Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 710 of 1833

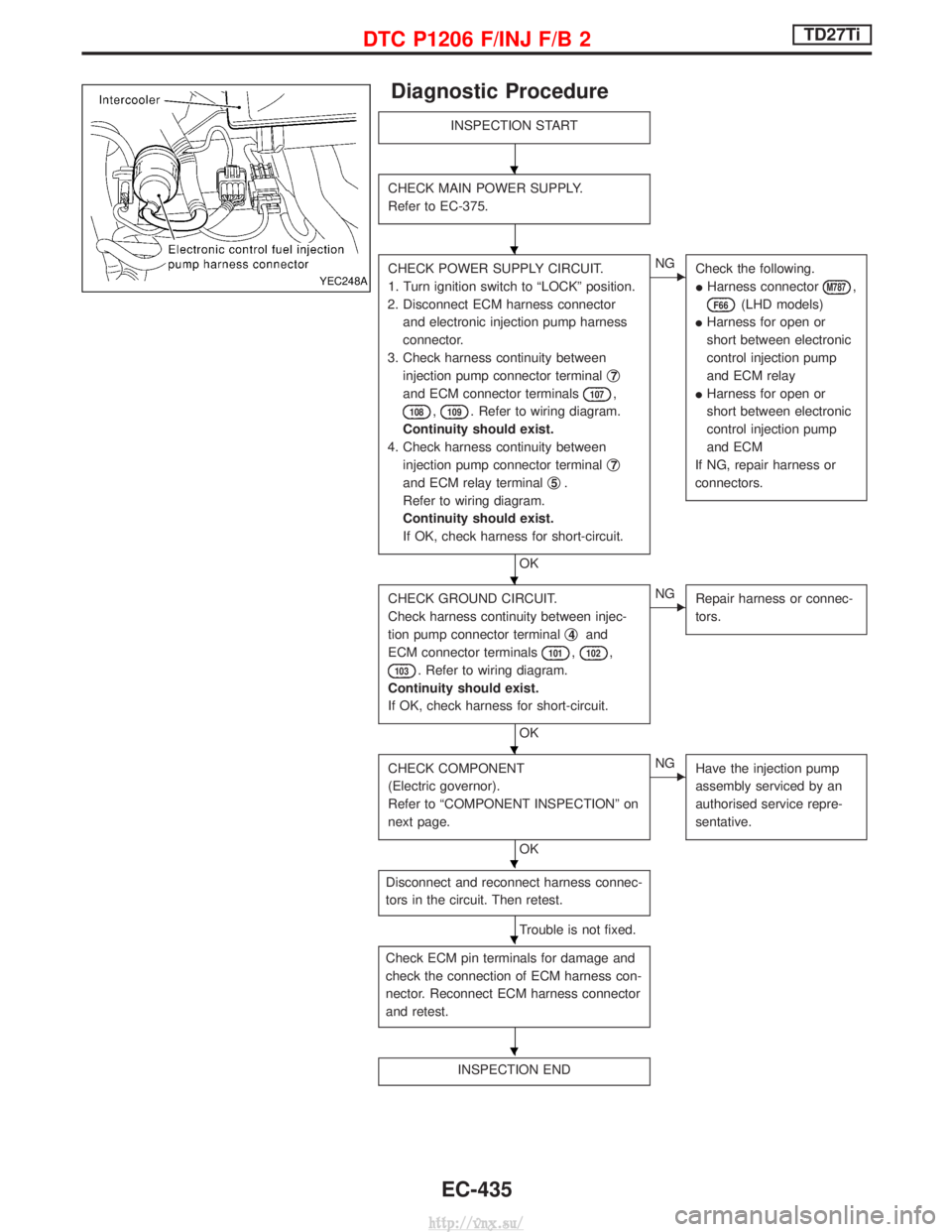

Diagnostic Procedure

INSPECTION START

CHECK MAIN POWER SUPPLY.

Refer to EC-375.

CHECK POWER SUPPLY CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector and electronic injection pump harness

connector.

3. Check harness continuity between injection pump connector terminal q

7

and ECM connector terminals107,

108,109. Refer to wiring diagram.

Continuity should exist.

4. Check harness continuity between injection pump connector terminal q

7

and ECM relay terminalq5.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following.

IHarness connector

M787,

F66(LHD models)

I Harness for open or

short between electronic

control injection pump

and ECM relay

I Harness for open or

short between electronic

control injection pump

and ECM

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

Check harness continuity between injec-

tion pump connector terminal q

4and

ECM connector terminals

101,102,

103. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Repair harness or connec-

tors.

CHECK COMPONENT

(Electric governor).

Refer to ªCOMPONENT INSPECTIONº on

next page.

OK

ENGHave the injection pump

assembly serviced by an

authorised service repre-

sentative.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

YEC248A

H

H

H

H

H

H

H

DTC P1206 F/INJ F/B 2TD27Ti

EC-435

http://vnx.su/

Page 712 of 1833

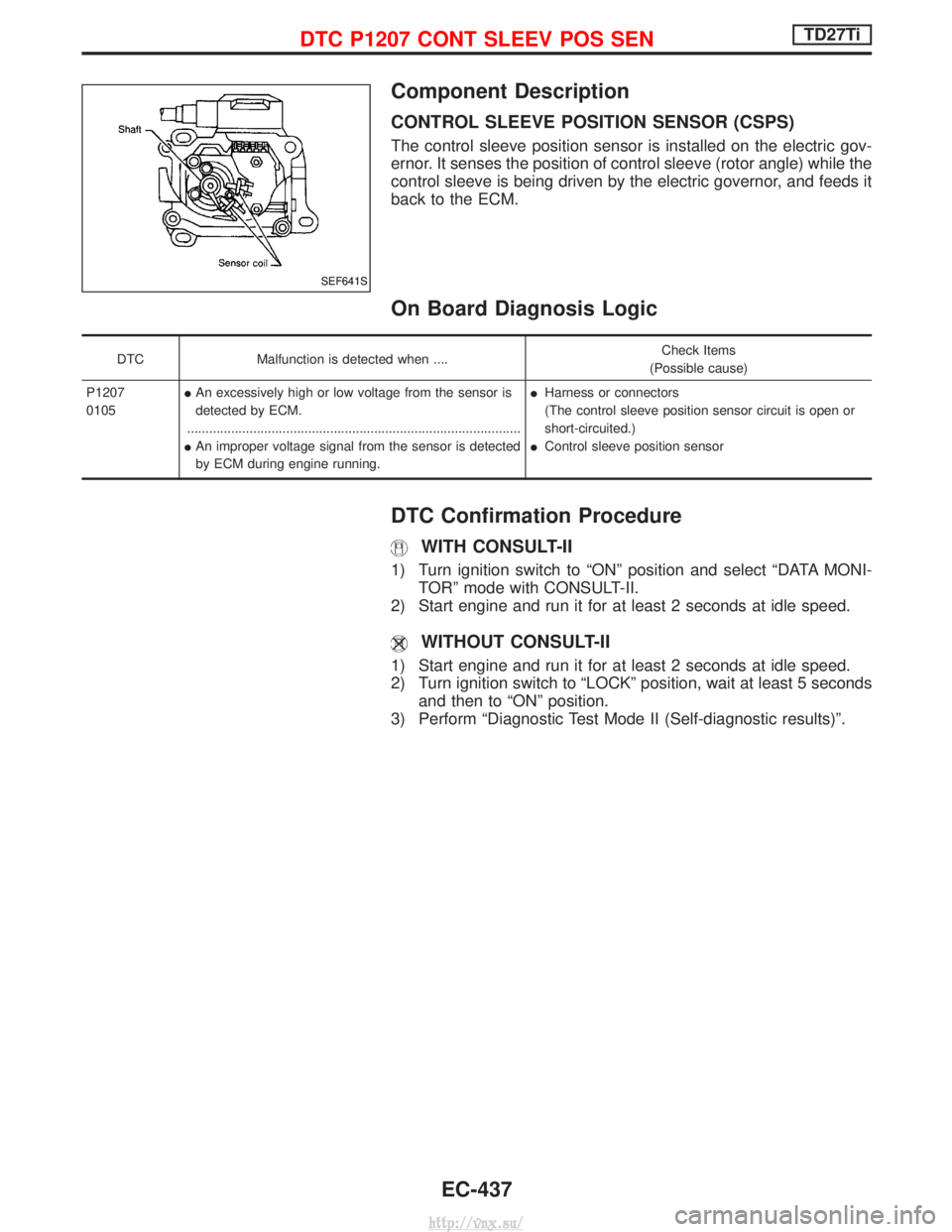

Component Description

CONTROL SLEEVE POSITION SENSOR (CSPS)

The control sleeve position sensor is installed on the electric gov-

ernor. It senses the position of control sleeve (rotor angle) while the

control sleeve is being driven by the electric governor, and feeds it

back to the ECM.

On Board Diagnosis Logic

DTCMalfunction is detected when .... Check Items

(Possible cause)

P1207

0105 I

An excessively high or low voltage from the sensor is

detected by ECM.

........................................................................\

...................

I An improper voltage signal from the sensor is detected

by ECM during engine running. I

Harness or connectors

(The control sleeve position sensor circuit is open or

short-circuited.)

I Control sleeve position sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-

TORº mode with CONSULT-II.

2) Start engine and run it for at least 2 seconds at idle speed.

WITHOUT CONSULT-II

1) Start engine and run it for at least 2 seconds at idle speed.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then to ªONº position.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º.

SEF641S

DTC P1207 CONT SLEEV POS SENTD27Ti

EC-437

http://vnx.su/

Page 714 of 1833

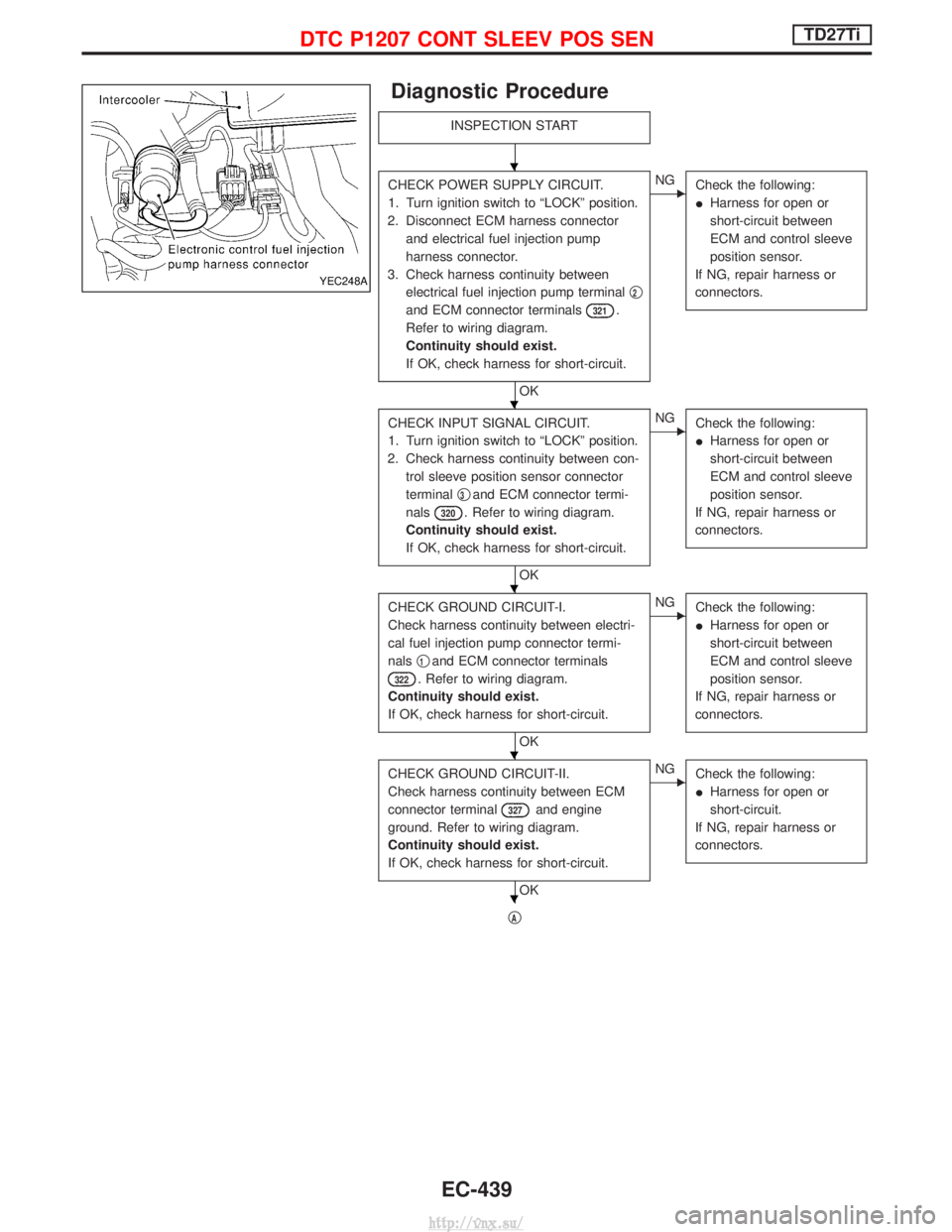

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector and electrical fuel injection pump

harness connector.

3. Check harness continuity between electrical fuel injection pump terminal q

2

and ECM connector terminals321.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and control sleeve

position sensor.

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between con- trol sleeve position sensor connector

terminal q

3and ECM connector termi-

nals

320. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and control sleeve

position sensor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-I.

Check harness continuity between electri-

cal fuel injection pump connector termi-

nals q

1and ECM connector terminals

322. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and control sleeve

position sensor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-II.

Check harness continuity between ECM

connector terminal

327and engine

ground. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit.

If NG, repair harness or

connectors.

qA

YEC248A

H

H

H

H

H

DTC P1207 CONT SLEEV POS SENTD27Ti

EC-439

http://vnx.su/

Page 717 of 1833

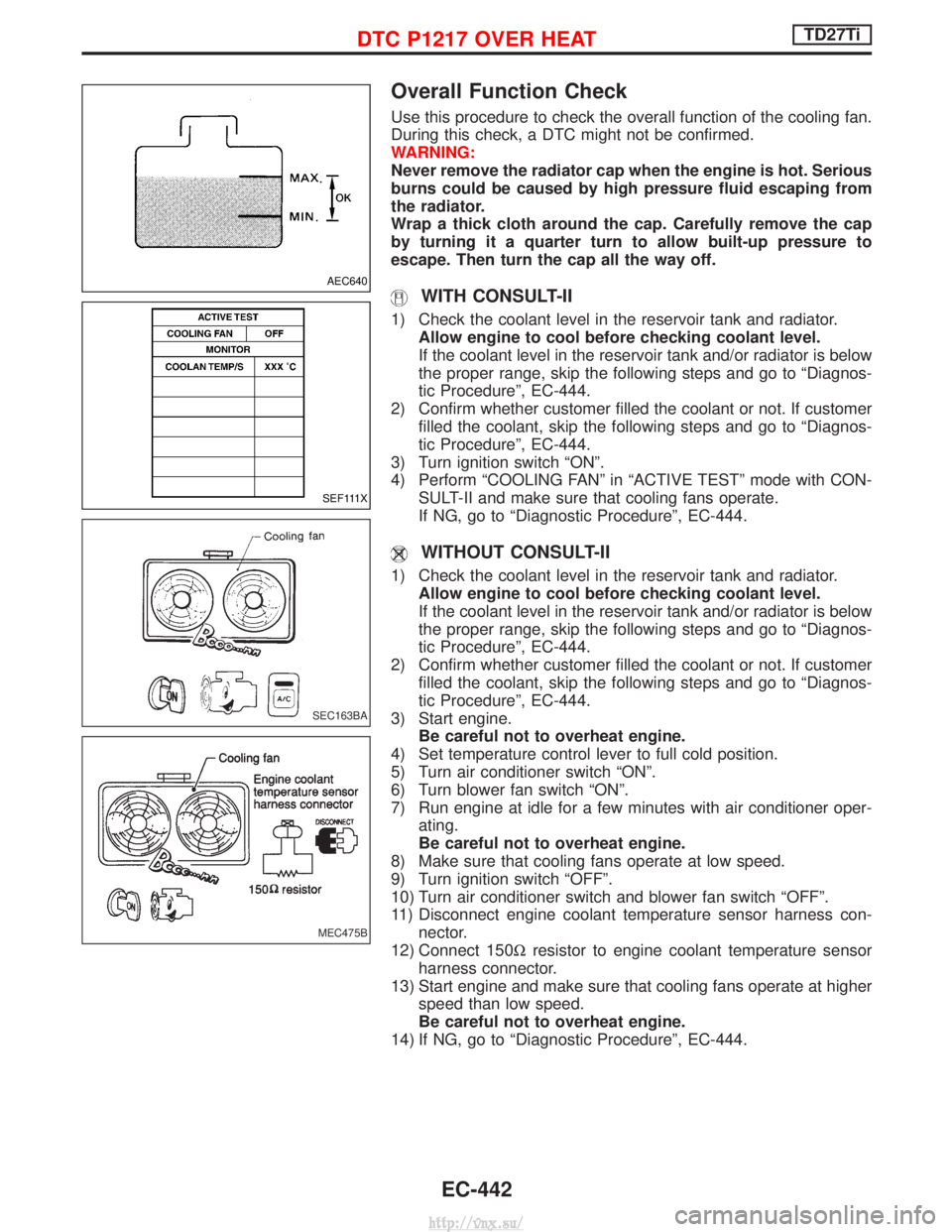

Overall Function Check

Use this procedure to check the overall function of the cooling fan.

During this check, a DTC might not be confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

WITH CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-444.

2) Confirm whether customer filled the coolant or not. If customer filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-444.

3) Turn ignition switch ªONº.

4) Perform ªCOOLING FANº in ªACTIVE TESTº mode with CON- SULT-II and make sure that cooling fans operate.

If NG, go to ªDiagnostic Procedureº, EC-444.

WITHOUT CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-444.

2) Confirm whether customer filled the coolant or not. If customer filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-444.

3) Start engine. Be careful not to overheat engine.

4) Set temperature control lever to full cold position.

5) Turn air conditioner switch ªONº.

6) Turn blower fan switch ªONº.

7) Run engine at idle for a few minutes with air conditioner oper- ating.

Be careful not to overheat engine.

8) Make sure that cooling fans operate at low speed.

9) Turn ignition switch ªOFFº.

10) Turn air conditioner switch and blower fan switch ªOFFº.

11) Disconnect engine coolant temperature sensor harness con- nector.

12) Connect 150W resistor to engine coolant temperature sensor

harness connector.

13) Start engine and make sure that cooling fans operate at higher speed than low speed.

Be careful not to overheat engine.

14) If NG, go to ªDiagnostic Procedureº, EC-444.

AEC640

SEF111X

SEC163BA

MEC475B

DTC P1217 OVER HEATTD27Ti

EC-442

http://vnx.su/

Page 719 of 1833

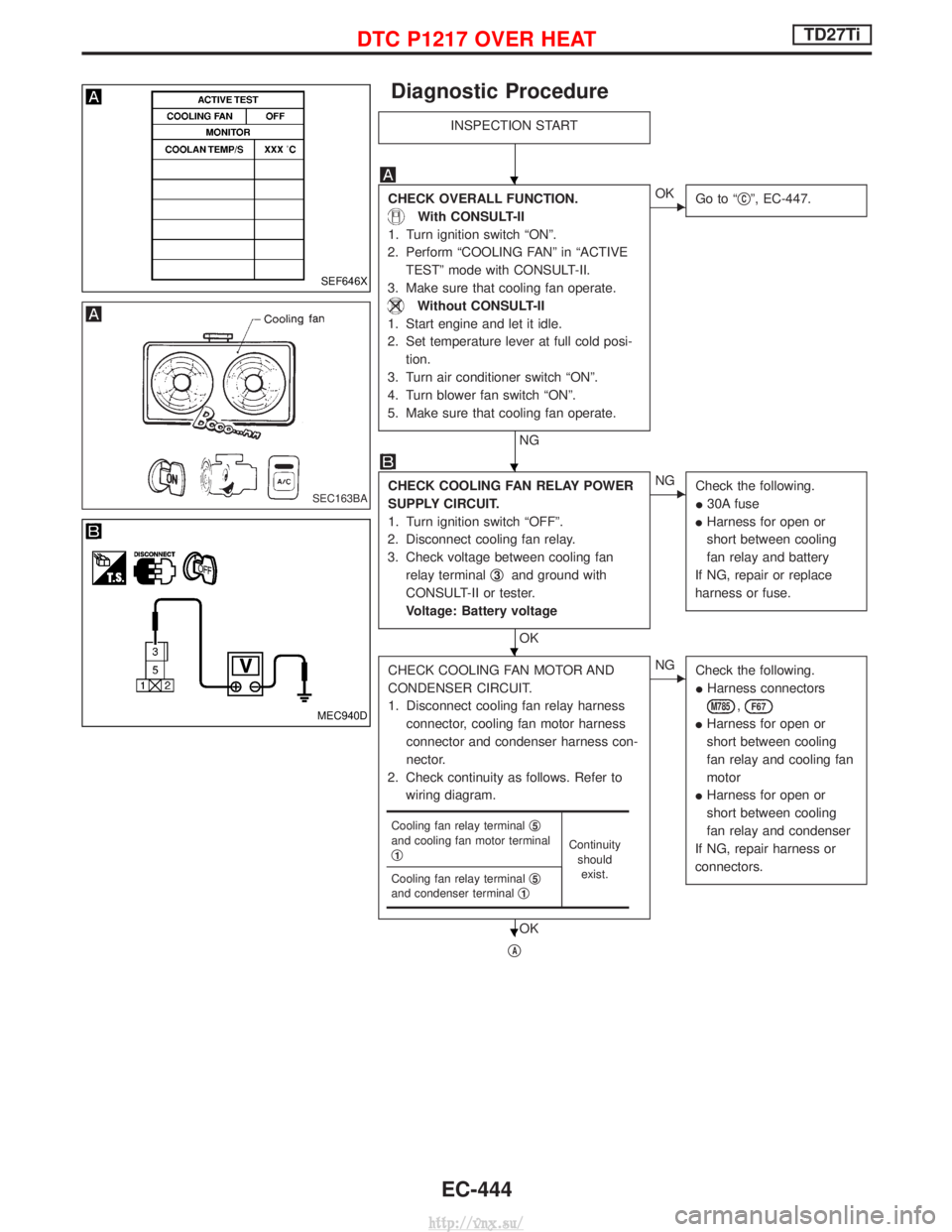

Diagnostic Procedure

INSPECTION START

CHECK OVERALL FUNCTION.

With CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªCOOLING FANº in ªACTIVE TESTº mode with CONSULT-II.

3. Make sure that cooling fan operate.

Without CONSULT-II

1. Start engine and let it idle.

2. Set temperature lever at full cold posi- tion.

3. Turn air conditioner switch ªONº.

4. Turn blower fan switch ªONº.

5. Make sure that cooling fan operate.

NG

EOK Go to ª qCº, EC-447.

CHECK COOLING FAN RELAY POWER

SUPPLY CIRCUIT.

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay.

3. Check voltage between cooling fan relay terminal q

3and ground with

CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG Check the following.

I30A fuse

I Harness for open or

short between cooling

fan relay and battery

If NG, repair or replace

harness or fuse.

CHECK COOLING FAN MOTOR AND

CONDENSER CIRCUIT.

1. Disconnect cooling fan relay harness connector, cooling fan motor harness

connector and condenser harness con-

nector.

2. Check continuity as follows. Refer to wiring diagram.

OK

ENG Check the following.

IHarness connectors

M785,F67

IHarness for open or

short between cooling

fan relay and cooling fan

motor

I Harness for open or

short between cooling

fan relay and condenser

If NG, repair harness or

connectors.

qA

Cooling fan relay terminal q5and cooling fan motor terminal

q1Continuity

shouldexist.

Cooling fan relay terminal q

5and condenser terminalq1

SEF646X

SEC163BA

MEC940D

H

H

H

H

DTC P1217 OVER HEATTD27Ti

EC-444

http://vnx.su/

Page 723 of 1833

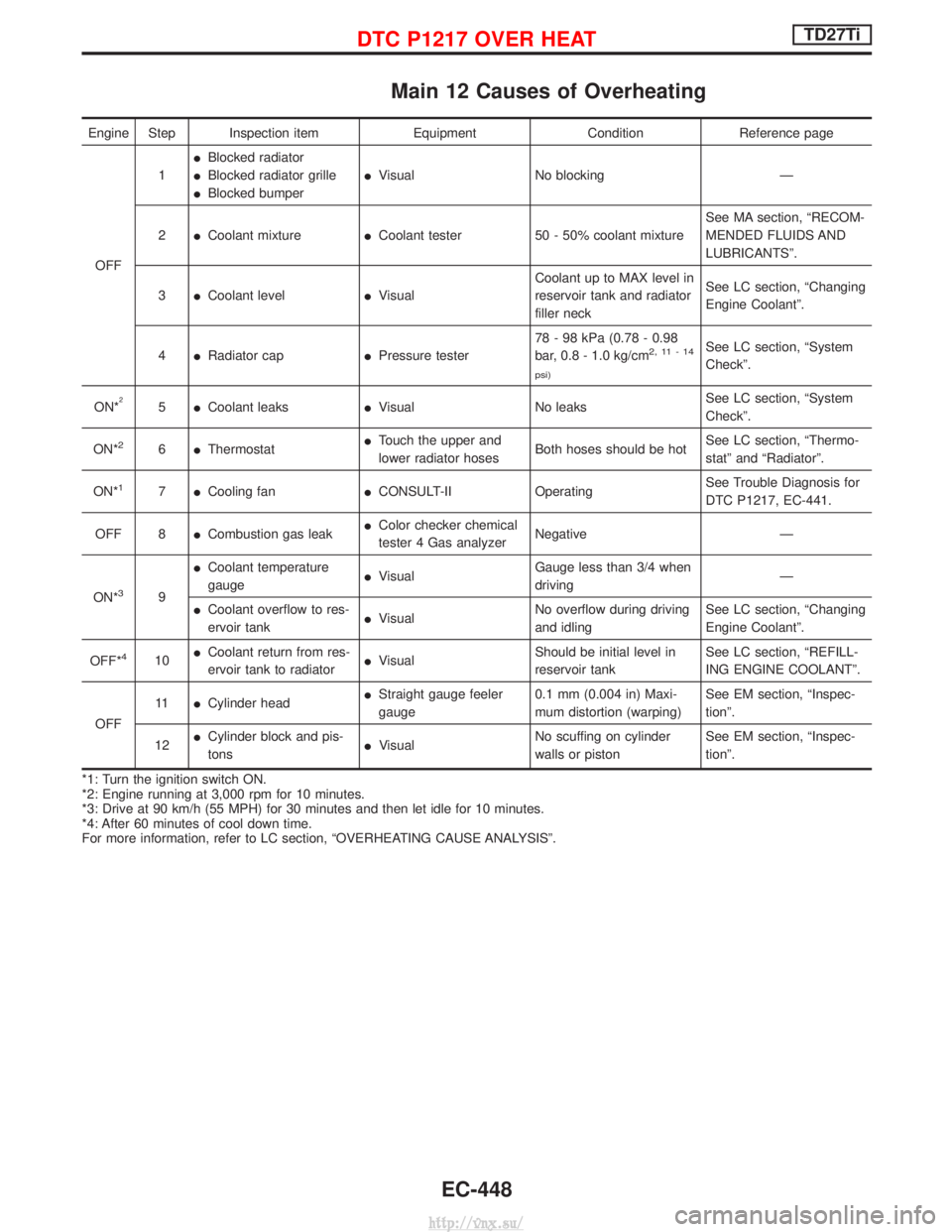

Main 12 Causes of Overheating

Engine Step Inspection itemEquipmentConditionReference page

OFF 1

I

Blocked radiator

I Blocked radiator grille

I Blocked bumper I

Visual No blocking Ð

2 ICoolant mixture ICoolant tester 50 - 50% coolant mixture See MA section, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3 ICoolant level IVisual Coolant up to MAX level in

reservoir tank and radiator

filler neck See LC section, ªChanging

Engine Coolantº.

4 IRadiator cap IPressure tester 78 - 98 kPa (0.78 - 0.98

bar, 0.8 - 1.0 kg/cm

2,11-14

psi)See LC section, ªSystem

Checkº.

ON*

25 ICoolant leaks IVisual No leaks See LC section, ªSystem

Checkº.

ON*

26 IThermostat I

Touch the upper and

lower radiator hoses Both hoses should be hot See LC section, ªThermo-

statº and ªRadiatorº.

ON*

17 ICooling fan ICONSULT-II Operating See Trouble Diagnosis for

DTC P1217, EC-441.

OFF 8 ICombustion gas leak I

Color checker chemical

tester 4 Gas analyzer Negative Ð

ON*

39 I

Coolant temperature

gauge I

Visual Gauge less than 3/4 when

driving Ð

I Coolant overflow to res-

ervoir tank I

Visual No overflow during driving

and idling See LC section, ªChanging

Engine Coolantº.

OFF*

410 I

Coolant return from res-

ervoir tank to radiator I

Visual Should be initial level in

reservoir tank See LC section, ªREFILL-

ING ENGINE COOLANTº.

OFF 11

ICylinder head I

Straight gauge feeler

gauge 0.1 mm (0.004 in) Maxi-

mum distortion (warping) See EM section, ªInspec-

tionº.

12 I

Cylinder block and pis-

tons I

Visual No scuffing on cylinder

walls or piston See EM section, ªInspec-

tionº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to LC section, ªOVERHEATING CAUSE ANALYSISº.

DTC P1217 OVER HEATTD27Ti

EC-448

http://vnx.su/

Page 724 of 1833

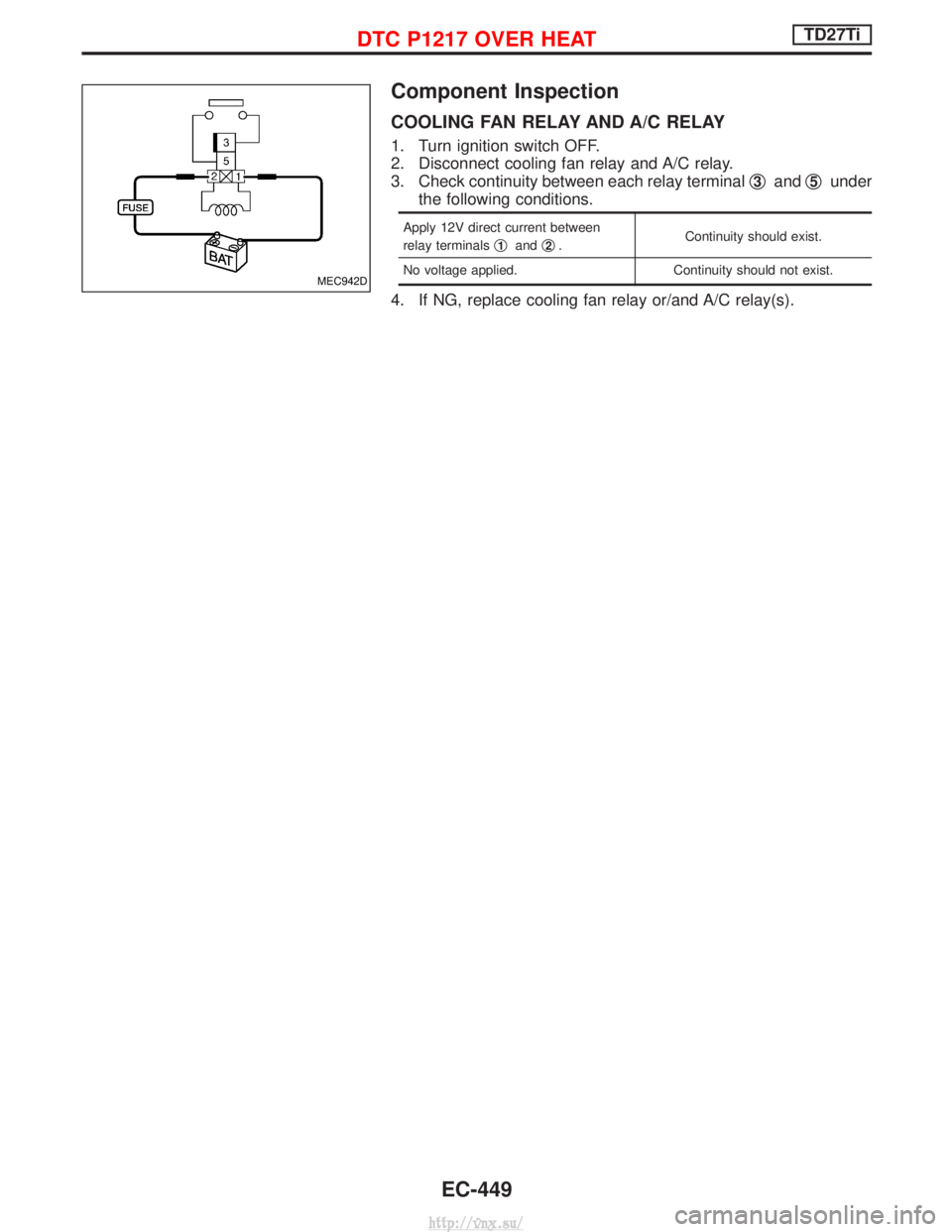

Component Inspection

COOLING FAN RELAY AND A/C RELAY

1. Turn ignition switch OFF.

2. Disconnect cooling fan relay and A/C relay.

3. Check continuity between each relay terminalq

3andq5under

the following conditions.

Apply 12V direct current between

relay terminals q

1andq2. Continuity should exist.

No voltage applied. Continuity should not exist.

4. If NG, replace cooling fan relay or/and A/C relay(s).

MEC942D

DTC P1217 OVER HEATTD27Ti

EC-449

http://vnx.su/

Page 725 of 1833

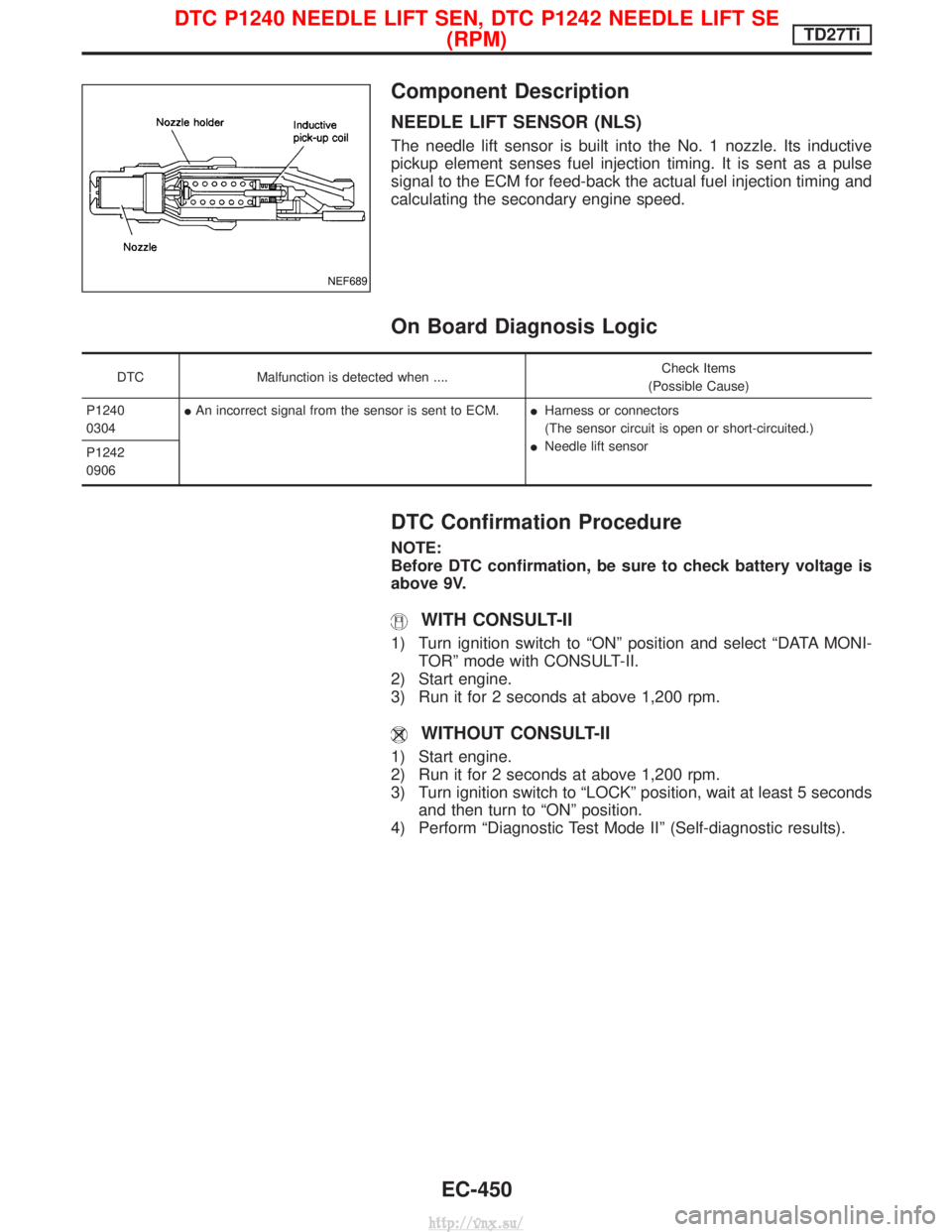

Component Description

NEEDLE LIFT SENSOR (NLS)

The needle lift sensor is built into the No. 1 nozzle. Its inductive

pickup element senses fuel injection timing. It is sent as a pulse

signal to the ECM for feed-back the actual fuel injection timing and

calculating the secondary engine speed.

On Board Diagnosis Logic

DTCMalfunction is detected when .... Check Items

(Possible Cause)

P1240

0304 I

An incorrect signal from the sensor is sent to ECM. IHarness or connectors

(The sensor circuit is open or short-circuited.)

I Needle lift sensor

P1242

0906

DTC Confirmation Procedure

NOTE:

Before DTC confirmation, be sure to check battery voltage is

above 9V.

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-

TORº mode with CONSULT-II.

2) Start engine.

3) Run it for 2 seconds at above 1,200 rpm.

WITHOUT CONSULT-II

1) Start engine.

2) Run it for 2 seconds at above 1,200 rpm.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

NEF689

DTC P1240 NEEDLE LIFT SEN, DTC P1242 NEEDLE LIFT SE (RPM)TD27Ti

EC-450

http://vnx.su/

Page 727 of 1833

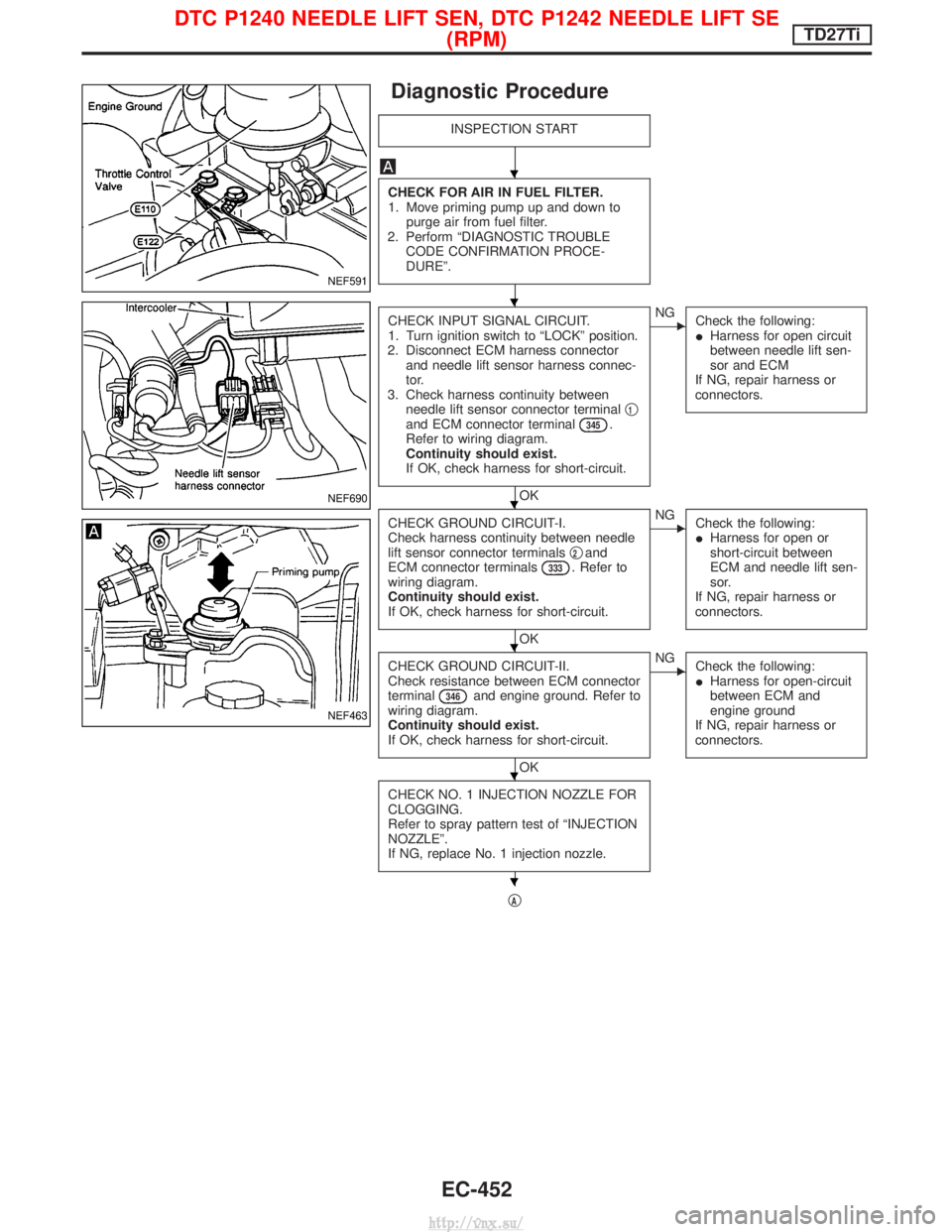

Diagnostic Procedure

INSPECTION START

CHECK FOR AIR IN FUEL FILTER.

1. Move priming pump up and down topurge air from fuel filter.

2. Perform ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector and needle lift sensor harness connec-

tor.

3. Check harness continuity between needle lift sensor connector terminal q

1and ECM connector terminal345.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open circuit

between needle lift sen-

sor and ECM

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-I.

Check harness continuity between needle

lift sensor connector terminals q

2and

ECM connector terminals333. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and needle lift sen-

sor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-II.

Check resistance between ECM connector

terminal

346and engine ground. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open-circuit

between ECM and

engine ground

If NG, repair harness or

connectors.

CHECK NO. 1 INJECTION NOZZLE FOR

CLOGGING.

Refer to spray pattern test of ªINJECTION

NOZZLEº.

If NG, replace No. 1 injection nozzle.

qA

NEF591

NEF690

NEF463

H

H

H

H

H

H

DTC P1240 NEEDLE LIFT SEN, DTC P1242 NEEDLE LIFT SE (RPM)TD27Ti

EC-452

http://vnx.su/

Page 729 of 1833

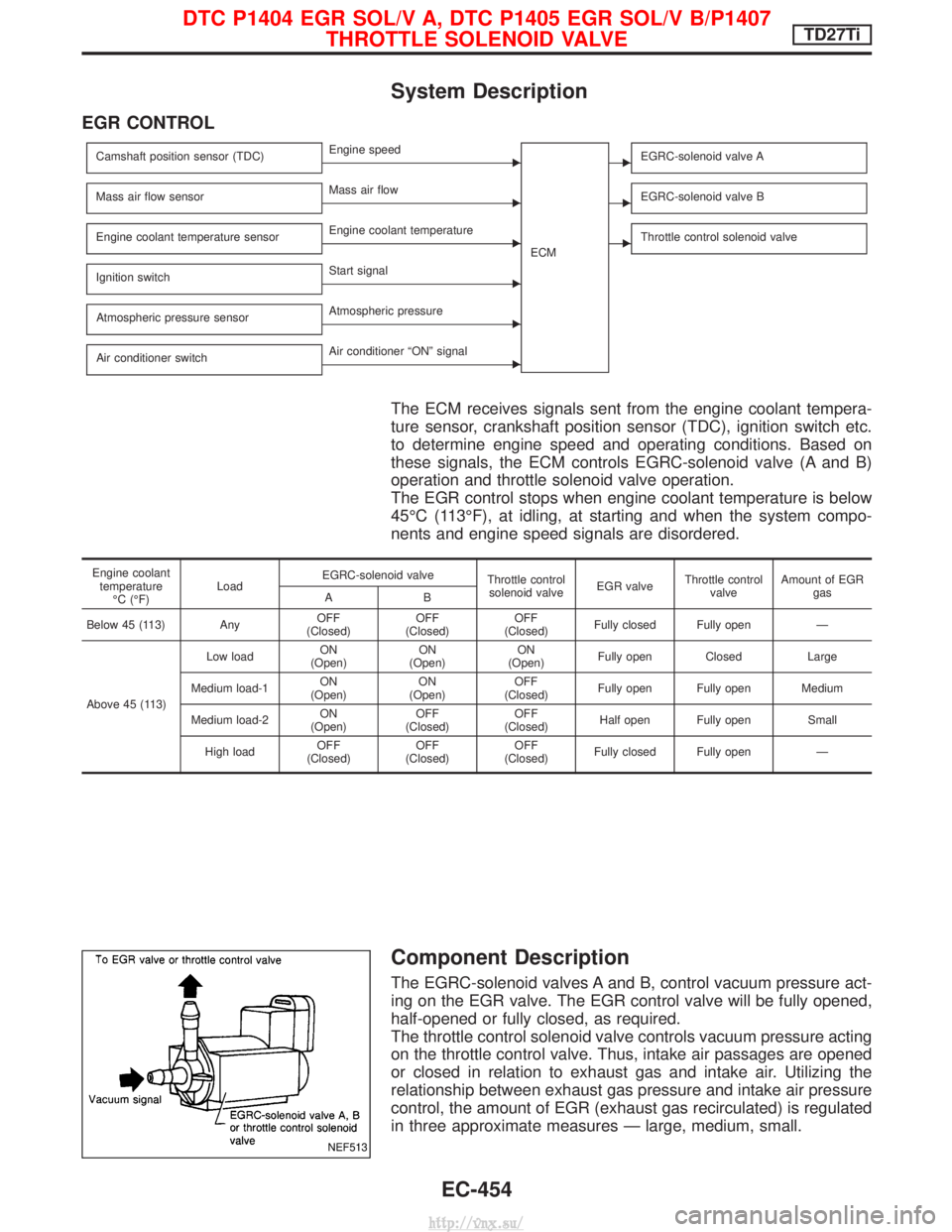

System Description

EGR CONTROL

Camshaft position sensor (TDC)EEngine speedECMEEGRC-solenoid valve A

Mass air flow sensorEMass air flowEEGRC-solenoid valve B

Engine coolant temperature sensorEEngine coolant temperatureEThrottle control solenoid valve

Ignition switchEStart signal

Atmospheric pressure sensor

EAtmospheric pressure

Air conditioner switch

EAir conditioner ªONº signal

The ECM receives signals sent from the engine coolant tempera-

ture sensor, crankshaft position sensor (TDC), ignition switch etc.

to determine engine speed and operating conditions. Based on

these signals, the ECM controls EGRC-solenoid valve (A and B)

operation and throttle solenoid valve operation.

The EGR control stops when engine coolant temperature is below

45ÉC (113ÉF), at idling, at starting and when the system compo-

nents and engine speed signals are disordered.

Engine coolant temperature ÉC (ÉF) Load

EGRC-solenoid valve

Throttle control

solenoid valve EGR valveThrottle control

valve Amount of EGR

gas

AB

Below 45 (113) Any OFF

(Closed) OFF

(Closed) OFF

(Closed) Fully closed Fully open Ð

Above 45 (113) Low load

ON

(Open) ON

(Open) ON

(Open) Fully open Closed Large

Medium load-1 ON

(Open) ON

(Open) OFF

(Closed) Fully open Fully open Medium

Medium load-2 ON

(Open) OFF

(Closed) OFF

(Closed) Half open Fully open Small

High load OFF

(Closed) OFF

(Closed) OFF

(Closed) Fully closed Fully open Ð

Component Description

The EGRC-solenoid valves A and B, control vacuum pressure act-

ing on the EGR valve. The EGR control valve will be fully opened,

half-opened or fully closed, as required.

The throttle control solenoid valve controls vacuum pressure acting

on the throttle control valve. Thus, intake air passages are opened

or closed in relation to exhaust gas and intake air. Utilizing the

relationship between exhaust gas pressure and intake air pressure

control, the amount of EGR (exhaust gas recirculated) is regulated

in three approximate measures Ð large, medium, small.

NEF513

DTC P1404 EGR SOL/V A, DTC P1405 EGR SOL/V B/P1407

THROTTLE SOLENOID VALVETD27Ti

EC-454

http://vnx.su/