Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 730 of 1833

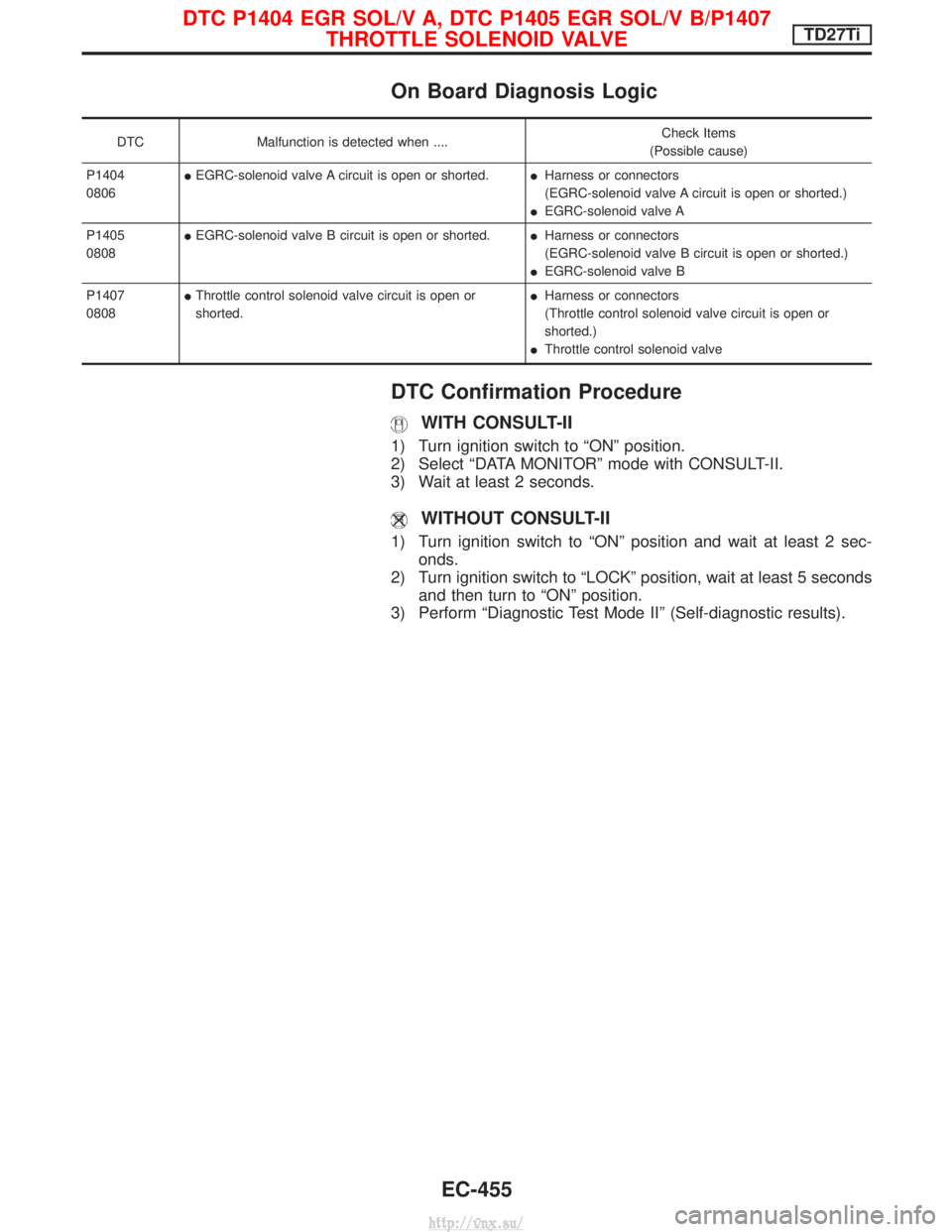

On Board Diagnosis Logic

DTCMalfunction is detected when .... Check Items

(Possible cause)

P1404

0806 I

EGRC-solenoid valve A circuit is open or shorted. IHarness or connectors

(EGRC-solenoid valve A circuit is open or shorted.)

I EGRC-solenoid valve A

P1405

0808 I

EGRC-solenoid valve B circuit is open or shorted. IHarness or connectors

(EGRC-solenoid valve B circuit is open or shorted.)

I EGRC-solenoid valve B

P1407

0808 I

Throttle control solenoid valve circuit is open or

shorted. I

Harness or connectors

(Throttle control solenoid valve circuit is open or

shorted.)

I Throttle control solenoid valve

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 2 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch to ªONº position and wait at least 2 sec-

onds.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

DTC P1404 EGR SOL/V A, DTC P1405 EGR SOL/V B/P1407 THROTTLE SOLENOID VALVETD27Ti

EC-455

http://vnx.su/

Page 735 of 1833

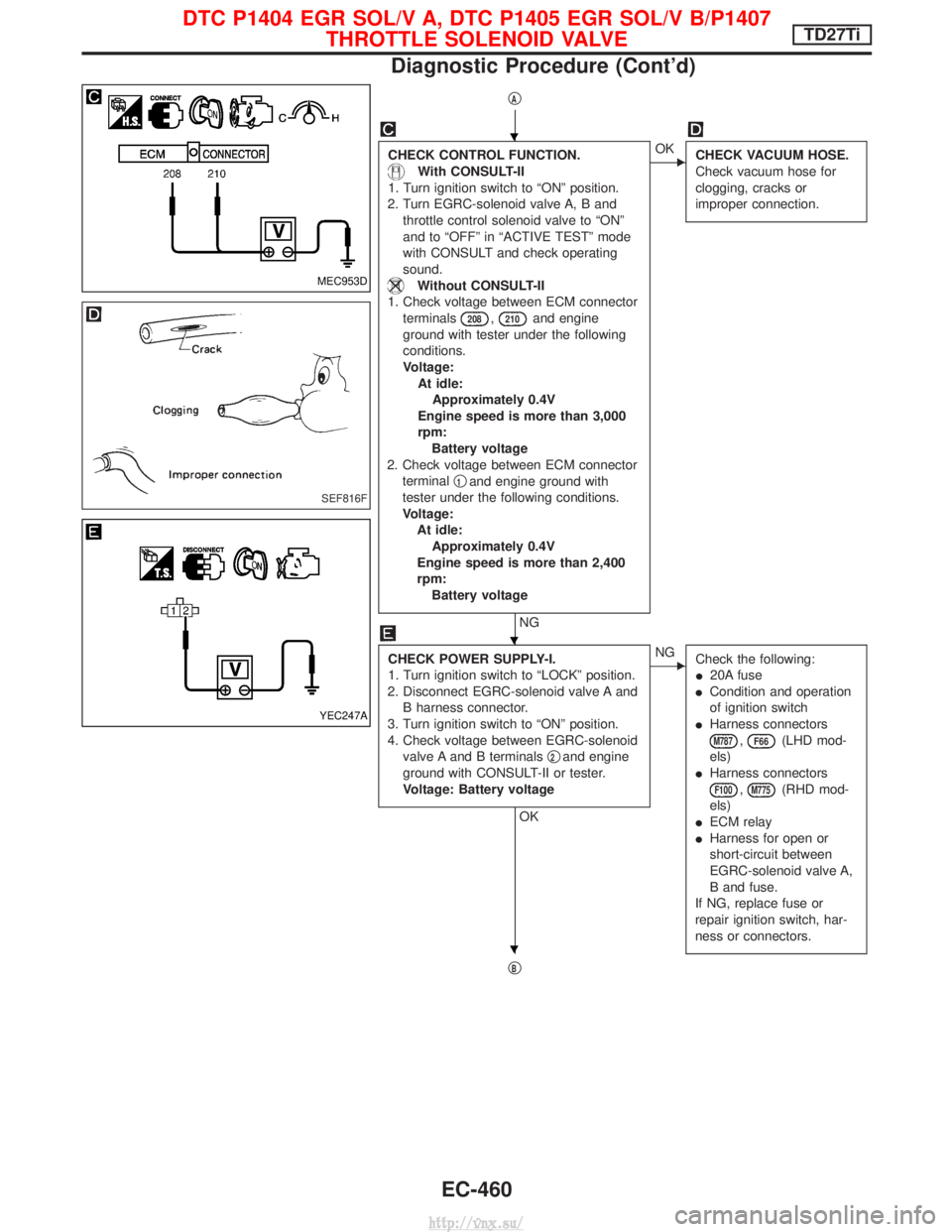

qA

CHECK CONTROL FUNCTION.

With CONSULT-II

1. Turn ignition switch to ªONº position.

2. Turn EGRC-solenoid valve A, B and throttle control solenoid valve to ªONº

and to ªOFFº in ªACTIVE TESTº mode

with CONSULT and check operating

sound.

Without CONSULT-II

1. Check voltage between ECM connector terminals

208,210and engine

ground with tester under the following

conditions.

Voltage: At idle:Approximately 0.4V

Engine speed is more than 3,000

rpm: Battery voltage

2. Check voltage between ECM connector terminal q

1and engine ground with

tester under the following conditions.

Voltage: At idle:Approximately 0.4V

Engine speed is more than 2,400

rpm: Battery voltage

NG

EOK CHECK VACUUM HOSE.

Check vacuum hose for

clogging, cracks or

improper connection.

CHECK POWER SUPPLY-I.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect EGRC-solenoid valve A and B harness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between EGRC-solenoid valve A and B terminals q

2and engine

ground with CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG Check the following:

I20A fuse

I Condition and operation

of ignition switch

I Harness connectors

M787,F66(LHD mod-

els)

I Harness connectors

F100,M775(RHD mod-

els)

I ECM relay

I Harness for open or

short-circuit between

EGRC-solenoid valve A,

B and fuse.

If NG, replace fuse or

repair ignition switch, har-

ness or connectors.

qB

MEC953D

SEF816F

YEC247A

H

H

H

DTC P1404 EGR SOL/V A, DTC P1405 EGR SOL/V B/P1407 THROTTLE SOLENOID VALVETD27Ti

Diagnostic Procedure (Cont'd)

EC-460

http://vnx.su/

Page 736 of 1833

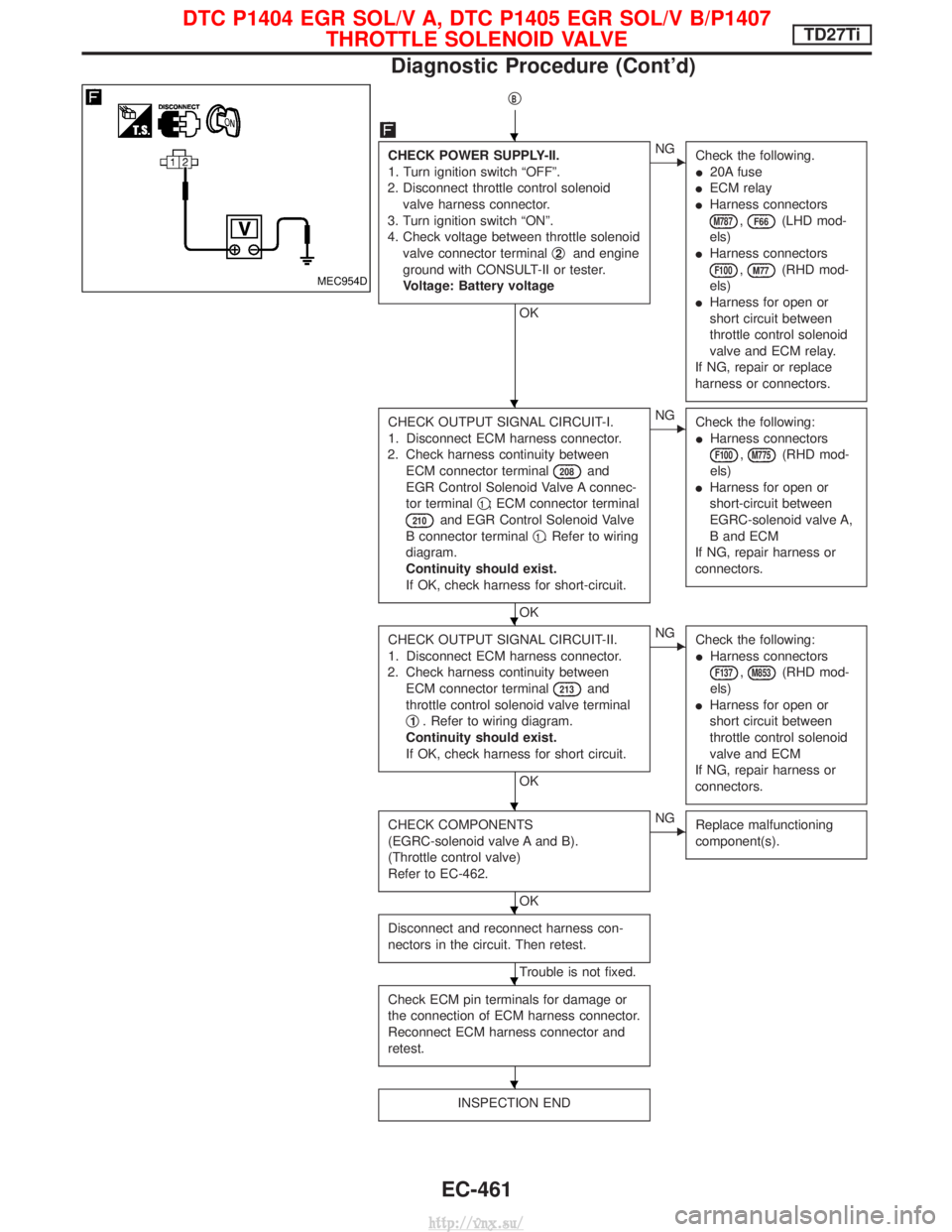

qB

CHECK POWER SUPPLY-II.

1. Turn ignition switch ªOFFº.

2. Disconnect throttle control solenoid valve harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between throttle solenoid valve connector terminal q

2and engine

ground with CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG Check the following.

I20A fuse

I ECM relay

I Harness connectors

M787,F66(LHD mod-

els)

I Harness connectors

F100,M77(RHD mod-

els)

I Harness for open or

short circuit between

throttle control solenoid

valve and ECM relay.

If NG, repair or replace

harness or connectors.

CHECK OUTPUT SIGNAL CIRCUIT-I.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM connector terminal

208and

EGR Control Solenoid Valve A connec-

tor terminal q

1; ECM connector terminal

210and EGR Control Solenoid Valve

B connector terminal q

1. Refer to wiring

diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness connectors

F100,M775(RHD mod-

els)

I Harness for open or

short-circuit between

EGRC-solenoid valve A,

B and ECM

If NG, repair harness or

connectors.

CHECK OUTPUT SIGNAL CIRCUIT-II.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM connector terminal

213and

throttle control solenoid valve terminal

q

1. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short circuit.

OK

ENG Check the following:

IHarness connectors

F137,M853(RHD mod-

els)

I Harness for open or

short circuit between

throttle control solenoid

valve and ECM

If NG, repair harness or

connectors.

CHECK COMPONENTS

(EGRC-solenoid valve A and B).

(Throttle control valve)

Refer to EC-462.

OK

ENG Replace malfunctioning

component(s).

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage or

the connection of ECM harness connector.

Reconnect ECM harness connector and

retest.

INSPECTION END

MEC954D

H

H

H

H

H

H

H

DTC P1404 EGR SOL/V A, DTC P1405 EGR SOL/V B/P1407 THROTTLE SOLENOID VALVETD27Ti

Diagnostic Procedure (Cont'd)

EC-461

http://vnx.su/

Page 738 of 1833

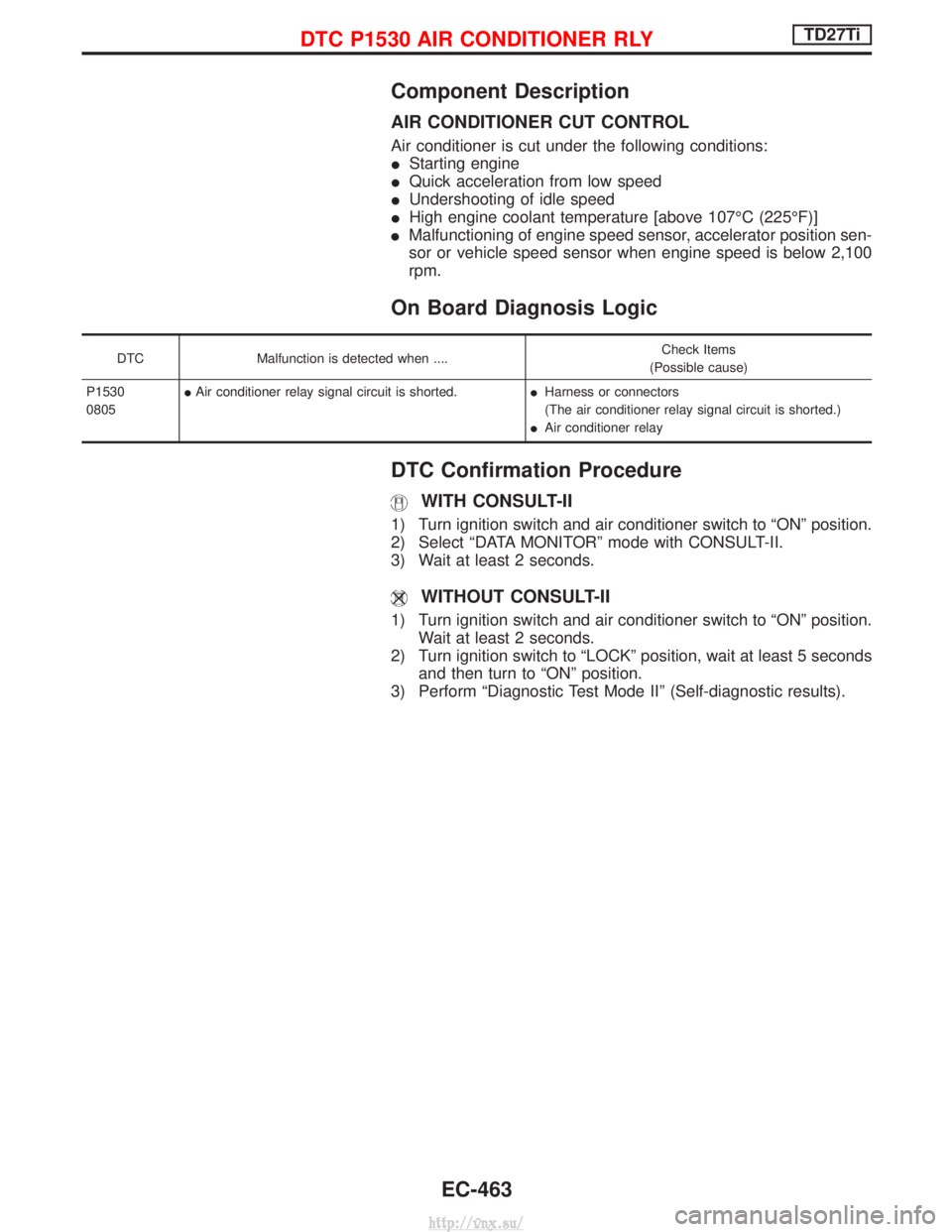

Component Description

AIR CONDITIONER CUT CONTROL

Air conditioner is cut under the following conditions:

IStarting engine

I Quick acceleration from low speed

I Undershooting of idle speed

I High engine coolant temperature [above 107ÉC (225ÉF)]

I Malfunctioning of engine speed sensor, accelerator position sen-

sor or vehicle speed sensor when engine speed is below 2,100

rpm.

On Board Diagnosis Logic

DTC Malfunction is detected when .... Check Items

(Possible cause)

P1530

0805 I

Air conditioner relay signal circuit is shorted. IHarness or connectors

(The air conditioner relay signal circuit is shorted.)

I Air conditioner relay

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch and air conditioner switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 2 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch and air conditioner switch to ªONº position.

Wait at least 2 seconds.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

DTC P1530 AIR CONDITIONER RLYTD27Ti

EC-463

http://vnx.su/

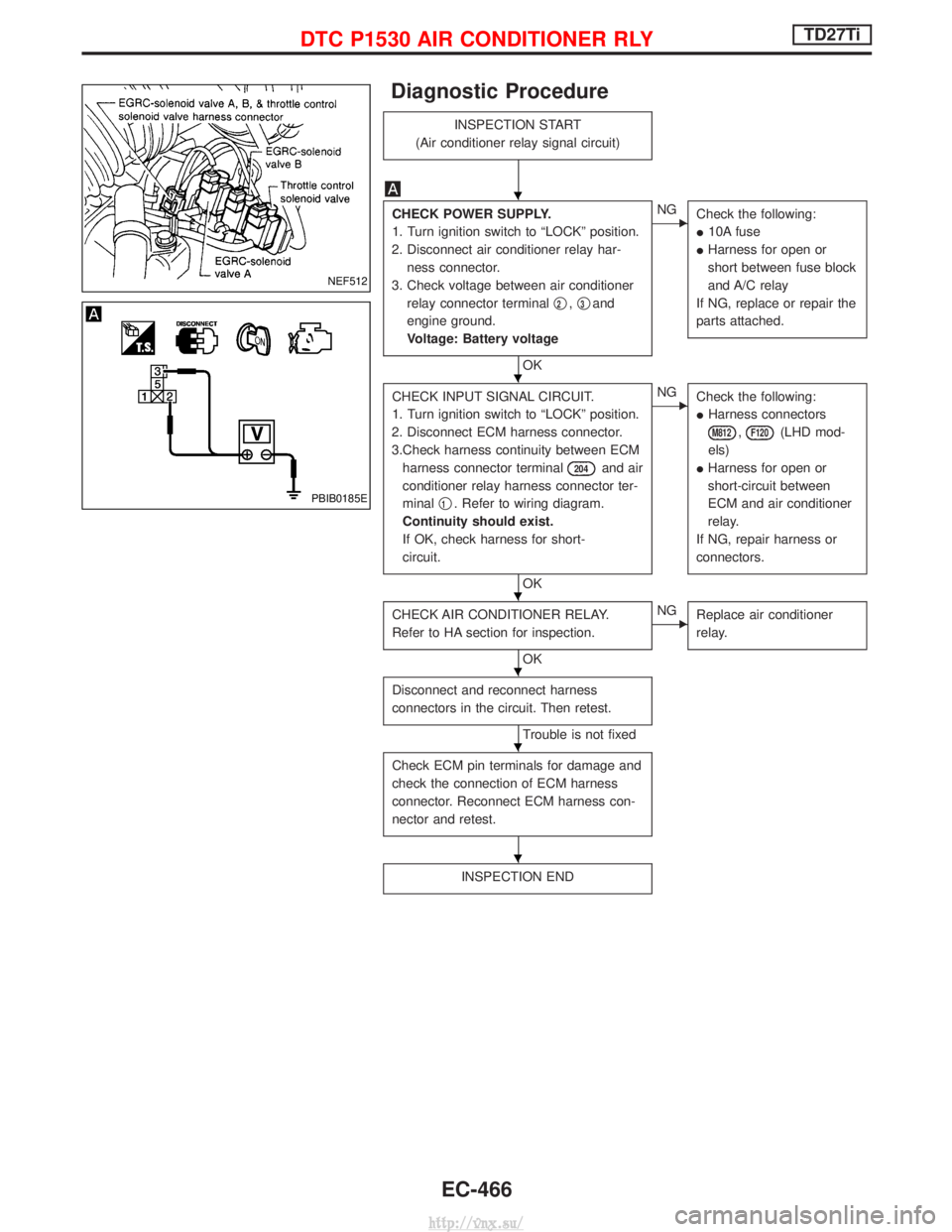

Page 741 of 1833

Diagnostic Procedure

INSPECTION START

(Air conditioner relay signal circuit)

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect air conditioner relay har- ness connector.

3. Check voltage between air conditioner relay connector terminal q

2,q3and

engine ground.

Voltage: Battery voltage

OK

ENG Check the following:

I10A fuse

I Harness for open or

short between fuse block

and A/C relay

If NG, replace or repair the

parts attached.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3.Check harness continuity between ECM harness connector terminal

204and air

conditioner relay harness connector ter-

minal q

1. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-

circuit.

OK

ENG Check the following:

IHarness connectors

M812,F120(LHD mod-

els)

I Harness for open or

short-circuit between

ECM and air conditioner

relay.

If NG, repair harness or

connectors.

CHECK AIR CONDITIONER RELAY.

Refer to HA section for inspection.

OK

ENG Replace air conditioner

relay.

Disconnect and reconnect harness

connectors in the circuit. Then retest.

Trouble is not fixed

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

NEF512

PBIB0185E

H

H

H

H

H

H

DTC P1530 AIR CONDITIONER RLYTD27Ti

EC-466

http://vnx.su/

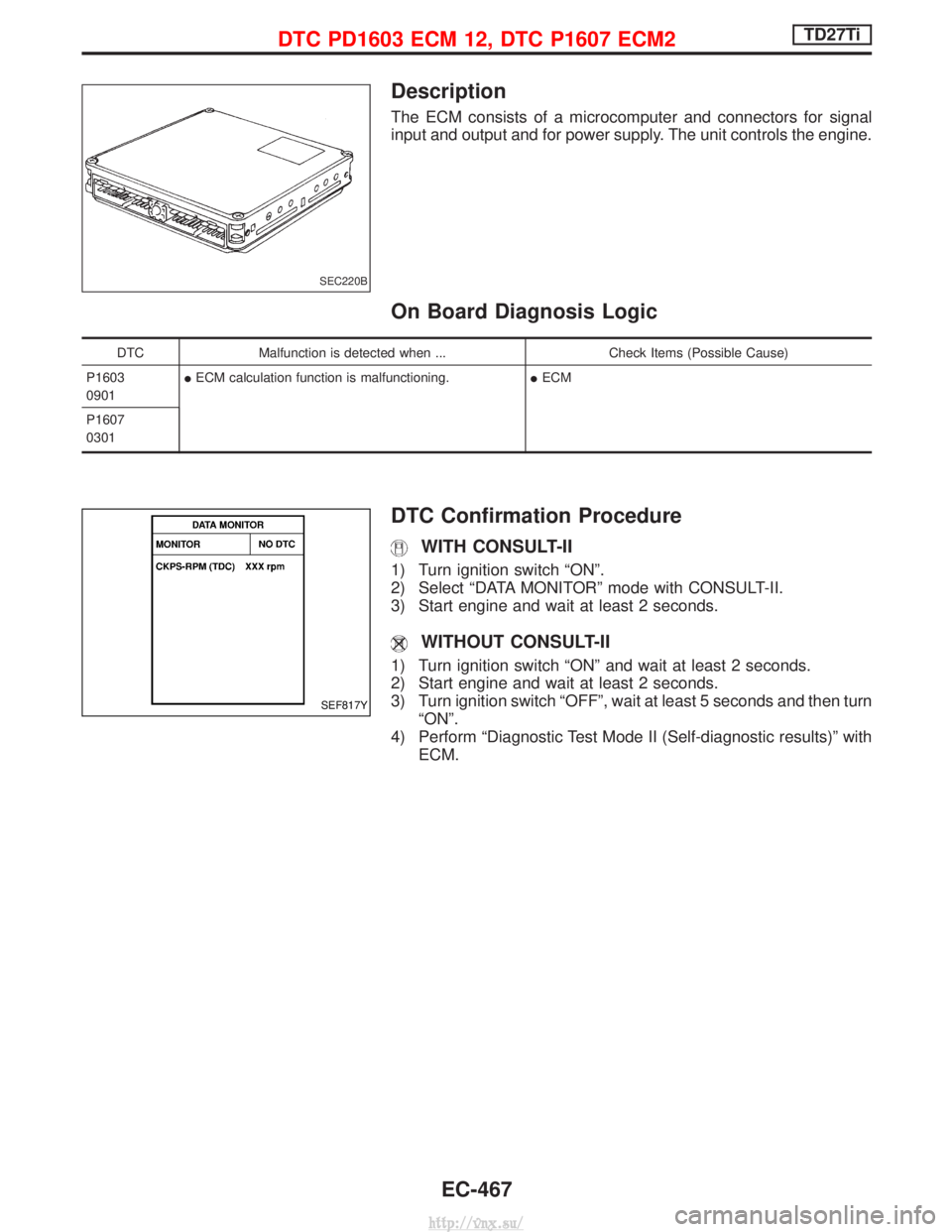

Page 742 of 1833

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis Logic

DTCMalfunction is detected when ... Check Items (Possible Cause)

P1603

0901 I

ECM calculation function is malfunctioning. IECM

P1607

0301

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

SEC220B

SEF817Y

DTC PD1603 ECM 12, DTC P1607 ECM2TD27Ti

EC-467

http://vnx.su/

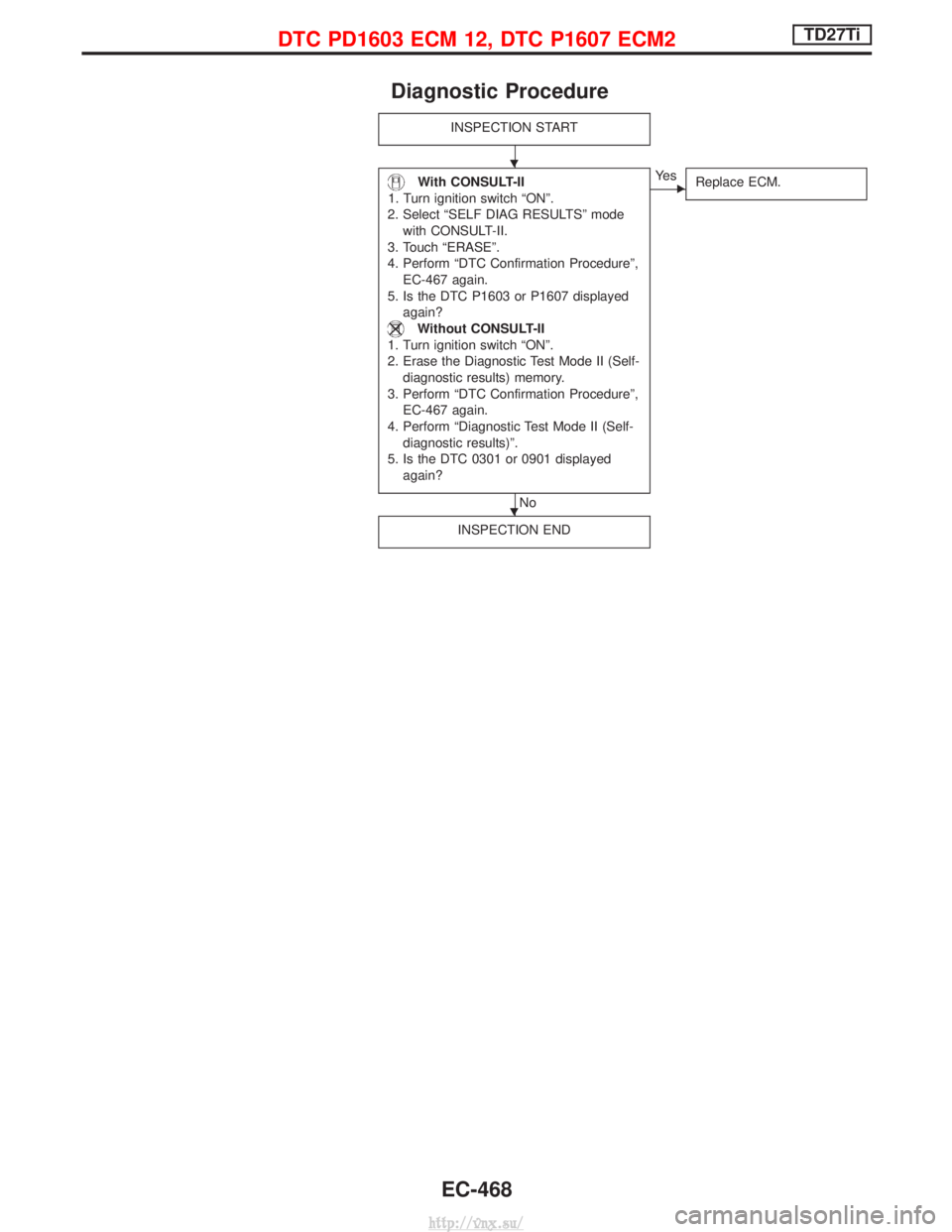

Page 743 of 1833

Diagnostic Procedure

INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº, EC-467 again.

5. Is the DTC P1603 or P1607 displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self- diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº, EC-467 again.

4. Perform ªDiagnostic Test Mode II (Self- diagnostic results)º.

5. Is the DTC 0301 or 0901 displayed again?

No

EYe s Replace ECM.

INSPECTION END

H

H

DTC PD1603 ECM 12, DTC P1607 ECM2TD27Ti

EC-468

http://vnx.su/

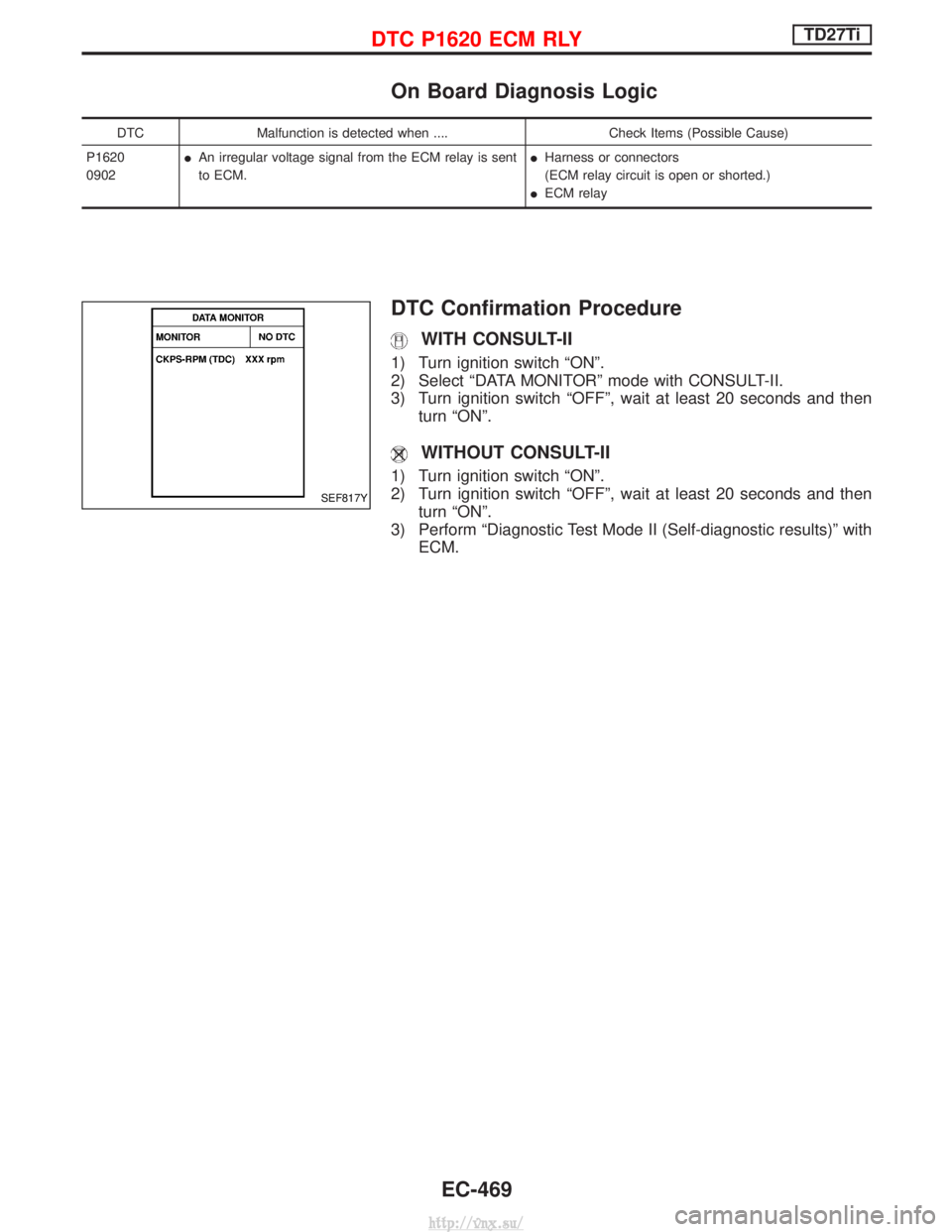

Page 744 of 1833

On Board Diagnosis Logic

DTCMalfunction is detected when .... Check Items (Possible Cause)

P1620

0902 I

An irregular voltage signal from the ECM relay is sent

to ECM. I

Harness or connectors

(ECM relay circuit is open or shorted.)

I ECM relay

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº.

2) Turn ignition switch ªOFFº, wait at least 20 seconds and thenturn ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

SEF817Y

DTC P1620 ECM RLYTD27Ti

EC-469

http://vnx.su/

Page 746 of 1833

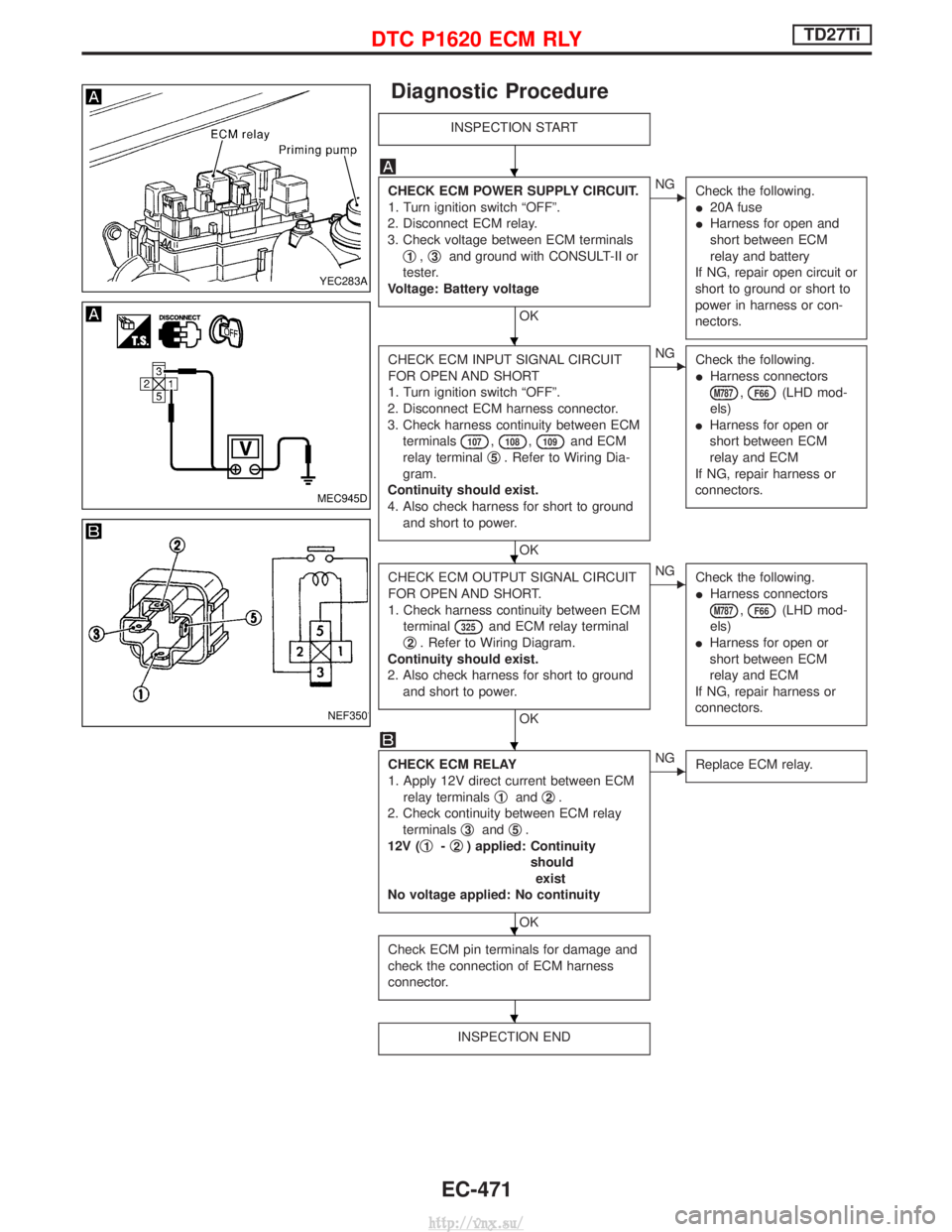

Diagnostic Procedure

INSPECTION START

CHECK ECM POWER SUPPLY CIRCUIT.

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay.

3. Check voltage between ECM terminals q

1,q3and ground with CONSULT-II or

tester.

Voltage: Battery voltage

OK

ENG Check the following.

I20A fuse

I Harness for open and

short between ECM

relay and battery

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK ECM INPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals

107,108,109and ECM

relay terminal q

5. Refer to Wiring Dia-

gram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK

ENG Check the following.

IHarness connectors

M787,F66(LHD mod-

els)

I Harness for open or

short between ECM

relay and ECM

If NG, repair harness or

connectors.

CHECK ECM OUTPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT.

1. Check harness continuity between ECM terminal

325and ECM relay terminal

q

2. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK

ENG Check the following.

IHarness connectors

M787,F66(LHD mod-

els)

I Harness for open or

short between ECM

relay and ECM

If NG, repair harness or

connectors.

CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals q

1andq2.

2. Check continuity between ECM relay terminals q

3andq5.

12V ( q

1-q2) applied: Continuity

shouldexist

No voltage applied: No continuity

OK

ENG Replace ECM relay.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector.

INSPECTION END

YEC283A

MEC945D

NEF350

H

H

H

H

H

H

DTC P1620 ECM RLYTD27Ti

EC-471

http://vnx.su/

Page 748 of 1833

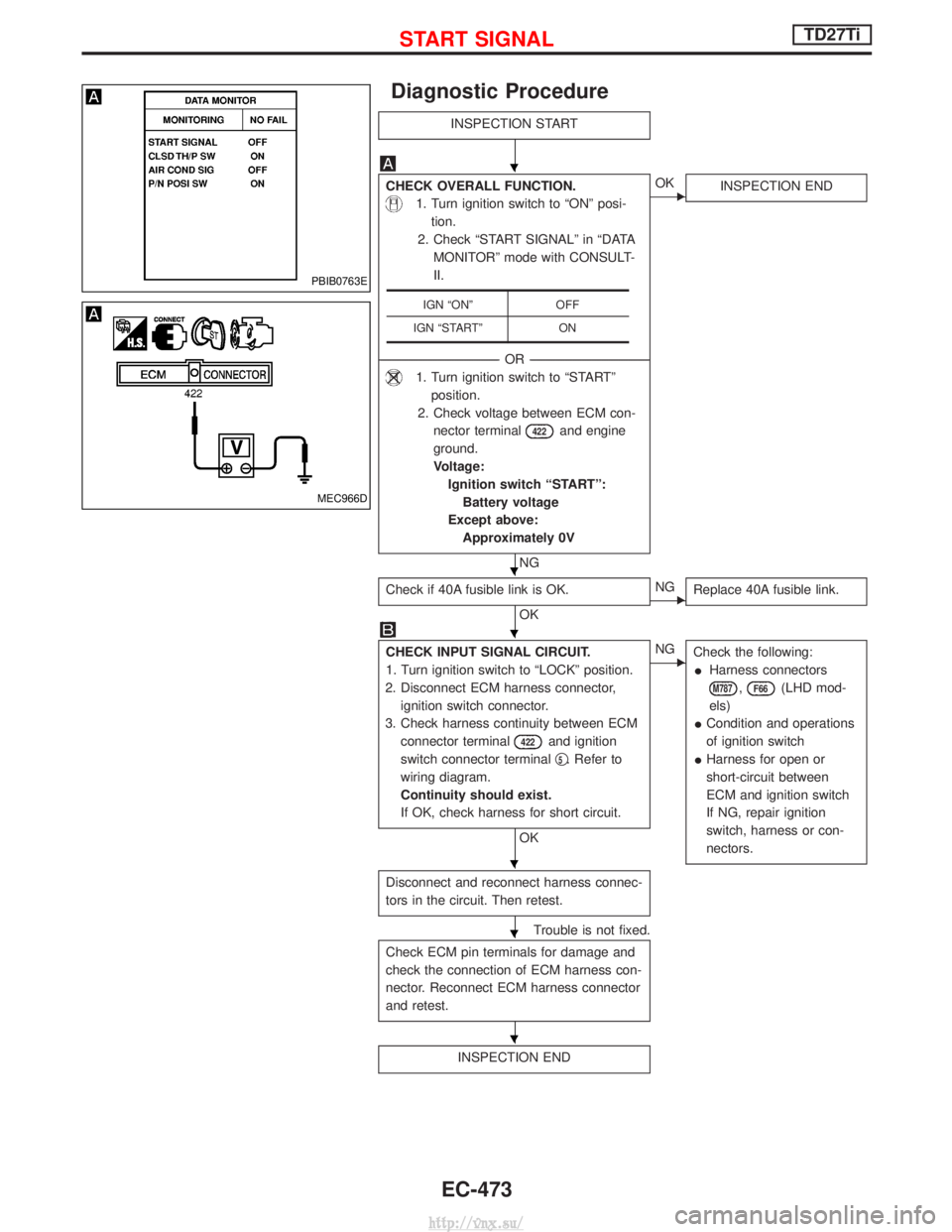

Diagnostic Procedure

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch to ªONº posi-tion.

2. Check ªSTART SIGNALº in ªDATA MONITORº mode with CONSULT-

II.

------------------------------------------------------------------------------------------------------------------------------------- -OR--------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªSTARTº

position.

2. Check voltage between ECM con- nector terminal

422and engine

ground.

Voltage: Ignition switch ªSTARTº:Battery voltage

Except above: Approximately 0V

NG

EOK INSPECTION END

Check if 40A fusible link is OK.

OKENGReplace 40A fusible link.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector, ignition switch connector.

3. Check harness continuity between ECM connector terminal

422and ignition

switch connector terminal q

5. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness for short circuit.

OK

ENG Check the following:

I Harness connectors

M787,F66(LHD mod-

els)

I Condition and operations

of ignition switch

I Harness for open or

short-circuit between

ECM and ignition switch

If NG, repair ignition

switch, harness or con-

nectors.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

IGN ªONº OFF

IGN ªSTARTº ON

PBIB0763E

MEC966D

H

H

H

H

H

H

START SIGNALTD27Ti

EC-473

http://vnx.su/