Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 892 of 1833

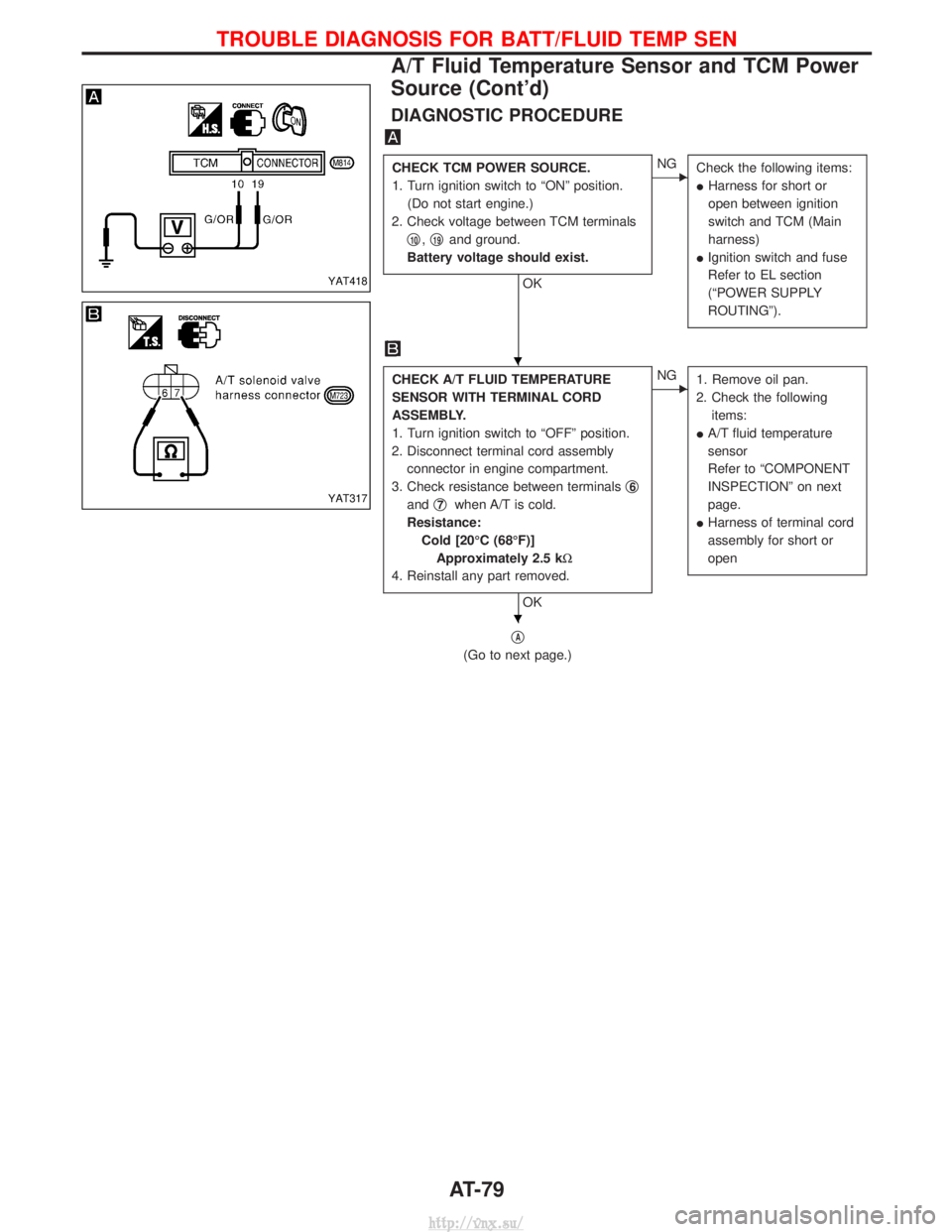

DIAGNOSTIC PROCEDURE

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.(Do not start engine.)

2. Check voltage between TCM terminals q

10,q19and ground.

Battery voltage should exist.

OK

ENG Check the following items:

IHarness for short or

open between ignition

switch and TCM (Main

harness)

I Ignition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK A/T FLUID TEMPERATURE

SENSOR WITH TERMINAL CORD

ASSEMBLY.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminals q

6

andq7when A/T is cold.

Resistance: Cold [20ÉC (68ÉF)]Approximately 2.5 kW

4. Reinstall any part removed.

OK

ENG 1. Remove oil pan.

2. Check the following items:

I A/T fluid temperature

sensor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

I Harness of terminal cord

assembly for short or

open

qA

(Go to next page.)

YAT418

YAT317

H

H

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM Power

Source (Cont'd)

AT-79

http://vnx.su/

Page 896 of 1833

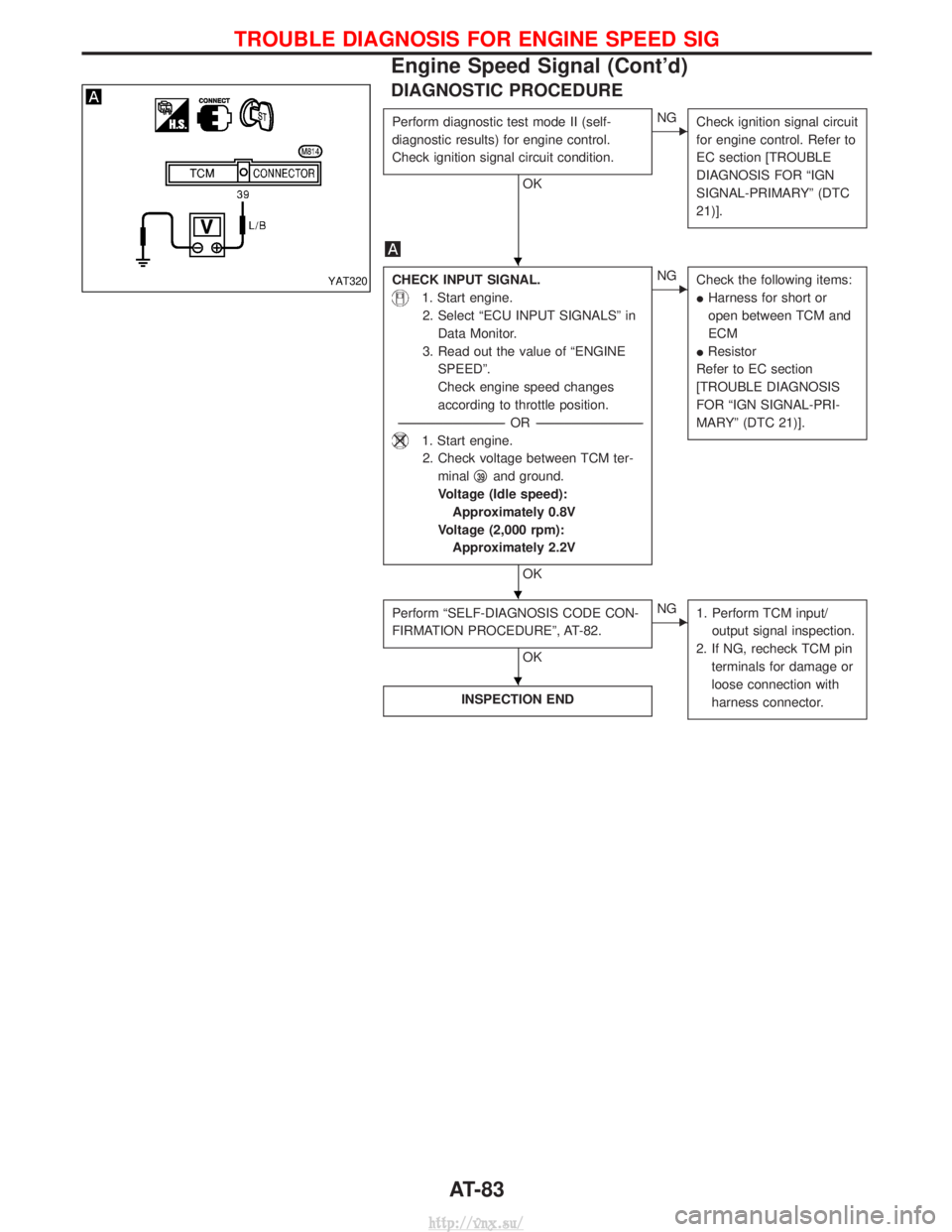

DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Check ignition signal circuit condition.

OK

ENGCheck ignition signal circuit

for engine control. Refer to

EC section [TROUBLE

DIAGNOSIS FOR ªIGN

SIGNAL-PRIMARYº (DTC

21)].

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªECU INPUT SIGNALSº in Data Monitor.

3. Read out the value of ªENGINE SPEEDº.

Check engine speed changes

according to throttle position.

---------------------------------------------------------------------------------------------------------------------- -OR -----------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM ter- minal q

39and ground.

Voltage (Idle speed): Approximately 0.8V

Voltage (2,000 rpm): Approximately 2.2V

OK

ENG Check the following items:

IHarness for short or

open between TCM and

ECM

I Resistor

Refer to EC section

[TROUBLE DIAGNOSIS

FOR ªIGN SIGNAL-PRI-

MARYº (DTC 21)].

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-82.

OK

ENG 1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT320

H

H

H

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG

Engine Speed Signal (Cont'd)

AT-83

http://vnx.su/

Page 900 of 1833

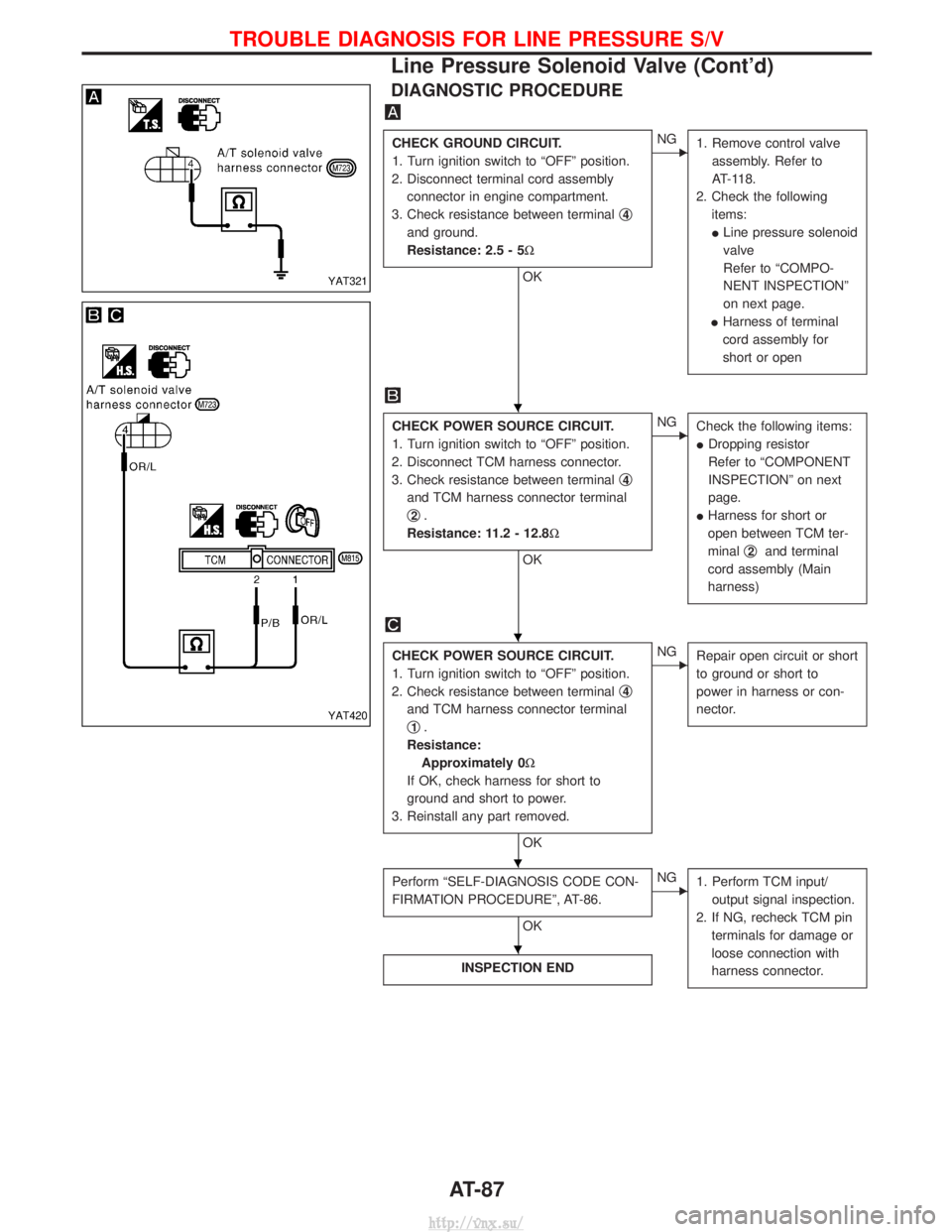

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal q

4

and ground.

Resistance: 2.5 - 5W

OK

ENG

1. Remove control valve

assembly. Refer to

AT-118.

2. Check the following items:

ILine pressure solenoid

valve

Refer to ªCOMPO-

NENT INSPECTIONº

on next page.

I Harness of terminal

cord assembly for

short or open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal q

4

and TCM harness connector terminal

q

2.

Resistance: 11.2 - 12.8W

OK

ENG Check the following items:

IDropping resistor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

I Harness for short or

open between TCM ter-

minal q

2and terminal

cord assembly (Main

harness)

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Check resistance between terminal q

4

and TCM harness connector terminal

q

1.

Resistance: Approximately 0W

If OK, check harness for short to

ground and short to power.

3. Reinstall any part removed.

OK

ENG Repair open circuit or short

to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-86.

OK

ENG1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT321

YAT420

H

H

H

H

TROUBLE DIAGNOSIS FOR LINE PRESSURE S/V

Line Pressure Solenoid Valve (Cont'd)

AT-87

http://vnx.su/

Page 907 of 1833

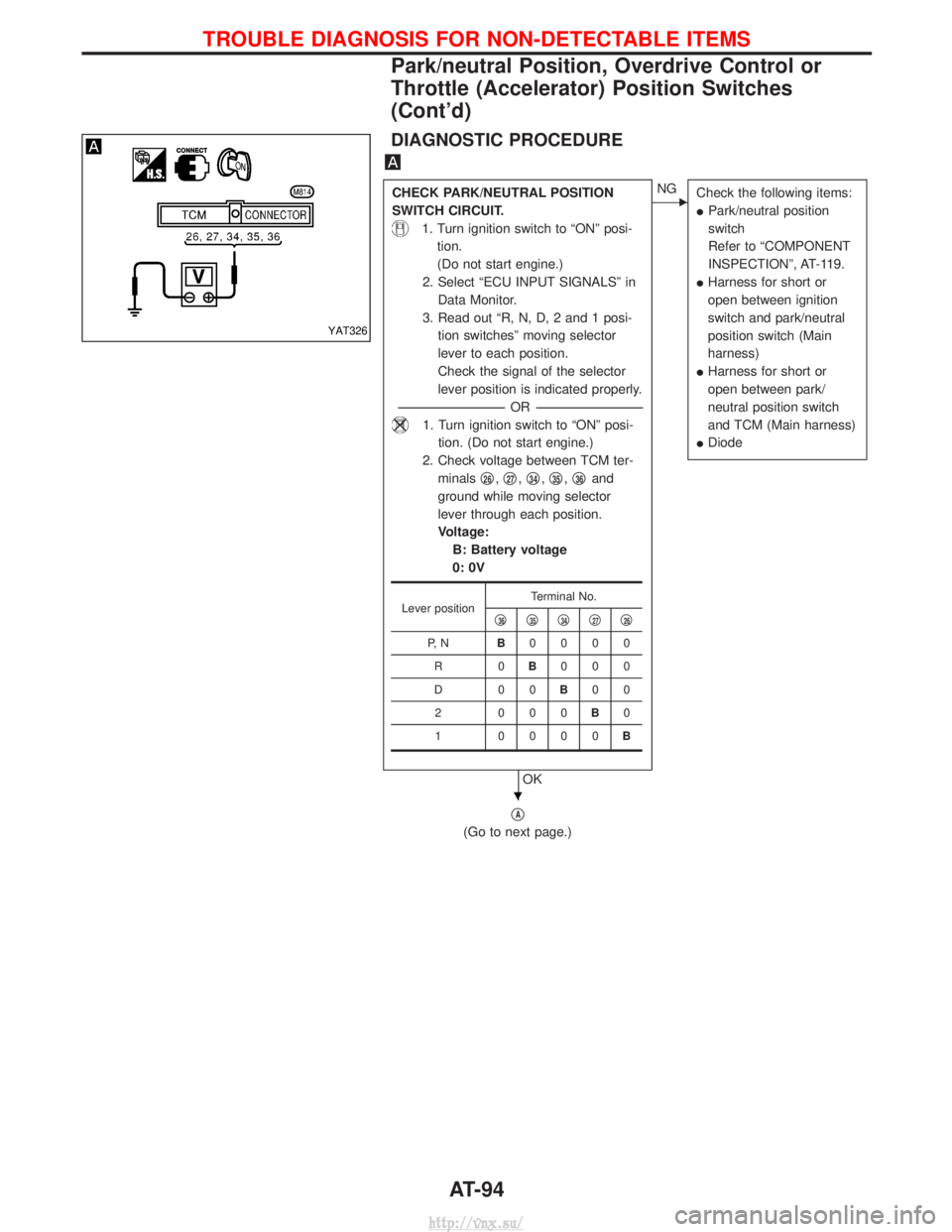

DIAGNOSTIC PROCEDURE

CHECK PARK/NEUTRAL POSITION

SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in Data Monitor.

3. Read out ªR, N, D, 2 and 1 posi- tion switchesº moving selector

lever to each position.

Check the signal of the selector

lever position is indicated properly.

---------------------------------------------------------------------------------------------------------------------- -OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion. (Do not start engine.)

2. Check voltage between TCM ter- minals q

26,q27,q34,q35,q36and

ground while moving selector

lever through each position.

Voltage: B: Battery voltage

0: 0V

OK

ENG Check the following items:

IPark/neutral position

switch

Refer to ªCOMPONENT

INSPECTIONº, AT-119.

I Harness for short or

open between ignition

switch and park/neutral

position switch (Main

harness)

I Harness for short or

open between park/

neutral position switch

and TCM (Main harness)

I Diode

qA

(Go to next page.)

Lever position Terminal No.

q36q35q34q27q26

P, N B0000

R0 B000

D00 B00

2 000 B0

1 0000 B

YAT326

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-94

http://vnx.su/

Page 908 of 1833

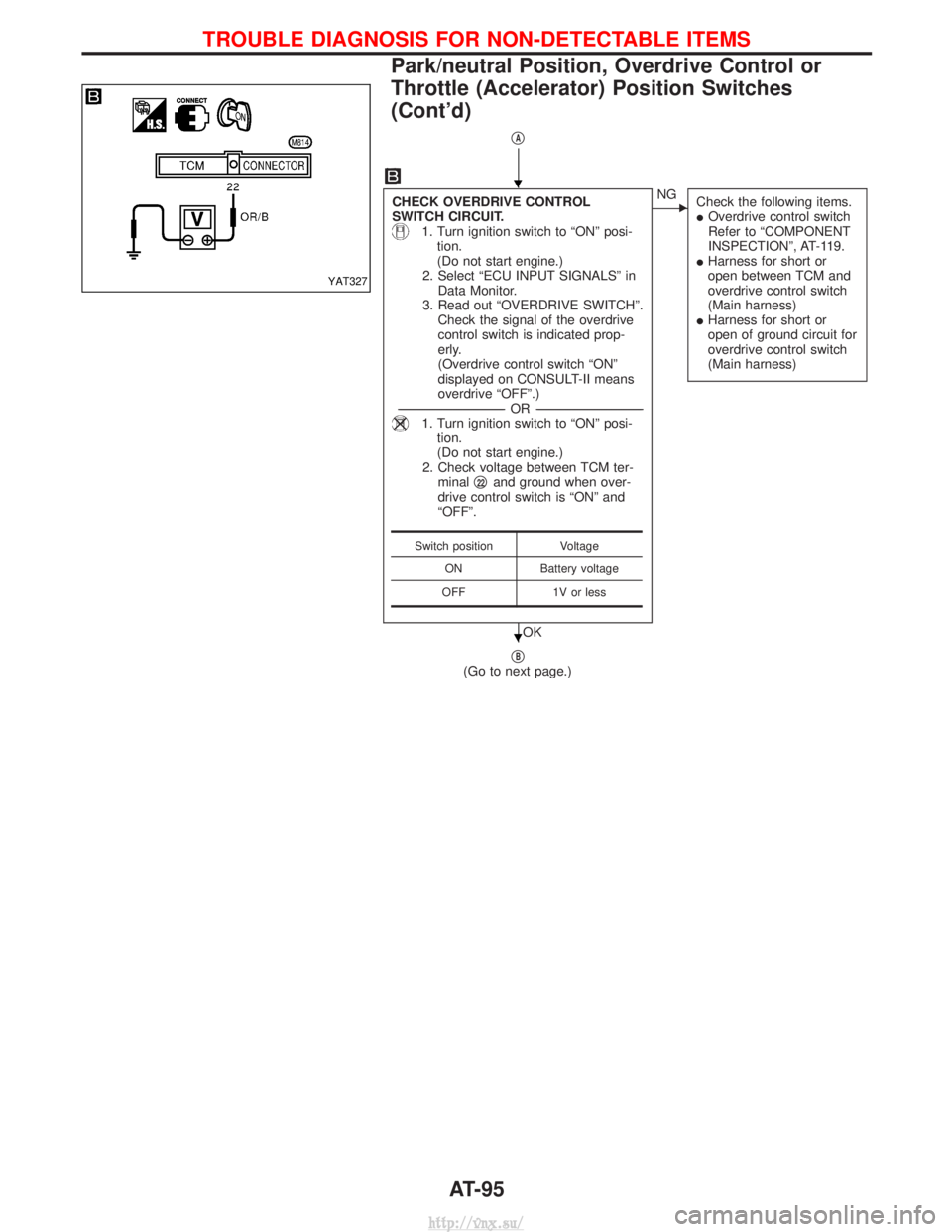

qA

CHECK OVERDRIVE CONTROL

SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in Data Monitor.

3. Read out ªOVERDRIVE SWITCHº. Check the signal of the overdrive

control switch is indicated prop-

erly.

(Overdrive control switch ªONº

displayed on CONSULT-II means

overdrive ªOFFº.)

---------------------------------------------------------------------------------------------------------------------- -OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Check voltage between TCM ter- minal q

22and ground when over-

drive control switch is ªONº and

ªOFFº.

OK

ENG Check the following items.

IOverdrive control switch

Refer to ªCOMPONENT

INSPECTIONº, AT-119.

I Harness for short or

open between TCM and

overdrive control switch

(Main harness)

I Harness for short or

open of ground circuit for

overdrive control switch

(Main harness)

qB(Go to next page.)

Switch position Voltage

ON Battery voltage

OFF 1V or less

YAT327

H

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-95

http://vnx.su/

Page 909 of 1833

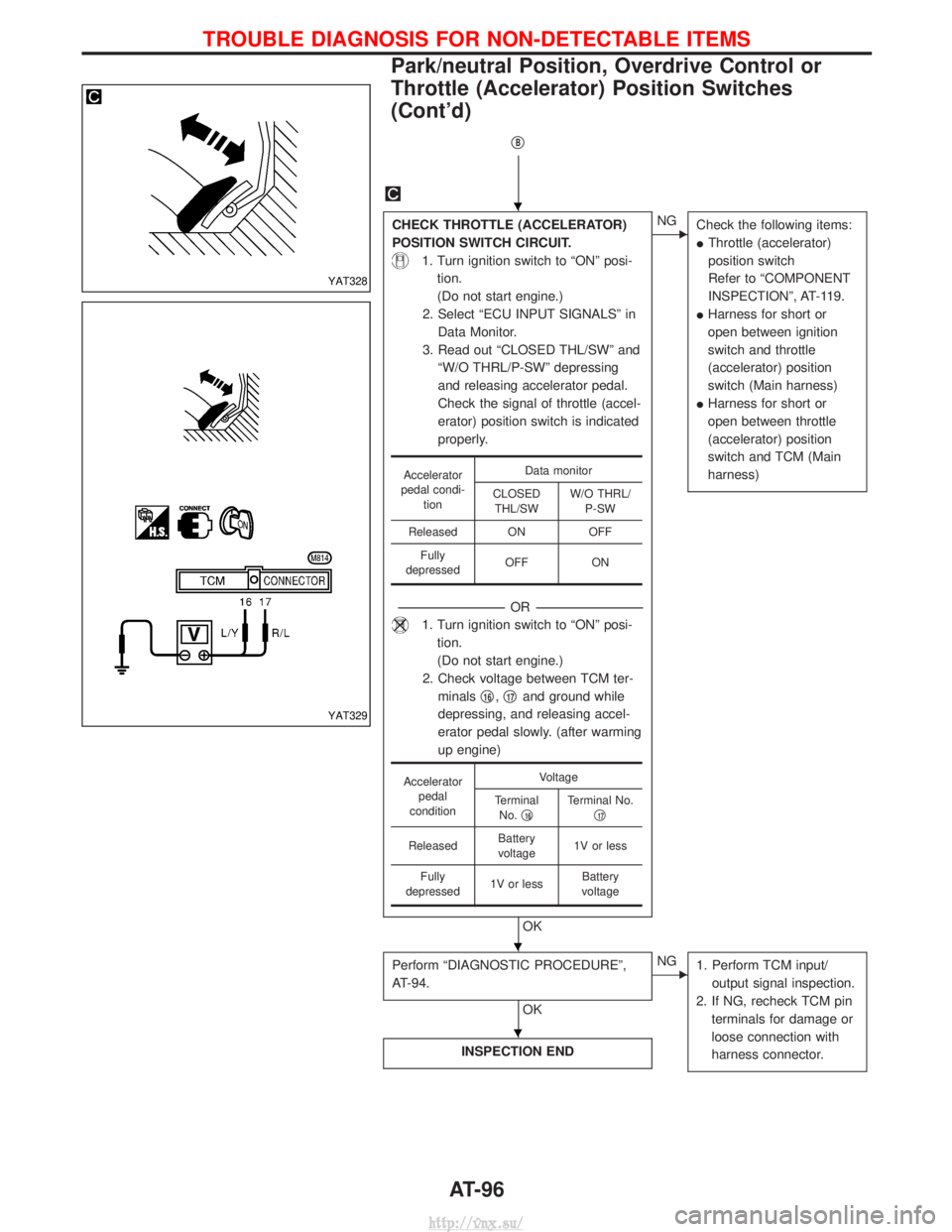

qB

CHECK THROTTLE (ACCELERATOR)

POSITION SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in Data Monitor.

3. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing

and releasing accelerator pedal.

Check the signal of throttle (accel-

erator) position switch is indicated

properly.

---------------------------------------------------------------------------------------------------------------------- -OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Check voltage between TCM ter- minals q

16,q17and ground while

depressing, and releasing accel-

erator pedal slowly. (after warming

up engine)

OK

ENG Check the following items:

IThrottle (accelerator)

position switch

Refer to ªCOMPONENT

INSPECTIONº, AT-119.

I Harness for short or

open between ignition

switch and throttle

(accelerator) position

switch (Main harness)

I Harness for short or

open between throttle

(accelerator) position

switch and TCM (Main

harness)

Perform ªDIAGNOSTIC PROCEDUREº,

AT-94.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin terminals for damage or

loose connection with

harness connector.

INSPECTION END

Accelerator

pedal condi- tion Data monitor

CLOSED THL/SW W/O THRL/

P-SW

Released ON OFF Fully

depressed OFF ON

Accelerator

pedal

condition Voltage

Terminal No. q

16Terminal No.

q17

Released Battery

voltage 1V or less

Fully

depressed 1V or less Battery

voltage

YAT328

YAT329

H

H

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-96

http://vnx.su/

Page 911 of 1833

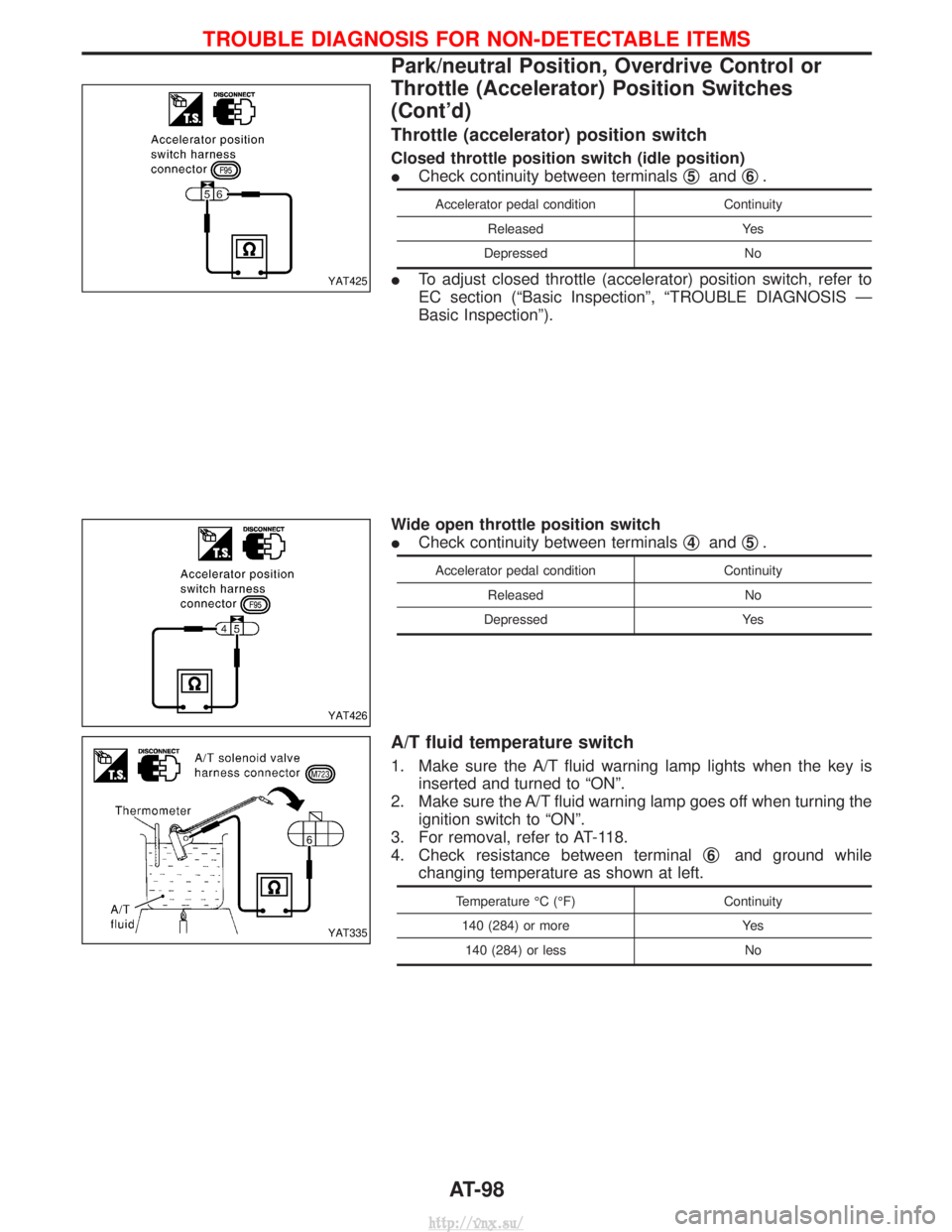

Throttle (accelerator) position switch

Closed throttle position switch (idle position)

ICheck continuity between terminals q

5andq6.

Accelerator pedal condition

Continuity

Released Yes

Depressed No

ITo adjust closed throttle (accelerator) position switch, refer to

EC section (ªBasic Inspectionº, ªTROUBLE DIAGNOSIS Ð

Basic Inspectionº).

Wide open throttle position switch

I Check continuity between terminals q

4andq5.

Accelerator pedal condition

Continuity

Released No

Depressed Yes

A/T fluid temperature switch

1. Make sure the A/T fluid warning lamp lights when the key is

inserted and turned to ªONº.

2. Make sure the A/T fluid warning lamp goes off when turning the ignition switch to ªONº.

3. For removal, refer to AT-118.

4. Check resistance between terminal q

6and ground while

changing temperature as shown at left.

Temperature ÉC (ÉF) Continuity

140 (284) or more Yes

140 (284) or less No

YAT425

YAT426

YAT335

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-98

http://vnx.su/

Page 912 of 1833

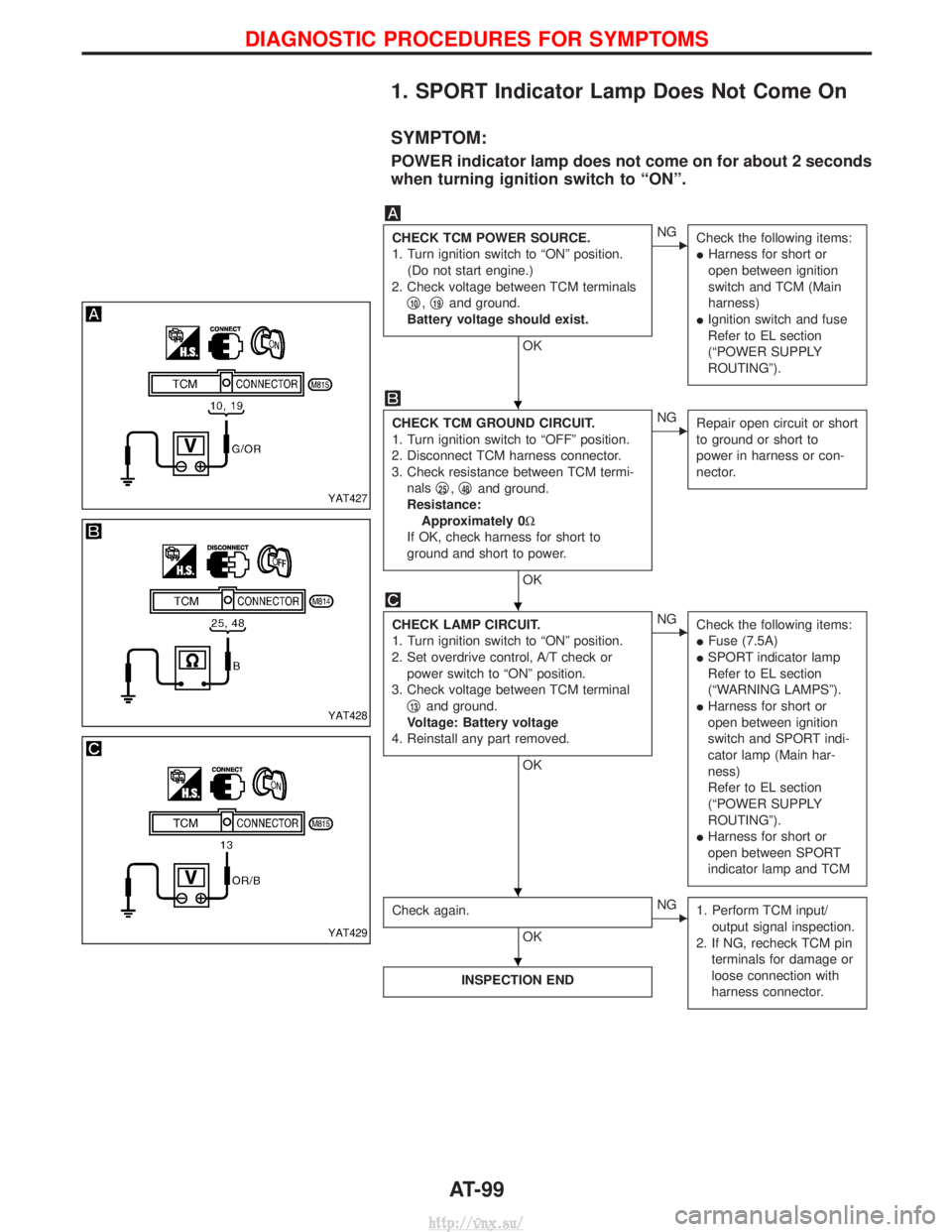

1. SPORT Indicator Lamp Does Not Come On

SYMPTOM:

POWER indicator lamp does not come on for about 2 seconds

when turning ignition switch to ªONº.

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.(Do not start engine.)

2. Check voltage between TCM terminals q

10,q19and ground.

Battery voltage should exist.

OK

ENG Check the following items:

IHarness for short or

open between ignition

switch and TCM (Main

harness)

I Ignition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK TCM GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between TCM termi- nals q

25,q48and ground.

Resistance: Approximately 0W

If OK, check harness for short to

ground and short to power.

OK

ENG Repair open circuit or short

to ground or short to

power in harness or con-

nector.

CHECK LAMP CIRCUIT.

1. Turn ignition switch to ªONº position.

2. Set overdrive control, A/T check or power switch to ªONº position.

3. Check voltage between TCM terminal q

13and ground.

Voltage: Battery voltage

4. Reinstall any part removed.

OK

ENG Check the following items:

IFuse (7.5A)

I SPORT indicator lamp

Refer to EL section

(ªWARNING LAMPSº).

I Harness for short or

open between ignition

switch and SPORT indi-

cator lamp (Main har-

ness)

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

I Harness for short or

open between SPORT

indicator lamp and TCM

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT427

YAT428

YAT429

H

H

HH

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-99

http://vnx.su/

Page 913 of 1833

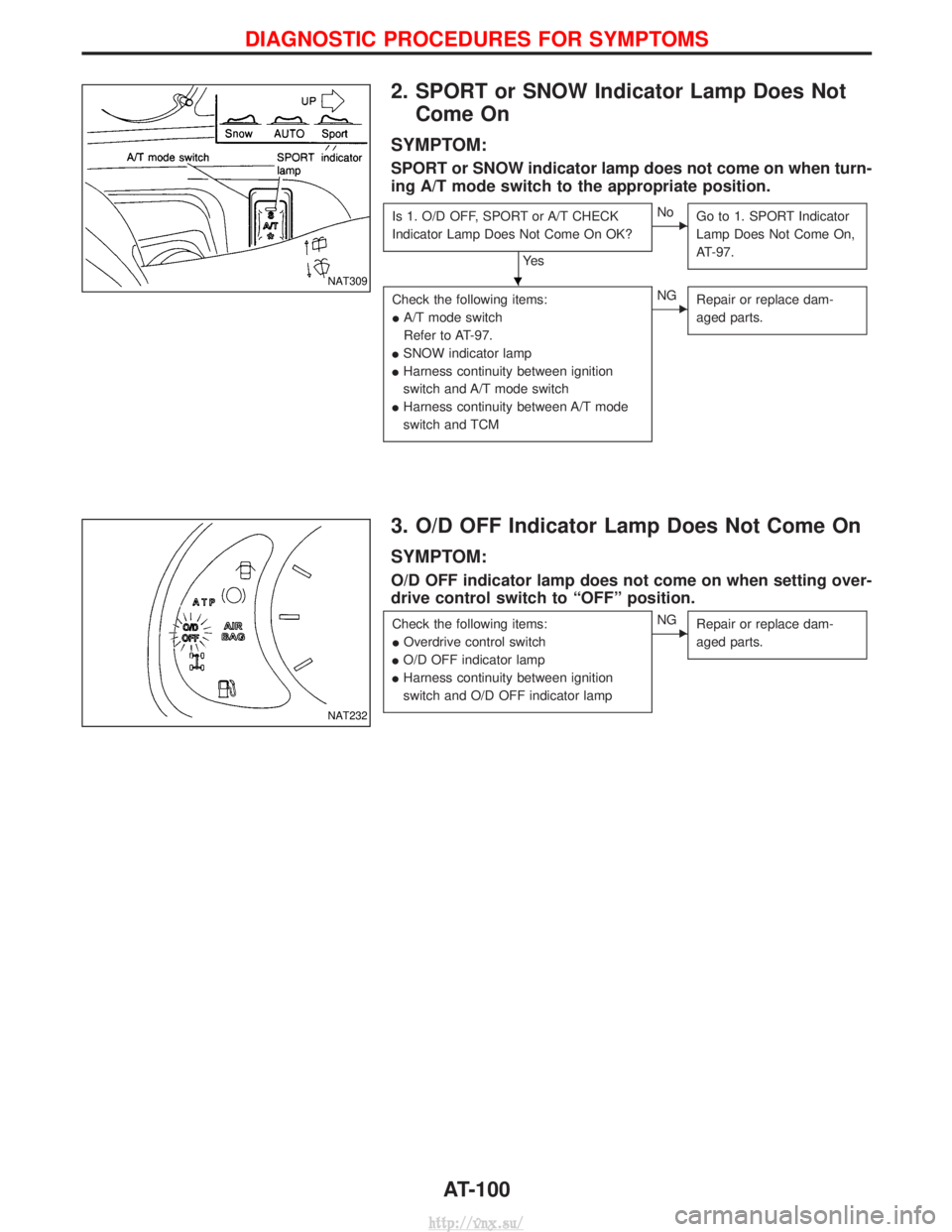

2. SPORT or SNOW Indicator Lamp Does NotCome On

SYMPTOM:

SPORT or SNOW indicator lamp does not come on when turn-

ing A/T mode switch to the appropriate position.

Is 1. O/D OFF, SPORT or A/T CHECK

Indicator Lamp Does Not Come On OK?

Ye s

ENo Go to 1. SPORT Indicator

Lamp Does Not Come On,

AT-97.

Check the following items:

IA/T mode switch

Refer to AT-97.

I SNOW indicator lamp

I Harness continuity between ignition

switch and A/T mode switch

I Harness continuity between A/T mode

switch and TCMENG

Repair or replace dam-

aged parts.

3. O/D OFF Indicator Lamp Does Not Come On

SYMPTOM:

O/D OFF indicator lamp does not come on when setting over-

drive control switch to ªOFFº position.

Check the following items:

IOverdrive control switch

I O/D OFF indicator lamp

I Harness continuity between ignition

switch and O/D OFF indicator lampENG

Repair or replace dam-

aged parts.

NAT309

NAT232

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-100

http://vnx.su/

Page 1168 of 1833

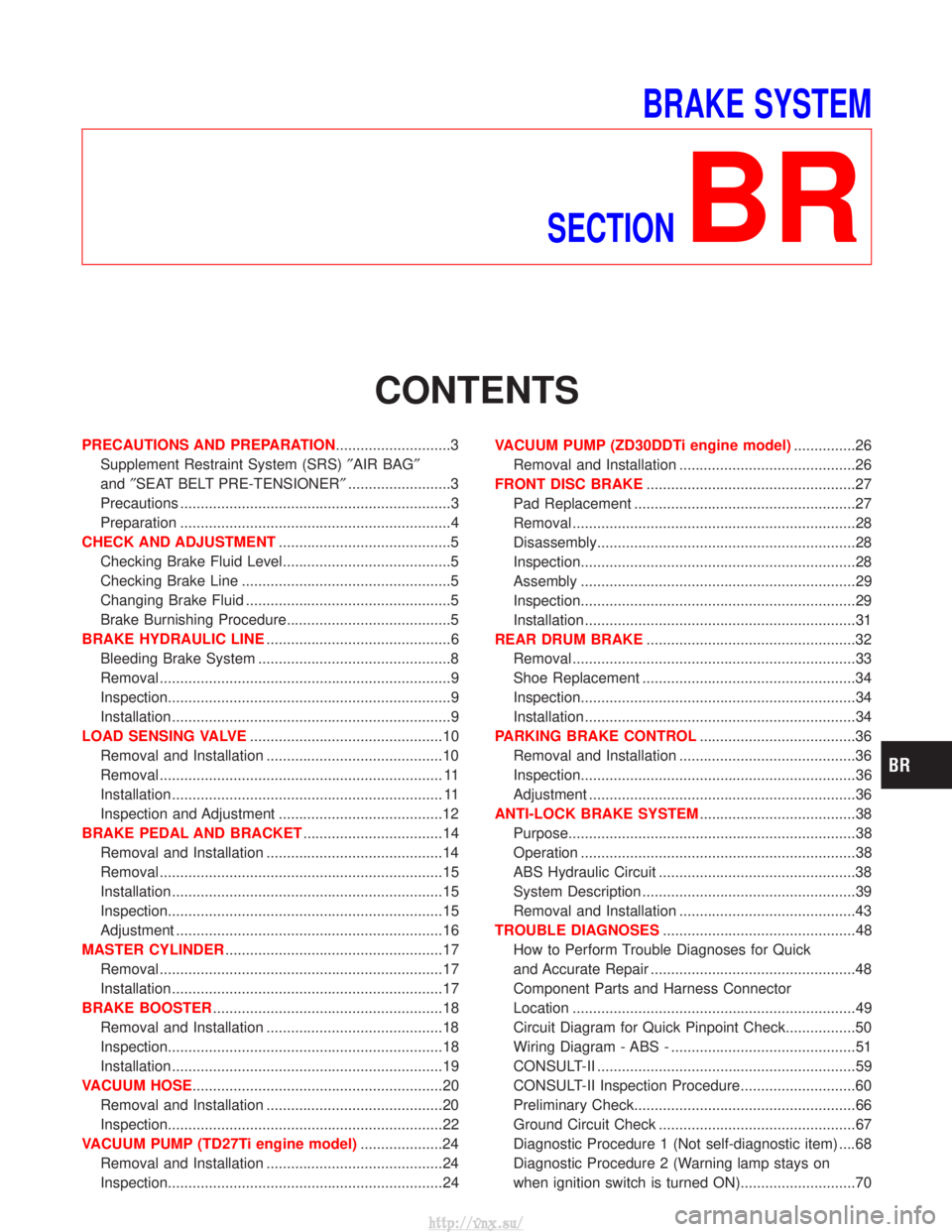

BRAKE SYSTEM

SECTION

BR

CONTENTS

PRECAUTIONS AND PREPARATION ............................3

Supplement Restraint System (SRS) ²AIR BAG²

and ²SEAT BELT PRE-TENSIONER² .........................3

Precautions ..................................................................3

Preparation ..................................................................4

CHECK AND ADJUSTMENT ..........................................5

Checking Brake Fluid Level.........................................5

Checking Brake Line ...................................................5

Changing Brake Fluid ..................................................5

Brake Burnishing Procedure........................................5

BRAKE HYDRAULIC LINE .............................................6

Bleeding Brake System ...............................................8

Removal .......................................................................9

Inspection.....................................................................9

Installation ....................................................................9

LOAD SENSING VALVE ...............................................10

Removal and Installation ...........................................10

Removal ..................................................................... 11

Installation .................................................................. 11

Inspection and Adjustment ........................................12

BRAKE PEDAL AND BRACKET ..................................14

Removal and Installation ...........................................14

Removal .....................................................................15

Installation ..................................................................15

Inspection...................................................................15

Adjustment .................................................................16

MASTER CYLINDER .....................................................17

Removal .....................................................................17

Installation ..................................................................17

BRAKE BOOSTER ........................................................18

Removal and Installation ...........................................18

Inspection...................................................................18

Installation ..................................................................19

VACUUM HOSE .............................................................20

Removal and Installation ...........................................20

Inspection...................................................................22

VACUUM PUMP (TD27Ti engine model) ....................24

Removal and Installation ...........................................24

Inspection...................................................................24 VACUUM PUMP (ZD30DDTi engine model)

...............26

Removal and Installation ...........................................26

FRONT DISC BRAKE ...................................................27

Pad Replacement ......................................................27

Removal .....................................................................28

Disassembly...............................................................28

Inspection...................................................................28

Assembly ...................................................................29

Inspection...................................................................29

Installation ..................................................................31

REAR DRUM BRAKE ...................................................32

Removal .....................................................................33

Shoe Replacement ....................................................34

Inspection...................................................................34

Installation ..................................................................34

PARKING BRAKE CONTROL ......................................36

Removal and Installation ...........................................36

Inspection...................................................................36

Adjustment .................................................................36

ANTI-LOCK BRAKE SYSTEM ......................................38

Purpose......................................................................38

Operation ...................................................................38

ABS Hydraulic Circuit ................................................38

System Description ....................................................39

Removal and Installation ...........................................43

TROUBLE DIAGNOSES ...............................................48

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................48

Component Parts and Harness Connector

Location .....................................................................49

Circuit Diagram for Quick Pinpoint Check.................50

Wiring Diagram - ABS - .............................................51

CONSULT-II ...............................................................59

CONSULT-II Inspection Procedure............................60

Preliminary Check......................................................66

Ground Circuit Check ................................................67

Diagnostic Procedure 1 (Not self-diagnostic item) ....68

Diagnostic Procedure 2 (Warning lamp stays on

when ignition switch is turned ON)............................70

http://vnx.su/