Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 661 of 1833

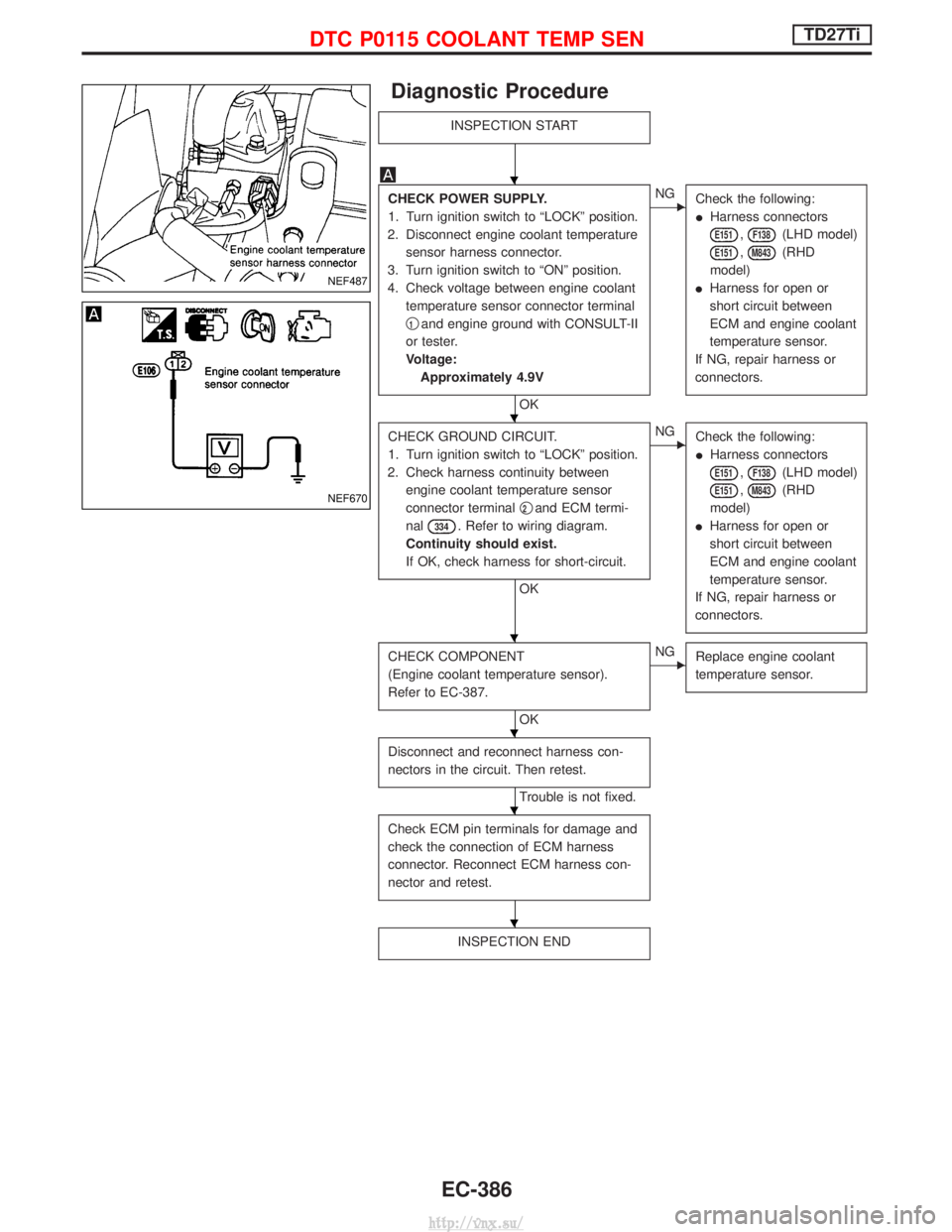

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect engine coolant temperature sensor harness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between engine coolant temperature sensor connector terminal

q

1and engine ground with CONSULT-II

or tester.

Voltage: Approximately 4.9V

OK

ENG Check the following:

IHarness connectors

E151,F138(LHD model)

E151,M843(RHD

model)

I Harness for open or

short circuit between

ECM and engine coolant

temperature sensor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between engine coolant temperature sensor

connector terminal q

2and ECM termi-

nal

334. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness connectors

E151,F138(LHD model)

E151,M843(RHD

model)

I Harness for open or

short circuit between

ECM and engine coolant

temperature sensor.

If NG, repair harness or

connectors.

CHECK COMPONENT

(Engine coolant temperature sensor).

Refer to EC-387.

OK

ENG Replace engine coolant

temperature sensor.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

NEF487

NEF670

H

H

H

H

H

H

DTC P0115 COOLANT TEMP SENTD27Ti

EC-386

http://vnx.su/

Page 663 of 1833

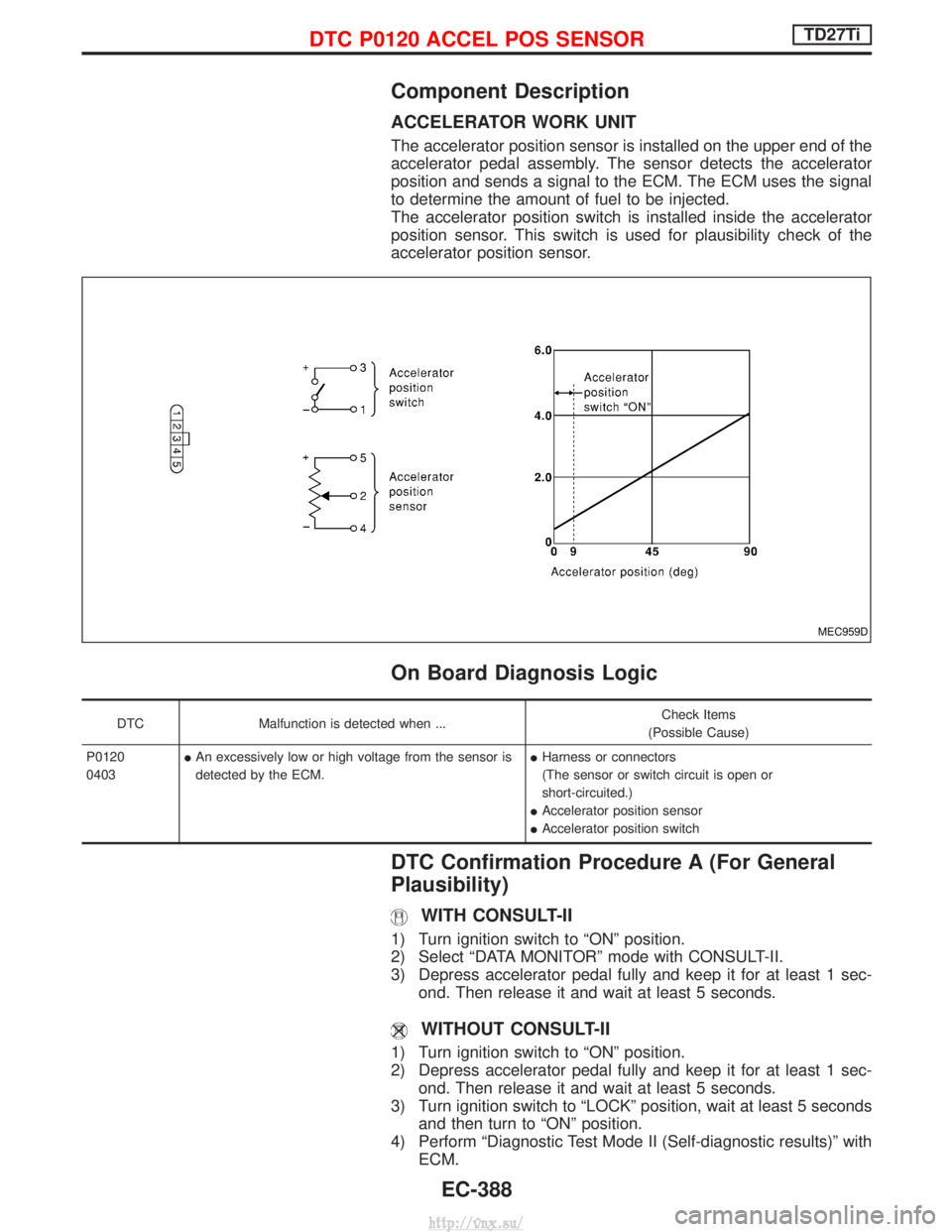

Component Description

ACCELERATOR WORK UNIT

The accelerator position sensor is installed on the upper end of the

accelerator pedal assembly. The sensor detects the accelerator

position and sends a signal to the ECM. The ECM uses the signal

to determine the amount of fuel to be injected.

The accelerator position switch is installed inside the accelerator

position sensor. This switch is used for plausibility check of the

accelerator position sensor.

On Board Diagnosis Logic

DTCMalfunction is detected when ... Check Items

(Possible Cause)

P0120

0403 I

An excessively low or high voltage from the sensor is

detected by the ECM. I

Harness or connectors

(The sensor or switch circuit is open or

short-circuited.)

I Accelerator position sensor

I Accelerator position switch

DTC Confirmation Procedure A (For General

Plausibility)

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Depress accelerator pedal fully and keep it for at least 1 sec-

ond. Then release it and wait at least 5 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch to ªONº position.

2) Depress accelerator pedal fully and keep it for at least 1 sec-ond. Then release it and wait at least 5 seconds.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

MEC959D

DTC P0120 ACCEL POS SENSORTD27Ti

EC-388

http://vnx.su/

Page 664 of 1833

DTC Confirmation Procedure B (For

Accelerator Sticking)

If DTC P0571 is displayed same time, cure it at first.

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and rev it up to above 1,300 rpm.

4) Depress brake pedal immediately after releasing acceleratorpedal and keep it at least 5 seconds.

WITHOUT CONSULT-II

1) Start engine and rev it up to above 1,300 rpm.

2) Depress brake pedal immediately after releasing acceleratorpedal and keep it at least 5 seconds.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

DTC P0120 ACCEL POS SENSORTD27Ti

EC-389

http://vnx.su/

Page 666 of 1833

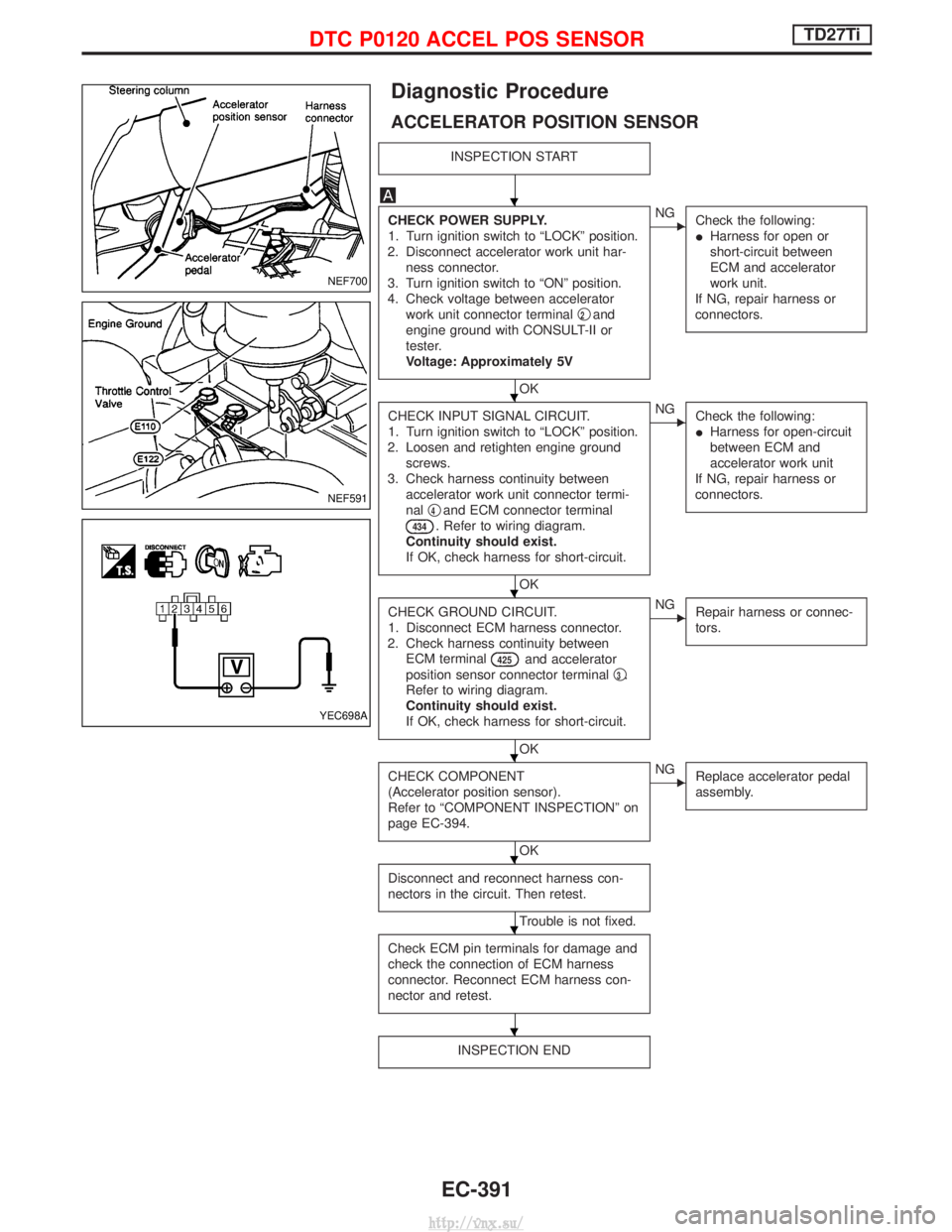

Diagnostic Procedure

ACCELERATOR POSITION SENSOR

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect accelerator work unit har- ness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between accelerator work unit connector terminal q

2and

engine ground with CONSULT-II or

tester.

Voltage: Approximately 5V

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and accelerator

work unit.

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Loosen and retighten engine ground screws.

3. Check harness continuity between accelerator work unit connector termi-

nal q

4and ECM connector terminal

434. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open-circuit

between ECM and

accelerator work unit

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal

425and accelerator

position sensor connector terminal q

3.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Repair harness or connec-

tors.

CHECK COMPONENT

(Accelerator position sensor).

Refer to ªCOMPONENT INSPECTIONº on

page EC-394.

OK

ENGReplace accelerator pedal

assembly.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

NEF700

NEF591

YEC698A

H

H

H

H

H

H

H

DTC P0120 ACCEL POS SENSORTD27Ti

EC-391

http://vnx.su/

Page 667 of 1833

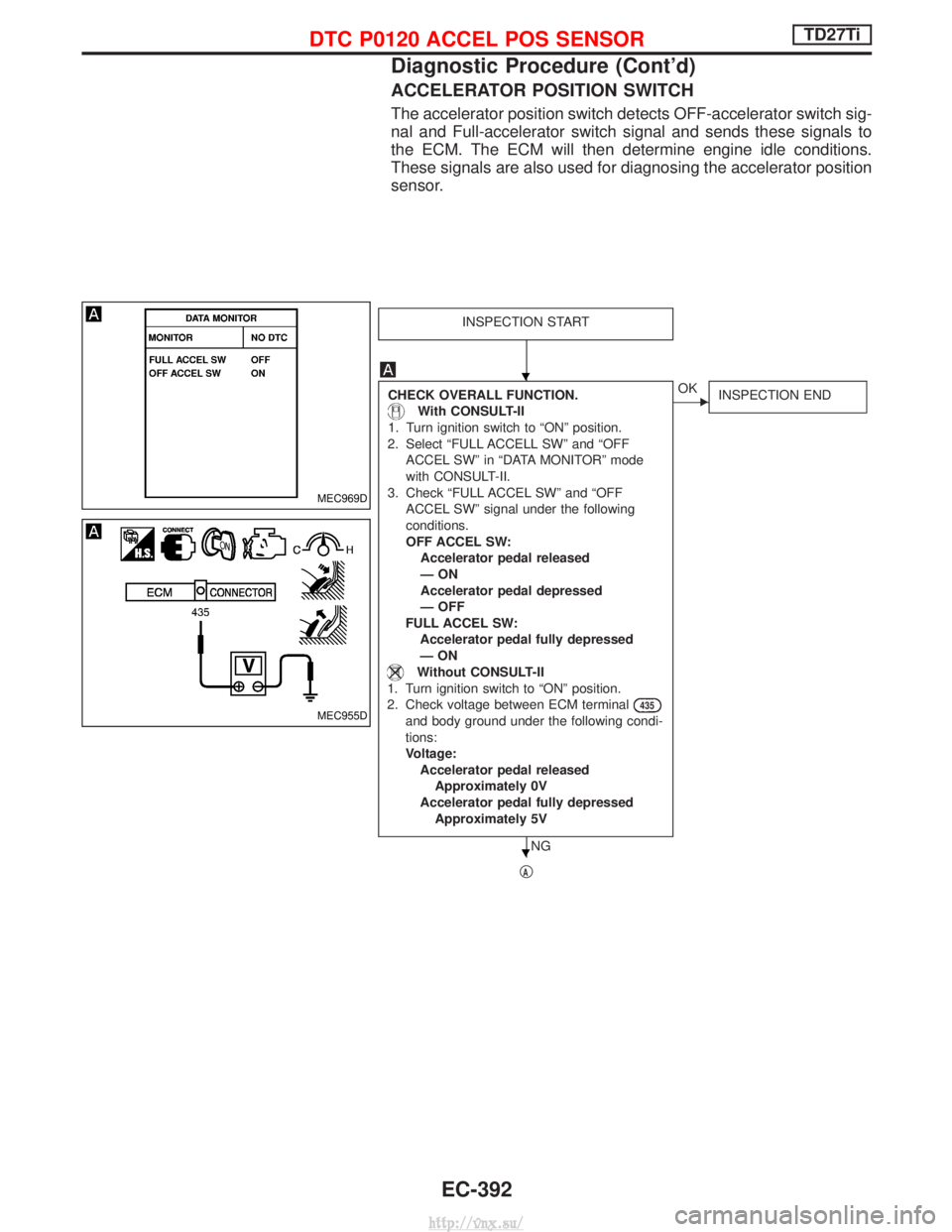

ACCELERATOR POSITION SWITCH

The accelerator position switch detects OFF-accelerator switch sig-

nal and Full-accelerator switch signal and sends these signals to

the ECM. The ECM will then determine engine idle conditions.

These signals are also used for diagnosing the accelerator position

sensor.

INSPECTION START

CHECK OVERALL FUNCTION.

With CONSULT-II

1. Turn ignition switch to ªONº position.

2. Select ªFULL ACCELL SWº and ªOFF ACCEL SWº in ªDATA MONITORº mode

with CONSULT-II.

3. Check ªFULL ACCEL SWº and ªOFF ACCEL SWº signal under the following

conditions.

OFF ACCEL SW:Accelerator pedal released

ÐON

Accelerator pedal depressed

Ð OFF

FULL ACCEL SW: Accelerator pedal fully depressed

ÐON

Without CONSULT-II

1. Turn ignition switch to ªONº position. 2. Check voltage between ECM terminal

435

and body ground under the following condi-

tions:

Voltage: Accelerator pedal releasedApproximately 0V

Accelerator pedal fully depressed Approximately 5V

NG

EOK INSPECTION END

qA

MEC969D

MEC955D

H

H

DTC P0120 ACCEL POS SENSORTD27Ti

Diagnostic Procedure (Cont'd)

EC-392

http://vnx.su/

Page 668 of 1833

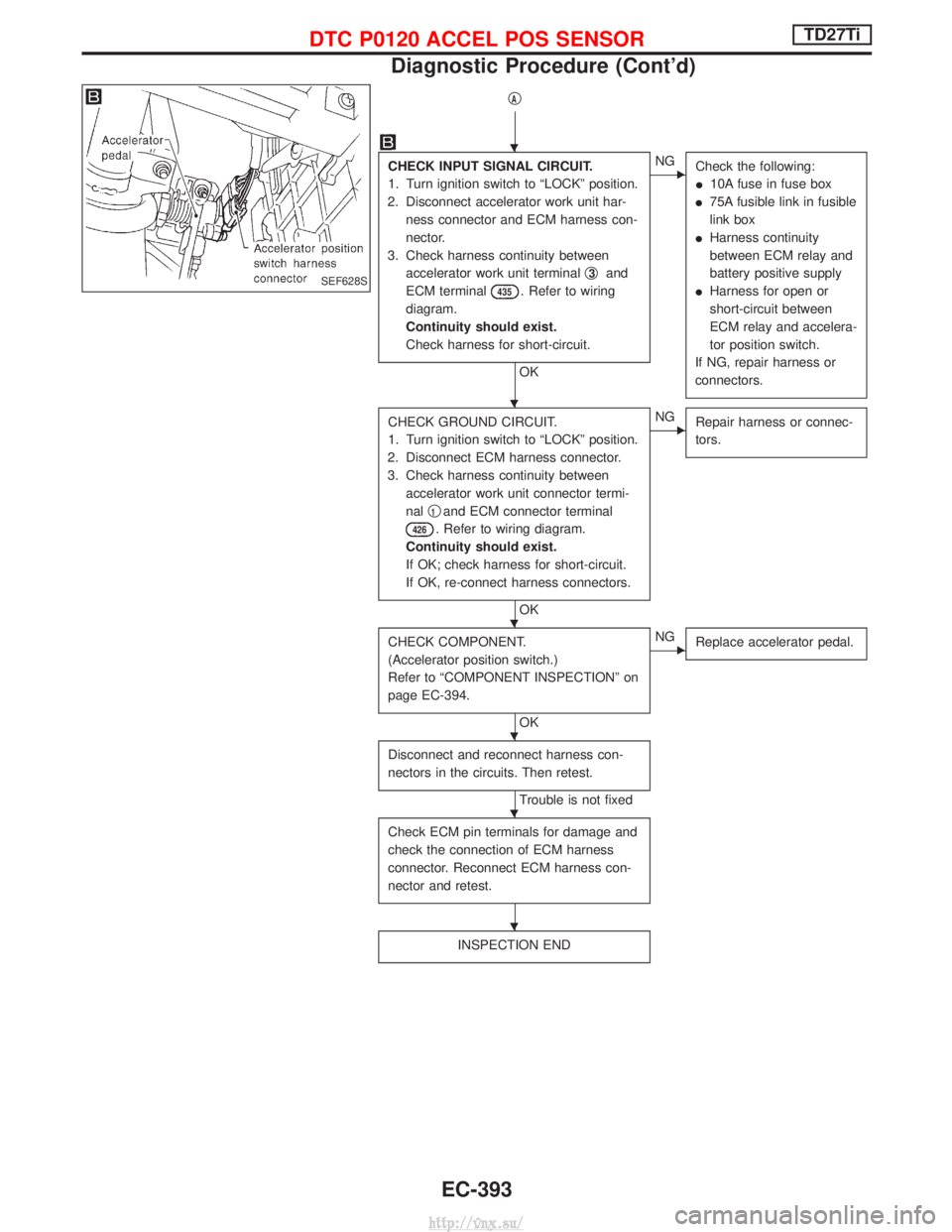

qA

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect accelerator work unit har- ness connector and ECM harness con-

nector.

3. Check harness continuity between accelerator work unit terminal q

3and

ECM terminal

435. Refer to wiring

diagram.

Continuity should exist.

Check harness for short-circuit.

OK

ENG Check the following:

I10A fuse in fuse box

I 75A fusible link in fusible

link box

I Harness continuity

between ECM relay and

battery positive supply

I Harness for open or

short-circuit between

ECM relay and accelera-

tor position switch.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3. Check harness continuity between accelerator work unit connector termi-

nal q

1and ECM connector terminal

426. Refer to wiring diagram.

Continuity should exist.

If OK; check harness for short-circuit.

If OK, re-connect harness connectors.

OK

ENG Repair harness or connec-

tors.

CHECK COMPONENT.

(Accelerator position switch.)

Refer to ªCOMPONENT INSPECTIONº on

page EC-394.

OK

ENGReplace accelerator pedal.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not fixed

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

SEF628S

H

H

H

H

H

H

DTC P0120 ACCEL POS SENSORTD27Ti

Diagnostic Procedure (Cont'd)

EC-393

http://vnx.su/

Page 670 of 1833

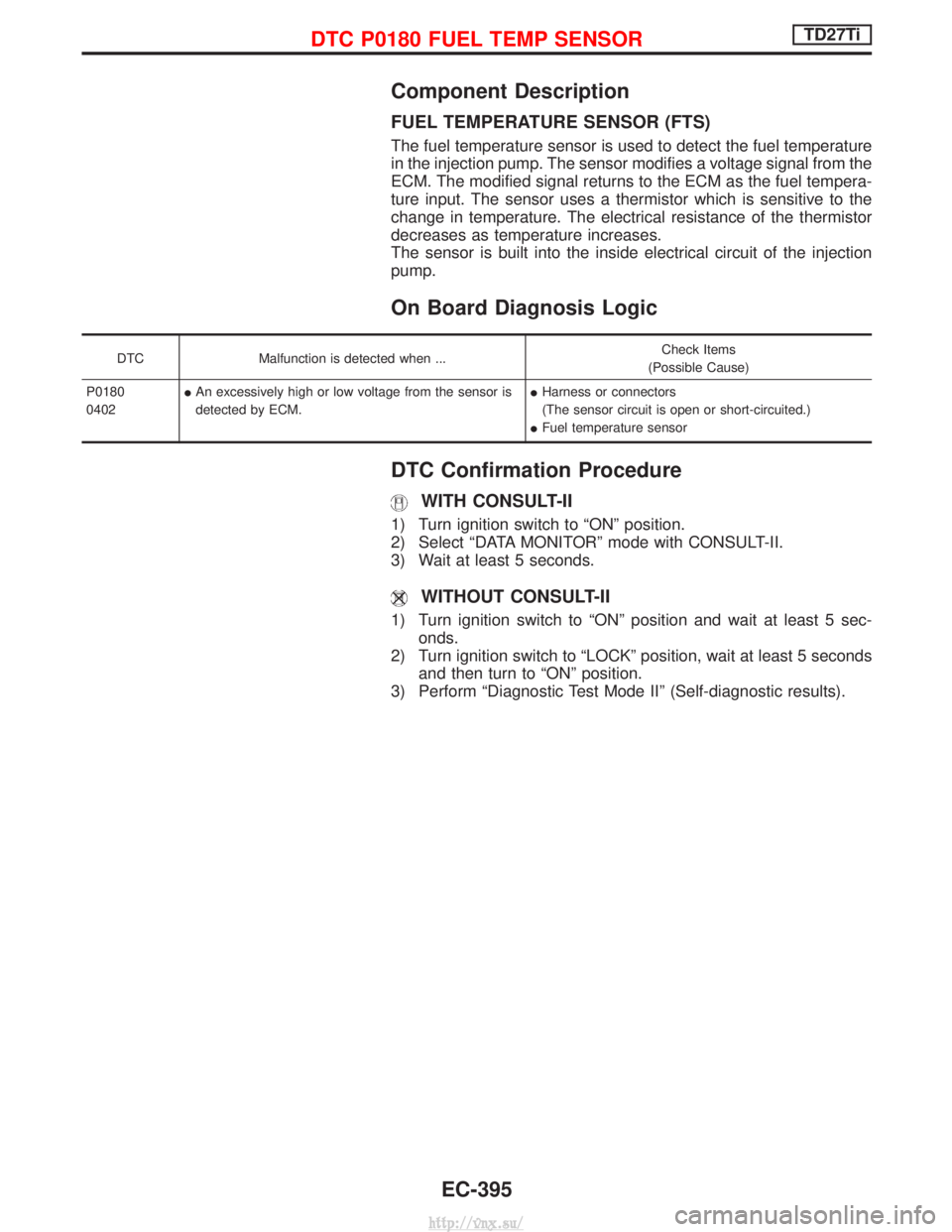

Component Description

FUEL TEMPERATURE SENSOR (FTS)

The fuel temperature sensor is used to detect the fuel temperature

in the injection pump. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the fuel tempera-

ture input. The sensor uses a thermistor which is sensitive to the

change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

The sensor is built into the inside electrical circuit of the injection

pump.

On Board Diagnosis Logic

DTCMalfunction is detected when ... Check Items

(Possible Cause)

P0180

0402 I

An excessively high or low voltage from the sensor is

detected by ECM. I

Harness or connectors

(The sensor circuit is open or short-circuited.)

I Fuel temperature sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch to ªONº position and wait at least 5 sec-

onds.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

DTC P0180 FUEL TEMP SENSORTD27Ti

EC-395

http://vnx.su/

Page 672 of 1833

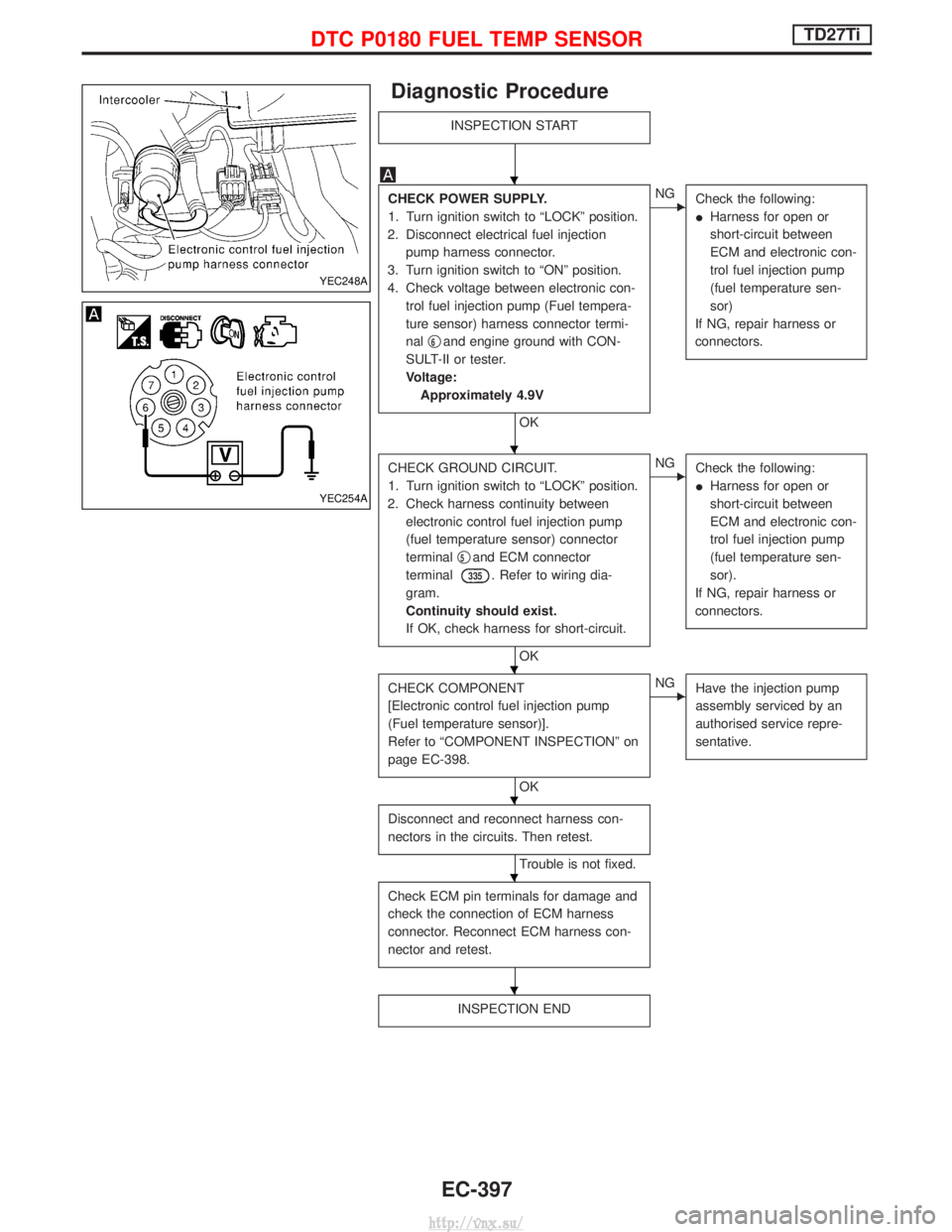

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect electrical fuel injection pump harness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between electronic con- trol fuel injection pump (Fuel tempera-

ture sensor) harness connector termi-

nal q

6and engine ground with CON-

SULT-II or tester.

Voltage: Approximately 4.9V

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and electronic con-

trol fuel injection pump

(fuel temperature sen-

sor)

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between electronic control fuel injection pump

(fuel temperature sensor) connector

terminal q

5and ECM connector

terminal

335. Refer to wiring dia-

gram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and electronic con-

trol fuel injection pump

(fuel temperature sen-

sor).

If NG, repair harness or

connectors.

CHECK COMPONENT

[Electronic control fuel injection pump

(Fuel temperature sensor)].

Refer to ªCOMPONENT INSPECTIONº on

page EC-398.

OK

ENG Have the injection pump

assembly serviced by an

authorised service repre-

sentative.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

YEC248A

YEC254A

H

H

H

H

H

H

DTC P0180 FUEL TEMP SENSORTD27Ti

EC-397

http://vnx.su/

Page 674 of 1833

Component Description

FUEL CUT SOLENOID VALVE

When the ignition switch is off, the ECM turns the fuel cut solenoid

valve OFF (under this condition, no current flows through the fuel

cut solenoid valve), shutting off fuel supply.

When the engine is not operating due to trouble, the fuel cut sole-

noid valve may or may not be OFF even when the ignition switch

is ON.

On Board Diagnosis Logic

DTCMalfunction is detected when ... Check Items

(Possible Cause)

P0125

0306 I

Fuel cut solenoid valve circuit is malfunctioning. IHarness or connectors

(The solenoid valve circuit is open or shorted.)

I Fuel cut solenoid valve

DTC Confirmation Procedure

NOTE:

If DTC P0115 or P0335 is displayed same time, perform trouble

diagnosis for P0115 or P0335 first.

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine. (If no start, circuit is open.)

4) Warm it up sufficiently.

5) Turn ignition switch to ªLOCKº position, wait at least 5 seconds.

6) Start engine and rev it up to above 1,300 rpm. Release pedal

and wait at least 3 seconds.

WITHOUT CONSULT-II

1) Start engine. (If no start, circuit is open.)

2) Warm it up sufficiently.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds.

4) Start engine and rev it up to above 1,300 rpm. Release pedaland wait at least 3 seconds.

5) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

6) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF667S

DTC P0215 FUEL CUT S/V 1TD27Ti

EC-399

http://vnx.su/

Page 676 of 1833

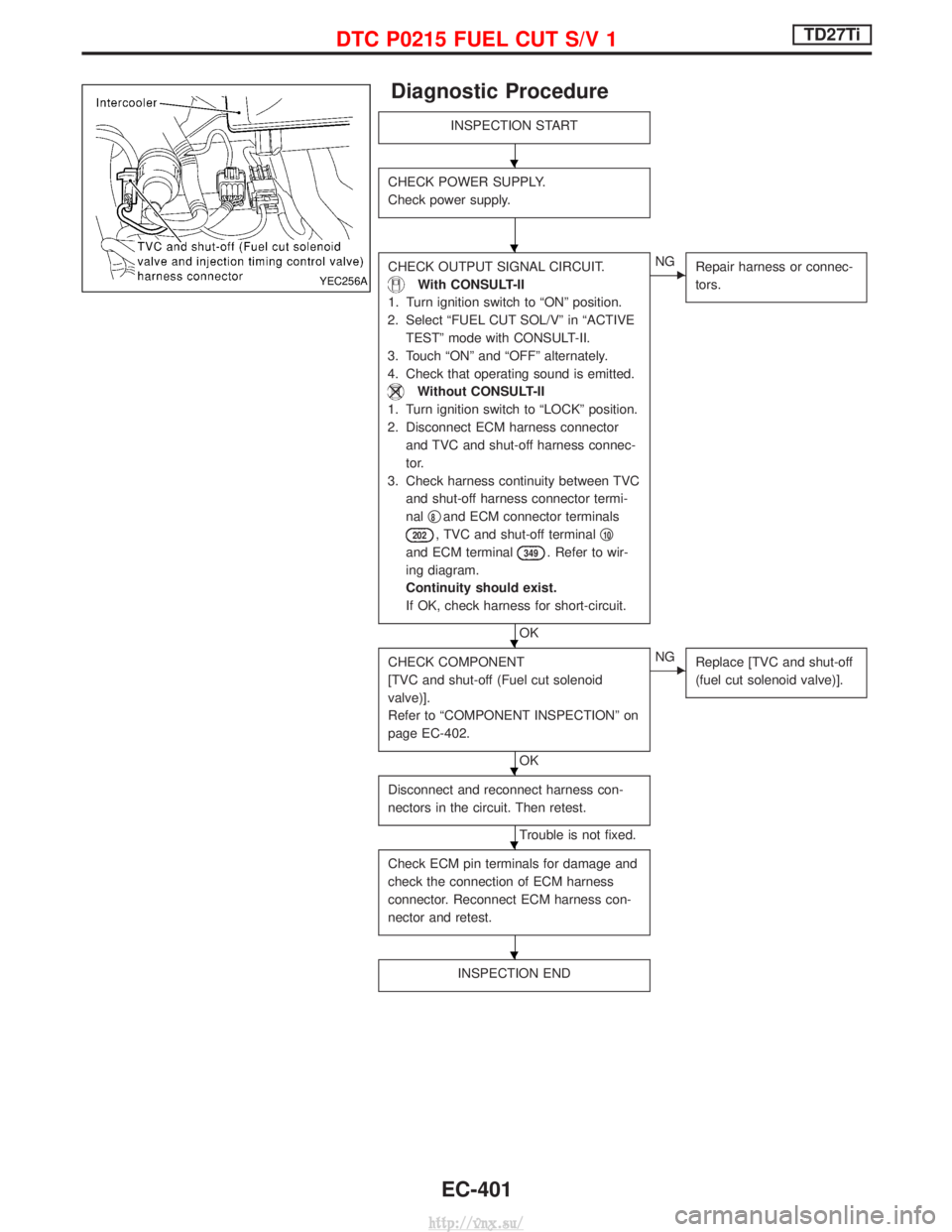

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY.

Check power supply.

CHECK OUTPUT SIGNAL CIRCUIT.

With CONSULT-II

1. Turn ignition switch to ªONº position.

2. Select ªFUEL CUT SOL/Vº in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªONº and ªOFFº alternately.

4. Check that operating sound is emitted.

Without CONSULT-II

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector and TVC and shut-off harness connec-

tor.

3. Check harness continuity between TVC and shut-off harness connector termi-

nal q

8and ECM connector terminals

202, TVC and shut-off terminal q10

and ECM terminal349. Refer to wir-

ing diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Repair harness or connec-

tors.

CHECK COMPONENT

[TVC and shut-off (Fuel cut solenoid

valve)].

Refer to ªCOMPONENT INSPECTIONº on

page EC-402.

OK

ENGReplace [TVC and shut-off

(fuel cut solenoid valve)].

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

YEC256A

H

H

H

H

H

H

DTC P0215 FUEL CUT S/V 1TD27Ti

EC-401

http://vnx.su/