Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1237 of 1833

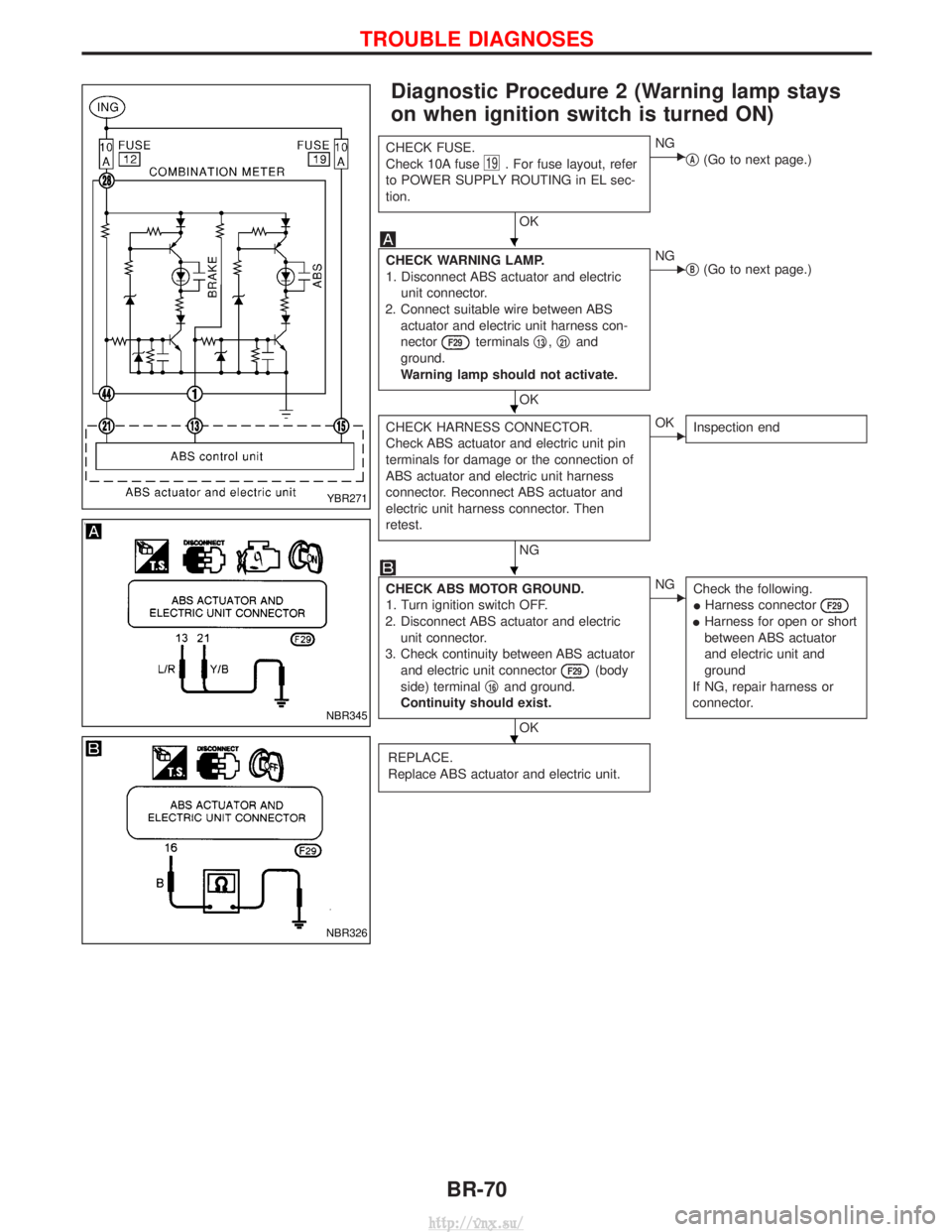

Diagnostic Procedure 2 (Warning lamp stays

on when ignition switch is turned ON)

CHECK FUSE.

Check 10A fuse

19. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

ENG qA(Go to next page.)

CHECK WARNING LAMP.

1. Disconnect ABS actuator and electric

unit connector.

2. Connect suitable wire between ABS actuator and electric unit harness con-

nector

F29terminals q13,q21and

ground.

Warning lamp should not activate.

OK

ENG qB(Go to next page.)

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

NG

EOK Inspection end

CHECK ABS MOTOR GROUND.

1. Turn ignition switch OFF.

2. Disconnect ABS actuator and electric unit connector.

3. Check continuity between ABS actuator and electric unit connector

F29(body

side) terminal q

16and ground.

Continuity should exist.

OK

ENG Check the following.

IHarness connector

F29

IHarness for open or short

between ABS actuator

and electric unit and

ground

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

YBR271

NBR345

NBR326

H

H

H

H

TROUBLE DIAGNOSES

BR-70

http://vnx.su/

Page 1238 of 1833

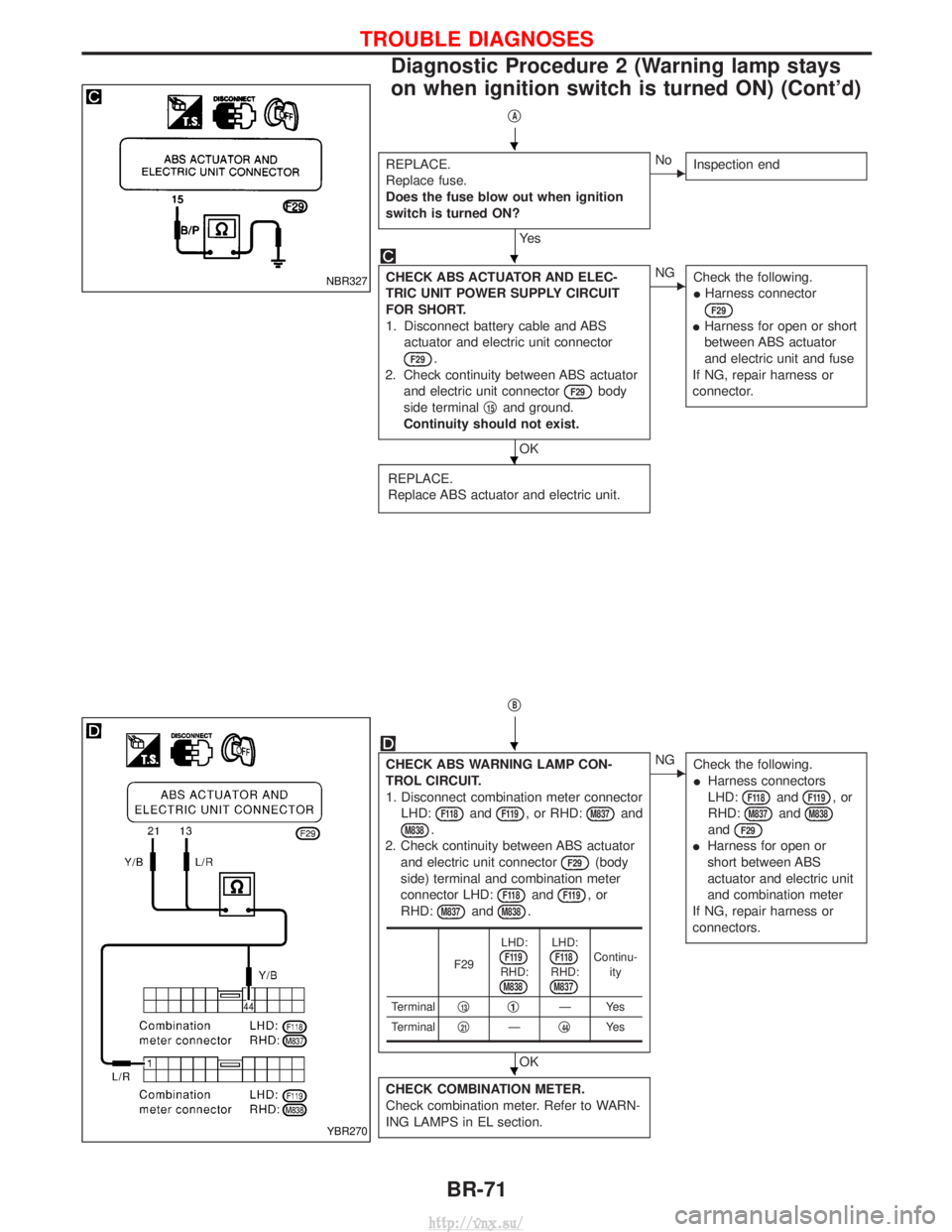

qA

REPLACE.

Replace fuse.

Does the fuse blow out when ignition

switch is turned ON?

Ye s

ENoInspection end

CHECK ABS ACTUATOR AND ELEC-

TRIC UNIT POWER SUPPLY CIRCUIT

FOR SHORT.

1. Disconnect battery cable and ABS

actuator and electric unit connector

F29.

2. Check continuity between ABS actuator and electric unit connector

F29body

side terminal q

15and ground.

Continuity should not exist.

OK

ENG Check the following.

IHarness connector

F29

IHarness for open or short

between ABS actuator

and electric unit and fuse

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

qB

CHECK ABS WARNING LAMP CON-

TROL CIRCUIT.

1. Disconnect combination meter connector LHD:

F118andF119, or RHD:M837and

M838.

2. Check continuity between ABS actuator and electric unit connector

F29(body

side) terminal and combination meter

connector LHD:

F118andF119,or

RHD:

M837andM838.

OK

ENG Check the following.

IHarness connectors

LHD:

F118andF119,or

RHD:

M837andM838

andF29

I Harness for open or

short between ABS

actuator and electric unit

and combination meter

If NG, repair harness or

connectors.

CHECK COMBINATION METER.

Check combination meter. Refer to WARN-

ING LAMPS in EL section.

F29 LHD:F119RHD:M838

LHD:F118RHD:M837

Continu-

ity

Terminal q

13q1ÐYes

Terminal q

21Ðq44Ye s

NBR327

YBR270

H

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Warning lamp stays

on when ignition switch is turned ON) (Cont'd)

BR-71

http://vnx.su/

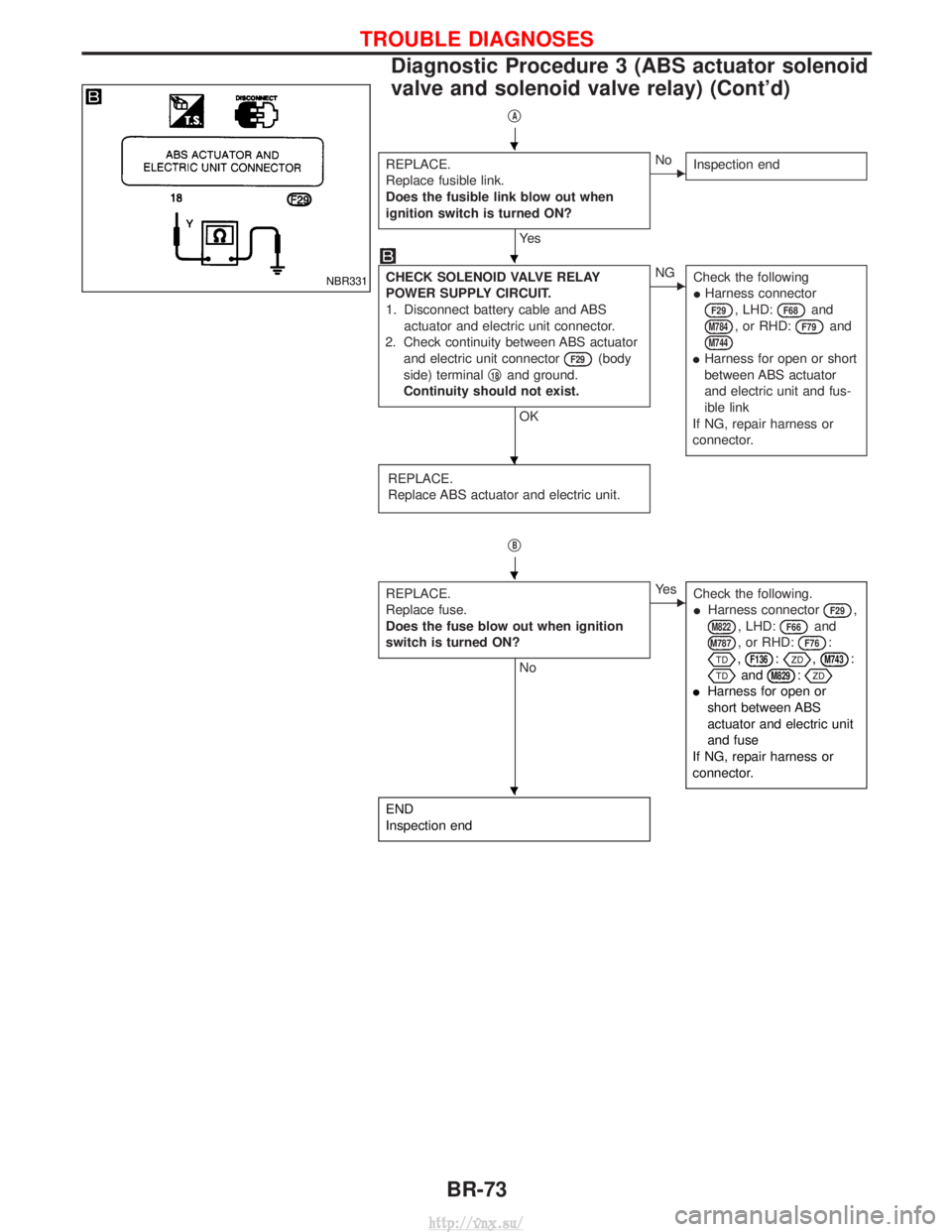

Page 1240 of 1833

qA

REPLACE.

Replace fusible link.

Does the fusible link blow out when

ignition switch is turned ON?

Ye s

ENoInspection end

CHECK SOLENOID VALVE RELAY

POWER SUPPLY CIRCUIT.

1. Disconnect battery cable and ABS

actuator and electric unit connector.

2. Check continuity between ABS actuator and electric unit connector

F29(body

side) terminal q

18and ground.

Continuity should not exist.

OK

ENG Check the following

IHarness connector

F29, LHD:F68and

M784, or RHD:F79and

M744

IHarness for open or short

between ABS actuator

and electric unit and fus-

ible link

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

qB

REPLACE.

Replace fuse.

Does the fuse blow out when ignition

switch is turned ON?

No

EYe s Check the following.

IHarness connector

F29,

M822, LHD:F66and

M787, or RHD:F76:

,F136:,M743:

andM829:

IHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

END

Inspection end

NBR331

H

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay) (Cont'd)

BR-73

http://vnx.su/

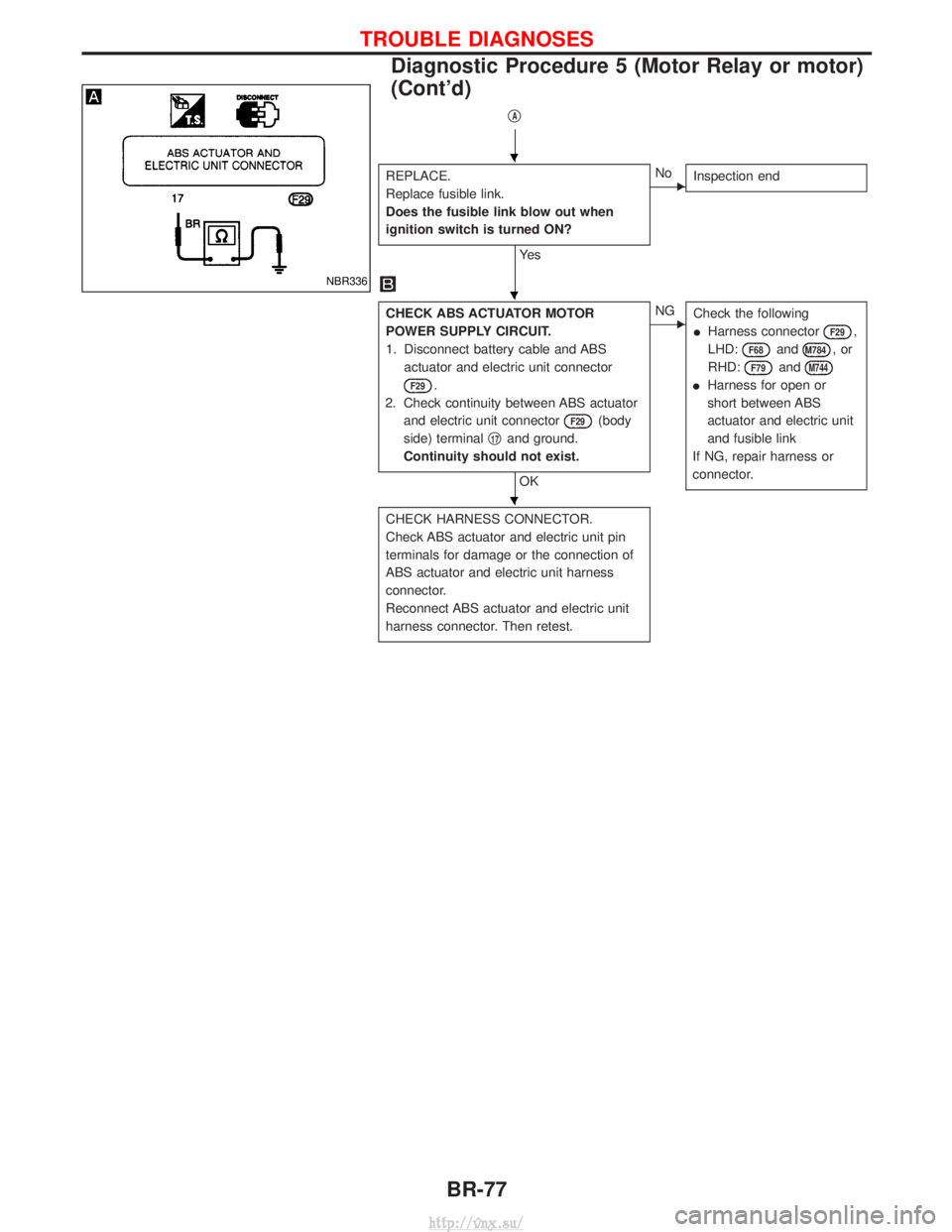

Page 1244 of 1833

qA

REPLACE.

Replace fusible link.

Does the fusible link blow out when

ignition switch is turned ON?

Ye s

ENoInspection end

CHECK ABS ACTUATOR MOTOR

POWER SUPPLY CIRCUIT.

1. Disconnect battery cable and ABS

actuator and electric unit connector

F29.

2. Check continuity between ABS actuator and electric unit connector

F29(body

side) terminal q

17and ground.

Continuity should not exist.

OK

ENG Check the following

IHarness connector

F29,

LHD:

F68andM784,or

RHD:

F79andM744

I Harness for open or

short between ABS

actuator and electric unit

and fusible link

If NG, repair harness or

connector.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

NBR336

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 5 (Motor Relay or motor)

(Cont'd)

BR-77

http://vnx.su/

Page 1245 of 1833

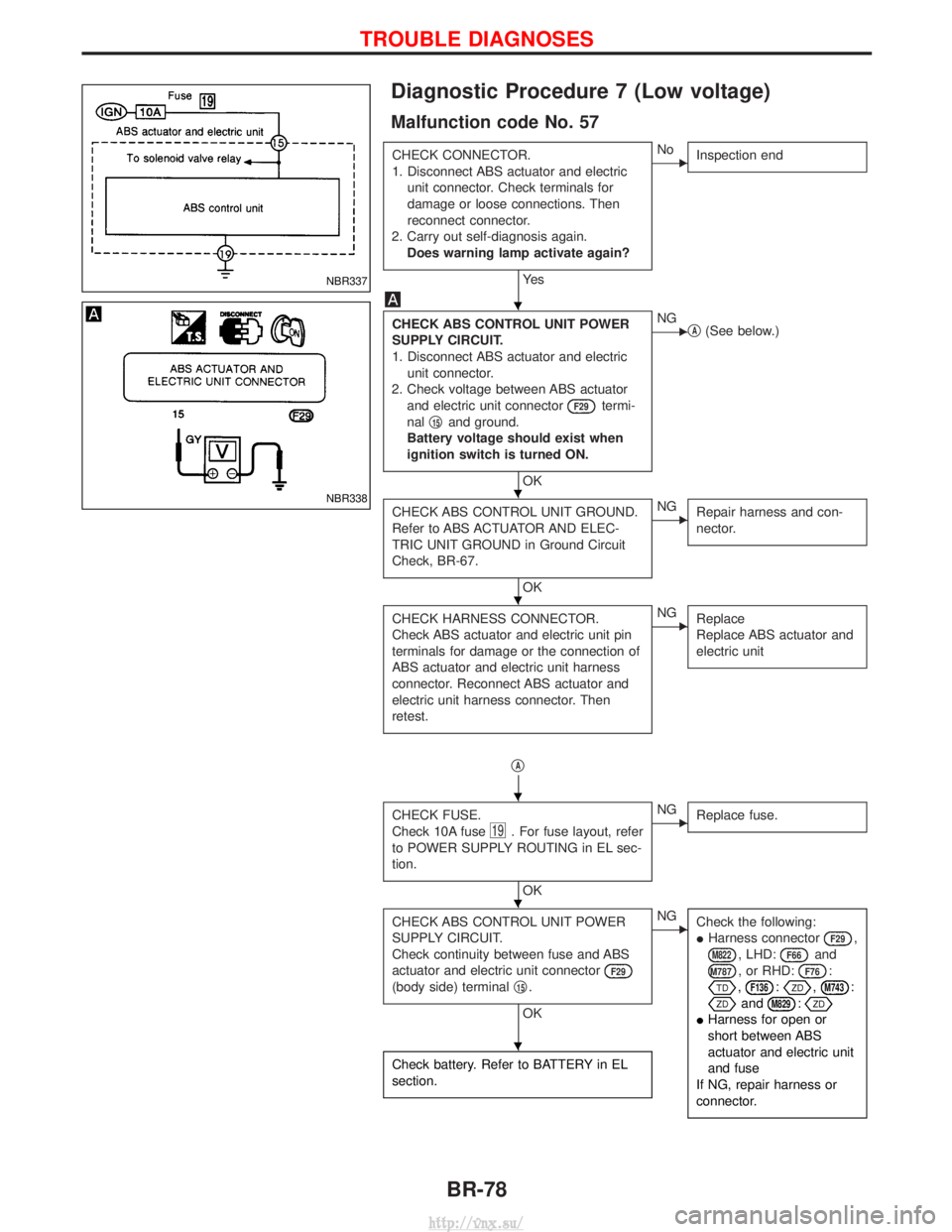

Diagnostic Procedure 7 (Low voltage)

Malfunction code No. 57

CHECK CONNECTOR.

1. Disconnect ABS actuator and electricunit connector. Check terminals for

damage or loose connections. Then

reconnect connector.

2. Carry out self-diagnosis again. Does warning lamp activate again?

Ye s

ENo Inspection end

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT.

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator and electric unit connector

F29termi-

nal q

15and ground.

Battery voltage should exist when

ignition switch is turned ON.

OK

ENG qA(See below.)

CHECK ABS CONTROL UNIT GROUND.

Refer to ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND in Ground Circuit

Check, BR-67.

OK

ENG Repair harness and con-

nector.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.ENGReplace

Replace ABS actuator and

electric unit

qA

CHECK FUSE.

Check 10A fuse

19. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

ENG Replace fuse.

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT.

Check continuity between fuse and ABS

actuator and electric unit connector

F29

(body side) terminal q15.

OK

ENG

Check the following:

IHarness connector

F29,

M822, LHD:F66and

M787, or RHD:F76:

,F136:,M743:

andM829:

IHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

Check battery. Refer to BATTERY in EL

section.

NBR337

NBR338

H

H

H

H

H

H

TROUBLE DIAGNOSES

BR-78

http://vnx.su/

Page 1255 of 1833

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for SRS ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº Service

IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

I Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

I Diagnosis sensor unit must always be installed with their arrow marks ª +º pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

I The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

I Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module (built-in type) standing with stud bolt side setting

bottom.

I Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

I After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Precautions for Steering System

IBefore disassembly, thoroughly clean the outside of the unit.

I Disassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

I When disassembling parts, be sure to place them in order on a part rack so they can be reinstalled

in their proper positions.

I Use nylon cloths or paper towels to clean the parts; common shop rags can leave lint that might

interfere with their operation.

I Before inspection or reassembly, carefully clean all parts with a general purpose, non-flammable

solvent.

I Before assembly, apply a coat of recommended ATF* to hydraulic parts. Vaseline may be applied

to O-rings and seals. Do not use any grease.

I Replace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during instal-

lation. Perform functional tests whenever designated.

*: Automatic transmission fluid

PRECAUTIONS

ST-2

http://vnx.su/

Page 1277 of 1833

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precaution for Seat Belt Service

CAUTION:

IBefore removing the seat belt pre-tensioner assembly, turn the ignition switch off, disconnect both

battery cables and wait at least 3 minutes.

I Do not use electrical test equipment for seat belt pre-tensioner connector.

I After replacing or reinstalling seat belt pre-tensioner assembly, or reconnecting seat belt pre-ten-

sioner connector, check the system function. Refer to ªSRS Operation Checkº for details. (RS-38)

I Do not disassemble buckle or seat belt assembly.

I Replace anchor bolts if they are deformed or worn out.

I Never oil tongue and buckle.

I If any component of seat belt assembly is questionable, do not repair. Replace the whole seat belt

assembly.

I If webbing is cut, frayed, or damaged, replace seat belt assembly.

I When replacing seat belt assembly, use a genuine seat belt assembly.

After A Collision

WARNING:

Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an accident. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or improper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly if:

IThe seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

I The seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide, etc.)

I The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for dam-

age or distortion and repair as necessary before installing a new seat belt assembly.

I Anchor bolts are deformed or worn out.

SEAT BELTS

RS-2

http://vnx.su/

Page 1283 of 1833

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL R20 is as follows (The composition

varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS FOR SRS ªAIR BAGº AND ªSEAT BELT PRE-TENSIONERº SERVICE

IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

I Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

I Diagnosis sensor unit must always be installed with their arrow marks ª +º pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

I The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

I Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module (built-in type) standing with stud bolt side setting

bottom.

I Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

I After air bag inflates, the front instrument panel assembly should be replaced if damaged.

WIRING DIAGRAMS AND TROUBLE DIAGNOSIS

When you read wiring diagrams, refer to the following:

IGI-10, ªHOW TO READ WIRING DIAGRAMSº

I EL-8, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

I GI-25, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSISº

I GI-22, ªHOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENTº

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-8

http://vnx.su/

Page 1285 of 1833

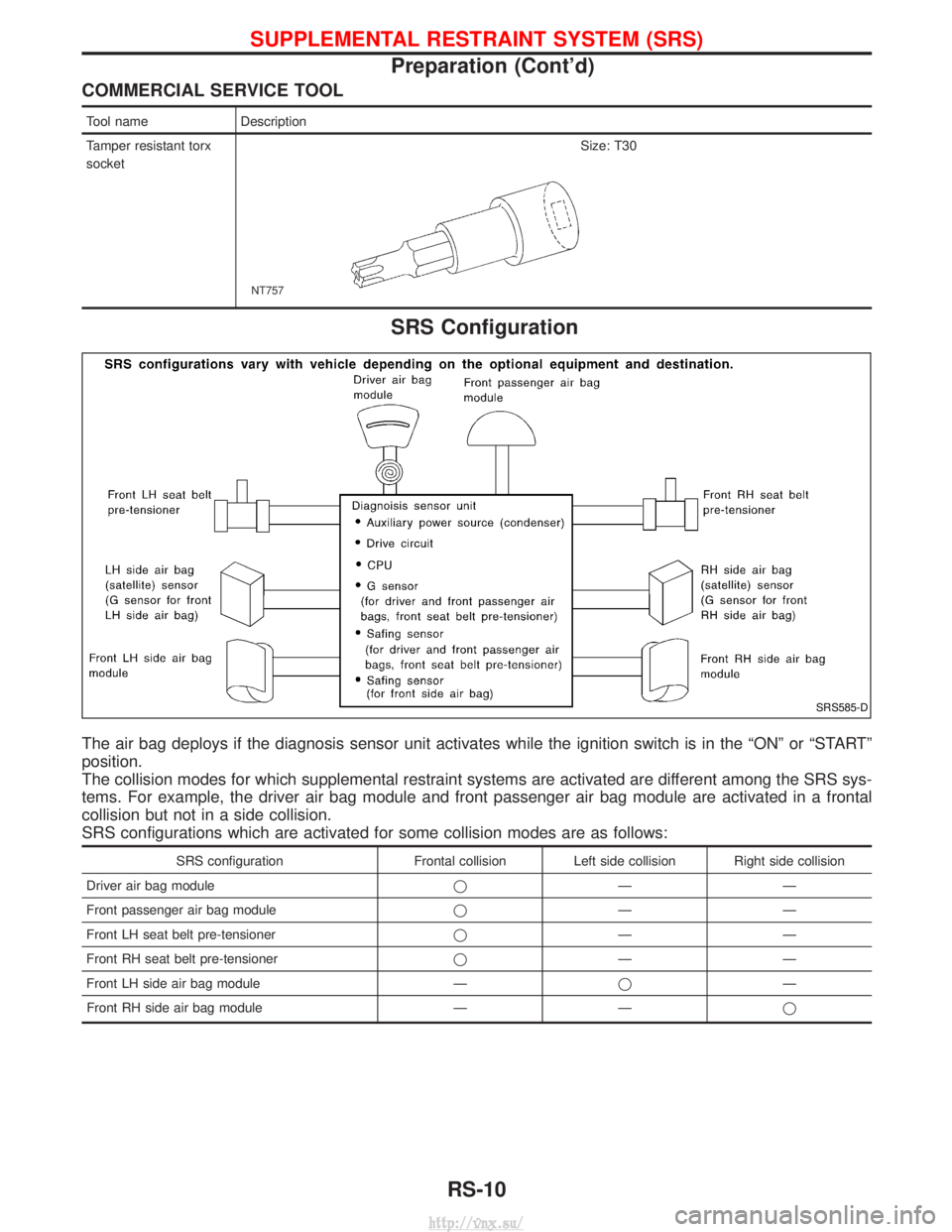

COMMERCIAL SERVICE TOOL

Tool nameDescription

Tamper resistant torx

socket

NT757

Size: T30

SRS Configuration

The air bag deploys if the diagnosis sensor unit activates while the ignition switch is in the ªONº or ªSTARTº

position.

The collision modes for which supplemental restraint systems are activated are different among the SRS sys-

tems. For example, the driver air bag module and front passenger air bag module are activated in a frontal

collision but not in a side collision.

SRS configurations which are activated for some collision modes are as follows:

SRS configuration Frontal collisionLeft side collision Right side collision

Driver air bag module qÐÐ

Front passenger air bag module qÐÐ

Front LH seat belt pre-tensioner qÐÐ

Front RH seat belt pre-tensioner qÐÐ

Front LH side air bag module Ð qÐ

Front RH side air bag module Ð Ð q

SRS585-D

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Preparation (Cont'd)

RS-10

http://vnx.su/

Page 1287 of 1833

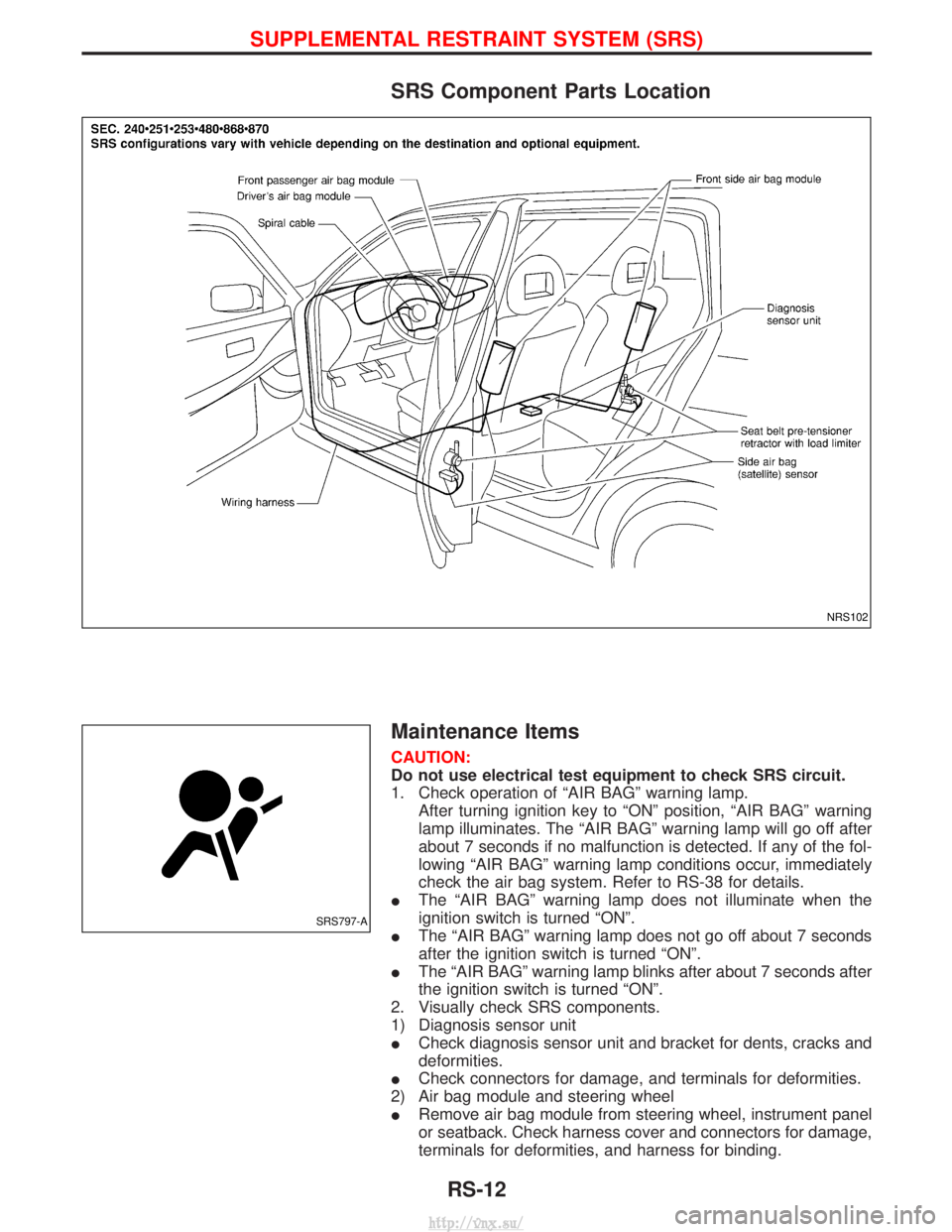

SRS Component Parts Location

Maintenance Items

CAUTION:

Do not use electrical test equipment to check SRS circuit.

1. Check operation of ªAIR BAGº warning lamp.After turning ignition key to ªONº position, ªAIR BAGº warning

lamp illuminates. The ªAIR BAGº warning lamp will go off after

about 7 seconds if no malfunction is detected. If any of the fol-

lowing ªAIR BAGº warning lamp conditions occur, immediately

check the air bag system. Refer to RS-38 for details.

I The ªAIR BAGº warning lamp does not illuminate when the

ignition switch is turned ªONº.

I The ªAIR BAGº warning lamp does not go off about 7 seconds

after the ignition switch is turned ªONº.

I The ªAIR BAGº warning lamp blinks after about 7 seconds after

the ignition switch is turned ªONº.

2. Visually check SRS components.

1) Diagnosis sensor unit

I Check diagnosis sensor unit and bracket for dents, cracks and

deformities.

I Check connectors for damage, and terminals for deformities.

2) Air bag module and steering wheel

I Remove air bag module from steering wheel, instrument panel

or seatback. Check harness cover and connectors for damage,

terminals for deformities, and harness for binding.

NRS102

SRS797-A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-12

http://vnx.su/