engine NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4720 of 5883

![NISSAN TIIDA 2007 Service Repair Manual B2192, P1611 ID DISCORD, IMMU-ECM

SEC-95

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

B2192, P1611 ID DISCORD, IMMU-ECM

DescriptionINFOID:0000000001404180

B NISSAN TIIDA 2007 Service Repair Manual B2192, P1611 ID DISCORD, IMMU-ECM

SEC-95

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

B2192, P1611 ID DISCORD, IMMU-ECM

DescriptionINFOID:0000000001404180

B](/img/5/57395/w960_57395-4719.png)

B2192, P1611 ID DISCORD, IMMU-ECM

SEC-95

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

B2192, P1611 ID DISCORD, IMMU-ECM

DescriptionINFOID:0000000001404180

BCM performs the ID verification with ECM that allows the engine to start. BCM starts the communication with

ECM if ignition switch is turned ON starts the engine if the ID is OK. ECM prevents the engine from starting if

the ID is not registered.

DTC LogicINFOID:0000000001404181

DTC DETECTION LOGIC

NOTE:

If DTC B2192 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

SEC-90, "

DTC Logic".

If DTC B2192 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to

SEC-91, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

Is DTC detected?

YES >> Refer to SEC-95, "Diagnosis Procedure".

NO >> INSPECTION END.

Diagnosis ProcedureINFOID:0000000001404182

1.PERFORM INITIALIZATION

Perform initialization with CONSULT-III. Re-register all ignition keys.

For initialization and registration of ignition key. Refer to CONSULT-III Operation Manual.

Can the system be initialized and can the engine be started with re-registered ignition key?

YES >> ID was unregistered.

NO >> GO TO 2.

2.PEPLACE BCM

1. Replace BCM. Refer to XX-XX, "*****"

.

2. Perform initialization with CONSULT-III. Re-register all ignition keys.

For initialization and registration of ignition key. Refer to “CONSULT-III Operation Manual.

Can the system be initialized and can the engine be started with re-registered ignition key?

YES >> BCM is malfunctioning.

NO >> GO TO 3.

3.PEPLACE ECM

1. Replace ECM.

2. Perform initialization with CONSULT-III. Re-register all ignition keys.

For initialization and registration of ignition key. Refer to “CONSULT-III Operation Manual.

Can the system be initialized and can the engine be started with re-registered ignition key?

YES >> ECM is malfunctioning.

NO >> GO TO 4.

4.CHECK INTERMITTENT INCIDENT

Refer to @@@.

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

B2192

ID DISCORD BCM-

ECMThe ID verification results between BCM and ECM

are NG. The registration is necessary.BCM

ECM

P1611

Page 4722 of 5883

![NISSAN TIIDA 2007 Service Repair Manual B2193, P1612 CHAIN OF ECM-IMMU

SEC-97

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

B2193, P1612 CHAIN OF ECM-IMMU

DescriptionINFOID:0000000001404183

BCM per NISSAN TIIDA 2007 Service Repair Manual B2193, P1612 CHAIN OF ECM-IMMU

SEC-97

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

B2193, P1612 CHAIN OF ECM-IMMU

DescriptionINFOID:0000000001404183

BCM per](/img/5/57395/w960_57395-4721.png)

B2193, P1612 CHAIN OF ECM-IMMU

SEC-97

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

B2193, P1612 CHAIN OF ECM-IMMU

DescriptionINFOID:0000000001404183

BCM performs the ID verification with ECM that allows the engine to start. BCM starts the communication with

ECM if ignition switch is turned ON and starts the engine if the ID is OK. ECM prevents the engine from start-

ing if the ID is not registered.

DTC LogicINFOID:0000000001404184

DTC DETECTION LOGIC

NOTE:

If DTC B2193 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to XX-

XX, "*****".

If DTC B2193 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to XX-

XX, "*****".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

Is DTC detected?

YES >> Refer to SEC-97, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000001404185

1.REPLACE BCM

1. Replace BCM. Refer to XX-XX, "*****"

.

2. Perform initialization with CONSULT-III.

For initialization, refer to CONSULT-III Operation Manual.

Does the engine start?

YES >> BCM was malfunctioning.

NO >> ECM is malfunctioning.

Replace ECM.

Perform ECM re-communicating function.

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

B2193

CHAIN OF BCM-

ECMInactive communication between ECM and BCM Harness or connectors

(The CAN communication line is

open or short)

BCM

ECM P1612

Page 4723 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SEC-98

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

B2196 DONGLE NG

B2196 DONGLE NG

DescriptionINFOID:0000000001404189

BCM performs the ID verification with the slave control units (ECM, AB NISSAN TIIDA 2007 Service Repair Manual SEC-98

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

B2196 DONGLE NG

B2196 DONGLE NG

DescriptionINFOID:0000000001404189

BCM performs the ID verification with the slave control units (ECM, AB](/img/5/57395/w960_57395-4722.png)

SEC-98

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

B2196 DONGLE NG

B2196 DONGLE NG

DescriptionINFOID:0000000001404189

BCM performs the ID verification with the slave control units (ECM, ABS actuator, EPS column assy, IPDM E/

R, combination meter).

If either slave control unit is replaced by used part, perform initialization with CONSULT-III. But if the control

unit is replaced by new part, the system does not need initialization.

DTC LogicINFOID:0000000001404190

DTC DETECTION LOGIC

NOTE:

If DTC B2196 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

SEC-90, "

DTC Logic".

If DTC B2196 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to

SEC-91, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self Diagnostic Result” with CONSULT-III.

Is the DTC detected?

YES >> Refer to SEC-98, "Diagnosis Procedure".

NO >> INSPECTION END.

Diagnosis ProcedureINFOID:0000000001404191

1.PERFORM INITIALIZATION

1. Perform initialization with CONSULT-III. Re-register all ignition keys. Refer to “SEC-87, "

COMMON ITEM :

CONSULT-III Function (BCM - COMMON ITEM)"”.

2. Start the engine.

Dose the engine start?

YES >> INSPECTION END

NO >> Perform “Self Diagnosis Result” for each control unit.

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

B2196 DONGLE NGThe ID verification results between BCM

and each slave control unit are NG.ECM

ABS actuator assy

EPS column assy

Combination meter

IPDM E/R

Page 4724 of 5883

![NISSAN TIIDA 2007 Service Repair Manual P1610 LOCK MODE

SEC-99

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

P1610 LOCK MODE

DescriptionINFOID:0000000001404192

When the starting operation is carrie NISSAN TIIDA 2007 Service Repair Manual P1610 LOCK MODE

SEC-99

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

P1610 LOCK MODE

DescriptionINFOID:0000000001404192

When the starting operation is carrie](/img/5/57395/w960_57395-4723.png)

P1610 LOCK MODE

SEC-99

< COMPONENT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

P1610 LOCK MODE

DescriptionINFOID:0000000001404192

When the starting operation is carried more than five times consecutively under the following conditions, NATS

will shift to the mode which prevents the engine from being started.

Unregistered mechanical key is used.

BCM or ECM's malfunctioning.

DTC LogicINFOID:0000000001404193

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

Is DTC detected?

YES >> Refer to SEC-99, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000001404194

1.CHECK ENGINE START FUNCTION

1. Perform the check for DTC except DTC P1610.

2. Use CONSULT-III to erase DTC after fixing.

3. Check that engine can start with registered mechanical key.

Does the engine start?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK INTERMITTENT INCIDENT

Refer to @@@.

>> INSPECTION END

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

P1610 LOCK MODEWhen the starting operation is carried out

five or more times consecutively under the

following conditions.

Unregistered mechanical key

BCM or ECM's malfunctioning.—

Page 4737 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SEC-112

< ECU DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

REAR WIPER CONTROL

BCM detects a rear wiper stopping position according to a rear wiper auto stop signal.

When a rea NISSAN TIIDA 2007 Service Repair Manual SEC-112

< ECU DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

REAR WIPER CONTROL

BCM detects a rear wiper stopping position according to a rear wiper auto stop signal.

When a rea](/img/5/57395/w960_57395-4736.png)

SEC-112

< ECU DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

REAR WIPER CONTROL

BCM detects a rear wiper stopping position according to a rear wiper auto stop signal.

When a rear wiper auto stop signal is in the condition listed below, BCM stops power supply to rear wiper after

rear wiper is activated for five seconds.

NOTE:

The above operation is repeated when operating the rear wiper switch one minute after the stop of the rear

wiper caused by Fail-safe.

TURN SIGNAL LAMP CONTROL

BCM detects the turn signal lamp circuit status from the terminal voltage.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

LIGHT & RAIN SENSOR MALFUNCTION DETECTION FUNCTION

BCM controls the following items when LIGHT & RAIN sensor has a malfunction.

Auto Light Control

Headlamp is turned ON.

Front Wiper Control

The condition just before the activation of Fail-safe is maintained until the front wiper switch is turned OFF.

Display contents of CONSULT Fail-safe Cancellation

B2190: NATS ANTENNA AMP Inhibits engine cranking

Inhibits steering lock unlocking (Intelligent Key unit)

Fuel cut (ECM)Erase DTC

B2191: DIFFERENCE OF KEY Inhibits engine cranking

Inhibits steering lock unlocking (Intelligent Key unit)

Fuel cut (ECM)Erase DTC

B2192: ID DISCORD BCM-ECM Fuel cut (ECM) Erase DTC

B2193: CHAIN OF BCM-ECM Fuel cut (ECM) Erase DTC

B2194: DISCORD BCM-I-KEY Inhibits engine cranking

Inhibits steering lock unlocking (Intelligent Key unit)

Fuel cut (ECM)Erase DTC

B2195: ANTI SCANNING Inhibits engine cranking

Inhibits steering lock unlocking (Intelligent Key unit)

Fuel cut (ECM)Erase DTC

B2196: DONGLE NG Inhibits engine cranking

Inhibits steering lock unlocking (Intelligent Key unit)

Fuel cut (ECM)Erase DTC

Ignition switch Rear wiper switch Auto stop signal

ONOFFRear wiper stop position signal cannot be

input 5 seconds.

ON The signal does not change for 5 seconds.

Page 4739 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SEC-114

< ECU DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOI NISSAN TIIDA 2007 Service Repair Manual SEC-114

< ECU DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOI](/img/5/57395/w960_57395-4738.png)

SEC-114

< ECU DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000001404226

Refer to IPDM E/R.

Fail SafeINFOID:0000000001404229

CAN communication control

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If no CAN communication is available with ECM

*1: HR engine models

*2: MR engine and K9K engine models

If no CAN communication is available with BCM

Ignition relay malfunction detection function

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

Control part Fail-safe in operation

Cooling fan The cooling fan relay-2*

1 or the cooling fan relay-3*2 turns ON when the ignition switch

is turned ON

Turns off the fan motor low relay when the ignition switch is turned OFF

A/C compressor A/C relay OFF

Control part Fail-safe in operation

Headlamp The headlamp low relay turns ON when the ignition switch is turned ON

The headlamp low relay turns OFF when the ignition switch is turned OFF

Headlamp high relay OFF

Parking lamps

License plate lamps

Tail lamps

Illuminations The tail lamp relay turns ON when the ignition switch is turned ON

The tail lamp relay turns OFF when the ignition switch is turned OFF

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The front wiper is operated at LO speed until the ignition switch is turned OFF if the

fail-safe control is activated while the front wiper is set in the INT mode and the front

wiper motor is operating.

Front fog lamps Front fog lamp relay OFF

Starter motor Inhibit relay OFF

Rear window defogger Rear window defogger relay OFF

Headlamp washer Headlamp washer relay OFF

PTC heater PTC heater relay OFF

DTC Ignition switch Ignition relay Tail lamp relay

—ONON—

—OFFOFF—

B2098: IGN RLY ON OFFONON (10 minutes)

B2099: IGN RLY OFF ON OFF —

Page 4740 of 5883

![NISSAN TIIDA 2007 Service Repair Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-115

< ECU DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

NOTE:

The tail lamp relay is turned OFF when the NISSAN TIIDA 2007 Service Repair Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-115

< ECU DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

NOTE:

The tail lamp relay is turned OFF when the](/img/5/57395/w960_57395-4739.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-115

< ECU DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

NOTE:

The tail lamp relay is turned OFF when the ignition switch is turned ON.

Front wiper control

IPDM E/R detects the front wiper stop position with the front wiper auto stop signal.

When the front wiper auto stop signal is in the conditions listed below, IPDM E/R repeats a front wiper 10 sec-

onds operation and 20 seconds stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R “Data Monitor” that displays “BLOCK” for the item

“WIP PROT” while the wiper is stopped.

DTC IndexINFOID:0000000001404230

NOTE:

The details of time display are as follows.

CRNT: The malfunctions that are detected now.

PAST: The number is indicated when it is normal at present and a malfunction was detected in the past.Ignition switch Front wiper switch Front wiper auto stop signal

ONOFFThe front wiper auto stop signal (stop posi-

tion) cannot be input for 10 seconds.

ONThe front wiper auto stop signal does not

change for 10 seconds.

CONSULT display Fail-safe

TimingNOTEReference page

No DTC is detected.

further testing

may be required.————

U1000: CAN COMM CIRCUIT×CRNT PASTXX-XX, "*****"

B2098: IGN RELAY ON×CRNT PASTXX-XX, "*****"

B2099: IGN RELAY OFF — CRNT PASTXX-XX, "*****"

B2100: EEPROM — CRNT PASTXX-XX, "*****"

Page 4861 of 5883

ST-6

< ON-VEHICLE MAINTENANCE >

STEERING WHEEL

ON-VEHICLE MAINTENANCE

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000001282496

CHECKING CONDITION OF INSTALLATION

Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

Check steering gear assembly mounting bolts and nuts for looseness. Refer to ST-12, "

Removal and Instal-

lation" .

CHECKING STEERING WHEEL PLAY

Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on the

outer circumference.

When the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

Perform neutral position inspection after wheel alignment. Refer to SR-2, "

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"" .

Set vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if steer-

ing wheel is not in the neutral position.

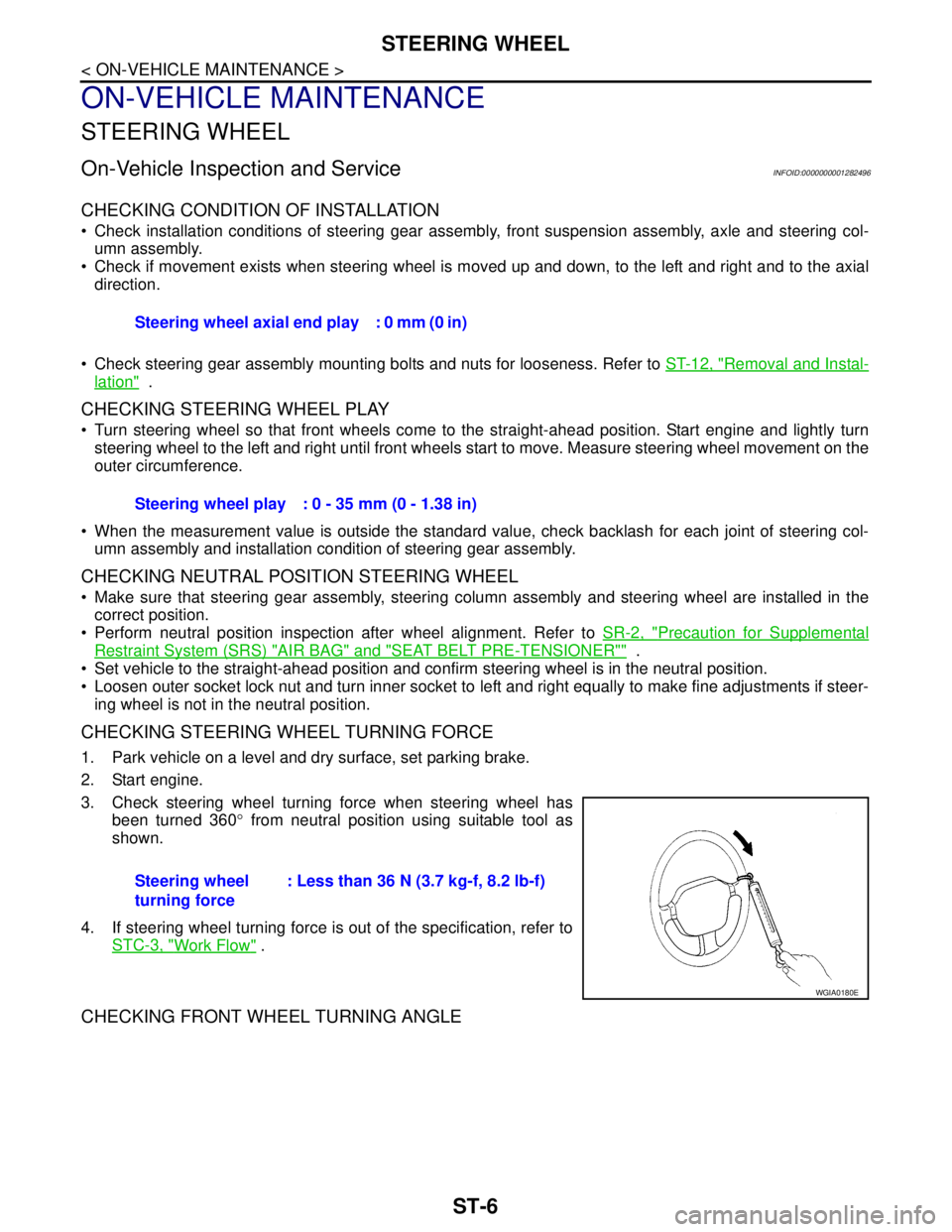

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Check steering wheel turning force when steering wheel has

been turned 360° from neutral position using suitable tool as

shown.

4. If steering wheel turning force is out of the specification, refer to

STC-3, "

Work Flow" .

CHECKING FRONT WHEEL TURNING ANGLE

Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel

turning force: Less than 36 N (3.7 kg-f, 8.2 lb-f)

WGIA0180E

Page 4862 of 5883

STEERING WHEEL

ST-7

< ON-VEHICLE MAINTENANCE >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

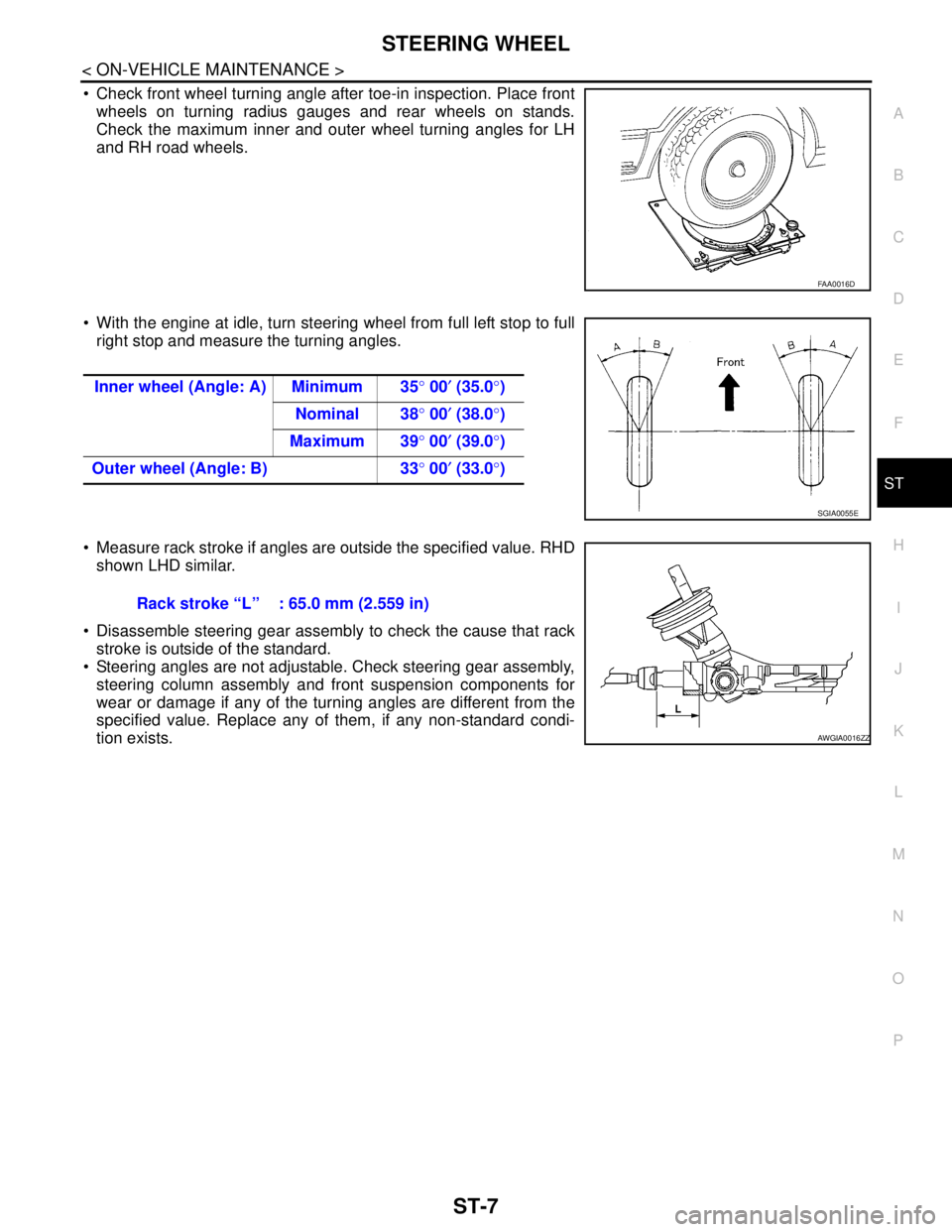

Check front wheel turning angle after toe-in inspection. Place front

wheels on turning radius gauges and rear wheels on stands.

Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

With the engine at idle, turn steering wheel from full left stop to full

right stop and measure the turning angles.

Measure rack stroke if angles are outside the specified value. RHD

shown LHD similar.

Disassemble steering gear assembly to check the cause that rack

stroke is outside of the standard.

Steering angles are not adjustable. Check steering gear assembly,

steering column assembly and front suspension components for

wear or damage if any of the turning angles are different from the

specified value. Replace any of them, if any non-standard condi-

tion exists.

FAA0016D

Inner wheel (Angle: A) Minimum 35° 00′ (35.0°)

Nominal 38° 00′ (38.0°)

Maximum 39° 00′ (39.0°)

Outer wheel (Angle: B) 33° 00′ (33.0°)

SGIA0055E

Rack stroke “L” : 65.0 mm (2.559 in)

AWGIA0016ZZ

Page 4878 of 5883

![NISSAN TIIDA 2007 Service Repair Manual STC-4

< FUNCTION DIAGNOSIS >[EPS]

EPS SYSTEM

FUNCTION DIAGNOSIS

EPS SYSTEM

System DiagramINFOID:0000000001697715

System DescriptionINFOID:0000000001697714

EPS CONTROL UNIT

• EPS control unit perform NISSAN TIIDA 2007 Service Repair Manual STC-4

< FUNCTION DIAGNOSIS >[EPS]

EPS SYSTEM

FUNCTION DIAGNOSIS

EPS SYSTEM

System DiagramINFOID:0000000001697715

System DescriptionINFOID:0000000001697714

EPS CONTROL UNIT

• EPS control unit perform](/img/5/57395/w960_57395-4877.png)

STC-4

< FUNCTION DIAGNOSIS >[EPS]

EPS SYSTEM

FUNCTION DIAGNOSIS

EPS SYSTEM

System DiagramINFOID:0000000001697715

System DescriptionINFOID:0000000001697714

EPS CONTROL UNIT

• EPS control unit performs an arithmetical operation on data, such as steering wheel turning force (sensor

signal) from the torque sensor, vehicle speed signal, etc. Then it generates an optimum assist torque to the

EPS motor according to the driving condition.

EPS control unit decreases the output to EPS motor while extremely using the power steering function (e.g.,

full steering) for protecting EPS motor and EPS control unit (Protect overload status). While activating pro-

tect overload status, the assist torque gradually decreases, and the steering wheel turning force becomes

heavy. The normal assist torque reactivates by not steering.

In case of an error in the electrical system, the fail-safe function stops output signals to the EPS motor. Then

the previous state is changed to the manual steering state.

Self-diagnosis can be done with CONSULT-III.

EPS MOTOR

EPS motor provides the assist torque by control signal from EPS control unit.

TORQUE SENSOR

Torque sensor detects the steering torque, and transmit the signal to EPS control unit.

REDUCTION GEAR

Reduction gear increases the assist torque provided from EPS motor with worm gears, and outputs to the col-

umn shaft.

EPS WARNING LAMP

Turns ON when there is a malfunction in EPS system. It indicates that fail-safe mode is engaged and enters a

manual steering state (Control turning force steering wheel becomes heavy).

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF after the engine starts

if system is normal.

EPS Warning Lamp Indication

SGIA1649E

Condition EPS warning lamp

Lamp checkTurns ON when ignition switch is turned ON.

Turns OFF after engine start.