engine coolant NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 63 of 1833

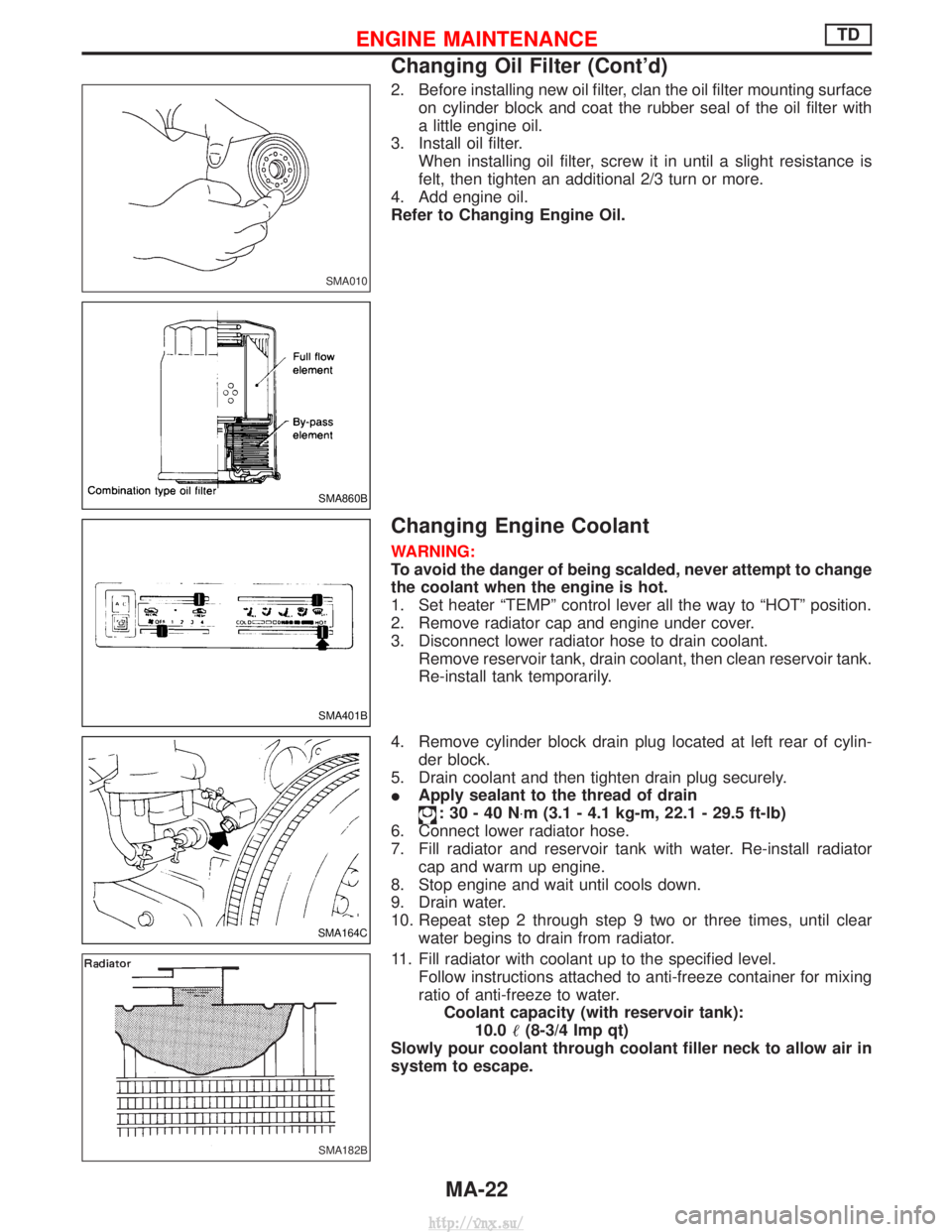

2. Before installing new oil filter, clan the oil filter mounting surfaceon cylinder block and coat the rubber seal of the oil filter with

a little engine oil.

3. Install oil filter. When installing oil filter, screw it in until a slight resistance is

felt, then tighten an additional 2/3 turn or more.

4. Add engine oil.

Refer to Changing Engine Oil.

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never attempt to change

the coolant when the engine is hot.

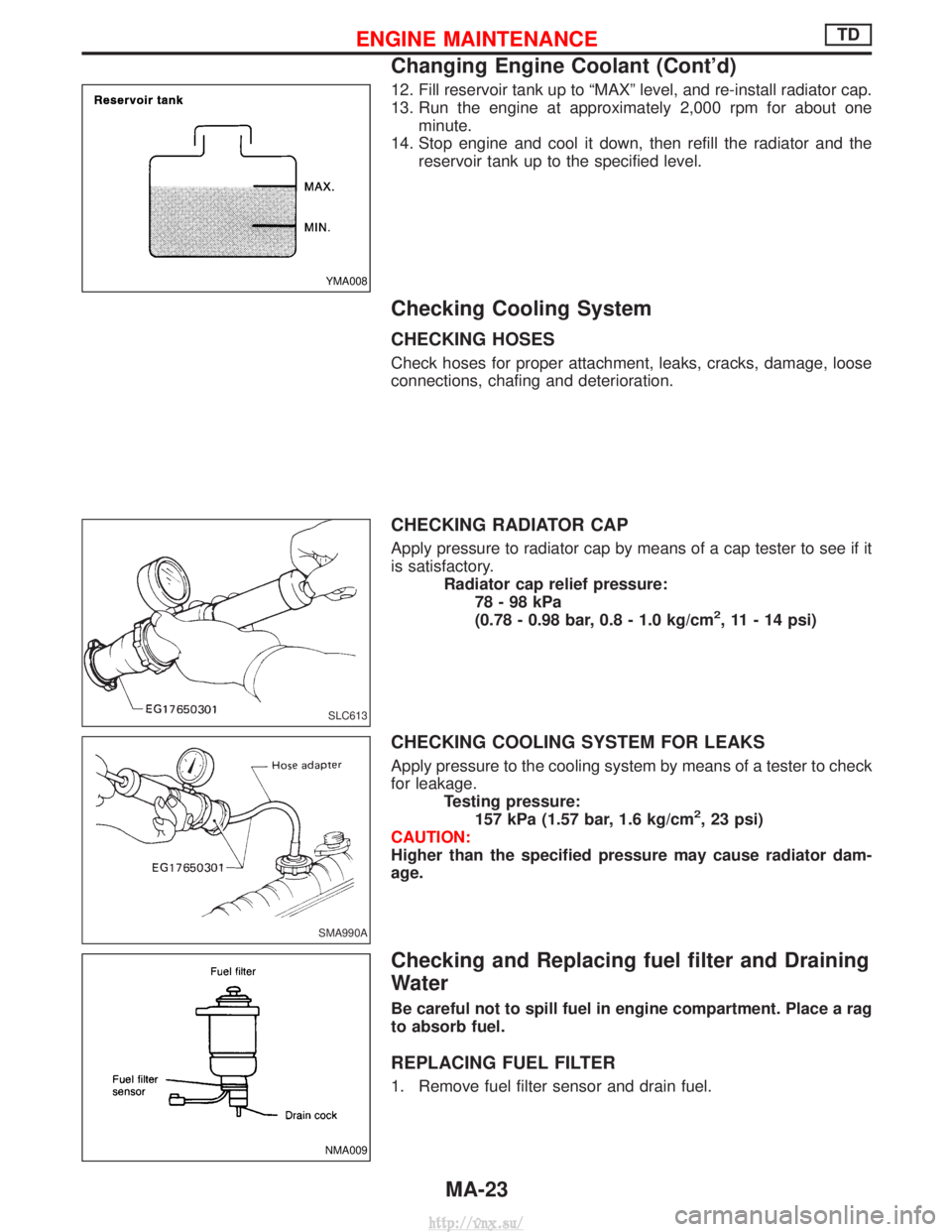

1. Set heater ªTEMPº control lever all the way to ªHOTº position.

2. Remove radiator cap and engine under cover.

3. Disconnect lower radiator hose to drain coolant. Remove reservoir tank, drain coolant, then clean reservoir tank.

Re-install tank temporarily.

4. Remove cylinder block drain plug located at left rear of cylin- der block.

5. Drain coolant and then tighten drain plug securely.

I Apply sealant to the thread of drain

:30-40N ×m (3.1 - 4.1 kg-m, 22.1 - 29.5 ft-lb)

6. Connect lower radiator hose.

7. Fill radiator and reservoir tank with water. Re-install radiator cap and warm up engine.

8. Stop engine and wait until cools down.

9. Drain water.

10. Repeat step 2 through step 9 two or three times, until clear water begins to drain from radiator.

11. Fill radiator with coolant up to the specified level. Follow instructions attached to anti-freeze container for mixing

ratio of anti-freeze to water.Coolant capacity (with reservoir tank): 10.0 (8-3/4 Imp qt)

Slowly pour coolant through coolant filler neck to allow air in

system to escape.

SMA010

SMA860B

SMA401B

SMA164C

SMA182B

ENGINE MAINTENANCETD

Changing Oil Filter (Cont'd)

MA-22

http://vnx.su/

Page 64 of 1833

12. Fill reservoir tank up to ªMAXº level, and re-install radiator cap.

13. Run the engine at approximately 2,000 rpm for about oneminute.

14. Stop engine and cool it down, then refill the radiator and the reservoir tank up to the specified level.

Checking Cooling System

CHECKING HOSES

Check hoses for proper attachment, leaks, cracks, damage, loose

connections, chafing and deterioration.

CHECKING RADIATOR CAP

Apply pressure to radiator cap by means of a cap tester to see if it

is satisfactory. Radiator cap relief pressure:78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system by means of a tester to check

for leakage. Testing pressure:157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator dam-

age.

Checking and Replacing fuel filter and Draining

Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

REPLACING FUEL FILTER

1. Remove fuel filter sensor and drain fuel.

YMA008

SLC613

SMA990A

NMA009

ENGINE MAINTENANCETD

Changing Engine Coolant (Cont'd)

MA-23

http://vnx.su/

Page 67 of 1833

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzle are in good condition.

3. Make sure that the following parts are in good condition.

IAir cleaner clogging

I Glow system

I Engine oil and coolant levels

I Valve clearance

I Air intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ªNeutralº position. Engage parking brake and lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

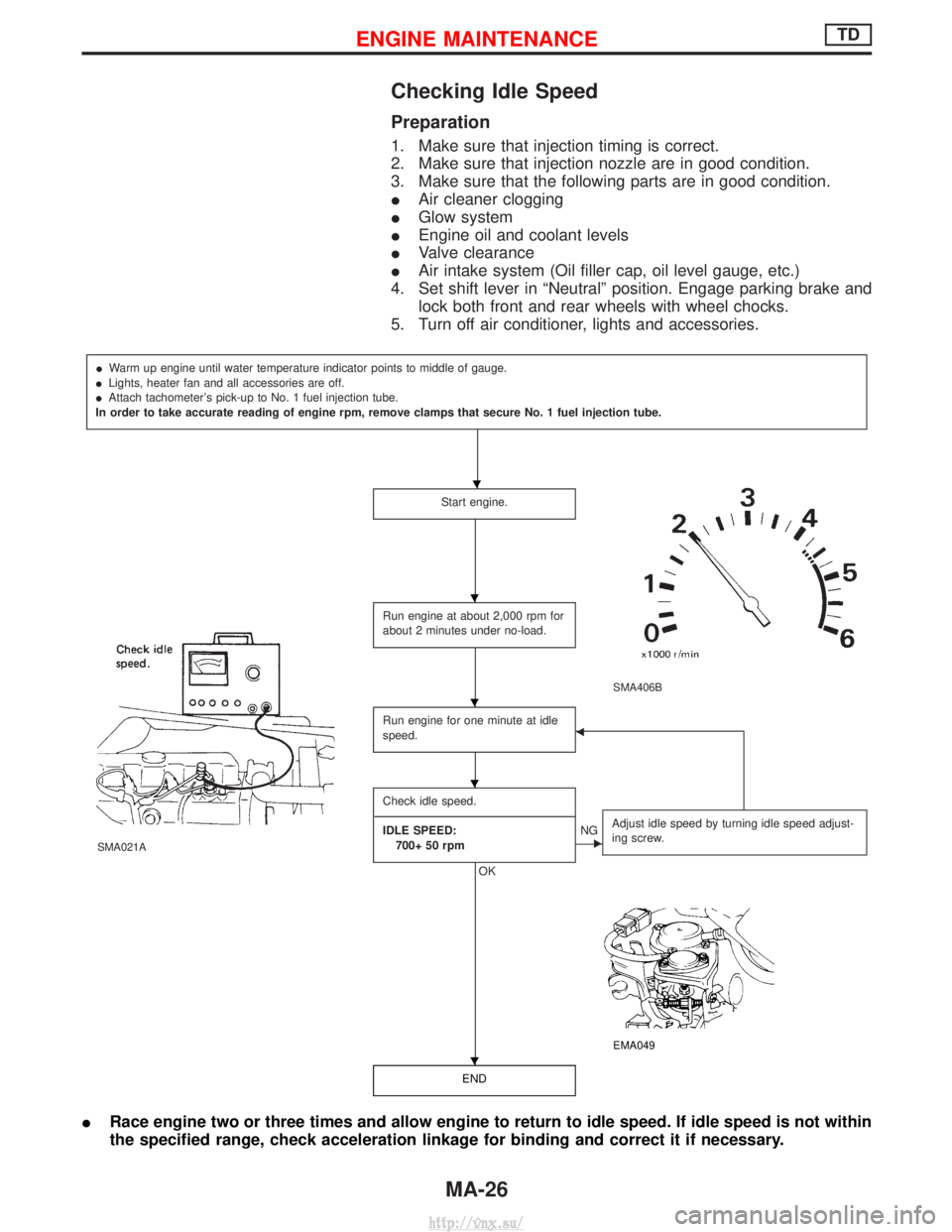

I Warm up engine until water temperature indicator points to middle of gauge.

I Lights, heater fan and all accessories are off.

I Attach tachometer's pick-up to No. 1 fuel injection tube.

In order to take accurate reading of engine rpm, remove clamps that secure No. 1 fuel injection tube.

Start engine.

SMA406B

SMA021A

Run engine at about 2,000 rpm for

about 2 minutes under no-load.

Run engine for one minute at idle

speed.F

Check idle speed.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- IDLE SPEED: 700+ 50 rpm

OK

ENG Adjust idle speed by turning idle speed adjust-

ing screw.

EMA049

END

I

Race engine two or three times and allow engine to return to idle speed. If idle speed is not within

the specified range, check acceleration linkage for binding and correct it if necessary.

H

H

H

H

H

ENGINE MAINTENANCETD

MA-26

http://vnx.su/

Page 70 of 1833

Removal

WATER PUMP, ALTERNATOR AND AIR CONDITIONER

BELT

1. Remove radiator shroud.

2. Contract and hold the auto tensioner using the following proce-dure.

a. Securely hold the 19 mm (0.75 in) hexagonal portion A of auto tensioner with a closed wrench.

I Preferably use a tool with a handhold of 500 mm (19.69 in) or

more in length.

I No bolts or nuts are required to be loosened during the opera-

tion.

b. Turn the hexagonal portion A in the direction shown by the arrow to contract the damper unit of the auto tensioner.

CAUTION:

I Because the tensioner has a high tension, it shall be

securely held and turned with a closed wrench.

I Because the hexagonal portion A of the tensioner is made

of aluminum and may be damaged by sudden input, turn

it slowly according to the contraction of the damper unit.

3. Remove the belt from the alternator pulley first, and then remove it from the other pulleys.

I If the tensioner is not held firmly, your finger may get caught

between the belt and the pulleys. Confirm the holding of the

tensioner, and then hold the belt side in the place away from

the pulleys to attach or remove the belt, paying attention to

prevent your finger from being caught.

CAUTION:

I When handling the belt, pay attention to prevent the oil or

coolant from adhering to the belt.

I Do not distort or bend the belt intensively.

Installation

IInstall the belt in the reverse order of removal.

I After installation of the belt, confirm that the belt engages the

pulleys securely.

I Depending on the engagement between the belt and the idler

pulley, noise (belt noise) may be heard when the engine is

started just after installation. This noise will stop with time.

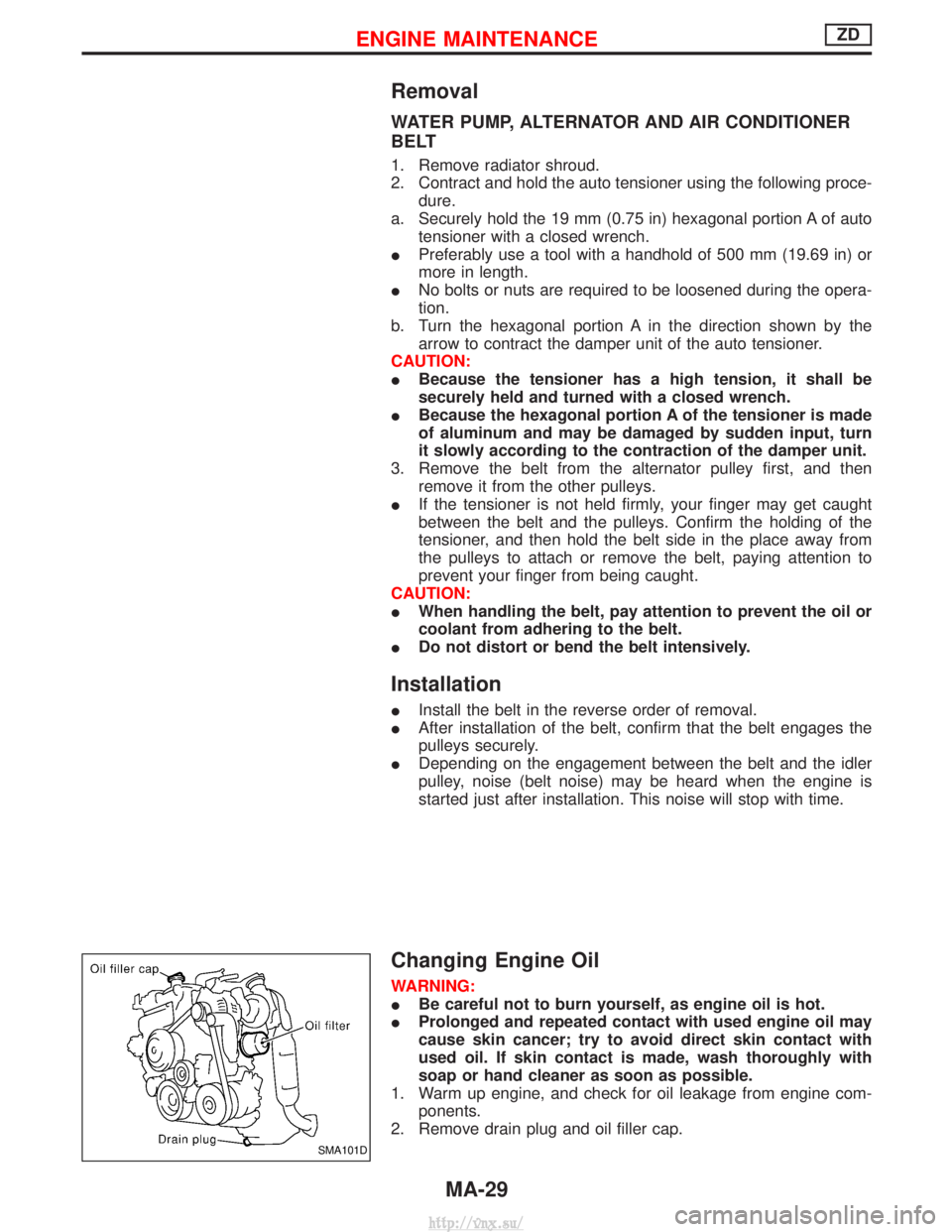

Changing Engine Oil

WARNING:

IBe careful not to burn yourself, as engine oil is hot.

I Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com- ponents.

2. Remove drain plug and oil filler cap.

SMA101D

ENGINE MAINTENANCEZD

MA-29

http://vnx.su/

Page 72 of 1833

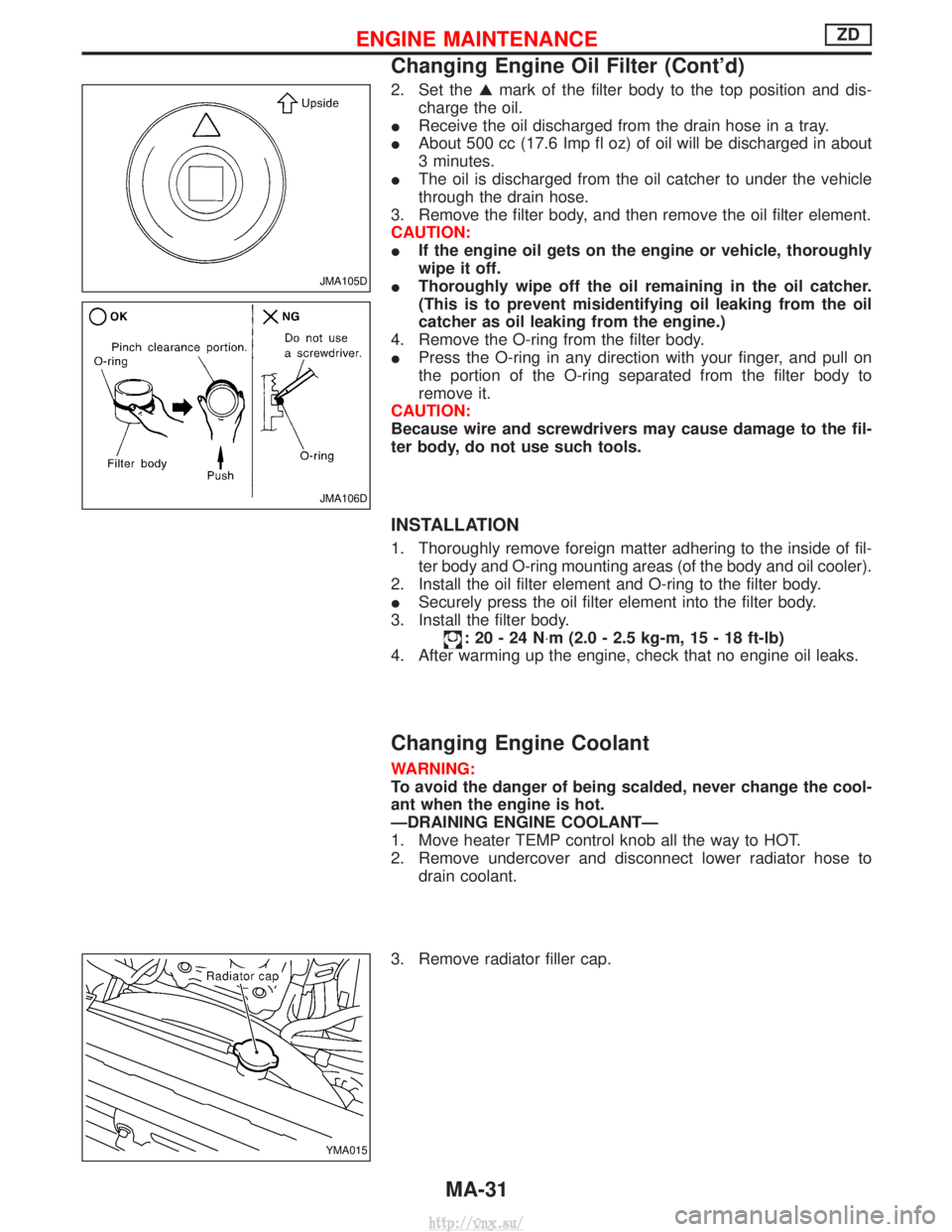

2. Set theGmark of the filter body to the top position and dis-

charge the oil.

I Receive the oil discharged from the drain hose in a tray.

I About 500 cc (17.6 Imp fl oz) of oil will be discharged in about

3 minutes.

I The oil is discharged from the oil catcher to under the vehicle

through the drain hose.

3. Remove the filter body, and then remove the oil filter element.

CAUTION:

I If the engine oil gets on the engine or vehicle, thoroughly

wipe it off.

I Thoroughly wipe off the oil remaining in the oil catcher.

(This is to prevent misidentifying oil leaking from the oil

catcher as oil leaking from the engine.)

4. Remove the O-ring from the filter body.

I Press the O-ring in any direction with your finger, and pull on

the portion of the O-ring separated from the filter body to

remove it.

CAUTION:

Because wire and screwdrivers may cause damage to the fil-

ter body, do not use such tools.

INSTALLATION

1. Thoroughly remove foreign matter adhering to the inside of fil- ter body and O-ring mounting areas (of the body and oil cooler).

2. Install the oil filter element and O-ring to the filter body.

I Securely press the oil filter element into the filter body.

3. Install the filter body.

:20-24N ×m (2.0 - 2.5 kg-m, 15 - 18 ft-lb)

4. After warming up the engine, check that no engine oil leaks.

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never change the cool-

ant when the engine is hot.

ÐDRAINING ENGINE COOLANTÐ

1. Move heater TEMP control knob all the way to HOT.

2. Remove undercover and disconnect lower radiator hose to drain coolant.

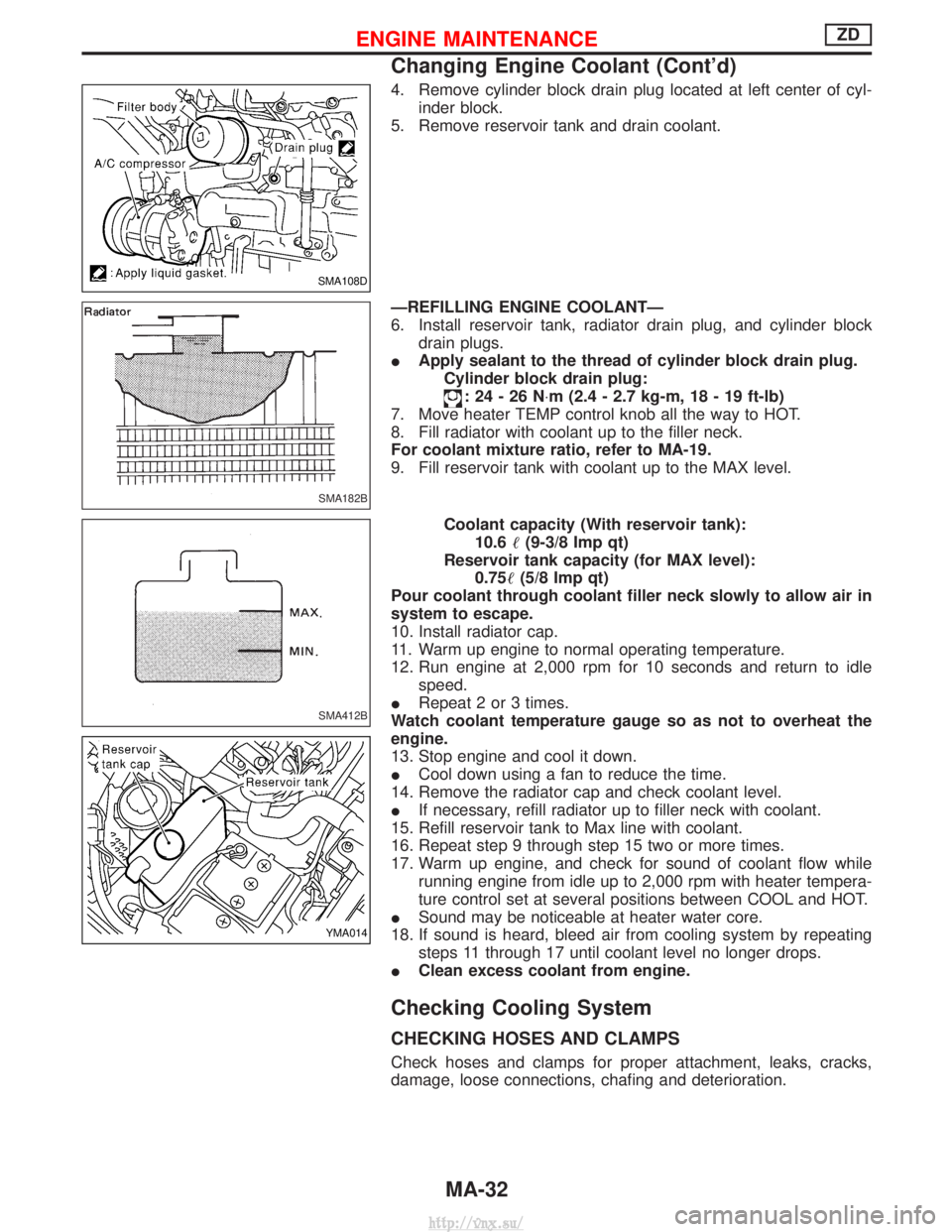

3. Remove radiator filler cap.

JMA105D

JMA106D

YMA015

ENGINE MAINTENANCEZD

Changing Engine Oil Filter (Cont'd)

MA-31

http://vnx.su/

Page 73 of 1833

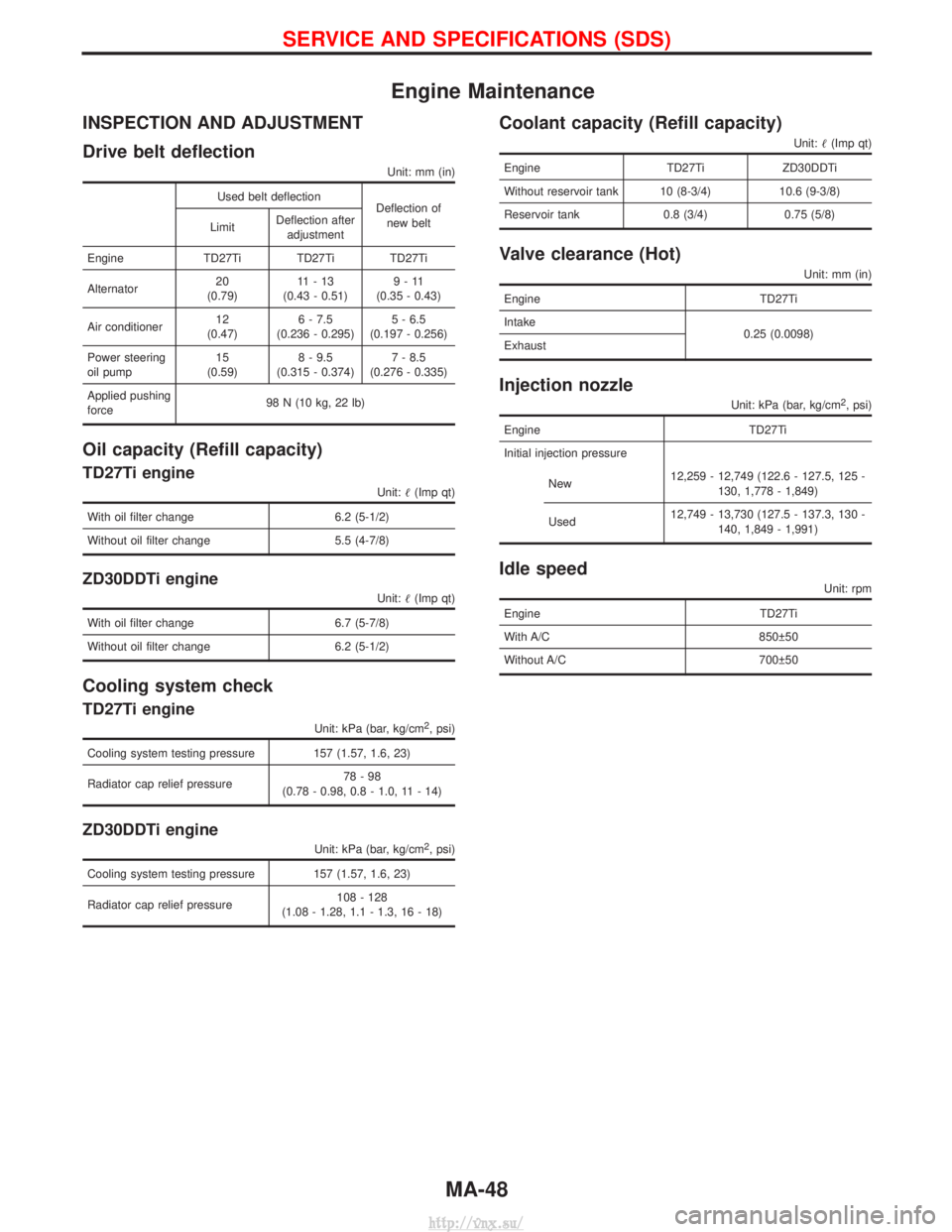

4. Remove cylinder block drain plug located at left center of cyl-inder block.

5. Remove reservoir tank and drain coolant.

ÐREFILLING ENGINE COOLANTÐ

6. Install reservoir tank, radiator drain plug, and cylinder block drain plugs.

I Apply sealant to the thread of cylinder block drain plug.

Cylinder block drain plug:

:24-26N ×m (2.4 - 2.7 kg-m, 18 - 19 ft-lb)

7. Move heater TEMP control knob all the way to HOT.

8. Fill radiator with coolant up to the filler neck.

For coolant mixture ratio, refer to MA-19.

9. Fill reservoir tank with coolant up to the MAX level.

Coolant capacity (With reservoir tank):10.6 (9-3/8 Imp qt)

Reservoir tank capacity (for MAX level): 0.75 (5/8 Imp qt)

Pour coolant through coolant filler neck slowly to allow air in

system to escape.

10. Install radiator cap.

11. Warm up engine to normal operating temperature.

12. Run engine at 2,000 rpm for 10 seconds and return to idle speed.

I Repeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

13. Stop engine and cool it down.

I Cool down using a fan to reduce the time.

14. Remove the radiator cap and check coolant level.

I If necessary, refill radiator up to filler neck with coolant.

15. Refill reservoir tank to Max line with coolant.

16. Repeat step 9 through step 15 two or more times.

17. Warm up engine, and check for sound of coolant flow while running engine from idle up to 2,000 rpm with heater tempera-

ture control set at several positions between COOL and HOT.

I Sound may be noticeable at heater water core.

18. If sound is heard, bleed air from cooling system by repeating steps 11 through 17 until coolant level no longer drops.

I Clean excess coolant from engine.

Checking Cooling System

CHECKING HOSES AND CLAMPS

Check hoses and clamps for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

SMA108D

SMA182B

SMA412B

YMA014

ENGINE MAINTENANCEZD

Changing Engine Coolant (Cont'd)

MA-32

http://vnx.su/

Page 89 of 1833

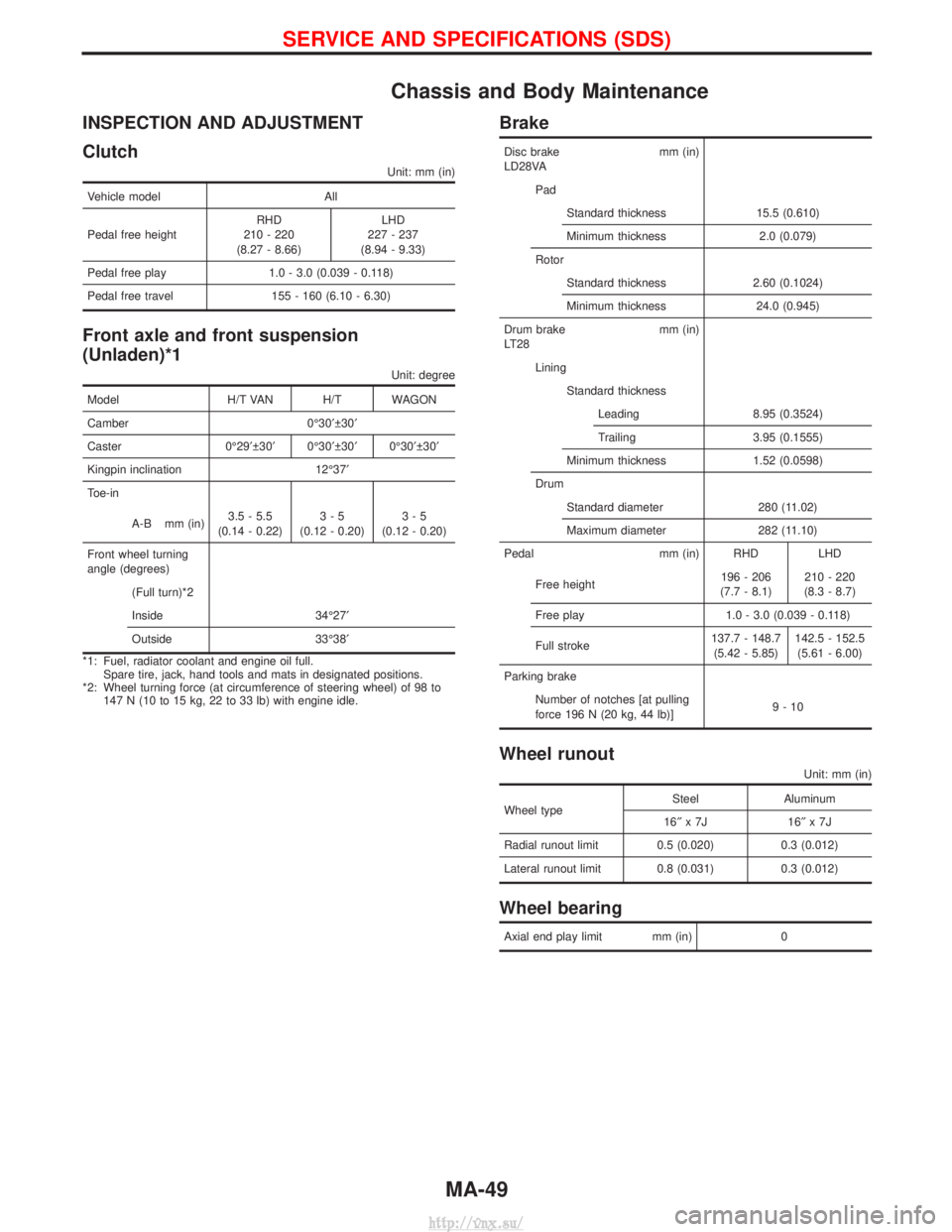

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflectionDeflection of

new belt

Limit Deflection after

adjustment

Engine TD27Ti TD27Ti TD27Ti

Alternator 20

(0.79) 11-13

(0.43 - 0.51) 9-11

(0.35 - 0.43)

Air conditioner 12

(0.47) 6 - 7.5

(0.236 - 0.295) 5 - 6.5

(0.197 - 0.256)

Power steering

oil pump 15

(0.59) 8 - 9.5

(0.315 - 0.374) 7 - 8.5

(0.276 - 0.335)

Applied pushing

force 98 N (10 kg, 22 lb)

Oil capacity (Refill capacity)

TD27Ti engine

Unit:

(Imp qt)

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

ZD30DDTi engine

Unit: (Imp qt)

With oil filter change 6.7 (5-7/8)

Without oil filter change 6.2 (5-1/2)

Cooling system check

TD27Ti engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

ZD30DDTi engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 108 - 128

(1.08 - 1.28, 1.1 - 1.3, 16 - 18)

Coolant capacity (Refill capacity)

Unit: (Imp qt)

Engine TD27TiZD30DDTi

Without reservoir tank 10 (8-3/4) 10.6 (9-3/8)

Reservoir tank 0.8 (3/4) 0.75 (5/8)

Valve clearance (Hot)

Unit: mm (in)

Engine TD27Ti

Intake 0.25 (0.0098)

Exhaust

Injection nozzle

Unit: kPa (bar, kg/cm2, psi)

Engine TD27Ti

Initial injection pressure

New 12,259 - 12,749 (122.6 - 127.5, 125 -

130, 1,778 - 1,849)

Used 12,749 - 13,730 (127.5 - 137.3, 130 -

140, 1,849 - 1,991)

Idle speed

Unit: rpm

Engine TD27Ti

With A/C 850 50

Without A/C 700 50

SERVICE AND SPECIFICATIONS (SDS)

MA-48

http://vnx.su/

Page 90 of 1833

Chassis and Body Maintenance

INSPECTION AND ADJUSTMENT

Clutch

Unit: mm (in)

Vehicle modelAll

Pedal free height RHD

210 - 220

(8.27 - 8.66) LHD

227 - 237

(8.94 - 9.33)

Pedal free play 1.0 - 3.0 (0.039 - 0.118)

Pedal free travel 155 - 160 (6.10 - 6.30)

Front axle and front suspension

(Unladen)*1

Unit: degree

Model H/T VAN H/T WAGON

Camber 0É30¢ 30¢

Caster 0É29¢ 30¢ 0É30¢ 30¢ 0É30¢ 30¢

Kingpin inclination 12É37¢

Toe-in

A-B mm (in) 3.5 - 5.5

(0.14 - 0.22) 3-5

(0.12 - 0.20) 3-5

(0.12 - 0.20)

Front wheel turning

angle (degrees) (Full turn)*2

Inside 34É27¢

Outside 33É38¢

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

Brake

Disc brake mm (in)

LD28VA

PadStandard thickness 15.5 (0.610)

Minimum thickness 2.0 (0.079)

Rotor Standard thickness 2.60 (0.1024)

Minimum thickness 24.0 (0.945)

Drum brake mm (in)

LT28 LiningStandard thicknessLeading 8.95 (0.3524)

Trailing 3.95 (0.1555)

Minimum thickness 1.52 (0.0598)

Drum Standard diameter 280 (11.02)

Maximum diameter 282 (11.10)

Pedal mm (in) RHD LHD

Free height 196 - 206

(7.7 - 8.1) 210 - 220

(8.3 - 8.7)

Free play 1.0 - 3.0 (0.039 - 0.118)

Full stroke 137.7 - 148.7

(5.42 - 5.85) 142.5 - 152.5

(5.61 - 6.00)

Parking brake Number of notches [at pulling

force 196 N (20 kg, 44 lb)] 9-10

Wheel runout

Unit: mm (in)

Wheel typeSteel Aluminum

16² x7J 16 ²x7J

Radial runout limit 0.5 (0.020) 0.3 (0.012)

Lateral runout limit 0.8 (0.031) 0.3 (0.012)

Wheel bearing

Axial end play limit mm (in) 0

SERVICE AND SPECIFICATIONS (SDS)

MA-49

http://vnx.su/

Page 94 of 1833

Parts Requiring Angular Tightening

IUse an angle wrench for the final tightening of the cylinder head

bolts.

I Do not use a torque value for final tightening.

I The torque value for these parts are for a preliminary step.

I Ensure thread and seat surfaces are clean and coated with

engine oil.

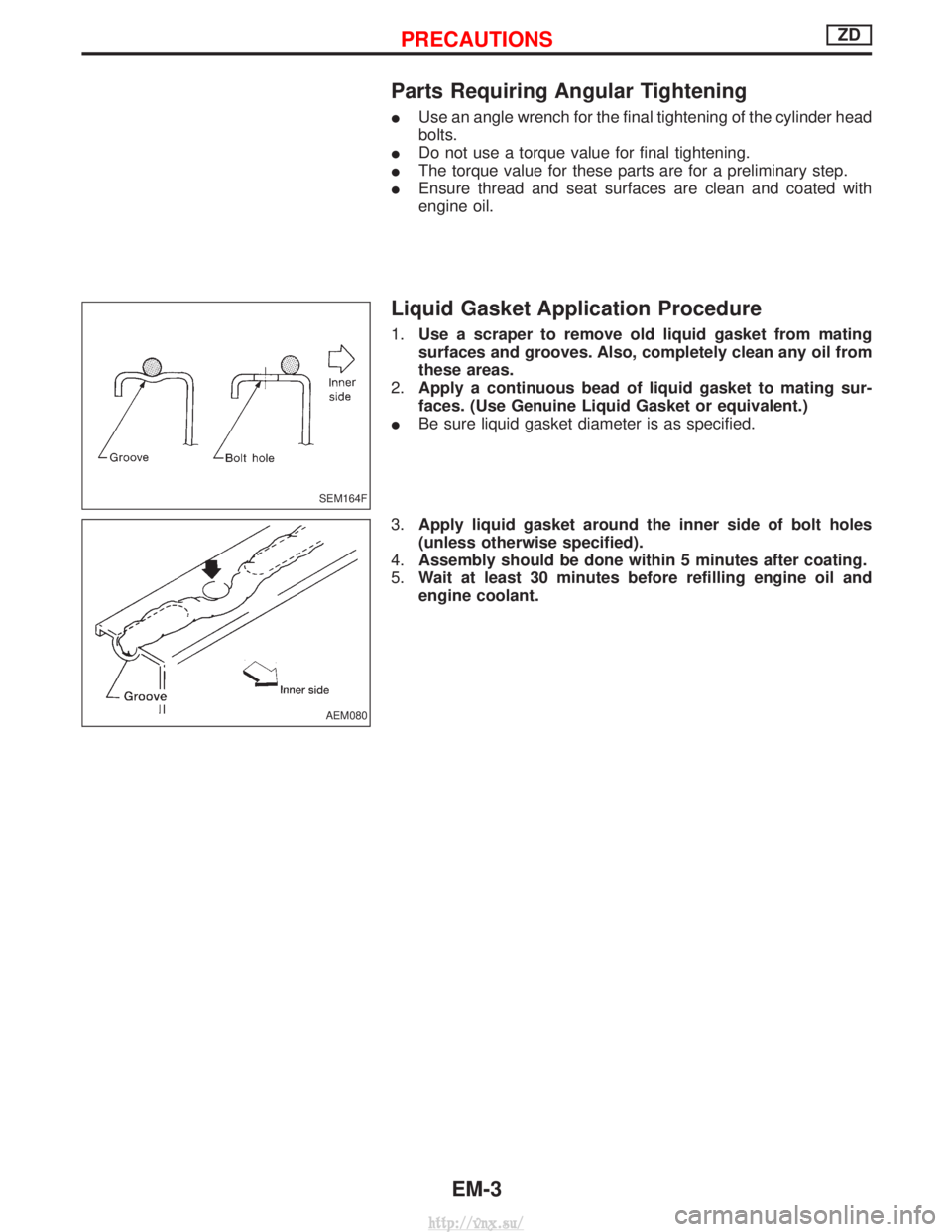

Liquid Gasket Application Procedure

1.Use a scraper to remove old liquid gasket from mating

surfaces and grooves. Also, completely clean any oil from

these areas.

2. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

I Be sure liquid gasket diameter is as specified.

3. Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and

engine coolant.

SEM164F

AEM080

PRECAUTIONSZD

EM-3

http://vnx.su/

Page 104 of 1833

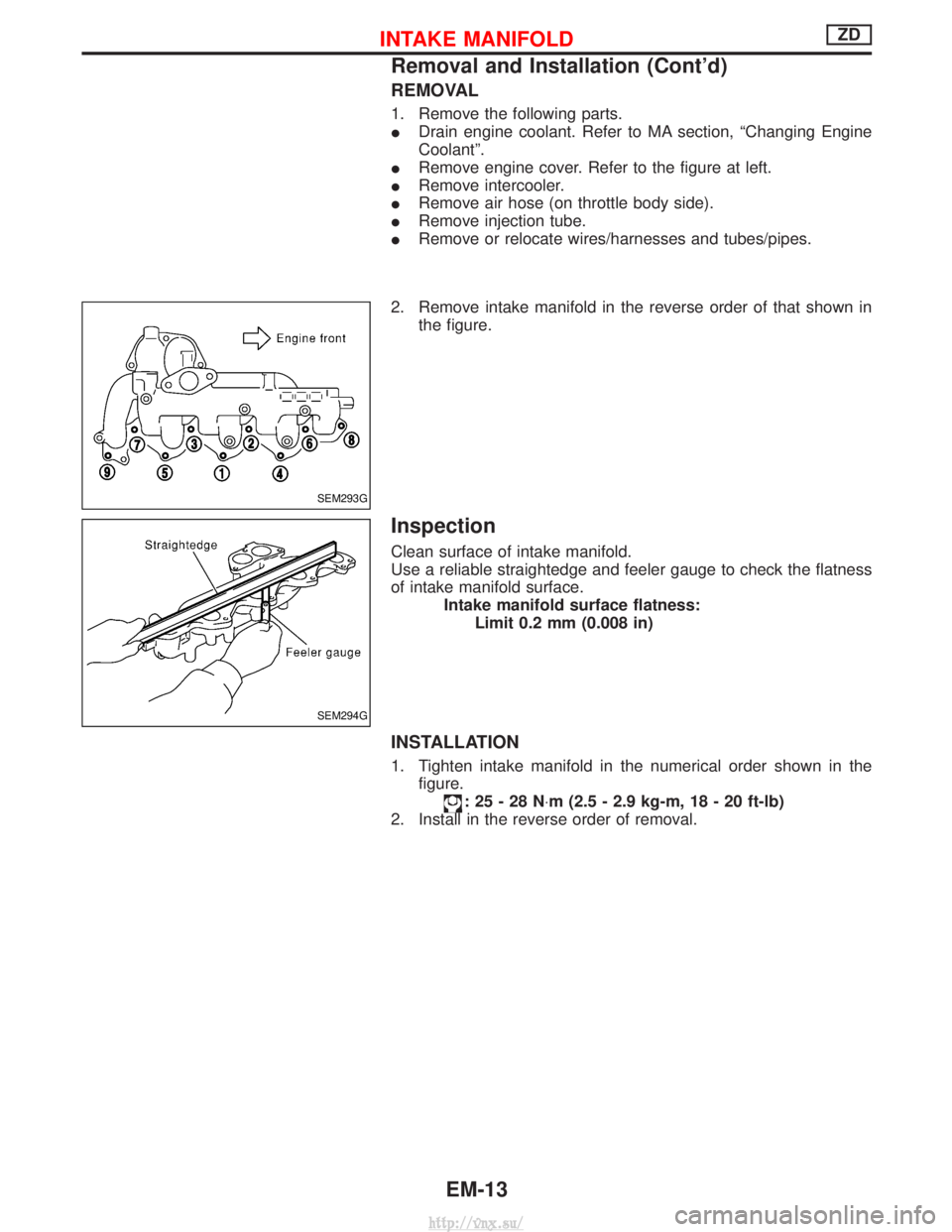

REMOVAL

1. Remove the following parts.

IDrain engine coolant. Refer to MA section, ªChanging Engine

Coolantº.

I Remove engine cover. Refer to the figure at left.

I Remove intercooler.

I Remove air hose (on throttle body side).

I Remove injection tube.

I Remove or relocate wires/harnesses and tubes/pipes.

2. Remove intake manifold in the reverse order of that shown in the figure.

Inspection

Clean surface of intake manifold.

Use a reliable straightedge and feeler gauge to check the flatness

of intake manifold surface. Intake manifold surface flatness:Limit 0.2 mm (0.008 in)

INSTALLATION

1. Tighten intake manifold in the numerical order shown in thefigure.

:25-28N ×m (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

2. Install in the reverse order of removal.

SEM293G

SEM294G

INTAKE MANIFOLDZD

Removal and Installation (Cont'd)

EM-13

http://vnx.su/