Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1331 of 1833

DIAGNOSTIC PROCEDURE 8 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 6)

Inspecting SRS malfunctioning record

1 CONSIDER POSSIBILITY OF NOT ERASING SELF-DIAGNOSTIC RESULT AFTER REPAIRING

Is it the first time for maintenance of SRS?YesorNo

Ye s EGo to DIAGNOSTIC PROCEDURE 5 (RS-44). (Further inspection cannot be performed without CONSULT-II.)

No EDiagnosis results (previously stored in the memory) might not be erased after repair. Go to DIAGNOSTIC PRO-

CEDURE 7, step 5 (RS-53).

Trouble Diagnoses: ªAIR BAGº Warning Lamp

Does Not Turn Off

DIAGNOSTIC PROCEDURE 9

1 SEE THE DEPLOYMENT OF AIR BAG MODULE

Is air bag module deployed?

YesorNo

Ye s ERefer to COLLISION DIAGNOSIS (RS-59).

No EGO TO 2.

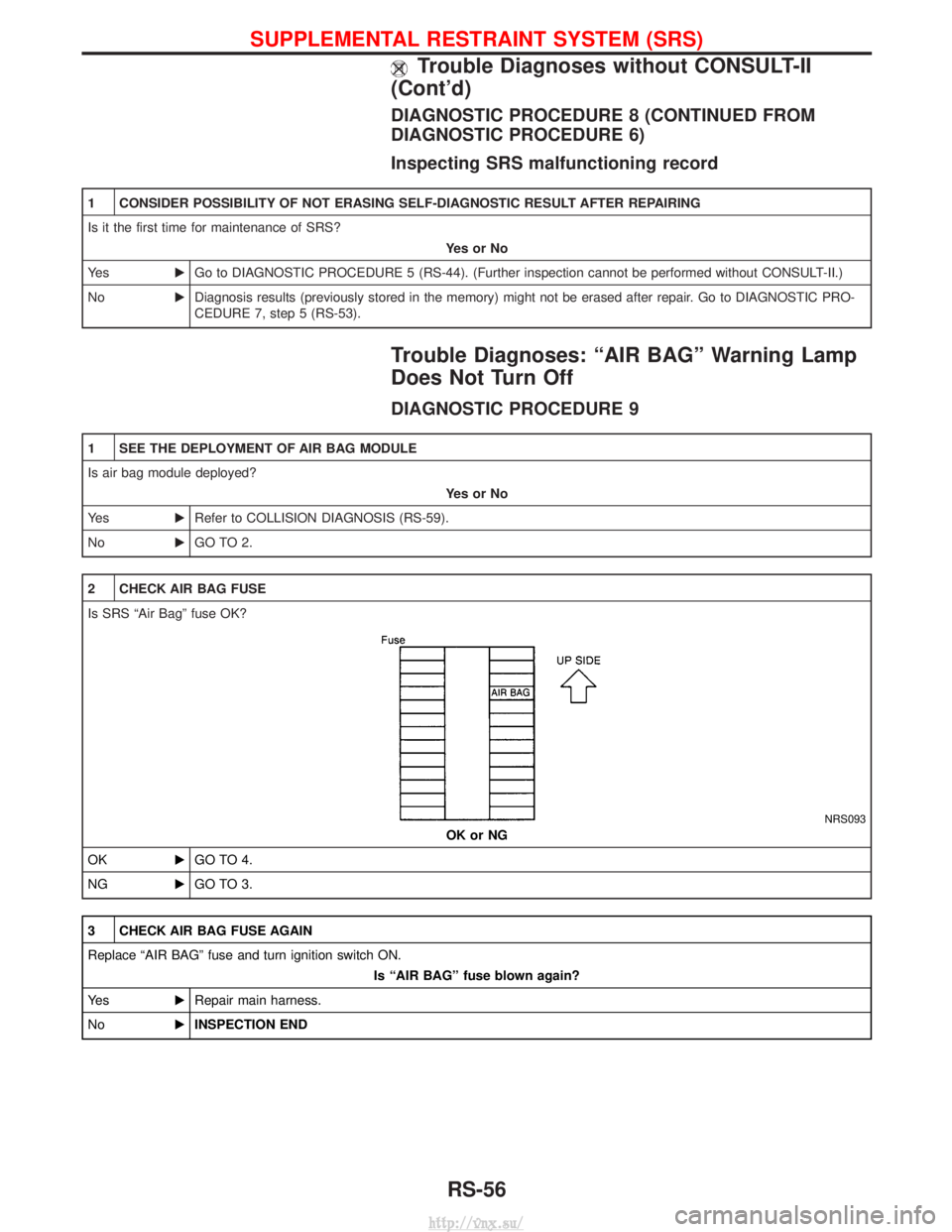

2 CHECK AIR BAG FUSE

Is SRS ªAir Bagº fuse OK?

NRS093

OK or NG

OK EGO TO 4.

NG EGO TO 3.

3 CHECK AIR BAG FUSE AGAIN

Replace ªAIR BAGº fuse and turn ignition switch ON.

Is ªAIR BAGº fuse blown again?

Ye s ERepair main harness.

No EINSPECTION END

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II

(Cont'd)

RS-56

http://vnx.su/

Page 1333 of 1833

Trouble Diagnoses: ªAIR BAGº Warning Lamp

Does Not Turn On

DIAGNOSTIC PROCEDURE 10

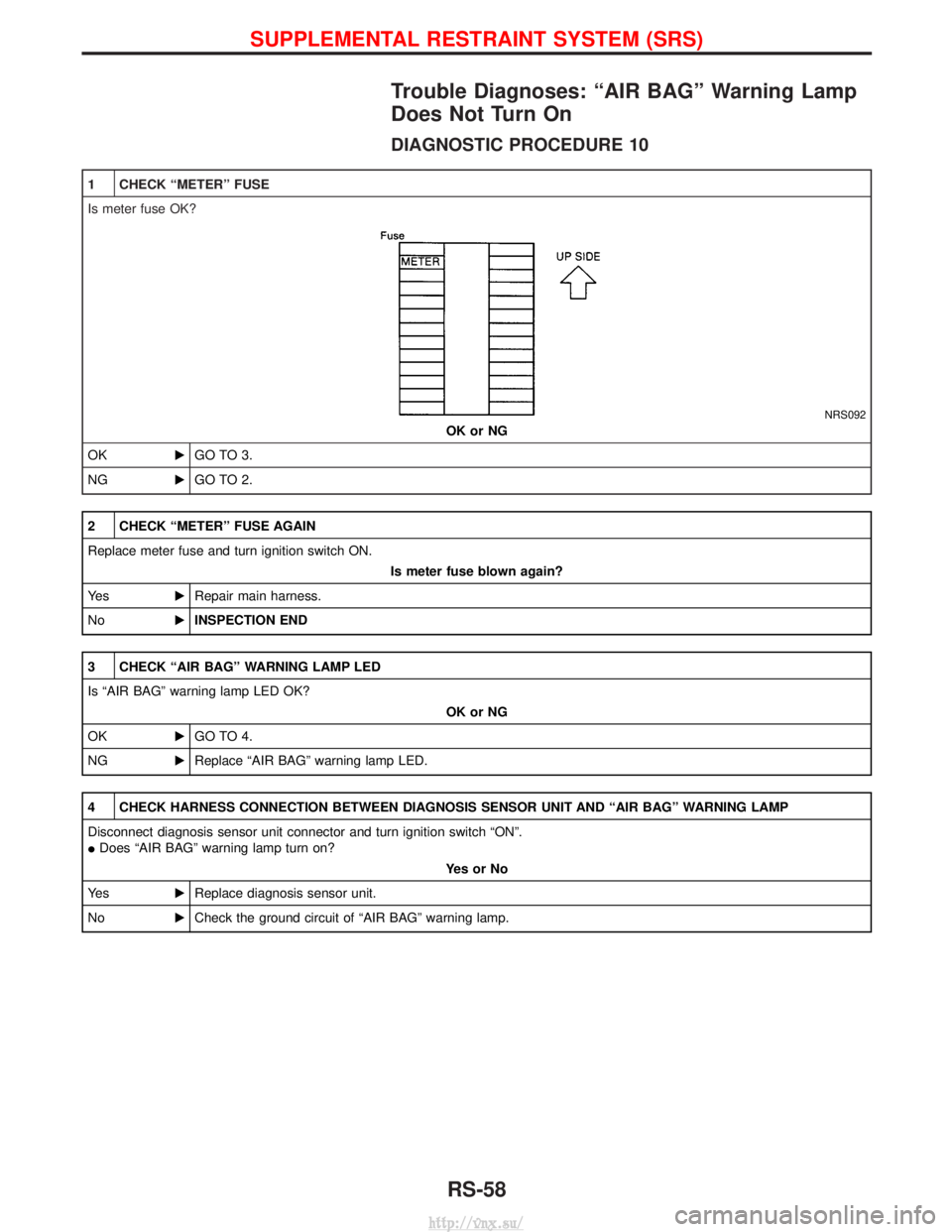

1 CHECK ªMETERº FUSE

Is meter fuse OK?

NRS092

OK or NG

OK EGO TO 3.

NG EGO TO 2.

2 CHECK ªMETERº FUSE AGAIN

Replace meter fuse and turn ignition switch ON.

Is meter fuse blown again?

Ye s ERepair main harness.

No EINSPECTION END

3 CHECK ªAIR BAGº WARNING LAMP LED

Is ªAIR BAGº warning lamp LED OK?

OK or NG

OK EGO TO 4.

NG EReplace ªAIR BAGº warning lamp LED.

4 CHECK HARNESS CONNECTION BETWEEN DIAGNOSIS SENSOR UNIT AND ªAIR BAGº WARNING LAMP

Disconnect diagnosis sensor unit connector and turn ignition switch ªONº.

IDoes ªAIR BAGº warning lamp turn on?

YesorNo

Ye s EReplace diagnosis sensor unit.

No ECheck the ground circuit of ªAIR BAGº warning lamp.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-58

http://vnx.su/

Page 1371 of 1833

Removal and Installation

IWhen removing or installing the seat trim, carefully handle it to keep dirt out and avoid damage.

CAUTION:

I Before removing the front seat, turn the ignition switch off, disconnect both battery cables and wait

at least 3 minutes (models with side air bag).

I Do not drop, tilt, or bump the side air bag module installed in the seat. Always handle it with care.

I Disconnect the side air bag harness connector and heated seat harness connector from under the

seat before removing the seat.

I Disconnect the side air bag harness connector before removing the seatback. Refer to RS-29,

ªFront Side Air Bag Moduleº for details.

FRONT SEAT

BT-34

http://vnx.su/

Page 1435 of 1833

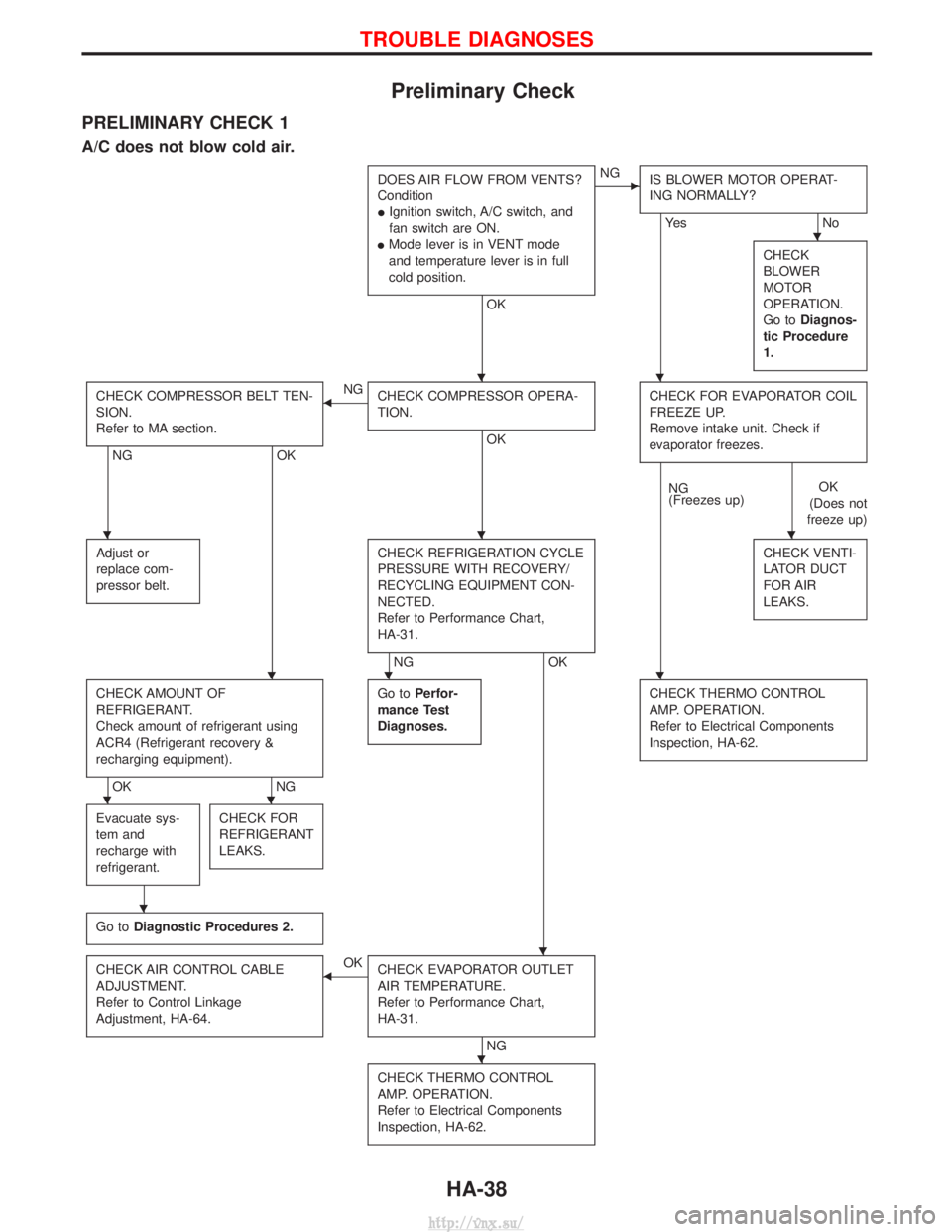

Preliminary Check

PRELIMINARY CHECK 1

A/C does not blow cold air.

DOES AIR FLOW FROM VENTS?

Condition

IIgnition switch, A/C switch, and

fan switch are ON.

I Mode lever is in VENT mode

and temperature lever is in full

cold position.

OK

ENG

IS BLOWER MOTOR OPERAT-

ING NORMALLY?

Ye s N o

CHECK

BLOWER

MOTOR

OPERATION.

Go to Diagnos-

tic Procedure

1.

CHECK COMPRESSOR BELT TEN-

SION.

Refer to MA section.

NG OK

FNG

CHECK COMPRESSOR OPERA-

TION.

OK CHECK FOR EVAPORATOR COIL

FREEZE UP.

Remove intake unit. Check if

evaporator freezes.

NG

(Freezes up)

OK

(Does not

freeze up)

Adjust or

replace com-

pressor belt.

CHECK REFRIGERATION CYCLE

PRESSURE WITH RECOVERY/

RECYCLING EQUIPMENT CON-

NECTED.

Refer to Performance Chart,

HA-31.

NG OK CHECK VENTI-

LATOR DUCT

FOR AIR

LEAKS.

CHECK AMOUNT OF

REFRIGERANT.

Check amount of refrigerant using

ACR4 (Refrigerant recovery &

recharging equipment).

OK

NGGo to

Perfor-

mance Test

Diagnoses.

CHECK THERMO CONTROL

AMP. OPERATION.

Refer to Electrical Components

Inspection, HA-62.

Evacuate sys-

tem and

recharge with

refrigerant.CHECK FOR

REFRIGERANT

LEAKS.

Go to Diagnostic Procedures 2.

CHECK AIR CONTROL CABLE

ADJUSTMENT.

Refer to Control Linkage

Adjustment, HA-64.FOK

CHECK EVAPORATOR OUTLET

AIR TEMPERATURE.

Refer to Performance Chart,

HA-31.

NG

CHECK THERMO CONTROL

AMP. OPERATION.

Refer to Electrical Components

Inspection, HA-62.

H

HH

HHH

HHH

HH

H

H

H

TROUBLE DIAGNOSES

HA-38

http://vnx.su/

Page 1450 of 1833

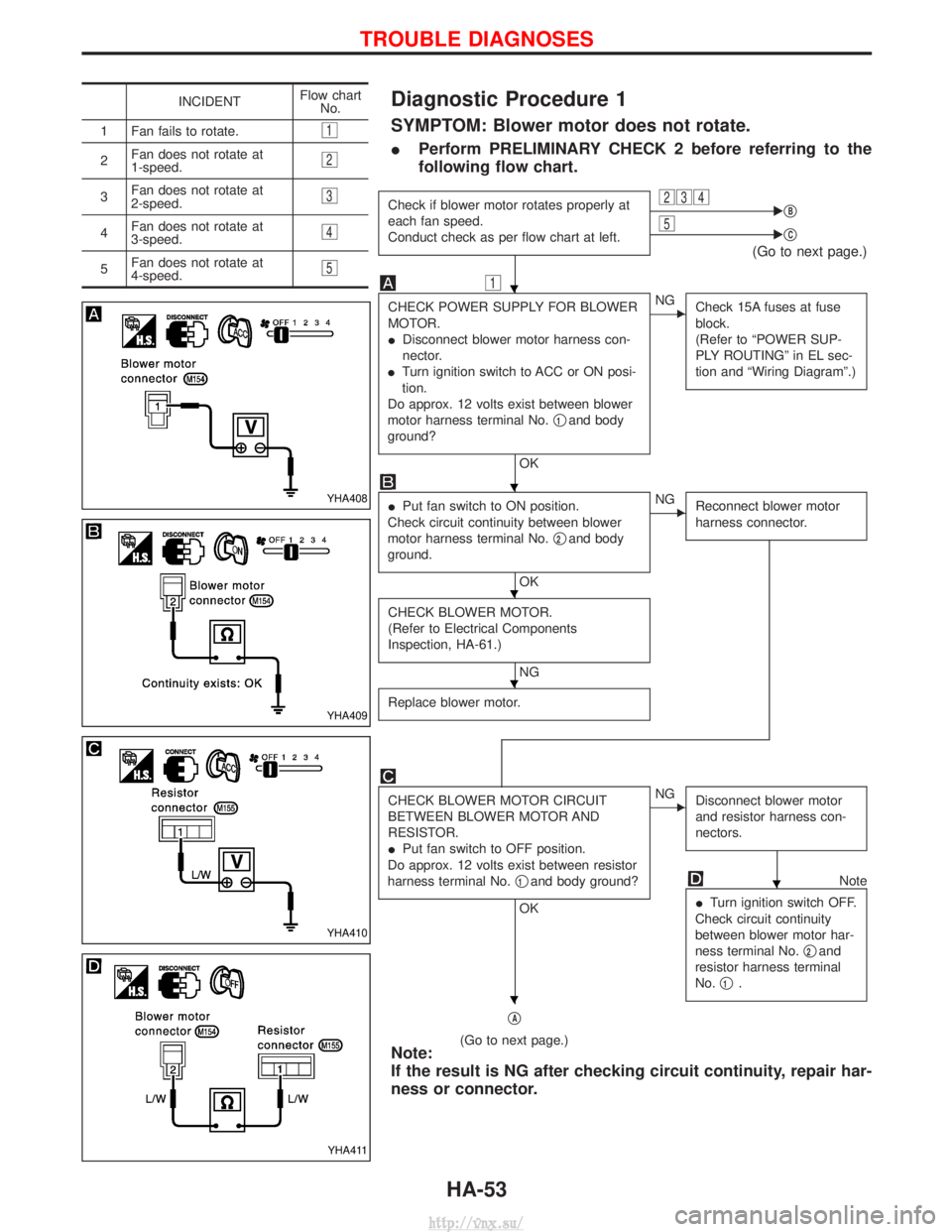

Diagnostic Procedure 1

SYMPTOM: Blower motor does not rotate.

IPerform PRELIMINARY CHECK 2 before referring to the

following flow chart.

Check if blower motor rotates properly at

each fan speed.

Conduct check as per flow chart at left.234EqB5EqC

(Go to next page.)

1

CHECK POWER SUPPLY FOR BLOWER

MOTOR.

I

Disconnect blower motor harness con-

nector.

I Turn ignition switch to ACC or ON posi-

tion.

Do approx. 12 volts exist between blower

motor harness terminal No. q

1and body

ground?

OK

ENG Check 15A fuses at fuse

block.

(Refer to ªPOWER SUP-

PLY ROUTINGº in EL sec-

tion and ªWiring Diagramº.)

IPut fan switch to ON position.

Check circuit continuity between blower

motor harness terminal No. q

2and body

ground.

OK

ENG Reconnect blower motor

harness connector.

CHECK BLOWER MOTOR.

(Refer to Electrical Components

Inspection, HA-61.)

NG

Replace blower motor.

CHECK BLOWER MOTOR CIRCUIT

BETWEEN BLOWER MOTOR AND

RESISTOR.

I Put fan switch to OFF position.

Do approx. 12 volts exist between resistor

harness terminal No. q

1and body ground?

OK

ENG

Disconnect blower motor

and resistor harness con-

nectors.

Note

I Turn ignition switch OFF.

Check circuit continuity

between blower motor har-

ness terminal No. q

2and

resistor harness terminal

No. q

1.

qA

(Go to next page.)Note:

If the result is NG after checking circuit continuity, repair har-

ness or connector.

INCIDENT Flow chart

No.

1 Fan fails to rotate.

1

2 Fan does not rotate at

1-speed.2

3Fan does not rotate at

2-speed.3

4Fan does not rotate at

3-speed.4

5Fan does not rotate at

4-speed.5

YHA408

YHA409

YHA410

YHA411

H

H

H

H

H

H

TROUBLE DIAGNOSES

HA-53

http://vnx.su/

Page 1452 of 1833

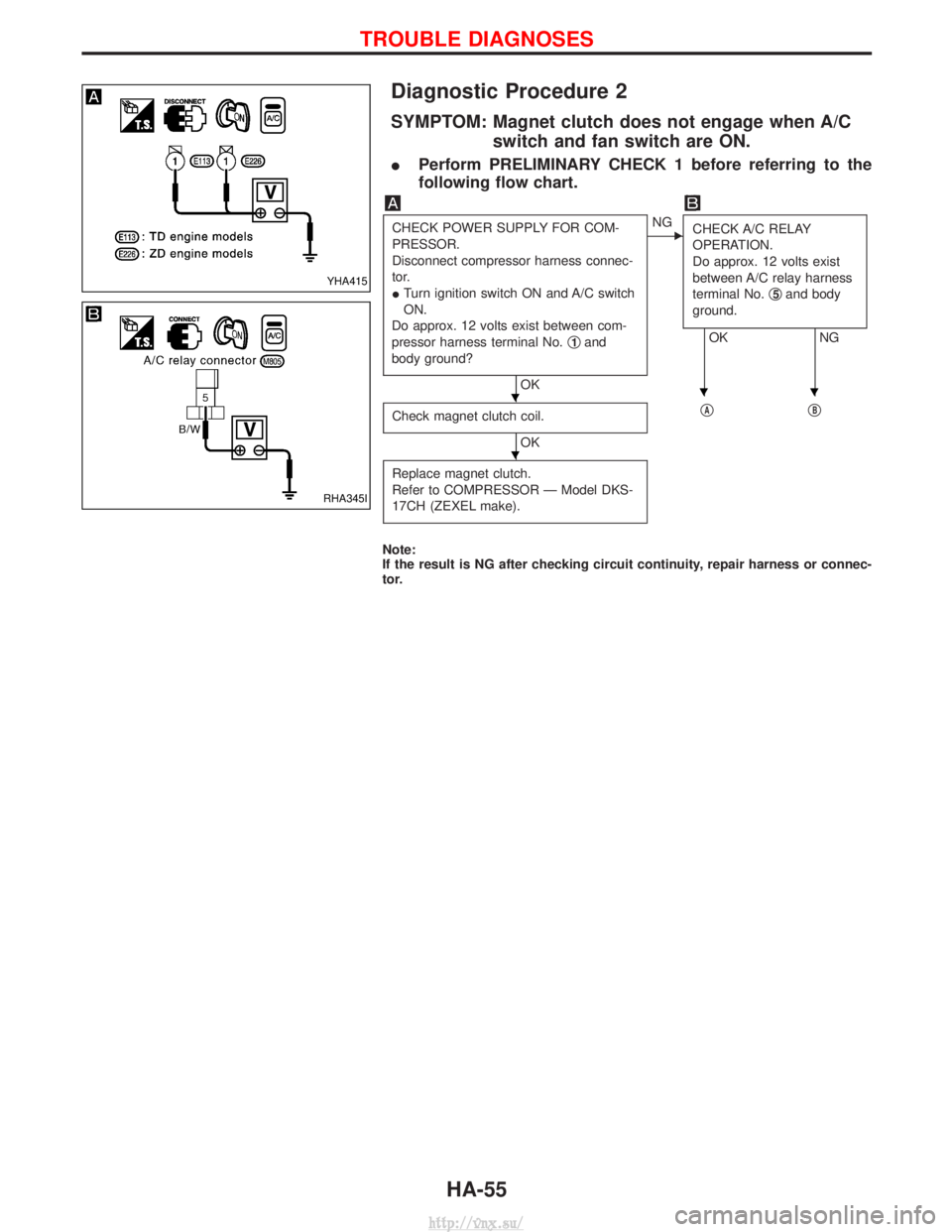

Diagnostic Procedure 2

SYMPTOM: Magnet clutch does not engage when A/Cswitch and fan switch are ON.

IPerform PRELIMINARY CHECK 1 before referring to the

following flow chart.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connec-

tor.

ITurn ignition switch ON and A/C switch

ON.

Do approx. 12 volts exist between com-

pressor harness terminal No. q

1and

body ground?

OK

ENG CHECK A/C RELAY

OPERATION.

Do approx. 12 volts exist

between A/C relay harness

terminal No. q

5and body

ground.

OK NG

Check magnet clutch coil.

OK q

AqB

Replace magnet clutch.

Refer to COMPRESSOR Ð Model DKS-

17CH (ZEXEL make).

Note:

If the result is NG after checking circuit continuity, repair harness or connec-

tor.

YHA415

RHA345I

HHH

H

TROUBLE DIAGNOSES

HA-55

http://vnx.su/

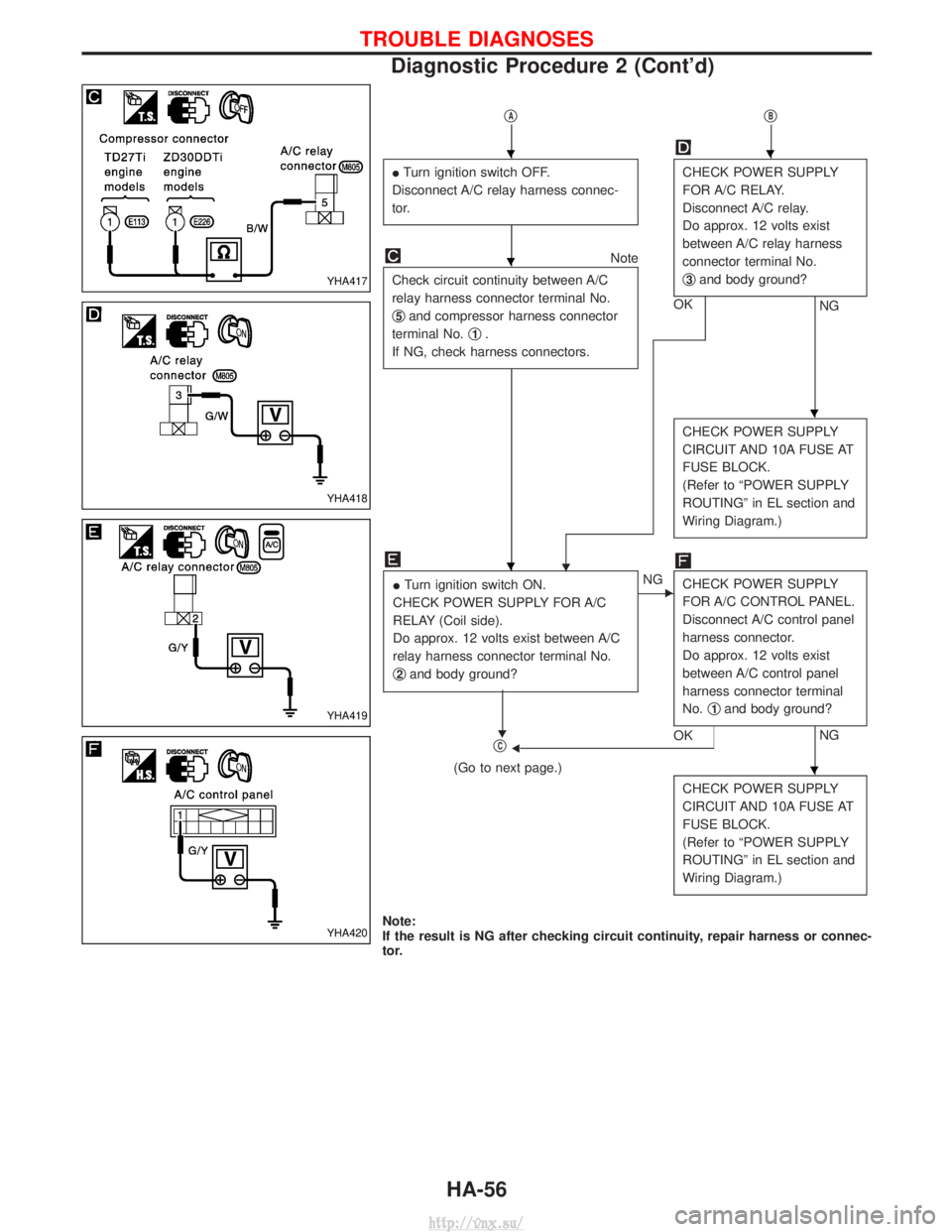

Page 1453 of 1833

qAqB

ITurn ignition switch OFF.

Disconnect A/C relay harness connec-

tor.CHECK POWER SUPPLY

FOR A/C RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist

between A/C relay harness

connector terminal No.

q

3and body ground?

NG

OK

Note

Check circuit continuity between A/C

relay harness connector terminal No.

q

5and compressor harness connector

terminal No. q

1.

If NG, check harness connectors.

H

CHECK POWER SUPPLY

CIRCUIT AND 10A FUSE AT

FUSE BLOCK.

(Refer to ªPOWER SUPPLY

ROUTINGº in EL section and

Wiring Diagram.)

I Turn ignition switch ON.

CHECK POWER SUPPLY FOR A/C

RELAY (Coil side).

Do approx. 12 volts exist between A/C

relay harness connector terminal No.

q

2and body ground?

H

ENG CHECK POWER SUPPLY

FOR A/C CONTROL PANEL.

Disconnect A/C control panel

harness connector.

Do approx. 12 volts exist

between A/C control panel

harness connector terminal

No.q

1and body ground?

NG

OKFqC

(Go to next page.)

CHECK POWER SUPPLY

CIRCUIT AND 10A FUSE AT

FUSE BLOCK.

(Refer to ªPOWER SUPPLY

ROUTINGº in EL section and

Wiring Diagram.)

Note:

If the result is NG after checking circuit continuity, repair harness or connec-

tor.

YHA417

YHA418

YHA419

YHA420

HH

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Cont'd)

HA-56

http://vnx.su/

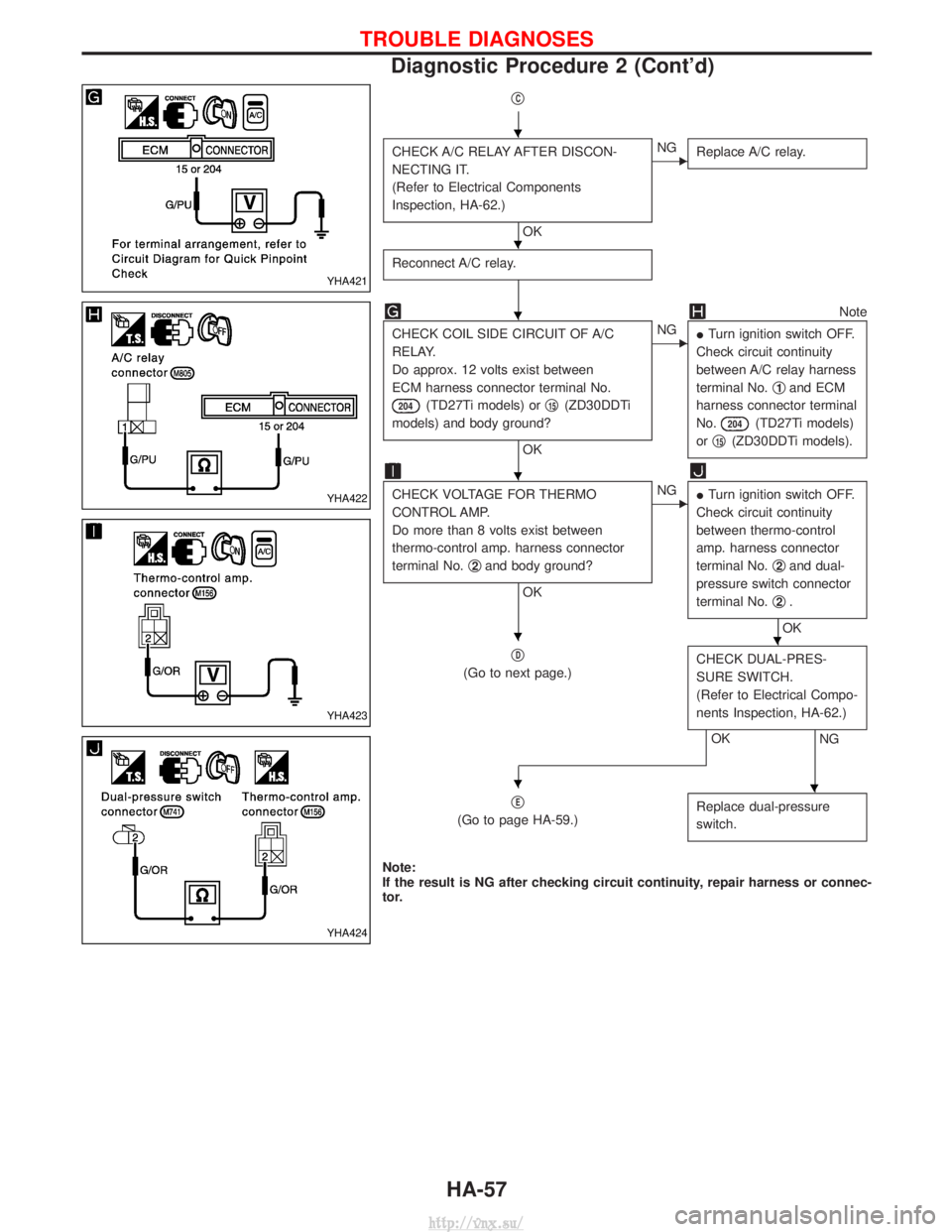

Page 1454 of 1833

qC

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

(Refer to Electrical Components

Inspection, HA-62.)

OK

ENGReplace A/C relay.

Reconnect A/C relay.

Note

CHECK COIL SIDE CIRCUIT OF A/C

RELAY.

Do approx. 12 volts exist between

ECM harness connector terminal No.

204(TD27Ti models) or q15(ZD30DDTi

models) and body ground?

OK

ENG ITurn ignition switch OFF.

Check circuit continuity

between A/C relay harness

terminal No. q

1and ECM

harness connector terminal

No.

204(TD27Ti models)

or q

15(ZD30DDTi models).

CHECK VOLTAGE FOR THERMO

CONTROL AMP.

Do more than 8 volts exist between

thermo-control amp. harness connector

terminal No. q

2and body ground?

OK

ENG

ITurn ignition switch OFF.

Check circuit continuity

between thermo-control

amp. harness connector

terminal No. q

2and dual-

pressure switch connector

terminal No. q

2.

OK

q

D

(Go to next page.) CHECK DUAL-PRES-

SURE SWITCH.

(Refer to Electrical Compo-

nents Inspection, HA-62.)

NGOK

q

E

(Go to page HA-59.) Replace dual-pressure

switch.

Note:

If the result is NG after checking circuit continuity, repair harness or connec-

tor.

YHA421

YHA422

YHA423

YHA424

H

H

H

H

HH

HH

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Cont'd)

HA-57

http://vnx.su/

Page 1455 of 1833

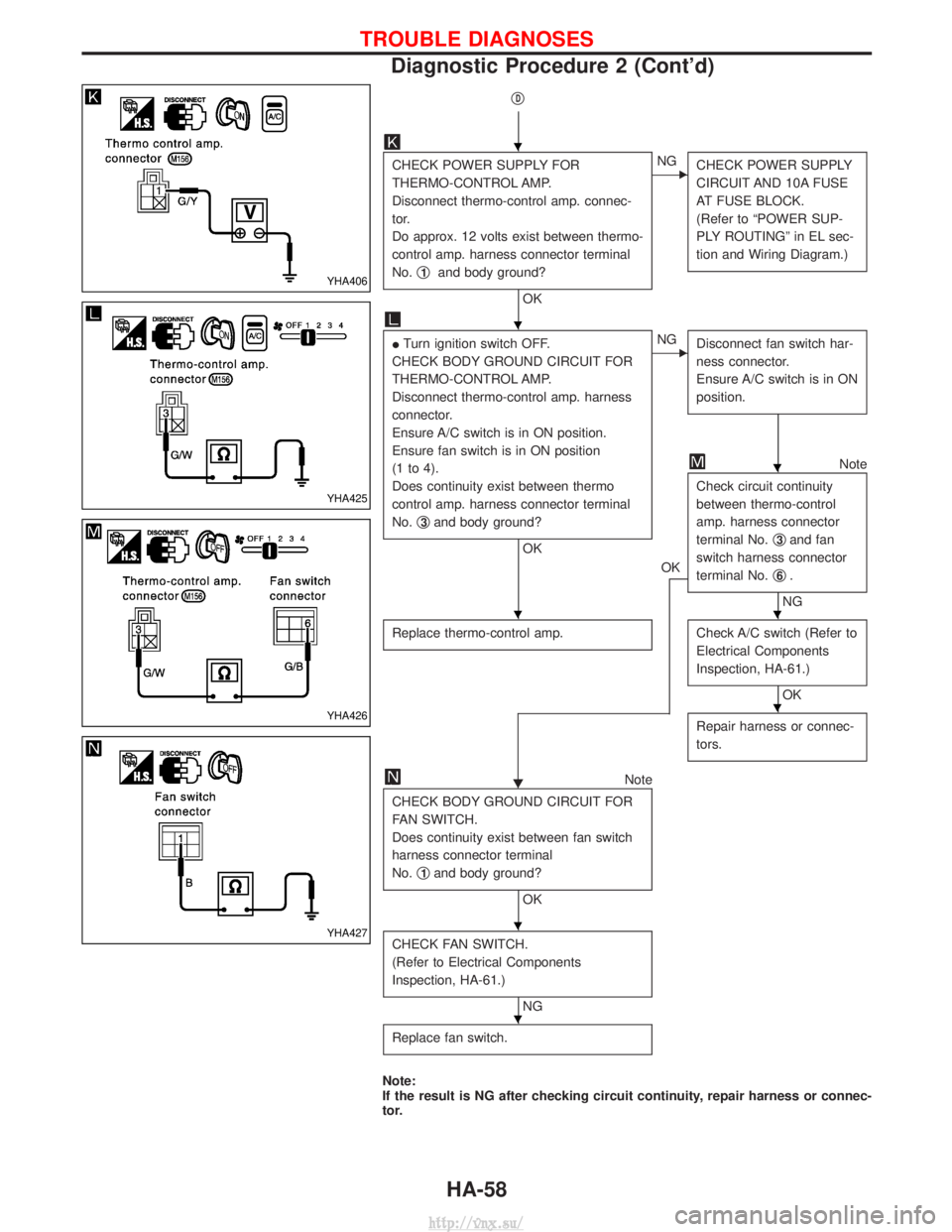

qD

CHECK POWER SUPPLY FOR

THERMO-CONTROL AMP.

Disconnect thermo-control amp. connec-

tor.

Do approx. 12 volts exist between thermo-

control amp. harness connector terminal

No.q

1and body ground?

OK

ENG

CHECK POWER SUPPLY

CIRCUIT AND 10A FUSE

AT FUSE BLOCK.

(Refer to ªPOWER SUP-

PLY ROUTINGº in EL sec-

tion and Wiring Diagram.)

ITurn ignition switch OFF.

CHECK BODY GROUND CIRCUIT FOR

THERMO-CONTROL AMP.

Disconnect thermo-control amp. harness

connector.

Ensure A/C switch is in ON position.

Ensure fan switch is in ON position

(1 to 4).

Does continuity exist between thermo

control amp. harness connector terminal

No. q

3and body ground?

OK

ENG

Disconnect fan switch har-

ness connector.

Ensure A/C switch is in ON

position.

OK

Note

Check circuit continuity

between thermo-control

amp. harness connector

terminal No. q

3and fan

switch harness connector

terminal No. q

6.

NG

Replace thermo-control amp.

Check A/C switch (Refer to

Electrical Components

Inspection, HA-61.)

OK

H Repair harness or connec-

tors.Note

CHECK BODY GROUND CIRCUIT FOR

FAN SWITCH.

Does continuity exist between fan switch

harness connector terminal

No. q

1and body ground?

OK

CHECK FAN SWITCH.

(Refer to Electrical Components

Inspection, HA-61.)

NG

Replace fan switch.

Note:

If the result is NG after checking circuit continuity, repair harness or connec-

tor.

YHA406

YHA425

YHA426

YHA427

H

H

H

HH

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Cont'd)

HA-58

http://vnx.su/

Page 1457 of 1833

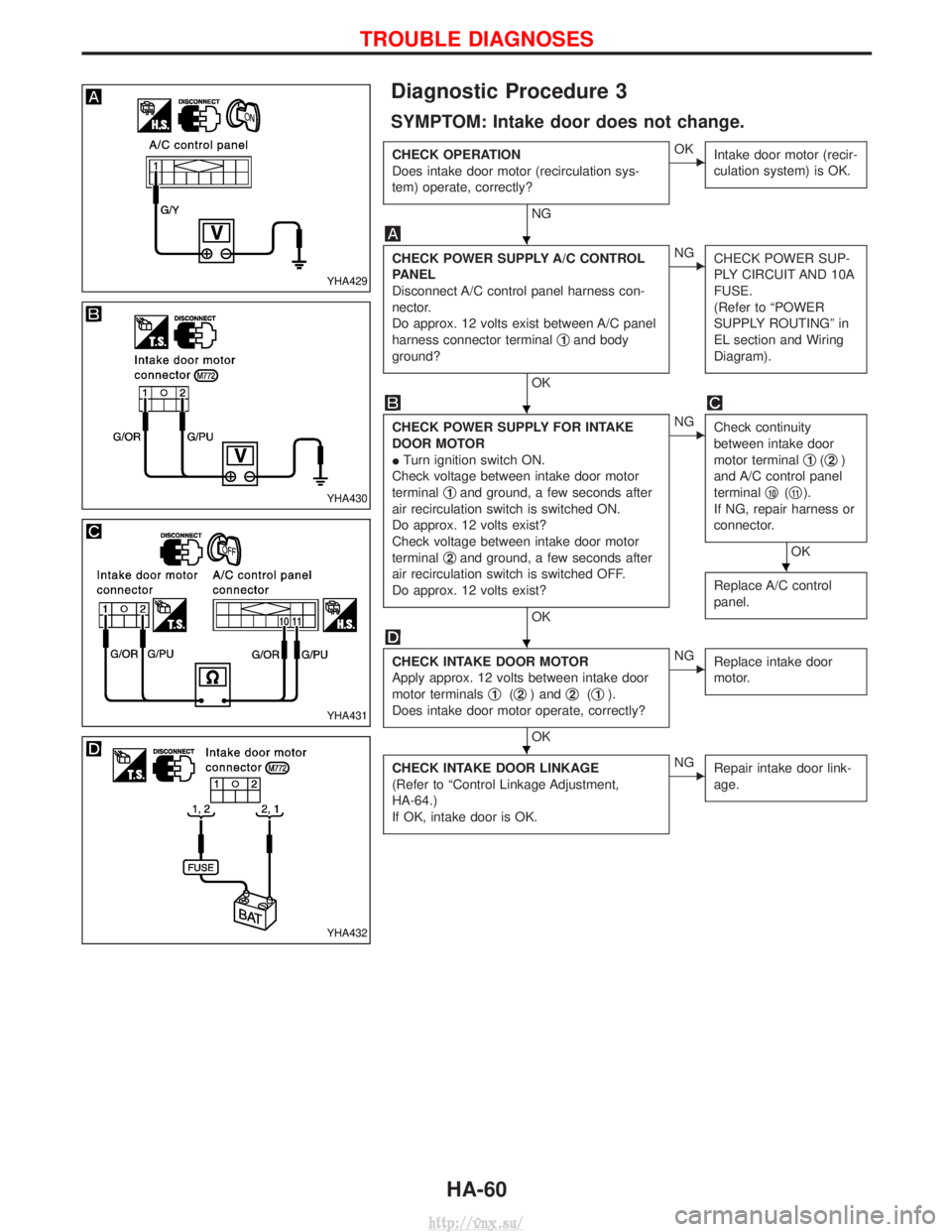

Diagnostic Procedure 3

SYMPTOM: Intake door does not change.

CHECK OPERATION

Does intake door motor (recirculation sys-

tem) operate, correctly?

NG

EOKIntake door motor (recir-

culation system) is OK.

CHECK POWER SUPPLY A/C CONTROL

PANEL

Disconnect A/C control panel harness con-

nector.

Do approx. 12 volts exist between A/C panel

harness connector terminal q

1and body

ground?

OK

ENG CHECK POWER SUP-

PLY CIRCUIT AND 10A

FUSE.

(Refer to ªPOWER

SUPPLY ROUTINGº in

EL section and Wiring

Diagram).

CHECK POWER SUPPLY FOR INTAKE

DOOR MOTOR

ITurn ignition switch ON.

Check voltage between intake door motor

terminal q

1and ground, a few seconds after

air recirculation switch is switched ON.

Do approx. 12 volts exist?

Check voltage between intake door motor

terminal q

2and ground, a few seconds after

air recirculation switch is switched OFF.

Do approx. 12 volts exist?

OK

ENG Check continuity

between intake door

motor terminal q

1(q2)

and A/C control panel

terminal q

10(q11).

If NG, repair harness or

connector.

OK

Replace A/C control

panel.

CHECK INTAKE DOOR MOTOR

Apply approx. 12 volts between intake door

motor terminals q

1(q2) and q2(q1).

Does intake door motor operate, correctly?

OK

ENG Replace intake door

motor.

CHECK INTAKE DOOR LINKAGE

(Refer to ªControl Linkage Adjustment,

HA-64.)

If OK, intake door is OK.ENGRepair intake door link-

age.

YHA429

YHA430

YHA431

YHA432

H

H

H

H

H

TROUBLE DIAGNOSES

HA-60

http://vnx.su/