light system NISSAN TIIDA 2007 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2642 of 5883

![NISSAN TIIDA 2007 Service Owners Manual PRECAUTIONS

EC-1293

< PRECAUTION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000 NISSAN TIIDA 2007 Service Owners Manual PRECAUTIONS

EC-1293

< PRECAUTION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000](/img/5/57395/w960_57395-2641.png)

PRECAUTIONS

EC-1293

< PRECAUTION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001706108

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000001162744

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

On Board Diagnostic (OBD) System of EngineINFOID:0000000001162745

The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

Be sure to turn the ignition switch OFF and disconnect the battery negative cable before any repair

or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will

cause the MI to light up.

Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to XX-XX, "*****"

.

Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel system, etc.

Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM before

returning the vehicle to the customer.

PIIB3706J

Page 2643 of 5883

![NISSAN TIIDA 2007 Service Owners Manual EC-1294

< PRECAUTION >[K9K]

PRECAUTIONS

General Precautions

INFOID:0000000001162746

Always use a 12 volt battery as power source.

Do not attempt to disconnect battery cables while engine is

running. NISSAN TIIDA 2007 Service Owners Manual EC-1294

< PRECAUTION >[K9K]

PRECAUTIONS

General Precautions

INFOID:0000000001162746

Always use a 12 volt battery as power source.

Do not attempt to disconnect battery cables while engine is

running.](/img/5/57395/w960_57395-2642.png)

EC-1294

< PRECAUTION >[K9K]

PRECAUTIONS

General Precautions

INFOID:0000000001162746

Always use a 12 volt battery as power source.

Do not attempt to disconnect battery cables while engine is

running.

Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF, wait 3 minutes and discon-

nect battery negative cable. Failure to do so may damage the

ECM because battery voltage is applied to ECM even if igni-

tion switch is turned OFF.

Before removing parts, turn ignition switch OFF and then dis-

connect battery negative cable.

Do not disassemble ECM.

When connecting ECM harness connector, fasten (A) it

securely with levers (1) as far as they will go as shown in the

figure.

-ECM (2)

-Loosen (B)

When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and condenser, thus resulting in dam-

age to IC's.

Keep engine control system harness at least 10cm (4 in) away

from adjacent harness, to prevent engine control system mal-

functions due to receiving external noise, degraded operation

of IC's, etc.

Keep engine control system parts and harness dry.

Handle mass air flow sensor carefully to avoid damage.

Do not disassemble mass air flow sensor.

Do not clean mass air flow sensor with any type of detergent.

Even a slight leak in the air intake system can cause serious incidents.

Do not shock or jar the camshaft position sensor, crankshaft position sensor.

SEF289H

MBIB1517E

MBIB1518E

SEF291H

Page 2857 of 5883

![NISSAN TIIDA 2007 Service Owners Manual EM-210

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

When installation directions are specified, install parts according to the directions. Refer to EM-207, "Com-

ponent".

Prior to installi NISSAN TIIDA 2007 Service Owners Manual EM-210

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

When installation directions are specified, install parts according to the directions. Refer to EM-207, "Com-

ponent".

Prior to installi](/img/5/57395/w960_57395-2856.png)

EM-210

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

When installation directions are specified, install parts according to the directions. Refer to EM-207, "Com-

ponent".

Prior to installing the upper torque rod, apply a light coat of silicone

lubricant (A) to the washer facing side of the bushing inner tube as

shown.

NOTE:

Apply silicone lubricant (A) by dabbing the outward facing tube

surface with a sponge or suitable tool.

Do not apply excess lubricant.

Make sure that each mounting insulator is seated properly, and tighten nuts and bolts.

Tighten engine mounting insulator (RH) bolts in the numerical

order shown.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to LU-15, "

Inspection", CO-35, "Inspection".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle fluid, power steering fluid, brake fluid, etc.: Vehicle front

LBIA0470E

: Vehicle front

WBIA0785E

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2900 of 5883

![NISSAN TIIDA 2007 Service Owners Manual PRECAUTIONS

EM-253

< PRECAUTION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Precaution for Liquid GasketINFOID:0000000001381456

REMOVAL OF LIQUID GASKET

After removing the mounting bolts and nuts, separa NISSAN TIIDA 2007 Service Owners Manual PRECAUTIONS

EM-253

< PRECAUTION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Precaution for Liquid GasketINFOID:0000000001381456

REMOVAL OF LIQUID GASKET

After removing the mounting bolts and nuts, separa](/img/5/57395/w960_57395-2899.png)

PRECAUTIONS

EM-253

< PRECAUTION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Precaution for Liquid GasketINFOID:0000000001381456

REMOVAL OF LIQUID GASKET

After removing the mounting bolts and nuts, separate the mating

surface using a seal cutter and remove the liquid gasket.

CAUTION:

Be careful not to damage the mating surfaces.

In areas where the cutter is difficult to use, use a plastic hammer to

lightly tap the liquid gasket applied area.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

Remove the liquid gasket completely from the groove of the

gasket application surface, mounting bolts and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the liquid gasket without breaks to the specified location

with the specified dimensions.

If there is a groove for the liquid gasket application, apply the

gasket to the groove.

As for the bolt holes, normally apply the gasket inside the

holes. If specified, it should be applied outside the holes. Make

sure to read the instruction in this manual.

Within five minutes of gasket application, install the mating

component.

If the liquid gasket protrudes, wipe it off immediately.

Do not retighten after the installation.

After 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are instructions in this manual, observe them.

Precaution for Diesel EquipmentINFOID:0000000001381457

CLEANLINESS

CLEANLINESS INSTRUCTIONS WHICH MUST BE FOLLOWED WHEN WORKING ON THE HIGH PRES-

SURE DIRECT INJECTION SYSTEM

Risks relating to contamination

PBIC0275E

PBIC0003E

EMA0622D

SEM159F

Page 2903 of 5883

![NISSAN TIIDA 2007 Service Owners Manual EM-256

< PRECAUTION >[K9K]

PRECAUTIONS

SPECIAL FEATURES

CAUTION:

The engine must not operate with:

- Diesel engine fuel containing more than 10% diester,

- Petrol, even in tiny quantities.

The sys NISSAN TIIDA 2007 Service Owners Manual EM-256

< PRECAUTION >[K9K]

PRECAUTIONS

SPECIAL FEATURES

CAUTION:

The engine must not operate with:

- Diesel engine fuel containing more than 10% diester,

- Petrol, even in tiny quantities.

The sys](/img/5/57395/w960_57395-2902.png)

EM-256

< PRECAUTION >[K9K]

PRECAUTIONS

SPECIAL FEATURES

CAUTION:

The engine must not operate with:

- Diesel engine fuel containing more than 10% diester,

- Petrol, even in tiny quantities.

The system can inject the diesel into the engine at a pressure up to 1400 bars. Before carrying out

any work, check that the injector rail is not under pressure and that the fuel temperature is not too

high.

You must respect the cleaning and safety advice specified in this document for any work on the high

pressure injection system.

Removal of the interior of the pump and injectors is prohibited. Only the flow actuator, the fuel tem-

perature sensor and the venturi can be replaced.

For safety reasons, it is strictly forbidden to slacken a injection tube union when the engine is run-

ning.

It is not possible to remove the pressure sensor from the fuel rail because this may cause circuit

contamination malfunctions. If the pressure sensor fails, the pressure sensor, the rail and the five

injection tubes must be replaced.

It is strictly forbidden to remove any high pressure supply pump pulley marked number 070 575. If

the pump is being replaced, the pulley must be replaced.

It is forbidden to repair the wiring connecting the knock sensor (accelerometer) and the CKP sensor

(engine speed sensor). If the wiring should fail, it has to be replaced with new wiring.

Applying 12 volts directly to any component in the system is prohibited.

Ultrasonic carbon removal and cleaning are prohibited.

Never start the engine without the battery being connected correctly.

It is essential to replace all the disconnected air inlet plastic pipes.

INSTRUCTIONS FOR INJECTION TUBES

CAUTION:

All the injection tube removed must be systematically replaced along with the clips.

TIGHTENING THE INJECTION TUBES

NOTE:

fit the pump/rail pipe before the rail/injector pipes.

Rail-pump pipe

Undo the rail,

Grease the threads of the injection tube nuts,

Insert the injection tube olive into the taper of the high pressure pump outlet,

Insert the injection tube olive into the taper of the high pressure rail inlet.

Move the nut into position by hand, on the rail side then the pump side,

Tighten the rail,

Tighten the injection tube nuts on the rail side then on the pump side.

Rail/injector pipes

Undo the rail,

Grease the threads of the injection tube nuts,

Insert the injection tube olive into the taper of the high pressure injector inlet,

Insert the injection tube olive into the taper of the high pressure rail outlet,

Move the nuts into position by hand, on the injector side then the rail side,

Tighten the rail,

Ensure that the new clip, supplied with the new injection tube, is fitted,

Tighten the nuts of the injection tubes on the injector side first and then on the fuel rail side.

NOTE:

Before fitting a new injection tube, move back the nuts on the pipe then lightly lubricate the nut

threads with the oil from the sachet provided in the parts kit.

CHECKING SEALING AFTER REPAIR

CAUTION:

After any operation, check that there are no diesel leaks.

Reprime the circuit using the priming pump.

Start the engine and allow to warm up at idle speed, visually inspecting for any fuel leaks.

Apply tracing fluid around the high pressure connections of the pipe that has been replaced.

Once the engine coolant temperature is above 50°C and provided there are no malfunctions present, carry

out a road test, taking the engine speed up to 4000 rpm at least once to check that there are no leaks.

Perform a visual inspection after the road test to make sure that there are no high pressure leaks.

Clean off the tracing fluid.

Page 2929 of 5883

![NISSAN TIIDA 2007 Service Owners Manual EM-282

< ON-VEHICLE REPAIR >[K9K]

INJECTION TUBE AND FUEL INJECTOR

6. Remove fuel hose shield.

7. Disconnect fuel feed hose.

8. Remove high pressure pipes protection cover (upper).

9. Remove the neck NISSAN TIIDA 2007 Service Owners Manual EM-282

< ON-VEHICLE REPAIR >[K9K]

INJECTION TUBE AND FUEL INJECTOR

6. Remove fuel hose shield.

7. Disconnect fuel feed hose.

8. Remove high pressure pipes protection cover (upper).

9. Remove the neck](/img/5/57395/w960_57395-2928.png)

EM-282

< ON-VEHICLE REPAIR >[K9K]

INJECTION TUBE AND FUEL INJECTOR

6. Remove fuel hose shield.

7. Disconnect fuel feed hose.

8. Remove high pressure pipes protection cover (upper).

9. Remove the neck located on the fuel rail.

NOTE:

Undo the nut on the pump side or the injector side, then the nut located on the rail side. Undo the

nuts for each pipe in turn. Move the nut along the pipe keeping the olive in contact with the taper.

10. Remove all the injection tubes.

11. Plug all the holes in the injection circuit.

12. Remove fuel rail.

13. Disconnect fuel return pipe.

14. Remove retaining clip and disconnect the diesel return pipe on

the injector.

15. Plug all the holes of the injection circuit.

16. Disconnect the injector harness connector (1).

17. Remove the injector bracket (2).

18. Remove the injector.

19. Pull off the flame shield washer.

20. Disconnect the fuel pressure sensor.

21. Remove the high pressure pipes protection cover (lower).

INSTALLATION

CAUTION:

All the injection tubes removed must be systematically replaced.

1. Clean the injector sockets and the injector bodies, as well as their brackets using a lint-free cloth (use the

wipes recommended for this purpose, dipped in clean solvent.

2. Dry off using a different new wipe.

3. Replace the flame shield washer with a new one.

4. Position the injector.

5. Tighten the mounting bracket bolts.

6. Install injection tubes with new one.

7. Finger tighten the nuts.

8. Before fitting the new injection tubes, lightly lubricate the nut threads with the oil from the sachet provided

in the new parts kit.

NOTE:

Fit the pump/rail pipe before the rail/injector tubes.

9. Fit the pump-rail injection tube as follows:

Remove the protective plugs from the high pressure pump outlet, the high pressure rail inlet and the

pipe.

E1BIA0049ZZ

MBIB9030E

: 30.0 N·m (3.1 kg-m, 22 ft-lb)

Page 3002 of 5883

EXL-1

DRIVER CONTROLS

C

D

E

F

G

H

I

J

K

M

SECTION EXL

A

B

EXL

N

O

P

CONTENTS

EXTERIOR LIGHTING SYSTEM

BASIC INSPECTION ....................................5

DIAGNOSIS AND REPAIR WORKFLOW ..........5

Work Flow .................................................................5

FUNCTION DIAGNOSIS ...............................8

HEADLAMP (HALOGEN) ...................................8

System Diagram ........................................................8

System Description ...................................................8

Component Parts Location ........................................8

Component Description .............................................8

HEADLAMP (XENON) .......................................10

System Diagram ......................................................10

System Description .................................................10

Component Parts Location ......................................10

Component Description ..........................................11

AUTO LIGHT SYSTEM ......................................12

System Diagram ......................................................12

System Description .................................................12

Component Parts Location ......................................12

Component Description ...........................................13

HEADLAMP AIMING SYSTEM (MANUAL) .......14

System Diagram ......................................................14

System Description .................................................14

Component Parts Location ......................................14

Component Description ...........................................14

HEADLAMP AIMING SYSTEM (AUTOMAT-

IC) .......................................................................

15

System Diagram ......................................................15

System Description .................................................15

Component Parts Location ......................................15

Component Description ...........................................15

DAYTIME LIGHT SYSTEM ................................17

System Diagram ......................................................17

System Description .................................................17

Component Parts Location ......................................17

Component Description ..........................................18

FRONT FOG LAMP ..........................................19

System Diagram ......................................................19

System Description ..................................................19

Component Parts Location ......................................19

Component Description ...........................................20

REAR FOG LAMP .............................................21

System Diagram ......................................................21

System Description ..................................................21

Component Parts Location ......................................21

Component Description ..........................................21

TURN SIGNAL AND HAZARD WARNING

LAMPS ..............................................................

22

System Diagram ......................................................22

System Description ..................................................22

Component Parts Location ......................................22

Component Description ...........................................23

PARKING, LICENSE PLATE AND TAIL

LAMPS ..............................................................

24

System Diagram ......................................................24

System Description ..................................................24

Component Parts Location ......................................25

Component Description ...........................................25

DIAGNOSIS SYSTEM (BCM) ...........................26

COMMON ITEM .........................................................26

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

26

BCM ...........................................................................26

BCM : CONSULT-III Function (BCM - BCM) ...........26

HEADLAMP ...............................................................26

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP) ...........................................................

26

FLASHER ...................................................................27

Page 3003 of 5883

EXL-2

FLASHER : CONSULT-III Function (BCM -

FLASHER) ..............................................................

27

COMB SW .................................................................28

COMB SW : CONSULT-III Function (BCM -

COMB SW) .............................................................

28

BATTERY SAVER ....................................................28

BATTERY SAVER : CONSULT-III Function (BCM

- BATTERY SAVER) ..............................................

28

DIAGNOSIS SYSTEM (IPDM E/R) ....................30

CONSULT - III Function (IPDM E/R) ......................30

DIAGNOSIS SYSTEM (HEADLAMP LEVEL-

IZER) ..................................................................

31

CONSULT-III Function ...........................................31

COMPONENT DIAGNOSIS ........................32

POWER SUPPLY AND GROUND CIRCUIT .....32

BCM (BODY CONTROL MODULE) .........................32

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ...............................................................

32

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .............................

32

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .....................................................................

32

HEADLAMP (HI) CIRCUIT ................................33

HEADLAMP (HALOGEN) .........................................33

HEADLAMP (HALOGEN) : Description ..................33

HEADLAMP (HALOGEN) : Component Function

Check .....................................................................

33

HEADLAMP (HALOGEN) : Diagnosis Procedure ...33

HEADLAMP (XENON) ..............................................34

HEADLAMP (XENON) : Description .......................34

HEADLAMP (XENON) : Component Function

Check .....................................................................

34

HEADLAMP (XENON) : Diagnosis Procedure .......35

HEADLAMP (LO) CIRCUIT ...............................37

HEADLAMP (HALOGEN) .........................................37

HEADLAMP (HALOGEN) : Description ..................37

HEADLAMP (HALOGEN) : Component Function

Check .....................................................................

37

HEADLAMP (HALOGEN) : Diagnosis Procedure ...37

HEADLAMP (XENON) ..............................................38

HEADLAMP (XENON) : Description .......................38

HEADLAMP (XENON) : Component Function

Check .....................................................................

38

HEADLAMP (XENON) : Diagnosis Procedure .......39

FRONT FOG LAMP CIRCUIT ...........................41

Description ..............................................................41

Component Function Check ...................................41

Diagnosis Procedure ...............................................41

REAR FOG LAMP CIRCUIT .............................43

Description ..............................................................43

Component Function Check ...................................43

Diagnosis Procedure ...............................................43

PARKING LAMP CIRCUIT ................................46

WITH DAYTIME LIGHT SYSTEM .............................46

WITH DAYTIME LIGHT SYSTEM : Description .....46

WITH DAYTIME LIGHT SYSTEM : Component

Function Check .......................................................

46

WITH DAYTIME LIGHT SYSTEM : Diagnosis Pro-

cedure .....................................................................

46

WITHOUT DAYTIME LIGHT SYSTEM .....................48

WITHOUT DAYTIME LIGHT SYSTEM : Descrip-

tion ..........................................................................

48

WITHOUT DAYTIME LIGHT SYSTEM : Compo-

nent Function Check ...............................................

48

WITHOUT DAYTIME LIGHT SYSTEM : Diagno-

sis Procedure ..........................................................

49

TURN SIGNAL LAMP CIRCUIT ........................52

Description ..............................................................52

Component Function Check ...................................52

Diagnosis Procedure ...............................................52

LIGHT & RAIN SENSOR ...................................55

Description ..............................................................55

Component Function Check ...................................55

Diagnosis Procedure ...............................................55

HEADLAMP AIMER SWITCH ...........................57

Description ..............................................................57

Diagnosis Procedure ...............................................57

HEADLAMP (HALOGEN) .................................58

Wiring Diagram .......................................................58

HEADLAMP (XENON) .......................................59

Wiring Diagram .......................................................59

AUTO LIGHT SYSTEM .....................................60

Wiring Diagram .......................................................60

HEADLAMP AIMING SYSTEM (MANUAL) ......61

Wiring Diagram .......................................................61

HEADLAMP AIMING SYSTEM (AUTOMAT-

IC) ......................................................................

62

Wiring Diagram .......................................................62

DAYTIME LIGHT SYSTEM ...............................63

Wiring Diagram .......................................................63

FRONT FOG LAMP ...........................................64

Wiring Diagram .......................................................64

REAR FOG LAMP .............................................65

Wiring Diagram .......................................................65

Page 3004 of 5883

EXL-3

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

TURN SIGNAL AND HAZARD WARNING

LAMPS ...............................................................

66

Wiring Diagram .......................................................66

PARKING, LICENSE PLATE AND TAIL

LAMPS ...............................................................

67

WITH DAYTIME LIGHT SYSTEM .............................67

WITH DAYTIME LIGHT SYSTEM : Wiring Dia-

gram ........................................................................

67

WITHOUT DAYTIME LIGHT SYSTEM ......................67

WITHOUT DAYTIME LIGHT SYSTEM : Wiring Di-

agram ......................................................................

68

STOP LAMP .......................................................69

Wiring Diagram .......................................................69

BACK-UP LAMP ................................................70

Wiring Diagram .......................................................70

ECU DIAGNOSIS .........................................71

BCM (BODY CONTROL MODULE) ...................71

Description ..............................................................71

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

72

Description ..............................................................72

SYMPTOM DIAGNOSIS ..............................73

EXTERIOR LIGHTING SYSTEM SYMPTOMS ....73

Symptom Table .......................................................73

NORMAL OPERATING CONDITION .................75

Description ..............................................................75

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM .................................................

76

Description ..............................................................76

Diagnosis Procedure ...............................................76

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON .......................................................

77

Description ..............................................................77

Diagnosis Procedure ...............................................77

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON ........................

78

Description ..............................................................78

Diagnosis Procedure ...............................................78

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON .......................................................

79

Description ..............................................................79

Diagnosis Procedure ...............................................79

PRECAUTION ..............................................80

PRECAUTIONS ..................................................80

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

80

ON-VEHICLE MAINTENANCE ....................81

HEADLAMP ......................................................81

Aiming Adjustment ...................................................81

FRONT FOG LAMP ..........................................83

Aiming Adjustment ...................................................83

ON-VEHICLE REPAIR .................................84

HEADLAMP ......................................................84

Bulb Replacement ...................................................84

Removal and Installation .........................................84

Disassembly and Assembly - Halogen ....................85

Disassembly and Assembly - Xenon .......................86

FRONT FOG LAMP ..........................................87

Bulb Replacement ...................................................87

Removal and Installation .........................................87

HEADLAMP AIMING CONTROL ......................88

Removal and Installation of Headlamp Aiming

Switch ......................................................................

88

Removal and Installation of Height Sensor .............89

AUTO LIGHT SYSTEM .....................................91

Removal and Installation of Light and Rain Sensor

....

91

SIDE TURN SIGNAL LAMP ..............................92

Bulb Replacement ...................................................92

Removal and Installation .........................................92

REAR COMBINATION LAMP ...........................93

Bulb Replacement ...................................................93

Removal and Installation .........................................93

Disassembly and Assembly .....................................93

HIGH-MOUNTED STOP LAMP ........................96

Bulb Replacement ...................................................96

Removal and Installation .........................................96

LICENSE PLATE LAMP ...................................98

Bulb Replacement ...................................................98

Removal and Installation .........................................98

REAR FOG LAMP ...........................................100

Bulb Replacement .................................................100

Removal and Installation .......................................100

LIGHTING & TURN SIGNAL SWITCH ...........101

Removal and Installation .......................................101

HAZARD SWITCH ..........................................102

Removal and Installation .......................................102

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

103

Page 3009 of 5883

EXL-8

< FUNCTION DIAGNOSIS >

HEADLAMP (HALOGEN)

FUNCTION DIAGNOSIS

HEADLAMP (HALOGEN)

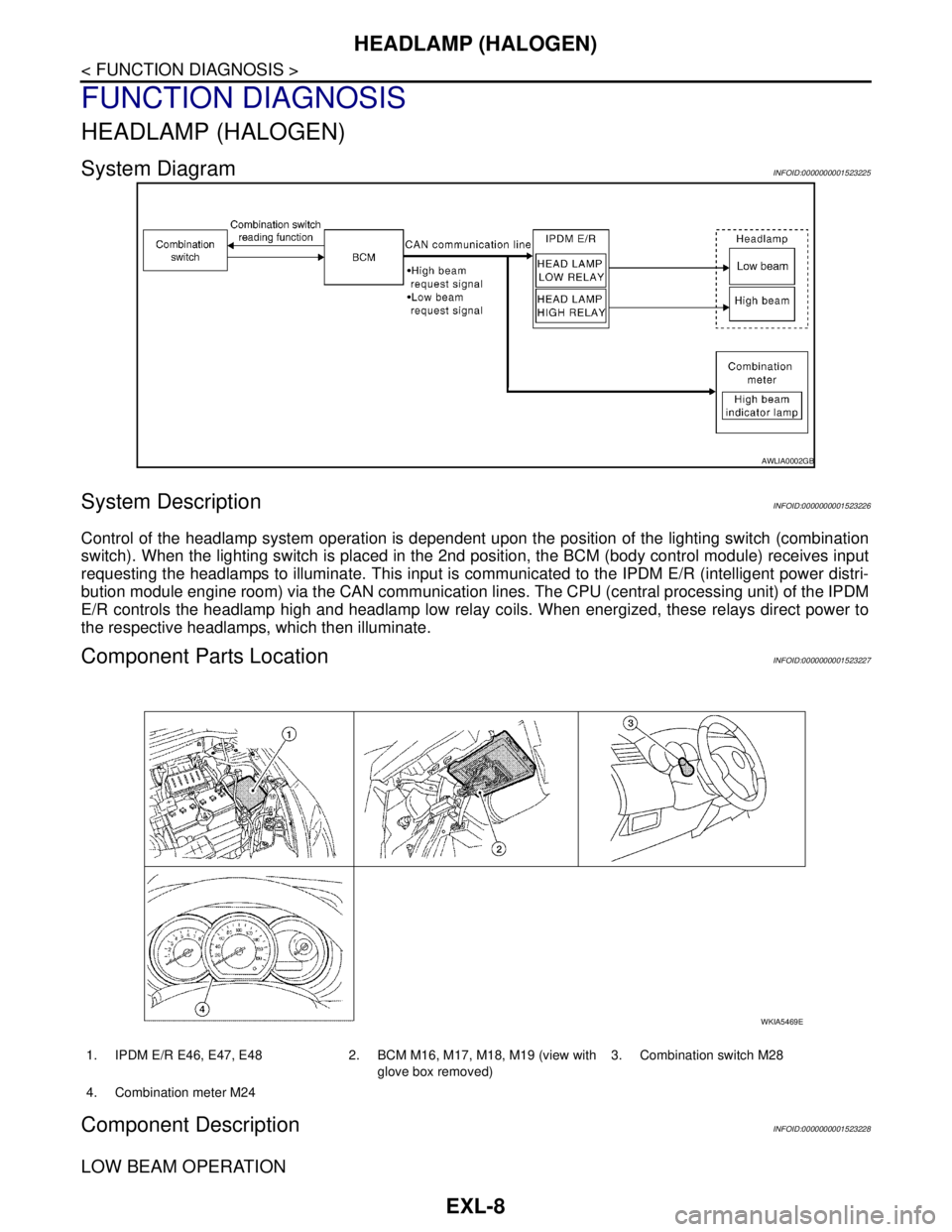

System DiagramINFOID:0000000001523225

System DescriptionINFOID:0000000001523226

Control of the headlamp system operation is dependent upon the position of the lighting switch (combination

switch). When the lighting switch is placed in the 2nd position, the BCM (body control module) receives input

requesting the headlamps to illuminate. This input is communicated to the IPDM E/R (intelligent power distri-

bution module engine room) via the CAN communication lines. The CPU (central processing unit) of the IPDM

E/R controls the headlamp high and headlamp low relay coils. When energized, these relays direct power to

the respective headlamps, which then illuminate.

Component Parts LocationINFOID:0000000001523227

Component DescriptionINFOID:0000000001523228

LOW BEAM OPERATION

AWLIA0002GB

1. IPDM E/R E46, E47, E48 2. BCM M16, M17, M18, M19 (view with

glove box removed)3. Combination switch M28

4. Combination meter M24

WKIA5469E