engine coolant NISSAN TERRANO 2004 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 260 of 1833

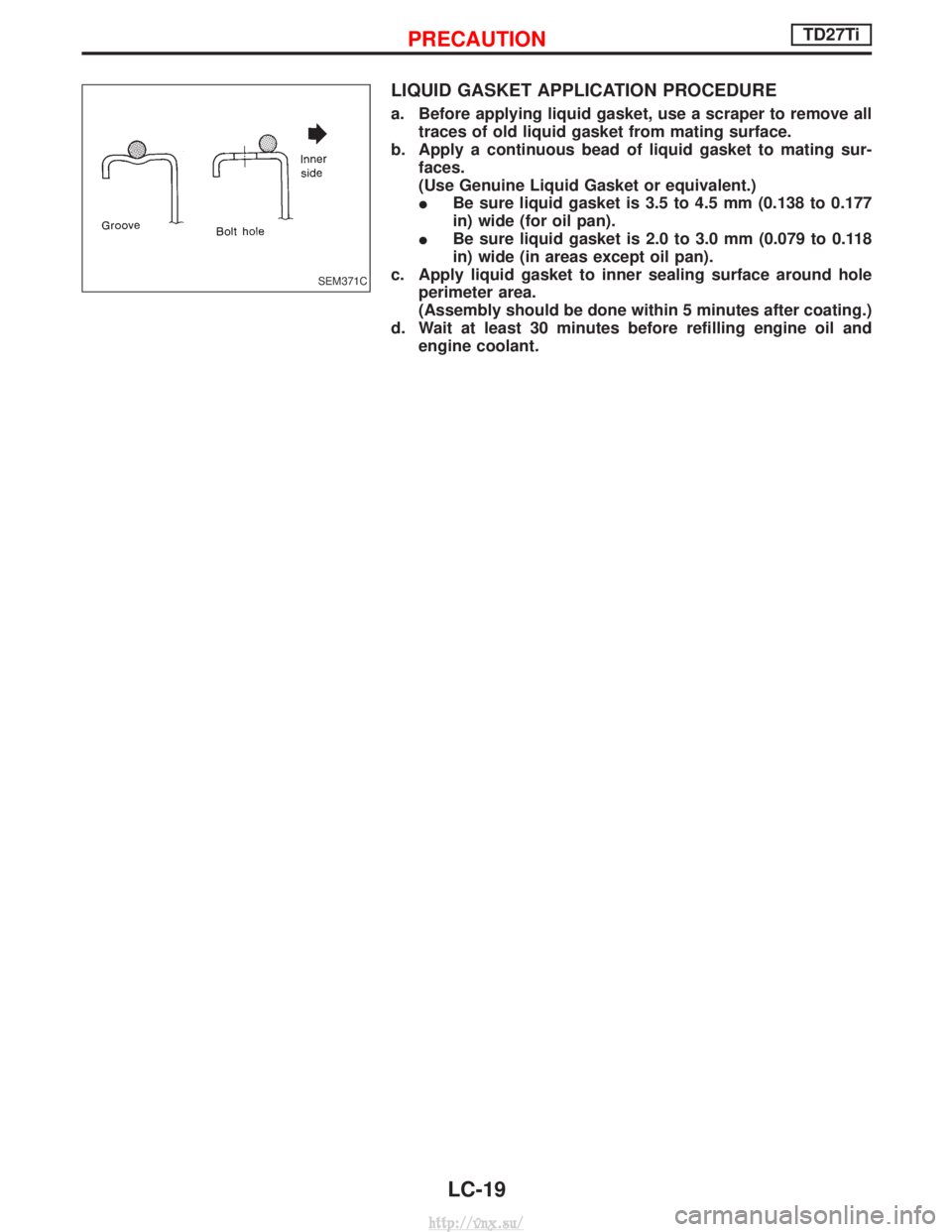

LIQUID GASKET APPLICATION PROCEDURE

a. Before applying liquid gasket, use a scraper to remove alltraces of old liquid gasket from mating surface.

b. Apply a continuous bead of liquid gasket to mating sur- faces.

(Use Genuine Liquid Gasket or equivalent.)

I Be sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177

in) wide (for oil pan).

I Be sure liquid gasket is 2.0 to 3.0 mm (0.079 to 0.118

in) wide (in areas except oil pan).

c. Apply liquid gasket to inner sealing surface around hole perimeter area.

(Assembly should be done within 5 minutes after coating.)

d. Wait at least 30 minutes before refilling engine oil and engine coolant.

SEM371C

PRECAUTIONTD27Ti

LC-19

http://vnx.su/

Page 270 of 1833

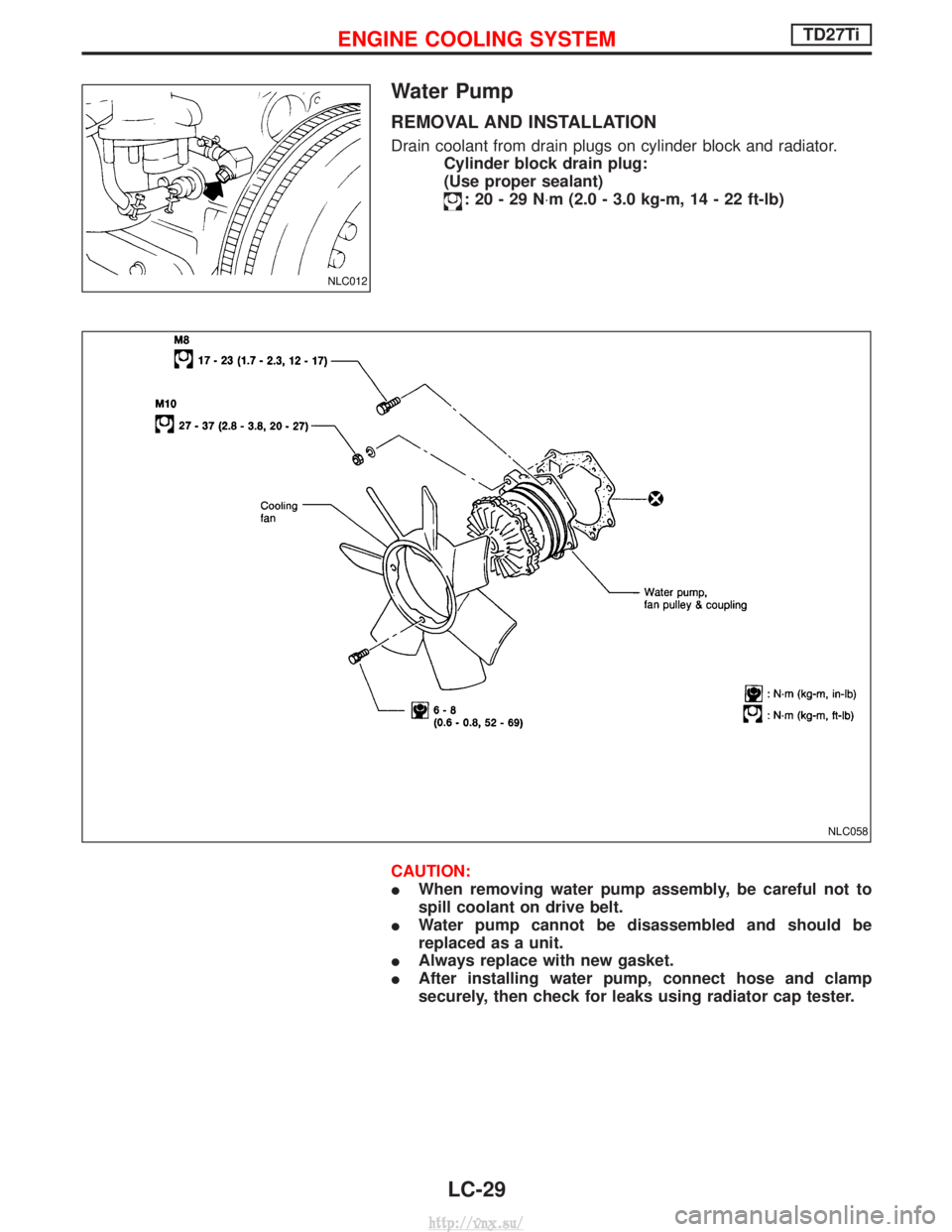

Water Pump

REMOVAL AND INSTALLATION

Drain coolant from drain plugs on cylinder block and radiator.Cylinder block drain plug:

(Use proper sealant)

:20-29N ×m (2.0 - 3.0 kg-m, 14 - 22 ft-lb)

CAUTION:

I When removing water pump assembly, be careful not to

spill coolant on drive belt.

I Water pump cannot be disassembled and should be

replaced as a unit.

I Always replace with new gasket.

I After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

NLC012

NLC058

ENGINE COOLING SYSTEMTD27Ti

LC-29

http://vnx.su/

Page 272 of 1833

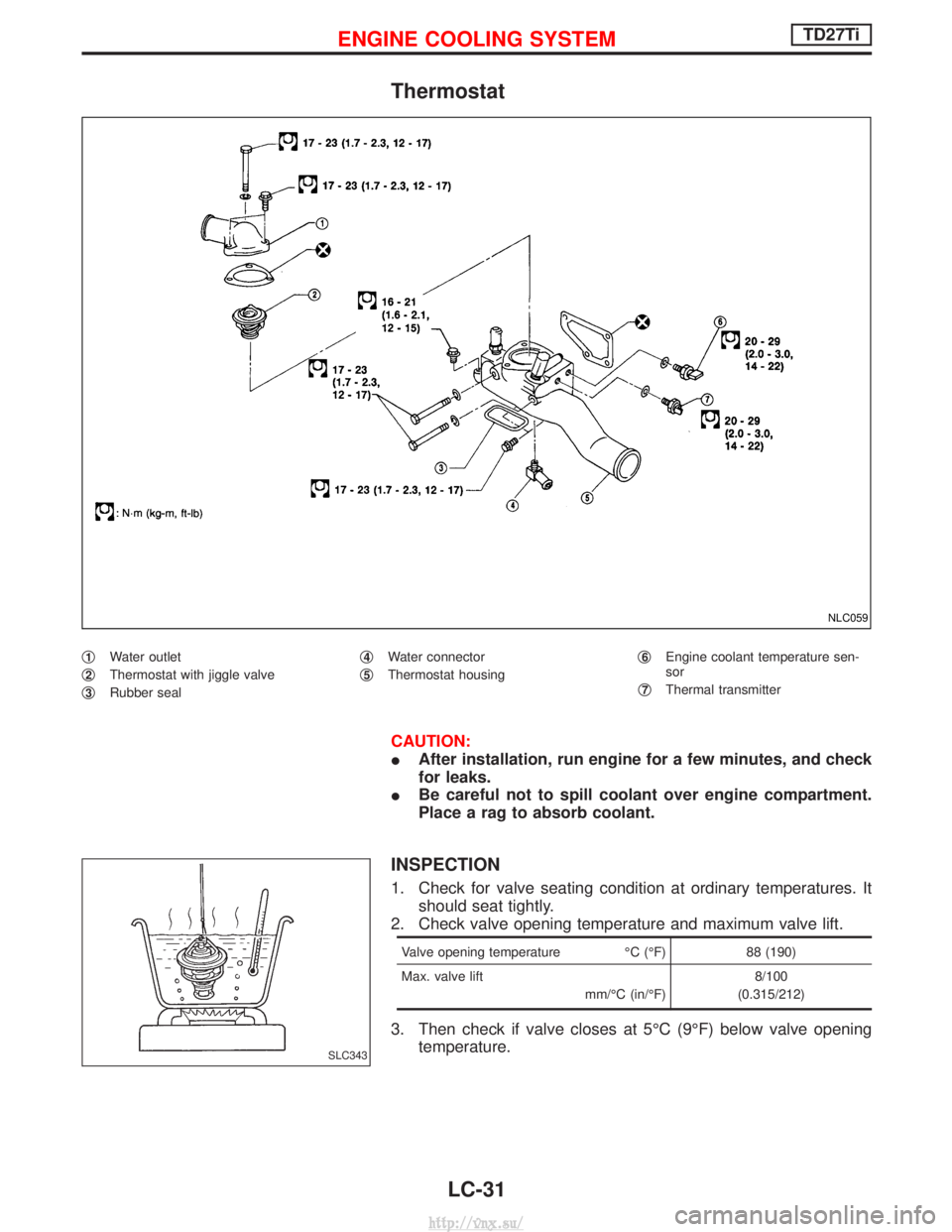

Thermostat

q1Water outlet

q

2Thermostat with jiggle valve

q

3Rubber seal q

4Water connector

q

5Thermostat housing q

6Engine coolant temperature sen-

sor

q

7Thermal transmitter

CAUTION:

I After installation, run engine for a few minutes, and check

for leaks.

I Be careful not to spill coolant over engine compartment.

Place a rag to absorb coolant.

INSPECTION

1. Check for valve seating condition at ordinary temperatures. It

should seat tightly.

2. Check valve opening temperature and maximum valve lift.

Valve opening temperature ÉC (ÉF) 88 (190)

Max. valve lift mm/ÉC (in/ÉF)8/100

(0.315/212)

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening temperature.

NLC059

SLC343

ENGINE COOLING SYSTEMTD27Ti

LC-31

http://vnx.su/

Page 273 of 1833

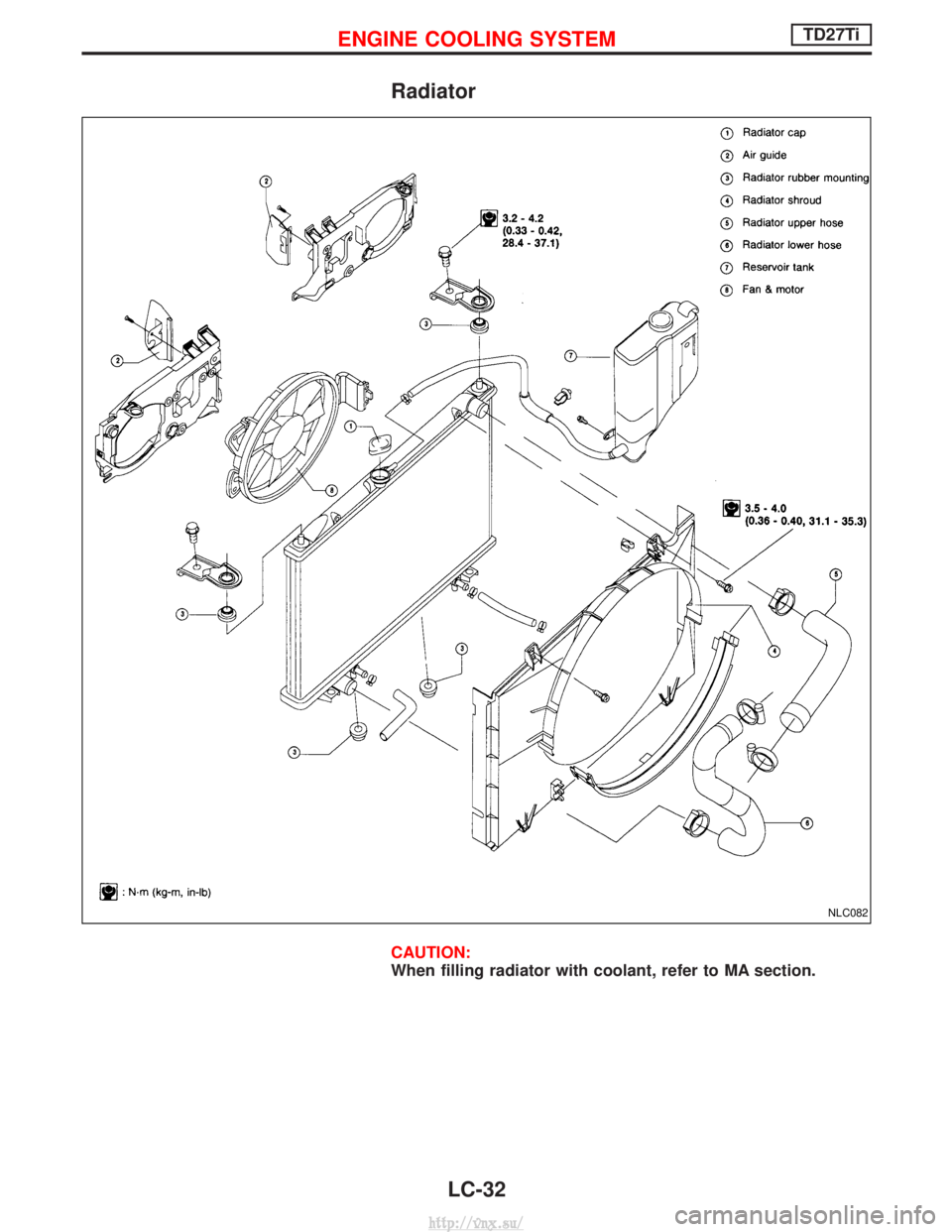

Radiator

CAUTION:

When filling radiator with coolant, refer to MA section.

NLC082

ENGINE COOLING SYSTEMTD27Ti

LC-32

http://vnx.su/

Page 276 of 1833

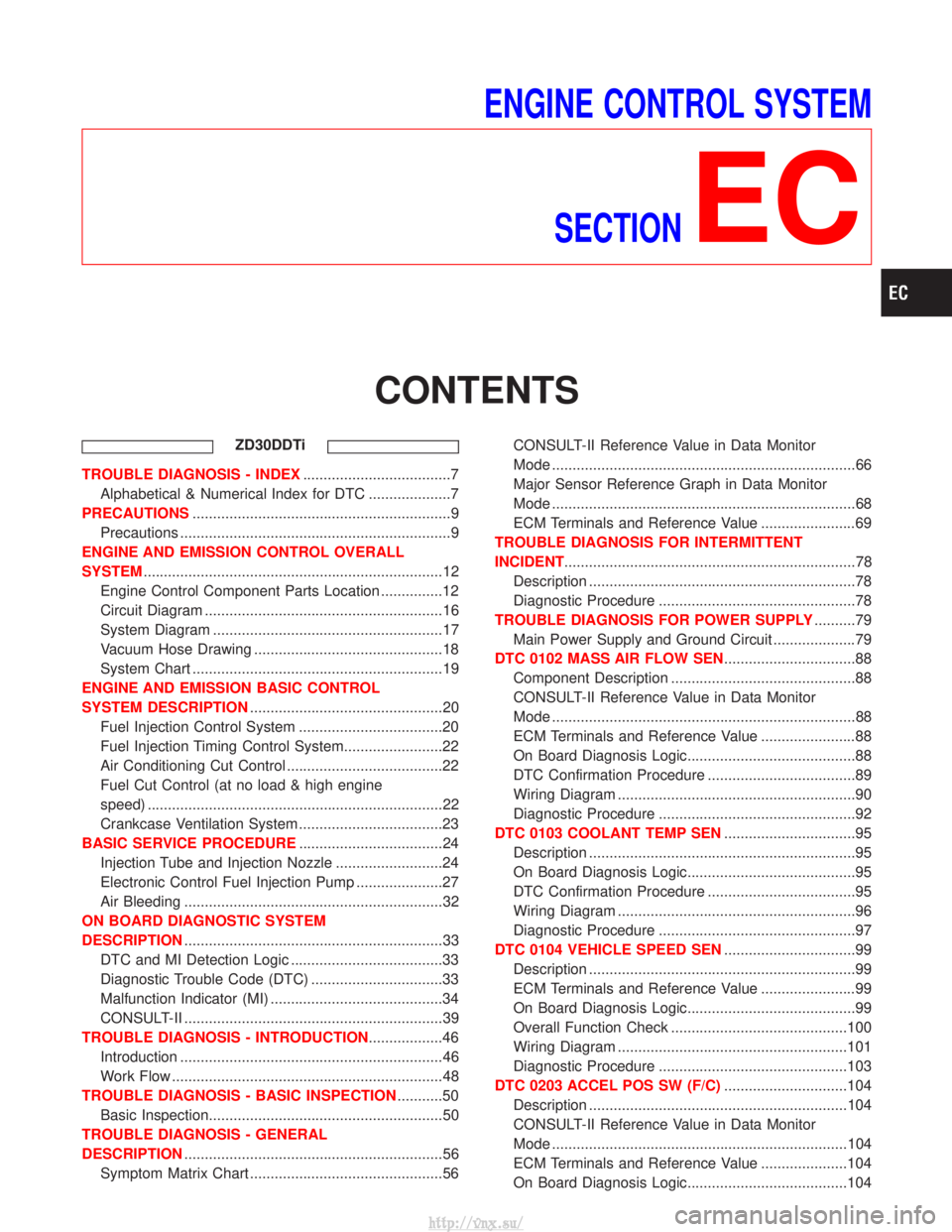

ENGINE CONTROL SYSTEMSECTION

EC

CONTENTS

ZD30DDTi

TROUBLE DIAGNOSIS - INDEX ....................................7

Alphabetical & Numerical Index for DTC ....................7

PRECAUTIONS ...............................................................9

Precautions ..................................................................9

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM ........................................................................\

.12

Engine Control Component Parts Location ...............12

Circuit Diagram ..........................................................16

System Diagram ........................................................17

Vacuum Hose Drawing ..............................................18

System Chart .............................................................19

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION ...............................................20

Fuel Injection Control System ...................................20

Fuel Injection Timing Control System........................22

Air Conditioning Cut Control ......................................22

Fuel Cut Control (at no load & high engine

speed) ........................................................................\

22

Crankcase Ventilation System ...................................23

BASIC SERVICE PROCEDURE ...................................24

Injection Tube and Injection Nozzle ..........................24

Electronic Control Fuel Injection Pump .....................27

Air Bleeding ...............................................................32

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION ...............................................................33

DTC and MI Detection Logic .....................................33

Diagnostic Trouble Code (DTC) ................................33

Malfunction Indicator (MI) ..........................................34

CONSULT-II ...............................................................39

TROUBLE DIAGNOSIS - INTRODUCTION ..................46

Introduction ................................................................46

Work Flow ..................................................................48

TROUBLE DIAGNOSIS - BASIC INSPECTION ...........50

Basic Inspection.........................................................50

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION ...............................................................56

Symptom Matrix Chart ...............................................56 CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

..66

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................\

..68

ECM Terminals and Reference Value .......................69

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT .......................................................................78

Description .................................................................78

Diagnostic Procedure ................................................78

TROUBLE DIAGNOSIS FOR POWER SUPPLY ..........79

Main Power Supply and Ground Circuit ....................79

DTC 0102 MASS AIR FLOW SEN ................................88

Component Description .............................................88

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

..88

ECM Terminals and Reference Value .......................88

On Board Diagnosis Logic.........................................88

DTC Confirmation Procedure ....................................89

Wiring Diagram ..........................................................90

Diagnostic Procedure ................................................92

DTC 0103 COOLANT TEMP SEN ................................95

Description .................................................................95

On Board Diagnosis Logic.........................................95

DTC Confirmation Procedure ....................................95

Wiring Diagram ..........................................................96

Diagnostic Procedure ................................................97

DTC 0104 VEHICLE SPEED SEN ................................99

Description .................................................................99

ECM Terminals and Reference Value .......................99

On Board Diagnosis Logic.........................................99

Overall Function Check ...........................................100

Wiring Diagram ........................................................101

Diagnostic Procedure ..............................................103

DTC 0203 ACCEL POS SW (F/C) ..............................104

Description ...............................................................104

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

104

ECM Terminals and Reference Value .....................104

On Board Diagnosis Logic.......................................104

http://vnx.su/

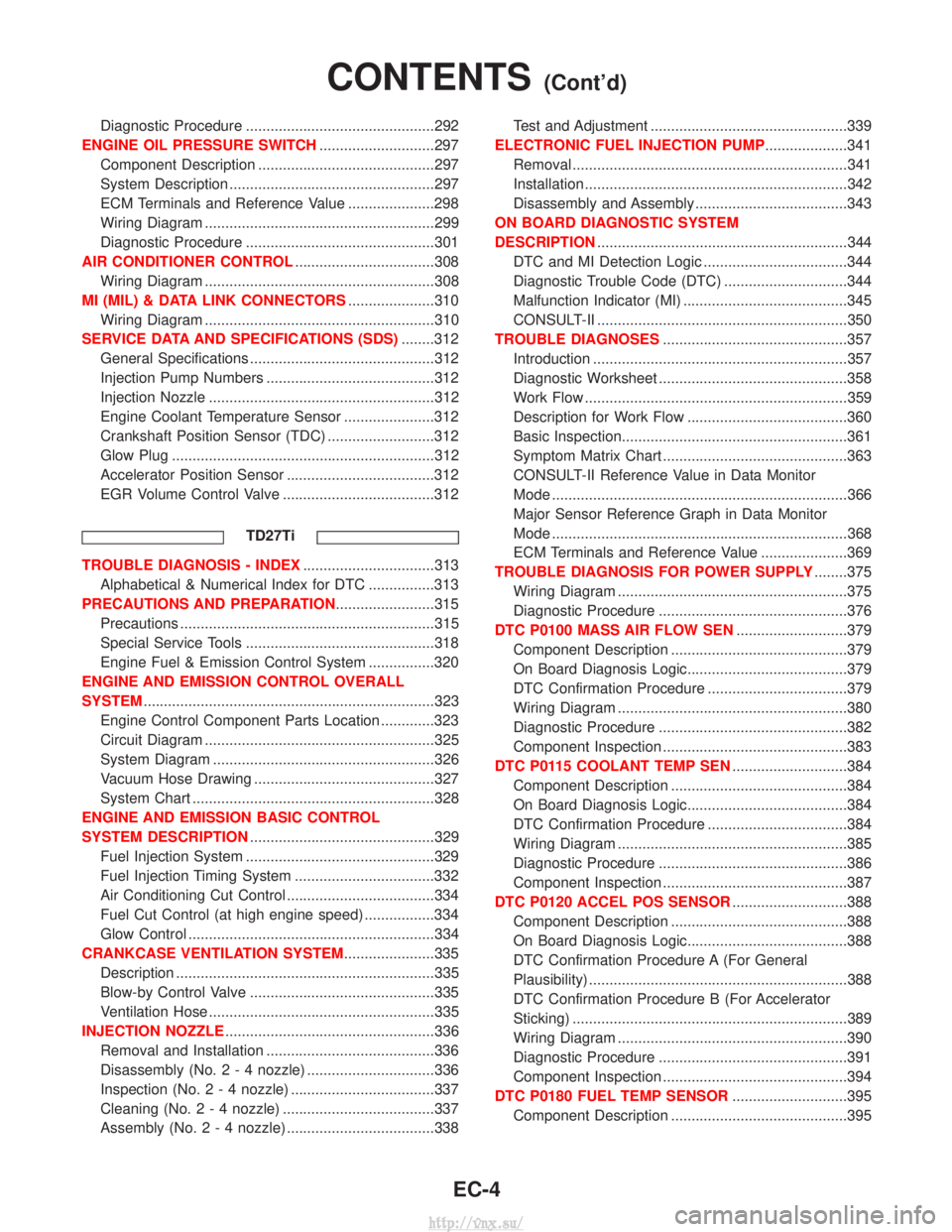

Page 279 of 1833

Diagnostic Procedure ..............................................292

ENGINE OIL PRESSURE SWITCH ............................297

Component Description ...........................................297

System Description ..................................................297

ECM Terminals and Reference Value .....................298

Wiring Diagram ........................................................299

Diagnostic Procedure ..............................................301

AIR CONDITIONER CONTROL ..................................308

Wiring Diagram ........................................................308

MI (MIL) & DATA LINK CONNECTORS .....................310

Wiring Diagram ........................................................310

SERVICE DATA AND SPECIFICATIONS (SDS) ........312

General Specifications .............................................312

Injection Pump Numbers .........................................312

Injection Nozzle .......................................................312

Engine Coolant Temperature Sensor ......................312

Crankshaft Position Sensor (TDC) ..........................312

Glow Plug ................................................................312

Accelerator Position Sensor ....................................312

EGR Volume Control Valve .....................................312

TD27Ti

TROUBLE DIAGNOSIS - INDEX ................................313

Alphabetical & Numerical Index for DTC ................313

PRECAUTIONS AND PREPARATION ........................315

Precautions ..............................................................315

Special Service Tools ..............................................318

Engine Fuel & Emission Control System ................320

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM .......................................................................323

Engine Control Component Parts Location .............323

Circuit Diagram ........................................................325

System Diagram ......................................................326

Vacuum Hose Drawing ............................................327

System Chart ...........................................................328

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION .............................................329

Fuel Injection System ..............................................329

Fuel Injection Timing System ..................................332

Air Conditioning Cut Control ....................................334

Fuel Cut Control (at high engine speed) .................334

Glow Control ............................................................334

CRANKCASE VENTILATION SYSTEM ......................335

Description ...............................................................335

Blow-by Control Valve .............................................335

Ventilation Hose .......................................................335

INJECTION NOZZLE ...................................................336

Removal and Installation .........................................336

Disassembly (No.2-4 nozzle) ...............................336

Inspection (No.2-4 nozzle) ...................................337

Cleaning (No.2-4 nozzle) .....................................337

Assembly (No.2-4 nozzle) ....................................338 Test and Adjustment ................................................339

ELECTRONIC FUEL INJECTION PUMP ....................341

Removal ...................................................................341

Installation ................................................................342

Disassembly and Assembly .....................................343

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION .............................................................344

DTC and MI Detection Logic ...................................344

Diagnostic Trouble Code (DTC) ..............................344

Malfunction Indicator (MI) ........................................345

CONSULT-II .............................................................350

TROUBLE DIAGNOSES .............................................357

Introduction ..............................................................357

Diagnostic Worksheet ..............................................358

Work Flow ................................................................359

Description for Work Flow .......................................360

Basic Inspection.......................................................361

Symptom Matrix Chart .............................................363

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

366

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................\

368

ECM Terminals and Reference Value .....................369

TROUBLE DIAGNOSIS FOR POWER SUPPLY ........375

Wiring Diagram ........................................................375

Diagnostic Procedure ..............................................376

DTC P0100 MASS AIR FLOW SEN ...........................379

Component Description ...........................................379

On Board Diagnosis Logic.......................................379

DTC Confirmation Procedure ..................................379

Wiring Diagram ........................................................380

Diagnostic Procedure ..............................................382

Component Inspection .............................................383

DTC P0115 COOLANT TEMP SEN ............................384

Component Description ...........................................384

On Board Diagnosis Logic.......................................384

DTC Confirmation Procedure ..................................384

Wiring Diagram ........................................................385

Diagnostic Procedure ..............................................386

Component Inspection .............................................387

DTC P0120 ACCEL POS SENSOR ............................388

Component Description ...........................................388

On Board Diagnosis Logic.......................................388

DTC Confirmation Procedure A (For General

Plausibility) ...............................................................388

DTC Confirmation Procedure B (For Accelerator

Sticking) ...................................................................389

Wiring Diagram ........................................................390

Diagnostic Procedure ..............................................391

Component Inspection .............................................394

DTC P0180 FUEL TEMP SENSOR ............................395

Component Description ...........................................395

CONTENTS(Cont'd)

EC-4

http://vnx.su/

Page 294 of 1833

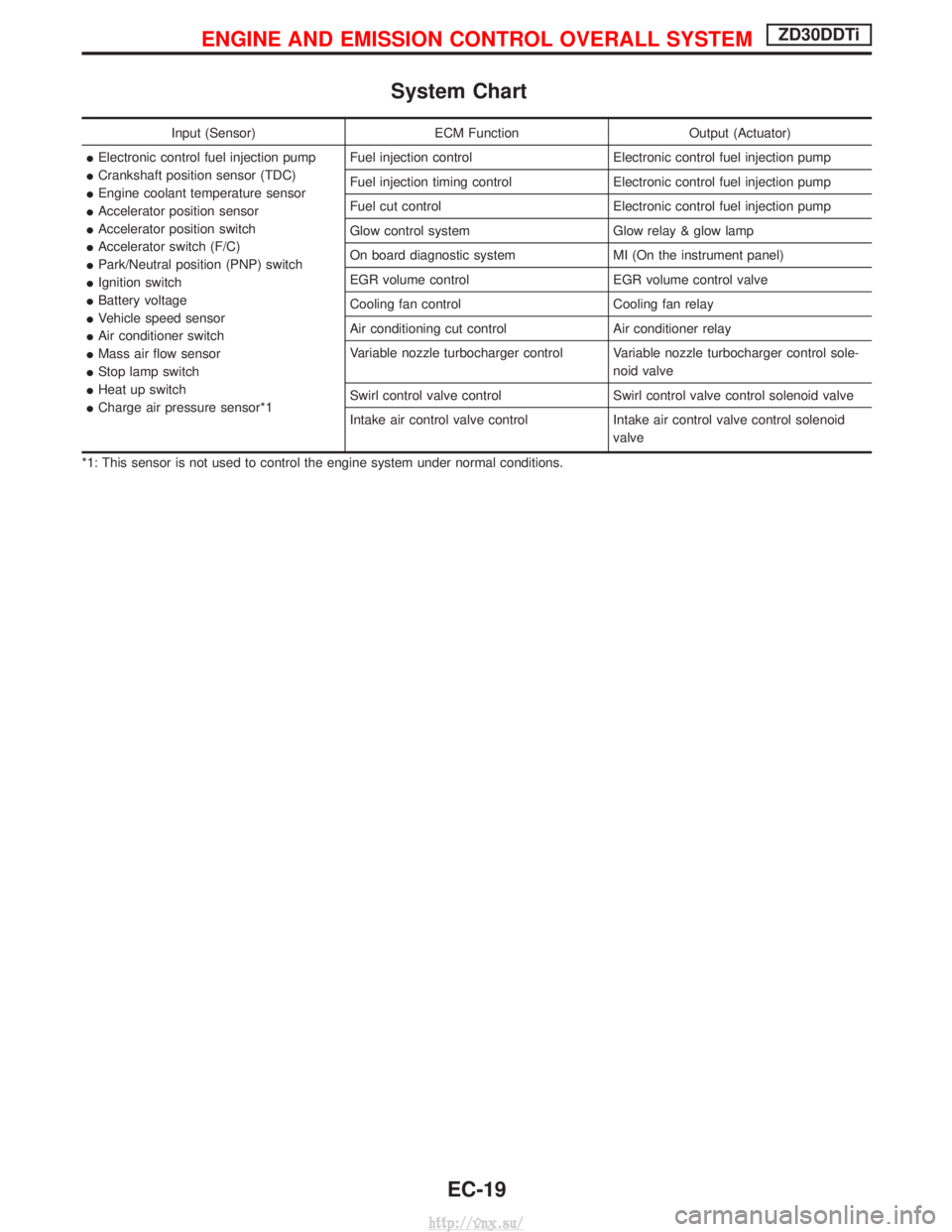

System Chart

Input (Sensor)ECM FunctionOutput (Actuator)

I Electronic control fuel injection pump

I Crankshaft position sensor (TDC)

I Engine coolant temperature sensor

I Accelerator position sensor

I Accelerator position switch

I Accelerator switch (F/C)

I Park/Neutral position (PNP) switch

I Ignition switch

I Battery voltage

I Vehicle speed sensor

I Air conditioner switch

I Mass air flow sensor

I Stop lamp switch

I Heat up switch

I Charge air pressure sensor*1 Fuel injection control

Electronic control fuel injection pump

Fuel injection timing control Electronic control fuel injection pump

Fuel cut control Electronic control fuel injection pump

Glow control system Glow relay & glow lamp

On board diagnostic system MI (On the instrument panel)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Variable nozzle turbocharger control Variable nozzle turbocharger control sole- noid valve

Swirl control valve control Swirl control valve control solenoid valve

Intake air control valve control Intake air control valve control solenoid

valve

*1: This sensor is not used to control the engine system under normal conditions.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-19

http://vnx.su/

Page 295 of 1833

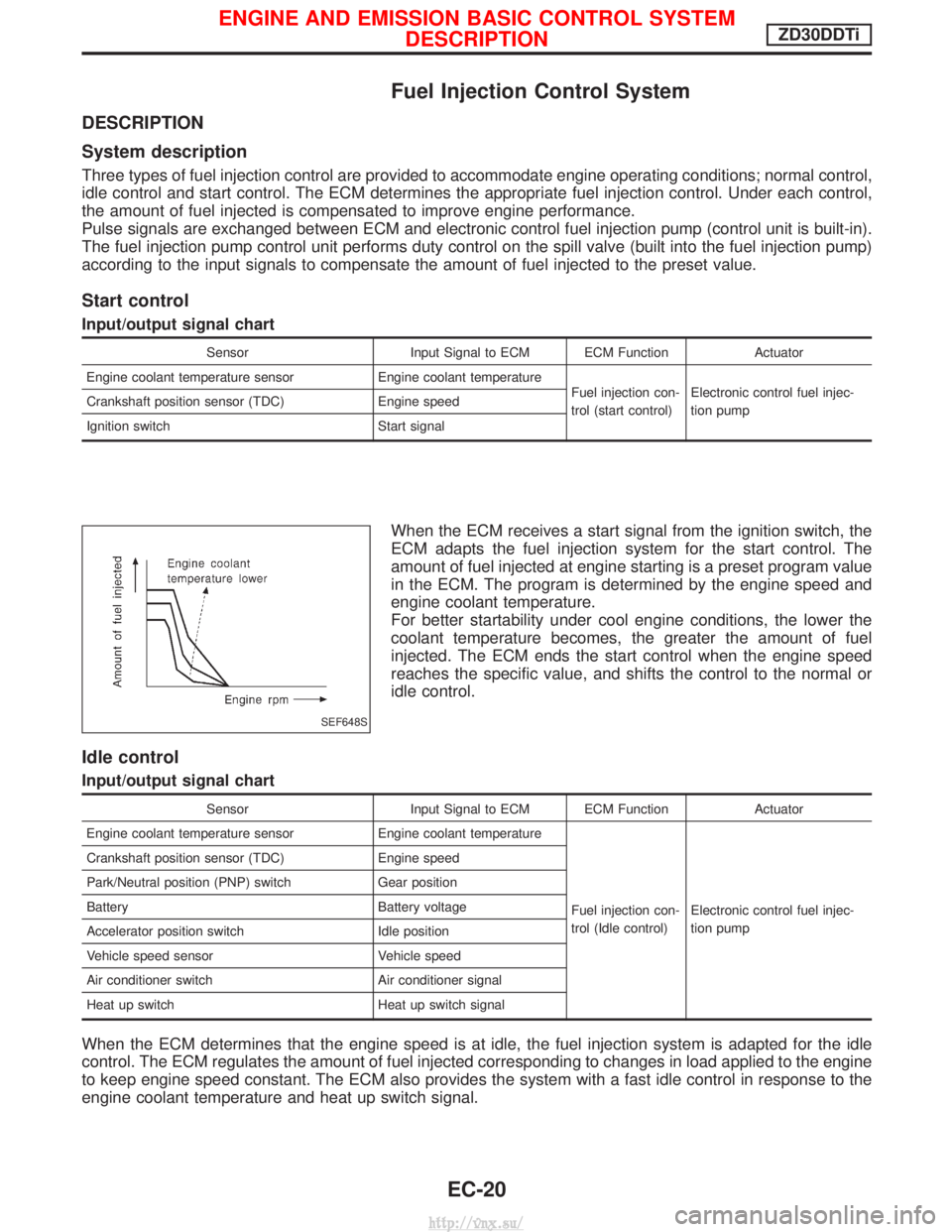

Fuel Injection Control System

DESCRIPTION

System description

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is compensated to improve engine performance.

Pulse signals are exchanged between ECM and electronic control fuel injection pump (control unit is built-in).

The fuel injection pump control unit performs duty control on the spill valve (built into the fuel injection pump)

according to the input signals to compensate the amount of fuel injected to the preset value.

Start control

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (start control)Electronic control fuel injec-

tion pump

Crankshaft position sensor (TDC)

Engine speed

Ignition switch Start signal

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed and

engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal or

idle control.

Idle control

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (Idle control)Electronic control fuel injec-

tion pump

Crankshaft position sensor (TDC)

Engine speed

Park/Neutral position (PNP) switch Gear position

Battery Battery voltage

Accelerator position switch Idle position

Vehicle speed sensor Vehicle speed

Air conditioner switch Air conditioner signal

Heat up switch Heat up switch signal

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the engine

to keep engine speed constant. The ECM also provides the system with a fast idle control in response to the

engine coolant temperature and heat up switch signal.

SEF648S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-20

http://vnx.su/

Page 296 of 1833

Normal control

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Crankshaft position sensor (TDC) Engine speed

Fuel injection con-

trol (Normal con-

trol)Electronic control fuel injec-

tion pump

Accelerator position sensor

Accelerator position

Vehicle speed sensor Vehicle speed

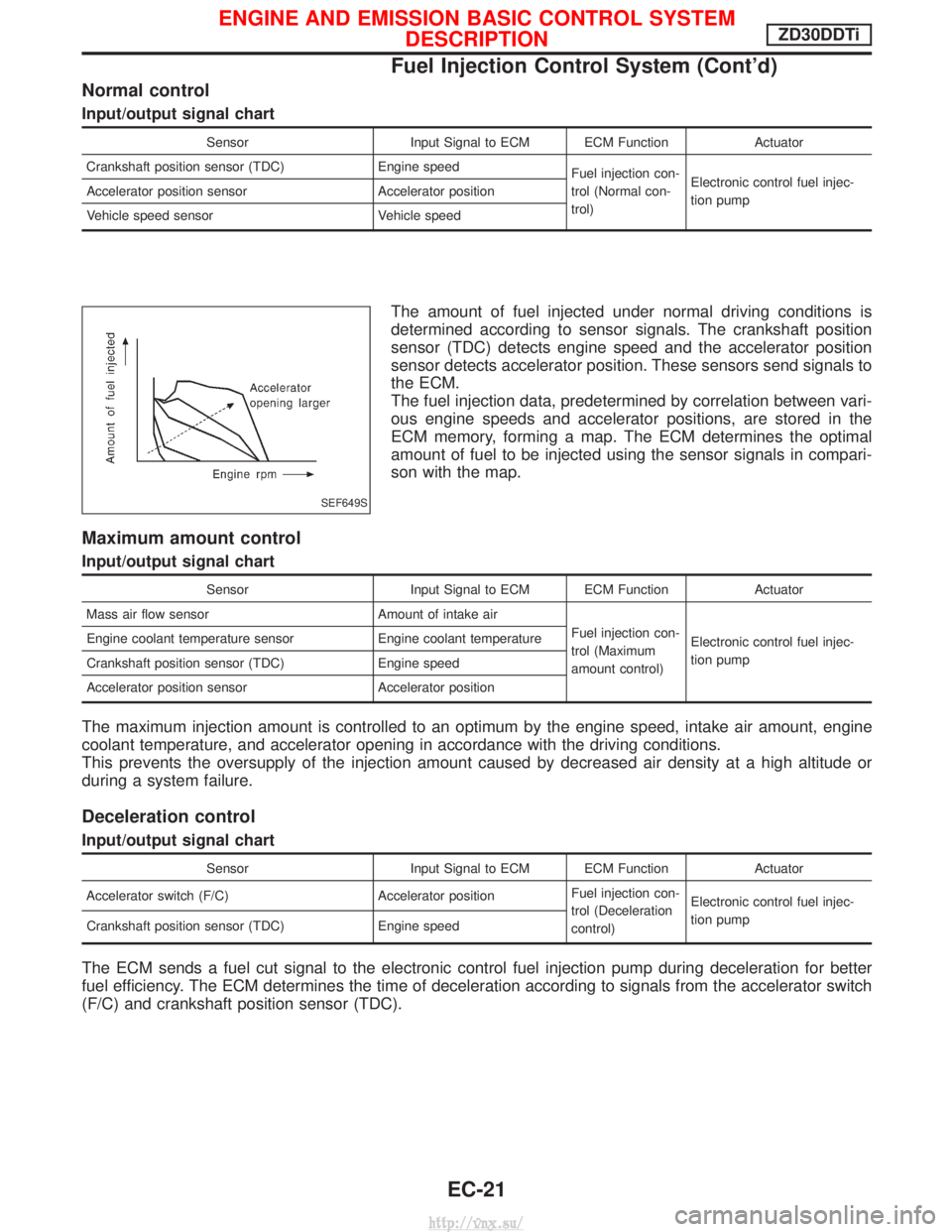

The amount of fuel injected under normal driving conditions is

determined according to sensor signals. The crankshaft position

sensor (TDC) detects engine speed and the accelerator position

sensor detects accelerator position. These sensors send signals to

the ECM.

The fuel injection data, predetermined by correlation between vari-

ous engine speeds and accelerator positions, are stored in the

ECM memory, forming a map. The ECM determines the optimal

amount of fuel to be injected using the sensor signals in compari-

son with the map.

Maximum amount control

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Mass air flow sensor Amount of intake air

Fuel injection con-

trol (Maximum

amount control)Electronic control fuel injec-

tion pump

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

Accelerator position sensor Accelerator position

The maximum injection amount is controlled to an optimum by the engine speed, intake air amount, engine

coolant temperature, and accelerator opening in accordance with the driving conditions.

This prevents the oversupply of the injection amount caused by decreased air density at a high altitude or

during a system failure.

Deceleration control

Input/output signal chart

Sensor

Input Signal to ECM ECM Function Actuator

Accelerator switch (F/C) Accelerator positionFuel injection con-

trol (Deceleration

control)Electronic control fuel injec-

tion pump

Crankshaft position sensor (TDC) Engine speed

The ECM sends a fuel cut signal to the electronic control fuel injection pump during deceleration for better

fuel efficiency. The ECM determines the time of deceleration according to signals from the accelerator switch

(F/C) and crankshaft position sensor (TDC).

SEF649S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

Fuel Injection Control System (Cont'd)

EC-21

http://vnx.su/

Page 297 of 1833

Fuel Injection Timing Control System

DESCRIPTION

The target fuel injection timing in accordance with the engine speed and the fuel injection amount are recorded

as a map in the ECM beforehand. The ECM and the injection pump control unit exchange signals and per-

form feedback control for optimum injection timing in accordance with the map.

Air Conditioning Cut Control

DESCRIPTION

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Air conditioner switch Air conditioner ªONº signal

Air conditioner cut

controlAir conditioner relay

Accelerator position sensor

Accelerator valve opening

angle

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

System description

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds.

When engine coolant temperature becomes excessively high, the air conditioner is turned off. This continues

until the engine coolant temperature returns to normal.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTION

Input/output signal chart

SensorInput Signal to ECM ECM Function Actuator

Vehicle speed sensor Vehicle speed

Fuel cut controlElectronic control fuel injec-

tion pump

Park/Neutral position (PNP) switch

Neutral position

Accelerator position switch or Accelerator

switch (F/C) Accelerator position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

If the engine speed is above 2,700 rpm with no load (for example, in neutral and engine speed over 2,700

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªFuel Injection Control Systemº, EC-20.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-22

http://vnx.su/