brake sensor NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 316 of 1833

![NISSAN TERRANO 2004 Service Repair Manual Monitored item

[Unit]ECM

input

signals Main

signals Description Remarks

FUEL TEMP SEN

[ÉC] or [ÉF] qqI

The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL NISSAN TERRANO 2004 Service Repair Manual Monitored item

[Unit]ECM

input

signals Main

signals Description Remarks

FUEL TEMP SEN

[ÉC] or [ÉF] qqI

The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL](/img/5/57394/w960_57394-315.png)

Monitored item

[Unit]ECM

input

signals Main

signals Description Remarks

FUEL TEMP SEN

[ÉC] or [ÉF] qqI

The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL POS SEN [V] qqI

The accelerator position sensor signal

voltage is displayed.

FULL ACCEL SW

[ON/OFF] qqI

Indicates [ON/OFF] condition from the

accelerator position switch signal.

ACCEL SW (FC)

[OPEN/CLOSE] qqI

Indicates [OPEN/CLOSE] condition from

the accelerator switch (FC) signal.

OFF ACCEL SW

[ON/OFF] qqI

Indicates [ON/OFF] condition from the

accelerator position switch signal.

SPILL/V [ÉCA] qI

The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [V] qqI

The power supply voltage of ECM is dis-

played.

P/N POSI SW

[ON/OFF] qqI

Indicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF] qqI

Indicates [ON/OFF] condition from the

starter signal. I

After starting the engine, [OFF] is dis-

played regardless of the starter signal.

AIR COND SIG

[ON/OFF] qqI

Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

BRAKE SW [ON/OFF] qqI

Indicates [ON/OFF] condition from the

stop lamp switch signal.

IGN SW

[ON/OFF] qqI

Indicates [ON/OFF] condition from igni-

tion switch signal.

WARM UP SW

[ON/OFF] qI

Indicates [ON/OFF] condition from the

heat up switch signal.

MAS AIR/FL SE [V] qqI

The signal voltage of the mass air flow

sensor is displayed. I

When the engine is stopped, a certain

value is indicated.

DECELER F/CUT

[ON/OFF] qI

The [ON/OFF] condition from decelera-

tion fuel cut signal (sent from electronic

control fuel injection pump) is displayed.

INJ TIMG C/V [%] qI

The duty ratio of fuel injection timing

control valve (sent from electronic control

fuel injection pump) is displayed.

AIR COND RLY

[ON/OFF] qI

Indicates the control condition of the air

conditioner relay (determined by ECM

according to the input signals).

GLOW RLY [ON/OFF] qI

The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[ON/OFF] qI

Indicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

I ON ... Operates.

OFF ... Stopped.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-41

http://vnx.su/

Page 347 of 1833

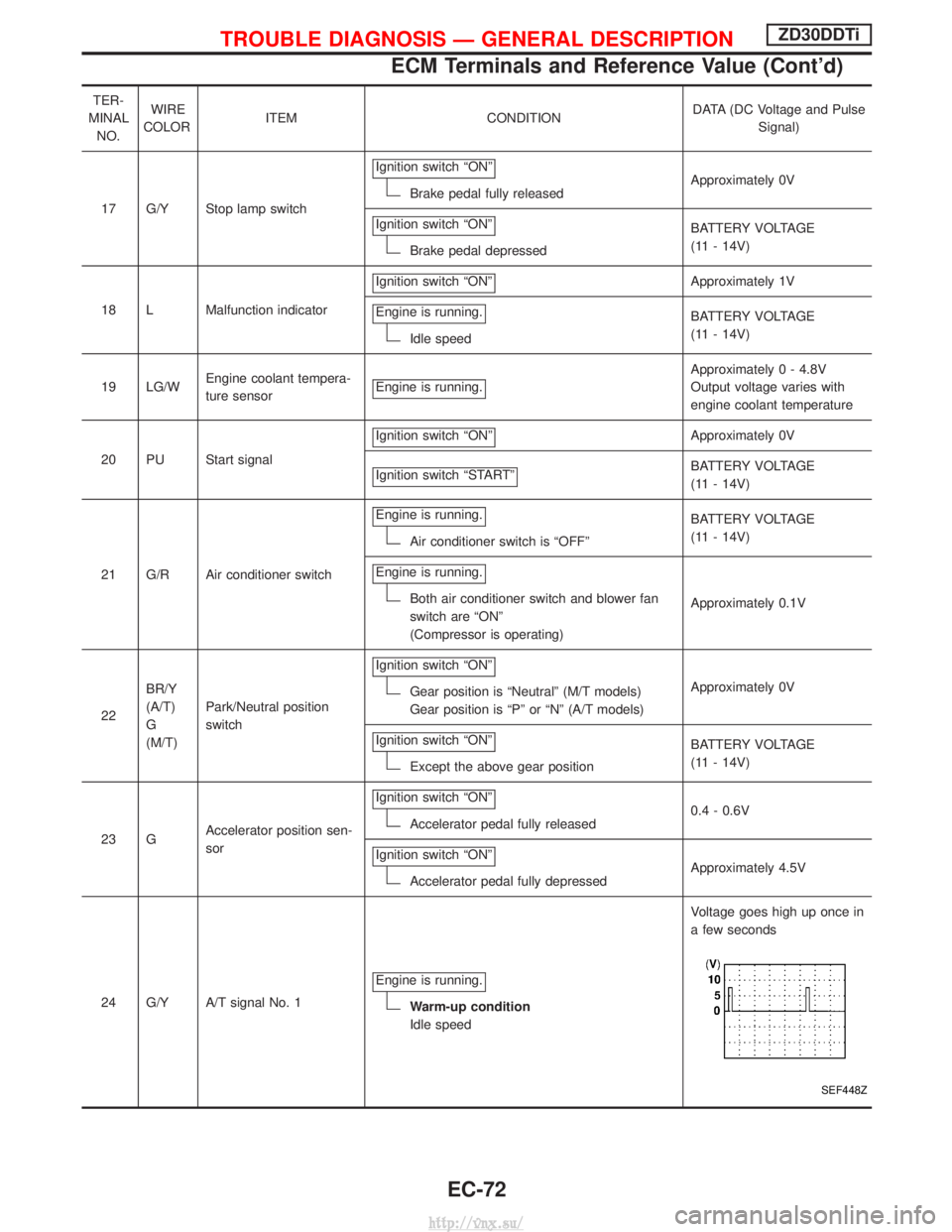

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and Pulse

Signal)

17 G/Y Stop lamp switch Ignition switch ªONº

Brake pedal fully released

Approximately 0V

Ignition switch ªONº

Brake pedal depressed BATTERY VOLTAGE

(11 - 14V)

18 L Malfunction indicator Ignition switch ªONº

Approximately 1V

Engine is running.

Idle speed BATTERY VOLTAGE

(11 - 14V)

19 LG/W Engine coolant tempera-

ture sensor Engine is running.

Approximately 0 - 4.8V

Output voltage varies with

engine coolant temperature

20 PU Start signal Ignition switch ªONº

Approximately 0V

Ignition switch ªSTARTº

BATTERY VOLTAGE

(11 - 14V)

21 G/R Air conditioner switch Engine is running.

Air conditioner switch is ªOFFº

BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Both air conditioner switch and blower fan

switch are ªONº

(Compressor is operating) Approximately 0.1V

22 BR/Y

(A/T)

G

(M/T) Park/Neutral position

switch Ignition switch ªONº

Gear position is ªNeutralº (M/T models)

Gear position is ªPº or ªNº (A/T models)

Approximately 0V

Ignition switch ªONº

Except the above gear position BATTERY VOLTAGE

(11 - 14V)

23 G Accelerator position sen-

sor Ignition switch ªONº

Accelerator pedal fully released

0.4 - 0.6V

Ignition switch ªONº

Accelerator pedal fully depressed Approximately 4.5V

24 G/Y A/T signal No. 1 Engine is running.

Warm-up condition

Idle speed Voltage goes high up once in

a few seconds

SEF448Z

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-72

http://vnx.su/

Page 588 of 1833

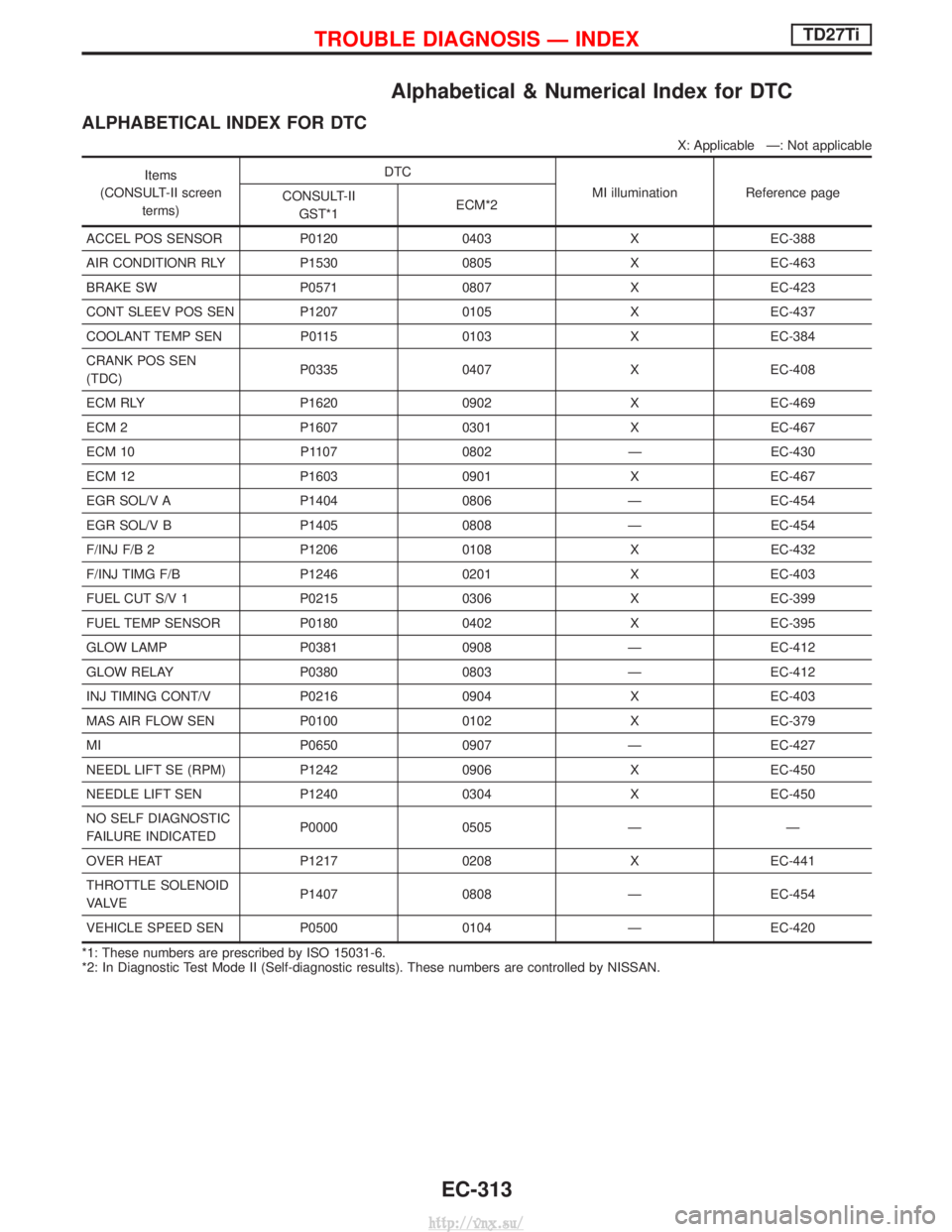

Alphabetical & Numerical Index for DTC

ALPHABETICAL INDEX FOR DTC

X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms) DTC

MI illuminationReference page

CONSULT-II

GST*1 ECM*2

ACCEL POS SENSOR P0120 0403 X EC-388

AIR CONDITIONR RLY P1530 0805 X EC-463

BRAKE SW P0571 0807 X EC-423

CONT SLEEV POS SEN P1207 0105 X EC-437

COOLANT TEMP SEN P0115 0103 X EC-384

CRANK POS SEN

(TDC) P0335 0407 X EC-408

ECM RLY P1620 0902 X EC-469

ECM 2 P1607 0301 X EC-467

ECM 10 P1107 0802 Ð EC-430

ECM 12 P1603 0901 X EC-467

EGR SOL/V A P1404 0806 Ð EC-454

EGR SOL/V B P1405 0808 Ð EC-454

F/INJ F/B 2 P1206 0108 X EC-432

F/INJ TIMG F/B P1246 0201 X EC-403

FUEL CUT S/V 1 P0215 0306 X EC-399

FUEL TEMP SENSOR P0180 0402 X EC-395

GLOW LAMP P0381 0908 Ð EC-412

GLOW RELAY P0380 0803 Ð EC-412

INJ TIMING CONT/V P0216 0904 X EC-403

MAS AIR FLOW SEN P0100 0102 X EC-379

MI P0650 0907 Ð EC-427

NEEDL LIFT SE (RPM) P1242 0906 X EC-450

NEEDLE LIFT SEN P1240 0304 X EC-450

NO SELF DIAGNOSTIC

FAILURE INDICATED P0000 0505 Ð Ð

OVER HEAT P1217 0208 X EC-441

THROTTLE SOLENOID

VA LV E P1407 0808 Ð EC-454

VEHICLE SPEED SEN P0500 0104 Ð EC-420

*1: These numbers are prescribed by ISO 15031-6.

*2: In Diagnostic Test Mode II (Self-diagnostic results). These numbers are controlled by NISSAN.

TROUBLE DIAGNOSIS Ð INDEXTD27Ti

EC-313

http://vnx.su/

Page 589 of 1833

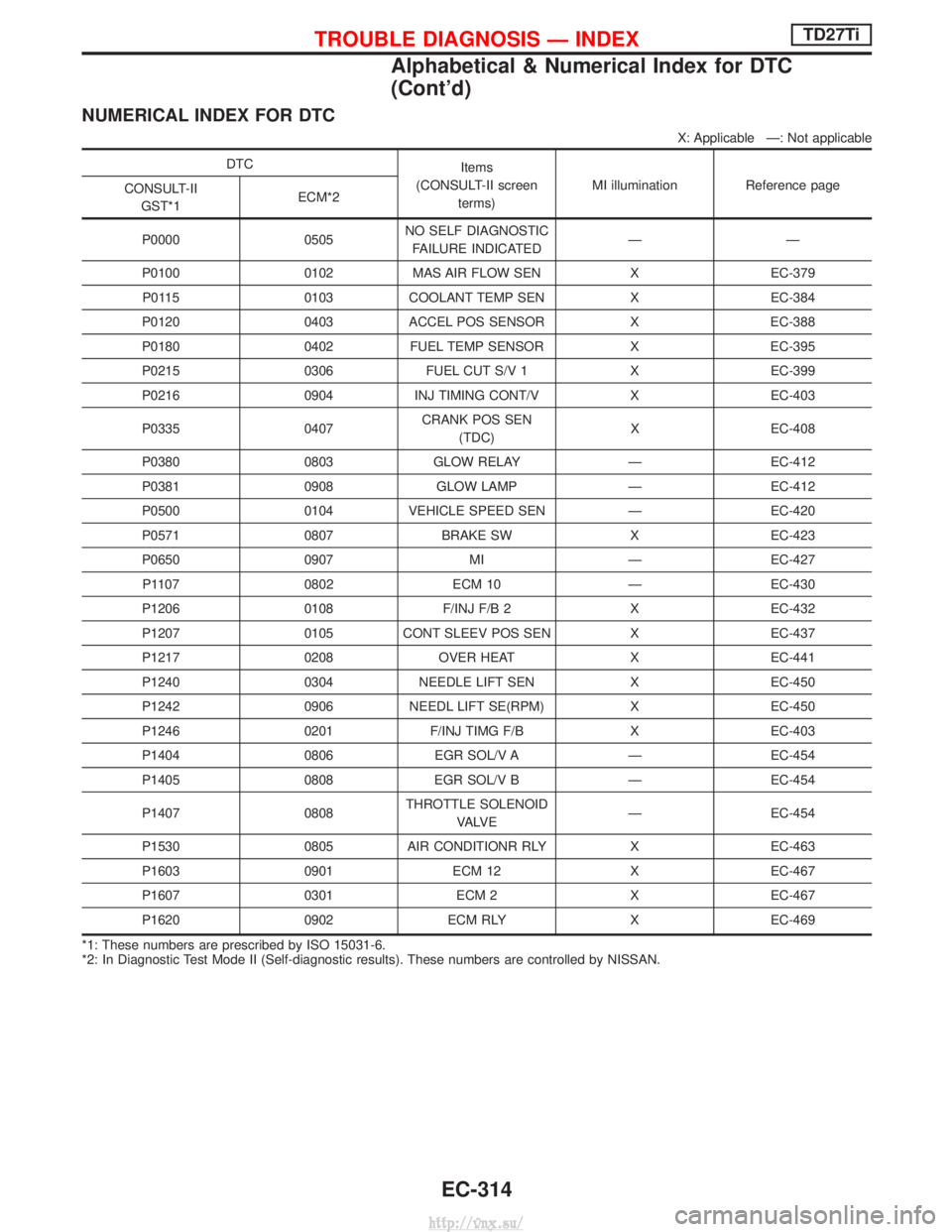

NUMERICAL INDEX FOR DTC

X: Applicable Ð: Not applicable

DTCItems

(CONSULT-II screen terms) MI illumination Reference page

CONSULT-II

GST*1 ECM*2

P0000 0505 NO SELF DIAGNOSTIC

FAILURE INDICATED ÐÐ

P0100 0102 MAS AIR FLOW SEN X EC-379 P0115 0103 COOLANT TEMP SEN X EC-384

P0120 0403 ACCEL POS SENSOR X EC-388

P0180 0402 FUEL TEMP SENSOR X EC-395

P0215 0306 FUEL CUT S/V 1 X EC-399

P0216 0904 INJ TIMING CONT/V X EC-403

P0335 0407 CRANK POS SEN

(TDC) X EC-408

P0380 0803 GLOW RELAY Ð EC-412

P0381 0908 GLOW LAMP Ð EC-412

P0500 0104 VEHICLE SPEED SEN Ð EC-420

P0571 0807 BRAKE SW X EC-423

P0650 0907 MI Ð EC-427 P1107 0802 ECM 10 Ð EC-430

P1206 0108 F/INJ F/B 2 X EC-432

P1207 0105 CONT SLEEV POS SEN X EC-437

P1217 0208 OVER HEAT X EC-441

P1240 0304 NEEDLE LIFT SEN X EC-450

P1242 0906 NEEDL LIFT SE(RPM) X EC-450

P1246 0201 F/INJ TIMG F/B X EC-403

P1404 0806 EGR SOL/V A Ð EC-454

P1405 0808 EGR SOL/V B Ð EC-454

P1407 0808 THROTTLE SOLENOID

VA LV E Ð EC-454

P1530 0805 AIR CONDITIONR RLY X EC-463

P1603 0901 ECM 12 X EC-467

P1607 0301 ECM 2 X EC-467

P1620 0902 ECM RLY X EC-469

*1: These numbers are prescribed by ISO 15031-6.

*2: In Diagnostic Test Mode II (Self-diagnostic results). These numbers are controlled by NISSAN.

TROUBLE DIAGNOSIS Ð INDEXTD27Ti

Alphabetical & Numerical Index for DTC

(Cont'd)

EC-314

http://vnx.su/

Page 603 of 1833

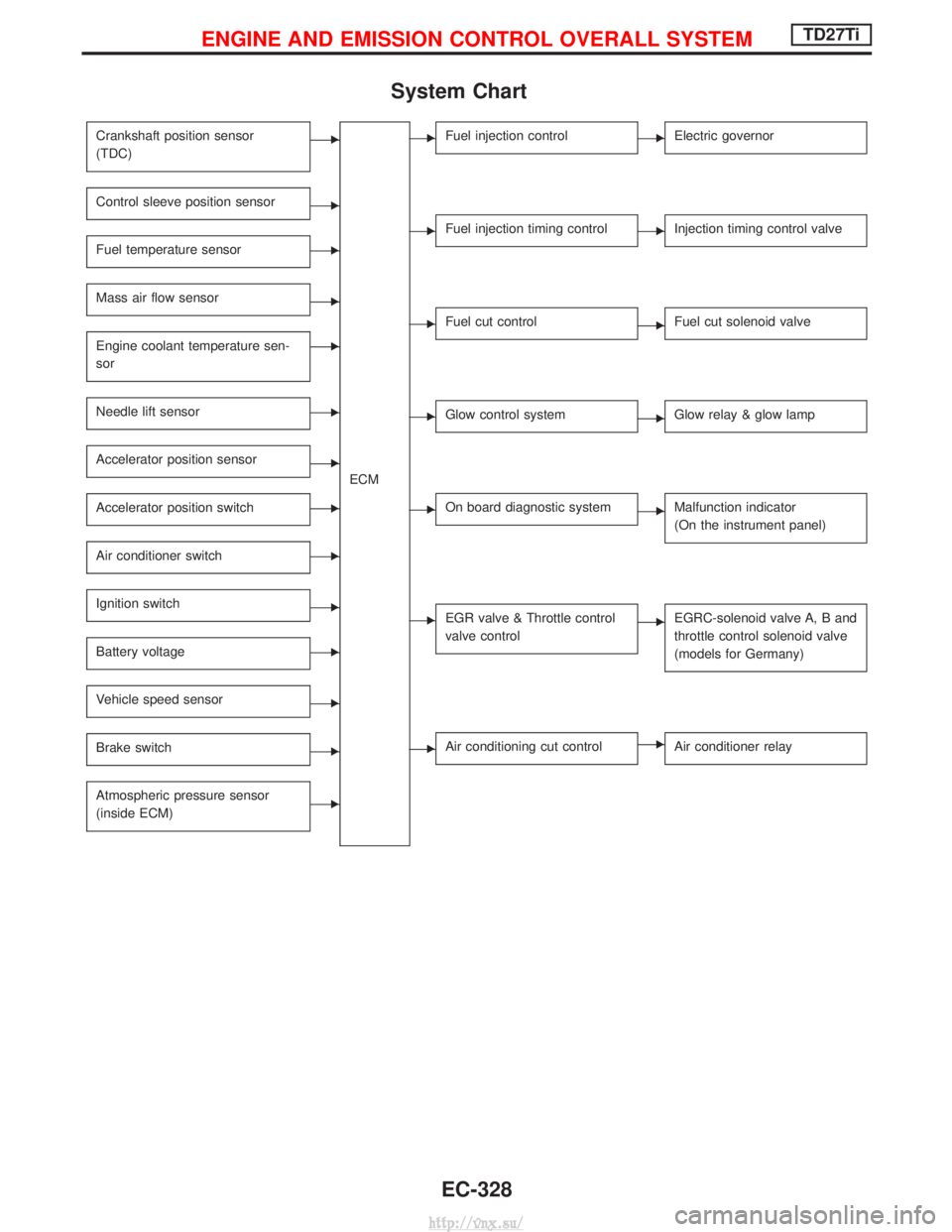

System Chart

Crankshaft position sensor

(TDC)E

ECM

Control sleeve position sensorE

Fuel temperature sensorE

Mass air flow sensorE

Engine coolant temperature sen-

sorE

Needle lift sensorE

Accelerator position sensorE

Accelerator position switchE

Air conditioner switchE

Ignition switchE

Battery voltageE

Vehicle speed sensorE

Brake switchE

Atmospheric pressure sensor

(inside ECM)E

EFuel injection controlEElectric governor

EFuel injection timing controlEInjection timing control valve

EFuel cut controlEFuel cut solenoid valve

EGlow control systemEGlow relay & glow lamp

EOn board diagnostic systemEMalfunction indicator

(On the instrument panel)

EEGR valve & Throttle control

valve controlEEGRC-solenoid valve A, B and

throttle control solenoid valve

(models for Germany)

EAir conditioning cut controlEAir conditioner relay

ENGINE AND EMISSION CONTROL OVERALL SYSTEMTD27Ti

EC-328

http://vnx.su/

Page 626 of 1833

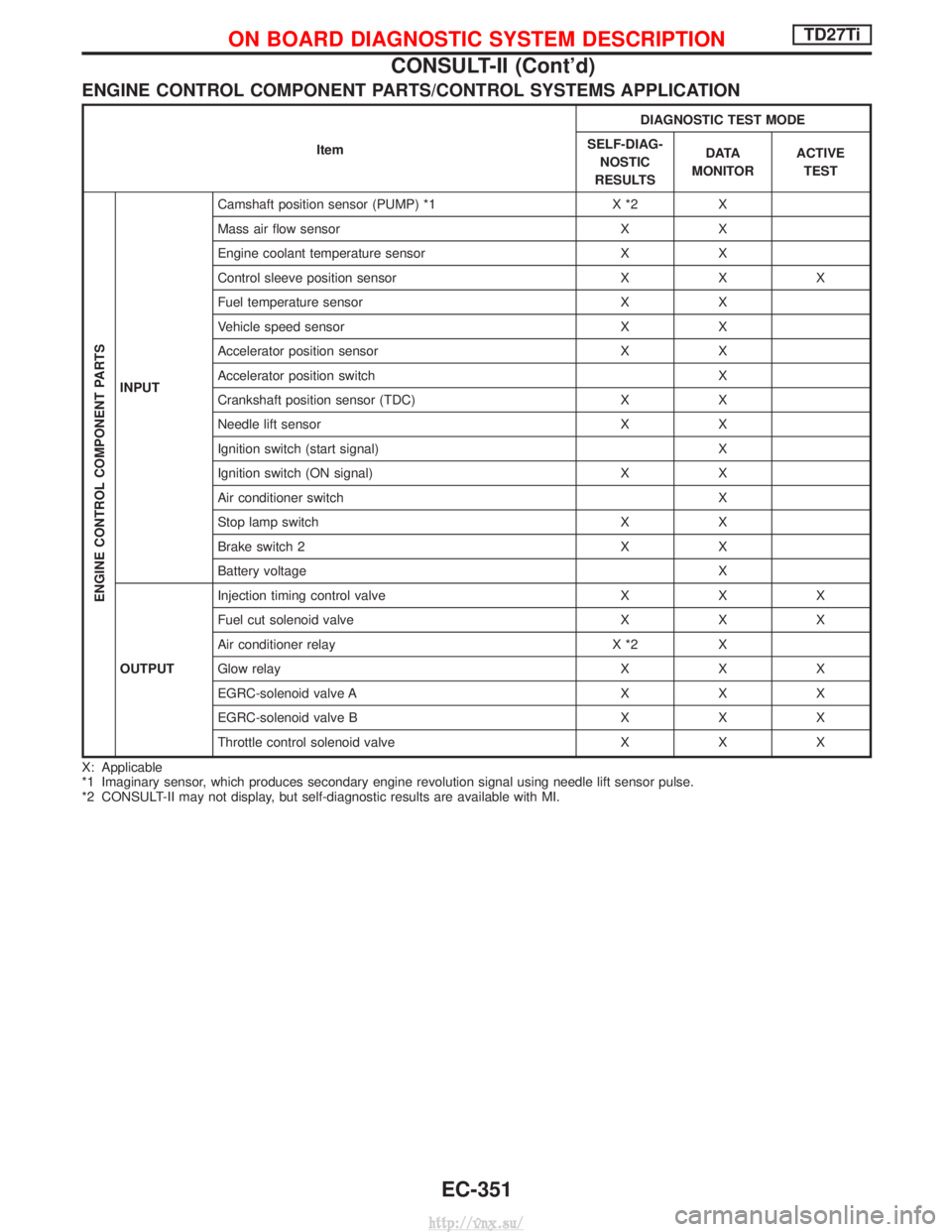

ENGINE CONTROL COMPONENT PARTS/CONTROL SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

SELF-DIAG- NOSTIC

RESULTS D ATA

MONITOR ACTIVE

TEST

ENGINE CONTROL COMPONENT PARTS

INPUT Camshaft position sensor (PUMP) *1 X *2 X

Mass air flow sensor X X

Engine coolant temperature sensor X X

Control sleeve position sensor X X X

Fuel temperature sensor X X

Vehicle speed sensor X X

Accelerator position sensor X X

Accelerator position switch X

Crankshaft position sensor (TDC) X X

Needle lift sensor X X

Ignition switch (start signal) X

Ignition switch (ON signal) X X

Air conditioner switch X

Stop lamp switch X X

Brake switch 2 X X

Battery voltage X

OUTPUT Injection timing control valve X X X

Fuel cut solenoid valve X X X

Air conditioner relay X *2 X

Glow relay X X X

EGRC-solenoid valve A X X X

EGRC-solenoid valve B X X X

Throttle control solenoid valve X X X

X: Applicable

*1 Imaginary sensor, which produces secondary engine revolution signal using needle lift sensor pulse.

*2 CONSULT-II may not display, but self-diagnostic results are available with MI.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

CONSULT-II (Cont'd)

EC-351

http://vnx.su/

Page 627 of 1833

![NISSAN TERRANO 2004 Service Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode, refer to ªTROUBLE DIAGNOSIS Ð INDEXº,

EC-313.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signals Main

signals Desc NISSAN TERRANO 2004 Service Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode, refer to ªTROUBLE DIAGNOSIS Ð INDEXº,

EC-313.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signals Main

signals Desc](/img/5/57394/w960_57394-626.png)

SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode, refer to ªTROUBLE DIAGNOSIS Ð INDEXº,

EC-313.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signals Main

signals Description

Remarks

CKPS×RPM

(TDC) [rpm]

qq

I The engine speed computed from the

crankshaft position sensor (TDC) signal

is displayed.

CMPS×RPM -

PUMP [rpm]

qqI The engine speed computed from the

needle lift sensor signal is displayed.

COOLAN TEMP/S

[ÉC] or [ÉF]

qq

I The engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed. I

When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The same data as

the fuel temperature is displayed.

VHCL SPEED SE

[km/h] or [mph]

qqI The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC] or [ÉF]

qq

I The fuel temperature (determined by the

signal voltage of the fuel temperature

sensor) is displayed.

ACCEL POS SEN [V]

qqI The accelerator position sensor signal

voltage is displayed.

OFF ACCEL POS

[ON/OFF]

qqI Indicates [ON/OFF] condition from the

accelerator position switch signal. I

Signal at approximately 9É opened.

C/SLEEV POS/S [V]

qqI The control sleeve position sensor signal

voltage is displayed.

BATTERY VOLT [V]

qqI The power supply voltage of ECM is dis-

played.

START SIGNAL

[ON/OFF]

qqI Indicates [ON/OFF] condition from the

starter signal. I

After starting the engine, [OFF] is dis-

played regardless of the starter signal.

AIR COND SIG

[ON/OFF]

qq

I Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

BRAKE SW

[ON/OFF]

qI Indicates [ON/OFF] condition of the stop

lamp switch.

BRAKE SW2

[ON/OFF]

qI Indicates [ON/OFF] condition of the

brake switch 2.

IGN SW

[ON/OFF]

qqI Indicates [ON/OFF] condition from igni-

tion switch.

MAS AIR/FL SE [V]

qqI The signal voltage of the mass air flow

sensor is displayed. I

When the engine is stopped, a certain

value is indicated.

ACT INJ TIMG [É]

q

I The actual injection timing angle deter-

mined by the ECM (an approximate aver-

age angle between injection start and

end from TDC) is displayed.

TARGET F/INJ

[mm

3/stroke]qI The target fuel injection quantity (deter-

mined by the ECM according to the input

signal) is indicated.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

CONSULT-II (Cont'd)

EC-352

http://vnx.su/

Page 648 of 1833

![NISSAN TERRANO 2004 Service Repair Manual TERMI-NALNO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

347 LG/W Engine coolant tempera-

ture sensor [Engine is running] Approximately 0 - 4.8V

Output voltage varies with

engine cool NISSAN TERRANO 2004 Service Repair Manual TERMI-NALNO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

347 LG/W Engine coolant tempera-

ture sensor [Engine is running] Approximately 0 - 4.8V

Output voltage varies with

engine cool](/img/5/57394/w960_57394-647.png)

TERMI-NALNO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

347 LG/W Engine coolant tempera-

ture sensor [Engine is running] Approximately 0 - 4.8V

Output voltage varies with

engine coolant tempera-

ture

348 Y/B Fuel temperature sensor [Engine is running] 0.6-5V

Output voltage varies with

fuel temperature.

349 G/R Injection timing control

valve ground [Ignition switch ªONº]

Approximately 0V

403 G/R Air conditioner switch [Engine is running]

I

Air conditioner switch is ªOFFº BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

I Both air conditioner switch and blower fan switch

are ªONº

(Compressor is operating) Approximately 0.1V

405 G/Y Stop lamp switch [Ignition switch ªONº]

I

Brake pedal fully released Approximately 0V

[Ignition switch ªONº]

I Brake pedal depressed BATTERY VOLTAGE

(11 - 14V)

416 Y/R Brake pedal position

switch [Ignition switch ªONº]

I

Brake pedal fully released BATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

I Brake pedal depressed Approximately 0V

415 OR Data link connector for

CONSULT-II [Engine is running]

I

Idle speed (CONSULT-II is connected and turned

on) Approximately 0V

420 R BATTERY VOLTAGE

(11 - 14V)

417 Y/B Vehicle speed sensor [Engine is running]

I

Lift up the vehicle

I In 1st gear position

I Vehicle speed is 10 km/h (6 MPH) 0 - Approximately 8V

SEF891Y

[Engine is running]

I

Lift up the vehicle

I In 2nd gear position

I Vehicle speed is 30 km/h (19 MPH) Approximately 6V

SEF892Y

422 PU Start signal

[Ignition switch ªONº]

Approximately 0V

[Ignition switch ªSTARTº] BATTERY VOLTAGE

(11 - 14V)

425 R/B Accelerator position sen-

sor ground [Engine is running]

I

Warm-up condition

I Idle speed Approximately 0V

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-373

http://vnx.su/

Page 664 of 1833

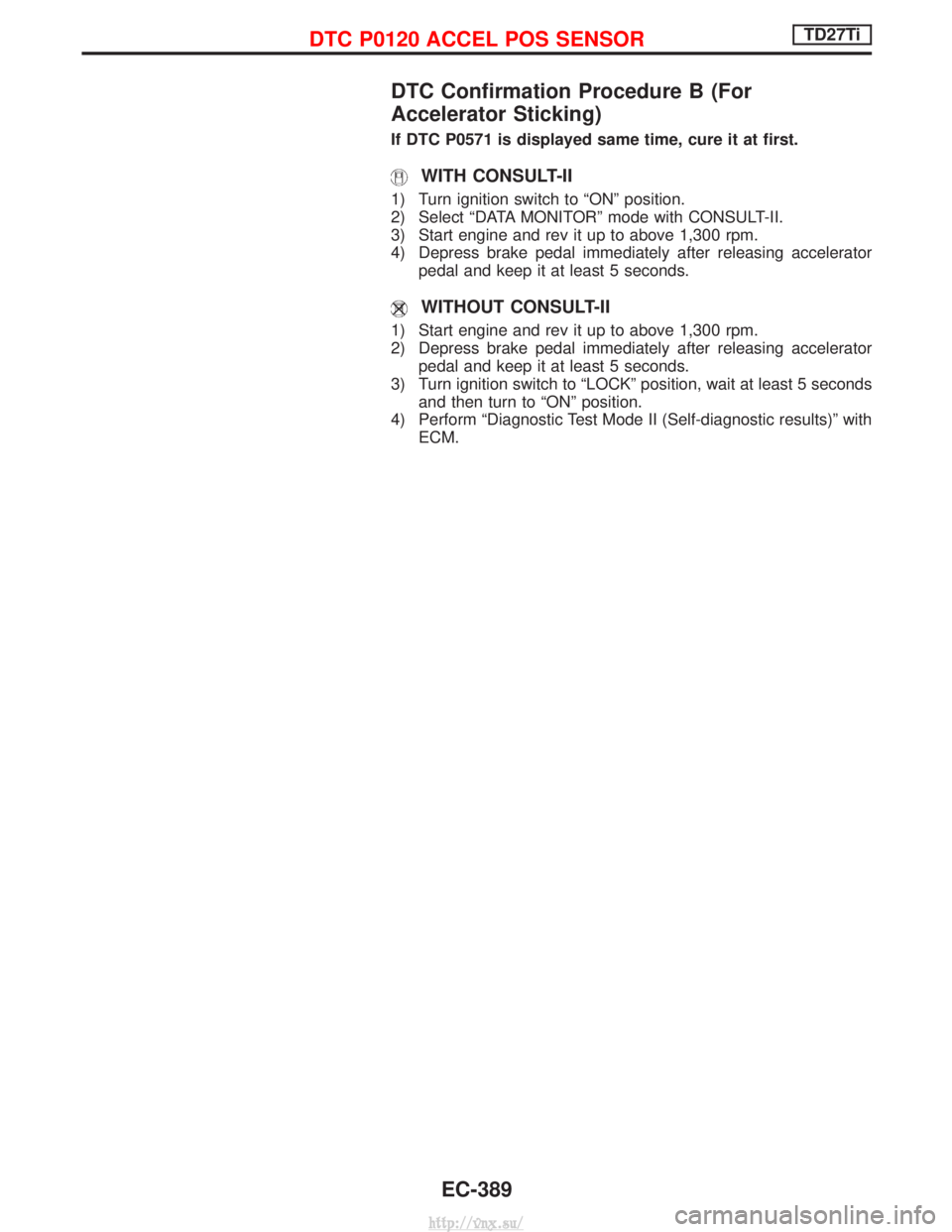

DTC Confirmation Procedure B (For

Accelerator Sticking)

If DTC P0571 is displayed same time, cure it at first.

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and rev it up to above 1,300 rpm.

4) Depress brake pedal immediately after releasing acceleratorpedal and keep it at least 5 seconds.

WITHOUT CONSULT-II

1) Start engine and rev it up to above 1,300 rpm.

2) Depress brake pedal immediately after releasing acceleratorpedal and keep it at least 5 seconds.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

DTC P0120 ACCEL POS SENSORTD27Ti

EC-389

http://vnx.su/

Page 815 of 1833

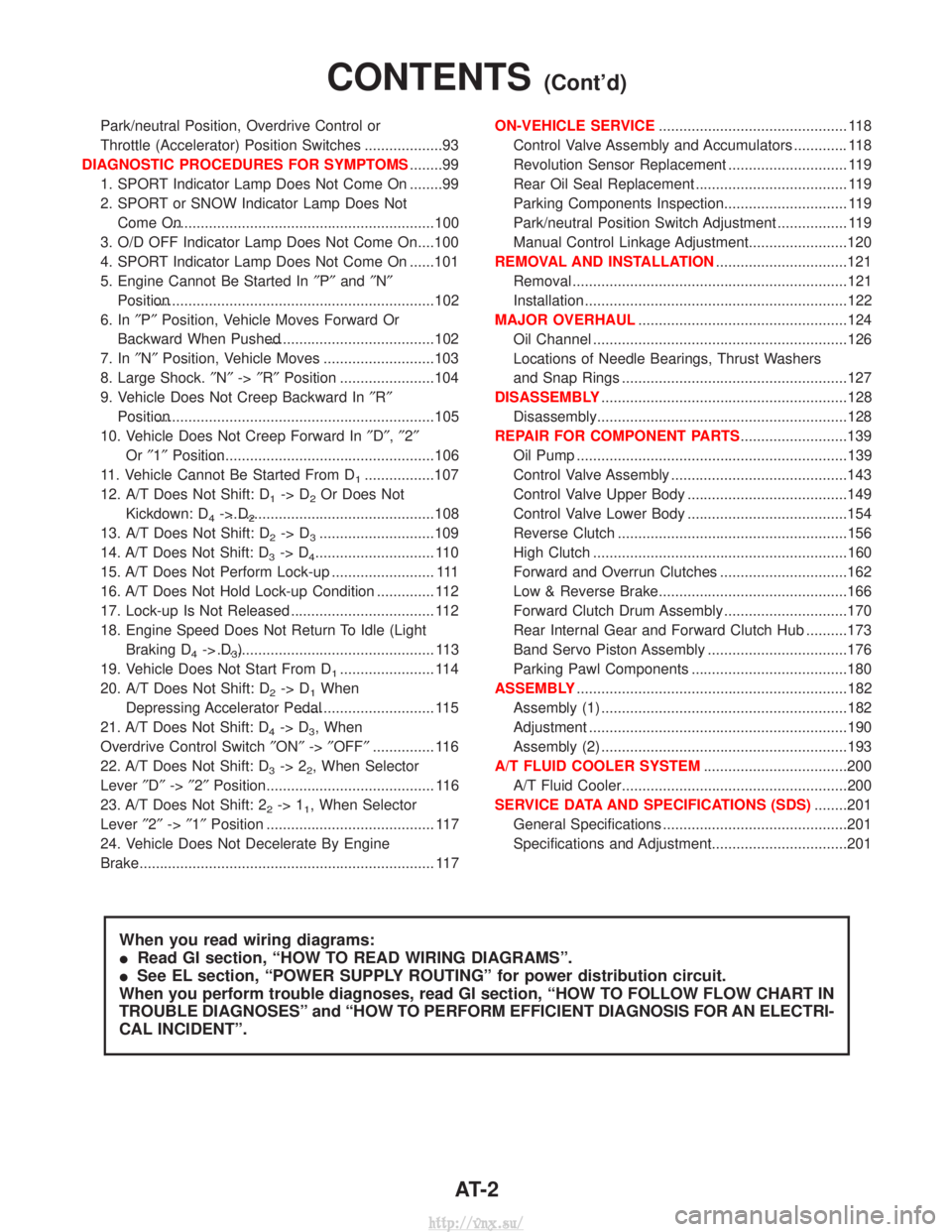

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches ...................93

DIAGNOSTIC PROCEDURES FOR SYMPTOMS ........99

1. SPORT Indicator Lamp Does Not Come On ........99

2. SPORT or SNOW Indicator Lamp Does Not Come On.................................................................100

3. O/D OFF Indicator Lamp Does Not Come On....100

4. SPORT Indicator Lamp Does Not Come On ......101

5. Engine Cannot Be Started In ²P² and ²N²

Position....................................................................102

6. In ²P² Position, Vehicle Moves Forward Or

Backward When Pushed.........................................102

7. In ²N² Position, Vehicle Moves ...........................103

8. Large Shock. ²N² ->²R² Position .......................104

9. Vehicle Does Not Creep Backward In ²R²

Position....................................................................105

10. Vehicle Does Not Creep Forward In ²D² ,²2²

Or ²1² Position.........................................................106

11. Vehicle Cannot Be Started From D

1.................107

12. A/T Does Not Shift: D

1-> D2Or Does Not

Kickdown: D

4-> D2..................................................108

13. A/T Does Not Shift: D

2-> D3............................109

14. A/T Does Not Shift: D

3-> D4............................. 110

15. A/T Does Not Perform Lock-up ......................... 111

16. A/T Does Not Hold Lock-up Condition .............. 112

17. Lock-up Is Not Released ................................... 112

18. Engine Speed Does Not Return To Idle (Light Braking D

4-> D3)..................................................... 113

19. Vehicle Does Not Start From D

1....................... 114

20. A/T Does Not Shift: D

2-> D1When

Depressing Accelerator Pedal................................. 115

21. A/T Does Not Shift: D

4-> D3, When

Overdrive Control Switch ²ON² ->²OFF² ............... 116

22. A/T Does Not Shift: D

3-> 22, When Selector

Lever ²D² ->²2² Position......................................... 116

23. A/T Does Not Shift: 2

2-> 11, When Selector

Lever ²2² ->²1² Position ......................................... 117

24. Vehicle Does Not Decelerate By Engine

Brake........................................................................\

117 ON-VEHICLE SERVICE

.............................................. 118

Control Valve Assembly and Accumulators ............. 118

Revolution Sensor Replacement ............................. 119

Rear Oil Seal Replacement ..................................... 119

Parking Components Inspection.............................. 119

Park/neutral Position Switch Adjustment ................. 119

Manual Control Linkage Adjustment........................120

REMOVAL AND INSTALLATION ................................121

Removal ...................................................................121

Installation ................................................................122

MAJOR OVERHAUL ...................................................124

Oil Channel ..............................................................126

Locations of Needle Bearings, Thrust Washers

and Snap Rings .......................................................127

DISASSEMBLY ............................................................128

Disassembly.............................................................128

REPAIR FOR COMPONENT PARTS ..........................139

Oil Pump ..................................................................139

Control Valve Assembly ...........................................143

Control Valve Upper Body .......................................149

Control Valve Lower Body .......................................154

Reverse Clutch ........................................................156

High Clutch ..............................................................160

Forward and Overrun Clutches ...............................162

Low & Reverse Brake..............................................166

Forward Clutch Drum Assembly ..............................170

Rear Internal Gear and Forward Clutch Hub ..........173

Band Servo Piston Assembly ..................................176

Parking Pawl Components ......................................180

ASSEMBLY ..................................................................182

Assembly (1) ............................................................182

Adjustment ...............................................................190

Assembly (2) ............................................................193

A/T FLUID COOLER SYSTEM ...................................200

A/T Fluid Cooler.......................................................200

SERVICE DATA AND SPECIFICATIONS (SDS) ........201

General Specifications .............................................201

Specifications and Adjustment.................................201

When you read wiring diagrams:

I Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

I See EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRI-

CAL INCIDENTº.

CONTENTS(Cont'd)

AT- 2

http://vnx.su/