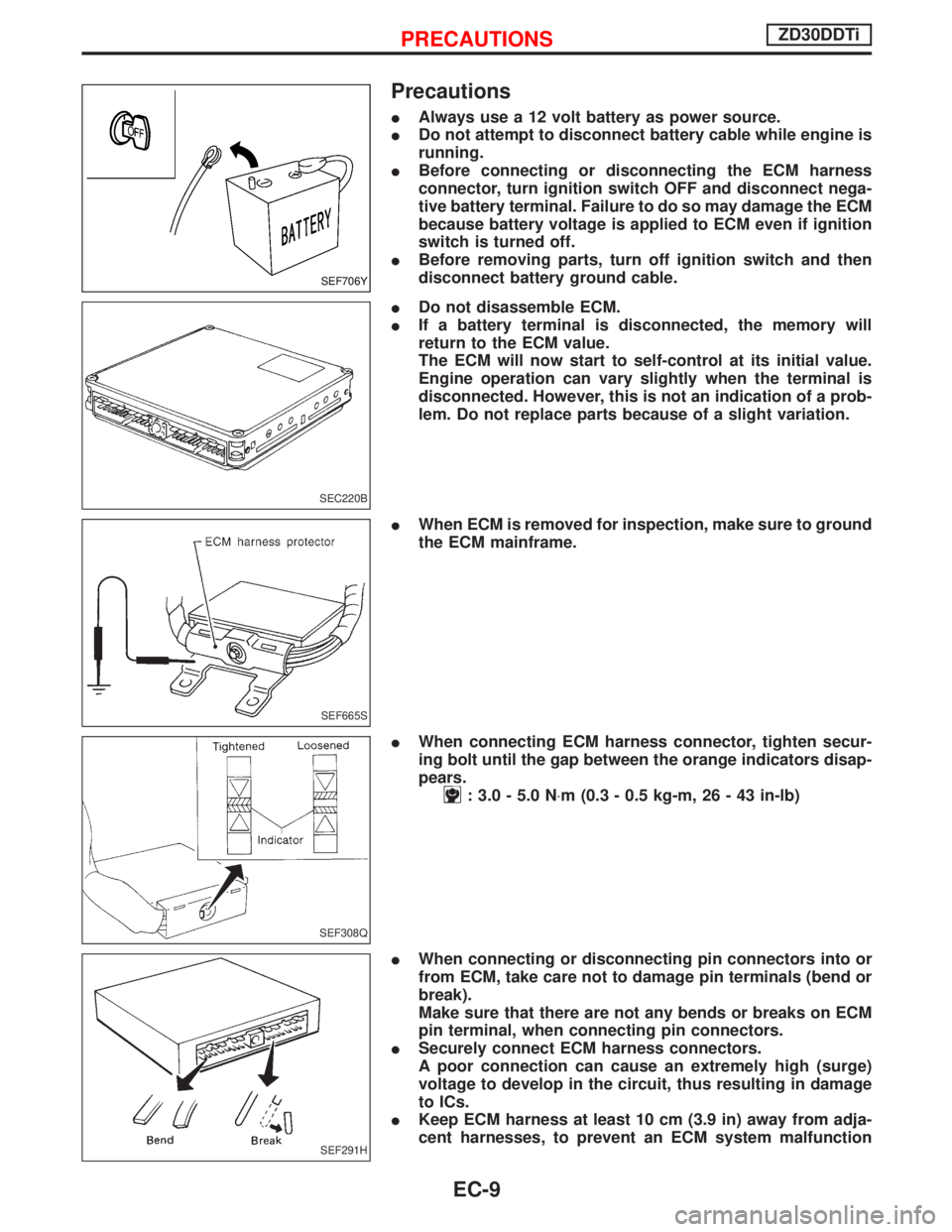

Precautions

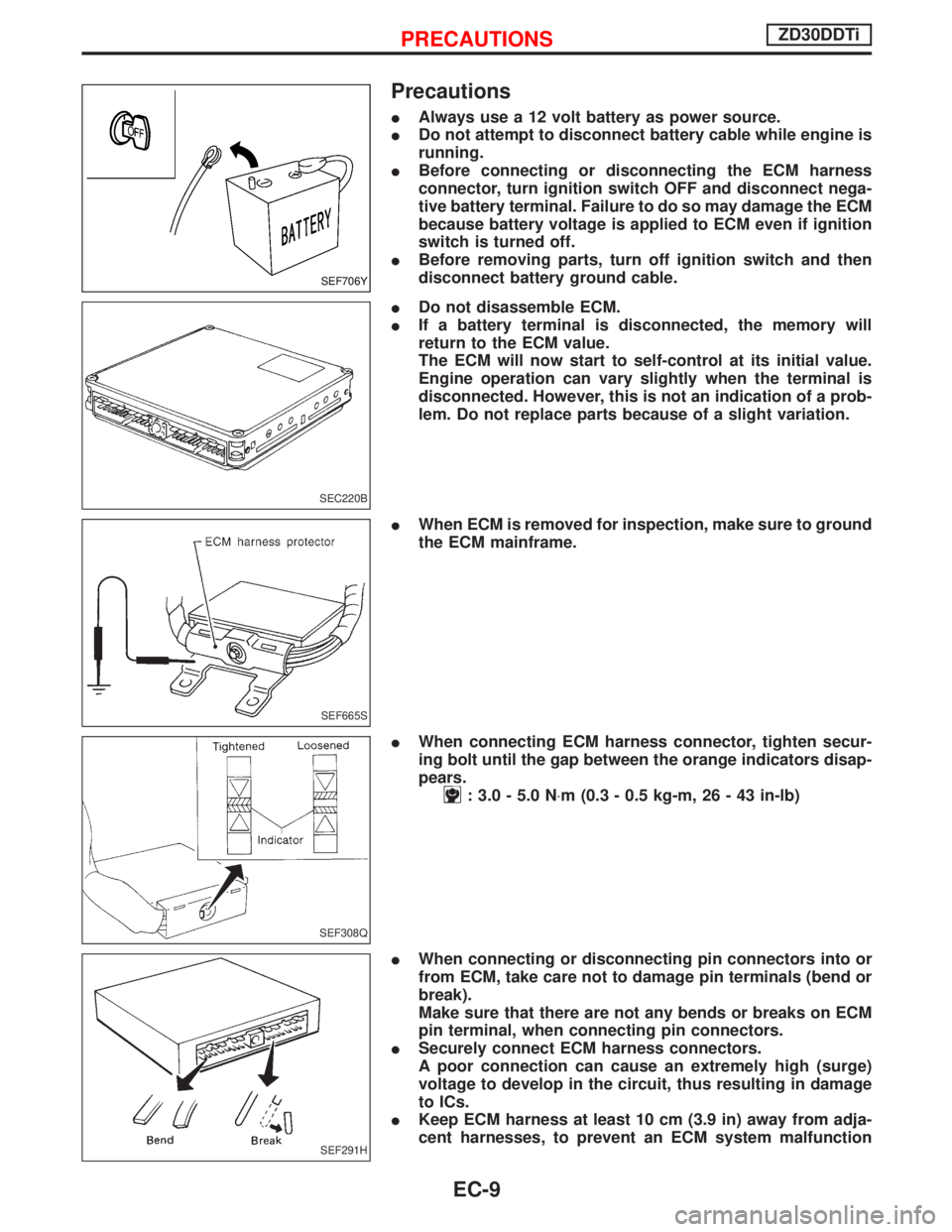

IAlways use a 12 volt battery as power source.

IDo not attempt to disconnect battery cable while engine is

running.

IBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

IBefore removing parts, turn off ignition switch and then

disconnect battery ground cable.

IDo not disassemble ECM.

IIf a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a prob-

lem. Do not replace parts because of a slight variation.

IWhen ECM is removed for inspection, make sure to ground

the ECM mainframe.

IWhen connecting ECM harness connector, tighten secur-

ing bolt until the gap between the orange indicators disap-

pears.

: 3.0 - 5.0 N×m (0.3 - 0.5 kg-m, 26 - 43 in-lb)

IWhen connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

ISecurely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in damage

to ICs.

IKeep ECM harness at least 10 cm (3.9 in) away from adja-

cent harnesses, to prevent an ECM system malfunction

SEF706Y

SEC220B

SEF665S

SEF308Q

SEF291H

PRECAUTIONSZD30DDTi

EC-9

Page 372 of 1767

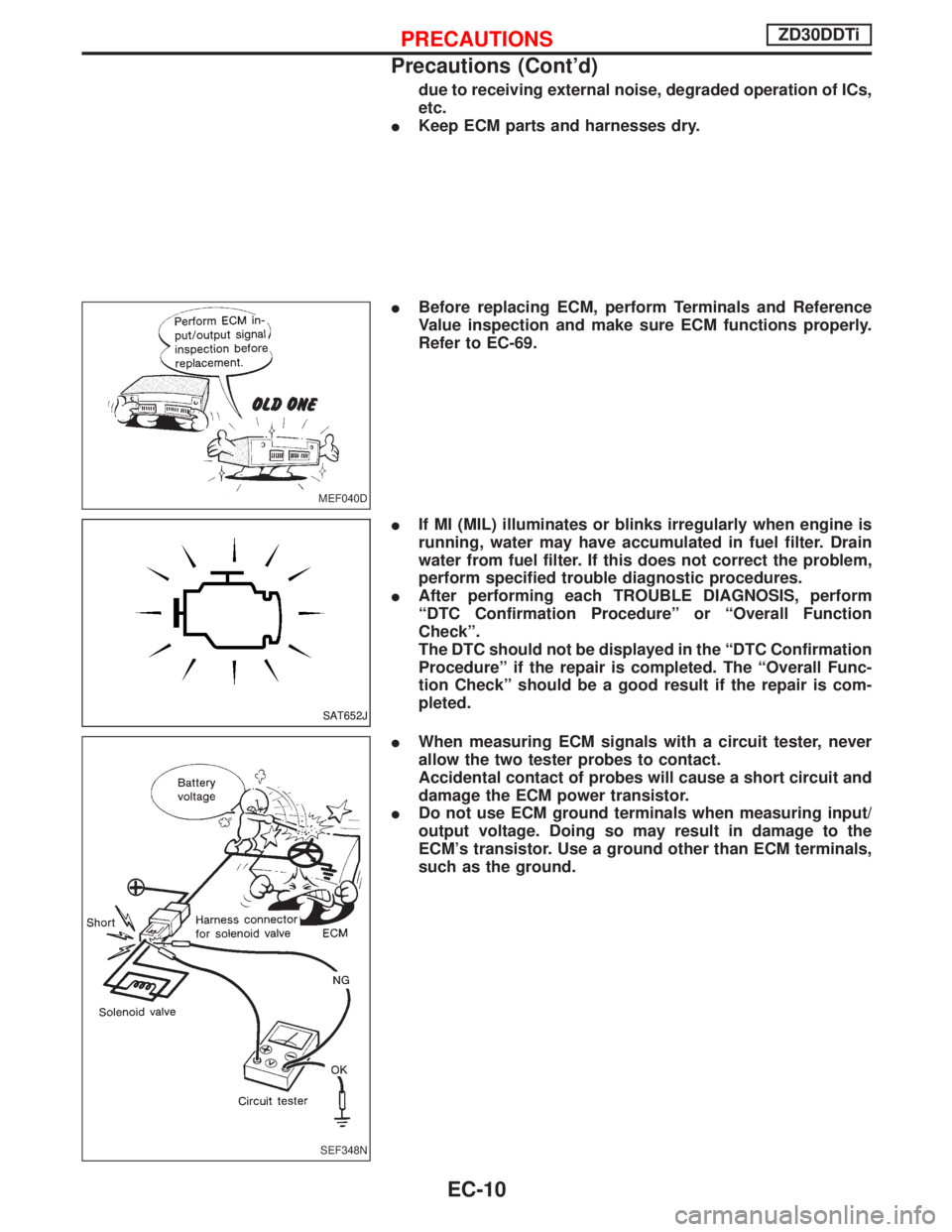

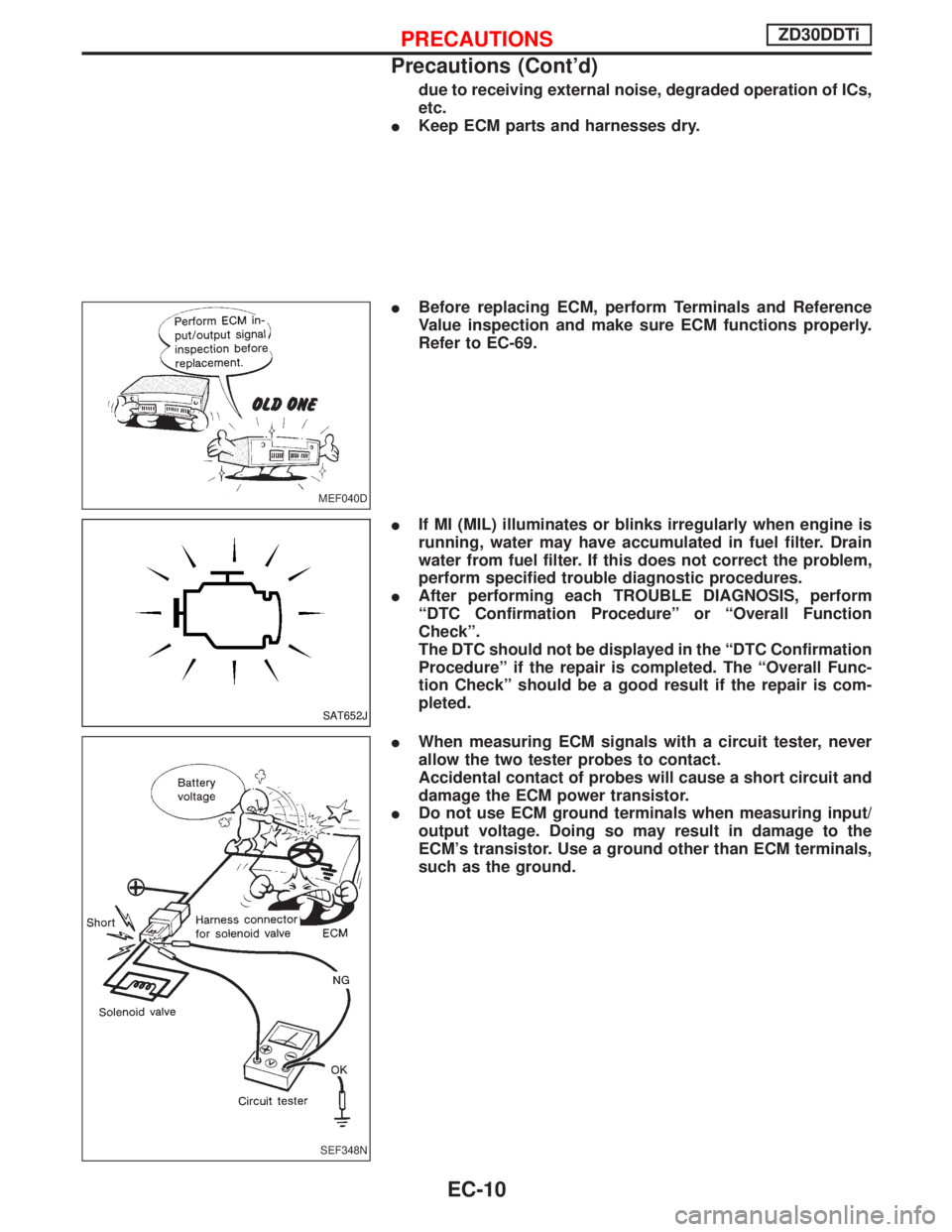

due to receiving external noise, degraded operation of ICs,

etc.

IKeep ECM parts and harnesses dry.

IBefore replacing ECM, perform Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-69.

IIf MI (MIL) illuminates or blinks irregularly when engine is

running, water may have accumulated in fuel filter. Drain

water from fuel filter. If this does not correct the problem,

perform specified trouble diagnostic procedures.

IAfter performing each TROUBLE DIAGNOSIS, perform

ªDTC Confirmation Procedureº or ªOverall Function

Checkº.

The DTC should not be displayed in the ªDTC Confirmation

Procedureº if the repair is completed. The ªOverall Func-

tion Checkº should be a good result if the repair is com-

pleted.

IWhen measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

IDo not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the

ECM's transistor. Use a ground other than ECM terminals,

such as the ground.

MEF040D

SAT652J

SEF348N

PRECAUTIONSZD30DDTi

Precautions (Cont'd)

EC-10

Page 373 of 1767

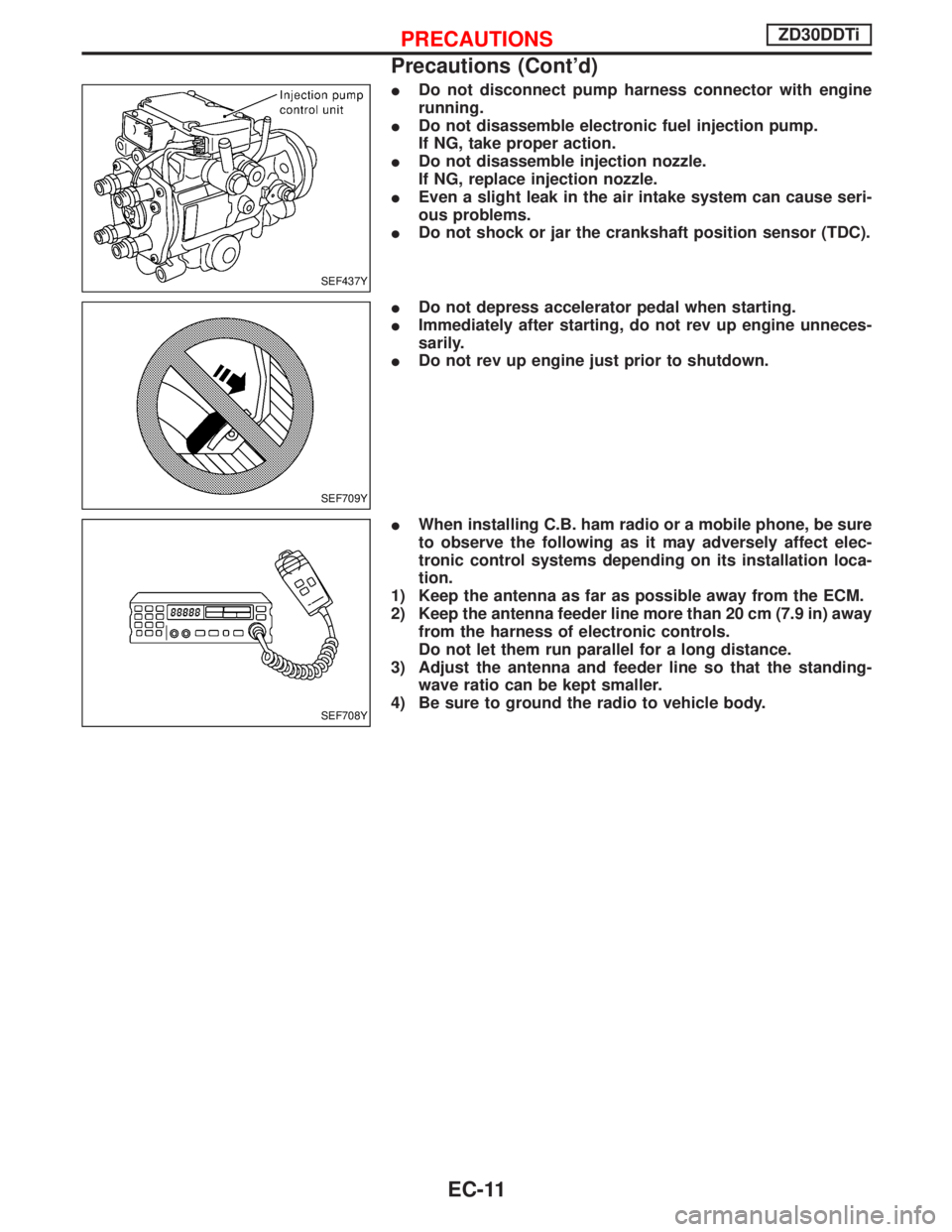

IDo not disconnect pump harness connector with engine

running.

IDo not disassemble electronic fuel injection pump.

If NG, take proper action.

IDo not disassemble injection nozzle.

If NG, replace injection nozzle.

IEven a slight leak in the air intake system can cause seri-

ous problems.

IDo not shock or jar the crankshaft position sensor (TDC).

IDo not depress accelerator pedal when starting.

IImmediately after starting, do not rev up engine unneces-

sarily.

IDo not rev up engine just prior to shutdown.

IWhen installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on its installation loca-

tion.

1) Keep the antenna as far as possible away from the ECM.

2) Keep the antenna feeder line more than 20 cm (7.9 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

3) Adjust the antenna and feeder line so that the standing-

wave ratio can be kept smaller.

4) Be sure to ground the radio to vehicle body.

SEF437Y

SEF709Y

SEF708Y

PRECAUTIONSZD30DDTi

Precautions (Cont'd)

EC-11

Page 374 of 1767

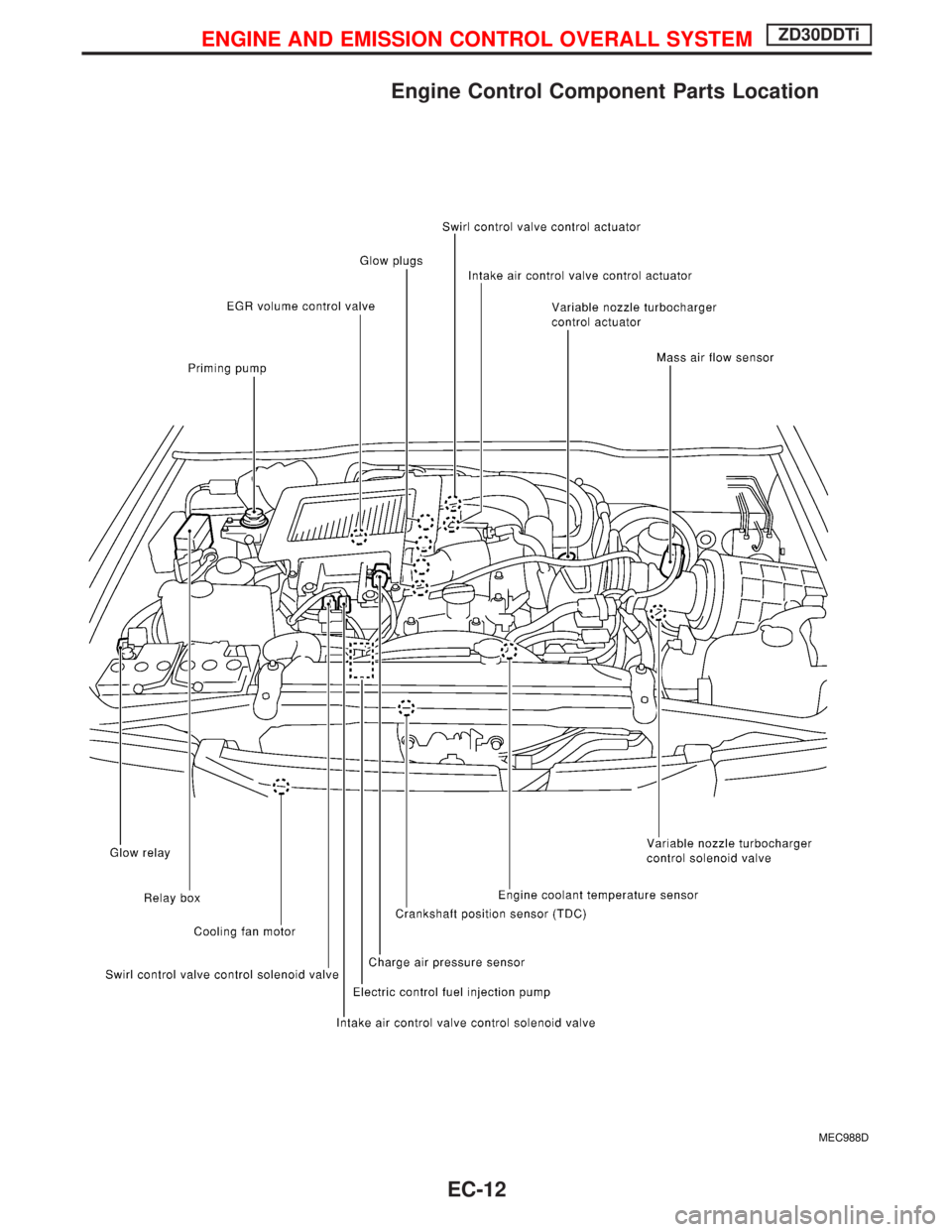

Engine Control Component Parts Location

MEC988D

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-12

Page 375 of 1767

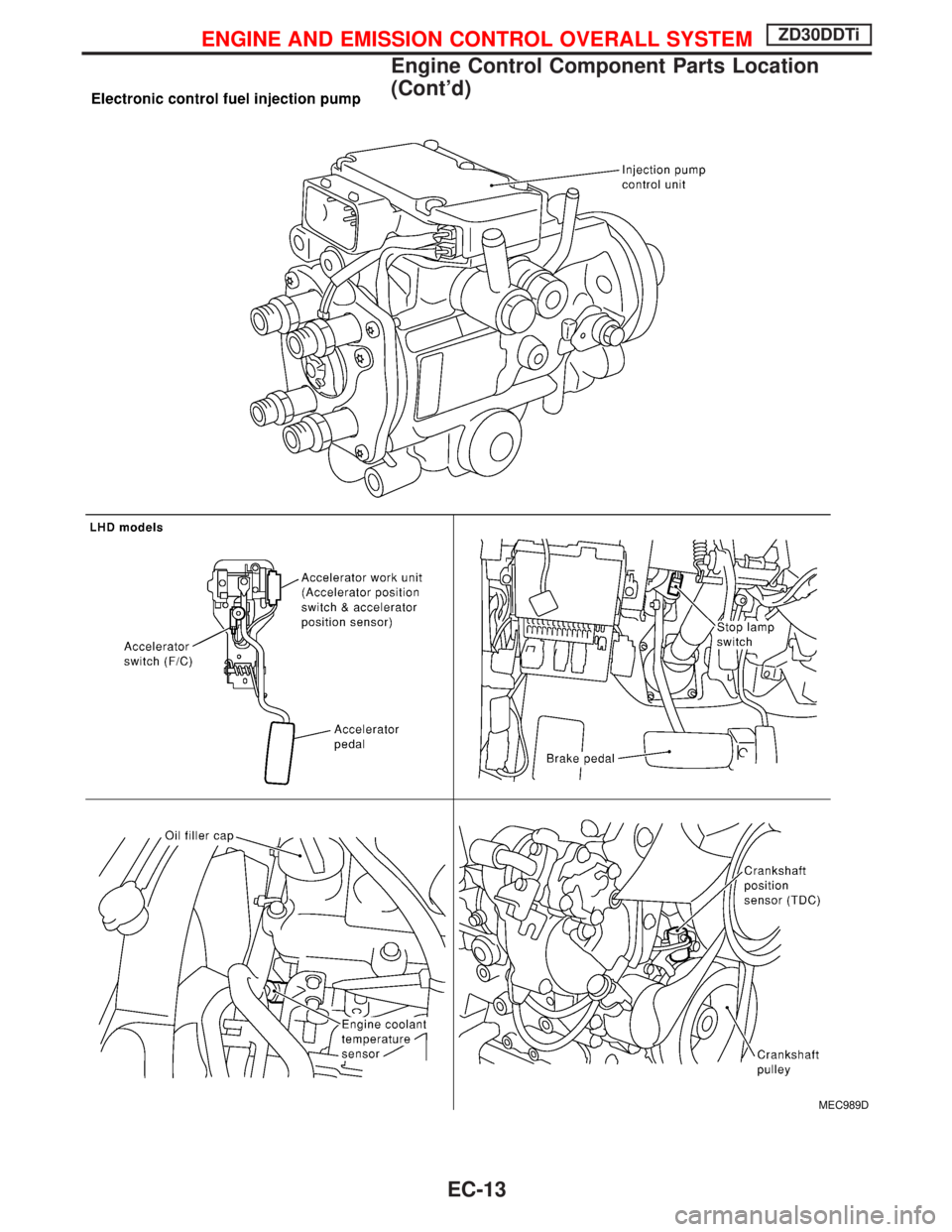

MEC989D

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

Engine Control Component Parts Location

(Cont'd)

EC-13

Page 376 of 1767

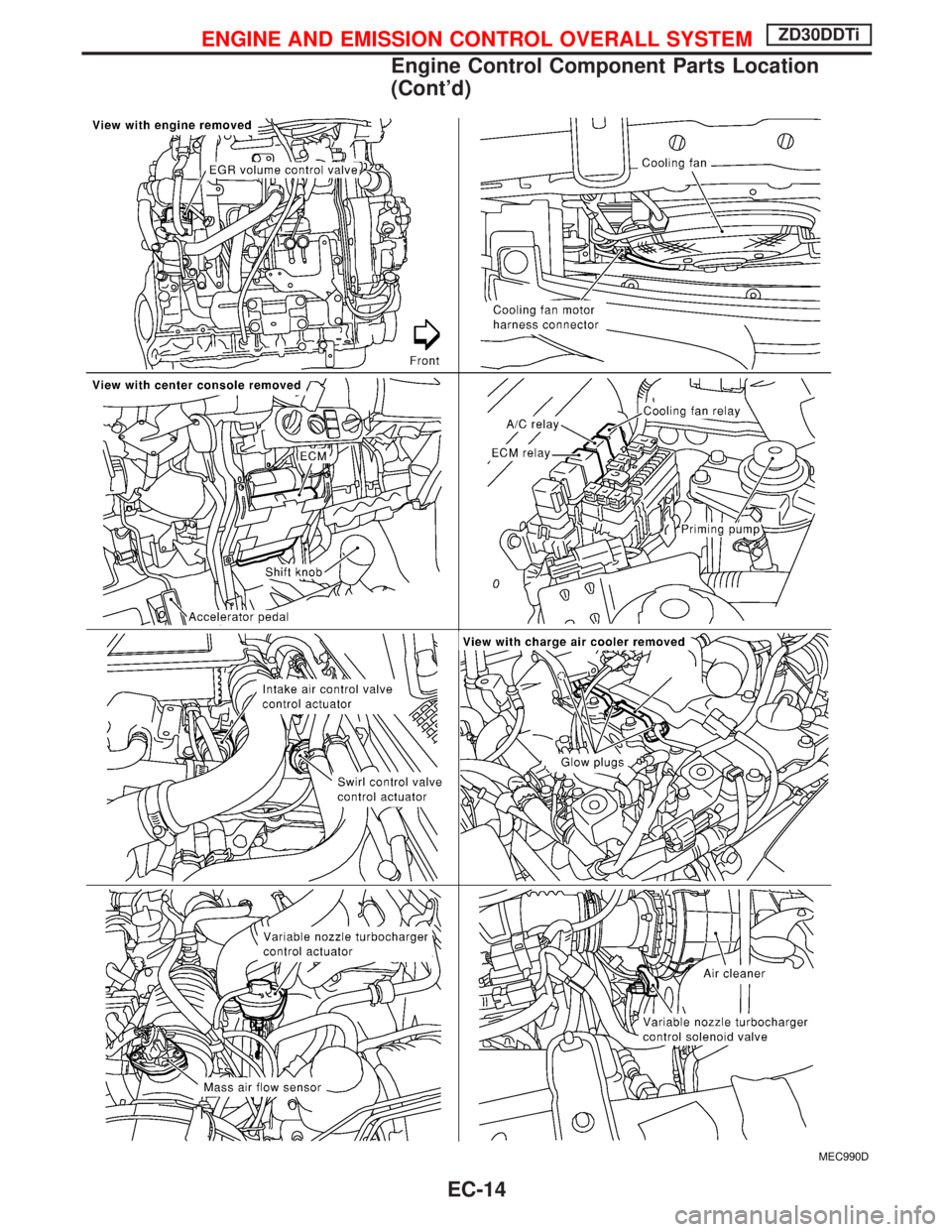

MEC990D

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

Engine Control Component Parts Location

(Cont'd)

EC-14

Page 377 of 1767

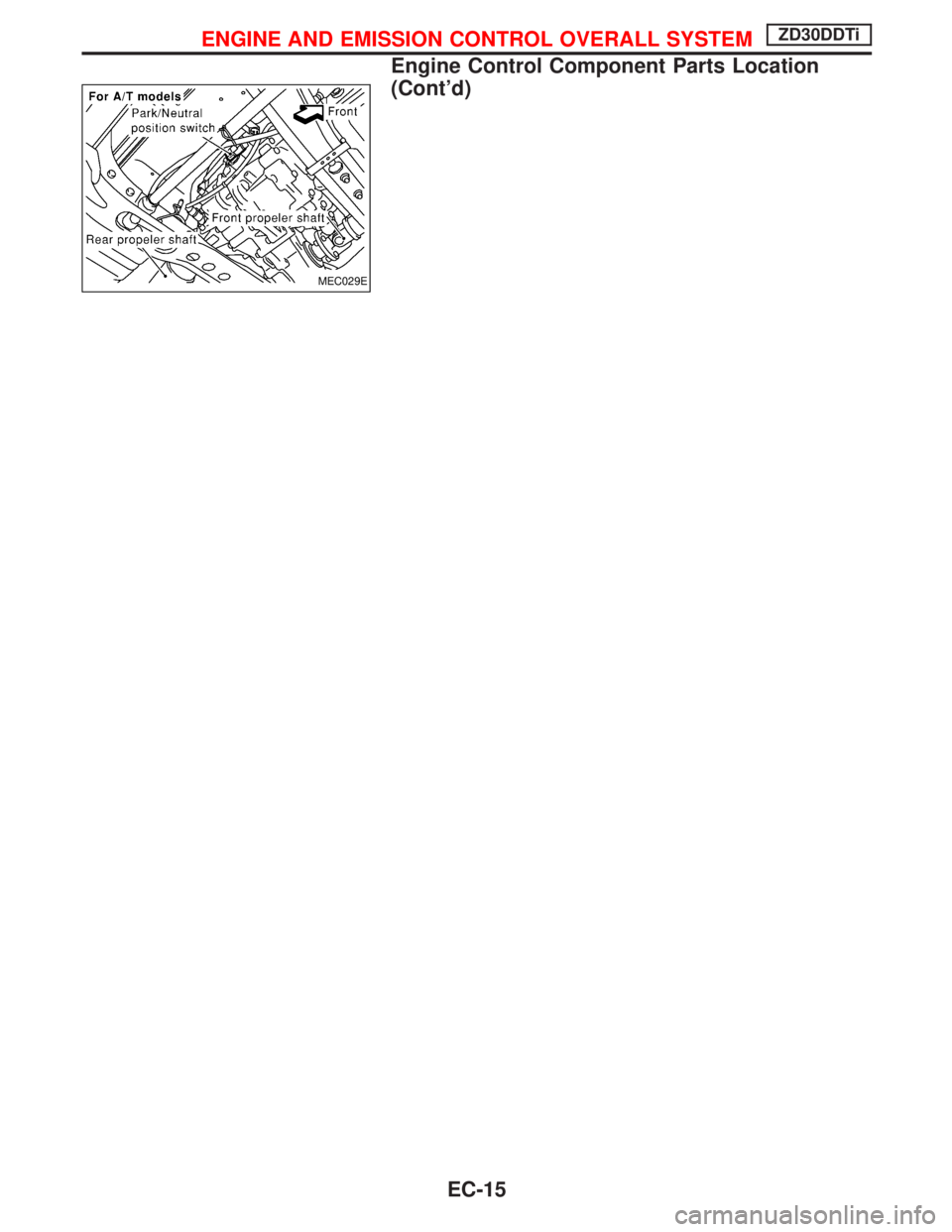

MEC029E

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

Engine Control Component Parts Location

(Cont'd)

EC-15

Page 378 of 1767

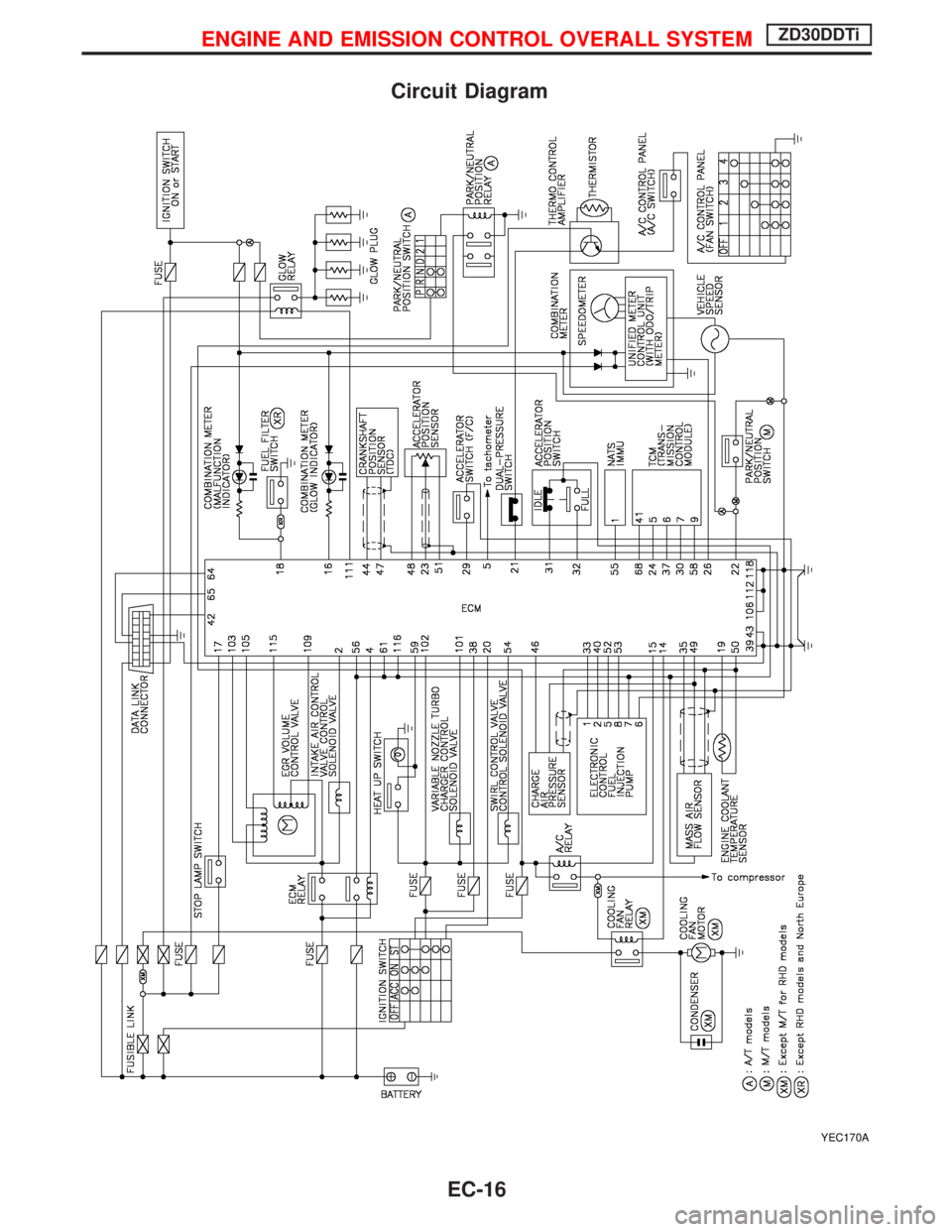

Circuit Diagram

YEC170A

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-16

Page 379 of 1767

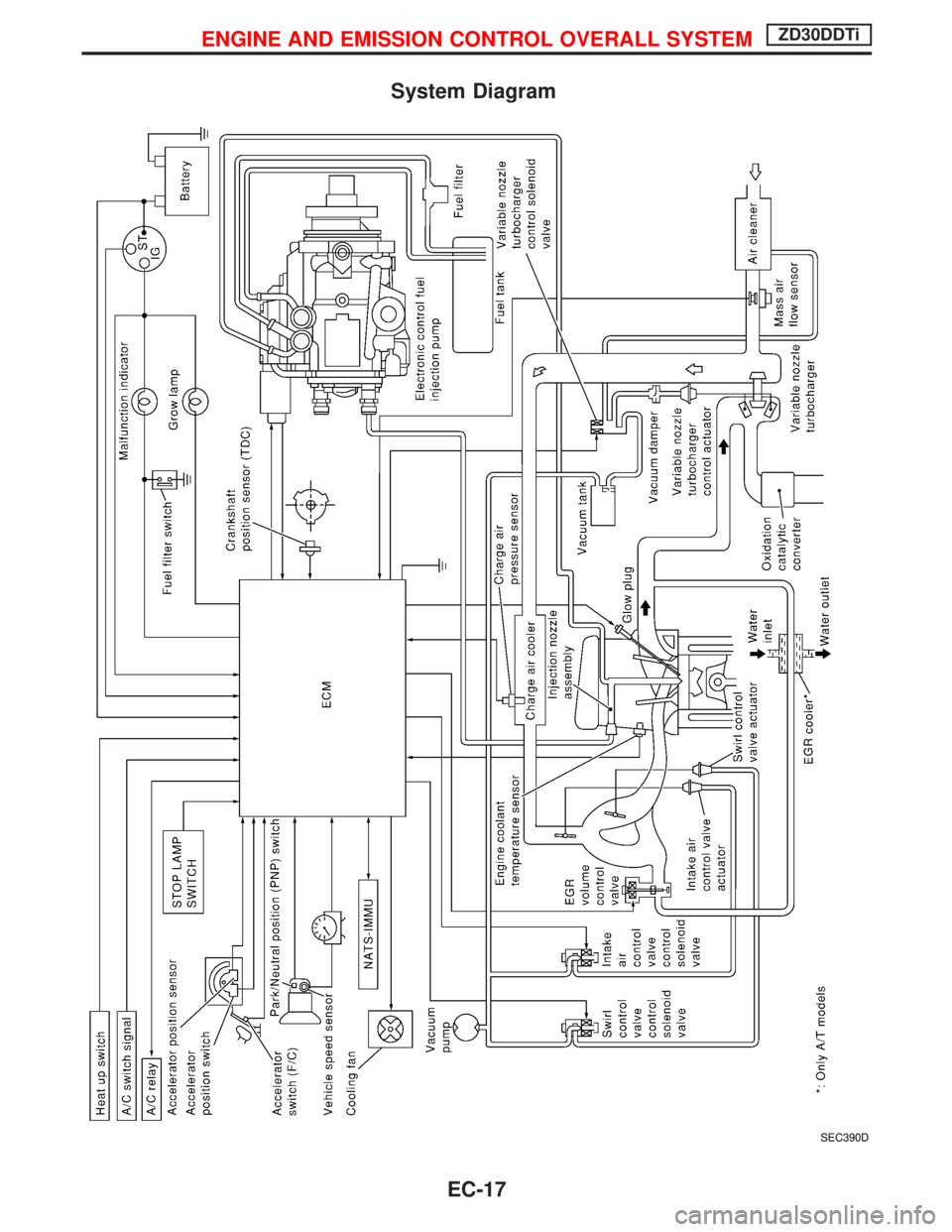

System Diagram

SEC390D

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-17

Page 380 of 1767

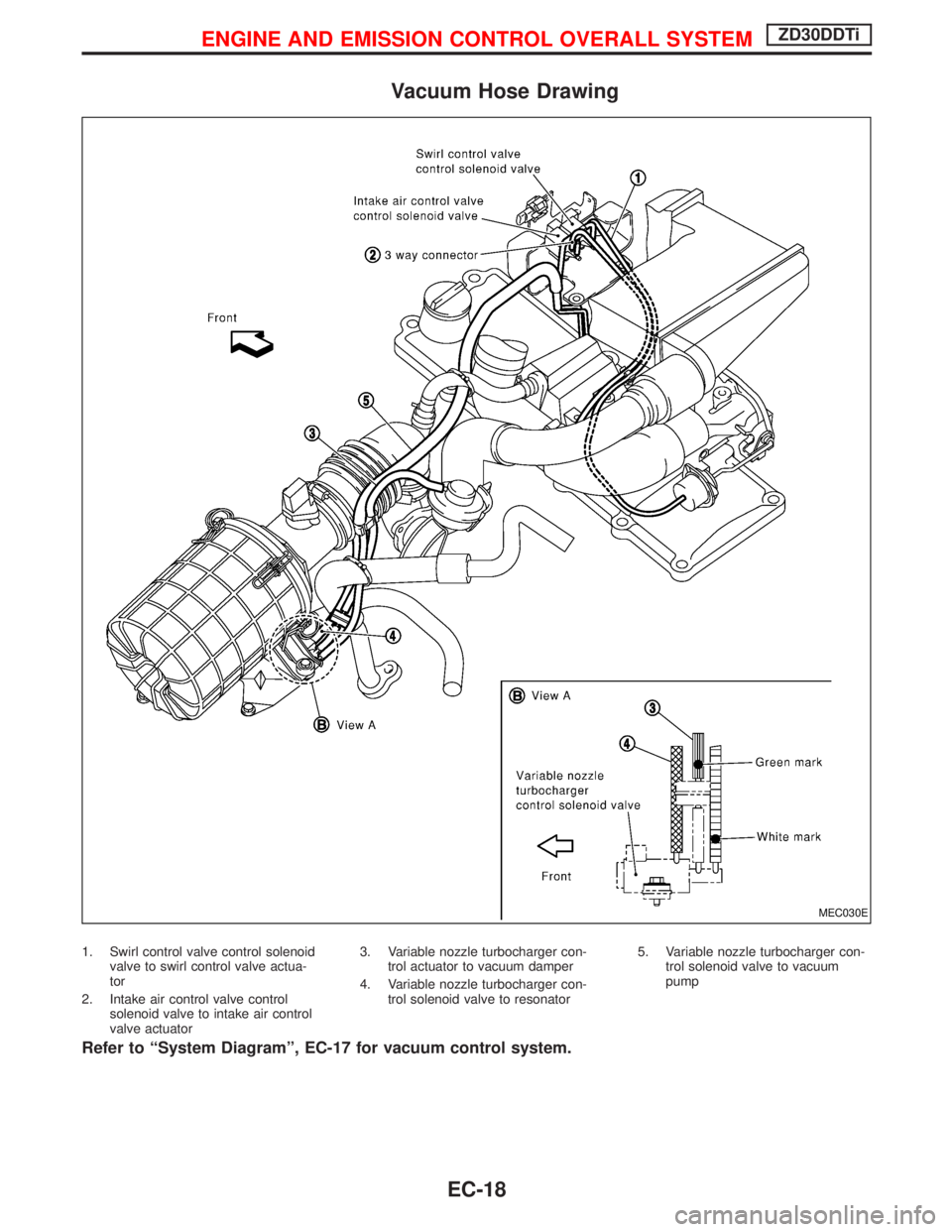

Vacuum Hose Drawing

1. Swirl control valve control solenoid

valve to swirl control valve actua-

tor

2. Intake air control valve control

solenoid valve to intake air control

valve actuator3. Variable nozzle turbocharger con-

trol actuator to vacuum damper

4. Variable nozzle turbocharger con-

trol solenoid valve to resonator5. Variable nozzle turbocharger con-

trol solenoid valve to vacuum

pump

Refer to ªSystem Diagramº, EC-17 for vacuum control system.

MEC030E

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-18

Trending: audio, jump cable, ground clearance, radiator, Oil grade, alternator, load capacity