electrical NISSAN TERRANO 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1454 of 1833

qC

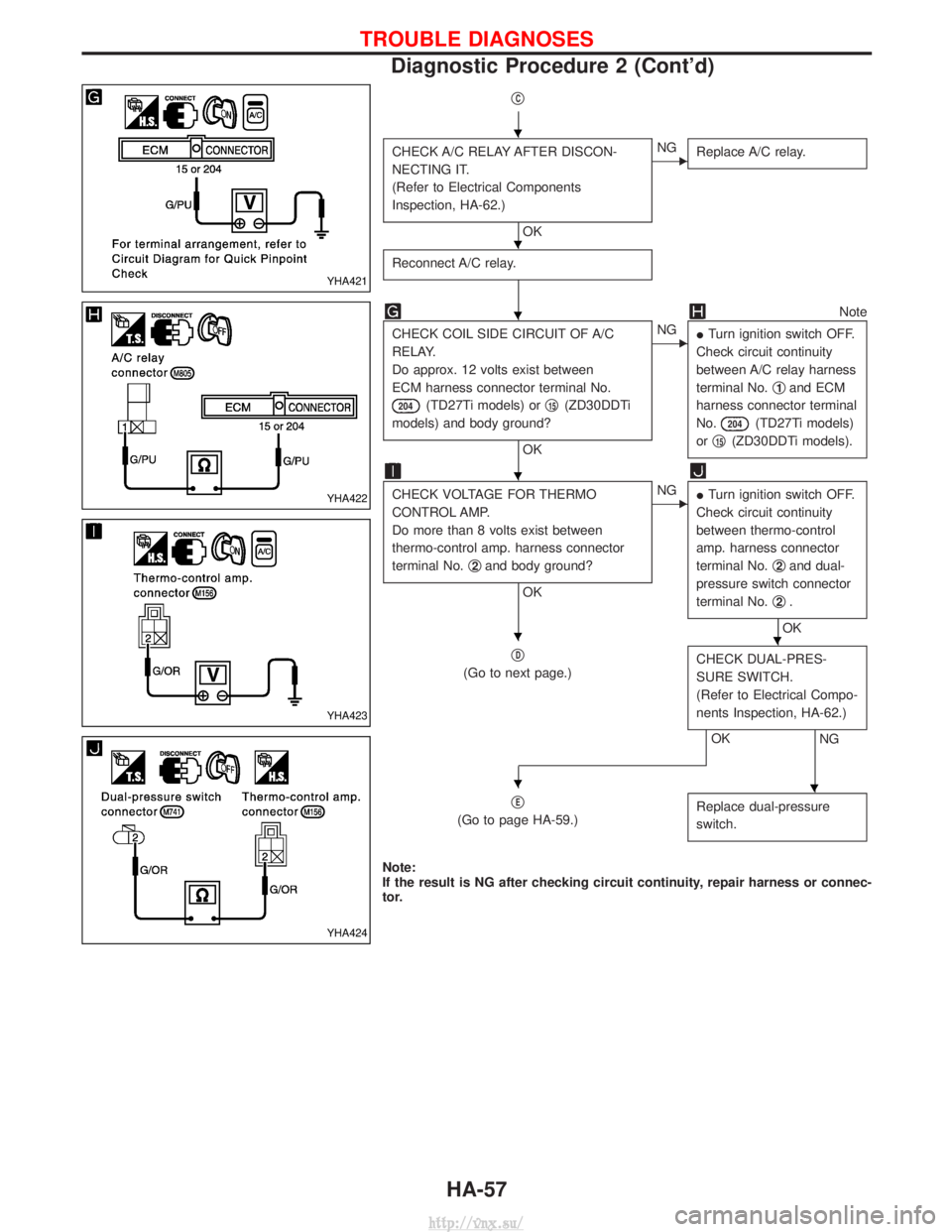

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

(Refer to Electrical Components

Inspection, HA-62.)

OK

ENGReplace A/C relay.

Reconnect A/C relay.

Note

CHECK COIL SIDE CIRCUIT OF A/C

RELAY.

Do approx. 12 volts exist between

ECM harness connector terminal No.

204(TD27Ti models) or q15(ZD30DDTi

models) and body ground?

OK

ENG ITurn ignition switch OFF.

Check circuit continuity

between A/C relay harness

terminal No. q

1and ECM

harness connector terminal

No.

204(TD27Ti models)

or q

15(ZD30DDTi models).

CHECK VOLTAGE FOR THERMO

CONTROL AMP.

Do more than 8 volts exist between

thermo-control amp. harness connector

terminal No. q

2and body ground?

OK

ENG

ITurn ignition switch OFF.

Check circuit continuity

between thermo-control

amp. harness connector

terminal No. q

2and dual-

pressure switch connector

terminal No. q

2.

OK

q

D

(Go to next page.) CHECK DUAL-PRES-

SURE SWITCH.

(Refer to Electrical Compo-

nents Inspection, HA-62.)

NGOK

q

E

(Go to page HA-59.) Replace dual-pressure

switch.

Note:

If the result is NG after checking circuit continuity, repair harness or connec-

tor.

YHA421

YHA422

YHA423

YHA424

H

H

H

H

HH

HH

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Cont'd)

HA-57

http://vnx.su/

Page 1455 of 1833

qD

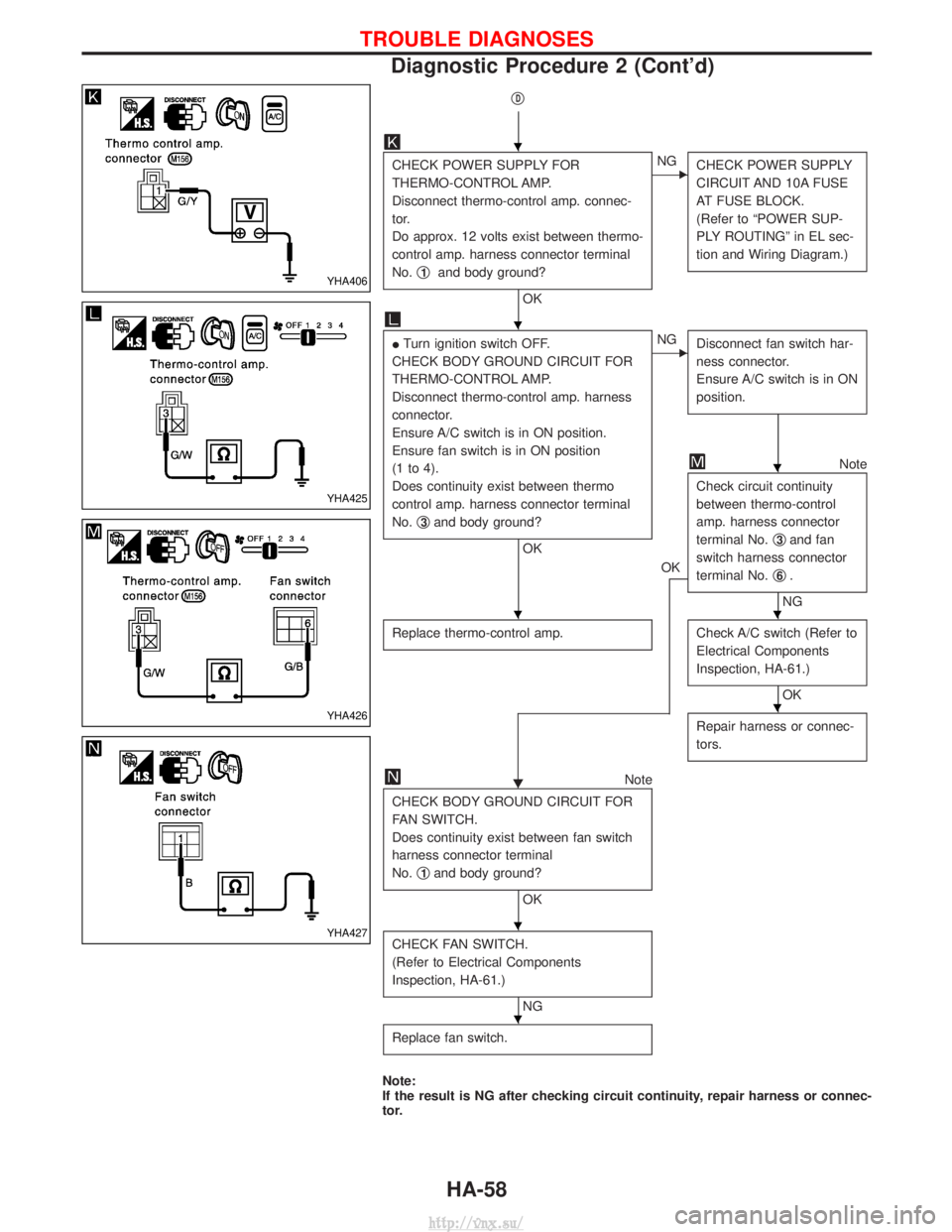

CHECK POWER SUPPLY FOR

THERMO-CONTROL AMP.

Disconnect thermo-control amp. connec-

tor.

Do approx. 12 volts exist between thermo-

control amp. harness connector terminal

No.q

1and body ground?

OK

ENG

CHECK POWER SUPPLY

CIRCUIT AND 10A FUSE

AT FUSE BLOCK.

(Refer to ªPOWER SUP-

PLY ROUTINGº in EL sec-

tion and Wiring Diagram.)

ITurn ignition switch OFF.

CHECK BODY GROUND CIRCUIT FOR

THERMO-CONTROL AMP.

Disconnect thermo-control amp. harness

connector.

Ensure A/C switch is in ON position.

Ensure fan switch is in ON position

(1 to 4).

Does continuity exist between thermo

control amp. harness connector terminal

No. q

3and body ground?

OK

ENG

Disconnect fan switch har-

ness connector.

Ensure A/C switch is in ON

position.

OK

Note

Check circuit continuity

between thermo-control

amp. harness connector

terminal No. q

3and fan

switch harness connector

terminal No. q

6.

NG

Replace thermo-control amp.

Check A/C switch (Refer to

Electrical Components

Inspection, HA-61.)

OK

H Repair harness or connec-

tors.Note

CHECK BODY GROUND CIRCUIT FOR

FAN SWITCH.

Does continuity exist between fan switch

harness connector terminal

No. q

1and body ground?

OK

CHECK FAN SWITCH.

(Refer to Electrical Components

Inspection, HA-61.)

NG

Replace fan switch.

Note:

If the result is NG after checking circuit continuity, repair harness or connec-

tor.

YHA406

YHA425

YHA426

YHA427

H

H

H

HH

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Cont'd)

HA-58

http://vnx.su/

Page 1458 of 1833

Electrical Components Inspection

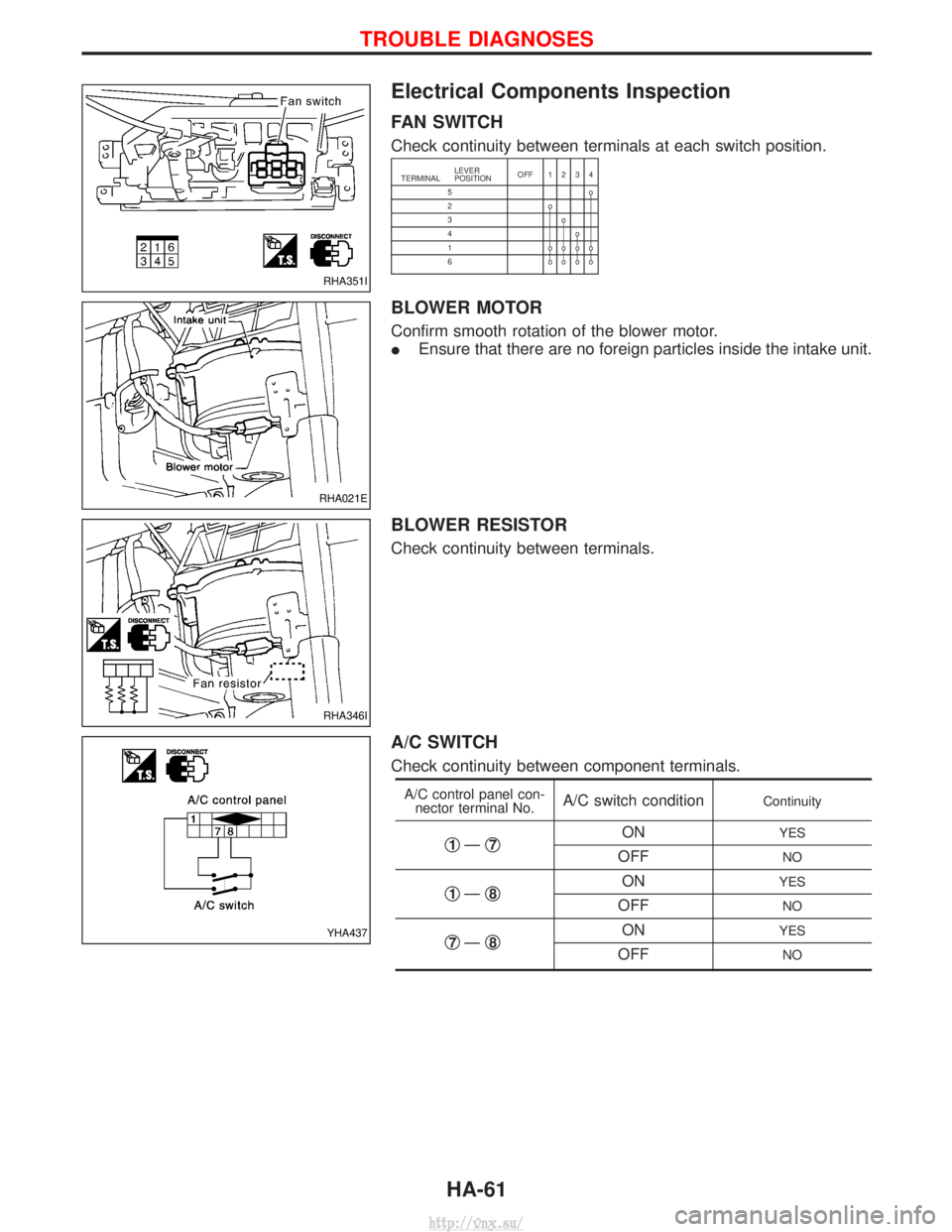

FAN SWITCH

Check continuity between terminals at each switch position.

TERMINALLEVER

POSITION

OFF 1234

5o

2o

3o

4o

1 oooo

6 oooo

BLOWER MOTOR

Confirm smooth rotation of the blower motor.

I Ensure that there are no foreign particles inside the intake unit.

BLOWER RESISTOR

Check continuity between terminals.

A/C SWITCH

Check continuity between component terminals.

A/C control panel con-

nector terminal No.A/C switch conditionContinuity

q1Ð q7ONYES

OFFNO

q1Ðq8ONYES

OFFNO

q7Ðq8ONYES

OFFNO

RHA351I

RHA021E

RHA346I

YHA437

TROUBLE DIAGNOSES

HA-61

http://vnx.su/

Page 1459 of 1833

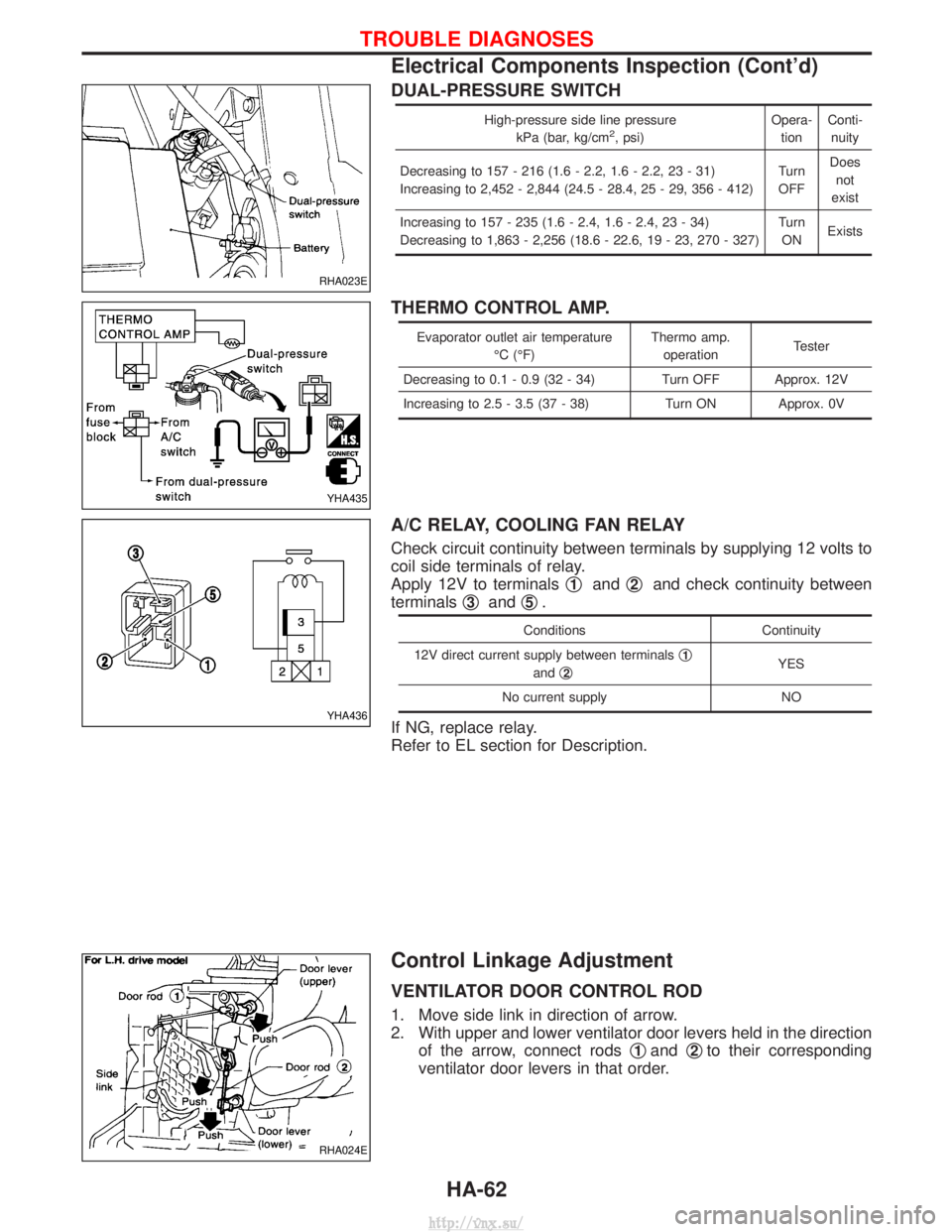

DUAL-PRESSURE SWITCH

High-pressure side line pressurekPa (bar, kg/cm2, psi) Opera-

tion Conti-

nuity

Decreasing to 157 - 216 (1.6 - 2.2, 1.6 - 2.2, 23 - 31)

Increasing to 2,452 - 2,844 (24.5 - 28.4, 25 - 29, 356 - 412) Turn

OFF Does

not

exist

Increasing to 157 - 235 (1.6 - 2.4, 1.6 - 2.4, 23 - 34)

Decreasing to 1,863 - 2,256 (18.6 - 22.6, 19 - 23, 270 - 327) Turn

ON Exists

THERMO CONTROL AMP.

Evaporator outlet air temperature

ÉC (ÉF) Thermo amp.

operation Tester

Decreasing to 0.1 - 0.9 (32 - 34) Turn OFF Approx. 12V

Increasing to 2.5 - 3.5 (37 - 38) Turn ON Approx. 0V

A/C RELAY, COOLING FAN RELAY

Check circuit continuity between terminals by supplying 12 volts to

coil side terminals of relay.

Apply 12V to terminals q

1andq2and check continuity between

terminals q

3andq5.

Conditions

Continuity

12V direct current supply between terminals q

1

andq2YES

No current supply NO

If NG, replace relay.

Refer to EL section for Description.

Control Linkage Adjustment

VENTILATOR DOOR CONTROL ROD

1. Move side link in direction of arrow.

2. With upper and lower ventilator door levers held in the direction of the arrow, connect rods q

1andq2to their corresponding

ventilator door levers in that order.

RHA023E

YHA435

YHA436

RHA024E

TROUBLE DIAGNOSES

Electrical Components Inspection (Cont'd)

HA-62

http://vnx.su/

Page 1465 of 1833

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL R20 is as follows (The compo-

sition varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in the RS sectionof this Service Manual.

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

Wiring Diagrams and Trouble Diagnoses

When you read wiring diagrams, refer to the following:

IGI section, ªHOW TO READ WIRING DIAGRAMSº

I EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnoses, refer to the following:

I GI section, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

I GI section, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

PRECAUTIONS

SC-2

http://vnx.su/

Page 1486 of 1833

System Description

The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) (ZD30DDTi engine models) through:

I10A fuse (No. 31, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage (ZD30DDTi engine models). The

charging circuit is protected by the 100A fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

I through 10A fuse [No. 12, located in the fuse block (J/B)]

I to combination meter terminal 28 for the charge warning lamp.

Ground is supplied to terminal 2 of the combination meter through terminal 1(L) (TD27Ti engine models) or

3(L) (ZD30DDTi engine models) of the alternator. With power and ground supplied, the charge warning lamp

will illuminate. When the alternator is providing sufficient voltage with the engine running, the ground is opened

and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

CHARGING SYSTEM

SC-23

http://vnx.su/

Page 1494 of 1833

ELECTRICAL SYSTEMSECTION

EL

When you read wiring diagrams:

I Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

CONTENTS

PRECAUTIONS ...............................................................4

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER² ...............4

Wiring Diagrams and Trouble Diagnoses....................4

HARNESS CONNECTOR ................................................5

Description ...................................................................5

STANDARDIZED RELAYS ..............................................6

Description ...................................................................6

POWER SUPPLY ROUTING ...........................................8

Schematic ....................................................................8

Wiring Diagram - POWER - ......................................10

Fuse ........................................................................\

...19

Fusible Link................................................................19

Circuit Breaker Inspection .........................................19

GROUND DISTRIBUTION .............................................20

COMBINATION SWITCH ...............................................25

Check ........................................................................\

.25

Replacement ..............................................................26

STEERING SWITCH ......................................................27

Check ........................................................................\

.27

HEADLAMP - Without Daytime Light System - .........28

Wiring Diagram - H/LAMP -.......................................28

Trouble Diagnoses.....................................................31

HEADLAMP - Daytime Light System - .......................32

Operation ...................................................................32

System Description ....................................................32

Schematic ..................................................................33

Wiring Diagram - DTRL - ...........................................34

Trouble Diagnoses.....................................................40

HEADLAMP - Headlamp Aiming Control - .................41

Description .................................................................41

Replacing Headlamp Aiming Actuator .......................42

Wiring Diagram - H/AIM - ..........................................43

Trouble Diagnoses.....................................................46 HEADLAMP

...................................................................47

Bulb Replacement .....................................................47

Aiming Adjustment .....................................................47

EXTERIOR LAMP ..........................................................49

Wiring Diagram - TAIL/L - ..........................................49

Wiring Diagram - STOP/L - .......................................52

Wiring Diagram - BACK/L - .......................................53

Wiring Diagram - F/FOG - .........................................55

Front Fog Lamp Aiming Adjustment ..........................57

Wiring Diagram - R/FOG -.........................................58

System Description ....................................................59

Schematic ..................................................................61

Wiring Diagram - TURN - ..........................................62

Trouble Diagnoses.....................................................66

INTERIOR LAMP ...........................................................67

Schematic ..................................................................67

Wiring Diagram - ILL - ...............................................68

System Description ....................................................72

Wiring Diagram - INT/L - ...........................................74

Trouble Diagnoses.....................................................78

METER AND GAUGES .................................................82

System Description ....................................................82

Combination Meter ....................................................84

Schematic ..................................................................85

Wiring Diagram - METER - .......................................86

Combination Meter Self-Diagnosis ............................90

Trouble Diagnoses.....................................................92

Components Inspection .............................................97

Fuel Level Sensor Unit Check...................................98

Thermal Transmitter Check .......................................98

WARNING LAMPS AND CHIME ...................................99

Schematic ..................................................................99

Wiring Diagram - WARN - .......................................100

Electrical Components Inspection ........................... 110

http://vnx.su/

Page 1495 of 1833

Oil Pressure Switch Check ...................................... 110

Wiring Diagram - CHIME - ...................................... 111

WIPER AND WASHER ................................................ 112

Wiring Diagram - WIPER - ...................................... 112

Wiring Diagram - WIP/R -........................................ 114

Installation ................................................................ 116

Washer Nozzle Adjustment ..................................... 117

Check Valve ............................................................. 117

Wiring Diagram - HLC - ........................................... 118

HORN, CIGARETTE LIGHTER AND CLOCK ............122

Wiring Diagram - HORN - .......................................122

Wiring Diagram - CIGAR -.......................................123

Wiring Diagram - CLOCK -......................................124

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER .................................................125

System Description ..................................................125

Wiring Diagram - DEF - ...........................................126

Trouble Diagnoses...................................................128

Filament Check ........................................................132

Filament Repair .......................................................133

AUDIO ........................................................................\

..134

System Description ..................................................134

Schematic ................................................................136

Wiring Diagram - AUDIO - .......................................138

Wiring Diagram - REMOTE -...................................145

Trouble Diagnoses...................................................147

Inspection.................................................................149

Location of Roof Mounted Antenna .........................150

HEATED SEAT ............................................................151

Wiring Diagram - HSEAT - ......................................151

SUNROOF ....................................................................153

Wiring Diagram - SROOF - .....................................153

DOOR MIRROR ...........................................................154

Wiring Diagram - MIRROR - ...................................154

POWER WINDOW .......................................................156

System Description ..................................................156

Schematic ................................................................158

Wiring Diagram - WINDOW - ..................................159

Trouble Diagnoses...................................................162

POWER DOOR LOCK .................................................163

System Description ..................................................163

Schematic ................................................................164

Wiring Diagram - D/LOCK -.....................................166

Trouble Diagnoses...................................................171

POWER DOOR LOCK - SUPER LOCK - ...................179

Component Parts Location ......................................179

System Description ..................................................180

Schematic ................................................................182 Wiring Diagram - S/LOCK - .....................................184

Trouble Diagnoses...................................................192

MULTI-REMOTE CONTROL SYSTEM .......................202

System Description ..................................................202

Schematic ................................................................204

Wiring Diagram - MULTI - .......................................205

Trouble Diagnoses...................................................213

ID Code Entry Procedure ........................................215

TIME CONTROL UNIT (TCU) .....................................216

System Description ..................................................216

Trouble Diagnosis ....................................................218

Schematic ................................................................220

NATS (Nissan Anti-Theft System) .............................222

System Description ..................................................222

System Composition ................................................223

Component Parts Location ......................................224

Wiring Diagram - NATS -.........................................225

CONSULT-II .............................................................229

Trouble Diagnoses...................................................231

How to Replace NATS IMMU ..................................242

THEFT WARNING SYSTEM .......................................243

Components Parts and Harness Connector

Location ...................................................................243

System Description ..................................................244

Theft Warning System/Schematic ...........................247

Wiring Diagram - THEFT -.......................................248

Trouble Diagnoses...................................................264

LOCATION OF ELECTRICAL UNITS .........................275

Engine Compartment ...............................................275

Passenger Compartment/LHD Models ....................276

Passenger Compartment/RHD Models ...................278

HARNESS LAYOUT ....................................................280

How to Read Harness Layout .................................280

Outline......................................................................281

Main Harness...........................................................282

EFC Harness ...........................................................298

Engine Harness .......................................................310

Body Harness ..........................................................312

Chassis Harness......................................................320

Room Lamp Harness...............................................321

Tailgate Harness ......................................................322

Door Harness (LH side)...........................................323

Door Harness (RH side) ..........................................324

BULB SPECIFICATIONS ............................................325

Headlamps ...............................................................325

Exterior Lamps.........................................................325

Interior Lamps ..........................................................325

WIRING DIAGRAM CODES (CELL CODES) .............326

CONTENTS(Cont'd)

EL-2

http://vnx.su/

Page 1497 of 1833

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL R20 is as follows (The compo-

sition varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in the RS sectionof this Service Manual.

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

Wiring Diagrams and Trouble Diagnoses

When you read wiring diagrams, refer to the following:

IGI section, ªHOW TO READ WIRING DIAGRAMSº

I EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnoses, refer to the following:

I GI section, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

I GI section, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

PRECAUTIONS

EL-4

http://vnx.su/

Page 1512 of 1833

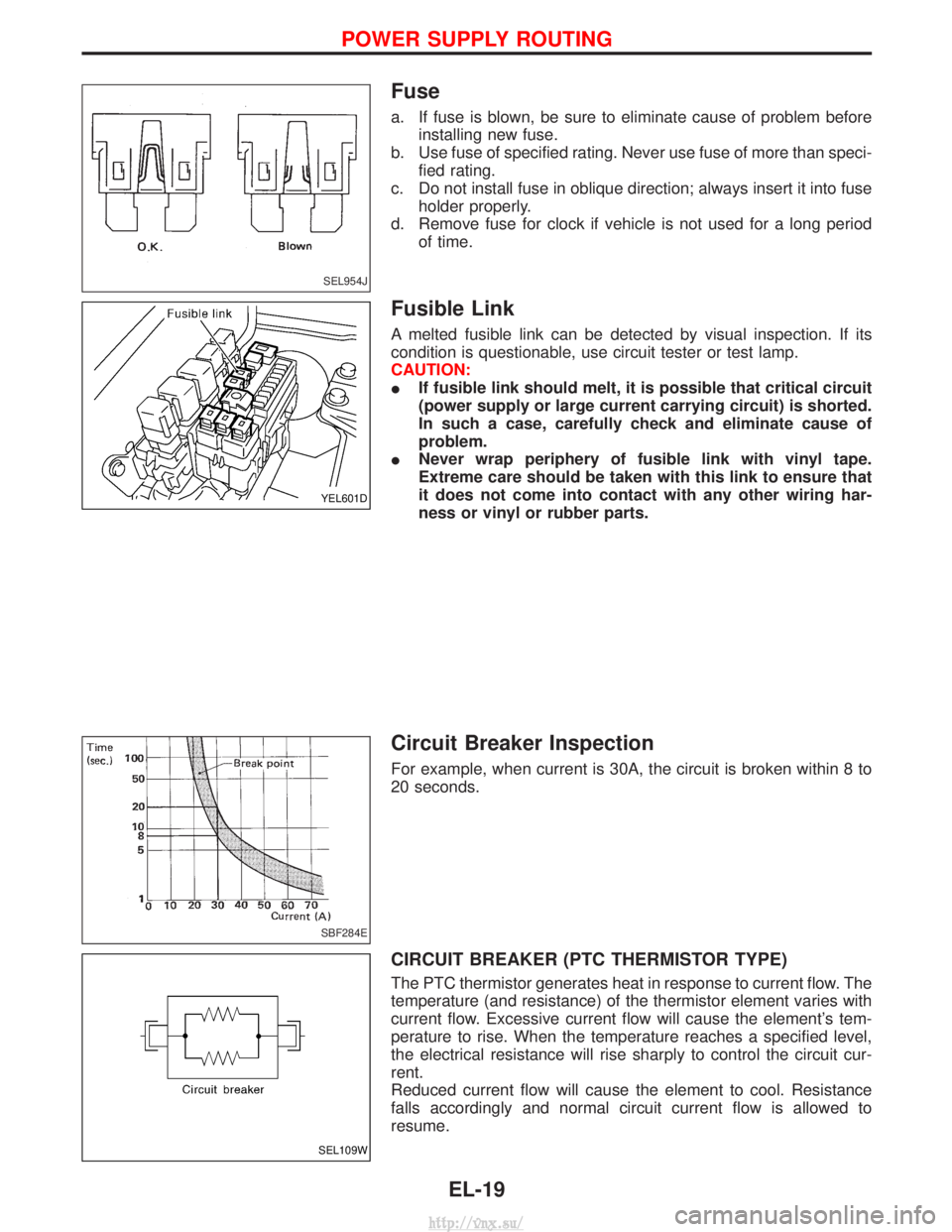

Fuse

a. If fuse is blown, be sure to eliminate cause of problem beforeinstalling new fuse.

b. Use fuse of specified rating. Never use fuse of more than speci- fied rating.

c. Do not install fuse in oblique direction; always insert it into fuse holder properly.

d. Remove fuse for clock if vehicle is not used for a long period of time.

Fusible Link

A melted fusible link can be detected by visual inspection. If its

condition is questionable, use circuit tester or test lamp.

CAUTION:

IIf fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted.

In such a case, carefully check and eliminate cause of

problem.

I Never wrap periphery of fusible link with vinyl tape.

Extreme care should be taken with this link to ensure that

it does not come into contact with any other wiring har-

ness or vinyl or rubber parts.

Circuit Breaker Inspection

For example, when current is 30A, the circuit is broken within 8 to

20 seconds.

CIRCUIT BREAKER (PTC THERMISTOR TYPE)

The PTC thermistor generates heat in response to current flow. The

temperature (and resistance) of the thermistor element varies with

current flow. Excessive current flow will cause the element's tem-

perature to rise. When the temperature reaches a specified level,

the electrical resistance will rise sharply to control the circuit cur-

rent.

Reduced current flow will cause the element to cool. Resistance

falls accordingly and normal circuit current flow is allowed to

resume.

SEL954J

YEL601D

SBF284E

SEL109W

POWER SUPPLY ROUTING

EL-19

http://vnx.su/