engine NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4895 of 5883

![NISSAN TIIDA 2007 Service Repair Manual U1000 CAN COMM CIRCUIT

STC-21

< COMPONENT DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001716748

CAN (Controller Area Network) is a serial communic NISSAN TIIDA 2007 Service Repair Manual U1000 CAN COMM CIRCUIT

STC-21

< COMPONENT DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001716748

CAN (Controller Area Network) is a serial communic](/img/5/57395/w960_57395-4894.png)

U1000 CAN COMM CIRCUIT

STC-21

< COMPONENT DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001716748

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

DTC LogicINFOID:0000000001716749

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES >> Proceed to diagnosis procedure. Refer to STC-21, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000001697731

1.CHECK CAN COMMUNICATION CIRCUIT

With CONSULT-III

1. Turn ignition switch ON and start engine.

2. Select “SELF-DIAG RESULTS” mode for “EPS” with CONSULT-III.

3. Perform the self-diagnosis.

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Print out CONSULT-II screen and go to LAN-30, "CAN System Specification Chart".

NO >>INSPECTION END

Special Repair Requirement (Models with ESP)INFOID:0000000001730970

1.ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

Always perform the neutral position adjustment for the steering angle sensor, when replacing the EPS control

unit. Refer to BRC-90, "

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Descrip-

tion".

>> END

DTC Display item Malfunction detected condition Possible cause

U1000 CAN COMM CIRCUITWhen EPS control unit is not transmitting or receiving

CAN communication signal for 2 seconds or more. Harness or connector

CAN communication line

EPS control unit

Self-diagnosis results

CAN COMM CIRCUIT

Page 4896 of 5883

![NISSAN TIIDA 2007 Service Repair Manual STC-22

< ECU DIAGNOSIS >[EPS]

EPS CONTROL UNIT

ECU DIAGNOSIS

EPS CONTROL UNIT

EPS Control Unit Input/Output Signal Reference ValueINFOID:0000000001716757

SPECIFICATIONS WITH CONSULT-III

CAUTION:

The o NISSAN TIIDA 2007 Service Repair Manual STC-22

< ECU DIAGNOSIS >[EPS]

EPS CONTROL UNIT

ECU DIAGNOSIS

EPS CONTROL UNIT

EPS Control Unit Input/Output Signal Reference ValueINFOID:0000000001716757

SPECIFICATIONS WITH CONSULT-III

CAUTION:

The o](/img/5/57395/w960_57395-4895.png)

STC-22

< ECU DIAGNOSIS >[EPS]

EPS CONTROL UNIT

ECU DIAGNOSIS

EPS CONTROL UNIT

EPS Control Unit Input/Output Signal Reference ValueINFOID:0000000001716757

SPECIFICATIONS WITH CONSULT-III

CAUTION:

The output signal indicates the EPS control unit calculation date. The normal values will be displayed

even in the event that the output circuit (harness) is open.

*1: In the front of the value, “L” is displayed at steering left and “R” is displayed at steering right.

*2: Almost in accordance with the value of “MOTOR SIG”. It is not a malfunction though these values are not accorded when steering

quickly.

*3: It is not a malfunction, though it might not be corresponding just after ignition switch is turned ON.

*4: It turns to OFF after waiting for a short period of time.Monitor item (Unit) Content Condition Display value

MOTOR VOL (V)Power supply voltage for

EPS control unitIgnition switch: ON Battery voltage

TORQUE SENSOR (Nm)Steering wheel turning

forceEngine runningSteering wheel: Not

steering (There is no

steering force) 0.00 Nm

Steering wheel: Steer-

ing0 – 8.19 Nm

*1 (The value

is changed according to

steering left or right)

MOTOR SIG (A)Command current to EPS

motorEngine runningSteering wheel: Not

steering (There is no

steering force)0.00 A

Steering wheel: Steer-

ing0 – 65.00 A (The value is

changed according to

steering left or right)

MOTOR CURRENT (A)Consumption current of

EPS motorEngine runningSteering wheel: Not

steering (There is no

steering force)0.00 A

Steering wheel: Steer-

ing0 – 65.00 A

*2 (The value

is changed according to

steering left or right)

VEHICLE SPEED (km/h) or (mph) Vehicle speedVehicle stopped 0 km/h (0 mph)

While drivingApproximately equal to

the indication on speed-

ometer (Inside of ±10%)

*3

WARNING LAMP (ON/OFF)EPS warning lamp condi-

tionEPS warning lamp: ON ON

EPS warning lamp: OFF OFF

DERATING STAT (ON/OFF) Protect overload status Engine runningSteering wheel: Nor-

mal steeringOFF

Steering wheel: Steer-

ing over the stopON

*4

ENGINE STATUS (RUN/STOP) Engine statusEngine stopped

(Engine speed: Less than 400 rpm)STOP

Engine running

(Engine speed: 400 rpm or more)RUN

Page 4897 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EPS CONTROL UNIT

STC-23

< ECU DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

EPS HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR EPS CONTROL UNIT

Data are reference values an NISSAN TIIDA 2007 Service Repair Manual EPS CONTROL UNIT

STC-23

< ECU DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

EPS HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR EPS CONTROL UNIT

Data are reference values an](/img/5/57395/w960_57395-4896.png)

EPS CONTROL UNIT

STC-23

< ECU DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

EPS HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR EPS CONTROL UNIT

Data are reference values and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

SGIA1624E

Te r m i n a lWire

colorItem Condition Data (Approx.)

4 V Torque sensor sub Engine runningSteering wheel: Not steering

(There in no steering force)2.5 V

Steering wheel: Steering1.7 V – 3.3 V

(The value is changed accord-

ing to steering left or right)

5 BR Torque sensor power supplyIgnition switch: ON 8 V

Ignition switch: OFF 0 V

6 G Torque sensor main Engine runningSteering wheel: Not steering

(There is no steering force)2.5 V

Steering wheel: Steering1.7 V – 3.3 V

(The value is changed accord-

ing to steering left or right)

7 R Torque sensor ground Always 0 V

9 L CAN-H — —

10 O Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF 0 V

16 P CAN-L — —

17 R Power supply (Memory back-up)Ignition switch: ON Battery voltage

Ignition switch: OFF Battery voltage

18 B Ground Always 0 V

19 — Motor (+) — —

20 — Motor (–) — —

Page 4903 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EPS SYSTEM SYMPTOMS

STC-29

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

SYMPTOM DIAGNOSIS

EPS SYSTEM SYMPTOMS

Symptom ChartINFOID:0000000001716771

If EPS warning lamp turns ON, perform NISSAN TIIDA 2007 Service Repair Manual EPS SYSTEM SYMPTOMS

STC-29

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

SYMPTOM DIAGNOSIS

EPS SYSTEM SYMPTOMS

Symptom ChartINFOID:0000000001716771

If EPS warning lamp turns ON, perform](/img/5/57395/w960_57395-4902.png)

EPS SYSTEM SYMPTOMS

STC-29

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

SYMPTOM DIAGNOSIS

EPS SYSTEM SYMPTOMS

Symptom ChartINFOID:0000000001716771

If EPS warning lamp turns ON, perform self-diagnosis. Refer to STC-7, "CONSULT-III Function (EPS)".

Symptom Condition Check item Reference page

EPS warning lamp does not turn ON when ig-

nition switch to “ON”.

(EPS warning lamp check)Ignition switch: ONCAN communication line

STC-30

Combination meter

EPS warning lamp does not turn OFF for sev-

eral seconds after starting the engineEngine runningCAN communication line

STC-31

Power supply and ground for

EPS control unit

Torque sensor

EPS motor

Vehicle speed signal

Engine status signal

Combination meter

Steering wheel turning force is heavy or light,

while driving While driving

Steering wheel turningCAN communication line

STC-33

Vehicle speed signal

Engine status signal

EPS motor

Steering wheel turning force

(Mechanical malfunction)

Unbalance steering wheel turning force and

return between right and left, while driving While driving

Steering wheel turningWheel alignment

STC-34

Steering wheel turning force

(Mechanical malfunction)

Unbalance steering wheel turning force,

while driving (Torque variation) While driving

Steering wheel turningSteering column intermediate

shaft installation condition

STC-35

Steering wheel turning force

(Mechanical malfunction)

Page 4905 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EPS WARNING LAMP DOES NOT TURN OFF

STC-31

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

EPS WARNING LAMP DOES NOT TURN OFF

Diagnosis ProcedureINFOID:0000000001697734

SYMPTOM:

EPS warnin NISSAN TIIDA 2007 Service Repair Manual EPS WARNING LAMP DOES NOT TURN OFF

STC-31

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

EPS WARNING LAMP DOES NOT TURN OFF

Diagnosis ProcedureINFOID:0000000001697734

SYMPTOM:

EPS warnin](/img/5/57395/w960_57395-4904.png)

EPS WARNING LAMP DOES NOT TURN OFF

STC-31

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

EPS WARNING LAMP DOES NOT TURN OFF

Diagnosis ProcedureINFOID:0000000001697734

SYMPTOM:

EPS warning lamp does not turn OFF for several seconds after starting the engine.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to STC-7, "

CONSULT-III Function (EPS)".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK EPS CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EPS control unit harness connector.

3. Turn ignition switch ON. (Do not start engine.)

4. Check voltage between EPS control unit harness connector

M53 (A) terminal 10 and M54 (B) terminal 17 and ground.

5. Turn ignition switch OFF.

6. Check voltage between EPS control unit harness connector

M53 (A) terminal 10 and M54 (B) terminal 17 and ground.

7. Connect EPS control unit harness connector.

OK or NG

OK >> GO TO 3.

NG >> Check the following. If any items are damaged, repair

or replace damaged parts.

60 A fusible link (letter m , located in the fuse and fusible link box).

10 A fuse [No. 2, located in the fuse block (J/B)].

Harness for short or open between battery and EPS control unit harness connector M54 termi-

nal 17.

Harness for short or open between ignition switch and EPS control unit harness connector M53

terminal 10.

3.CHECK EPS CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EPS control unit harness connector.

Connector Terminal Voltage

(A) M53 10 – Ground Battery voltage

(B) M54 17 – Ground Battery voltage

AWGIA0031ZZ

Connector Terminal Voltage

(A) M53 10 – Ground Approx. 0 V

(B) M54 17 – Ground Battery voltage

AWGIA0028ZZ

Page 4907 of 5883

![NISSAN TIIDA 2007 Service Repair Manual STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

STC-33

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

Diagnosis ProcedureINFOID:0000000001697 NISSAN TIIDA 2007 Service Repair Manual STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

STC-33

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

Diagnosis ProcedureINFOID:0000000001697](/img/5/57395/w960_57395-4906.png)

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

STC-33

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

Diagnosis ProcedureINFOID:0000000001697735

SYMPTOM:

Steering wheel turning force is heavy or light, while driving.

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to STC-7, "

CONSULT-III Function (EPS)".

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to STC-21, "Diagnosis Procedure".

NO >> GO TO 2.

2.CHECK VEHICLE SPEED SIGNAL

Perform self-diagnosis with ABS actuator and electric unit (control unit). Refer to BRC-25, "

CONSULT-III

Function (ABS)" (with ABS) or BRC-105, "CONSULT-III Function (ABS)" (with ESP).

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 3.

3.CHECK COMBINATION METER SIGNAL

Perform self-diagnosis with combination meter. Refer to MWI-22, "

CONSULT-III Function (METER/M&A)".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 4.

4.CHECK ENGINE STATUS SIGNAL

Perform self-diagnosis for ECM. Refer to EC-107, "

CONSULT-III Function" (HR16DE with EURO-OBD), EC-

462, "CONSULT-III Function" (HR16DE without EURO-OBD), EC-772, "CONSULT-III Function" (MR18DE),

EC-1104, "

Diagnosis Description" (K9K).

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 5.

5.CHECK EPS MOTOR SYSTEM

Perform trouble diagnosis for EPS motor. Refer to STC-13, "

Diagnosis Procedure".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK EPS CONTROL UNIT

Check EPS control unit input/output signal. Refer to STC-22, "

EPS Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 7.

NG >> Check EPS control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

7.SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> Check the steering wheel turning force because there may be mechanical malfunction. Refer to

ST-6, "

On-Vehicle Inspection and Service".

Page 4908 of 5883

![NISSAN TIIDA 2007 Service Repair Manual STC-34

< SYMPTOM DIAGNOSIS >[EPS]

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BETWEEN

RIGHT AND LEFT

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BE-

TWEEN RIGHT AND LEFT

Diagnosis Procedu NISSAN TIIDA 2007 Service Repair Manual STC-34

< SYMPTOM DIAGNOSIS >[EPS]

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BETWEEN

RIGHT AND LEFT

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BE-

TWEEN RIGHT AND LEFT

Diagnosis Procedu](/img/5/57395/w960_57395-4907.png)

STC-34

< SYMPTOM DIAGNOSIS >[EPS]

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BETWEEN

RIGHT AND LEFT

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BE-

TWEEN RIGHT AND LEFT

Diagnosis ProcedureINFOID:0000000001697736

SYMPTOM:

Unbalance steering wheel turning force and return between right and left, while driving.

DIAGNOSTIC PROCEDURE

1.CHECK EPS WARNING LAMP

Confirm EPS warning lamp during engine running.

Does EPS warning lamp turn OFF?

YES >> GO TO 2.

NO >> Go to STC-31, "

Diagnosis Procedure".

2.CHECK WHEEL ALIGNMENT

Check wheel alignment. Refer to FSU-6, "

Wheel Alignment Inspection".

OK or NG

OK >> GO TO 3.

NG >> Adjust wheel alignment. Refer to FSU-6, "

Wheel Alignment Inspection".

3.CHECK EPS CONTROL UNIT

Check EPS control unit input/output signal. Refer to STC-22, "

EPS Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 4.

NG >> Check EPS control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

4.SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> Check the steering wheel turning force because there may be mechanical malfunction. Refer to

ST-6, "

On-Vehicle Inspection and Service".

Page 4909 of 5883

![NISSAN TIIDA 2007 Service Repair Manual UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

STC-35

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIA-

TION)

Diagnosis Proce NISSAN TIIDA 2007 Service Repair Manual UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

STC-35

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIA-

TION)

Diagnosis Proce](/img/5/57395/w960_57395-4908.png)

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

STC-35

< SYMPTOM DIAGNOSIS >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIA-

TION)

Diagnosis ProcedureINFOID:0000000001697737

SYMPTOM:

Unbalance steering wheel turning force, while driving (Torque variation).

DIAGNOSTIC PROCEDURE

1.CHECK EPS WARNING LAMP

Confirm EPS warning lamp during engine running.

Does EPS warning lamp turn OFF?

YES >> GO TO 2.

NO >> Go to STC-31, "

Diagnosis Procedure".

2.CHECK STEERING COLUMN INTERMEDIATE SHAFT

Check the connection between intermediate shaft and the mounting part of steering column assembly and

steering gear assembly. Refer to ST-9, "

Removal and Installation".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK EPS CONTROL UNIT

Check EPS control unit input/output signal. Refer to STC-22, "

EPS Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 4.

NG >> Check EPS control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

4.SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> Check the steering wheel turning force because there may be mechanical malfunction. Refer to

ST-6, "

On-Vehicle Inspection and Service".

Page 4912 of 5883

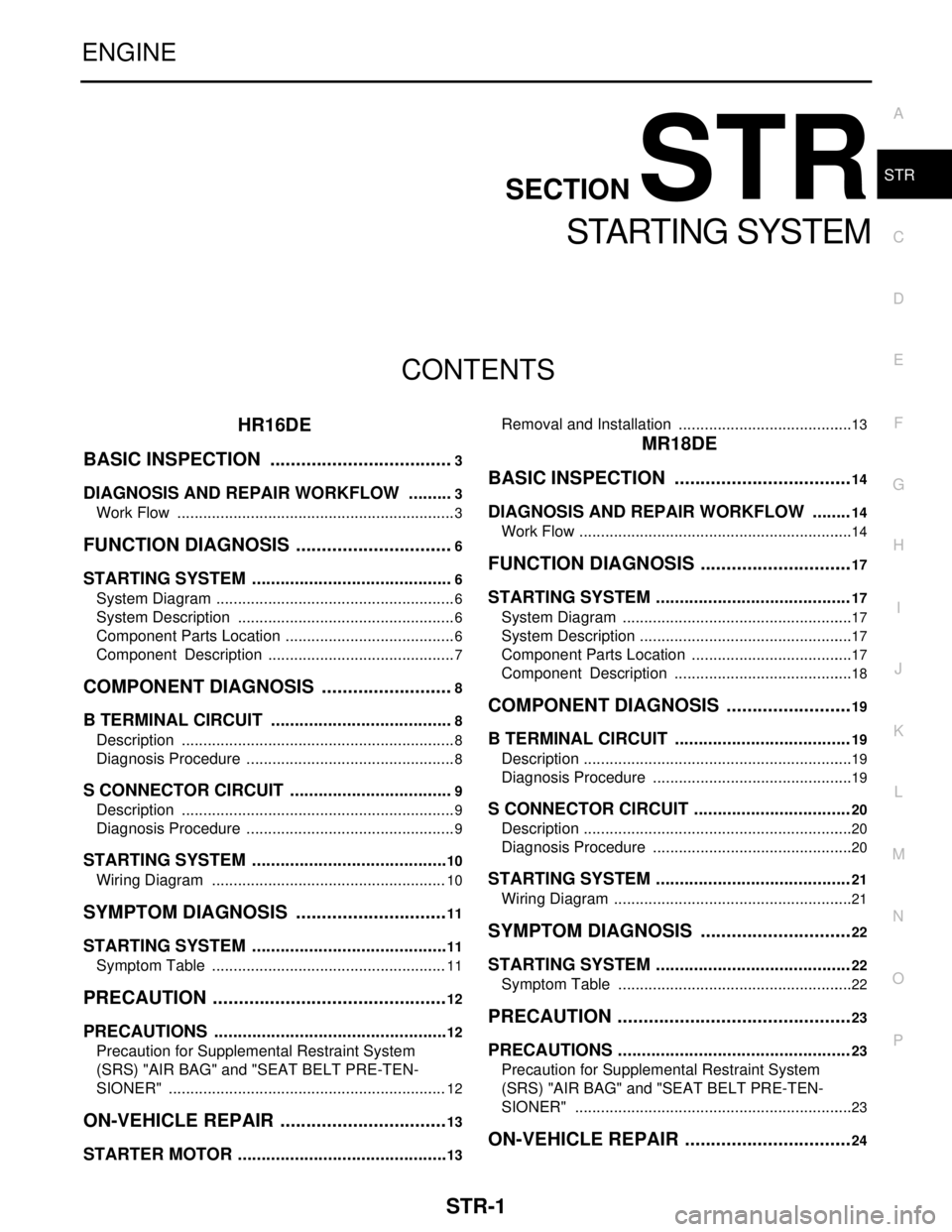

STR-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION STR

A

STR

N

O

P

CONTENTS

STARTING SYSTEM

HR16DE

BASIC INSPECTION ....................................

3

DIAGNOSIS AND REPAIR WORKFLOW ..........3

Work Flow .................................................................3

FUNCTION DIAGNOSIS ...............................6

STARTING SYSTEM ...........................................6

System Diagram ........................................................6

System Description ...................................................6

Component Parts Location ........................................6

Component Description ............................................7

COMPONENT DIAGNOSIS ..........................8

B TERMINAL CIRCUIT .......................................8

Description ................................................................8

Diagnosis Procedure .................................................8

S CONNECTOR CIRCUIT ...................................9

Description ................................................................9

Diagnosis Procedure .................................................9

STARTING SYSTEM ..........................................10

Wiring Diagram .......................................................10

SYMPTOM DIAGNOSIS ..............................11

STARTING SYSTEM ..........................................11

Symptom Table .......................................................11

PRECAUTION ..............................................12

PRECAUTIONS ..................................................12

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

12

ON-VEHICLE REPAIR .................................13

STARTER MOTOR .............................................13

Removal and Installation .........................................13

MR18DE

BASIC INSPECTION ...................................

14

DIAGNOSIS AND REPAIR WORKFLOW ........14

Work Flow ................................................................14

FUNCTION DIAGNOSIS ..............................17

STARTING SYSTEM .........................................17

System Diagram ......................................................17

System Description ..................................................17

Component Parts Location ......................................17

Component Description ..........................................18

COMPONENT DIAGNOSIS .........................19

B TERMINAL CIRCUIT .....................................19

Description ...............................................................19

Diagnosis Procedure ...............................................19

S CONNECTOR CIRCUIT .................................20

Description ...............................................................20

Diagnosis Procedure ...............................................20

STARTING SYSTEM .........................................21

Wiring Diagram ........................................................21

SYMPTOM DIAGNOSIS ..............................22

STARTING SYSTEM .........................................22

Symptom Table .......................................................22

PRECAUTION ..............................................23

PRECAUTIONS .................................................23

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

23

ON-VEHICLE REPAIR .................................24

Page 4915 of 5883

![NISSAN TIIDA 2007 Service Repair Manual STR-4

< BASIC INSPECTION >[HR16DE]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

If any malfunction is found, immediately disconnect the battery cable from the negative terminal.

1.CHECK ENGINE START

Crank the NISSAN TIIDA 2007 Service Repair Manual STR-4

< BASIC INSPECTION >[HR16DE]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

If any malfunction is found, immediately disconnect the battery cable from the negative terminal.

1.CHECK ENGINE START

Crank the](/img/5/57395/w960_57395-4914.png)

STR-4

< BASIC INSPECTION >[HR16DE]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

If any malfunction is found, immediately disconnect the battery cable from the negative terminal.

1.CHECK ENGINE START

Crank the engine and check that the engine starts.

Does the engine start?

YES >> GO TO 2

NO >> GO TO 3

2.CHECK THAT THE STARTER MOTOR STOPS

Check that the starter motor stops after starting the engine.

Does the starter motor stop?

YES >> INSPECTION END.

NO >> Replace magnetic switch.

3.CHECK THE ENGINE SPEED WITH CRANKING

Check that the engine runs at cranking.

Does engine turn by cranking?

YES >> GO TO 4

NO >> GO TO 5

4.CHECK THE ENGINE SPEED WITH CRANKING

Check that the engine speed is not low at cranking.

Does engine turn normally?

YES >> Check ignition/fuel system.

NO >> Check charge condition, corrosion and connection condition of the battery. Refer to PG-3, "

How to

Handle Battery".

5.CHECK STARTER MOTOR ACTIVATION

Check that the starter motor runs at cranking.

Does starter motor turn?

YES >> GO TO 6

NO >> GO TO 7

6.CHECK STARTER MOTOR UNIT

1. Remove starter motor.

2. Check that the gear shaft of starter motor rotates.

Does gear shaft turn?

YES >> • Check pinion clutch.

NO >> Check reduction gear, armature and gear shaft.

7.CHECK POWER SUPPLY CIRCUIT

Check the following conditions.

Fuse and fusible link

Charge condition, corrosion and connection condition of the battery. Refer to PG-3, "

How to Handle Battery".

Are these inspection results normal?

YES >> GO TO 8

NO >> Repair as needed.

8.CHECK STARTING SYSTEM WIRING

Check the following.

“B” terminal circuit. Refer to STR-8, "

Description".

“S” terminal circuit. Refer to STR-9, "

Description".

Are these inspection results normal?

YES >> GO TO 9

NO >> Repair as needed.