electrical NISSAN TERRANO 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 714 of 1833

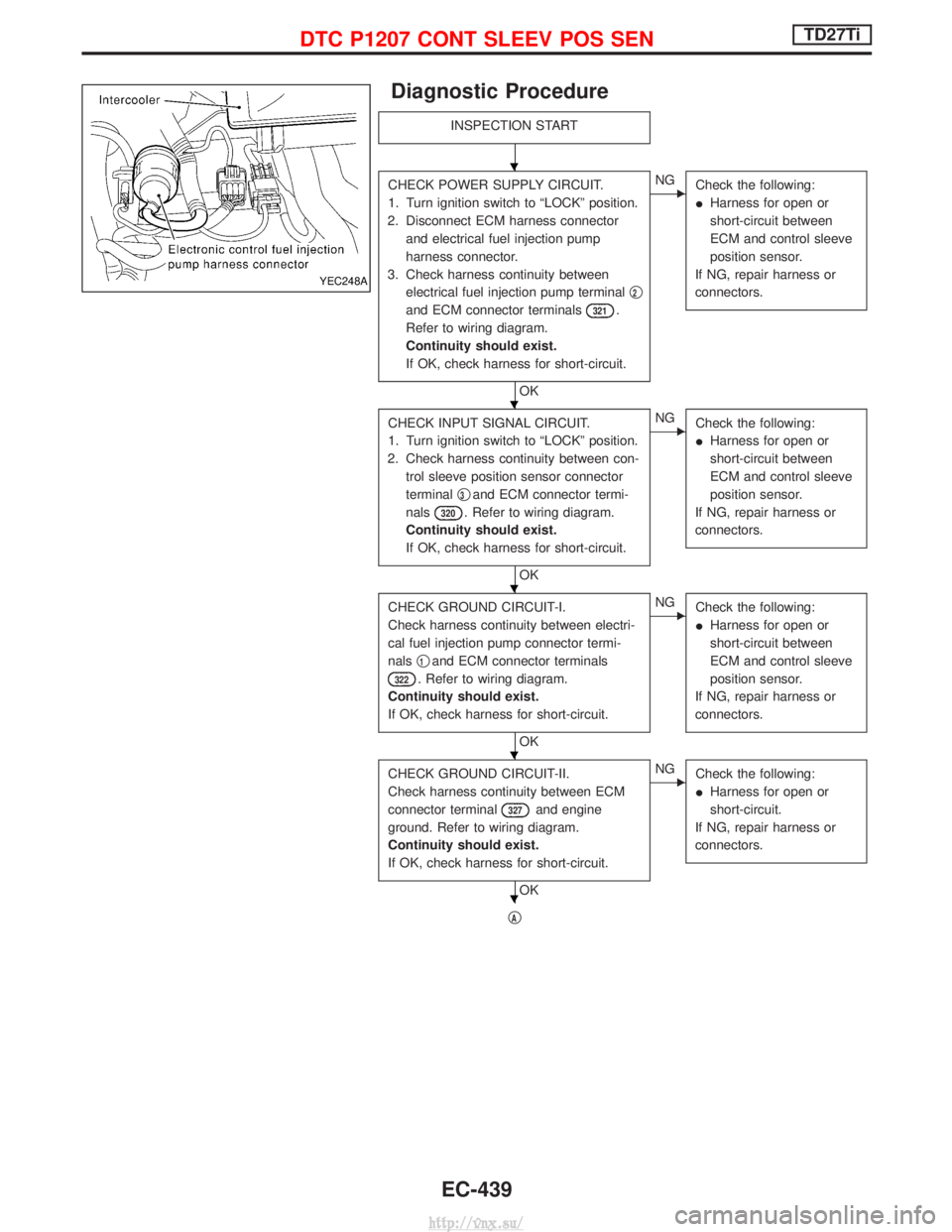

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector and electrical fuel injection pump

harness connector.

3. Check harness continuity between electrical fuel injection pump terminal q

2

and ECM connector terminals321.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and control sleeve

position sensor.

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between con- trol sleeve position sensor connector

terminal q

3and ECM connector termi-

nals

320. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and control sleeve

position sensor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-I.

Check harness continuity between electri-

cal fuel injection pump connector termi-

nals q

1and ECM connector terminals

322. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and control sleeve

position sensor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-II.

Check harness continuity between ECM

connector terminal

327and engine

ground. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit.

If NG, repair harness or

connectors.

qA

YEC248A

H

H

H

H

H

DTC P1207 CONT SLEEV POS SENTD27Ti

EC-439

http://vnx.su/

Page 784 of 1833

Removal

Transmission has to be removed as a unit together with transfer

box.

Remove transmission assembly as follows:

IDisconnect negative battery terminal.

I Remove shift levers of transmission and transfer.

I Remove front and rear propeller shafts. Ð Refer to PD section.

I Insert plug into rear oil seal after removing propeller shaft.

I Remove RPM-sensor from transmission upper side.

CAUTION:

Be careful not to damage spline, sleeve yoke and rear oil seal,

when removing propeller shaft.

I Remove torsion bar spring. Ð Refer to FA Section.

I Remove third crossmember (the one supporting front differen-

tial).

I Remove fifth crossmember (the one situated at the rear of

transfer).

I Support transmission and transfer with a suitable transmission

jack.

WARNING:

Support transmission and transfer with suitable jacks, while

removing them.

I Remove fourth crossmember (the one supporting transmis-

sion).

I Remove clutch operating cylinder.

I Remove starter motor.

I Remove exhaust tube bracket from transmission.

I Disconnect electrical connectors.

I Remove transmission from engine.

REMOVAL AND INSTALLATIONFS5R30A

MT-7

http://vnx.su/

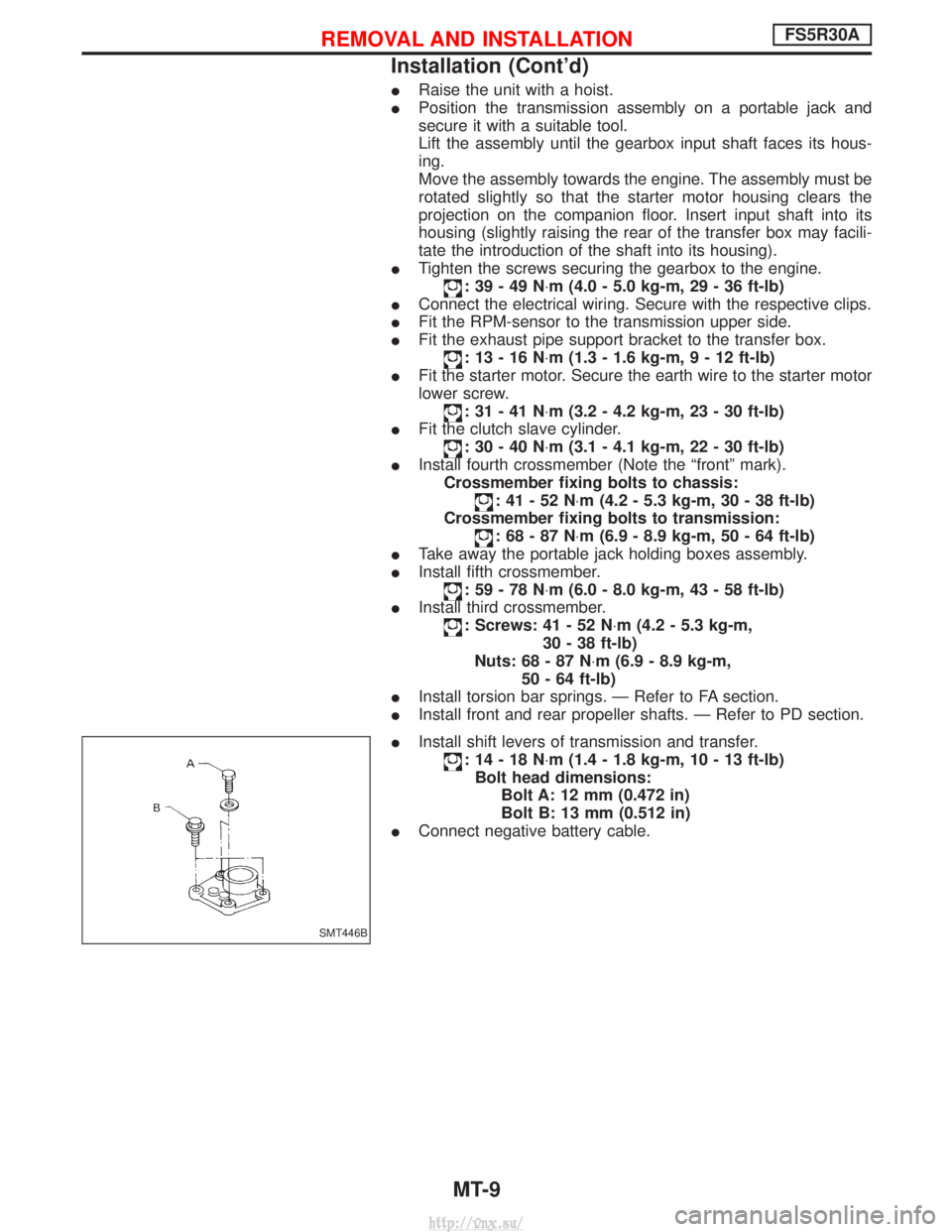

Page 786 of 1833

IRaise the unit with a hoist.

I Position the transmission assembly on a portable jack and

secure it with a suitable tool.

Lift the assembly until the gearbox input shaft faces its hous-

ing.

Move the assembly towards the engine. The assembly must be

rotated slightly so that the starter motor housing clears the

projection on the companion floor. Insert input shaft into its

housing (slightly raising the rear of the transfer box may facili-

tate the introduction of the shaft into its housing).

I Tighten the screws securing the gearbox to the engine.

:39-49N ×m (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

I Connect the electrical wiring. Secure with the respective clips.

I Fit the RPM-sensor to the transmission upper side.

I Fit the exhaust pipe support bracket to the transfer box.

:13-16N ×m (1.3 - 1.6 kg-m ,9-12ft-lb)

I Fit the starter motor. Secure the earth wire to the starter motor

lower screw.

:31-41N ×m (3.2 - 4.2 kg-m, 23 - 30 ft-lb)

I Fit the clutch slave cylinder.

:30-40N ×m (3.1 - 4.1 kg-m, 22 - 30 ft-lb)

I Install fourth crossmember (Note the ªfrontº mark).

Crossmember fixing bolts to chassis:

:41-52N ×m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

Crossmember fixing bolts to transmission:

:68-87N ×m (6.9 - 8.9 kg-m, 50 - 64 ft-lb)

I Take away the portable jack holding boxes assembly.

I Install fifth crossmember.

:59-78N ×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

I Install third crossmember.

: Screws: 41 - 52 N ×m (4.2 - 5.3 kg-m,

30 - 38 ft-lb)

Nuts: 68 - 87 N ×m (6.9 - 8.9 kg-m,

50 - 64 ft-lb)

I Install torsion bar springs. Ð Refer to FA section.

I Install front and rear propeller shafts. Ð Refer to PD section.

I Install shift levers of transmission and transfer.

:14-18N ×m (1.4 - 1.8 kg-m, 10 - 13 ft-lb)

Bolt head dimensions: Bolt A: 12 mm (0.472 in)

Bolt B: 13 mm (0.512 in)

I Connect negative battery cable.

SMT446B

REMOVAL AND INSTALLATIONFS5R30A

Installation (Cont'd)

MT-9

http://vnx.su/

Page 814 of 1833

AUTOMATIC TRANSMISSIONSECTION

AT

CONTENTS

PREPARATION AND PRECAUTIONS ............................3

Special Service Tools ..................................................3

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER² ...............4

Precautions for SRS ²AIR BAG² and²SEAT

BELT PRE-TENSIONER² Service ...............................4

Precautions ..................................................................4

Service Notice or Precautions .....................................5

OVERALL SYSTEM ........................................................6

A/T Electrical Parts Location .......................................6

Wiring Diagram - A/T -.................................................7

Cross-sectional View ...................................................8

Hydraulic Control Circuits ............................................9

Shift Mechanism ........................................................10

Control System ..........................................................12

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION ...............................................................14

Self-diagnosis ............................................................14

Diagnosis by CONSULT-II .........................................20

TROUBLE DIAGNOSIS - Introduction ........................22

Introduction ................................................................22

Diagnostic Worksheet ................................................23

Work Flow ..................................................................26

TROUBLE DIAGNOSIS - Basic Inspection ................27

A/T Fluid Check .........................................................27

Stall Test ....................................................................27

Line Pressure Test .....................................................30

Road Test...................................................................32

TROUBLE DIAGNOSIS - General Description ...........43

Symptom Chart ..........................................................43

TCM Terminals and Reference Value........................46

TROUBLE DIAGNOSIS FOR POWER SUPPLY ..........49

Wiring Diagram - AT - MAIN ......................................49

TCM Power Supply Circuit ........................................50

TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×A/T ........................................................................\

.51

Wiring Diagram - AT - VSSA/T ..................................51

Vehicle Speed Sensor×A/T (Revolution sensor) ........52 TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×MTR

.......................................................................54

Wiring Diagram - AT - VSSMTR ................................54

Vehicle Speed Sensor×MTR ......................................56

TROUBLE DIAGNOSIS FOR THROTTLE POSI

SEN ........................................................................\

........58

Wiring Diagram - AT - TPS ........................................58

Throttle (Accelerator) Position Sensor ......................62

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

A ........................................................................\

.............64

Wiring Diagram - AT - SSV/A ....................................64

Shift Solenoid Valve A ...............................................65

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

B ........................................................................\

.............67

Wiring Diagram - AT - SSV/B ....................................67

Shift Solenoid Valve B ...............................................68

TROUBLE DIAGNOSIS FOR OVERRUN CLUTCH

S/V ........................................................................\

..........70

Wiring Diagram - AT - OVRCSV................................70

Overrun Clutch Solenoid Valve .................................71

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V .....73

Wiring Diagram - AT - TCV........................................73

Torque Converter Clutch Solenoid Valve ..................74

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP

SEN ........................................................................\

........77

Wiring Diagram - AT - BA/FTS ..................................77

A/T Fluid Temperature Sensor and TCM Power

Source........................................................................\

78

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG ....81

Wiring Diagram - AT - ENGSS ..................................81

Engine Speed Signal .................................................82

TROUBLE DIAGNOSIS FOR LINE PRESSURE

S/V ........................................................................\

..........84

Wiring Diagram - AT - LPSV......................................84

Line Pressure Solenoid Valve ...................................86

TROUBLE DIAGNOSIS FOR NON-DETECTABLE

ITEMS........................................................................\

.....89 Wiring Diagram - AT - PNP/SW.................................89

http://vnx.su/

Page 817 of 1833

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for SRS ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº Service

IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

I Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

I Diagnosis sensor unit must always be installed with their arrow marks ª +º pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

I The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

I Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module (built-in type) standing with stud bolt side setting

bottom.

I Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

I After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Precautions

IBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

I Disassembly should be done in a clean work area.

I Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

I Place disassembled parts in order for easier and proper assembly.

I All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

I Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

I It is very important to perform functional tests whenever they are indicated.

I The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place removed parts in a parts rack in order to replace them in correct positions and sequences. Care will

also prevent springs and small parts from becoming scattered or lost.

I Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

PREPARATION AND PRECAUTIONS

AT- 4

http://vnx.su/

Page 818 of 1833

IBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

I Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

I After overhaul, refill the transmission with new ATF.

I When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under ªChanging A/T Fluidº in the MA section when changing A/T fluid.

Service Notice or Precautions

FAIL-SAFE

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear even with a shift lever position of ª1º, ª2º or ªDº. Cus-

tomer may complain of ªsluggish or poor accelerationº.

When the Fail-Safe operation occurs the next time the key is turned to the ªONº position, the SPORT indica-

tor lamp will blink for about 8 seconds. (For diagnosis, refer to AT-33.)

Fail-Safe may activate without electrical circuit damages if the vehicle is driven under extreme conditions (such

as excessive wheel spins and emergency braking immediately afterwards). In this case, turn the ignition key

ªOFFº for 5 seconds and then ªONº to recover normal shift pattern.

The blinking of the SPORT indicator lamp for about 8 seconds will appear only once and be cleared. The cus-

tomer may resume normal driving conditions by chance.

Always follow the ªWORK FLOWº (Refer to AT-26).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate the damage of the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS performed after checking the sensor, no damages will be indicated.

PREPARATION AND PRECAUTIONS

Precautions (Cont'd)

AT- 5

http://vnx.su/

Page 819 of 1833

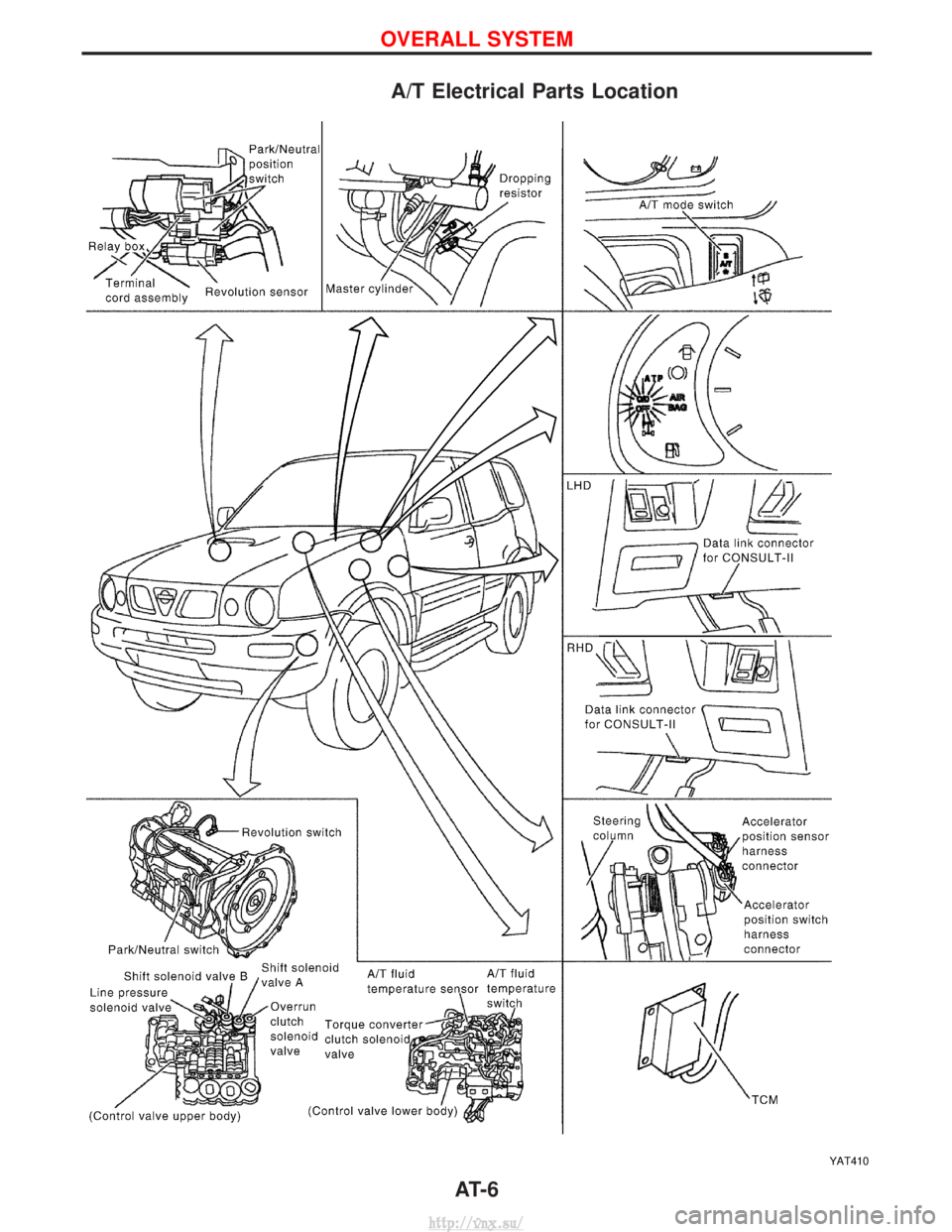

A/T Electrical Parts Location

YAT410

OVERALL SYSTEM

AT- 6

http://vnx.su/

Page 833 of 1833

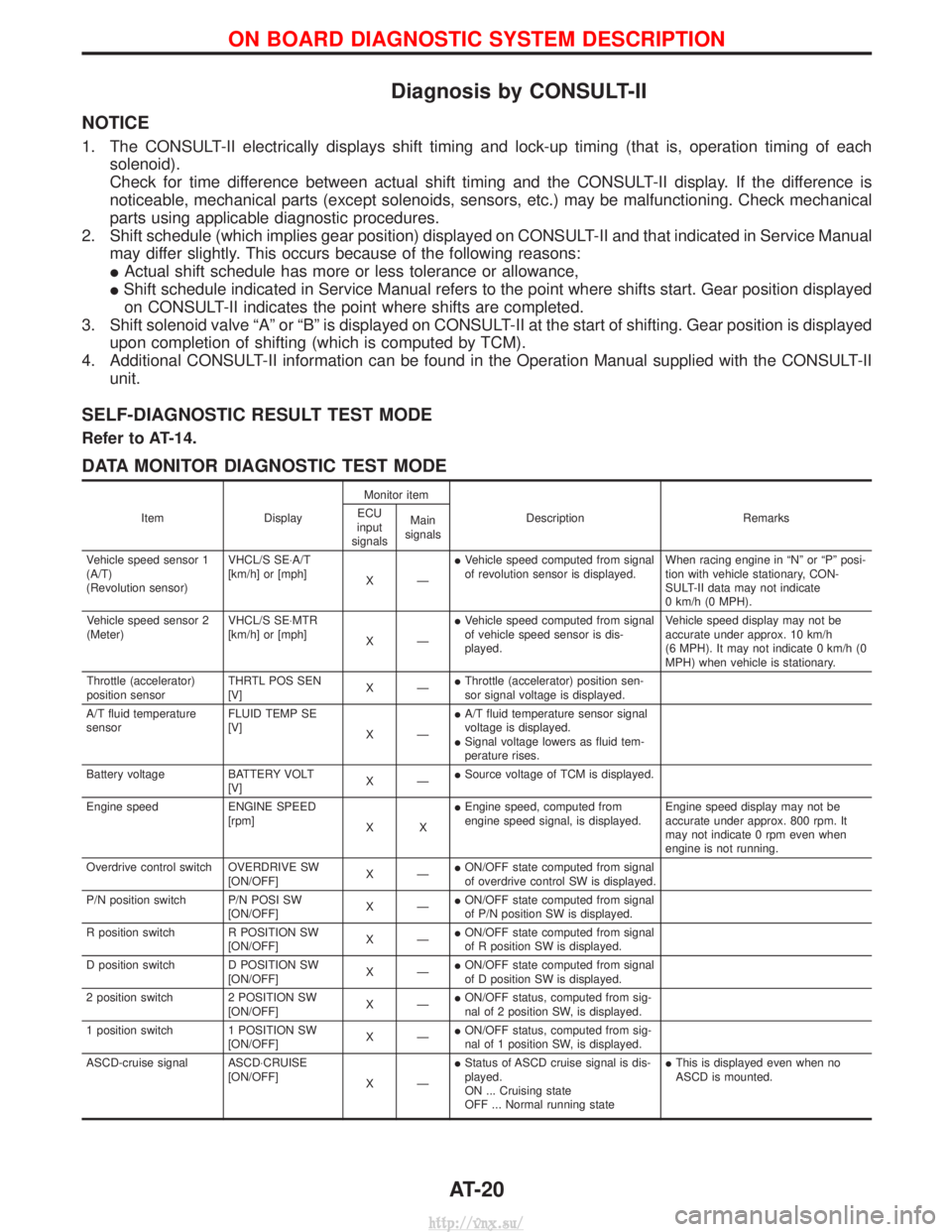

Diagnosis by CONSULT-II

NOTICE

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of eachsolenoid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Manual may differ slightly. This occurs because of the following reasons:

IActual shift schedule has more or less tolerance or allowance,

I Shift schedule indicated in Service Manual refers to the point where shifts start. Gear position displayed

on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve ªAº or ªBº is displayed on CONSULT-II at the start of shifting. Gear position is displayed upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II unit.

SELF-DIAGNOSTIC RESULT TEST MODE

Refer to AT-14.

DATA MONITOR DIAGNOSTIC TEST MODE

Item DisplayMonitor item

Description Remarks

ECU

input

signals Main

signals

Vehicle speed sensor 1

(A/T)

(Revolution sensor) VHCL/S SE×A/T

[km/h] or [mph]

XÐI

Vehicle speed computed from signal

of revolution sensor is displayed. When racing engine in ªNº or ªPº posi-

tion with vehicle stationary, CON-

SULT-II data may not indicate

0 km/h (0 MPH).

Vehicle speed sensor 2

(Meter) VHCL/S SE×MTR

[km/h] or [mph]

XÐI

Vehicle speed computed from signal

of vehicle speed sensor is dis-

played. Vehicle speed display may not be

accurate under approx. 10 km/h

(6 MPH). It may not indicate 0 km/h (0

MPH) when vehicle is stationary.

Throttle (accelerator)

position sensor THRTL POS SEN

[V]

XÐI

Throttle (accelerator) position sen-

sor signal voltage is displayed.

A/T fluid temperature

sensor FLUID TEMP SE

[V]

XÐI

A/T fluid temperature sensor signal

voltage is displayed.

I Signal voltage lowers as fluid tem-

perature rises.

Battery voltage BATTERY VOLT [V]XÐI

Source voltage of TCM is displayed.

Engine speed ENGINE SPEED [rpm]XXI

Engine speed, computed from

engine speed signal, is displayed. Engine speed display may not be

accurate under approx. 800 rpm. It

may not indicate 0 rpm even when

engine is not running.

Overdrive control switch OVERDRIVE SW [ON/OFF]XÐI

ON/OFF state computed from signal

of overdrive control SW is displayed.

P/N position switch P/N POSI SW [ON/OFF]XÐI

ON/OFF state computed from signal

of P/N position SW is displayed.

R position switch R POSITION SW [ON/OFF]XÐI

ON/OFF state computed from signal

of R position SW is displayed.

D position switch D POSITION SW [ON/OFF]XÐI

ON/OFF state computed from signal

of D position SW is displayed.

2 position switch 2 POSITION SW [ON/OFF]XÐI

ON/OFF status, computed from sig-

nal of 2 position SW, is displayed.

1 position switch 1 POSITION SW [ON/OFF]XÐI

ON/OFF status, computed from sig-

nal of 1 position SW, is displayed.

ASCD-cruise signal ASCD×CRUISE [ON/OFF]XÐI

Status of ASCD cruise signal is dis-

played.

ON ... Cruising state

OFF ... Normal running state I

This is displayed even when no

ASCD is mounted.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-20

http://vnx.su/

Page 1169 of 1833

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay) .................................72

Diagnostic Procedure 4 (Wheel sensor or rotor) ......74

Diagnostic Procedure 5 (Motor Relay or motor) .......76

Diagnostic Procedure 7 (Low voltage) ......................78

Diagnostic Procedure 8 (G sensor) ...........................79

Diagnostic Procedure 9 (Control unit) .......................80

Diagnostic Procedure 10 (Pedal vibration and

noise) ........................................................................\

.81

Diagnostic Procedure 11 (Long stopping

distance) ....................................................................81Diagnostic Procedure 12 (Unexpected pedal

action) ........................................................................\

82

Diagnostic Procedure 13 ...........................................83

Diagnostic Procedure 14 ...........................................83

Electrical Components Inspection .............................84

SERVICE DATA AND SPECIFICATIONS (SDS) ..........85

General Specifications ...............................................85

Inspection and Adjustment ........................................86

CONTENTS(Cont'd)

BR-2

http://vnx.su/

Page 1170 of 1833

Supplement Restraint System (SRS) ªAIR BAGº

and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-tensionerº, used along with a seat belt, help

to reduce the risk or severity or injury to the driver and front passenger in a collision. The Supplemental

Restraint System consists of an air bag module (located in the center of the steering wheel and on the instru-

ment panel on the passenger side, where fitted), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable. Information necessary to service the system safely is included in the

BT sectionof this Service Manual.

WARNING:

I To avoid rendering the SRS inoperative (which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation), all maintenance must be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT-TENSIONERº connector) can be iden-

tified with yellow harness connector and with yellow harness protector or yellow insulation tape

before the harness connectors.

Precautions

IUse only ªDOT 4º fluid from a sealed container.

I Never reuse drained brake fluid.

I Be careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

I To clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake fluid.

I Never use mineral oils such as Petrol or kerosene. They

will ruin rubber parts of hydraulic system.

I Use flare nut wrench when removing and installing brake

tubes.

I Always torque brake lines when installing.

I Burnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low speed. Refer to ªBrake

Burnishing Procedureº, ªCheck and Adjustmentº, BR-5.

WARNING:

I Clean brakes with a vacuum dust collector to minimize risk

of health hazard from airborne materials.

I Avoid prolonged and repeated skin contact with brake

fluid.

I Wear protective clothing, including impervious gloves.

I Where there is a risk of eye contact, eye protection should

be worn Ð for example chemical goggles or face shield.

YBR293

PRECAUTIONS AND PREPARATION

BR-3

http://vnx.su/