system NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 2 of 1833

Edition: February 2004

Release: February 2004 (01)

Publication No.: SM4E00-1R20E0E

Reference No.: 7711347141

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL,

FUEL & EXHAUST SYSTEMFE

CLUTCHCL

MANUAL TRANSMISSIONMT

AUTOMATIC TRANSMISSIONAT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

STARTING & CHARGING SYSTEMSSC

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

TERRANO

MODEL R20 SERIES

NISSAN EUROPE S.A.S.

2004 NISSAN EUROPE S.A.S.

Produced in The Netherlands

Not to be reproduced in whole or in part

without the prior written permission of

Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

http://vnx.su/

Page 4 of 1833

GENERAL INFORMATIONSECTION

GI

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL ........................................8

HOW TO READ WIRING DIAGRAMS ..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL .......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT ........................................22 Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES ..................................................................25

CONSULT-II CHECKING SYSTEM ...............................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............26

Checking Equipment..................................................26

IDENTIFICATION INFORMATION .................................27

Model Variation ..........................................................27

Identification Number .................................................28

Dimensions ................................................................30

Wheels and Tires .......................................................30

LIFTING POINTS AND TOW TRUCK TOWING ...........31

Garage Jack and Safety Stand .................................31

Screw Jack ................................................................31

4-pole Lift ...................................................................32

Tow Truck Towing ......................................................32

ISO 15031-2 TERMINOLOGY LIST ..............................34

ISO 15031-2 Terminology List ...................................34

TIGHTENING TORQUE OF STANDARD BOLTS ........37

http://vnx.su/

Page 6 of 1833

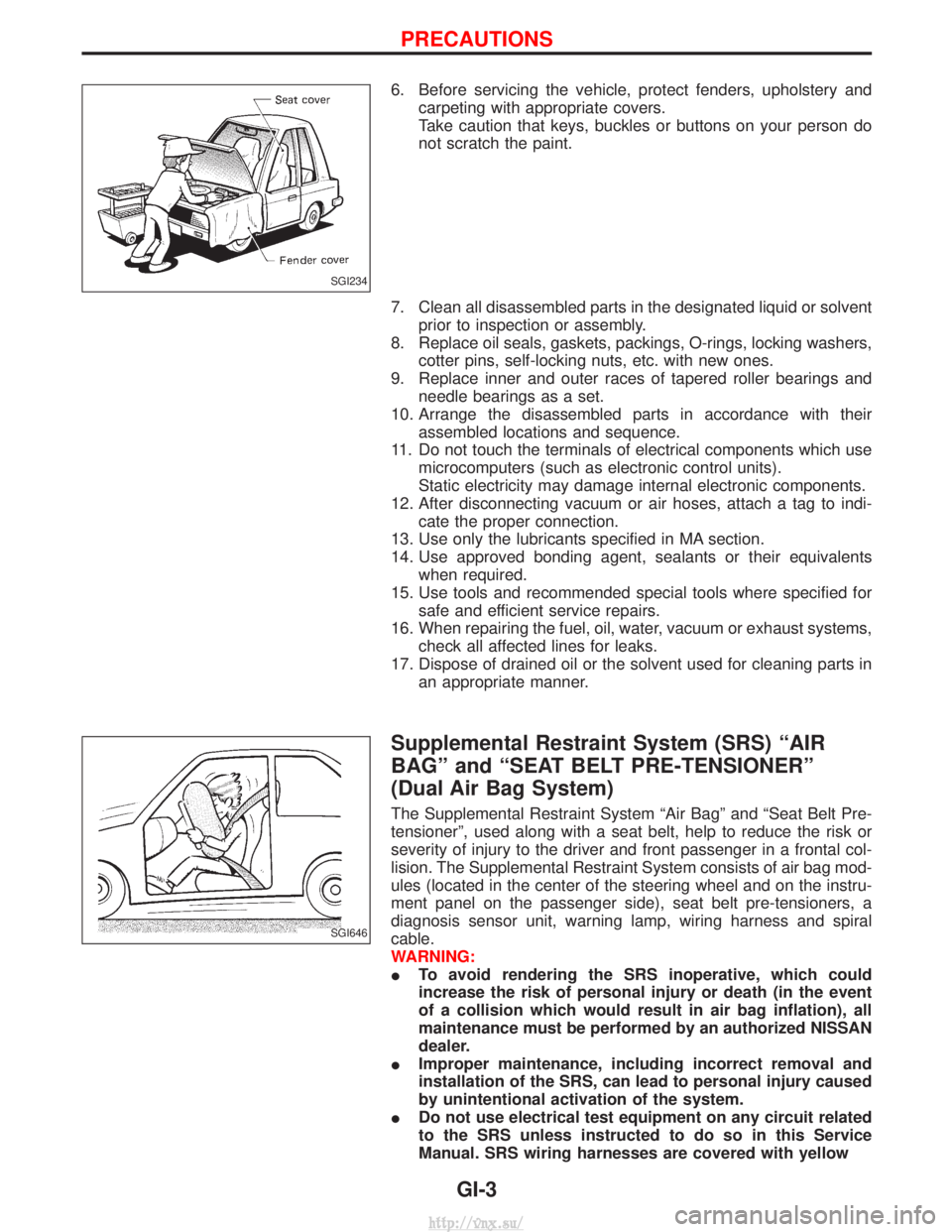

6. Before servicing the vehicle, protect fenders, upholstery andcarpeting with appropriate covers.

Take caution that keys, buckles or buttons on your person do

not scratch the paint.

7. Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

8. Replace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new ones.

9. Replace inner and outer races of tapered roller bearings and needle bearings as a set.

10. Arrange the disassembled parts in accordance with their assembled locations and sequence.

11. Do not touch the terminals of electrical components which use microcomputers (such as electronic control units).

Static electricity may damage internal electronic components.

12. After disconnecting vacuum or air hoses, attach a tag to indi- cate the proper connection.

13. Use only the lubricants specified in MA section.

14. Use approved bonding agent, sealants or their equivalents when required.

15. Use tools and recommended special tools where specified for safe and efficient service repairs.

16. When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

17. Dispose of drained oil or the solvent used for cleaning parts in an appropriate manner.

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

(Dual Air Bag System)

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-

tensionerº, used along with a seat belt, help to reduce the risk or

severity of injury to the driver and front passenger in a frontal col-

lision. The Supplemental Restraint System consists of air bag mod-

ules (located in the center of the steering wheel and on the instru-

ment panel on the passenger side), seat belt pre-tensioners, a

diagnosis sensor unit, warning lamp, wiring harness and spiral

cable.

WARNING:

ITo avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death (in the event

of a collision which would result in air bag inflation), all

maintenance must be performed by an authorized NISSAN

dealer.

I Improper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related

to the SRS unless instructed to do so in this Service

Manual. SRS wiring harnesses are covered with yellow

SGI234

SGI646

PRECAUTIONS

GI-3

http://vnx.su/

Page 7 of 1833

insulation (either just before the harness connectors or for

the complete harness), for easy identification.

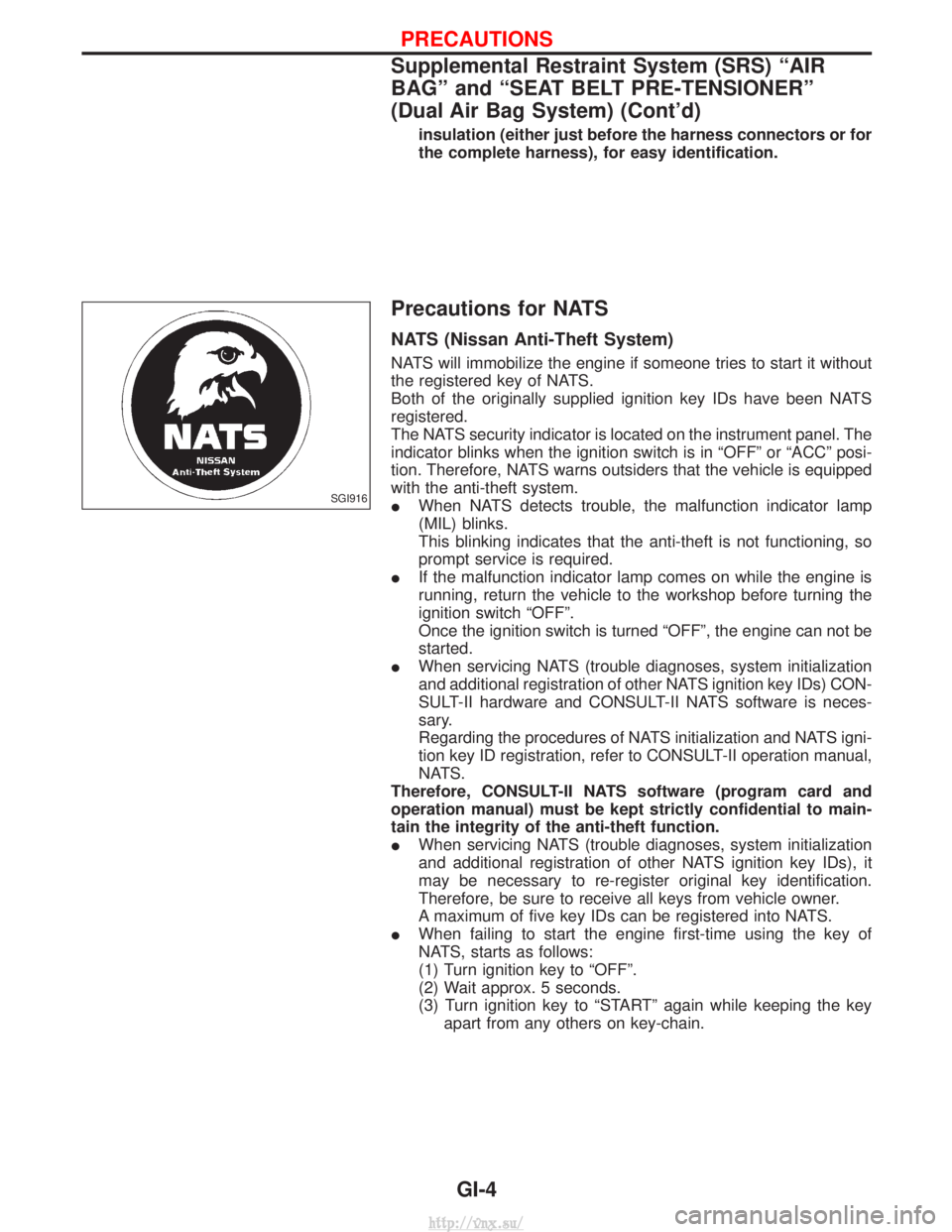

Precautions for NATS

NATS (Nissan Anti-Theft System)

NATS will immobilize the engine if someone tries to start it without

the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS

registered.

The NATS security indicator is located on the instrument panel. The

indicator blinks when the ignition switch is in ªOFFº or ªACCº posi-

tion. Therefore, NATS warns outsiders that the vehicle is equipped

with the anti-theft system.

IWhen NATS detects trouble, the malfunction indicator lamp

(MIL) blinks.

This blinking indicates that the anti-theft is not functioning, so

prompt service is required.

I If the malfunction indicator lamp comes on while the engine is

running, return the vehicle to the workshop before turning the

ignition switch ªOFFº.

Once the ignition switch is turned ªOFFº, the engine can not be

started.

I When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs) CON-

SULT-II hardware and CONSULT-II NATS software is neces-

sary.

Regarding the procedures of NATS initialization and NATS igni-

tion key ID registration, refer to CONSULT-II operation manual,

NATS.

Therefore, CONSULT-II NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

I When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs), it

may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner.

A maximum of five key IDs can be registered into NATS.

I When failing to start the engine first-time using the key of

NATS, starts as follows:

(1) Turn ignition key to ªOFFº.

(2) Wait approx. 5 seconds.

(3) Turn ignition key to ªSTARTº again while keeping the key

apart from any others on key-chain.

SGI916

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

(Dual Air Bag System) (Cont'd)

GI-4

http://vnx.su/

Page 8 of 1833

Precautions for Multiport Fuel Injection System

or Engine Control System

1. Before connecting or disconnecting any harness connector forthe multiport fuel injection system or ECM (Engine Control

Module):

Turn ignition switch to ªOFFº position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

2. Before disconnecting pressurized fuel line from fuel pump to injectors, be sure to release fuel pressure to eliminate danger.

3. Be careful not to jar components such as control unit and air flow meter.

Precautions for Catalyst

If a large amount of unburned fuel enters the converter, the con-

verter temperature will rise to excessively high values. To prevent

this, follow the procedure below:

1. Use unleaded gasoline only. Leaded gasoline will seriouslydamage the catalytic converter.

2. When checking for ignition spark or measuring engine compression, perform tests quickly and only when necessary.

3. Do not run engine when the fuel tank level is low, as a result the engine may misfire causing damage to the converter.

4. Do not place the vehicle on inflammable material. Keep inflam- mable material off the exhaust pipe.

Precautions for Turbocharger

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean

supply of oil flowing through the turbocharger and to follow all

required maintenance instructions and operating procedures.

For proper operation of the system, follow the procedure below:

1. Always use the recommended oil. Follow the instructions forproper time to change the oil and proper oil level.

2. Avoid accelerating engine to a high rpm immediately after start- ing.

3. If engine had been operating at high rpm for an extended period of time, let it idle for a few minutes prior to shutting it off.

SGI787

SGI290

SGI292

PRECAUTIONS

GI-5

http://vnx.su/

Page 11 of 1833

1.A QUICK REFERENCE INDEX , a black tab (e.g.) is provided on the first page. You can quickly find

the first page of each section by mating it to the section's black tab.

2. THE CONTENTS are listed on the first page of each section.

3. THE TITLE is indicated on the upper portion of each page and shows the part or system.

4. THE PAGE NUMBER of each section consists of two letters which designate the particular section and a

number (e.g. ªBR-5º).

5. THE LARGE ILLUSTRATIONS are exploded views (See below) and contain tightening torques, lubrica-

tion points and other information necessary to perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriate PARTS CATALOG .

6. THE SMALL ILLUSTRATIONS show the important steps such as inspection, use of special tools, knacks

of work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle

or transmission, etc. are presented in a step-by-step format where necessary.

SBR364AD

HOW TO USE THIS MANUAL

GI-8

http://vnx.su/

Page 12 of 1833

7. The followingSYMBOLS AND ABBREVIATIONS are used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use rec-

ommended multi-purpose grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disassem- bly.

L.H., R.H.: Left-Hand, Right-Hand

FR, RR : Front, Rear

2WD : 2-Wheel Drive

4WD : 4-Wheel Drive

qP: Apply petroleum jelly.

: Apply A.T.F.

A.T.F. : Automatic Transmission Fluid

H : Select with proper thickness.

I : Adjustment is required.

M/T : Manual Transaxle/Transmission

A/C : Air Conditioner

P/S : Power Steering

S.S.T. : Special Service Tools

S.D.S. : Service Data and Specifications

SAE : Society of Automotive Engineers, Inc.

L.H.D. : Left-Hand Drive

R.H.D. : Right-Hand Drive

8. The UNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system. ªExampleºTightening torque:59-78N ×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

9. TROUBLE DIAGNOSES are included in sections dealing with complicated components.

10. SERVICE DATA AND SPECIFICATIONS are contained at the end of each section for quick reference of

data.

11. The captions WARNINGandCAUTION warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

I WARNING indicates the possibility of personal injury if instructions are not followed.

I CAUTION indicates the possibility of component damage if instructions are not followed.

I BOLD TYPED STATEMENTS exceptWARNING andCAUTION give you helpful information.

HOW TO USE THIS MANUAL

GI-9

http://vnx.su/

Page 15 of 1833

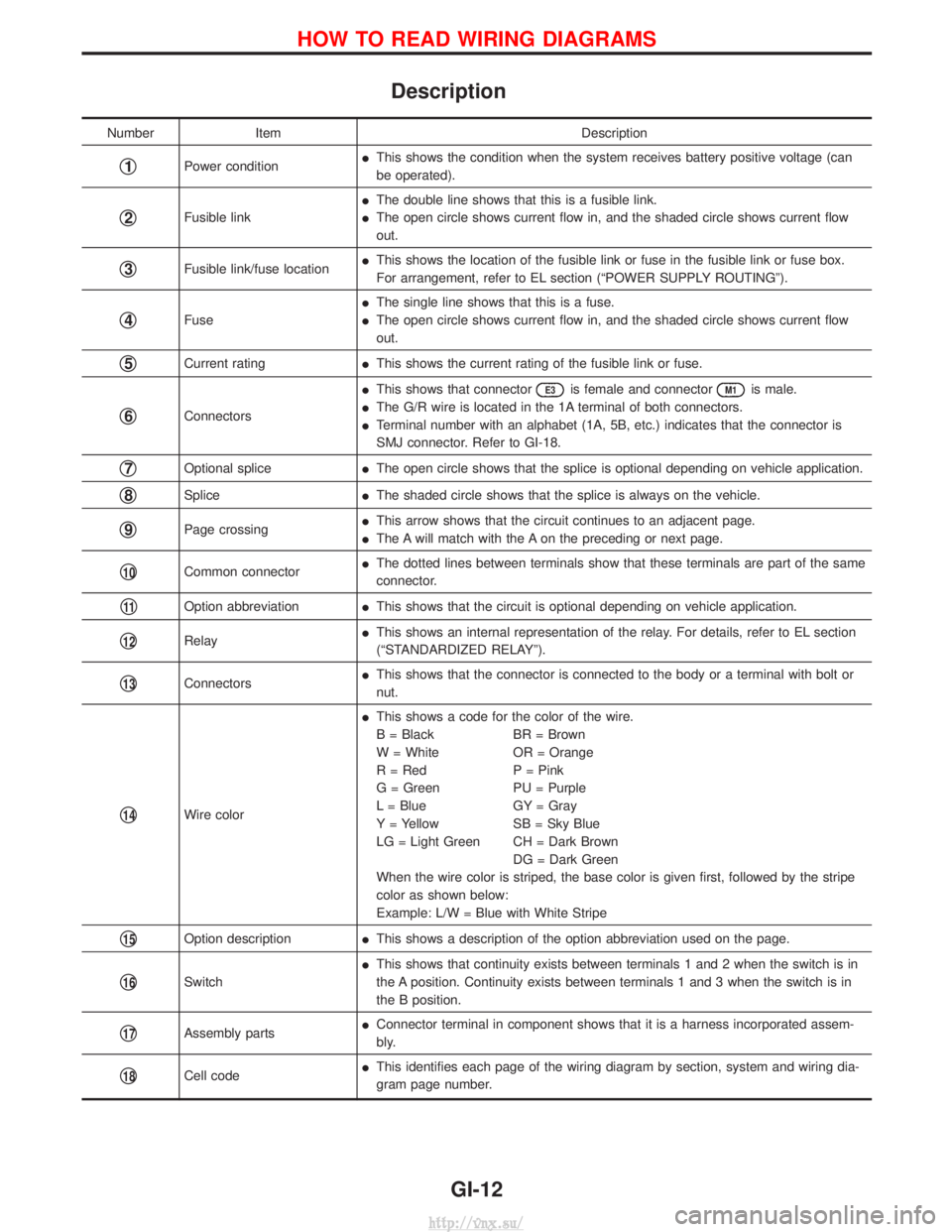

Description

NumberItem Description

q1Power conditionI

This shows the condition when the system receives battery positive voltage (can

be operated).

q2Fusible link I

The double line shows that this is a fusible link.

I The open circle shows current flow in, and the shaded circle shows current flow

out.

q3Fusible link/fuse location I

This shows the location of the fusible link or fuse in the fusible link or fuse box.

For arrangement, refer to EL section (ªPOWER SUPPLY ROUTINGº).

q4Fuse I

The single line shows that this is a fuse.

I The open circle shows current flow in, and the shaded circle shows current flow

out.

q5Current rating IThis shows the current rating of the fusible link or fuse.

q6Connectors I

This shows that connector

E3is female and connectorM1is male.

I The G/R wire is located in the 1A terminal of both connectors.

I Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is

SMJ connector. Refer to GI-18.

q7Optional splice IThe open circle shows that the splice is optional depending on vehicle application.

q8Splice IThe shaded circle shows that the splice is always on the vehicle.

q9Page crossing I

This arrow shows that the circuit continues to an adjacent page.

I The A will match with the A on the preceding or next page.

q10Common connector I

The dotted lines between terminals show that these terminals are part of the same

connector.

q11Option abbreviation IThis shows that the circuit is optional depending on vehicle application.

q12Relay I

This shows an internal representation of the relay. For details, refer to EL section

(ªSTANDARDIZED RELAYº).

q13Connectors I

This shows that the connector is connected to the body or a terminal with bolt or

nut.

q14Wire color I

This shows a code for the color of the wire.

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe

color as shown below:

Example: L/W = Blue with White Stripe

q15Option description IThis shows a description of the option abbreviation used on the page.

q16Switch I

This shows that continuity exists between terminals 1 and 2 when the switch is in

the A position. Continuity exists between terminals 1 and 3 when the switch is in

the B position.

q17Assembly parts I

Connector terminal in component shows that it is a harness incorporated assem-

bly.

q18Cell code I

This identifies each page of the wiring diagram by section, system and wiring dia-

gram page number.

HOW TO READ WIRING DIAGRAMS

GI-12

http://vnx.su/

Page 16 of 1833

NumberItem Description

q19Current flow arrowI

Arrow indicates electric current flow, especially where the direction of standard

flow (vertically downward or horizontally from left to right) is difficult to follow.

I A double arrow ªF Ð

Eº shows that current can flow in either direction depending on

circuit operation.

q20System branch I

This shows that the system branches to another system identified by cell code

(section and system).

q21Page crossing I

This arrow shows that the circuit continues to another page identified by cell code.

I The C will match with the C on another page within the system other than the next

or preceding pages.

q22Shielded line IThe line enclosed by broken line circle shows shield wire.

q23Component box in wave

line I

This shows that another part of the component is also shown on another page

(indicated by wave line) within the system.

q24Component name IThis shows the name of a component.

q25Connector number I

This shows the connector number.

I The letter shows which harness the connector is located in.

Example: M: main harness. For detail and to locate the connector, refer to EL sec-

tion (ªMain Harnessº, ªHARNESS LAYOUTº). A coordinate grid is included for com-

plex harnesses to aid in locating connectors.

q26Ground (GND) I

The line spliced and grounded under wire color shows that ground line is spliced

at the grounded connector.

q27Ground (GND) IThis shows the ground connection.

q28Connector views I

This area shows the connector faces of the components in the wiring diagram on

the page.

q29Common component I

Connectors enclosed in broken line show that these connectors belong to the

same component.

q30Connector color I

This shows a code for the color of the connector. For code meaning, refer to wire

color codes, Number q14of this chart.

q31Fusible link and fuse box I

This shows the arrangement of fusible link(s) and fuse(s), used for connector

views of ªPOWER SUPPLY ROUTINGº in EL section.

The open square shows current flow in, and the shaded square shows current

flow out.

q32Reference area I

This shows that more information on the Super Multiple Junction (SMJ) and Joint

Connectors (J/C) exists on the foldout page. Refer to GI-18 for details.

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-13

http://vnx.su/

Page 19 of 1833

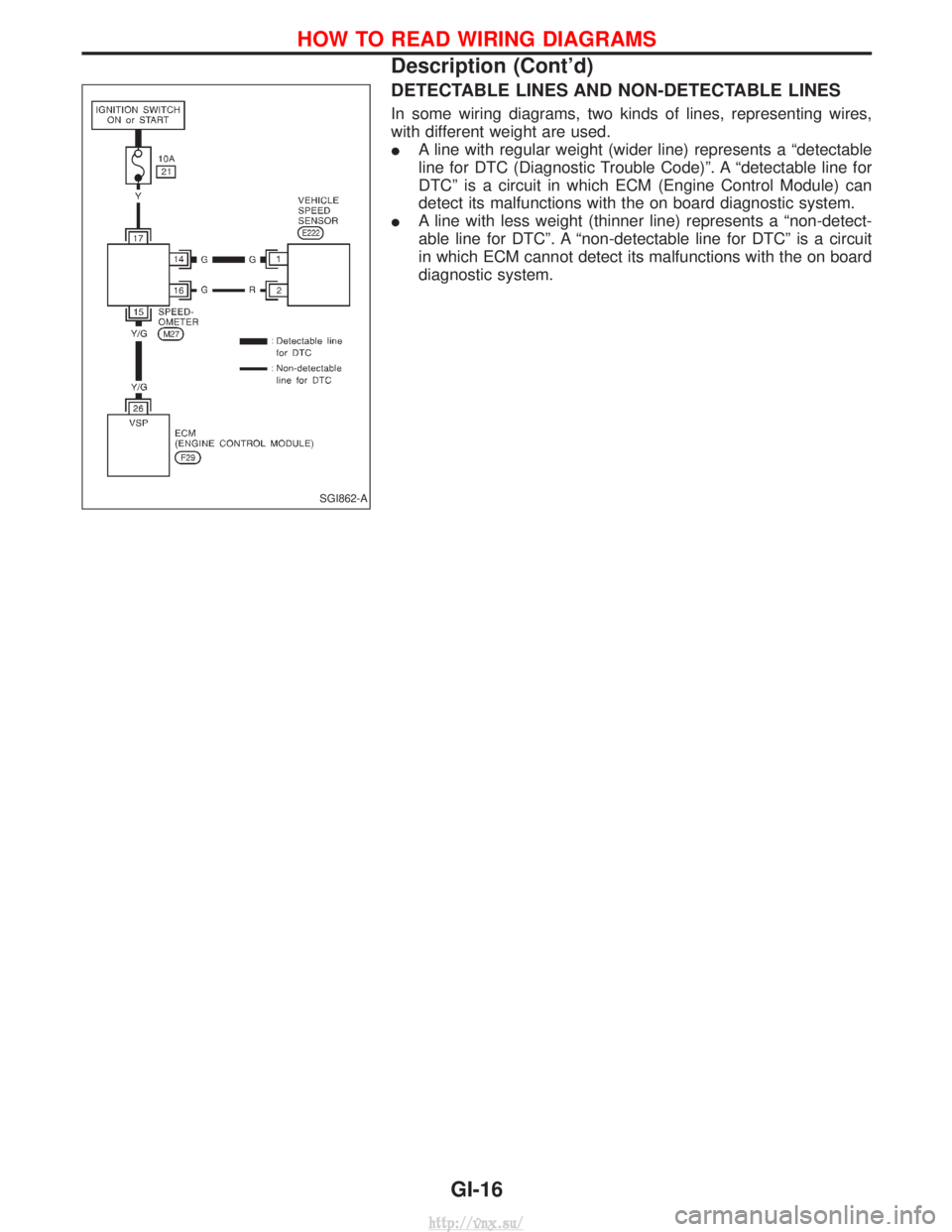

DETECTABLE LINES AND NON-DETECTABLE LINES

In some wiring diagrams, two kinds of lines, representing wires,

with different weight are used.

IA line with regular weight (wider line) represents a ªdetectable

line for DTC (Diagnostic Trouble Code)º. A ªdetectable line for

DTCº is a circuit in which ECM (Engine Control Module) can

detect its malfunctions with the on board diagnostic system.

I A line with less weight (thinner line) represents a ªnon-detect-

able line for DTCº. A ªnon-detectable line for DTCº is a circuit

in which ECM cannot detect its malfunctions with the on board

diagnostic system.

SGI862-A

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-16

http://vnx.su/