NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: check engine light, maintenance, wheel size, boot, low beam, key, headlamp

Page 351 of 1767

YCL022

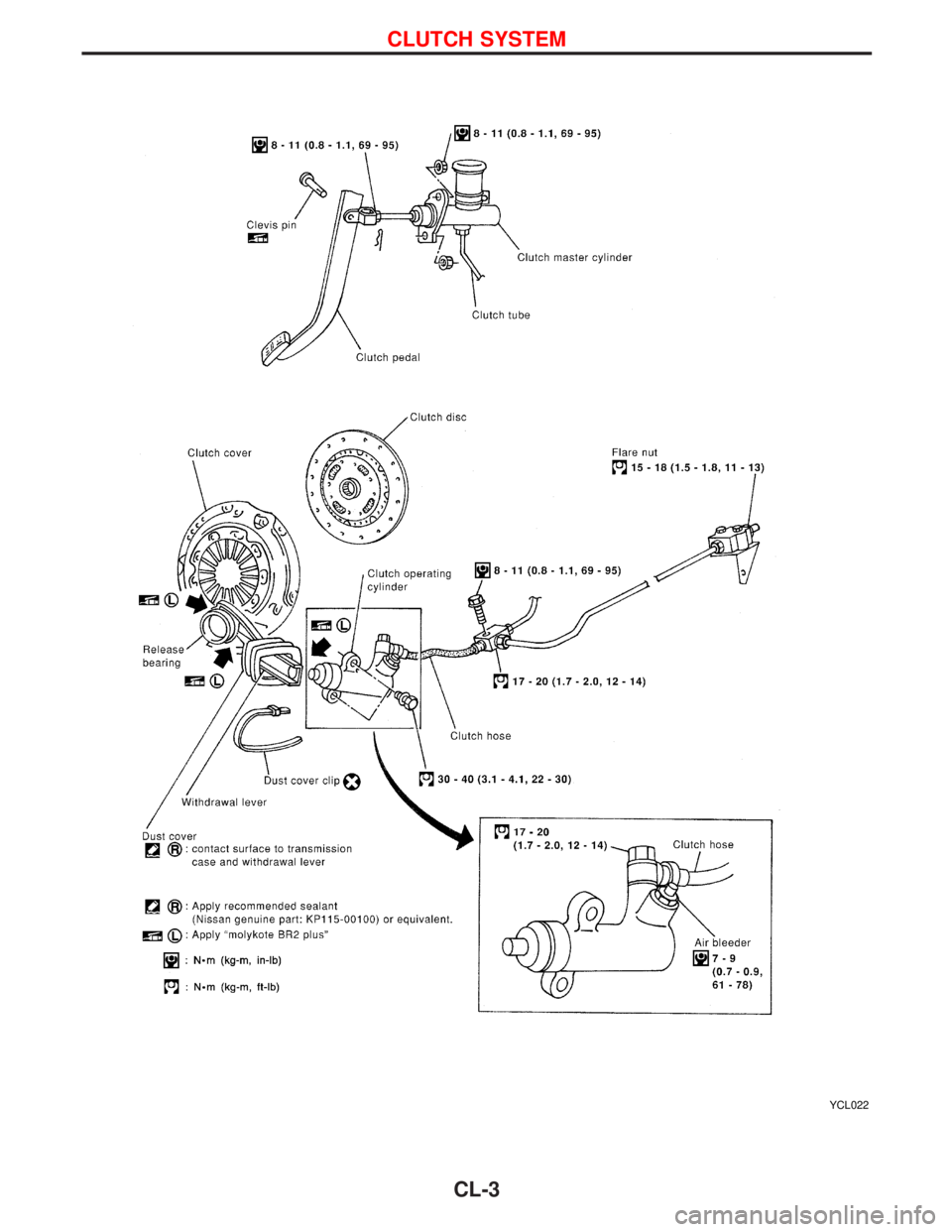

CLUTCH SYSTEM

CL-3

Page 352 of 1767

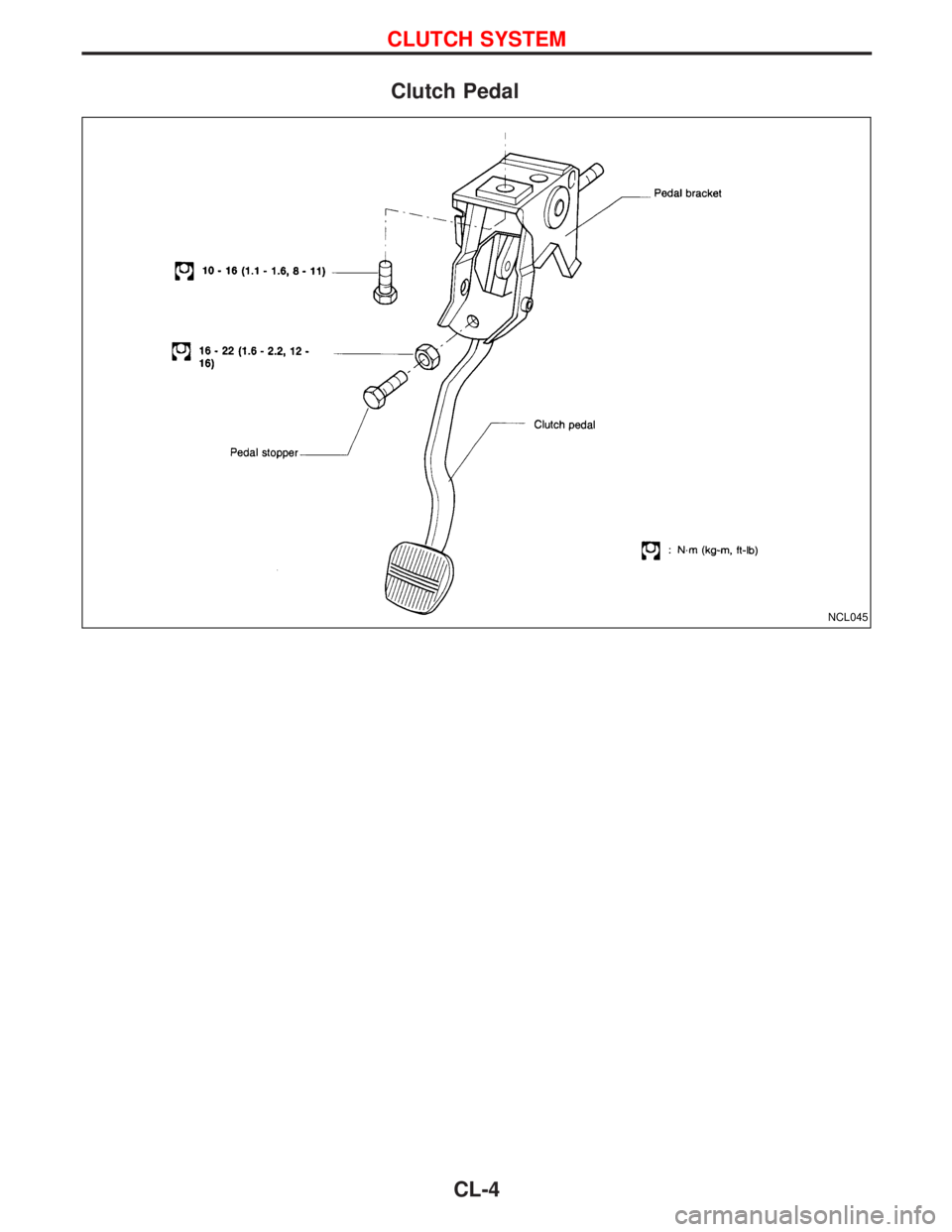

Clutch Pedal

NCL045

CLUTCH SYSTEM

CL-4

Page 353 of 1767

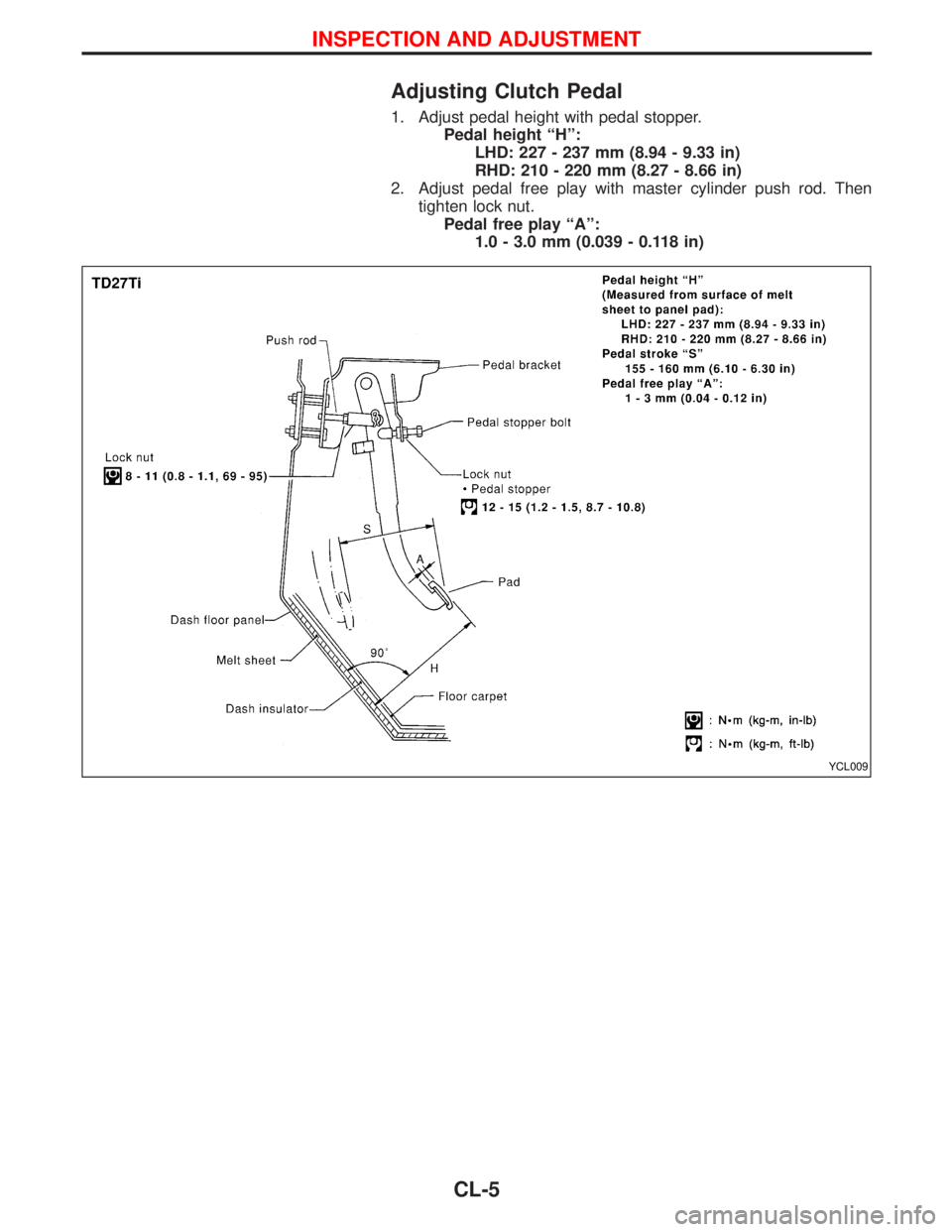

Adjusting Clutch Pedal

1. Adjust pedal height with pedal stopper.

Pedal height ªHº:

LHD: 227 - 237 mm (8.94 - 9.33 in)

RHD: 210 - 220 mm (8.27 - 8.66 in)

2. Adjust pedal free play with master cylinder push rod. Then

tighten lock nut.

Pedal free play ªAº:

1.0 - 3.0 mm (0.039 - 0.118 in)

YCL009

INSPECTION AND ADJUSTMENT

CL-5

Page 354 of 1767

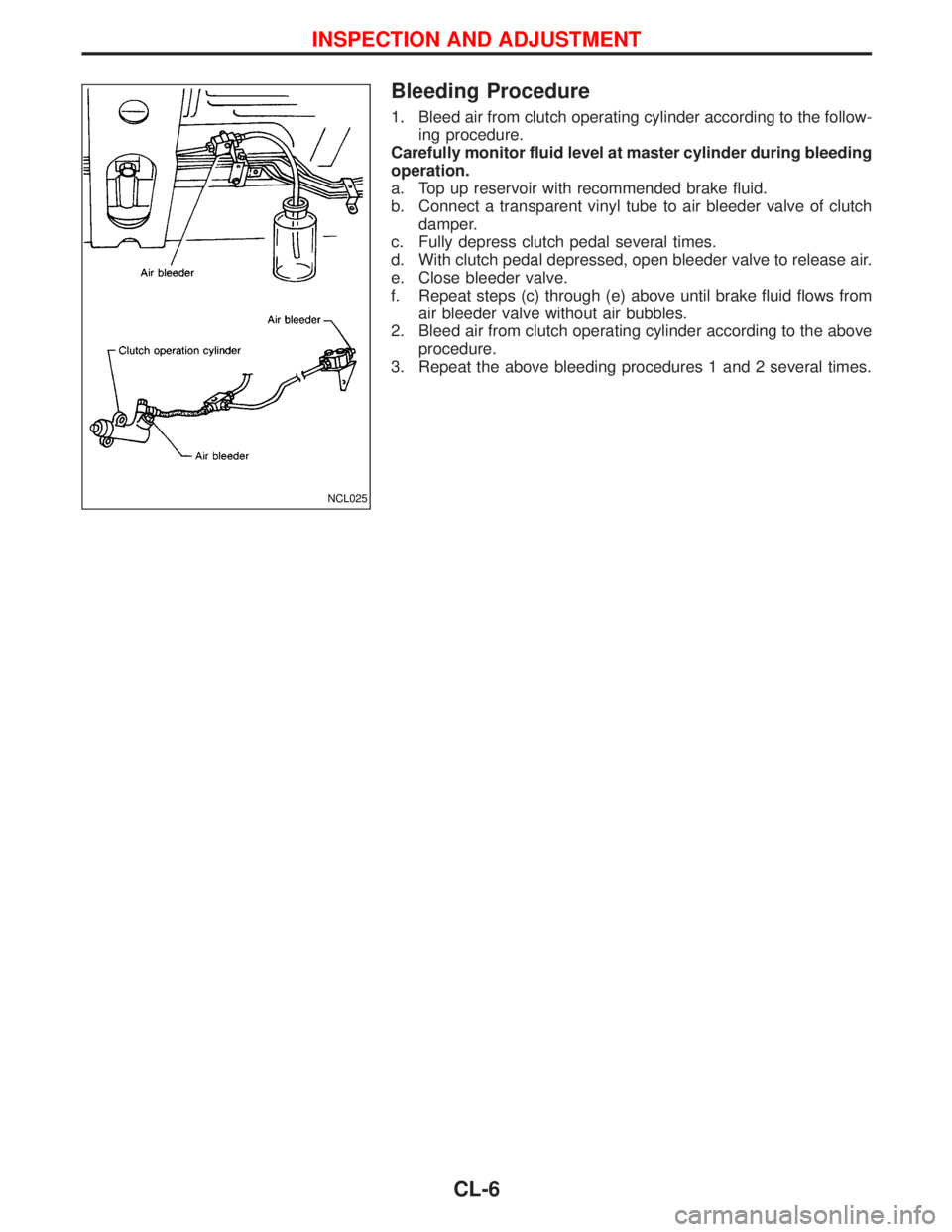

Bleeding Procedure

1. Bleed air from clutch operating cylinder according to the follow-

ing procedure.

Carefully monitor fluid level at master cylinder during bleeding

operation.

a. Top up reservoir with recommended brake fluid.

b. Connect a transparent vinyl tube to air bleeder valve of clutch

damper.

c. Fully depress clutch pedal several times.

d. With clutch pedal depressed, open bleeder valve to release air.

e. Close bleeder valve.

f. Repeat steps (c) through (e) above until brake fluid flows from

air bleeder valve without air bubbles.

2. Bleed air from clutch operating cylinder according to the above

procedure.

3. Repeat the above bleeding procedures 1 and 2 several times.

NCL025

INSPECTION AND ADJUSTMENT

CL-6

Page 355 of 1767

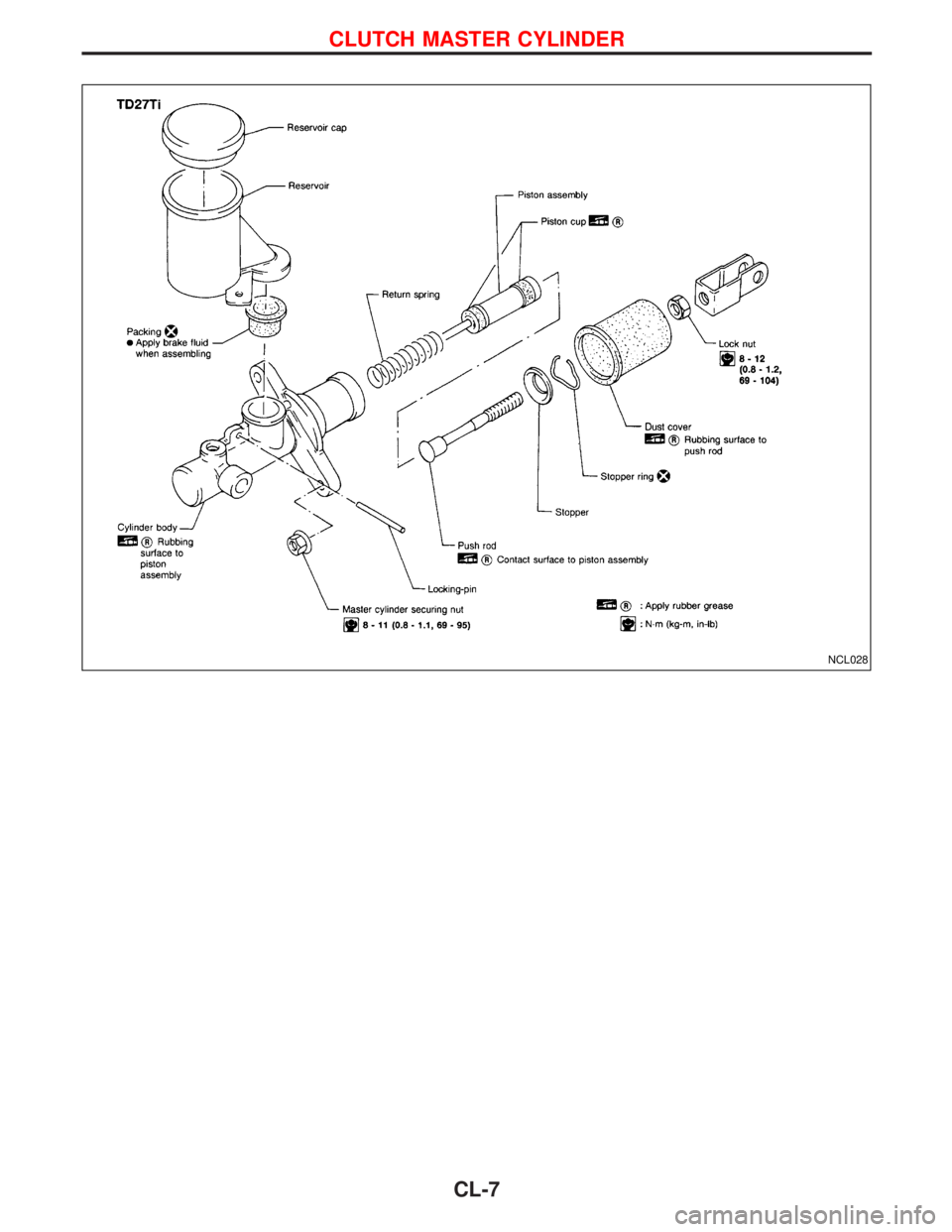

NCL028

CLUTCH MASTER CYLINDER

CL-7

Page 356 of 1767

Clutch Master Cylinder

INSPECTION

ICheck cylinder and piston rubbing surface for uneven wear,

rust or damage. Replace if necessary.

ICheck piston and piston cup for wear or damage. Replace if

necessary.

ICheck return spring for wear or damage. Replace if necessary.

ICheck reservoir for deformation or damage. Replace if neces-

sary.

ICheck dust cover for cracks, deformation or damage. Replace

if necessary.

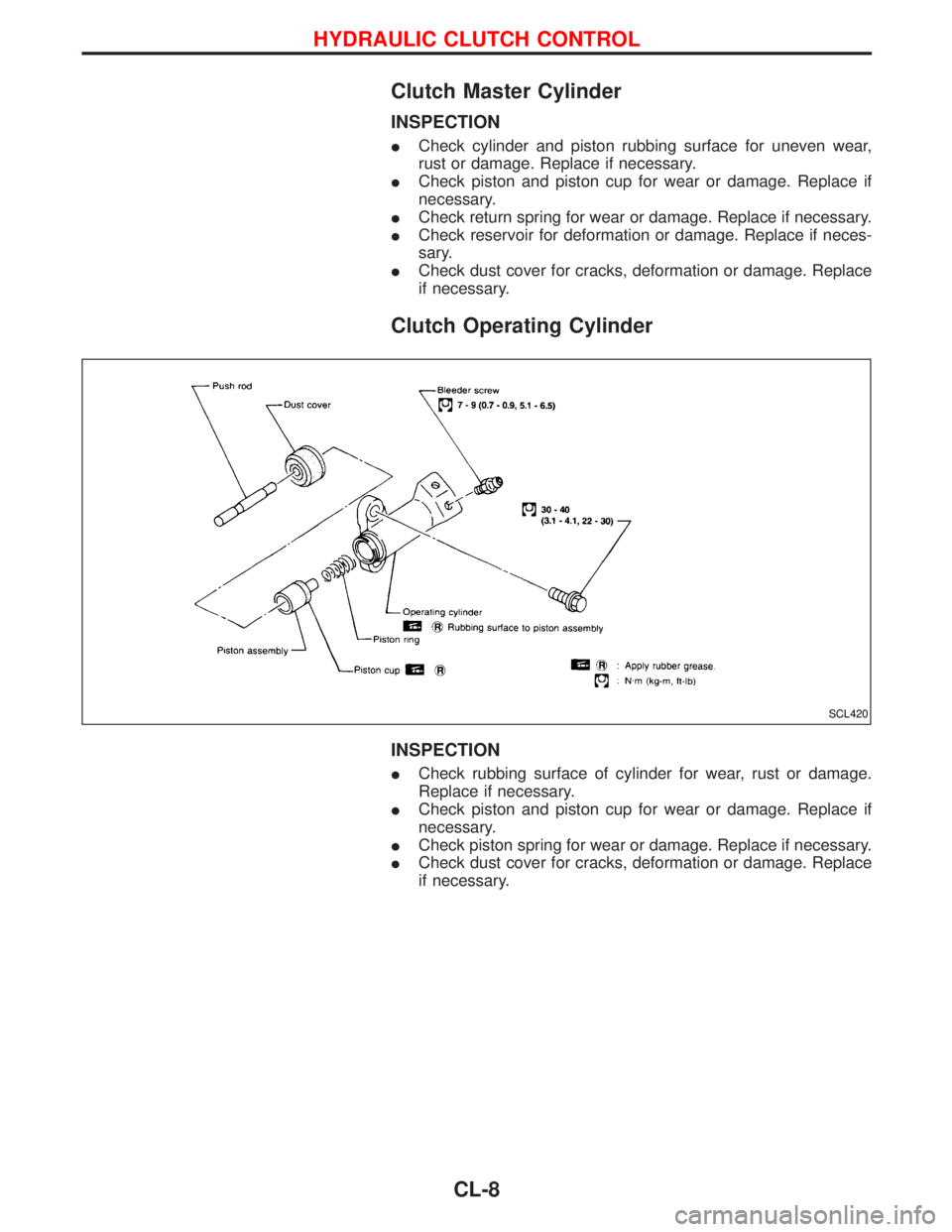

Clutch Operating Cylinder

INSPECTION

ICheck rubbing surface of cylinder for wear, rust or damage.

Replace if necessary.

ICheck piston and piston cup for wear or damage. Replace if

necessary.

ICheck piston spring for wear or damage. Replace if necessary.

ICheck dust cover for cracks, deformation or damage. Replace

if necessary.

SCL420

HYDRAULIC CLUTCH CONTROL

CL-8

Page 357 of 1767

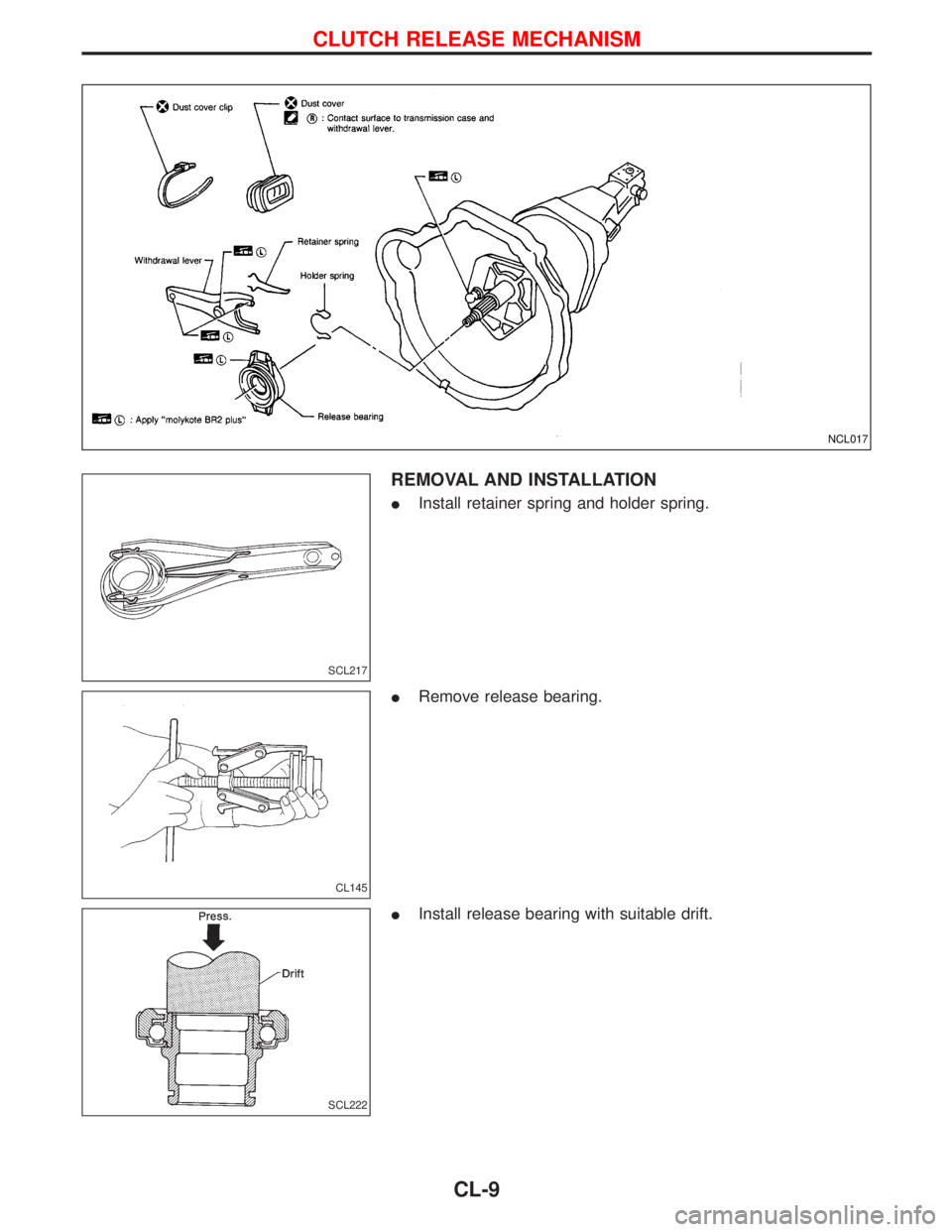

REMOVAL AND INSTALLATION

IInstall retainer spring and holder spring.

IRemove release bearing.

IInstall release bearing with suitable drift.

NCL017

SCL217

CL145

SCL222

CLUTCH RELEASE MECHANISM

CL-9

Page 358 of 1767

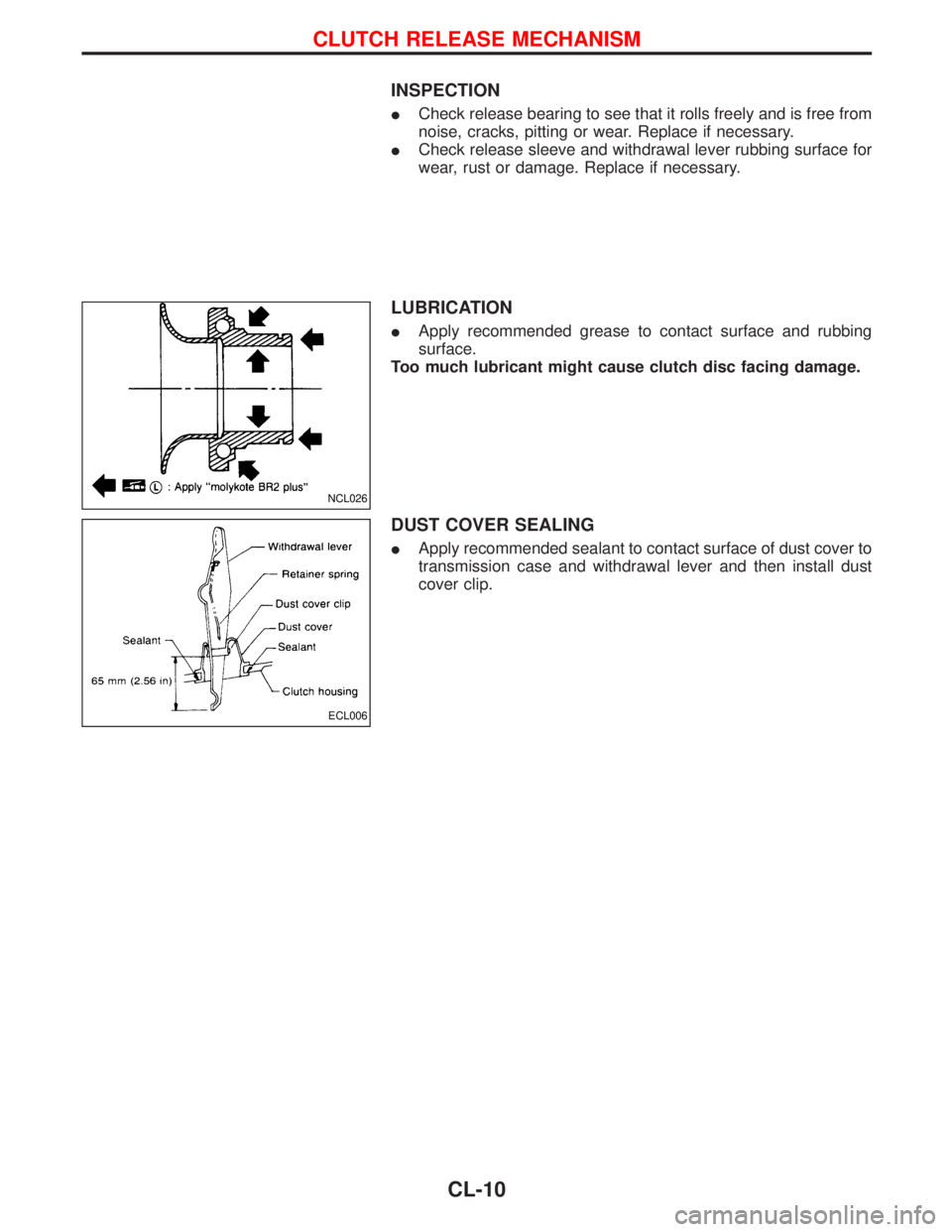

INSPECTION

ICheck release bearing to see that it rolls freely and is free from

noise, cracks, pitting or wear. Replace if necessary.

ICheck release sleeve and withdrawal lever rubbing surface for

wear, rust or damage. Replace if necessary.

LUBRICATION

IApply recommended grease to contact surface and rubbing

surface.

Too much lubricant might cause clutch disc facing damage.

DUST COVER SEALING

IApply recommended sealant to contact surface of dust cover to

transmission case and withdrawal lever and then install dust

cover clip.

NCL026

ECL006

CLUTCH RELEASE MECHANISM

CL-10

Page 359 of 1767

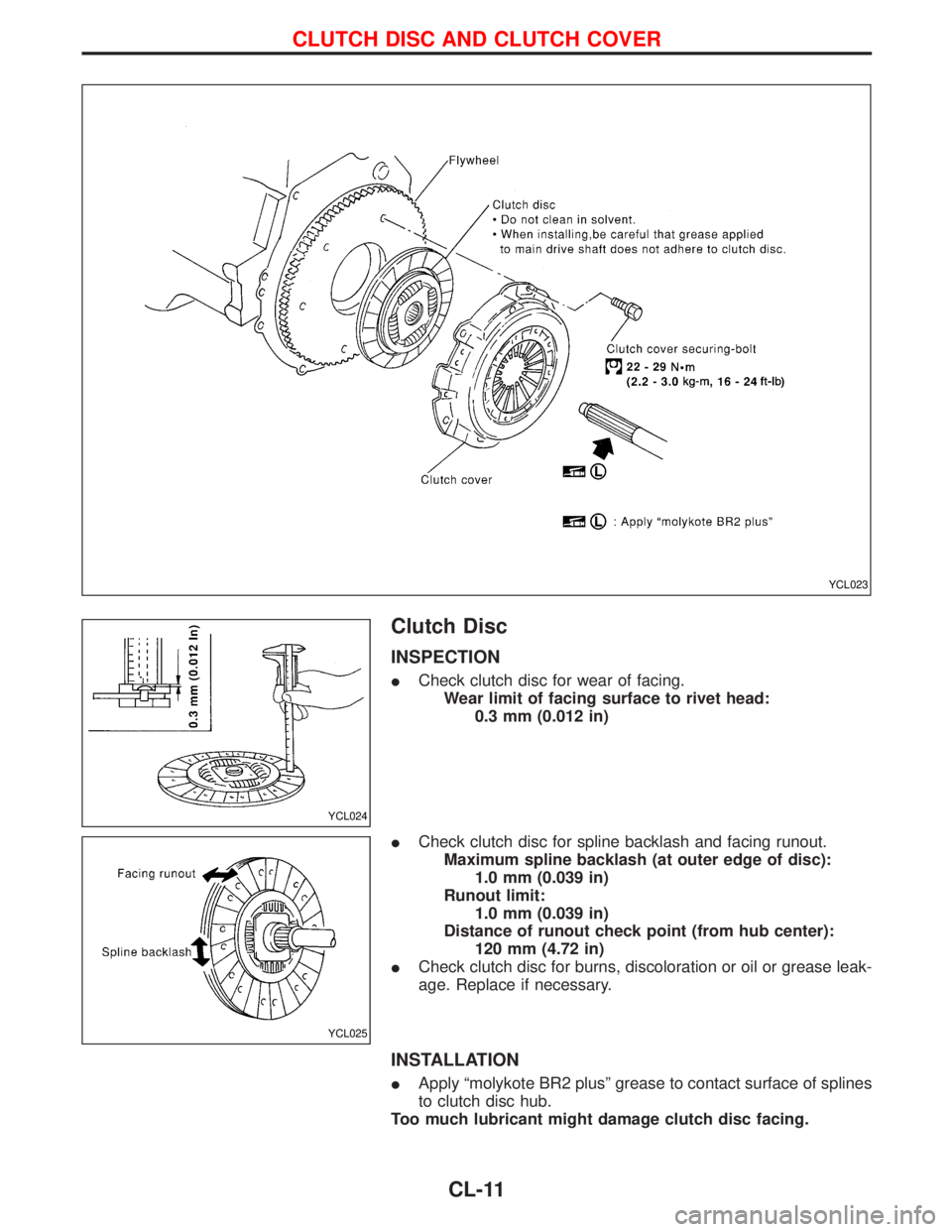

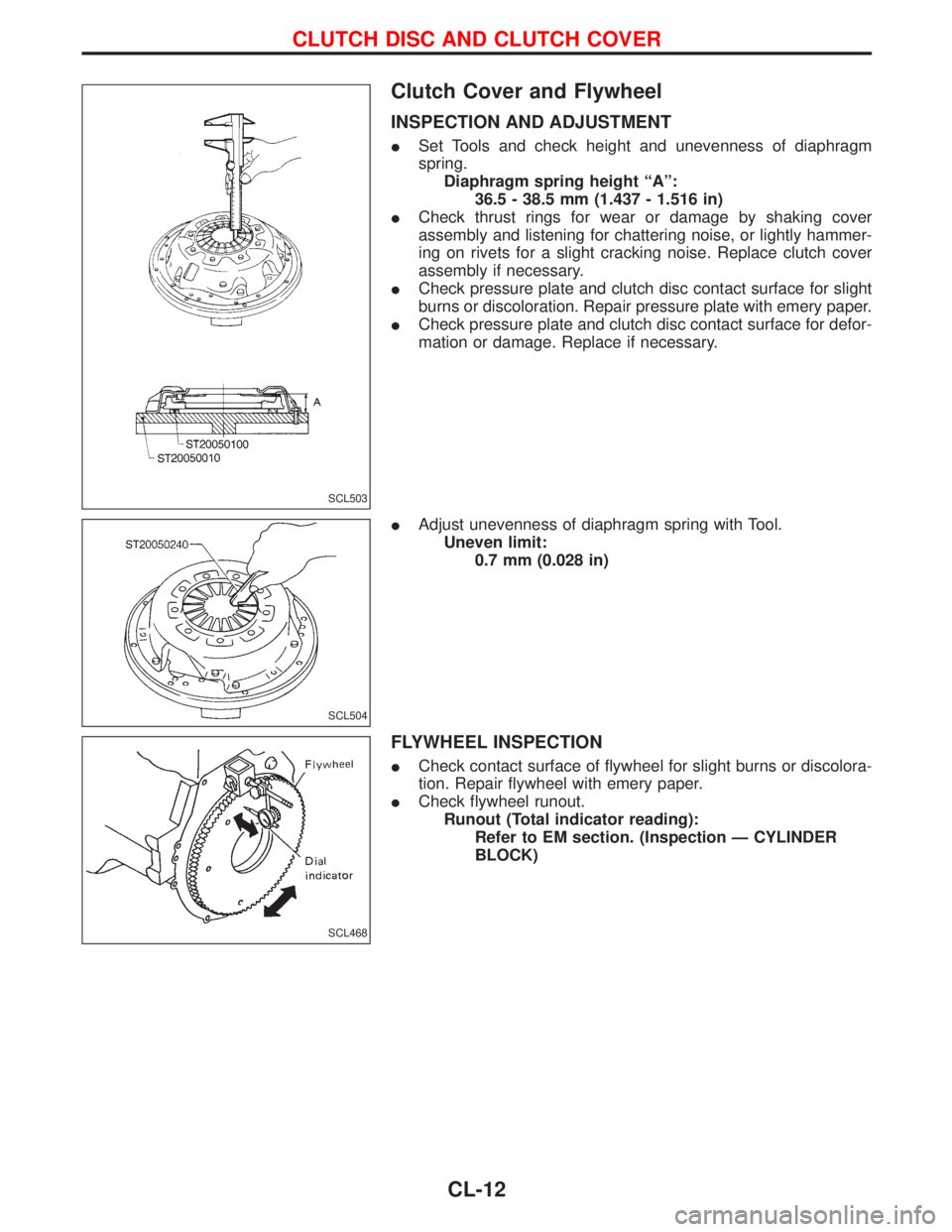

Clutch Disc

INSPECTION

ICheck clutch disc for wear of facing.

Wear limit of facing surface to rivet head:

0.3 mm (0.012 in)

ICheck clutch disc for spline backlash and facing runout.

Maximum spline backlash (at outer edge of disc):

1.0 mm (0.039 in)

Runout limit:

1.0 mm (0.039 in)

Distance of runout check point (from hub center):

120 mm (4.72 in)

ICheck clutch disc for burns, discoloration or oil or grease leak-

age. Replace if necessary.

INSTALLATION

IApply ªmolykote BR2 plusº grease to contact surface of splines

to clutch disc hub.

Too much lubricant might damage clutch disc facing.

YCL023

YCL024

YCL025

CLUTCH DISC AND CLUTCH COVER

CL-11

Page 360 of 1767

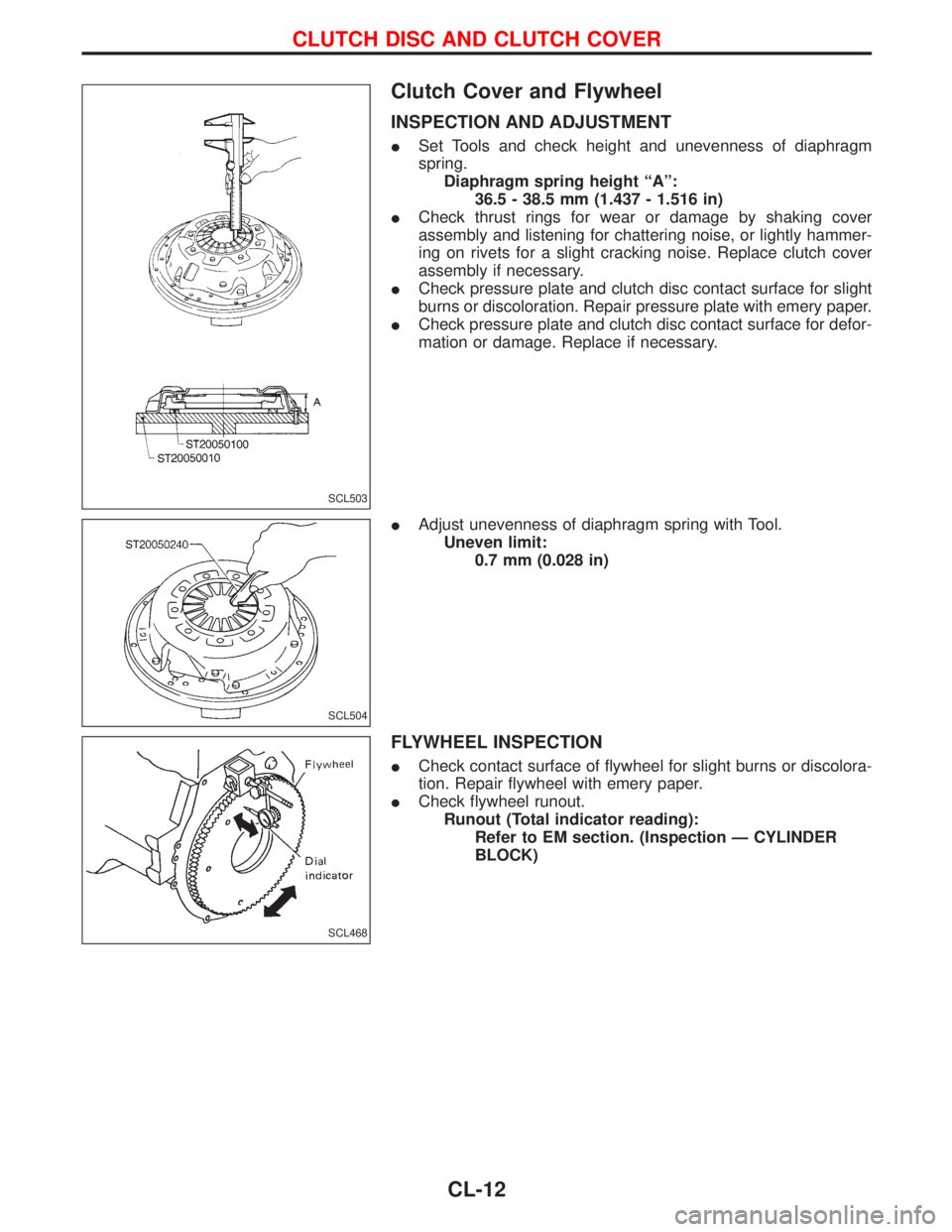

Clutch Cover and Flywheel

INSPECTION AND ADJUSTMENT

ISet Tools and check height and unevenness of diaphragm

spring.

Diaphragm spring height ªAº:

36.5 - 38.5 mm (1.437 - 1.516 in)

ICheck thrust rings for wear or damage by shaking cover

assembly and listening for chattering noise, or lightly hammer-

ing on rivets for a slight cracking noise. Replace clutch cover

assembly if necessary.

ICheck pressure plate and clutch disc contact surface for slight

burns or discoloration. Repair pressure plate with emery paper.

ICheck pressure plate and clutch disc contact surface for defor-

mation or damage. Replace if necessary.

IAdjust unevenness of diaphragm spring with Tool.

Uneven limit:

0.7 mm (0.028 in)

FLYWHEEL INSPECTION

ICheck contact surface of flywheel for slight burns or discolora-

tion. Repair flywheel with emery paper.

ICheck flywheel runout.

Runout (Total indicator reading):

Refer to EM section. (Inspection Ð CYLINDER

BLOCK)

SCL503

SCL504

SCL468

CLUTCH DISC AND CLUTCH COVER

CL-12

Trending: warning light, coolant capacity, cooling, headlamp, checking oil, keyless entry, ECU