torque NISSAN TERRANO 2002 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1263 of 1767

Front Axle and Front Suspension Parts

ICheck front axle and front suspension parts for looseness,

cracks, wear or other damage.

(1) Shake each front wheel.

(2) Make sure that cotter pin is inserted.

(3) Retighten all nuts and bolts to the specified torque.

: Refer to ªFRONT SUSPENSIONº, FA-29.

(4) Check front axle and front suspension parts for wear, cracks or

other damage.

ICheck shock absorber for oil leakage or other damage.

ICheck suspension ball joints for grease leakage and dust cov-

ers for cracks or other damage.

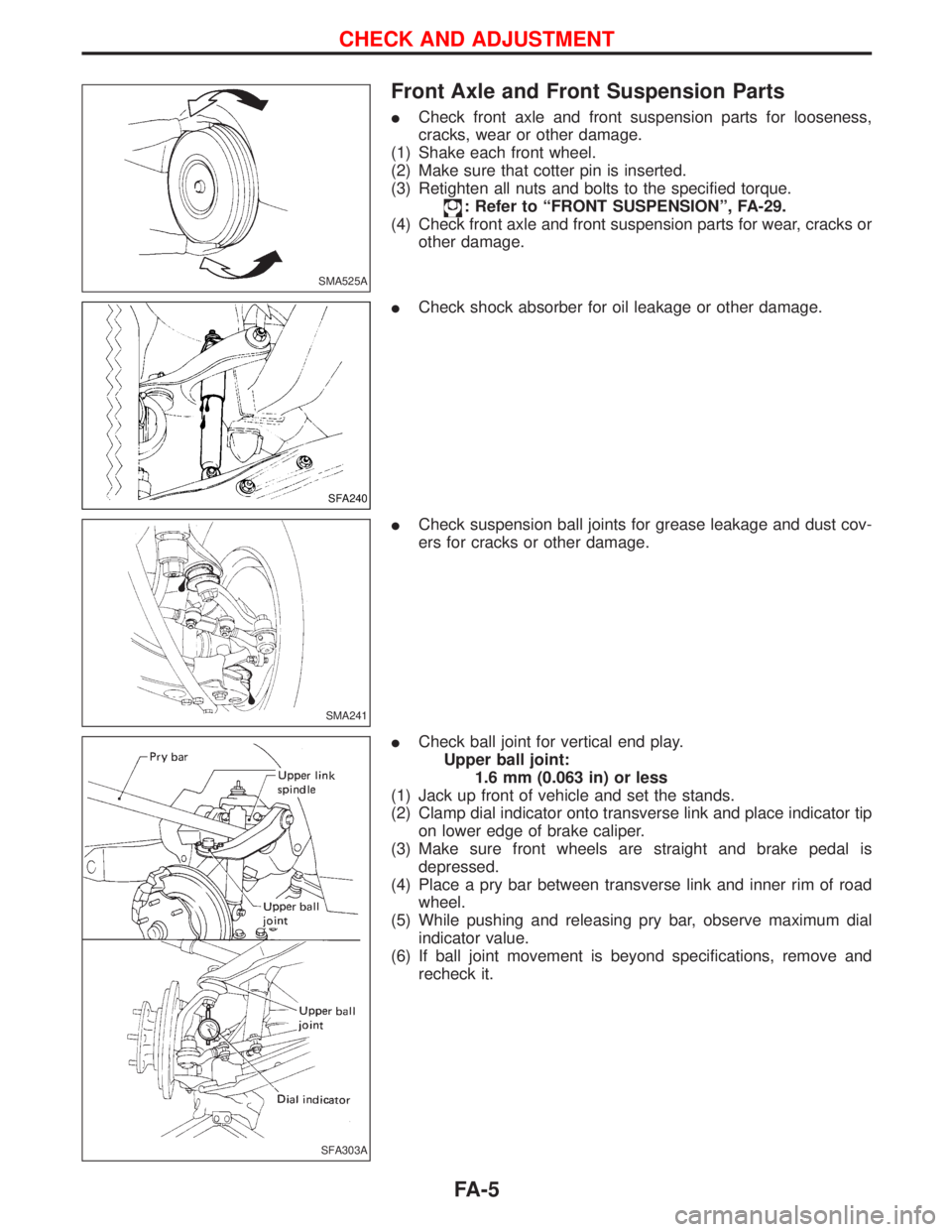

ICheck ball joint for vertical end play.

Upper ball joint:

1.6 mm (0.063 in) or less

(1) Jack up front of vehicle and set the stands.

(2) Clamp dial indicator onto transverse link and place indicator tip

on lower edge of brake caliper.

(3) Make sure front wheels are straight and brake pedal is

depressed.

(4) Place a pry bar between transverse link and inner rim of road

wheel.

(5) While pushing and releasing pry bar, observe maximum dial

indicator value.

(6) If ball joint movement is beyond specifications, remove and

recheck it.

SMA525A

SFA240

SMA241

SFA303A

CHECK AND ADJUSTMENT

FA-5

Page 1265 of 1767

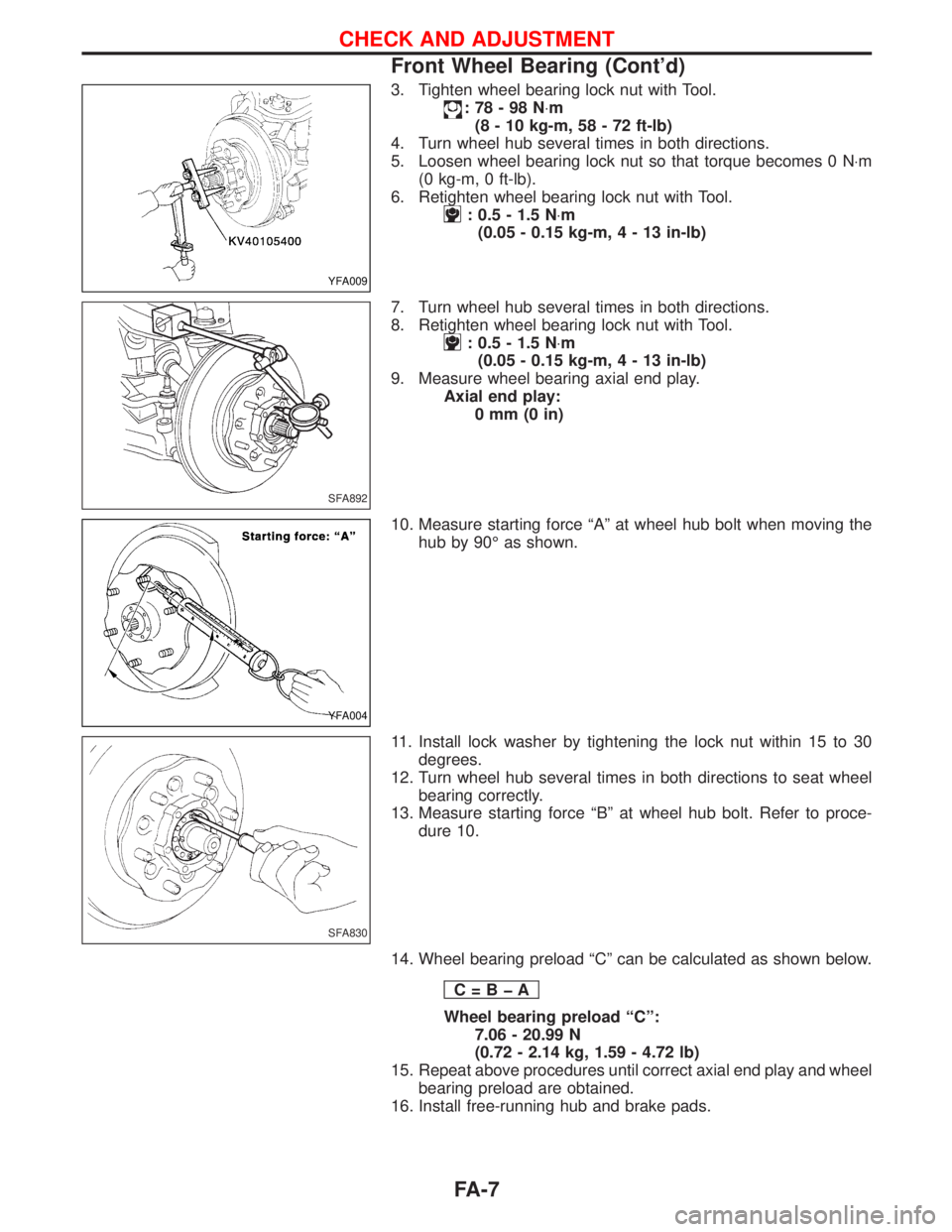

3. Tighten wheel bearing lock nut with Tool.

:78-98N×m

(8 - 10 kg-m, 58 - 72 ft-lb)

4. Turn wheel hub several times in both directions.

5. Loosen wheel bearing lock nut so that torque becomes 0 N×m

(0 kg-m, 0 ft-lb).

6. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

7. Turn wheel hub several times in both directions.

8. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

9. Measure wheel bearing axial end play.

Axial end play:

0mm(0in)

10. Measure starting force ªAº at wheel hub bolt when moving the

hub by 90É as shown.

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ªBº at wheel hub bolt. Refer to proce-

dure 10.

14. Wheel bearing preload ªCº can be calculated as shown below.

C=BþA

Wheel bearing preload ªCº:

7.06 - 20.99 N

(0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. Repeat above procedures until correct axial end play and wheel

bearing preload are obtained.

16. Install free-running hub and brake pads.

YFA009

SFA892

YFA004

SFA830

CHECK AND ADJUSTMENT

Front Wheel Bearing (Cont'd)

FA-7

Page 1269 of 1767

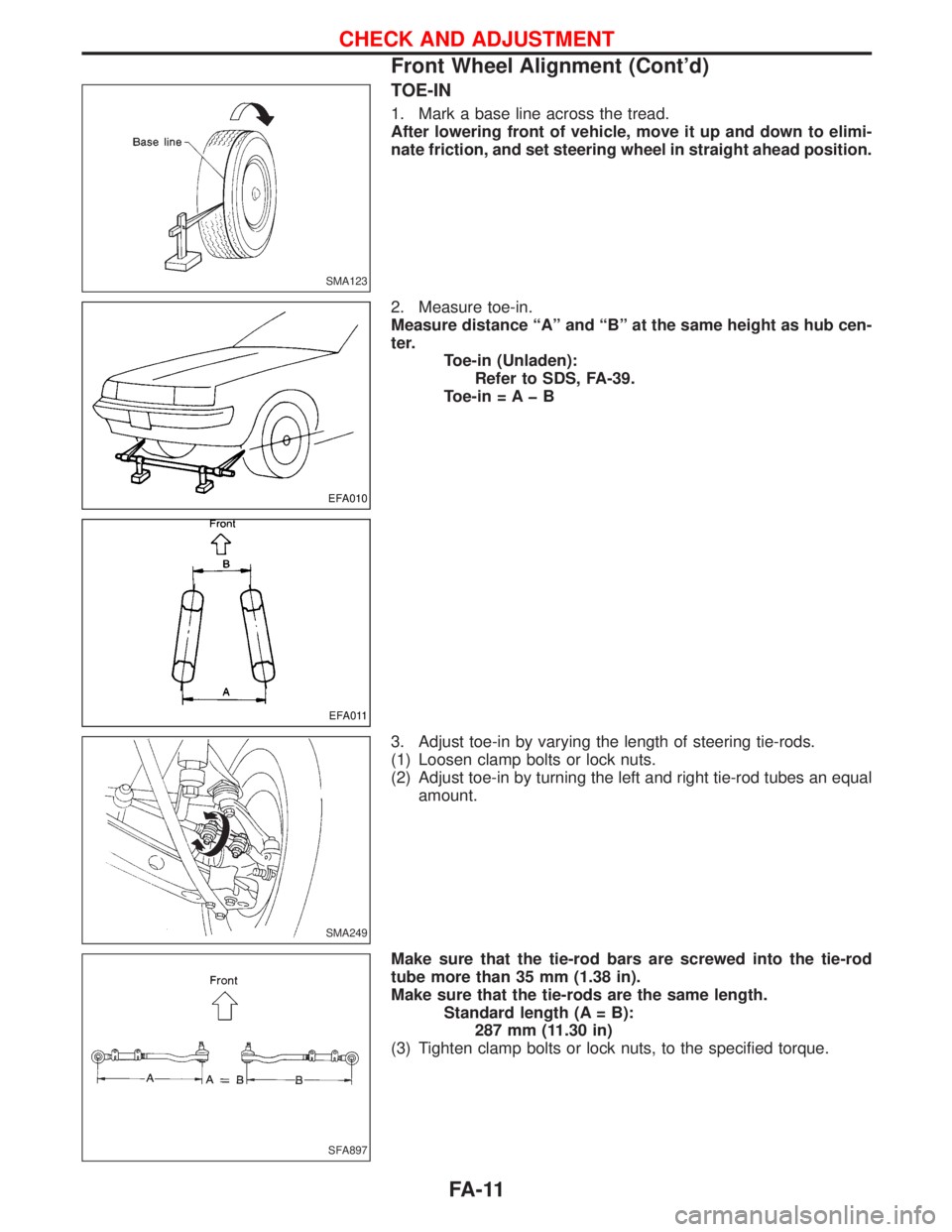

TOE-IN

1. Mark a base line across the tread.

After lowering front of vehicle, move it up and down to elimi-

nate friction, and set steering wheel in straight ahead position.

2. Measure toe-in.

Measure distance ªAº and ªBº at the same height as hub cen-

ter.

Toe-in (Unladen):

Refer to SDS, FA-39.

Toe-in = A þ B

3. Adjust toe-in by varying the length of steering tie-rods.

(1) Loosen clamp bolts or lock nuts.

(2) Adjust toe-in by turning the left and right tie-rod tubes an equal

amount.

Make sure that the tie-rod bars are screwed into the tie-rod

tube more than 35 mm (1.38 in).

Make sure that the tie-rods are the same length.

Standard length (A = B):

287 mm (11.30 in)

(3) Tighten clamp bolts or lock nuts, to the specified torque.

SMA123

EFA010

EFA011

SMA249

SFA897

CHECK AND ADJUSTMENT

Front Wheel Alignment (Cont'd)

FA-11

Page 1288 of 1767

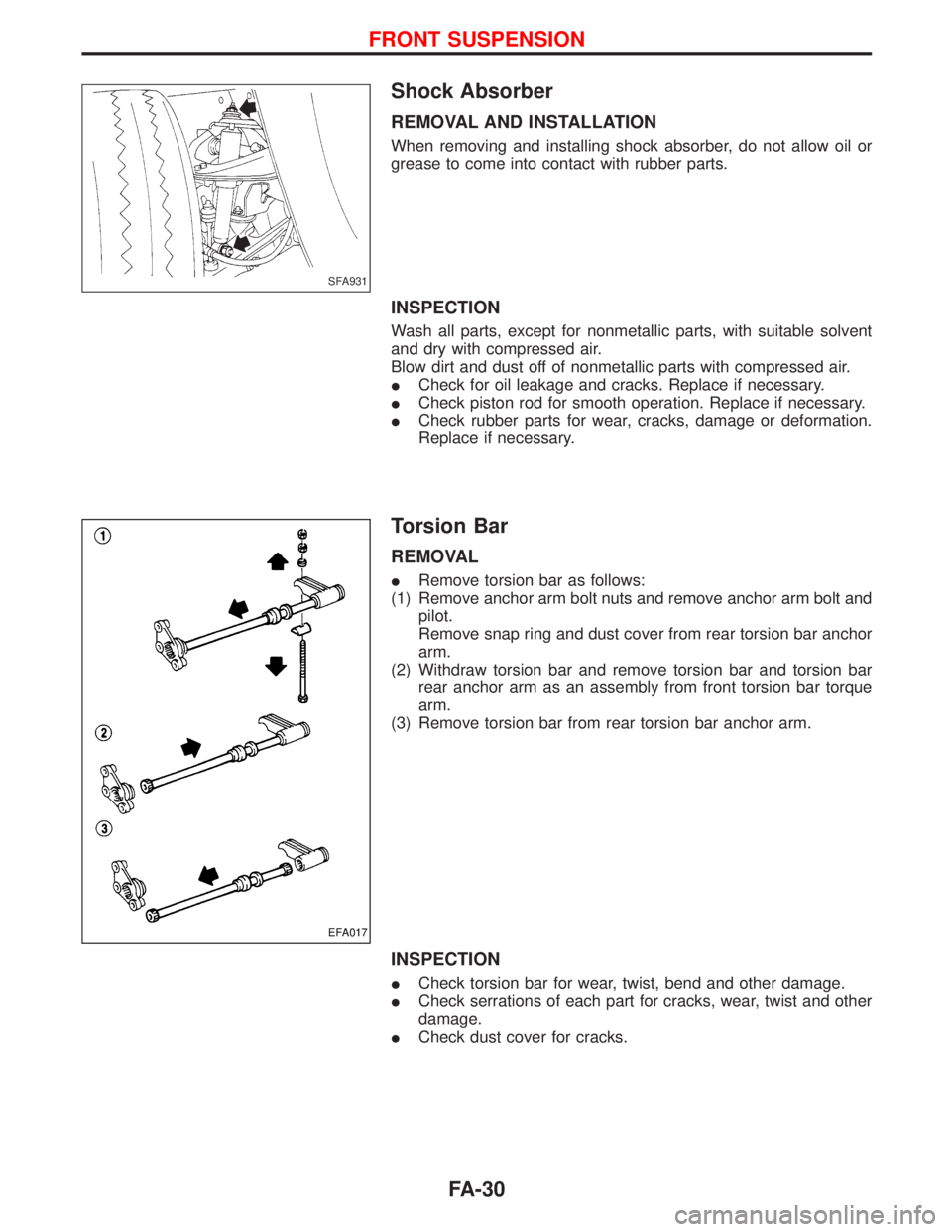

Shock Absorber

REMOVAL AND INSTALLATION

When removing and installing shock absorber, do not allow oil or

grease to come into contact with rubber parts.

INSPECTION

Wash all parts, except for nonmetallic parts, with suitable solvent

and dry with compressed air.

Blow dirt and dust off of nonmetallic parts with compressed air.

ICheck for oil leakage and cracks. Replace if necessary.

ICheck piston rod for smooth operation. Replace if necessary.

ICheck rubber parts for wear, cracks, damage or deformation.

Replace if necessary.

Torsion Bar

REMOVAL

IRemove torsion bar as follows:

(1) Remove anchor arm bolt nuts and remove anchor arm bolt and

pilot.

Remove snap ring and dust cover from rear torsion bar anchor

arm.

(2) Withdraw torsion bar and remove torsion bar and torsion bar

rear anchor arm as an assembly from front torsion bar torque

arm.

(3) Remove torsion bar from rear torsion bar anchor arm.

INSPECTION

ICheck torsion bar for wear, twist, bend and other damage.

ICheck serrations of each part for cracks, wear, twist and other

damage.

ICheck dust cover for cracks.

SFA931

EFA017

FRONT SUSPENSION

FA-30

Page 1289 of 1767

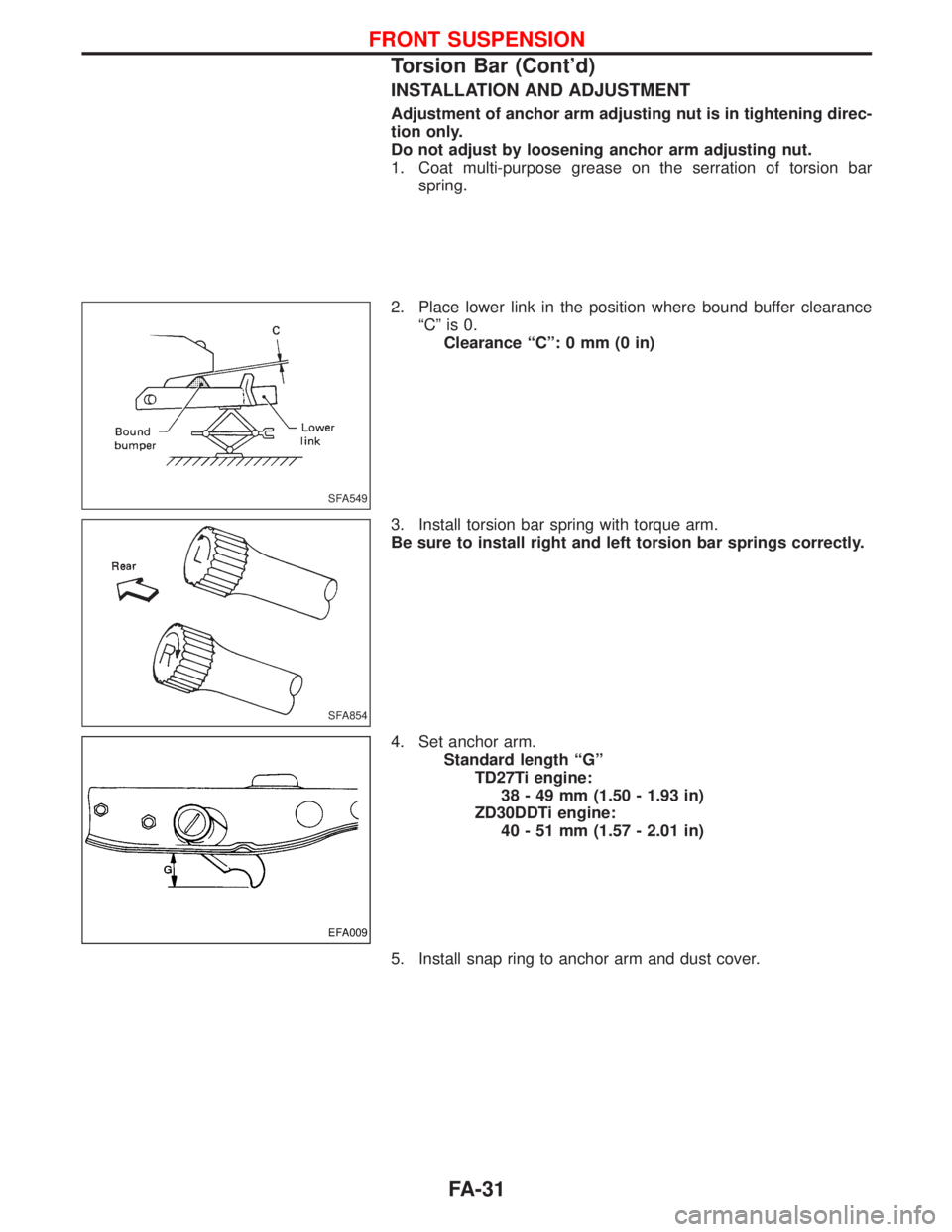

INSTALLATION AND ADJUSTMENT

Adjustment of anchor arm adjusting nut is in tightening direc-

tion only.

Do not adjust by loosening anchor arm adjusting nut.

1. Coat multi-purpose grease on the serration of torsion bar

spring.

2. Place lower link in the position where bound buffer clearance

ªCº is 0.

Clearance ªCº: 0 mm (0 in)

3. Install torsion bar spring with torque arm.

Be sure to install right and left torsion bar springs correctly.

4. Set anchor arm.

Standard length ªGº

TD27Ti engine:

38 - 49 mm (1.50 - 1.93 in)

ZD30DDTi engine:

40 - 51 mm (1.57 - 2.01 in)

5. Install snap ring to anchor arm and dust cover.

SFA549

SFA854

EFA009

FRONT SUSPENSION

Torsion Bar (Cont'd)

FA-31

Page 1295 of 1767

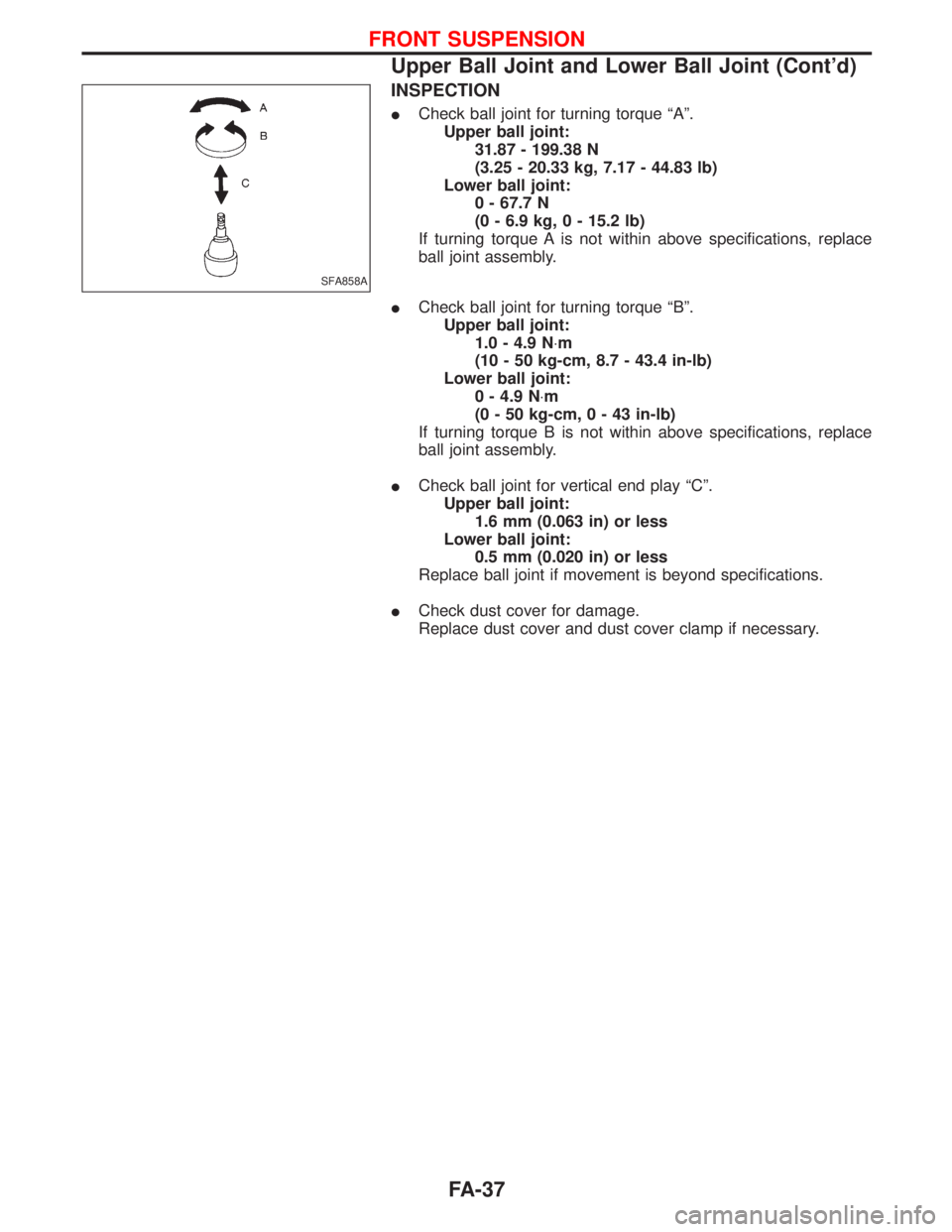

INSPECTION

ICheck ball joint for turning torque ªAº.

Upper ball joint:

31.87 - 199.38 N

(3.25 - 20.33 kg, 7.17 - 44.83 lb)

Lower ball joint:

0 - 67.7 N

(0 - 6.9 kg, 0 - 15.2 lb)

If turning torque A is not within above specifications, replace

ball joint assembly.

ICheck ball joint for turning torque ªBº.

Upper ball joint:

1.0 - 4.9 N×m

(10 - 50 kg-cm, 8.7 - 43.4 in-lb)

Lower ball joint:

0 - 4.9 N×m

(0 - 50 kg-cm,0-43in-lb)

If turning torque B is not within above specifications, replace

ball joint assembly.

ICheck ball joint for vertical end play ªCº.

Upper ball joint:

1.6 mm (0.063 in) or less

Lower ball joint:

0.5 mm (0.020 in) or less

Replace ball joint if movement is beyond specifications.

ICheck dust cover for damage.

Replace dust cover and dust cover clamp if necessary.

SFA858A

FRONT SUSPENSION

Upper Ball Joint and Lower Ball Joint (Cont'd)

FA-37

Page 1297 of 1767

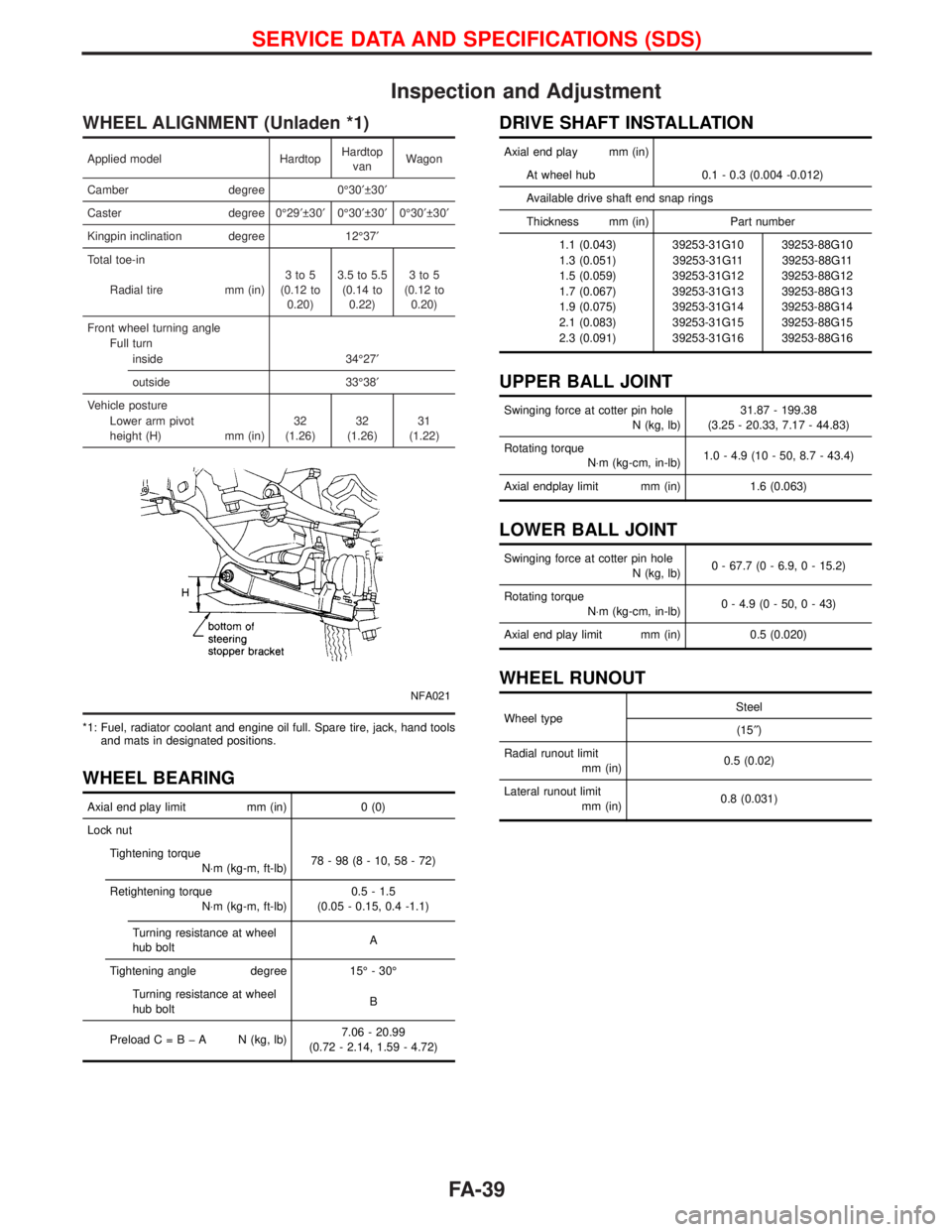

Inspection and Adjustment

WHEEL ALIGNMENT (Unladen *1)

Applied model HardtopHardtop

vanWagon

Camber degree 0É30¢ 30¢

Caster degree 0É29¢ 30¢0É30¢ 30¢0É30¢ 30¢

Kingpin inclination degree 12É37¢

Total toe-in

Radial tire mm (in)3to5

(0.12 to

0.20)3.5 to 5.5

(0.14 to

0.22)3to5

(0.12 to

0.20)

Front wheel turning angle

Full turn

inside 34É27¢

outside 33É38¢

Vehicle posture

Lower arm pivot

height (H) mm (in)32

(1.26)32

(1.26)31

(1.22)

NFA021

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools

and mats in designated positions.

WHEEL BEARING

Axial end play limit mm (in) 0 (0)

Lock nut

Tightening torque

N×m (kg-m, ft-lb)78-98(8-10,58-72)

Retightening torque

N×m (kg-m, ft-lb)0.5 - 1.5

(0.05 - 0.15, 0.4 -1.1)

Turning resistance at wheel

hub boltA

Tightening angle degree 15É - 30É

Turning resistance at wheel

hub boltB

PreloadC=BþA N(kg, lb)7.06 - 20.99

(0.72 - 2.14, 1.59 - 4.72)

DRIVE SHAFT INSTALLATION

Axial end play mm (in)

At wheel hub 0.1 - 0.3 (0.004 -0.012)

Available drive shaft end snap rings

Thickness mm (in) Part number

1.1 (0.043) 39253-31G10 39253-88G10

1.3 (0.051) 39253-31G11 39253-88G11

1.5 (0.059) 39253-31G12 39253-88G12

1.7 (0.067) 39253-31G13 39253-88G13

1.9 (0.075) 39253-31G14 39253-88G14

2.1 (0.083) 39253-31G15 39253-88G15

2.3 (0.091) 39253-31G16 39253-88G16

UPPER BALL JOINT

Swinging force at cotter pin hole

N (kg, lb)31.87 - 199.38

(3.25 - 20.33, 7.17 - 44.83)

Rotating torque

N×m (kg-cm, in-lb)1.0 - 4.9 (10 - 50, 8.7 - 43.4)

Axial endplay limit mm (in) 1.6 (0.063)

LOWER BALL JOINT

Swinging force at cotter pin hole

N (kg, lb)0 - 67.7 (0 - 6.9, 0 - 15.2)

Rotating torque

N×m (kg-cm, in-lb)0 - 4.9 (0 - 50, 0 - 43)

Axial end play limit mm (in) 0.5 (0.020)

WHEEL RUNOUT

Wheel typeSteel

(15²)

Radial runout limit

mm (in)0.5 (0.02)

Lateral runout limit

mm (in)0.8 (0.031)

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-39

Page 1306 of 1767

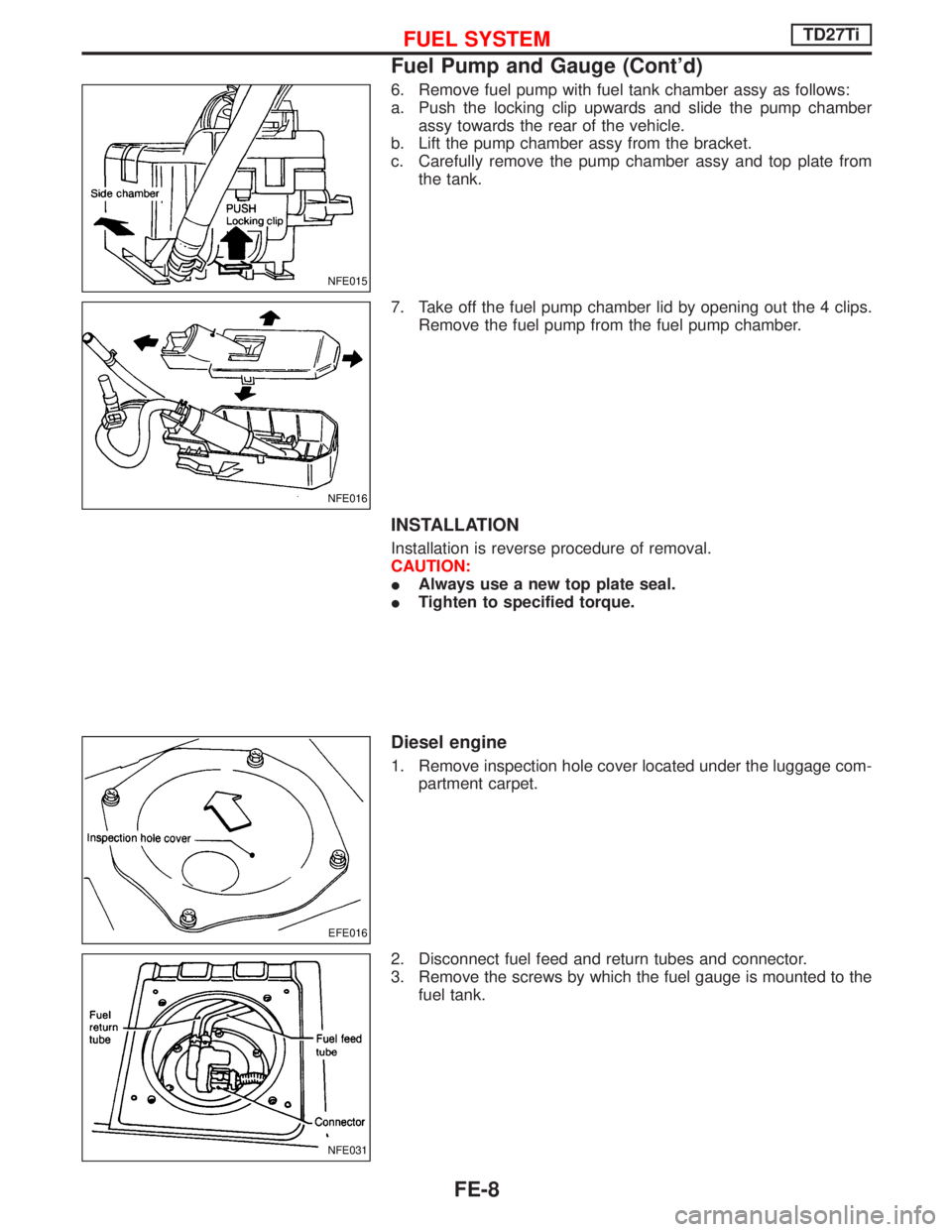

6. Remove fuel pump with fuel tank chamber assy as follows:

a. Push the locking clip upwards and slide the pump chamber

assy towards the rear of the vehicle.

b. Lift the pump chamber assy from the bracket.

c. Carefully remove the pump chamber assy and top plate from

the tank.

7. Take off the fuel pump chamber lid by opening out the 4 clips.

Remove the fuel pump from the fuel pump chamber.

INSTALLATION

Installation is reverse procedure of removal.

CAUTION:

IAlways use a new top plate seal.

ITighten to specified torque.

Diesel engine

1. Remove inspection hole cover located under the luggage com-

partment carpet.

2. Disconnect fuel feed and return tubes and connector.

3. Remove the screws by which the fuel gauge is mounted to the

fuel tank.

NFE015

NFE016

EFE016

NFE031

FUEL SYSTEMTD27Ti

Fuel Pump and Gauge (Cont'd)

FE-8

Page 1307 of 1767

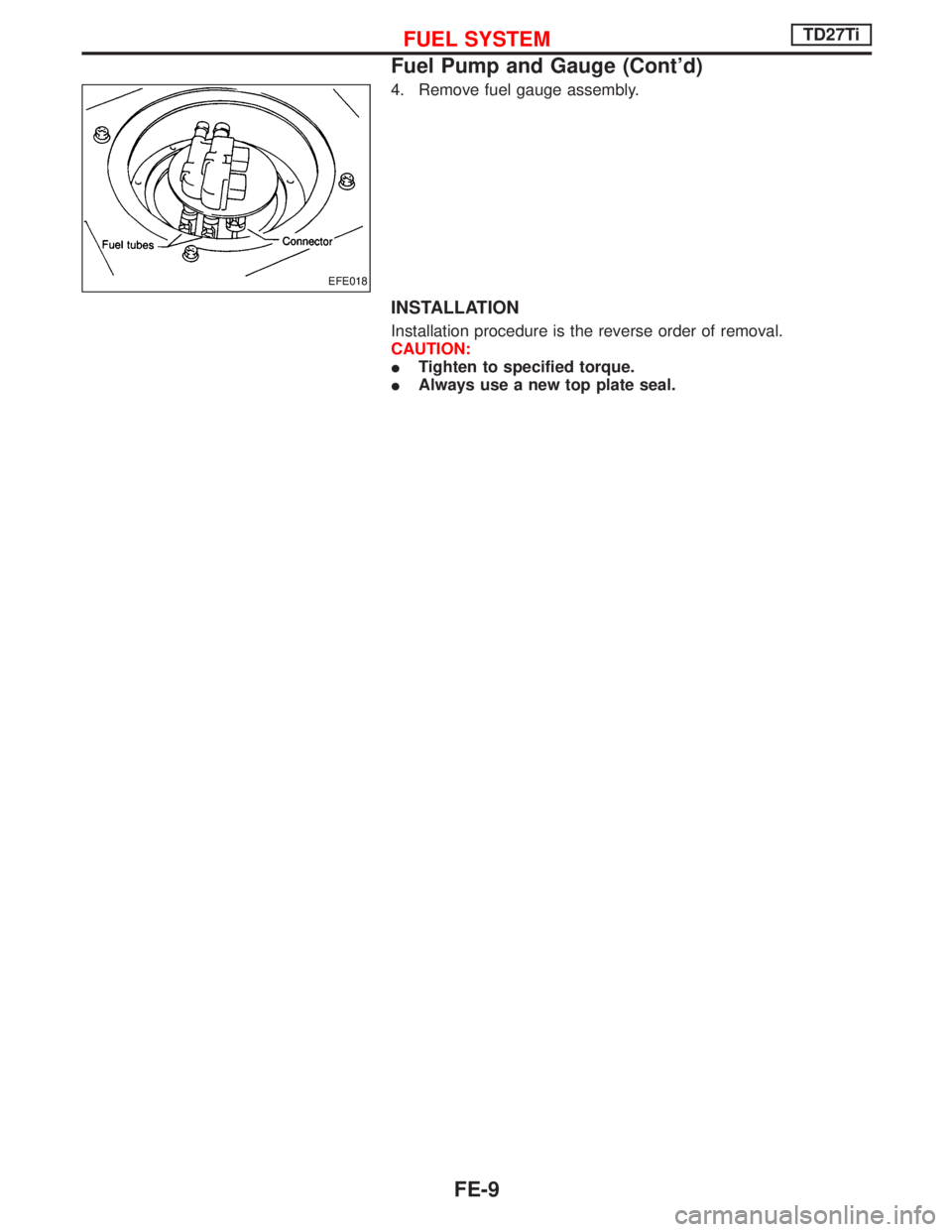

4. Remove fuel gauge assembly.

INSTALLATION

Installation procedure is the reverse order of removal.

CAUTION:

ITighten to specified torque.

IAlways use a new top plate seal.

EFE018

FUEL SYSTEMTD27Ti

Fuel Pump and Gauge (Cont'd)

FE-9

Page 1309 of 1767

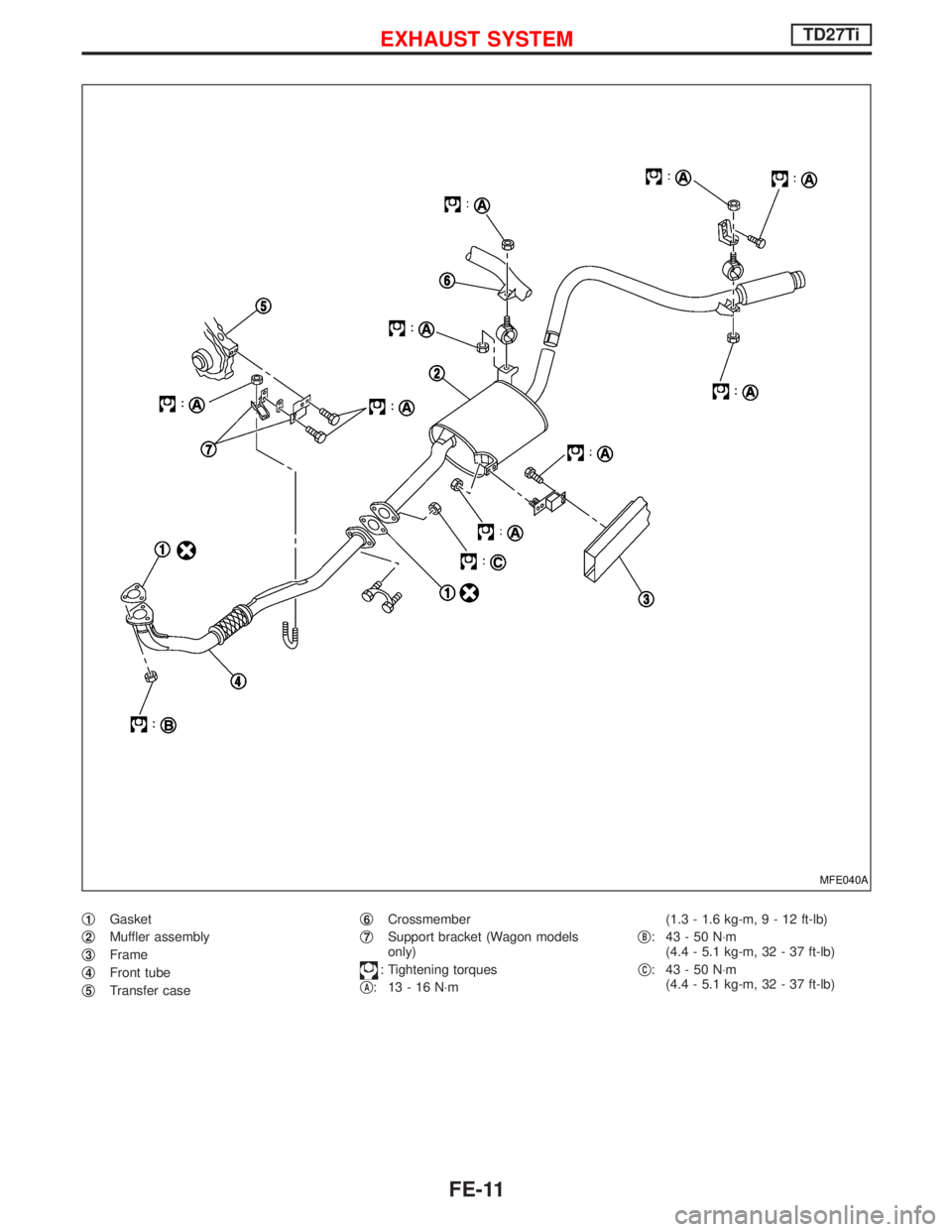

q1Gasket

q

2Muffler assembly

q

3Frame

q

4Front tube

q

5Transfer caseq

6Crossmember

q

7Support bracket (Wagon models

only)

: Tightening torques

q

A: 13-16N×m(1.3 - 1.6 kg-m,9-12ft-lb)

q

B: 43-50N×m

(4.4 - 5.1 kg-m, 32 - 37 ft-lb)

q

C: 43-50N×m

(4.4 - 5.1 kg-m, 32 - 37 ft-lb)

MFE040A

EXHAUST SYSTEMTD27Ti

FE-11