engine coolant NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1153 of 1833

Precautions

IWhen installing each rubber part, final tightening must be car-

ried out under unladen condition* with tires on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

I Use Tool when removing or installing brake tubes.

I If suspension or suspension parts are dismounted, check wheel

alignment and adjust if necessary.

I Do not jack up vehicle at lower link.

Preparation

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

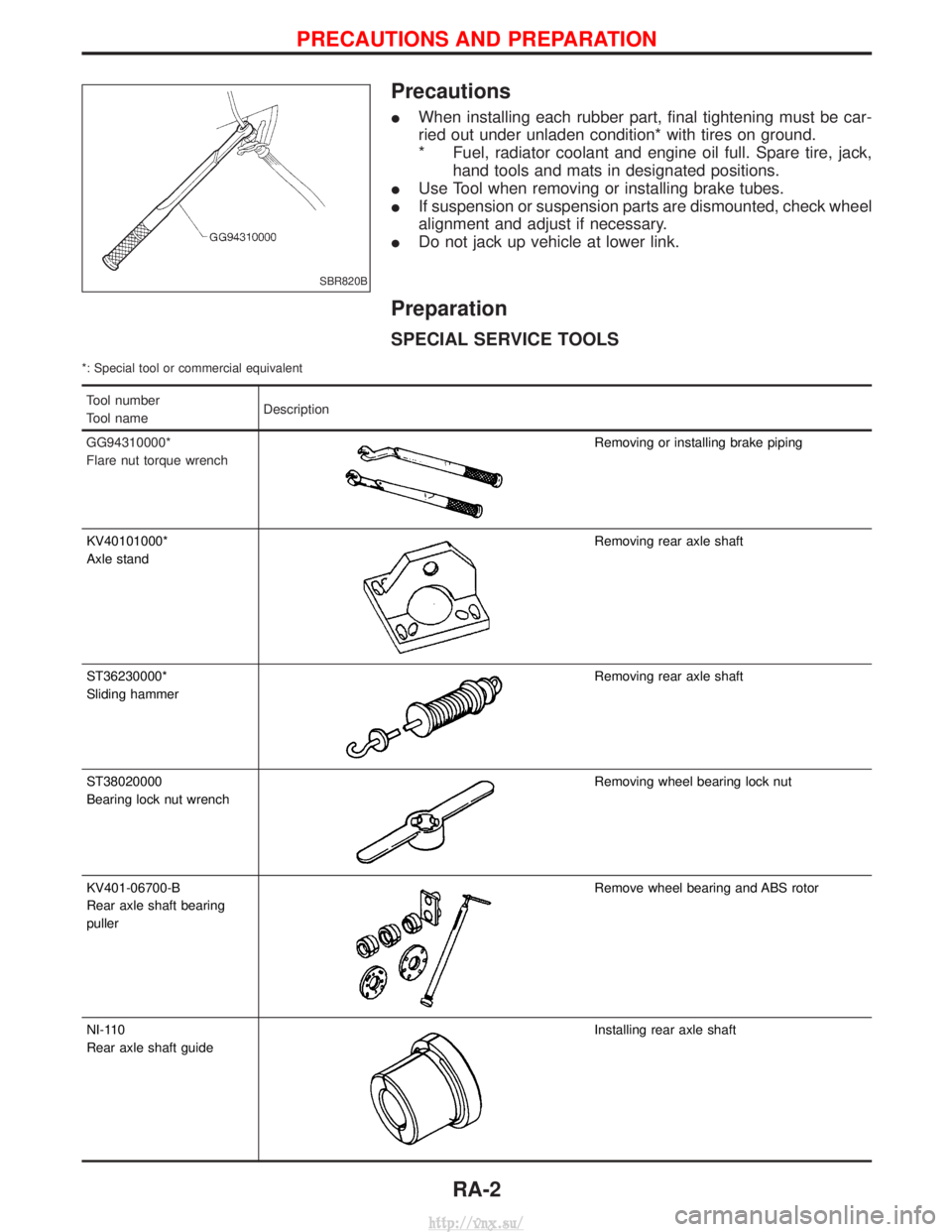

Tool number

Tool name Description

GG94310000*

Flare nut torque wrench

Removing or installing brake piping

KV40101000*

Axle stand

Removing rear axle shaft

ST36230000*

Sliding hammer

Removing rear axle shaft

ST38020000

Bearing lock nut wrench

Removing wheel bearing lock nut

KV401-06700-B

Rear axle shaft bearing

puller

Remove wheel bearing and ABS rotor

NI-110

Rear axle shaft guide

Installing rear axle shaft

SBR820B

PRECAUTIONS AND PREPARATION

RA-2

http://vnx.su/

Page 1180 of 1833

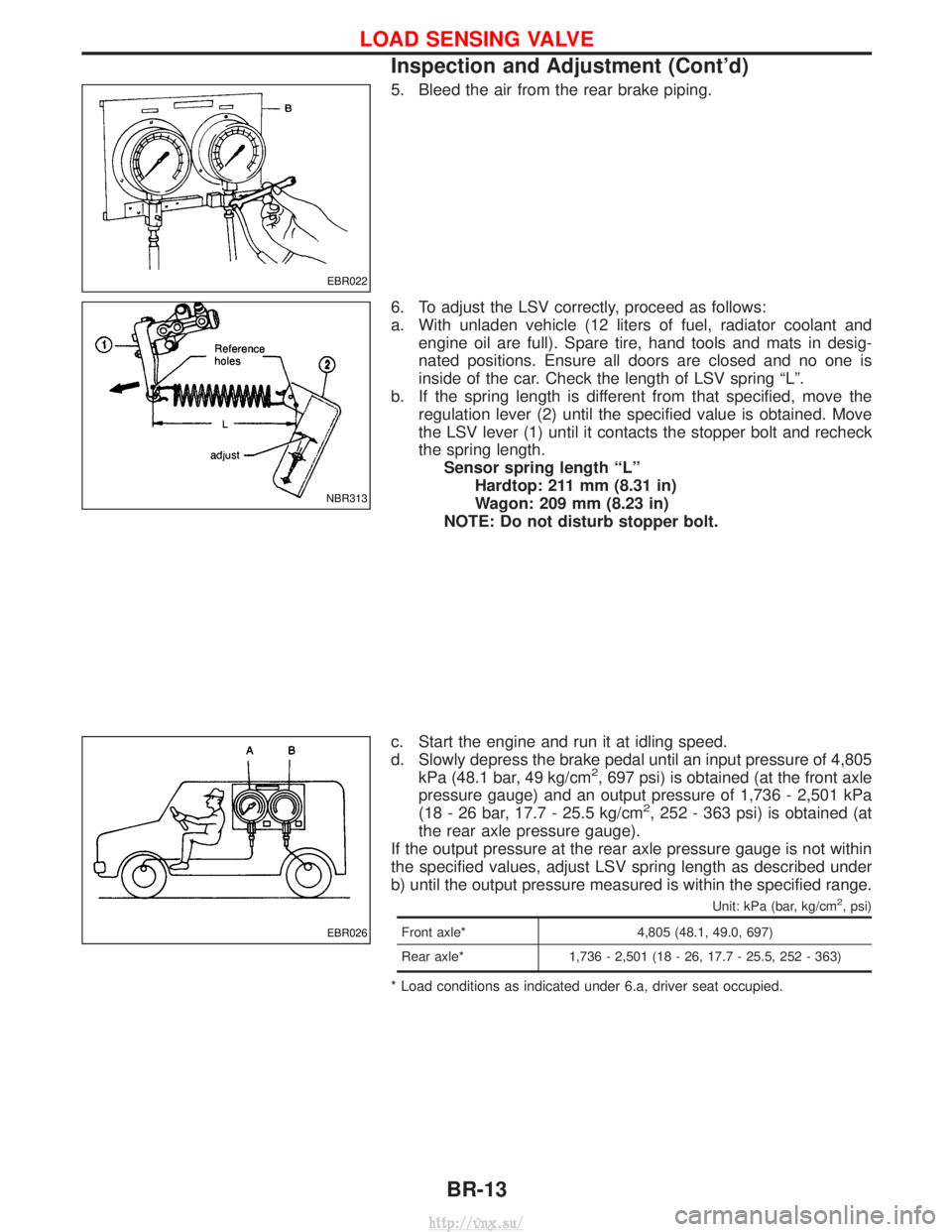

5. Bleed the air from the rear brake piping.

6. To adjust the LSV correctly, proceed as follows:

a. With unladen vehicle (12 liters of fuel, radiator coolant andengine oil are full). Spare tire, hand tools and mats in desig-

nated positions. Ensure all doors are closed and no one is

inside of the car. Check the length of LSV spring ªLº.

b. If the spring length is different from that specified, move the regulation lever (2) until the specified value is obtained. Move

the LSV lever (1) until it contacts the stopper bolt and recheck

the spring length.Sensor spring length ªLº Hardtop: 211 mm (8.31 in)

Wagon: 209 mm (8.23 in)

NOTE: Do not disturb stopper bolt.

c. Start the engine and run it at idling speed.

d. Slowly depress the brake pedal until an input pressure of 4,805 kPa (48.1 bar, 49 kg/cm

2, 697 psi) is obtained (at the front axle

pressure gauge) and an output pressure of 1,736 - 2,501 kPa

(18 - 26 bar, 17.7 - 25.5 kg/cm

2, 252 - 363 psi) is obtained (at

the rear axle pressure gauge).

If the output pressure at the rear axle pressure gauge is not within

the specified values, adjust LSV spring length as described under

b) until the output pressure measured is within the specified range.

Unit: kPa (bar, kg/cm2, psi)

Front axle* 4,805 (48.1, 49.0, 697)

Rear axle* 1,736 - 2,501 (18 - 26, 17.7 - 25.5, 252 - 363)

* Load conditions as indicated under 6.a, driver seat occupied.

EBR022

NBR313

EBR026

LOAD SENSING VALVE

Inspection and Adjustment (Cont'd)

BR-13

http://vnx.su/

Page 1540 of 1833

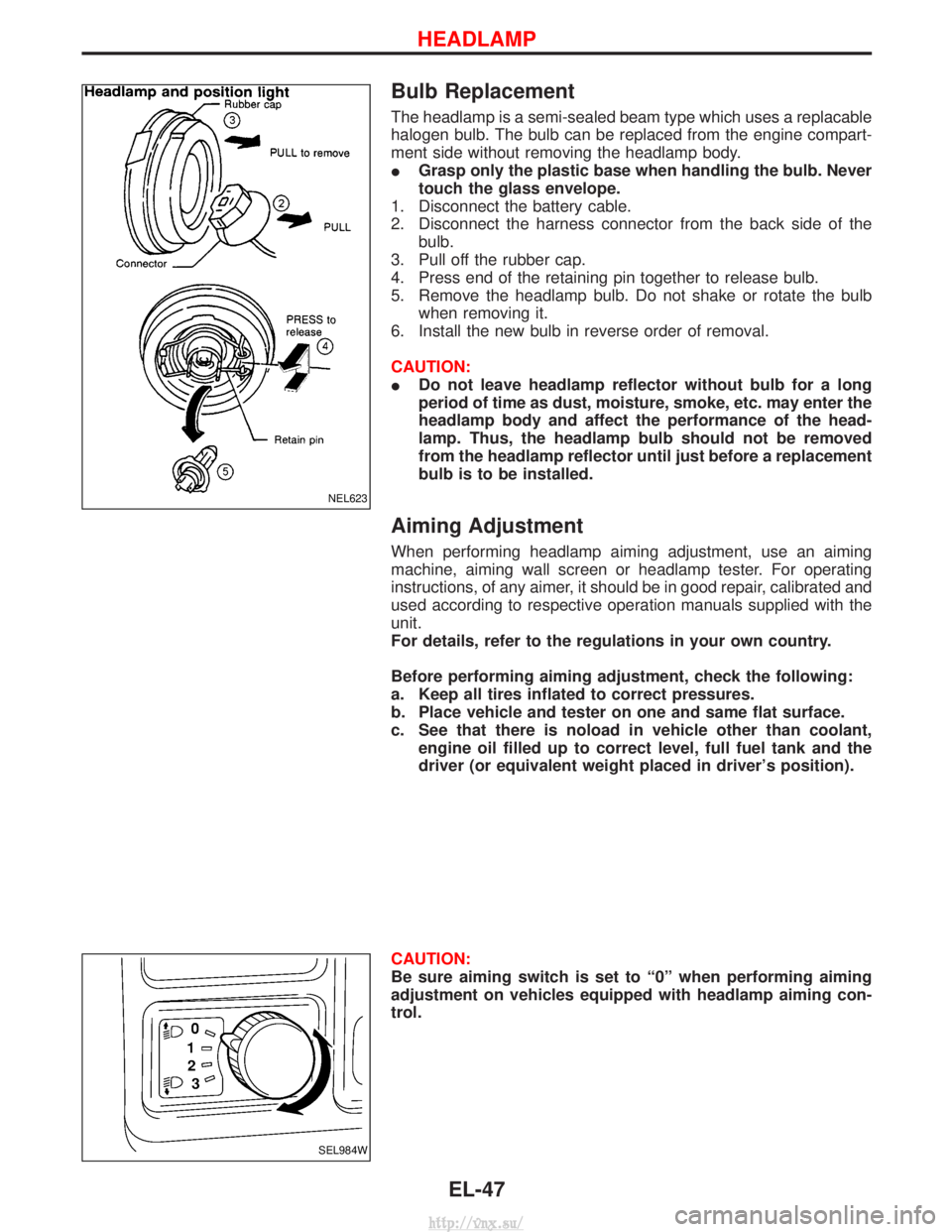

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replacable

halogen bulb. The bulb can be replaced from the engine compart-

ment side without removing the headlamp body.

IGrasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the bulb.

3. Pull off the rubber cap.

4. Press end of the retaining pin together to release bulb.

5. Remove the headlamp bulb. Do not shake or rotate the bulb when removing it.

6. Install the new bulb in reverse order of removal.

CAUTION:

I Do not leave headlamp reflector without bulb for a long

period of time as dust, moisture, smoke, etc. may enter the

headlamp body and affect the performance of the head-

lamp. Thus, the headlamp bulb should not be removed

from the headlamp reflector until just before a replacement

bulb is to be installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. For operating

instructions, of any aimer, it should be in good repair, calibrated and

used according to respective operation manuals supplied with the

unit.

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following:

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is noload in vehicle other than coolant,

engine oil filled up to correct level, full fuel tank and the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

NEL623

SEL984W

HEADLAMP

EL-47

http://vnx.su/

Page 1550 of 1833

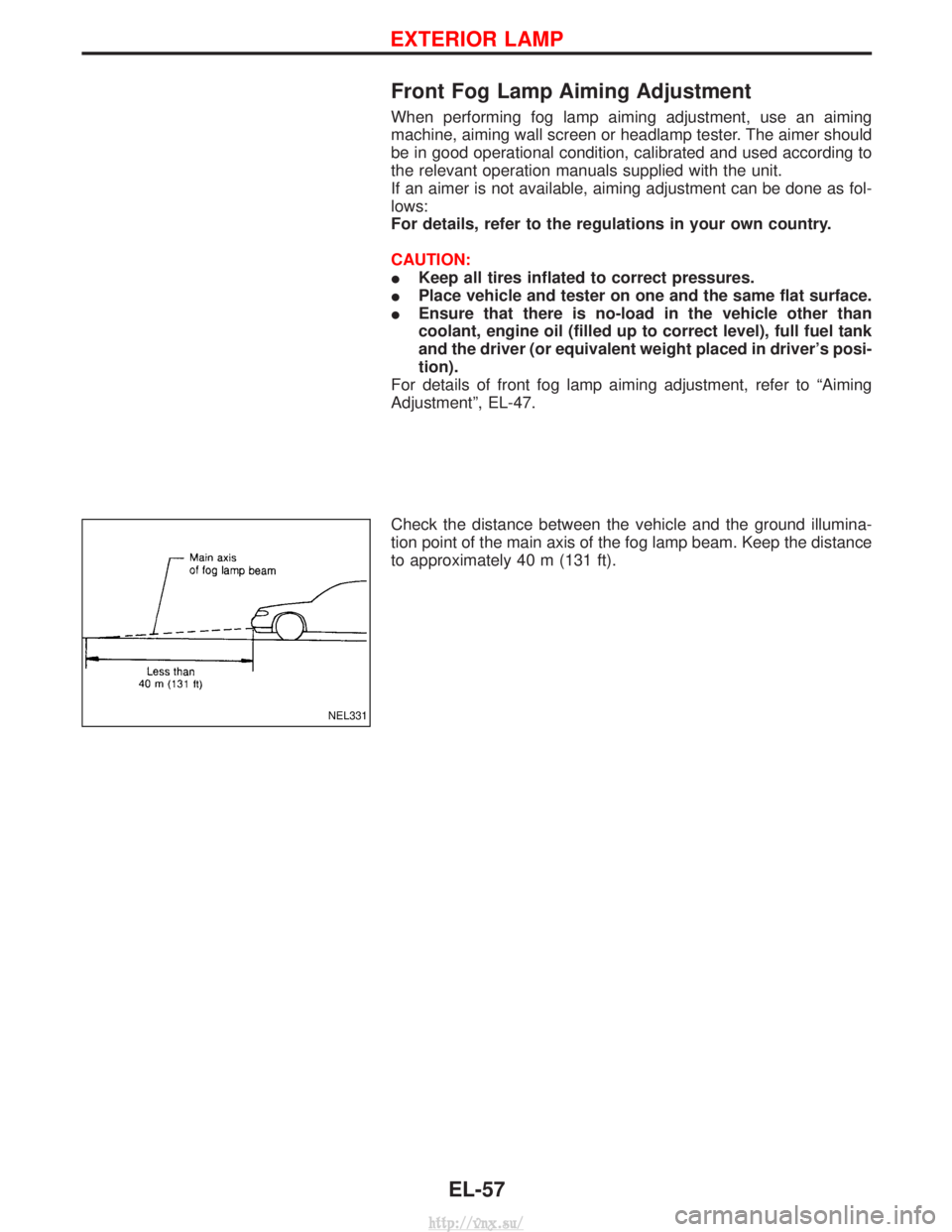

Front Fog Lamp Aiming Adjustment

When performing fog lamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. The aimer should

be in good operational condition, calibrated and used according to

the relevant operation manuals supplied with the unit.

If an aimer is not available, aiming adjustment can be done as fol-

lows:

For details, refer to the regulations in your own country.

CAUTION:

IKeep all tires inflated to correct pressures.

I Place vehicle and tester on one and the same flat surface.

I Ensure that there is no-load in the vehicle other than

coolant, engine oil (filled up to correct level), full fuel tank

and the driver (or equivalent weight placed in driver's posi-

tion).

For details of front fog lamp aiming adjustment, refer to ªAiming

Adjustmentº, EL-47.

Check the distance between the vehicle and the ground illumina-

tion point of the main axis of the fog lamp beam. Keep the distance

to approximately 40 m (131 ft).

NEL331

EXTERIOR LAMP

EL-57

http://vnx.su/

Page 1576 of 1833

![NISSAN TERRANO 2004 Service Repair Manual POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

Ithrough 10A fuse [No. 16, located in the fuse block (J/B)]

I to combination meter terminal 27.

With the ignition switch in the ON or STA NISSAN TERRANO 2004 Service Repair Manual POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

Ithrough 10A fuse [No. 16, located in the fuse block (J/B)]

I to combination meter terminal 27.

With the ignition switch in the ON or STA](/img/5/57394/w960_57394-1575.png)

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

Ithrough 10A fuse [No. 16, located in the fuse block (J/B)]

I to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

I through 10A fuse [No. 12, located in the fuse block (J/B)]

I to combination meter terminal 28.

Ground is supplied

I through body grounds F36, F47 (LHD models) or M33, M754 (RHD models)

I to combination meter terminal 29.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

Thermal transmitter provides a engine coolant temperature signal to combination meter for water temperature

gauge.

TACHOMETER

The tachometer indicates engine speed in revolution per minutes (rpm). ECM provides an engine speed sig-

nal to combination meter for tachometer.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by a variable ground signal supplied

Ifrom body grounds B10 and B18

I through terminal 3 of the fuel level sensor unit and

I through terminal 2 (TD27Ti engine) or 1 (ZD30DDTi engine) of the fuel level sensor unit

I to combination meter terminal 13 for the fuel gauge.

SPEEDOMETER

The combination meter receives a signal from vehicle speed sensor. The speedometer converts the signal into

the vehicle speed displayed.

AMBIENT TEMPERATURE GAUGE

Ambient temperature sensor provides the signal for ambient temperature to combination meter.

METER AND GAUGES

System Description (Cont'd)

EL-83

http://vnx.su/

Page 1819 of 1833

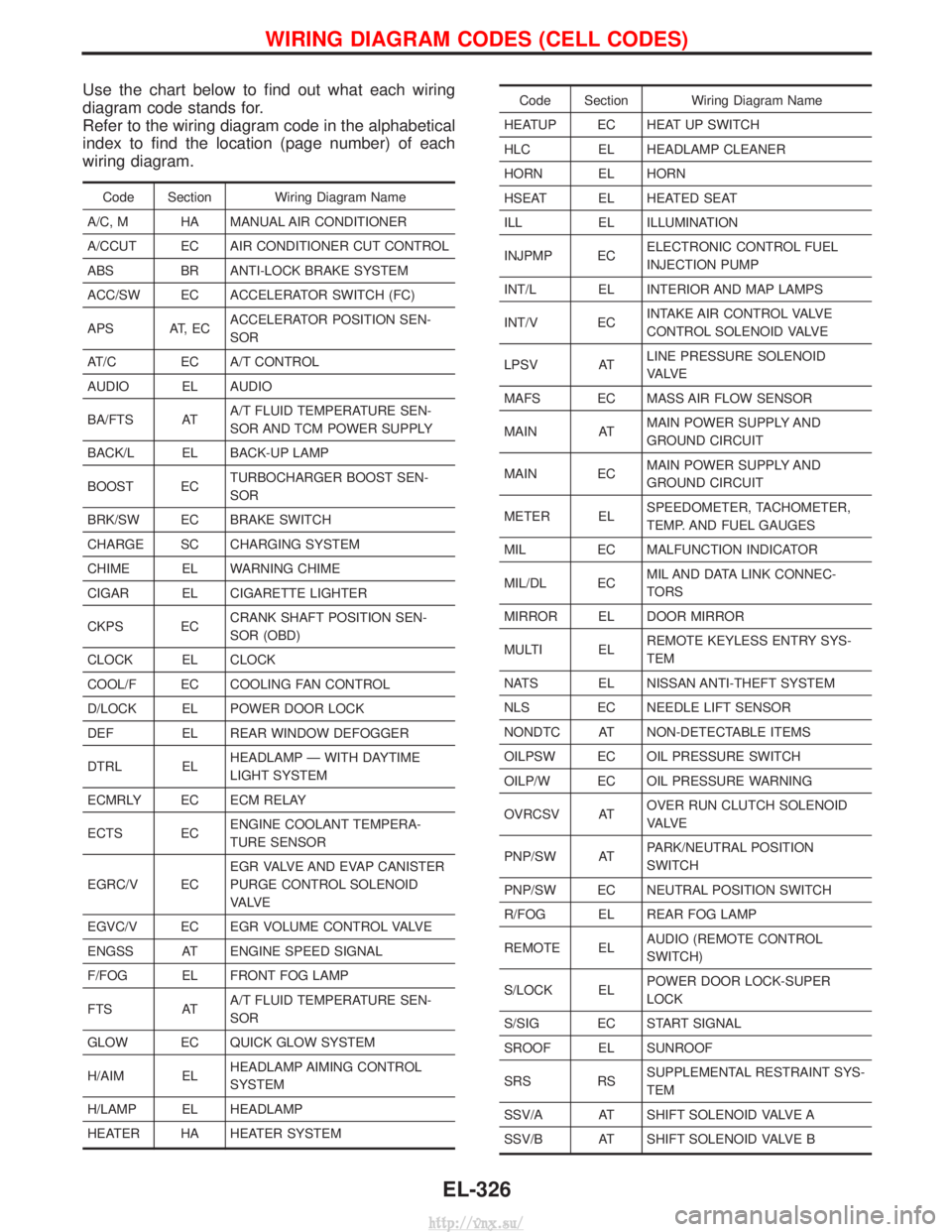

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

A/C, M HA MANUAL AIR CONDITIONER

A/CCUT EC AIR CONDITIONER CUT CONTROL

ABS BR ANTI-LOCK BRAKE SYSTEM

ACC/SW EC ACCELERATOR SWITCH (FC)

APS AT, EC ACCELERATOR POSITION SEN-

SOR

AT/C EC A/T CONTROL

AUDIO EL AUDIO

BA/FTS AT A/T FLUID TEMPERATURE SEN-

SOR AND TCM POWER SUPPLY

BACK/L EL BACK-UP LAMP

BOOST EC TURBOCHARGER BOOST SEN-

SOR

BRK/SW EC BRAKE SWITCH

CHARGE SC CHARGING SYSTEM

CHIME EL WARNING CHIME

CIGAR EL CIGARETTE LIGHTER

CKPS EC CRANK SHAFT POSITION SEN-

SOR (OBD)

CLOCK EL CLOCK

COOL/F EC COOLING FAN CONTROL

D/LOCK EL POWER DOOR LOCK

DEF EL REAR WINDOW DEFOGGER

DTRL EL HEADLAMP Ð WITH DAYTIME

LIGHT SYSTEM

ECMRLY EC ECM RELAY

ECTS EC ENGINE COOLANT TEMPERA-

TURE SENSOR

EGRC/V EC EGR VALVE AND EVAP CANISTER

PURGE CONTROL SOLENOID

VA LV E

EGVC/V EC EGR VOLUME CONTROL VALVE

ENGSS AT ENGINE SPEED SIGNAL

F/FOG EL FRONT FOG LAMP

FTS AT A/T FLUID TEMPERATURE SEN-

SOR

GLOW EC QUICK GLOW SYSTEM

H/AIM EL HEADLAMP AIMING CONTROL

SYSTEM

H/LAMP EL HEADLAMP

HEATER HA HEATER SYSTEM

Code Section Wiring Diagram Name

HEATUP EC HEAT UP SWITCH

HLC EL HEADLAMP CLEANER

HORN EL HORN

HSEAT EL HEATED SEAT

ILL EL ILLUMINATION

INJPMP EC ELECTRONIC CONTROL FUEL

INJECTION PUMP

INT/L EL INTERIOR AND MAP LAMPS

INT/V EC INTAKE AIR CONTROL VALVE

CONTROL SOLENOID VALVE

LPSV AT LINE PRESSURE SOLENOID

VA LV E

MAFS EC MASS AIR FLOW SENSOR

MAIN AT MAIN POWER SUPPLY AND

GROUND CIRCUIT

MAIN EC MAIN POWER SUPPLY AND

GROUND CIRCUIT

METER EL SPEEDOMETER, TACHOMETER,

TEMP. AND FUEL GAUGES

MIL EC MALFUNCTION INDICATOR

MIL/DL EC MIL AND DATA LINK CONNEC-

TORS

MIRROR EL DOOR MIRROR

MULTI EL REMOTE KEYLESS ENTRY SYS-

TEM

NATS EL NISSAN ANTI-THEFT SYSTEM

NLS EC NEEDLE LIFT SENSOR

NONDTC AT NON-DETECTABLE ITEMS

OILPSW EC OIL PRESSURE SWITCH

OILP/W EC OIL PRESSURE WARNING

OVRCSV AT OVER RUN CLUTCH SOLENOID

VA LV E

PNP/SW AT PARK/NEUTRAL POSITION

SWITCH

PNP/SW EC NEUTRAL POSITION SWITCH

R/FOG EL REAR FOG LAMP

REMOTE EL AUDIO (REMOTE CONTROL

SWITCH)

S/LOCK EL POWER DOOR LOCK-SUPER

LOCK

S/SIG EC START SIGNAL

SROOF EL SUNROOF

SRS RS SUPPLEMENTAL RESTRAINT SYS-

TEM

SSV/A AT SHIFT SOLENOID VALVE A

SSV/B AT SHIFT SOLENOID VALVE B

WIRING DIAGRAM CODES (CELL CODES)

EL-326

http://vnx.su/

Page 1828 of 1833

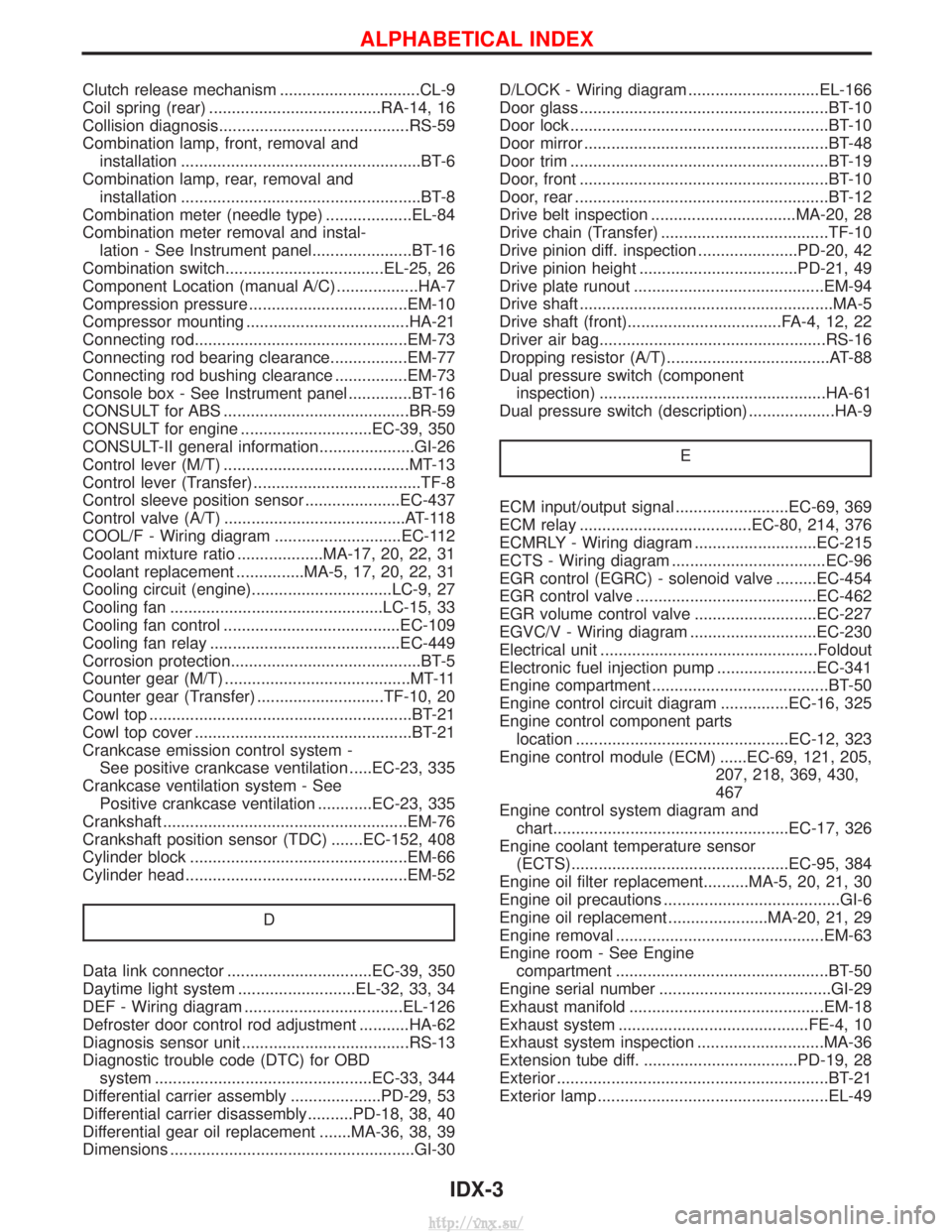

Clutch release mechanism ...............................CL-9

Coil spring (rear) ......................................RA-14, 16

Collision diagnosis..........................................RS-59

Combination lamp, front, removal andinstallation .....................................................BT-6

Combination lamp, rear, removal and installation .....................................................BT-8

Combination meter (needle type) ...................EL-84

Combination meter removal and instal- lation - See Instrument panel......................BT-16

Combination switch...................................EL-25, 26

Component Location (manual A/C) ..................HA-7

Compression pressure ...................................EM-10

Compressor mounting ....................................HA-21

Connecting rod...............................................EM-73

Connecting rod bearing clearance.................EM-77

Connecting rod bushing clearance ................EM-73

Console box - See Instrument panel ..............BT-16

CONSULT for ABS .........................................BR-59

CONSULT for engine .............................EC-39, 350

CONSULT-II general information.....................GI-26

Control lever (M/T) .........................................MT-13

Control lever (Transfer) .....................................TF-8

Control sleeve position sensor .....................EC-437

Control valve (A/T) ........................................AT-118

COOL/F - Wiring diagram ............................EC-112

Coolant mixture ratio ...................MA-17, 20, 22, 31

Coolant replacement ...............MA-5, 17, 20, 22, 31

Cooling circuit (engine)...............................LC-9, 27

Cooling fan ...............................................LC-15, 33

Cooling fan control .......................................EC-109

Cooling fan relay ..........................................EC-449

Corrosion protection..........................................BT-5

Counter gear (M/T) .........................................MT-11

Counter gear (Transfer) ............................TF-10, 20

Cowl top ..........................................................BT-21

Cowl top cover ................................................BT-21

Crankcase emission control system - See positive crankcase ventilation .....EC-23, 335

Crankcase ventilation system - See Positive crankcase ventilation ............EC-23, 335

Crankshaft ......................................................EM-76

Crankshaft position sensor (TDC) .......EC-152, 408

Cylinder block ................................................EM-66

Cylinder head .................................................EM-52

D

Data link connector ................................EC-39, 350

Daytime light system ..........................EL-32, 33, 34

DEF - Wiring diagram ...................................EL-126

Defroster door control rod adjustment ...........HA-62

Diagnosis sensor unit .....................................RS-13

Diagnostic trouble code (DTC) for OBDsystem ................................................EC-33, 344

Differential carrier assembly ....................PD-29, 53

Differential carrier disassembly..........PD-18, 38, 40

Differential gear oil replacement .......MA-36, 38, 39

Dimensions ......................................................GI-30 D/LOCK - Wiring diagram .............................EL-166

Door glass .......................................................BT-10

Door lock .........................................................BT-10

Door mirror ......................................................BT-48

Door trim .........................................................BT-19

Door, front .......................................................BT-10

Door, rear ........................................................BT-12

Drive belt inspection ................................MA-20, 28

Drive chain (Transfer) .....................................TF-10

Drive pinion diff. inspection ......................PD-20, 42

Drive pinion height ...................................PD-21, 49

Drive plate runout ..........................................EM-94

Drive shaft ........................................................MA-5

Drive shaft (front)..................................FA-4, 12, 22

Driver air bag..................................................RS-16

Dropping resistor (A/T)....................................AT-88

Dual pressure switch (component

inspection) ..................................................HA-61

Dual pressure switch (description) ...................HA-9

E

ECM input/output signal .........................EC-69, 369

ECM relay ......................................EC-80, 214, 376

ECMRLY - Wiring diagram ...........................EC-215

ECTS - Wiring diagram ..................................EC-96

EGR control (EGRC) - solenoid valve .........EC-454

EGR control valve ........................................EC-462

EGR volume control valve ...........................EC-227

EGVC/V - Wiring diagram ............................EC-230

Electrical unit ................................................Foldout

Electronic fuel injection pump ......................EC-341

Engine compartment .......................................BT-50

Engine control circuit diagram ...............EC-16, 325

Engine control component partslocation ...............................................EC-12, 323

Engine control module (ECM) ......EC-69, 121, 205, 207, 218, 369, 430,

467

Engine control system diagram and chart....................................................EC-17, 326

Engine coolant temperature sensor (ECTS)................................................EC-95, 384

Engine oil filter replacement..........MA-5, 20, 21, 30

Engine oil precautions .......................................GI-6

Engine oil replacement ......................MA-20, 21, 29

Engine removal ..............................................EM-63

Engine room - See Engine compartment ...............................................BT-50

Engine serial number ......................................GI-29

Exhaust manifold ...........................................EM-18

Exhaust system ..........................................FE-4, 10

Exhaust system inspection ............................MA-36

Extension tube diff. ..................................PD-19, 28

Exterior ............................................................BT-21

Exterior lamp ...................................................EL-49

ALPHABETICAL INDEX

IDX-3

http://vnx.su/