switch NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 182 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-47

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

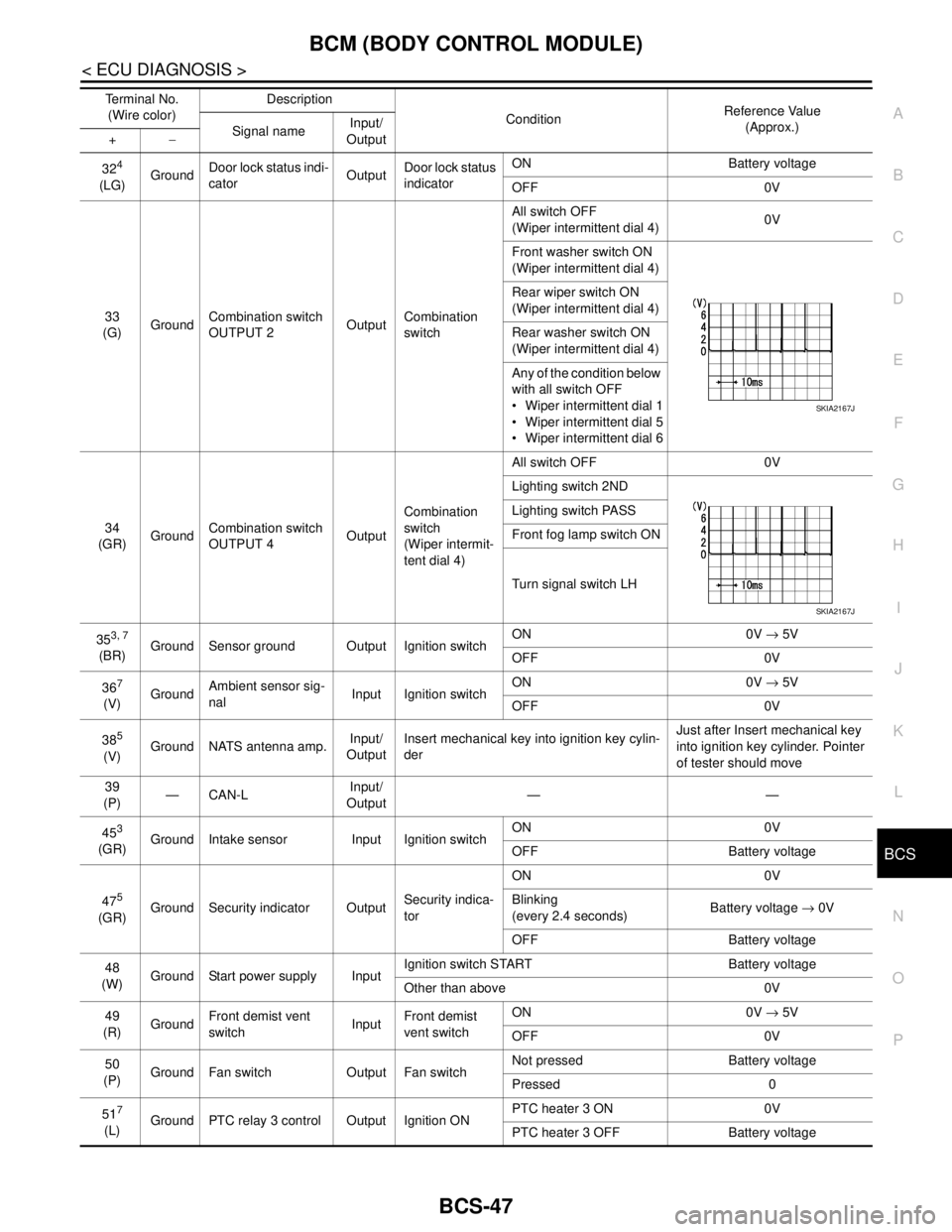

324

(LG)GroundDoor lock status indi-

catorOutputDoor lock status

indicatorON Battery voltage

OFF 0V

33

(G)GroundCombination switch

OUTPUT 2OutputCombination

switchAll switch OFF

(Wiper intermittent dial 4)0V

Front washer switch ON

(Wiper intermittent dial 4)

Rear wiper switch ON

(Wiper intermittent dial 4)

Rear washer switch ON

(Wiper intermittent dial 4)

Any of the condition below

with all switch OFF

Wiper intermittent dial 1

Wiper intermittent dial 5

Wiper intermittent dial 6

34

(GR)GroundCombination switch

OUTPUT 4OutputCombination

switch

(Wiper intermit-

tent dial 4)All switch OFF 0V

Lighting switch 2ND

Lighting switch PASS

Front fog lamp switch ON

Turn signal switch LH

35

3, 7

(BR)Ground Sensor ground Output Ignition switchON 0V → 5V

OFF 0V

36

7

(V)GroundAmbient sensor sig-

nalInput Ignition switchON 0V → 5V

OFF 0V

38

5

(V)Ground NATS antenna amp.Input/

OutputInsert mechanical key into ignition key cylin-

derJust after Insert mechanical key

into ignition key cylinder. Pointer

of tester should move

39

(P)—CAN-LInput/

Output——

45

3

(GR)Ground Intake sensor Input Ignition switchON 0V

OFF Battery voltage

47

5

(GR)Ground Security indicator OutputSecurity indica-

torON 0V

Blinking

(every 2.4 seconds)Battery voltage → 0V

OFF Battery voltage

48

(W)Ground Start power supply InputIgnition switch START Battery voltage

Other than above 0V

49

(R)GroundFront demist vent

switchInputFront demist

vent switchON 0V → 5V

OFF 0V

50

(P)Ground Fan switch Output Fan switchNot pressed Battery voltage

Pressed 0

51

7

(L)Ground PTC relay 3 control Output Ignition ONPTC heater 3 ON 0V

PTC heater 3 OFF Battery voltage Terminal No.

(Wire color)Description

ConditionReference Value

(Approx.)

Signal nameInput/

Output +−

SKIA2167J

SKIA2167J

Page 183 of 5883

BCS-48

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

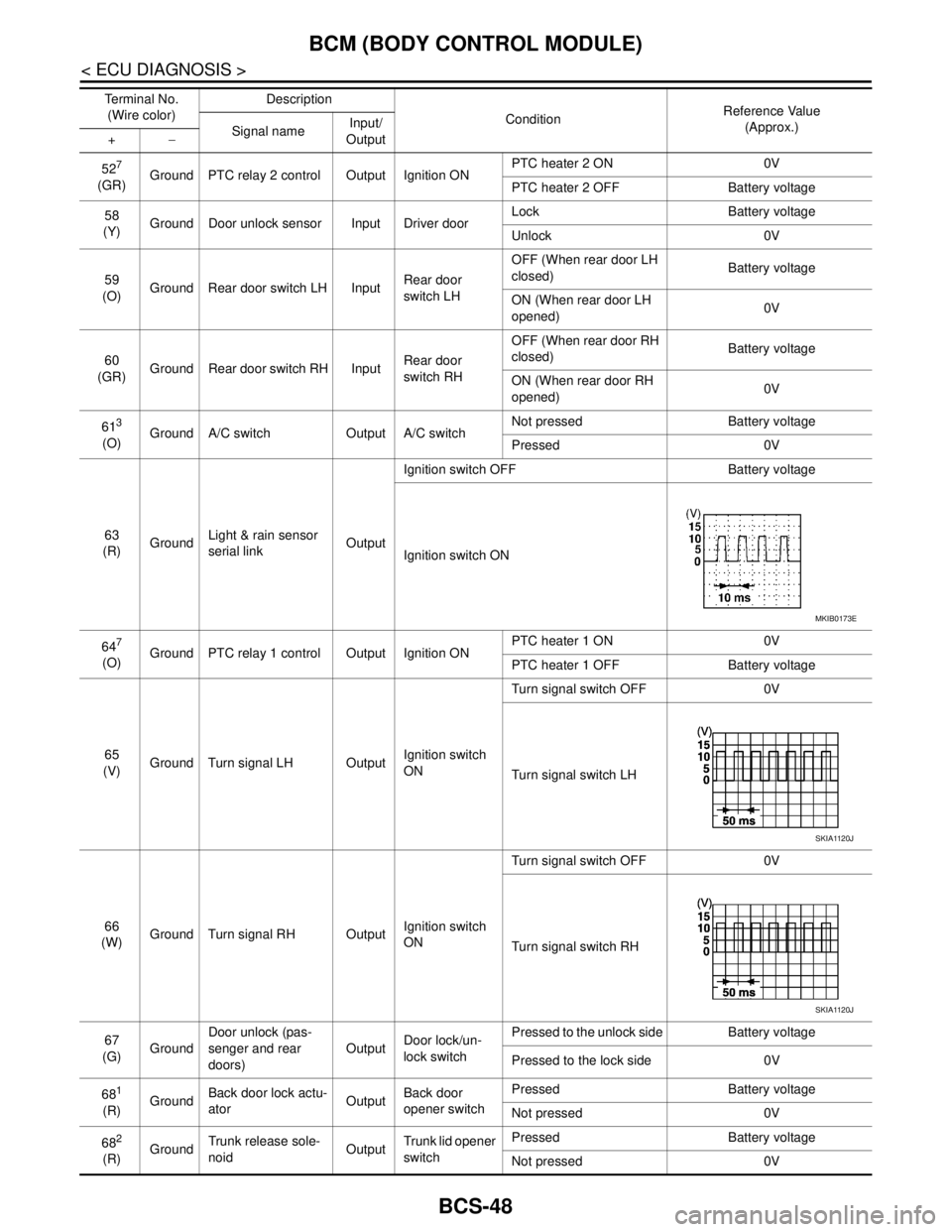

527

(GR)Ground PTC relay 2 control Output Ignition ONPTC heater 2 ON 0V

PTC heater 2 OFF Battery voltage

58

(Y)Ground Door unlock sensor Input Driver doorLock Battery voltage

Unlock 0V

59

(O)Ground Rear door switch LH InputRear door

switch LHOFF (When rear door LH

closed) Battery voltage

ON (When rear door LH

opened)0V

60

(GR)Ground Rear door switch RH InputRear door

switch RHOFF (When rear door RH

closed) Battery voltage

ON (When rear door RH

opened)0V

61

3

(O)Ground A/C switch Output A/C switchNot pressed Battery voltage

Pressed 0V

63

(R)GroundLight & rain sensor

serial linkOutputIgnition switch OFF Battery voltage

Ignition switch ON

64

7

(O)Ground PTC relay 1 control Output Ignition ONPTC heater 1 ON 0V

PTC heater 1 OFF Battery voltage

65

(V)Ground Turn signal LH OutputIgnition switch

ONTurn signal switch OFF 0V

Turn signal switch LH

66

(W)Ground Turn signal RH OutputIgnition switch

ONTurn signal switch OFF 0V

Turn signal switch RH

67

(G)GroundDoor unlock (pas-

senger and rear

doors)OutputDoor lock/un-

lock switchPressed to the unlock side Battery voltage

Pressed to the lock side 0V

68

1

(R)GroundBack door lock actu-

atorOutputBack door

opener switchPressed Battery voltage

Not pressed 0V

68

2

(R)GroundTrunk release sole-

noidOutputTrunk lid opener

switchPressed Battery voltage

Not pressed 0V Te r m i n a l N o .

(Wire color)Description

ConditionReference Value

(Approx.)

Signal nameInput/

Output +−

MKIB0173E

SKIA1120J

SKIA1120J

Page 184 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-49

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

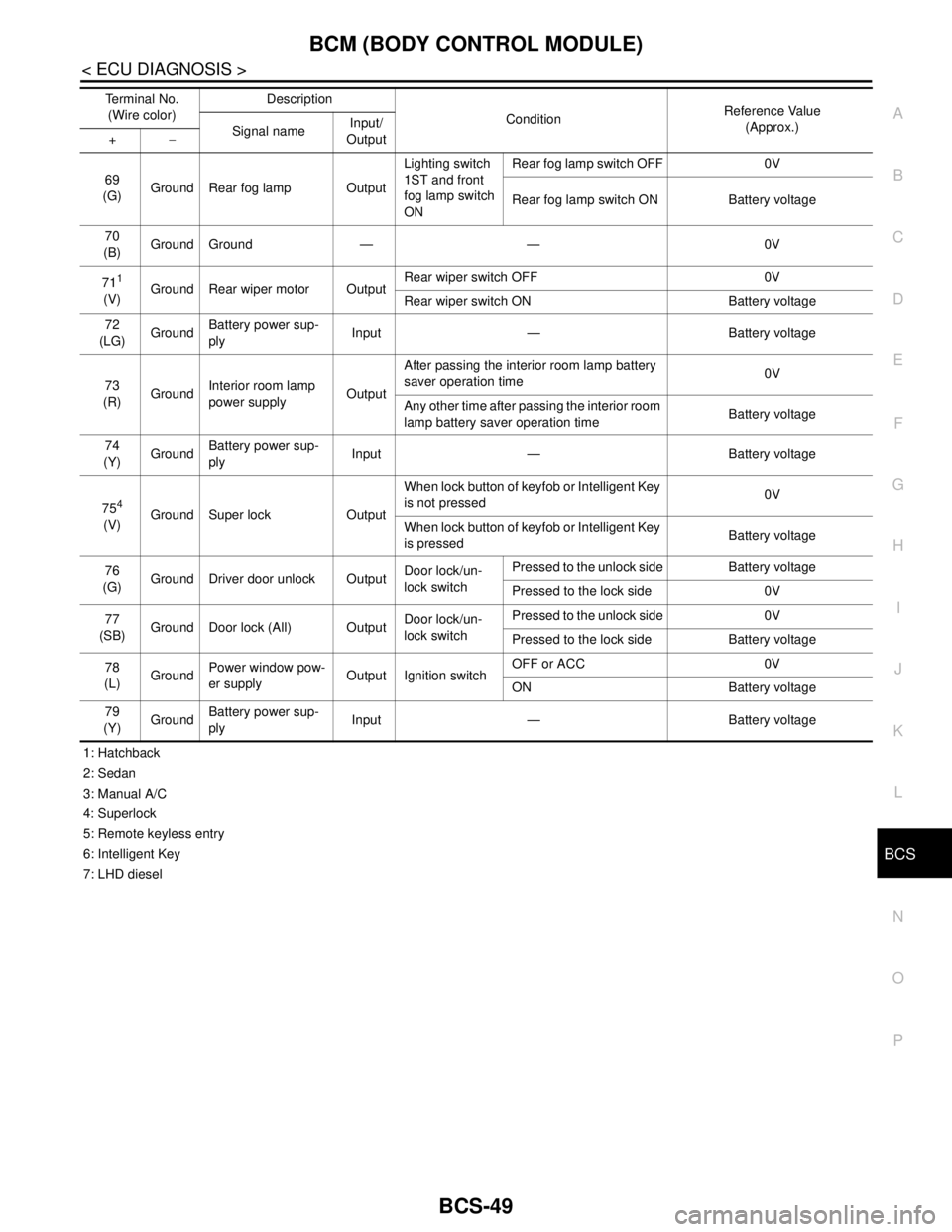

1: Hatchback

2: Sedan

3: Manual A/C

4: Superlock

5: Remote keyless entry

6: Intelligent Key

7: LHD diesel69

(G)Ground Rear fog lamp OutputLighting switch

1ST and front

fog lamp switch

ONRear fog lamp switch OFF 0V

Rear fog lamp switch ON Battery voltage

70

(B)Ground Ground — — 0V

71

1

(V)Ground Rear wiper motor OutputRear wiper switch OFF 0V

Rear wiper switch ON Battery voltage

72

(LG)GroundBattery power sup-

plyInput — Battery voltage

73

(R)GroundInterior room lamp

power supplyOutputAfter passing the interior room lamp battery

saver operation time0V

Any other time after passing the interior room

lamp battery saver operation timeBattery voltage

74

(Y)GroundBattery power sup-

plyInput — Battery voltage

75

4

(V)Ground Super lock OutputWhen lock button of keyfob or Intelligent Key

is not pressed 0V

When lock button of keyfob or Intelligent Key

is pressed Battery voltage

76

(G)Ground Driver door unlock OutputDoor lock/un-

lock switchPressed to the unlock side Battery voltage

Pressed to the lock side 0V

77

(SB)Ground Door lock (All) OutputDoor lock/un-

lock switchPressed to the unlock side 0V

Pressed to the lock side Battery voltage

78

(L)GroundPower window pow-

er supplyOutput Ignition switchOFF or ACC 0V

ON Battery voltage

79

(Y)GroundBattery power sup-

plyInput — Battery voltage Terminal No.

(Wire color)Description

ConditionReference Value

(Approx.)

Signal nameInput/

Output +−

Page 189 of 5883

BCS-54

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

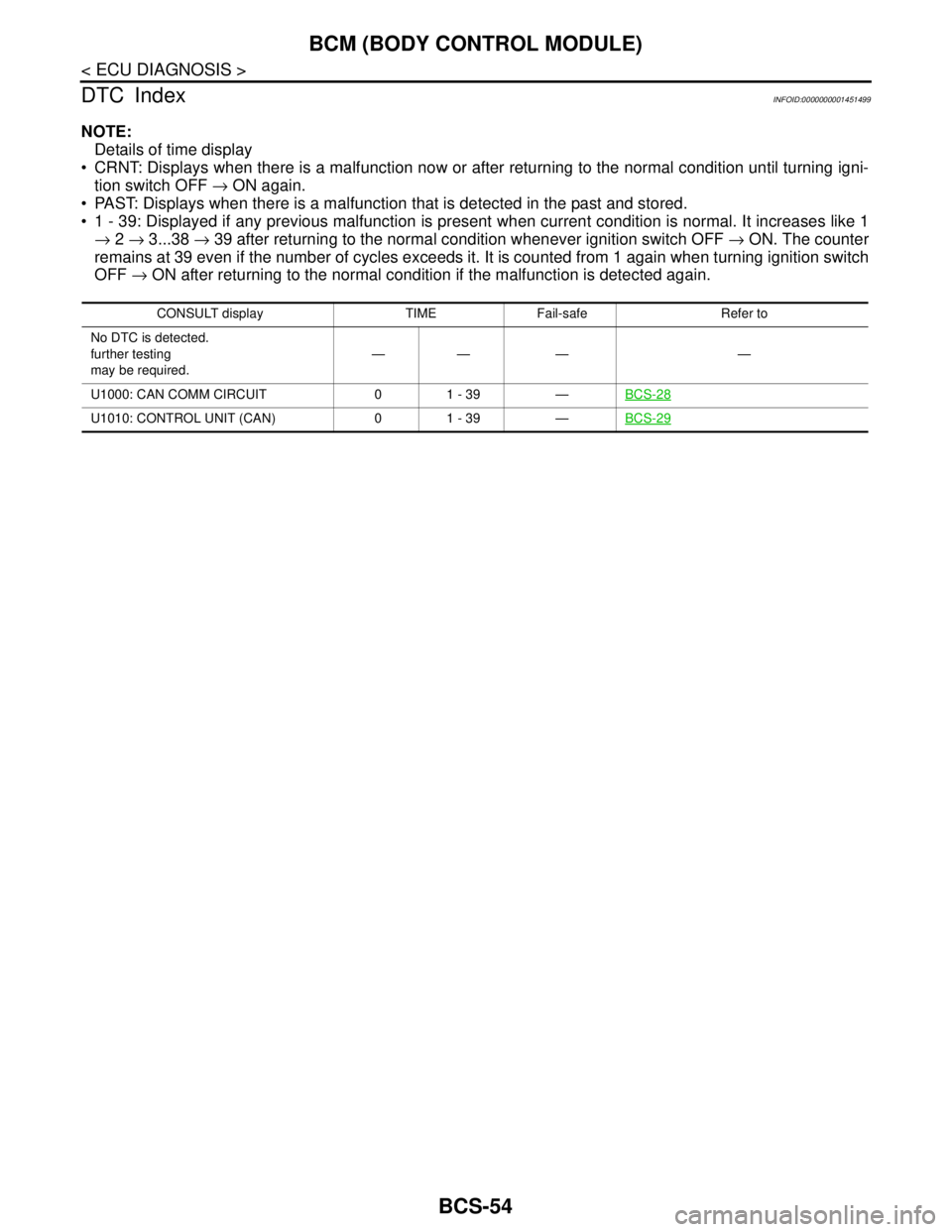

DTC Index

INFOID:0000000001451499

NOTE:

Details of time display

CRNT: Displays when there is a malfunction now or after returning to the normal condition until turning igni-

tion switch OFF → ON again.

PAST: Displays when there is a malfunction that is detected in the past and stored.

1 - 39: Displayed if any previous malfunction is present when current condition is normal. It increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition whenever ignition switch OFF → ON. The counter

remains at 39 even if the number of cycles exceeds it. It is counted from 1 again when turning ignition switch

OFF → ON after returning to the normal condition if the malfunction is detected again.

CONSULT display TIME Fail-safe Refer to

No DTC is detected.

further testing

may be required.—— — —

U1000: CAN COMM CIRCUIT 0 1 - 39 —BCS-28

U1010: CONTROL UNIT (CAN) 0 1 - 39 —BCS-29

Page 190 of 5883

BCS

COMBINATION SWITCH SYSTEM SYMPTOMS

BCS-55

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

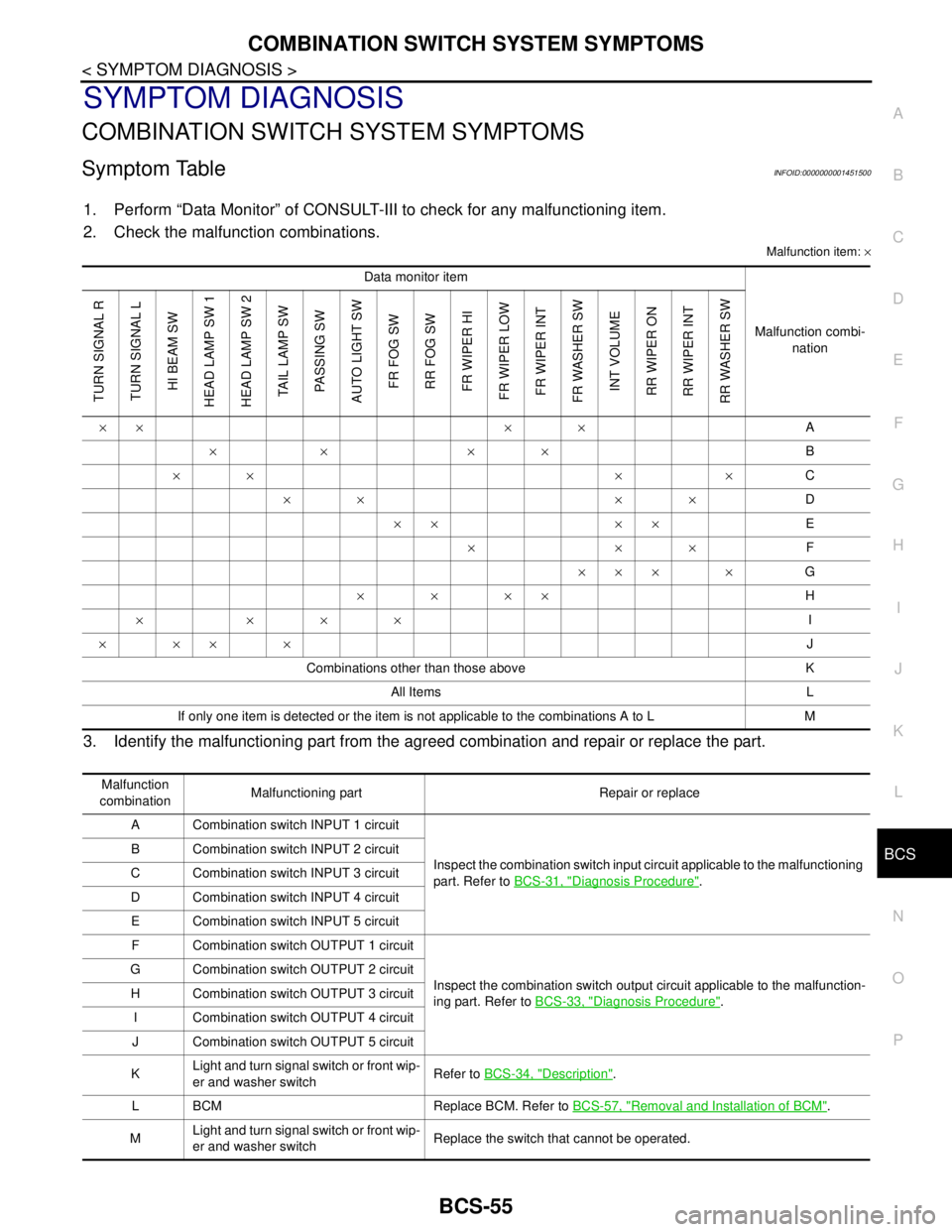

SYMPTOM DIAGNOSIS

COMBINATION SWITCH SYSTEM SYMPTOMS

Symptom TableINFOID:0000000001451500

1. Perform “Data Monitor” of CONSULT-III to check for any malfunctioning item.

2. Check the malfunction combinations.

Malfunction item: ×

3. Identify the malfunctioning part from the agreed combination and repair or replace the part.

Data monitor item

Malfunction combi-

nation

TURN SIGNAL R

TURN SIGNAL L

HI BEAM SW

HEAD LAMP SW 1

HEAD LAMP SW 2

TAIL LAMP SW

PASSING SW

AUTO LIGHT SW

FR FOG SW

RR FOG SW

FR WIPER HI

FR WIPER LOW

FR WIPER INT

FR WASHER SW

INT VOLUME

RR WIPER ON

RR WIPER INT

RR WASHER SW

×× × ×A

×× ××B

×× × ×C

×× ××D

×× ××E

×××F

××× ×G

××××H

××××I

××××J

Combinations other than those above K

All Items L

If only one item is detected or the item is not applicable to the combinations A to L M

Malfunction

combinationMalfunctioning part Repair or replace

A Combination switch INPUT 1 circuit

Inspect the combination switch input circuit applicable to the malfunctioning

part. Refer to BCS-31, "

Diagnosis Procedure". B Combination switch INPUT 2 circuit

C Combination switch INPUT 3 circuit

D Combination switch INPUT 4 circuit

E Combination switch INPUT 5 circuit

F Combination switch OUTPUT 1 circuit

Inspect the combination switch output circuit applicable to the malfunction-

ing part. Refer to BCS-33, "

Diagnosis Procedure". G Combination switch OUTPUT 2 circuit

H Combination switch OUTPUT 3 circuit

I Combination switch OUTPUT 4 circuit

J Combination switch OUTPUT 5 circuit

KLight and turn signal switch or front wip-

er and washer switchRefer to BCS-34, "

Description".

L BCM Replace BCM. Refer to BCS-57, "

Removal and Installation of BCM".

MLight and turn signal switch or front wip-

er and washer switchReplace the switch that cannot be operated.

Page 195 of 5883

PRECAUTIONS

BR-3

< PRECAUTION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001716907

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001716908

Refill using recommended brake fluid. Refer to MA-19, "Fluids and Lubricants".

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted surface of body. If brake fluid is splashed on painted surfaces

of body immediately wipe it off with cloth and then wash it away with water.

To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use new brake fluid.

Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

Use a flare nut wrench when removing a brake tube and use a

flare nut torque wrench when installing a brake tube.

When installing brake tubes and hoses, be sure to check torque.

Before working, turn ignition switch OFF and disconnect connec-

tors of ABS actuator and electric unit (control unit) or the battery

cable from the negative terminal.

Burnish the new braking surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-26, "

Brake Burnishing" .

SBR686C

Page 198 of 5883

BR-6

< ON-VEHICLE MAINTENANCE >

BRAKE PEDAL

ON-VEHICLE MAINTENANCE

BRAKE PEDAL

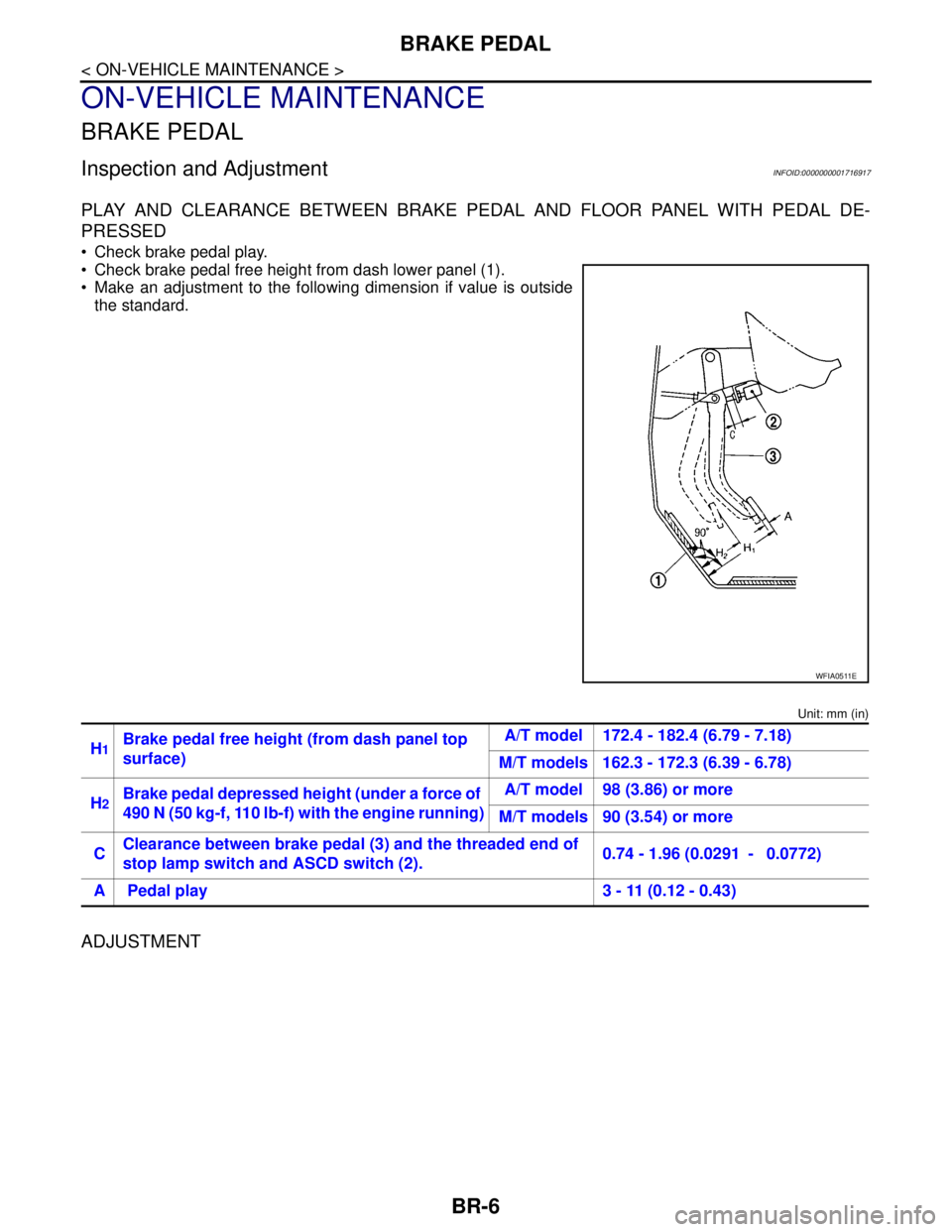

Inspection and AdjustmentINFOID:0000000001716917

PLAY AND CLEARANCE BETWEEN BRAKE PEDAL AND FLOOR PANEL WITH PEDAL DE-

PRESSED

Check brake pedal play.

Check brake pedal free height from dash lower panel (1).

Make an adjustment to the following dimension if value is outside

the standard.

Unit: mm (in)

ADJUSTMENT

WFIA0511E

H1Brake pedal free height (from dash panel top

surface)A/T model 172.4 - 182.4 (6.79 - 7.18)

M/T models 162.3 - 172.3 (6.39 - 6.78)

H

2Brake pedal depressed height (under a force of

490 N (50 kg-f, 110 lb-f) with the engine running)A/T model 98 (3.86) or more

M/T models 90 (3.54) or more

CClearance between brake pedal (3) and the threaded end of

stop lamp switch and ASCD switch (2).0.74 - 1.96 (0.0291 - 0.0772)

A Pedal play 3 - 11 (0.12 - 0.43)

Page 199 of 5883

BRAKE PEDAL

BR-7

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

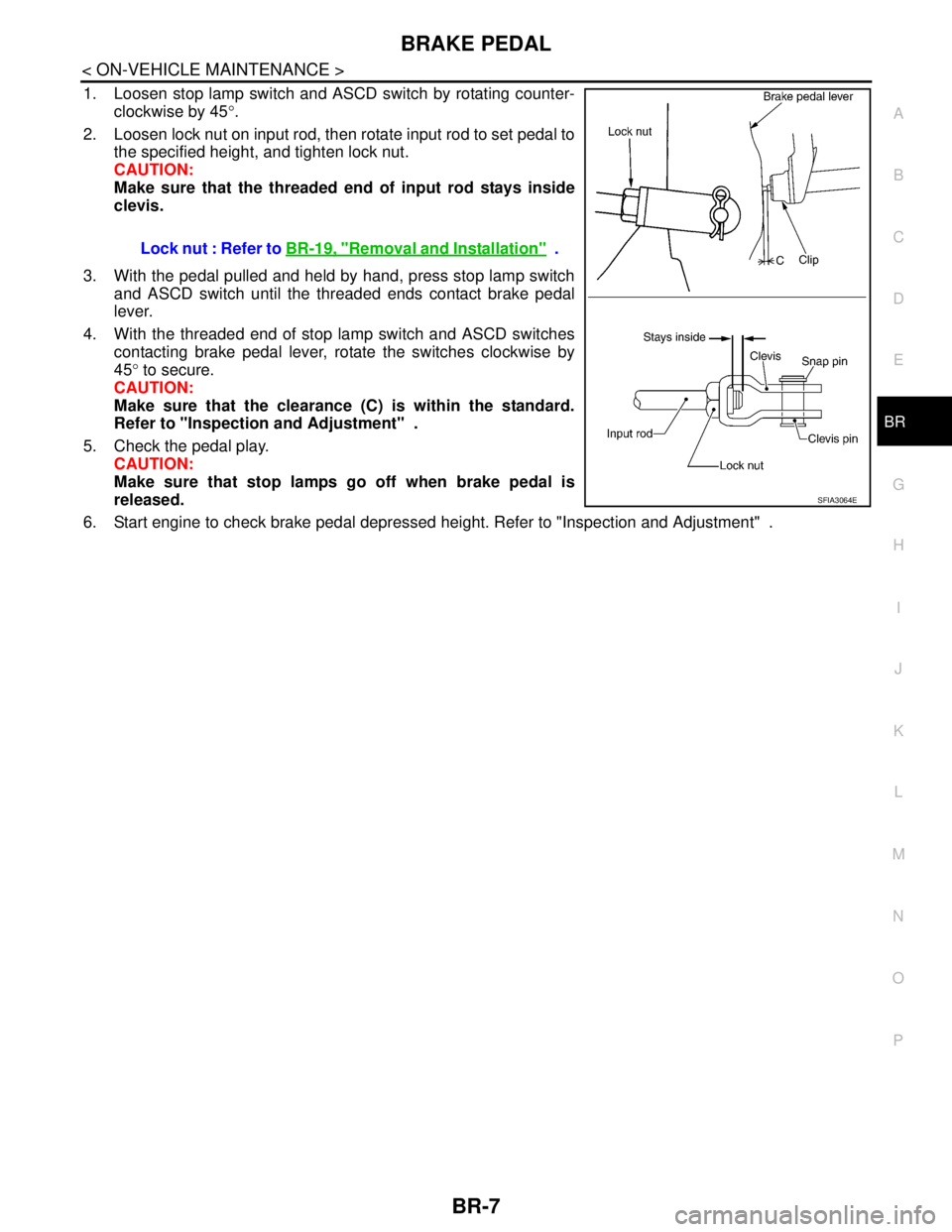

1. Loosen stop lamp switch and ASCD switch by rotating counter-

clockwise by 45°.

2. Loosen lock nut on input rod, then rotate input rod to set pedal to

the specified height, and tighten lock nut.

CAUTION:

Make sure that the threaded end of input rod stays inside

clevis.

3. With the pedal pulled and held by hand, press stop lamp switch

and ASCD switch until the threaded ends contact brake pedal

lever.

4. With the threaded end of stop lamp switch and ASCD switches

contacting brake pedal lever, rotate the switches clockwise by

45° to secure.

CAUTION:

Make sure that the clearance (C) is within the standard.

Refer to "Inspection and Adjustment" .

5. Check the pedal play.

CAUTION:

Make sure that stop lamps go off when brake pedal is

released.

6. Start engine to check brake pedal depressed height. Refer to "Inspection and Adjustment" . Lock nut : Refer to BR-19, "

Removal and Installation" .

SFIA3064E

Page 204 of 5883

BR-12

< ON-VEHICLE REPAIR >

BRAKE PEDAL

ON-VEHICLE REPAIR

BRAKE PEDAL

Removal and InstallationINFOID:0000000001716977

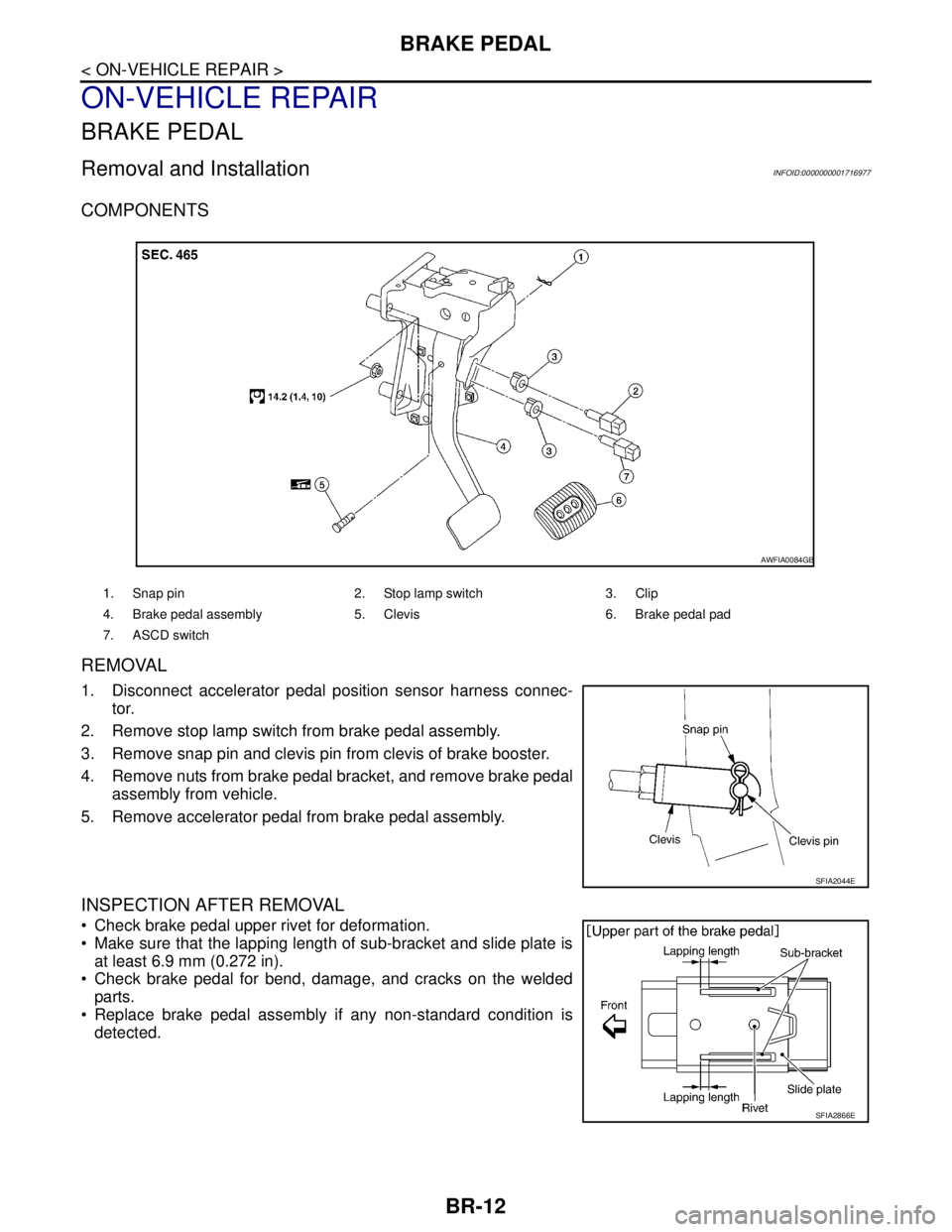

COMPONENTS

REMOVAL

1. Disconnect accelerator pedal position sensor harness connec-

tor.

2. Remove stop lamp switch from brake pedal assembly.

3. Remove snap pin and clevis pin from clevis of brake booster.

4. Remove nuts from brake pedal bracket, and remove brake pedal

assembly from vehicle.

5. Remove accelerator pedal from brake pedal assembly.

INSPECTION AFTER REMOVAL

Check brake pedal upper rivet for deformation.

Make sure that the lapping length of sub-bracket and slide plate is

at least 6.9 mm (0.272 in).

Check brake pedal for bend, damage, and cracks on the welded

parts.

Replace brake pedal assembly if any non-standard condition is

detected.

1. Snap pin 2. Stop lamp switch 3. Clip

4. Brake pedal assembly 5. Clevis 6. Brake pedal pad

7. ASCD switch

AWFIA0084GB

SFIA2044E

SFIA2866E

Page 210 of 5883

BR-18

< ON-VEHICLE REPAIR >

BRAKE MASTER CYLINDER

BRAKE MASTER CYLINDER

On-Board InspectionINFOID:0000000001716996

LEAK INSPECTION

Check for leaking in a master cylinder installation surface, a reservoir tank installation surface, and brake

tube connections.

Removal and InstallationINFOID:0000000001716997

CAUTION:

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe them with cloth and wash it away with water.

REMOVAL

1. Drain brake fluid. Refer to BR-8, "Drain and Refill" .

2. Remove battery. Refer to PG-6, "

Removal and Installation" .

3. Remove air duct and air cleaner. Refer to EM-27, "

Removal and Installation" (HR16DE), EM-154,

"Removal and Installation" (MR18DE), EM-269, "Removal and Installation" (K9K).

4. Disconnect brake fluid level switch harness connector.

5. Using a flare nut wrench, remove brake tube from master cylinder.

6. Remove master cylinder assembly nuts, and remove master cylinder assembly from vehicle..

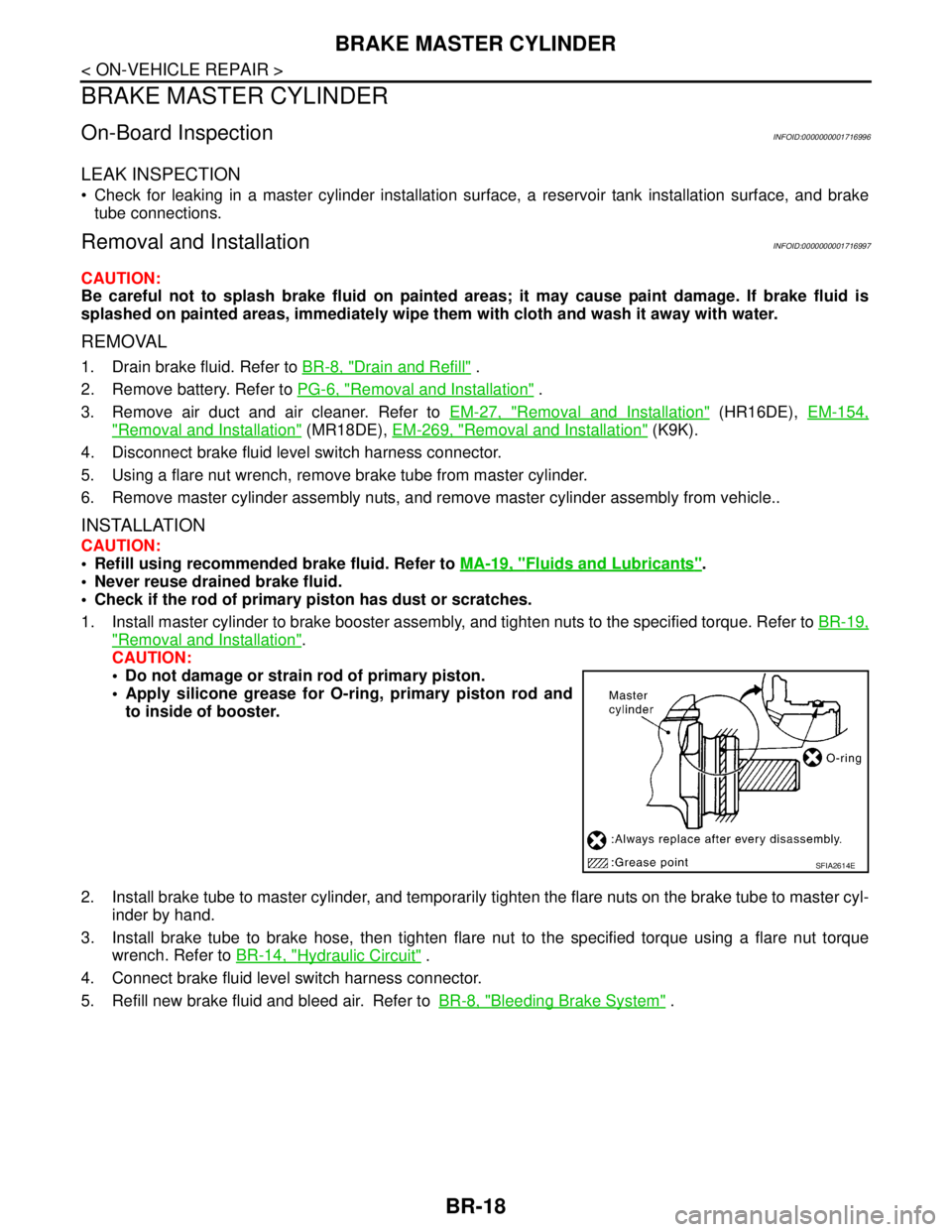

INSTALLATION

CAUTION:

Refill using recommended brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Check if the rod of primary piston has dust or scratches.

1. Install master cylinder to brake booster assembly, and tighten nuts to the specified torque. Refer to BR-19,

"Removal and Installation".

CAUTION:

Do not damage or strain rod of primary piston.

Apply silicone grease for O-ring, primary piston rod and

to inside of booster.

2. Install brake tube to master cylinder, and temporarily tighten the flare nuts on the brake tube to master cyl-

inder by hand.

3. Install brake tube to brake hose, then tighten flare nut to the specified torque using a flare nut torque

wrench. Refer to BR-14, "

Hydraulic Circuit" .

4. Connect brake fluid level switch harness connector.

5. Refill new brake fluid and bleed air. Refer toBR-8, "

Bleeding Brake System" .

SFIA2614E