electrical NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 325 of 1833

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IShift lever is in neutral position,

I Heat up switch is OFF,

I Headlamp switch is OFF,

I Air conditioner switch is OFF,

I Rear defogger switch is OFF,

I Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem.

2. Check the current need for scheduled maintenance, especially for fuel filter and air cleaner filter. Refer to MA section.

3. Open engine hood and check the following:

IHarness connectors for improper connections

I Vacuum hoses for splits, kinks, or improper connections

I Wiring for improper connections, pinches, or cuts

SEF142I

4. Start engine and warm it up to the normal operating temperature.

EGO TO 2.

2 PREPARATION FOR CHECKING IDLE SPEED

With CONSULT-II

Connect CONSULT-II to the data link connector.

Without CONSULT-II

Install diesel tacho tester to the vehicle.

EGO TO 3.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONZD30DDTi

EC-50

http://vnx.su/

Page 353 of 1833

Description

Intermittent incidents (I/I) may occur. In many cases, the problem resolves itself (the part or circuit function

returns to normal without intervention). It is important to realize that the symptoms described in the custom-

er's complaint often do not recur on DTC visits. Realize also that the most frequent cause of I/I occurrences

is poor electrical connections. Because of this, the conditions under which the incident occurred may not be

clear. Therefore, circuit checks made as part of the standard diagnostic procedure may not indicate the spe-

cific problem area.

COMMON I/I REPORT SITUATIONS

STEP in Work FlowSituation

II The CONSULT-II is used. The SELF-DIAG RESULTS screen shows time data other than ª0º.

III The symptom described by the customer does not recur.

IV DTC does not appear during the DTC Confirmation Procedure.

VI The Diagnostic Procedure for XXXX does not indicate the problem area.

Diagnostic Procedure

1 INSPECTION START

Erase DTCs. Refer to ªHOW TO ERASE DTCº, EC-33.

EGO TO 2.

2 CHECK GROUND TERMINALS

Check ground terminals for corroding or loose connection.

Refer to GI section (ªGROUND INSPECTIONº, ªCircuit Inspectionº).

OK or NG

OK EGO TO 3.

NG ERepair or replace.

3 SEARCH FOR ELECTRICAL INCIDENT

Perform GI section, ªIncident Simulation Testsº.

OK or NG

OK EINSPECTION END

NG ERepair or replace.

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTZD30DDTi

EC-78

http://vnx.su/

Page 370 of 1833

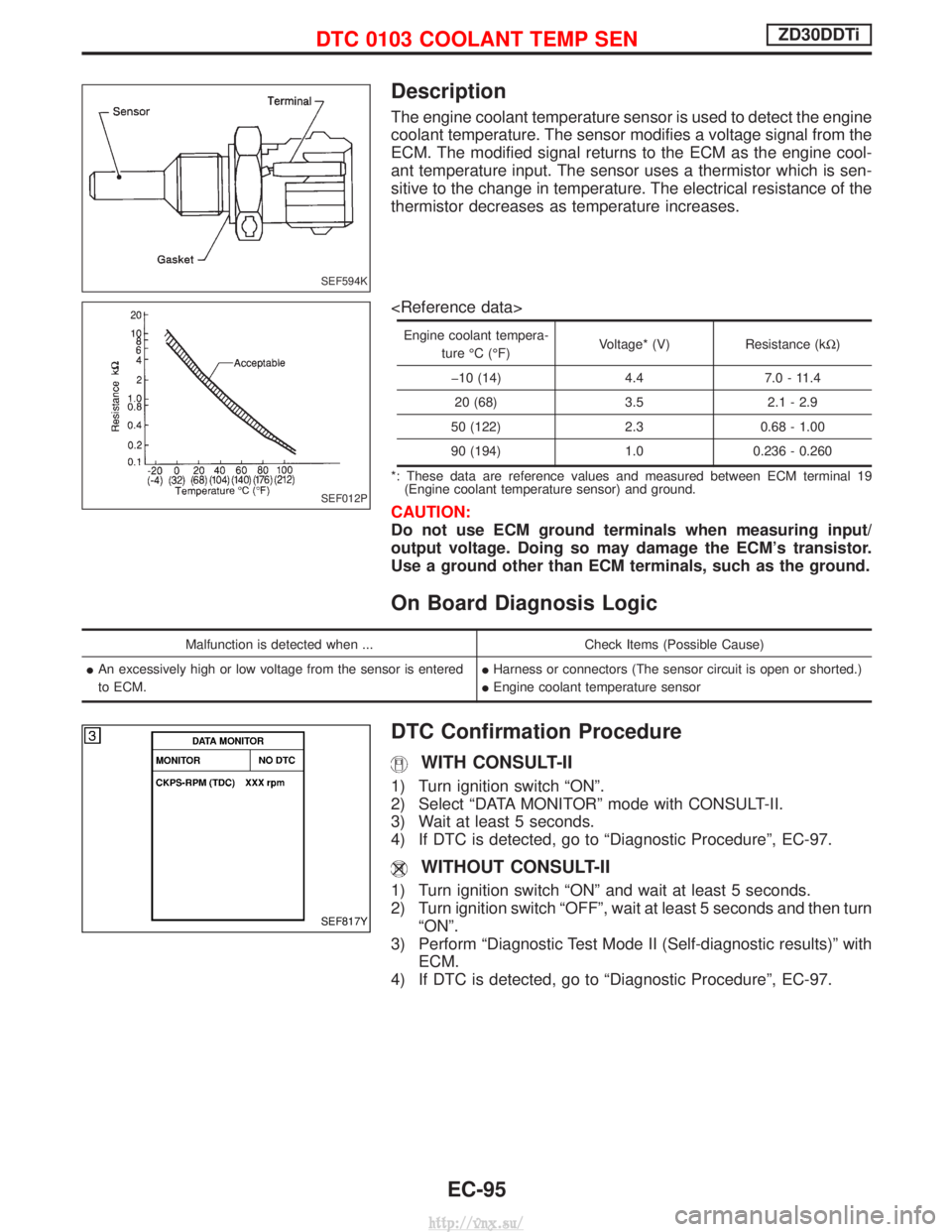

Description

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine cool-

ant temperature input. The sensor uses a thermistor which is sen-

sitive to the change in temperature. The electrical resistance of the

thermistor decreases as temperature increases.

Engine coolant tempera-ture ÉC (ÉF) Voltage* (V) Resistance (kW

)

þ10 (14) 4.4 7.0 - 11.4 20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

*: These data are reference values and measured between ECM terminal 19 (Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may damage the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

I An excessively high or low voltage from the sensor is entered

to ECM. I

Harness or connectors (The sensor circuit is open or shorted.)

I Engine coolant temperature sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-97.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 5 seconds.

2) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-97.

SEF594K

SEF012P

SEF817Y

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-95

http://vnx.su/

Page 502 of 1833

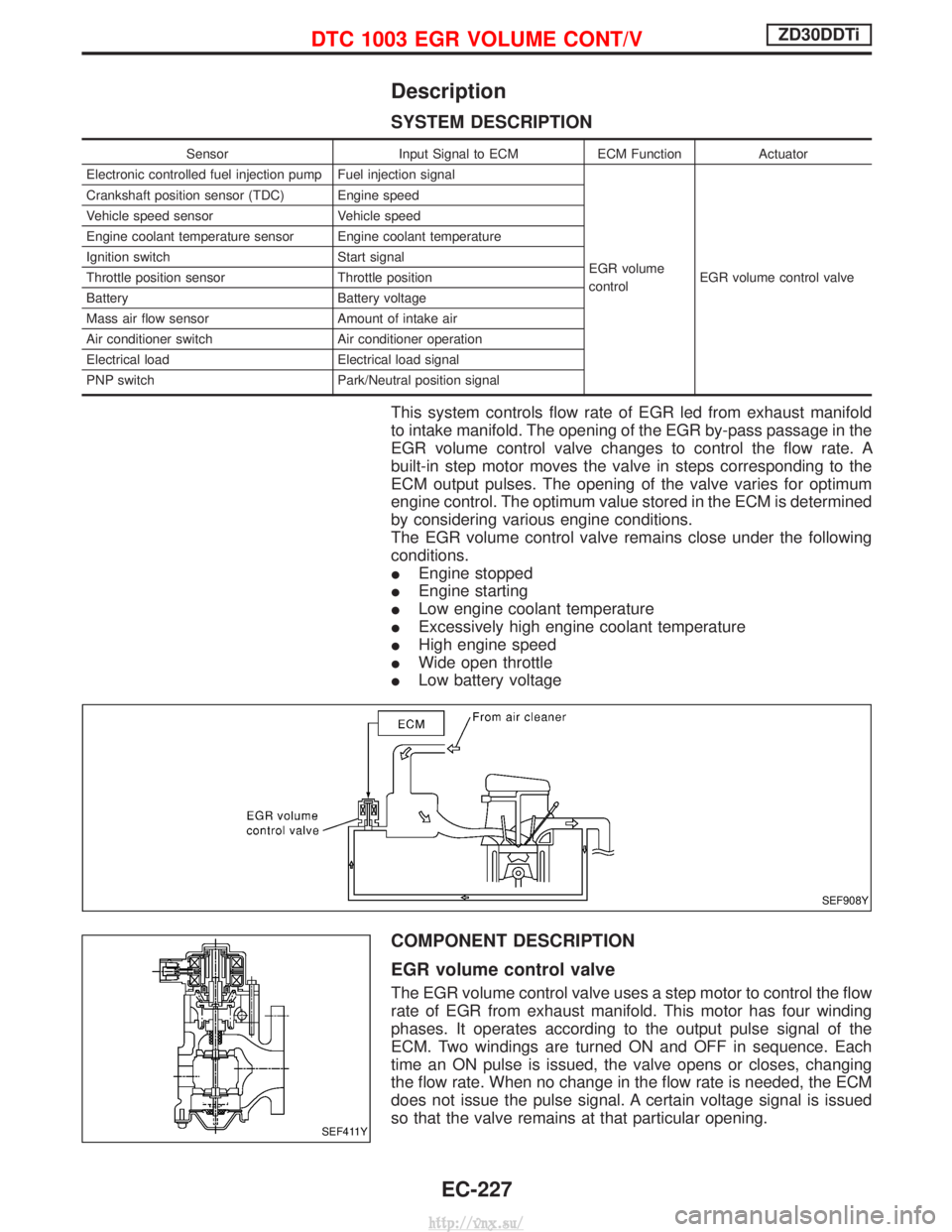

Description

SYSTEM DESCRIPTION

SensorInput Signal to ECMECM FunctionActuator

Electronic controlled fuel injection pump Fuel injection signal

EGR volume

controlEGR volume control valve

Crankshaft position sensor (TDC) Engine speed

Vehicle speed sensor

Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Battery Battery voltage

Mass air flow sensor Amount of intake air

Air conditioner switch Air conditioner operation

Electrical load Electrical load signal

PNP switch Park/Neutral position signal

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions.

The EGR volume control valve remains close under the following

conditions.

IEngine stopped

I Engine starting

I Low engine coolant temperature

I Excessively high engine coolant temperature

I High engine speed

I Wide open throttle

I Low battery voltage

COMPONENT DESCRIPTION

EGR volume control valve

The EGR volume control valve uses a step motor to control the flow

rate of EGR from exhaust manifold. This motor has four winding

phases. It operates according to the output pulse signal of the

ECM. Two windings are turned ON and OFF in sequence. Each

time an ON pulse is issued, the valve opens or closes, changing

the flow rate. When no change in the flow rate is needed, the ECM

does not issue the pulse signal. A certain voltage signal is issued

so that the valve remains at that particular opening.

SEF908Y

SEF411Y

DTC 1003 EGR VOLUME CONT/VZD30DDTi

EC-227

http://vnx.su/

Page 590 of 1833

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

IBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

I Do not disassemble ECM.

SEF289H

PRECAUTIONS AND PREPARATIONTD27Ti

EC-315

http://vnx.su/

Page 636 of 1833

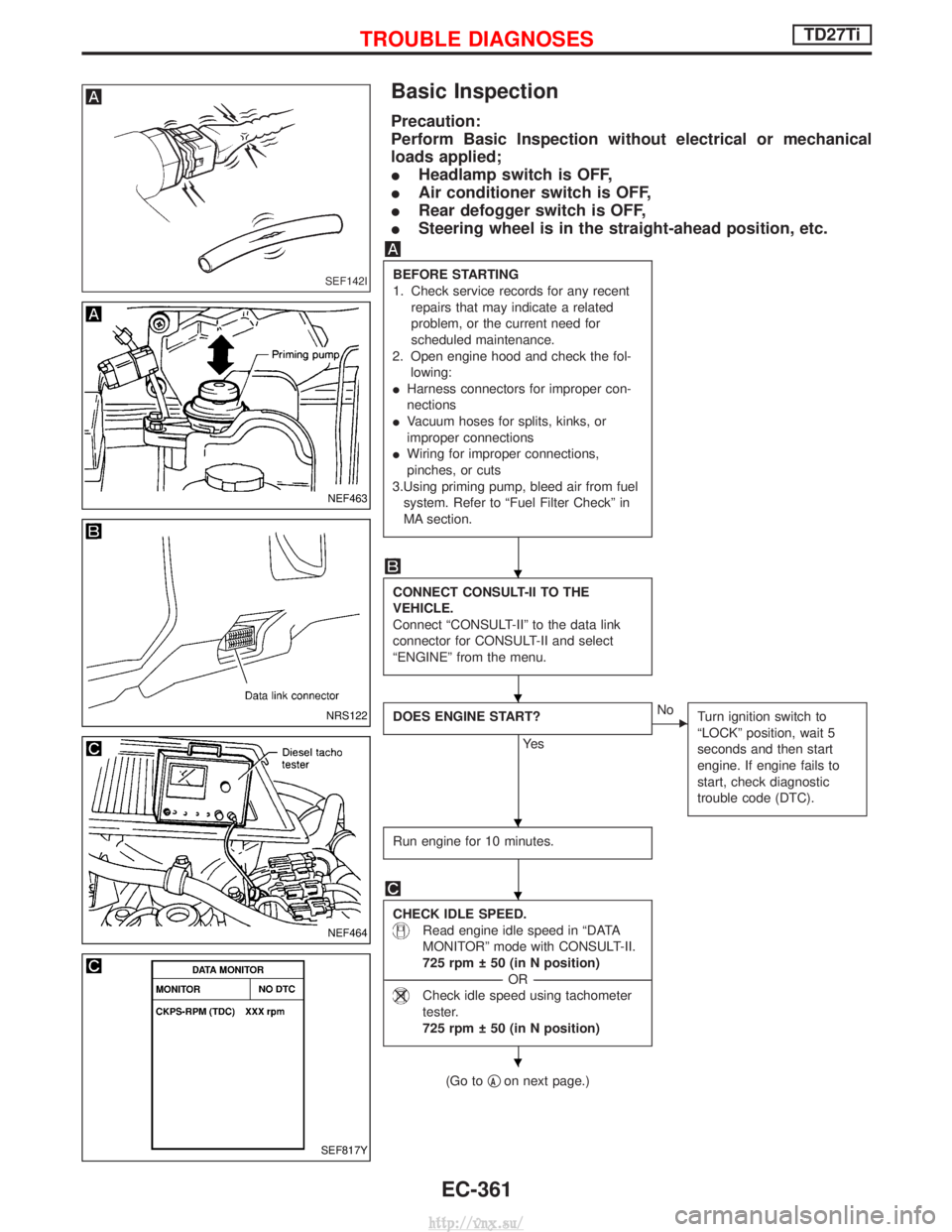

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IHeadlamp switch is OFF,

I Air conditioner switch is OFF,

I Rear defogger switch is OFF,

I Steering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any recent

repairs that may indicate a related

problem, or the current need for

scheduled maintenance.

2. Open engine hood and check the fol- lowing:

I Harness connectors for improper con-

nections

I Vacuum hoses for splits, kinks, or

improper connections

I Wiring for improper connections,

pinches, or cuts

3.Using priming pump, bleed air from fuel system. Refer to ªFuel Filter Checkº in

MA section.

CONNECT CONSULT-II TO THE

VEHICLE.

Connect ªCONSULT-IIº to the data link

connector for CONSULT-II and select

ªENGINEº from the menu.

DOES ENGINE START?

Ye s

ENo Turn ignition switch to

ªLOCKº position, wait 5

seconds and then start

engine. If engine fails to

start, check diagnostic

trouble code (DTC).

Run engine for 10 minutes.

CHECK IDLE SPEED.

Read engine idle speed in ªDATA

MONITORº mode with CONSULT-II.

725 rpm 50 (in N position)

----------------------------------------------------------------------------------------------------------------------------------- -OR------------------------------------------------------------------------------------------------------------------------------------

Check idle speed using tachometer

tester.

725 rpm 50 (in N position)

(Go to qAon next page.)

SEF142I

NEF463

NRS122

NEF464

SEF817Y

H

H

H

H

H

TROUBLE DIAGNOSESTD27Ti

EC-361

http://vnx.su/

Page 654 of 1833

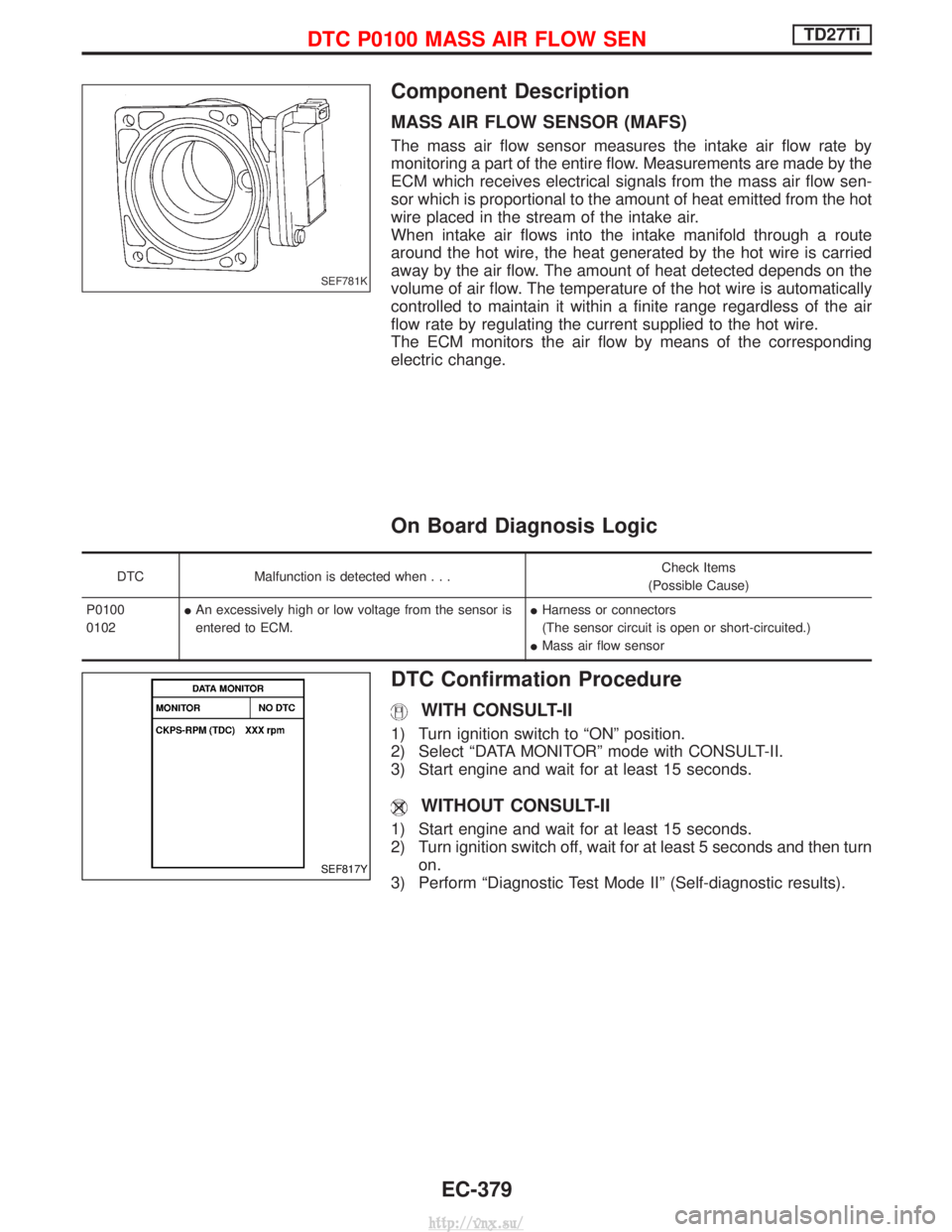

Component Description

MASS AIR FLOW SENSOR (MAFS)

The mass air flow sensor measures the intake air flow rate by

monitoring a part of the entire flow. Measurements are made by the

ECM which receives electrical signals from the mass air flow sen-

sor which is proportional to the amount of heat emitted from the hot

wire placed in the stream of the intake air.

When intake air flows into the intake manifold through a route

around the hot wire, the heat generated by the hot wire is carried

away by the air flow. The amount of heat detected depends on the

volume of air flow. The temperature of the hot wire is automatically

controlled to maintain it within a finite range regardless of the air

flow rate by regulating the current supplied to the hot wire.

The ECM monitors the air flow by means of the corresponding

electric change.

On Board Diagnosis Logic

DTCMalfunction is detected when... Check Items

(Possible Cause)

P0100

0102 I

An excessively high or low voltage from the sensor is

entered to ECM. I

Harness or connectors

(The sensor circuit is open or short-circuited.)

I Mass air flow sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait for at least 15 seconds.

WITHOUT CONSULT-II

1) Start engine and wait for at least 15 seconds.

2) Turn ignition switch off, wait for at least 5 seconds and then turn

on.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF781K

SEF817Y

DTC P0100 MASS AIR FLOW SENTD27Ti

EC-379

http://vnx.su/

Page 659 of 1833

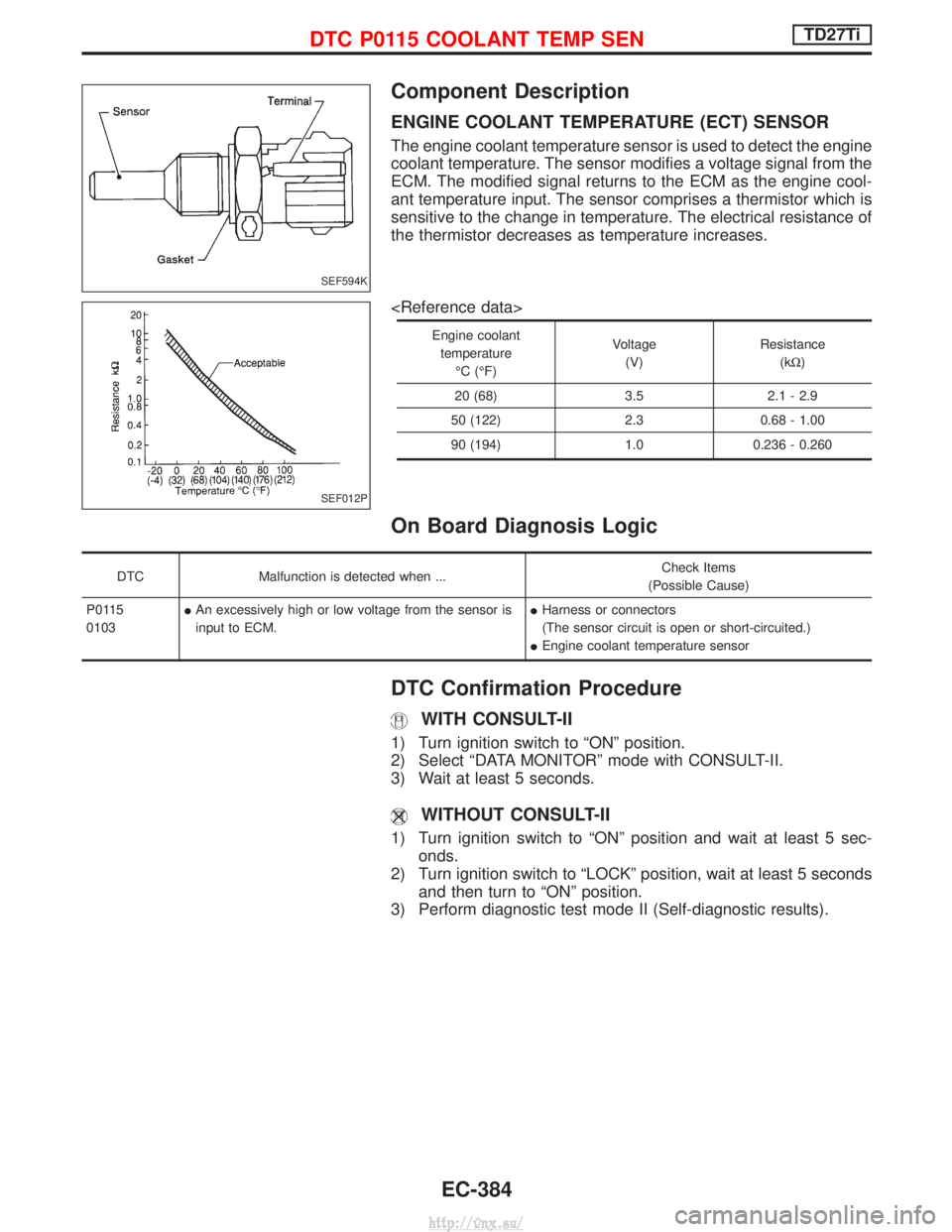

Component Description

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine cool-

ant temperature input. The sensor comprises a thermistor which is

sensitive to the change in temperature. The electrical resistance of

the thermistor decreases as temperature increases.

Engine coolanttemperature ÉC (ÉF) Voltage

(V) Resistance

(kW )

20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

On Board Diagnosis Logic

DTC Malfunction is detected when ... Check Items

(Possible Cause)

P0115

0103 I

An excessively high or low voltage from the sensor is

input to ECM. I

Harness or connectors

(The sensor circuit is open or short-circuited.)

I Engine coolant temperature sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch to ªONº position and wait at least 5 sec-

onds.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

3) Perform diagnostic test mode II (Self-diagnostic results).

SEF594K

SEF012P

DTC P0115 COOLANT TEMP SENTD27Ti

EC-384

http://vnx.su/

Page 670 of 1833

Component Description

FUEL TEMPERATURE SENSOR (FTS)

The fuel temperature sensor is used to detect the fuel temperature

in the injection pump. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the fuel tempera-

ture input. The sensor uses a thermistor which is sensitive to the

change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

The sensor is built into the inside electrical circuit of the injection

pump.

On Board Diagnosis Logic

DTCMalfunction is detected when ... Check Items

(Possible Cause)

P0180

0402 I

An excessively high or low voltage from the sensor is

detected by ECM. I

Harness or connectors

(The sensor circuit is open or short-circuited.)

I Fuel temperature sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch to ªONº position and wait at least 5 sec-

onds.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

DTC P0180 FUEL TEMP SENSORTD27Ti

EC-395

http://vnx.su/

Page 672 of 1833

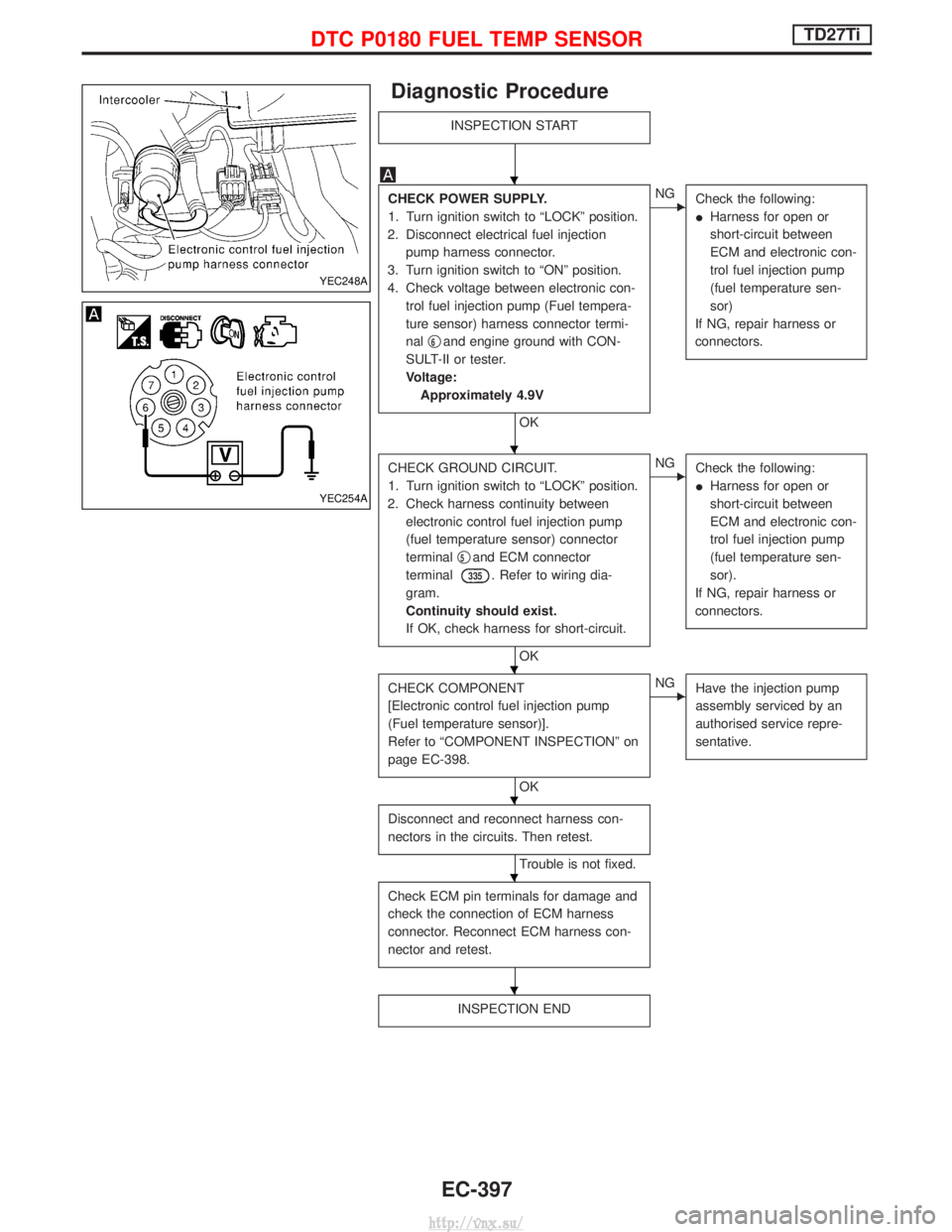

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect electrical fuel injection pump harness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between electronic con- trol fuel injection pump (Fuel tempera-

ture sensor) harness connector termi-

nal q

6and engine ground with CON-

SULT-II or tester.

Voltage: Approximately 4.9V

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and electronic con-

trol fuel injection pump

(fuel temperature sen-

sor)

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between electronic control fuel injection pump

(fuel temperature sensor) connector

terminal q

5and ECM connector

terminal

335. Refer to wiring dia-

gram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and electronic con-

trol fuel injection pump

(fuel temperature sen-

sor).

If NG, repair harness or

connectors.

CHECK COMPONENT

[Electronic control fuel injection pump

(Fuel temperature sensor)].

Refer to ªCOMPONENT INSPECTIONº on

page EC-398.

OK

ENG Have the injection pump

assembly serviced by an

authorised service repre-

sentative.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

YEC248A

YEC254A

H

H

H

H

H

H

DTC P0180 FUEL TEMP SENSORTD27Ti

EC-397

http://vnx.su/