Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 817 of 1833

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for SRS ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº Service

IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

I Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

I Diagnosis sensor unit must always be installed with their arrow marks ª +º pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

I The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

I Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module (built-in type) standing with stud bolt side setting

bottom.

I Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

I After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Precautions

IBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

I Disassembly should be done in a clean work area.

I Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

I Place disassembled parts in order for easier and proper assembly.

I All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

I Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

I It is very important to perform functional tests whenever they are indicated.

I The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place removed parts in a parts rack in order to replace them in correct positions and sequences. Care will

also prevent springs and small parts from becoming scattered or lost.

I Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

PREPARATION AND PRECAUTIONS

AT- 4

http://vnx.su/

Page 818 of 1833

IBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

I Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

I After overhaul, refill the transmission with new ATF.

I When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under ªChanging A/T Fluidº in the MA section when changing A/T fluid.

Service Notice or Precautions

FAIL-SAFE

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear even with a shift lever position of ª1º, ª2º or ªDº. Cus-

tomer may complain of ªsluggish or poor accelerationº.

When the Fail-Safe operation occurs the next time the key is turned to the ªONº position, the SPORT indica-

tor lamp will blink for about 8 seconds. (For diagnosis, refer to AT-33.)

Fail-Safe may activate without electrical circuit damages if the vehicle is driven under extreme conditions (such

as excessive wheel spins and emergency braking immediately afterwards). In this case, turn the ignition key

ªOFFº for 5 seconds and then ªONº to recover normal shift pattern.

The blinking of the SPORT indicator lamp for about 8 seconds will appear only once and be cleared. The cus-

tomer may resume normal driving conditions by chance.

Always follow the ªWORK FLOWº (Refer to AT-26).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate the damage of the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS performed after checking the sensor, no damages will be indicated.

PREPARATION AND PRECAUTIONS

Precautions (Cont'd)

AT- 5

http://vnx.su/

Page 828 of 1833

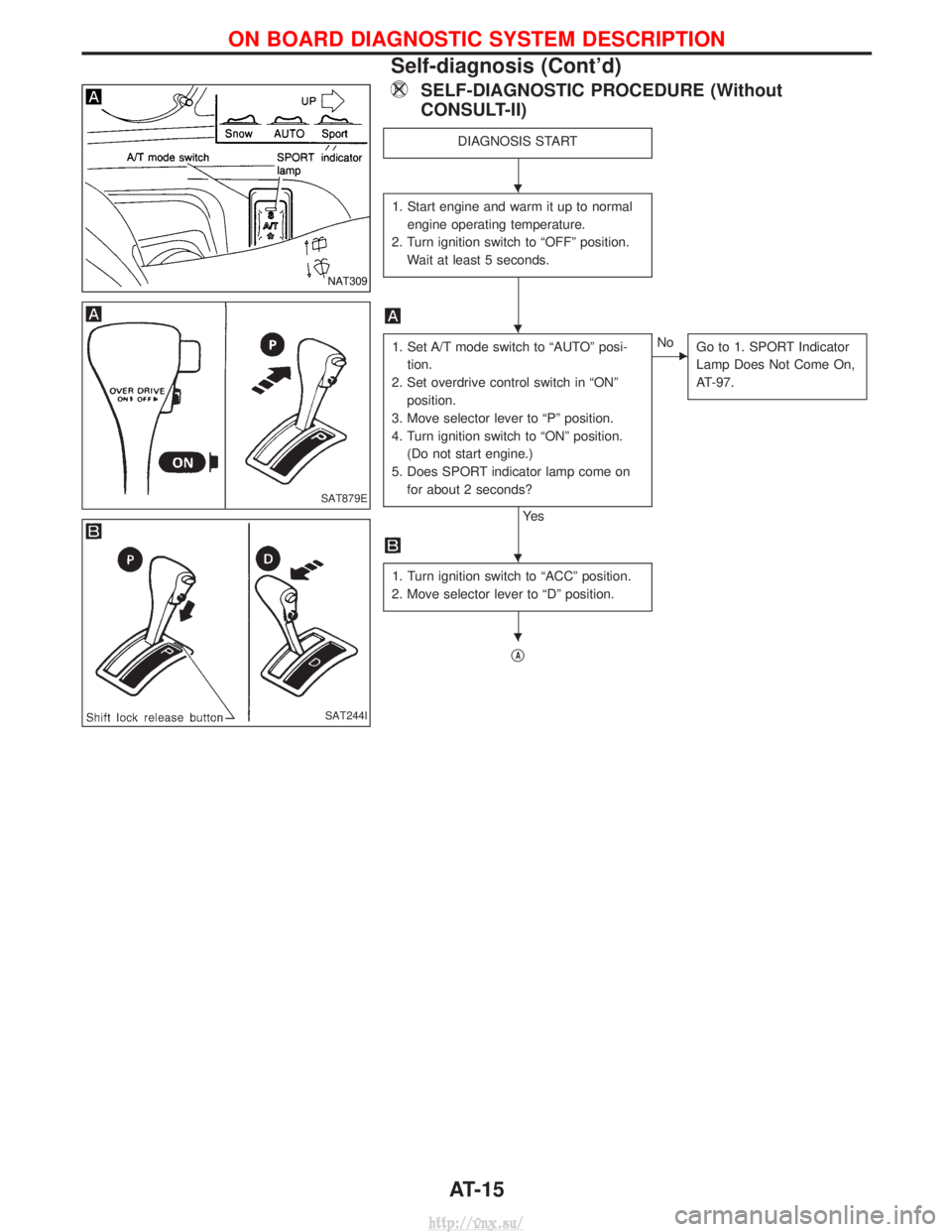

SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)

DIAGNOSIS START

1. Start engine and warm it up to normalengine operating temperature.

2. Turn ignition switch to ªOFFº position. Wait at least 5 seconds.

1. Set A/T mode switch to ªAUTOº posi-tion.

2. Set overdrive control switch in ªONº position.

3. Move selector lever to ªPº position.

4. Turn ignition switch to ªONº position. (Do not start engine.)

5. Does SPORT indicator lamp come on for about 2 seconds?

Ye s

ENo Go to 1. SPORT Indicator

Lamp Does Not Come On,

AT-97.

1. Turn ignition switch to ªACCº position.

2. Move selector lever to ªDº position.

qA

NAT309

SAT879E

SAT244I

H

H

H

H

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Self-diagnosis (Cont'd)

AT-15

http://vnx.su/

Page 829 of 1833

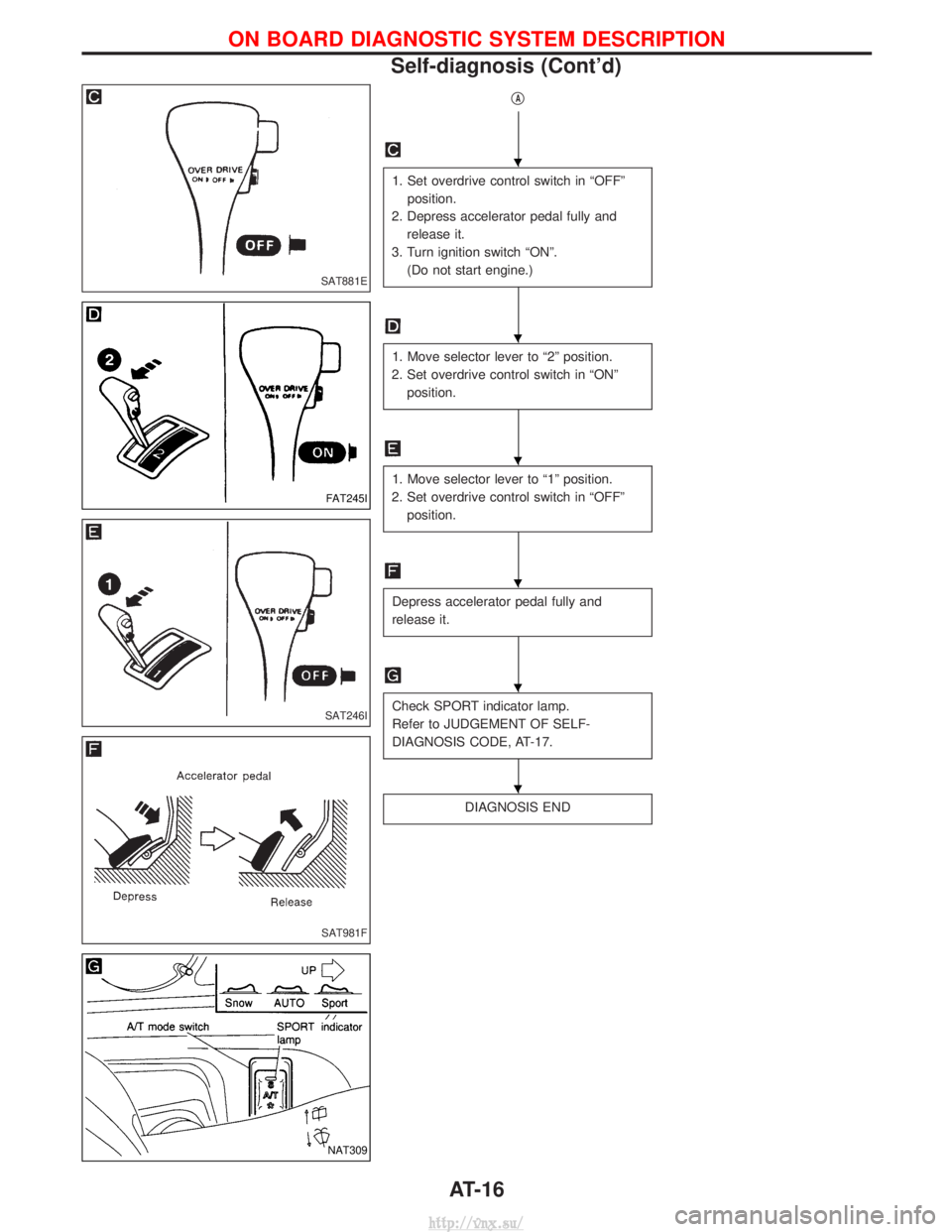

qA

1. Set overdrive control switch in ªOFFºposition.

2. Depress accelerator pedal fully and release it.

3. Turn ignition switch ªONº. (Do not start engine.)

1. Move selector lever to ª2º position.

2. Set overdrive control switch in ªONº position.

1. Move selector lever to ª1º position.

2. Set overdrive control switch in ªOFFº position.

Depress accelerator pedal fully and

release it.

Check SPORT indicator lamp.

Refer to JUDGEMENT OF SELF-

DIAGNOSIS CODE, AT-17.

DIAGNOSIS END

SAT881E

FAT245I

SAT246I

SAT981F

NAT309

H

H

H

H

H

H

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Self-diagnosis (Cont'd)

AT-16

http://vnx.su/

Page 832 of 1833

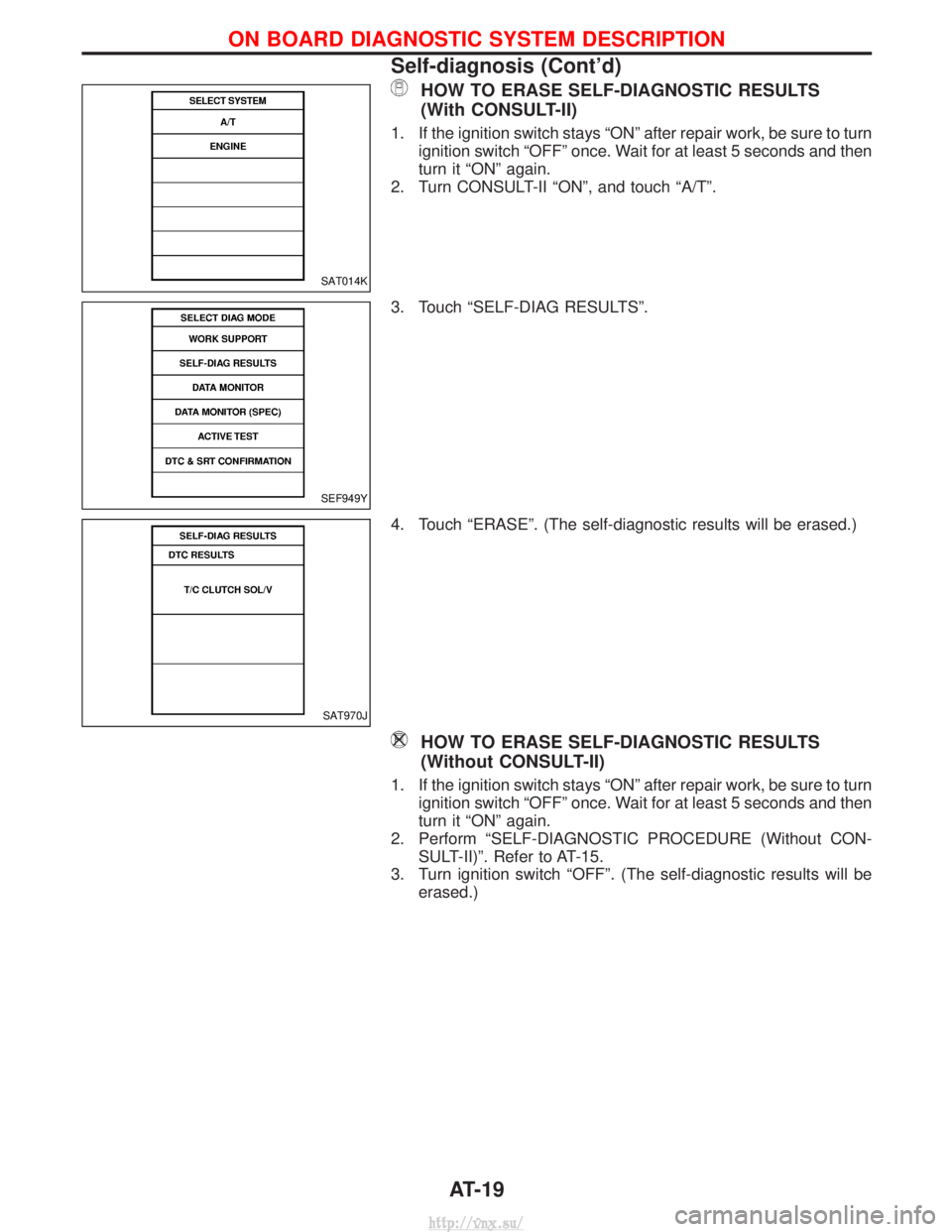

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

(With CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turnignition switch ªOFFº once. Wait for at least 5 seconds and then

turn it ªONº again.

2. Turn CONSULT-II ªONº, and touch ªA/Tº.

3. Touch ªSELF-DIAG RESULTSº.

4. Touch ªERASEº. (The self-diagnostic results will be erased.)

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

(Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait for at least 5 seconds and then

turn it ªONº again.

2. Perform ªSELF-DIAGNOSTIC PROCEDURE (Without CON- SULT-II)º. Refer to AT-15.

3. Turn ignition switch ªOFFº. (The self-diagnostic results will be erased.)

SAT014K

SEF949Y

SAT970J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Self-diagnosis (Cont'd)

AT-19

http://vnx.su/

Page 846 of 1833

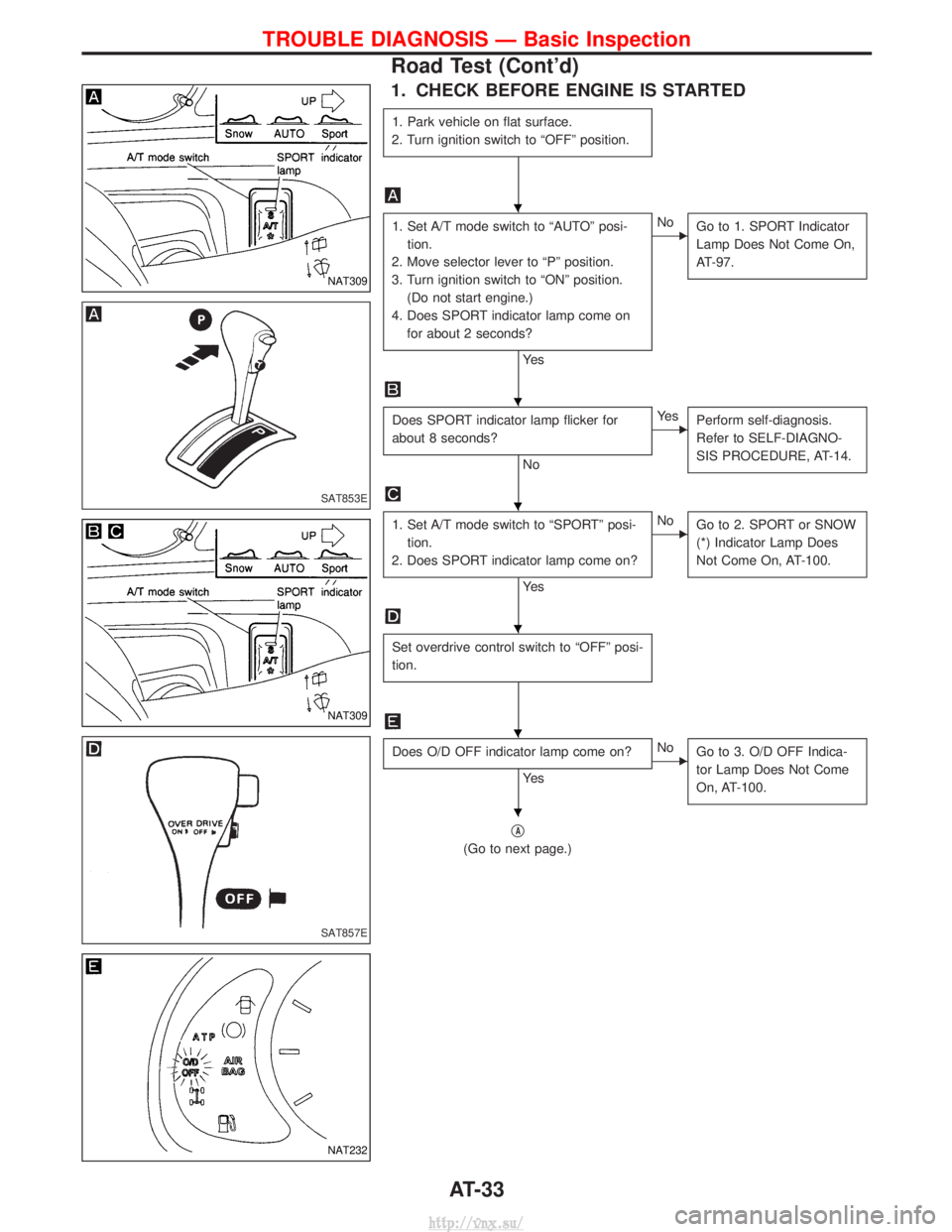

1. CHECK BEFORE ENGINE IS STARTED

1. Park vehicle on flat surface.

2. Turn ignition switch to ªOFFº position.

1. Set A/T mode switch to ªAUTOº posi- tion.

2. Move selector lever to ªPº position.

3. Turn ignition switch to ªONº position. (Do not start engine.)

4. Does SPORT indicator lamp come on for about 2 seconds?

Ye s

ENo Go to 1. SPORT Indicator

Lamp Does Not Come On,

AT-97.

Does SPORT indicator lamp flicker for

about 8 seconds?

No

EYe sPerform self-diagnosis.

Refer to SELF-DIAGNO-

SIS PROCEDURE, AT-14.

1. Set A/T mode switch to ªSPORTº posi-

tion.

2. Does SPORT indicator lamp come on?

Ye s

ENo Go to 2. SPORT or SNOW

(*) Indicator Lamp Does

Not Come On, AT-100.

Set overdrive control switch to ªOFFº posi-

tion.

Does O/D OFF indicator lamp come on?

Ye s

ENoGo to 3. O/D OFF Indica-

tor Lamp Does Not Come

On, AT-100.

qA

(Go to next page.)

NAT309

SAT853E

NAT309

SAT857E

NAT232

H

H

H

H

H

H

TROUBLE DIAGNOSIS Ð Basic Inspection

Road Test (Cont'd)

AT-33

http://vnx.su/

Page 847 of 1833

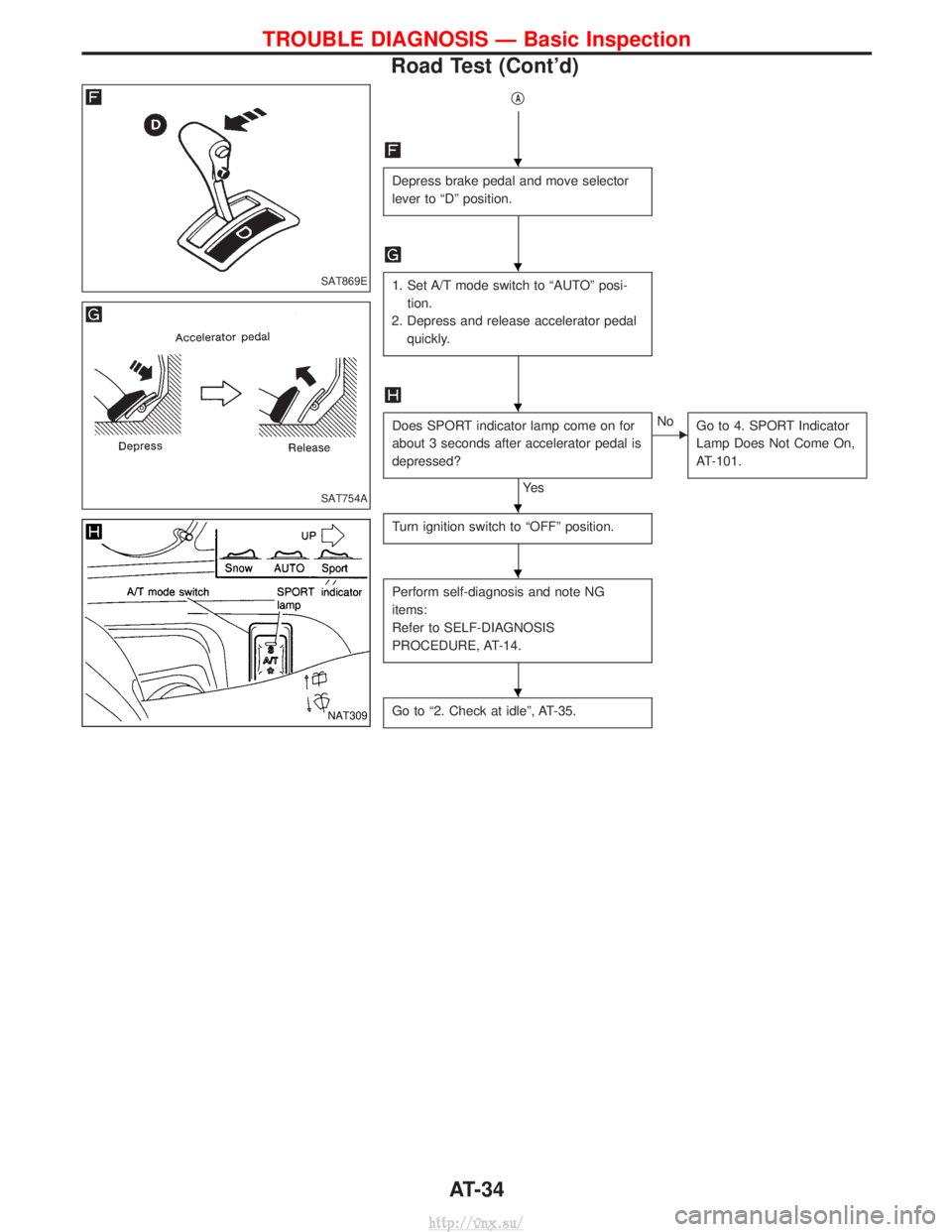

qA

Depress brake pedal and move selector

lever to ªDº position.

1. Set A/T mode switch to ªAUTOº posi-tion.

2. Depress and release accelerator pedal quickly.

Does SPORT indicator lamp come on for

about 3 seconds after accelerator pedal is

depressed?

Ye s

ENo Go to 4. SPORT Indicator

Lamp Does Not Come On,

AT-101.

Turn ignition switch to ªOFFº position.

Perform self-diagnosis and note NG

items:

Refer to SELF-DIAGNOSIS

PROCEDURE, AT-14.

Go to ª2. Check at idleº, AT-35.

SAT869E

SAT754A

NAT309

H

H

H

H

H

H

TROUBLE DIAGNOSIS Ð Basic Inspection

Road Test (Cont'd)

AT-34

http://vnx.su/

Page 848 of 1833

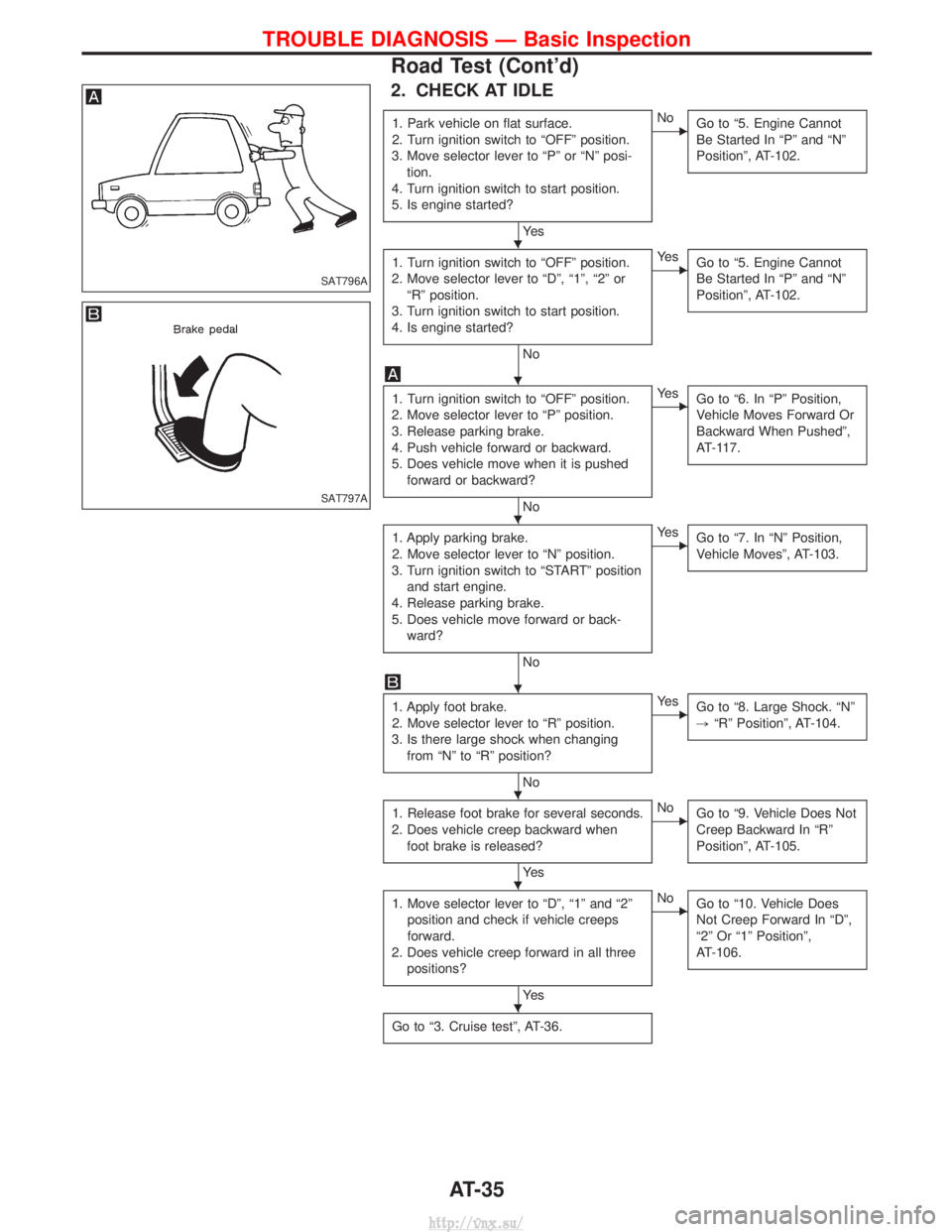

2. CHECK AT IDLE

1. Park vehicle on flat surface.

2. Turn ignition switch to ªOFFº position.

3. Move selector lever to ªPº or ªNº posi- tion.

4. Turn ignition switch to start position.

5. Is engine started?

Ye s

ENo Go to ª5. Engine Cannot

Be Started In ªPº and ªNº

Positionº, AT-102.

1. Turn ignition switch to ªOFFº position.

2. Move selector lever to ªDº, ª1º, ª2º or ªRº position.

3. Turn ignition switch to start position.

4. Is engine started?

No

EYe s Go to ª5. Engine Cannot

Be Started In ªPº and ªNº

Positionº, AT-102.

1. Turn ignition switch to ªOFFº position.

2. Move selector lever to ªPº position.

3. Release parking brake.

4. Push vehicle forward or backward.

5. Does vehicle move when it is pushed forward or backward?

No

EYe s Go to ª6. In ªPº Position,

Vehicle Moves Forward Or

Backward When Pushedº,

AT-117.

1. Apply parking brake.

2. Move selector lever to ªNº position.

3. Turn ignition switch to ªSTARTº position and start engine.

4. Release parking brake.

5. Does vehicle move forward or back- ward?

No

EYe s Go to ª7. In ªNº Position,

Vehicle Movesº, AT-103.

1. Apply foot brake.

2. Move selector lever to ªRº position.

3. Is there large shock when changing from ªNº to ªRº position?

No

EYe s Go to ª8. Large Shock. ªNº

,ªRº Positionº, AT-104.

1. Release foot brake for several seconds.

2. Does vehicle creep backward when foot brake is released?

Ye s

ENo Go to ª9. Vehicle Does Not

Creep Backward In ªRº

Positionº, AT-105.

1. Move selector lever to ªDº, ª1º and ª2º

position and check if vehicle creeps

forward.

2. Does vehicle creep forward in all three positions?

Ye s

ENo Go to ª10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Positionº,

AT-106.

Go to ª3. Cruise testº, AT-36.

SAT796A

SAT797A

H

H

H

H

H

H

H

TROUBLE DIAGNOSIS Ð Basic Inspection

Road Test (Cont'd)

AT-35

http://vnx.su/

Page 849 of 1833

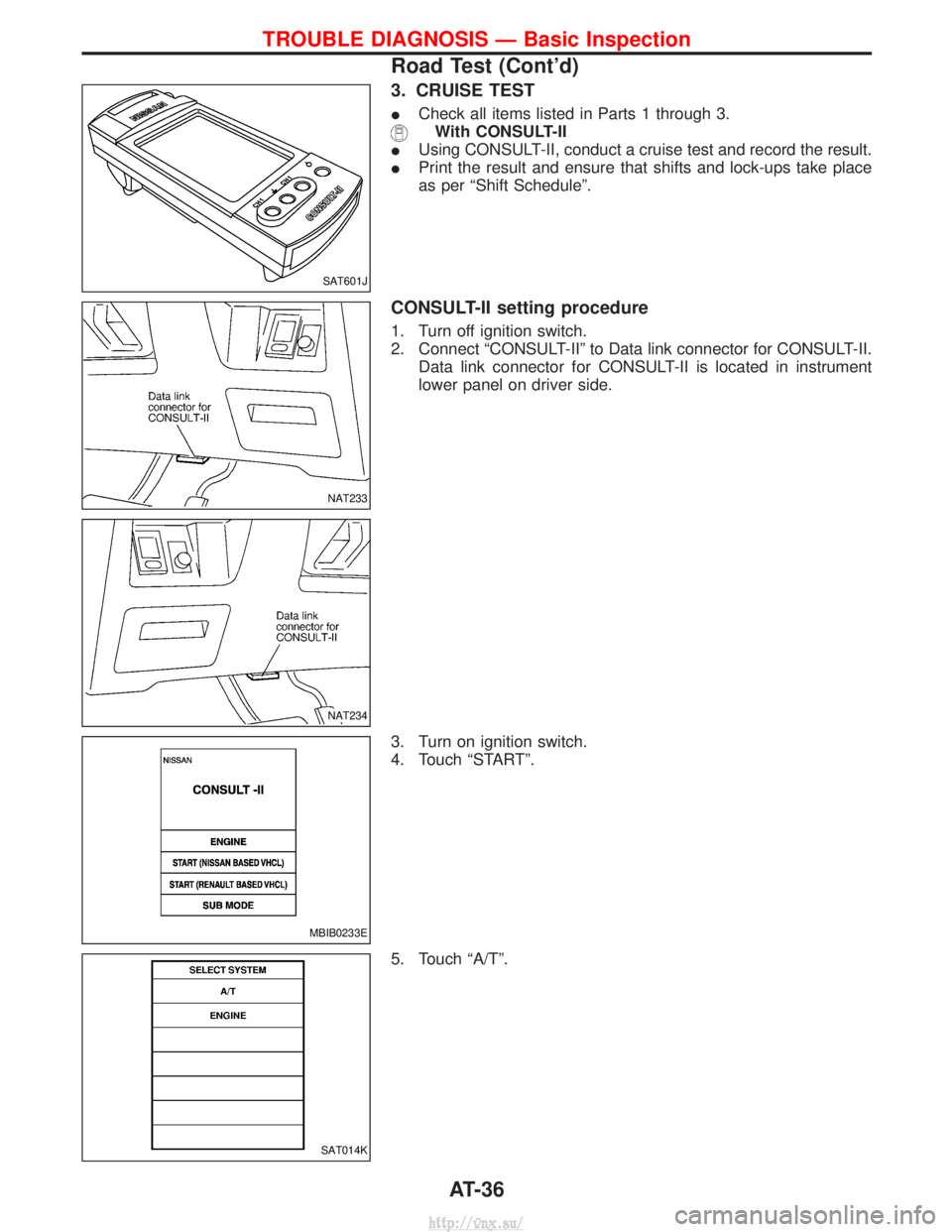

3. CRUISE TEST

ICheck all items listed in Parts 1 through 3.

With CONSULT-II

I Using CONSULT-II, conduct a cruise test and record the result.

I Print the result and ensure that shifts and lock-ups take place

as per ªShift Scheduleº.

CONSULT-II setting procedure

1. Turn off ignition switch.

2. Connect ªCONSULT-IIº to Data link connector for CONSULT-II.

Data link connector for CONSULT-II is located in instrument

lower panel on driver side.

3. Turn on ignition switch.

4. Touch ªSTARTº.

5. Touch ªA/Tº.

SAT601J

NAT233

NAT234

MBIB0233E

SAT014K

TROUBLE DIAGNOSIS Ð Basic Inspection

Road Test (Cont'd)

AT-36

http://vnx.su/

Page 856 of 1833

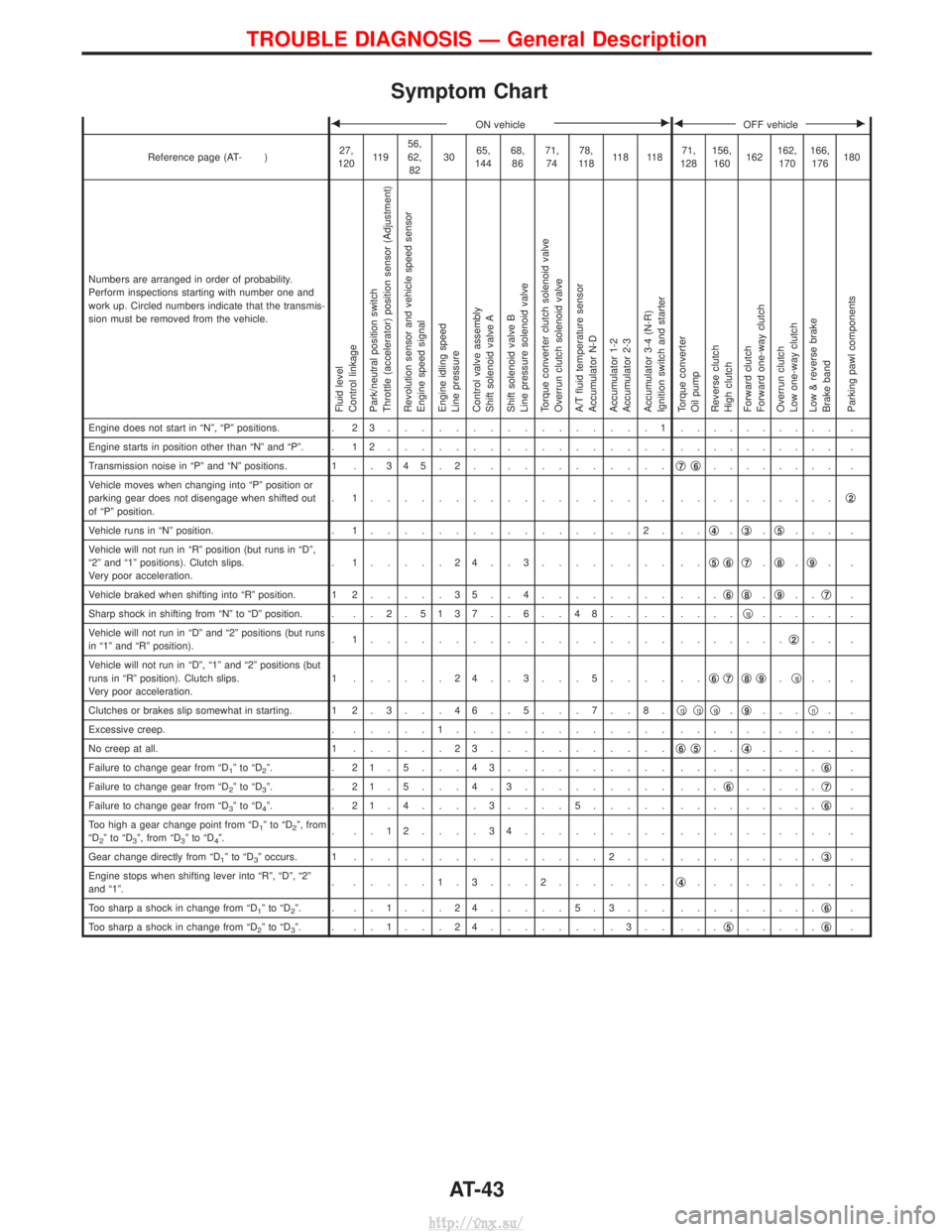

Symptom Chart

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

120 11 9 56,

62,

82 30

65,

144 68,

86 71,

74 78,

11 8 11 8 11 8 71,

128 156,

160 162162,

170 166,

176 180

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Engine does not start in ªNº, ªPº positions. . 2 3................1. ......... .

Engine starts in position other than ªNº and ªPº. . 1 2 ................. . ......... .

Transmission noise in ªPº and ªNº positions. 1 . . 3 4 5 . 2 ............q

7q6........ .

Vehicle moves when changing into ªPº position or

parking gear does not disengage when shifted out

of ªPº position. . 1.................. .

.........q

2

Vehicle runs in ªNº position.

. 1................2. .. q4.q3.q5... .

Vehicle will not run in ªRº position (but runs in ªDº,

ª2º and ª1º positions). Clutch slips.

Very poor acceleration. . 1.....24..3........ ..

q

5q6q7.q8.q9..

Vehicle braked when shifting into ªRº position. 1 2 .....35..4........ ... q

6q8.q9.. q7.

Sharp shock in shifting from ªNº to ªDº position. . . . 2 . 5137 . . 6 . . 48.... ....q

10..... .

Vehicle will not run in ªDº and ª2º positions (but runs

in ª1º and ªRº position). . 1.................. .

......q

2.. .

Vehicle will not run in ªDº, ª1º and ª2º positions (but

runs in ªRº position). Clutch slips.

Very poor acceleration. 1 ......24..3...5.... ..

q

6q7q8q9.q10.. .

Clutches or brakes slip somewhat in starting. 1 2 . 3 . . . 4 6 . . 5 . . . 7 . . 8 . q

13q12q10.q9... q11..

Excessive creep. . .....1............. . ......... .

No creep at all. 1 ......23........... q

6q5..q4..... .

Failure to change gear from ªD

1ºtoªD2º. . 21.5...43.......... . ........q6.

Failure to change gear from ªD

2ºtoªD3º. . 21.5...4.3......... ... q6.....q7.

Failure to change gear from ªD

3ºtoªD4º. . 21.4....3....5..... . ........q6.

Too high a gear change point from ªD

1ºtoªD2º, from

ªD2ºtoªD3º, from ªD3ºtoªD4º. . ..12....34......... .

......... .

Gear change directly from ªD

1ºtoªD3º occurs. 1 ...............2... . ........q3.

Engine stops when shifting lever into ªRº, ªDº, ª2º

and ª1º. . .....1.3...2.......

q

4......... .

Too sharp a shock in change from ªD

1ºtoªD2º. . ..1...24.....5.3... . ........q6.

Too sharp a shock in change from ªD

2ºtoªD3º. . ..1...24........3.. ... q5.....q6.

TROUBLE DIAGNOSIS Ð General Description

AT-43

http://vnx.su/