sensor NISSAN TIIDA 2007 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 141 of 5883

BCS-6

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

>> WORK END

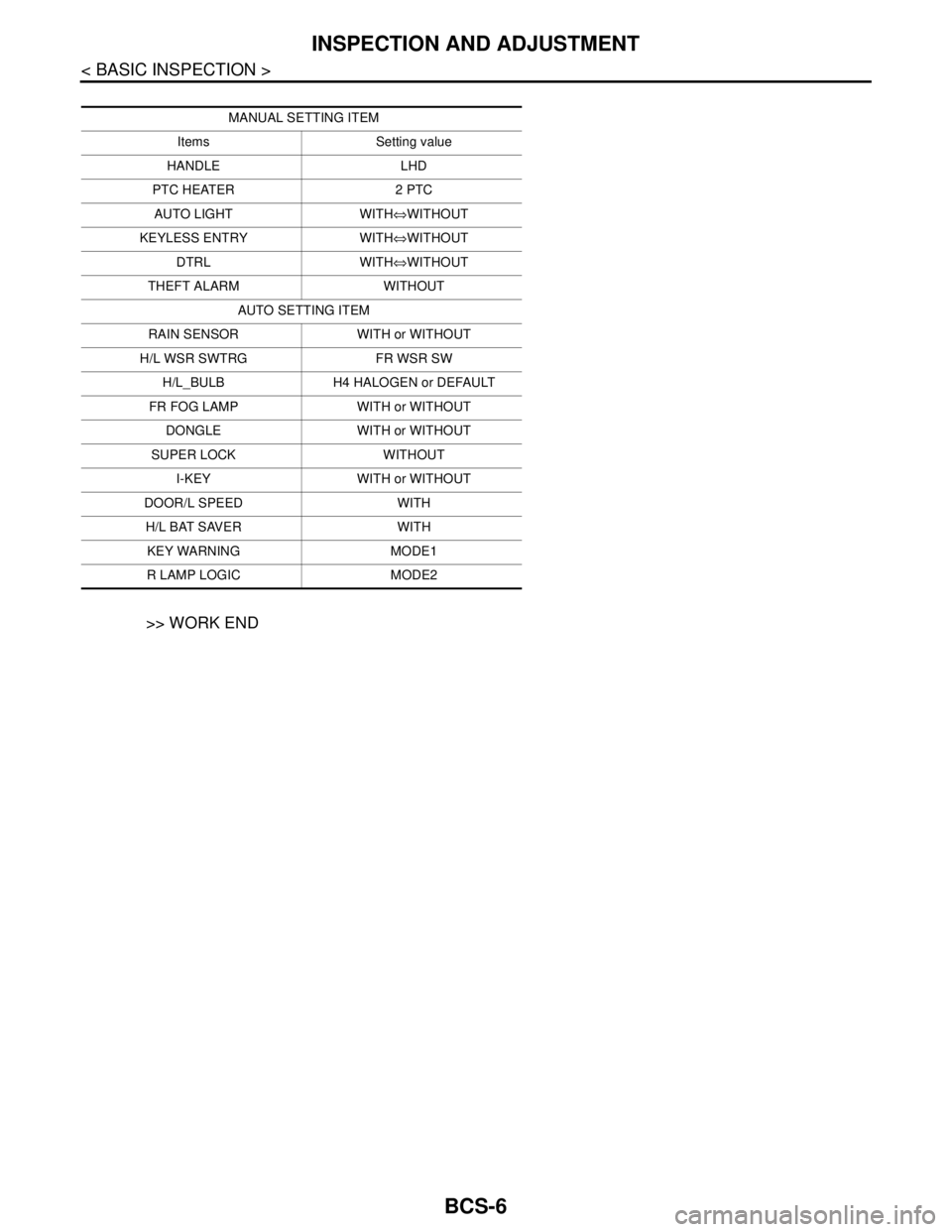

MANUAL SETTING ITEM

Items Setting value

HANDLE LHD

PTC HEATER 2 PTC

AUTO LIGHT WITH⇔WITHOUT

KEYLESS ENTRY WITH⇔WITHOUT

DTRL WITH⇔WITHOUT

THEFT ALARM WITHOUT

AUTO SETTING ITEM

RAIN SENSOR WITH or WITHOUT

H/L WSR SWTRG FR WSR SW

H/L_BULB H4 HALOGEN or DEFAULT

FR FOG LAMP WITH or WITHOUT

DONGLE WITH or WITHOUT

SUPER LOCK WITHOUT

I-KEY WITH or WITHOUT

DOOR/L SPEED WITH

H/L BAT SAVER WITH

KEY WARNING MODE1

R LAMP LOGIC MODE2

Page 142 of 5883

BCS

BODY CONTROL SYSTEM

BCS-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

FUNCTION DIAGNOSIS

BODY CONTROL SYSTEM

System DescriptionINFOID:0000000001451453

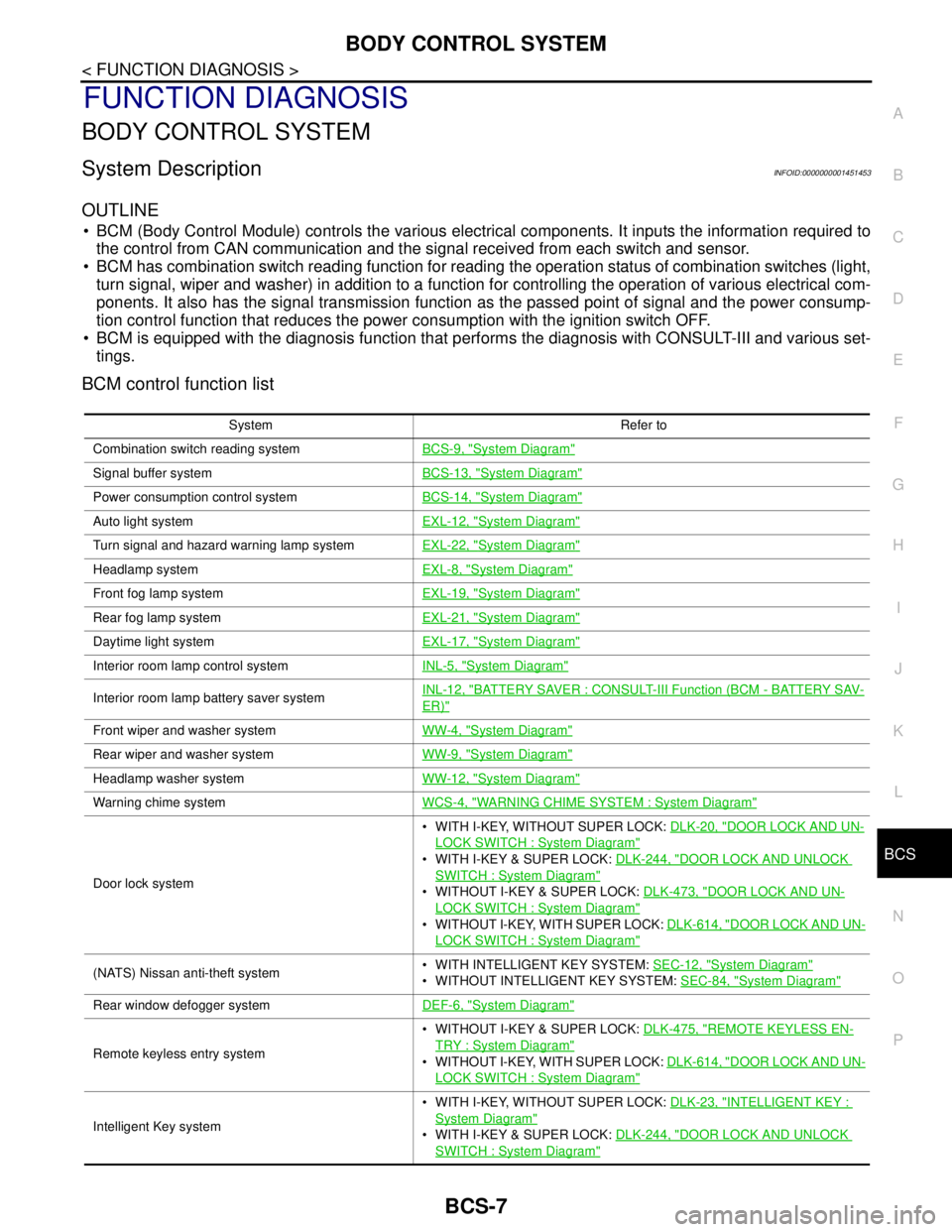

OUTLINE

BCM (Body Control Module) controls the various electrical components. It inputs the information required to

the control from CAN communication and the signal received from each switch and sensor.

BCM has combination switch reading function for reading the operation status of combination switches (light,

turn signal, wiper and washer) in addition to a function for controlling the operation of various electrical com-

ponents. It also has the signal transmission function as the passed point of signal and the power consump-

tion control function that reduces the power consumption with the ignition switch OFF.

BCM is equipped with the diagnosis function that performs the diagnosis with CONSULT-III and various set-

tings.

BCM control function list

System Refer to

Combination switch reading systemBCS-9, "

System Diagram"

Signal buffer systemBCS-13, "System Diagram"

Power consumption control systemBCS-14, "System Diagram"

Auto light systemEXL-12, "System Diagram"

Turn signal and hazard warning lamp systemEXL-22, "System Diagram"

Headlamp systemEXL-8, "System Diagram"

Front fog lamp systemEXL-19, "System Diagram"

Rear fog lamp systemEXL-21, "System Diagram"

Daytime light systemEXL-17, "System Diagram"

Interior room lamp control systemINL-5, "System Diagram"

Interior room lamp battery saver systemINL-12, "BATTERY SAVER : CONSULT-III Function (BCM - BATTERY SAV-

ER)"

Front wiper and washer systemWW-4, "System Diagram"

Rear wiper and washer systemWW-9, "System Diagram"

Headlamp washer systemWW-12, "System Diagram"

Warning chime systemWCS-4, "WARNING CHIME SYSTEM : System Diagram"

Door lock system WITH I-KEY, WITHOUT SUPER LOCK: DLK-20, "

DOOR LOCK AND UN-

LOCK SWITCH : System Diagram"

WITH I-KEY & SUPER LOCK: DLK-244, "DOOR LOCK AND UNLOCK

SWITCH : System Diagram"

WITHOUT I-KEY & SUPER LOCK: DLK-473, "DOOR LOCK AND UN-

LOCK SWITCH : System Diagram"

WITHOUT I-KEY, WITH SUPER LOCK: DLK-614, "DOOR LOCK AND UN-

LOCK SWITCH : System Diagram"

(NATS) Nissan anti-theft system WITH INTELLIGENT KEY SYSTEM: SEC-12, "System Diagram"

WITHOUT INTELLIGENT KEY SYSTEM: SEC-84, "System Diagram"

Rear window defogger systemDEF-6, "System Diagram"

Remote keyless entry system WITHOUT I-KEY & SUPER LOCK: DLK-475, "

REMOTE KEYLESS EN-

TRY : System Diagram"

WITHOUT I-KEY, WITH SUPER LOCK: DLK-614, "DOOR LOCK AND UN-

LOCK SWITCH : System Diagram"

Intelligent Key system WITH I-KEY, WITHOUT SUPER LOCK: DLK-23, "

INTELLIGENT KEY :

System Diagram"

WITH I-KEY & SUPER LOCK: DLK-244, "DOOR LOCK AND UNLOCK

SWITCH : System Diagram"

Page 156 of 5883

BCS

DIAGNOSIS SYSTEM (BCM)

BCS-21

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

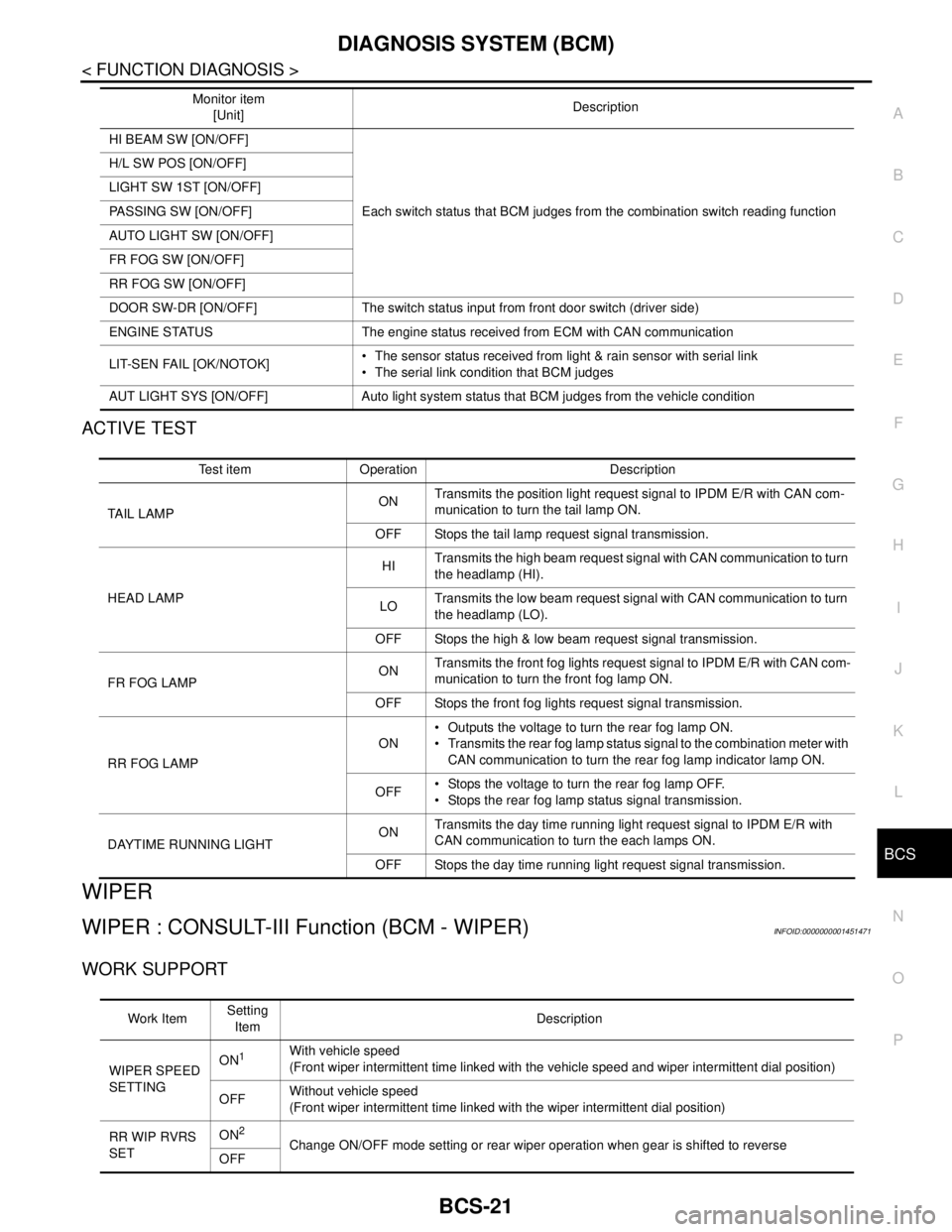

ACTIVE TEST

WIPER

WIPER : CONSULT-III Function (BCM - WIPER)INFOID:0000000001451471

WORK SUPPORT

HI BEAM SW [ON/OFF]

Each switch status that BCM judges from the combination switch reading function H/L SW POS [ON/OFF]

LIGHT SW 1ST [ON/OFF]

PASSING SW [ON/OFF]

AUTO LIGHT SW [ON/OFF]

FR FOG SW [ON/OFF]

RR FOG SW [ON/OFF]

DOOR SW-DR [ON/OFF] The switch status input from front door switch (driver side)

ENGINE STATUS The engine status received from ECM with CAN communication

LIT-SEN FAIL [OK/NOTOK] The sensor status received from light & rain sensor with serial link

The serial link condition that BCM judges

AUT LIGHT SYS [ON/OFF] Auto light system status that BCM judges from the vehicle conditionMonitor item

[Unit]Description

Test item Operation Description

TAIL LAMPONTransmits the position light request signal to IPDM E/R with CAN com-

munication to turn the tail lamp ON.

OFF Stops the tail lamp request signal transmission.

HEAD LAMPHITransmits the high beam request signal with CAN communication to turn

the headlamp (HI).

LOTransmits the low beam request signal with CAN communication to turn

the headlamp (LO).

OFF Stops the high & low beam request signal transmission.

FR FOG LAMPONTransmits the front fog lights request signal to IPDM E/R with CAN com-

munication to turn the front fog lamp ON.

OFF Stops the front fog lights request signal transmission.

RR FOG LAMPON Outputs the voltage to turn the rear fog lamp ON.

Transmits the rear fog lamp status signal to the combination meter with

CAN communication to turn the rear fog lamp indicator lamp ON.

OFF Stops the voltage to turn the rear fog lamp OFF.

Stops the rear fog lamp status signal transmission.

DAYTIME RUNNING LIGHTONTransmits the day time running light request signal to IPDM E/R with

CAN communication to turn the each lamps ON.

OFF Stops the day time running light request signal transmission.

Work ItemSetting

ItemDescription

WIPER SPEED

SETTINGON

1With vehicle speed

(Front wiper intermittent time linked with the vehicle speed and wiper intermittent dial position)

OFFWithout vehicle speed

(Front wiper intermittent time linked with the wiper intermittent dial position)

RR WIP RVRS

SETON

2Change ON/OFF mode setting or rear wiper operation when gear is shifted to reverse

OFF

Page 161 of 5883

BCS-26

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

*: Each lamp switch is in ON position.

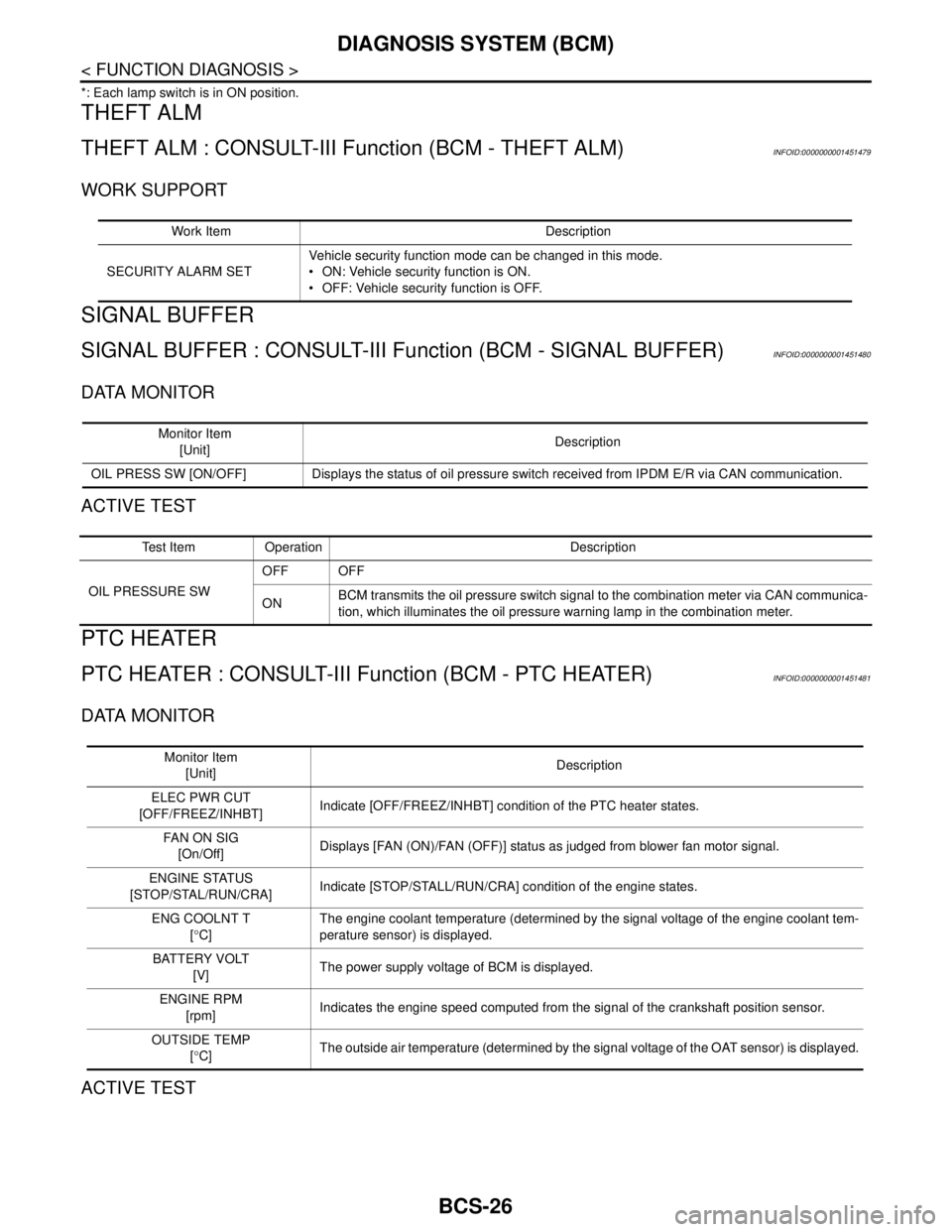

THEFT ALM

THEFT ALM : CONSULT-III Function (BCM - THEFT ALM)INFOID:0000000001451479

WORK SUPPORT

SIGNAL BUFFER

SIGNAL BUFFER : CONSULT-III Function (BCM - SIGNAL BUFFER)INFOID:0000000001451480

DATA MONITOR

ACTIVE TEST

PTC HEATER

PTC HEATER : CONSULT-III Function (BCM - PTC HEATER)INFOID:0000000001451481

DATA MONITOR

ACTIVE TEST

Work Item Description

SECURITY ALARM SETVehicle security function mode can be changed in this mode.

ON: Vehicle security function is ON.

OFF: Vehicle security function is OFF.

Monitor Item

[Unit]Description

OIL PRESS SW [ON/OFF] Displays the status of oil pressure switch received from IPDM E/R via CAN communication.

Test Item Operation Description

OIL PRESSURE SWOFF OFF

ONBCM transmits the oil pressure switch signal to the combination meter via CAN communica-

tion, which illuminates the oil pressure warning lamp in the combination meter.

Monitor Item

[Unit]Description

ELEC PWR CUT

[OFF/FREEZ/INHBT]Indicate [OFF/FREEZ/INHBT] condition of the PTC heater states.

FA N O N S I G

[On/Off]Displays [FAN (ON)/FAN (OFF)] status as judged from blower fan motor signal.

ENGINE STATUS

[STOP/STAL/RUN/CRA]Indicate [STOP/STALL/RUN/CRA] condition of the engine states.

ENG COOLNT T

[°C]The engine coolant temperature (determined by the signal voltage of the engine coolant tem-

perature sensor) is displayed.

BATTERY VOLT

[V]The power supply voltage of BCM is displayed.

ENGINE RPM

[rpm]Indicates the engine speed computed from the signal of the crankshaft position sensor.

OUTSIDE TEMP

[°C]The outside air temperature (determined by the signal voltage of the OAT sensor) is displayed.

Page 172 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-37

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

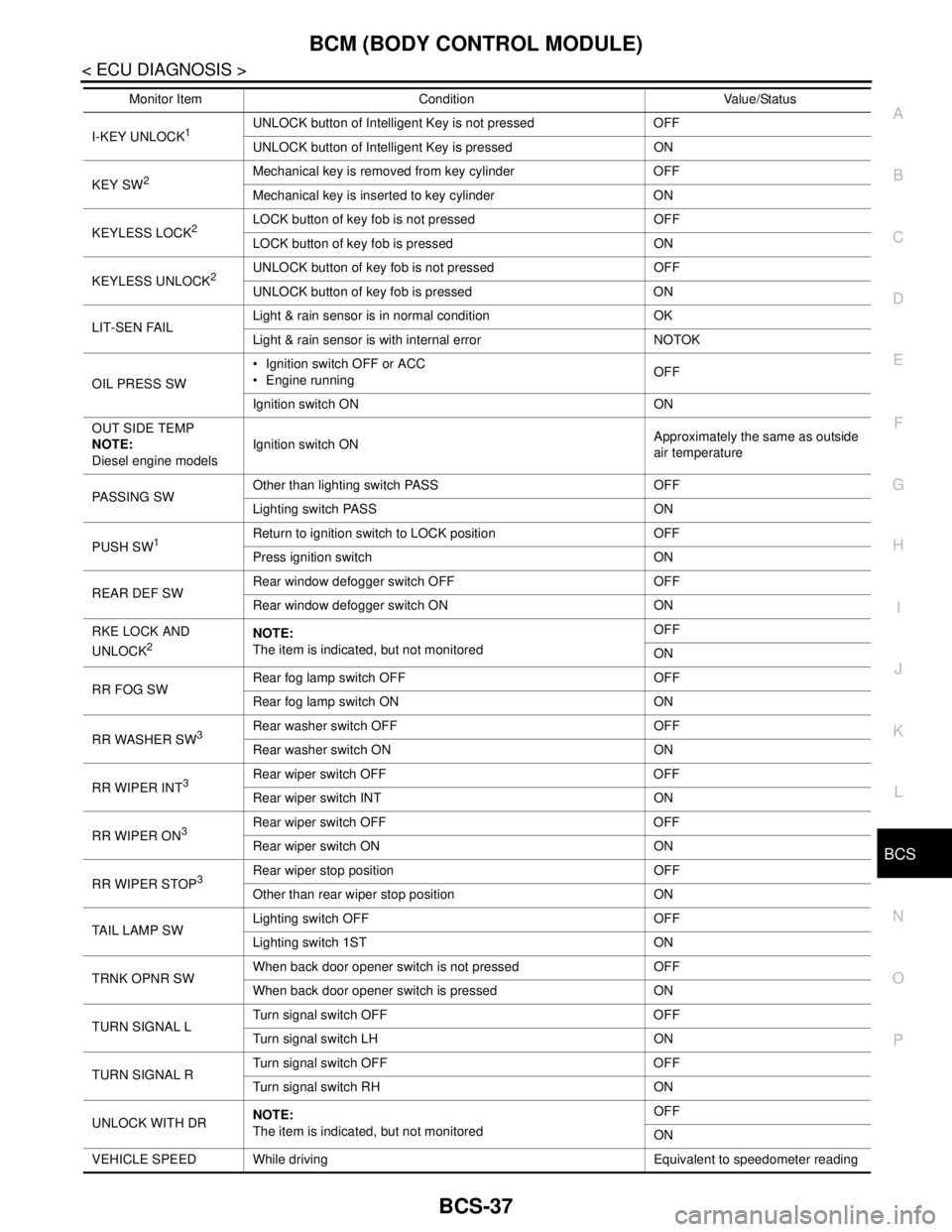

I-KEY UNLOCK1UNLOCK button of Intelligent Key is not pressed OFF

UNLOCK button of Intelligent Key is pressed ON

KEY SW

2Mechanical key is removed from key cylinder OFF

Mechanical key is inserted to key cylinder ON

KEYLESS LOCK

2LOCK button of key fob is not pressed OFF

LOCK button of key fob is pressed ON

KEYLESS UNLOCK

2UNLOCK button of key fob is not pressed OFF

UNLOCK button of key fob is pressed ON

LIT-SEN FAILLight & rain sensor is in normal condition OK

Light & rain sensor is with internal error NOTOK

OIL PRESS SW Ignition switch OFF or ACC

Engine runningOFF

Ignition switch ON ON

OUT SIDE TEMP

NOTE:

Diesel engine modelsIgnition switch ONApproximately the same as outside

air temperature

PASSING SWOther than lighting switch PASS OFF

Lighting switch PASS ON

PUSH SW

1Return to ignition switch to LOCK position OFF

Press ignition switch ON

REAR DEF SWRear window defogger switch OFF OFF

Rear window defogger switch ON ON

RKE LOCK AND

UNLOCK

2NOTE:

The item is indicated, but not monitoredOFF

ON

RR FOG SWRear fog lamp switch OFF OFF

Rear fog lamp switch ON ON

RR WASHER SW

3Rear washer switch OFF OFF

Rear washer switch ON ON

RR WIPER INT

3Rear wiper switch OFF OFF

Rear wiper switch INT ON

RR WIPER ON

3 Rear wiper switch OFF OFF

Rear wiper switch ON ON

RR WIPER STOP

3Rear wiper stop position OFF

Other than rear wiper stop position ON

TAIL LAMP SWLighting switch OFF OFF

Lighting switch 1ST ON

TRNK OPNR SWWhen back door opener switch is not pressed OFF

When back door opener switch is pressed ON

TURN SIGNAL LTurn signal switch OFF OFF

Turn signal switch LH ON

TURN SIGNAL RTurn signal switch OFF OFF

Turn signal switch RH ON

UNLOCK WITH DRNOTE:

The item is indicated, but not monitoredOFF

ON

VEHICLE SPEED While driving Equivalent to speedometer reading Monitor Item Condition Value/Status

Page 182 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-47

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

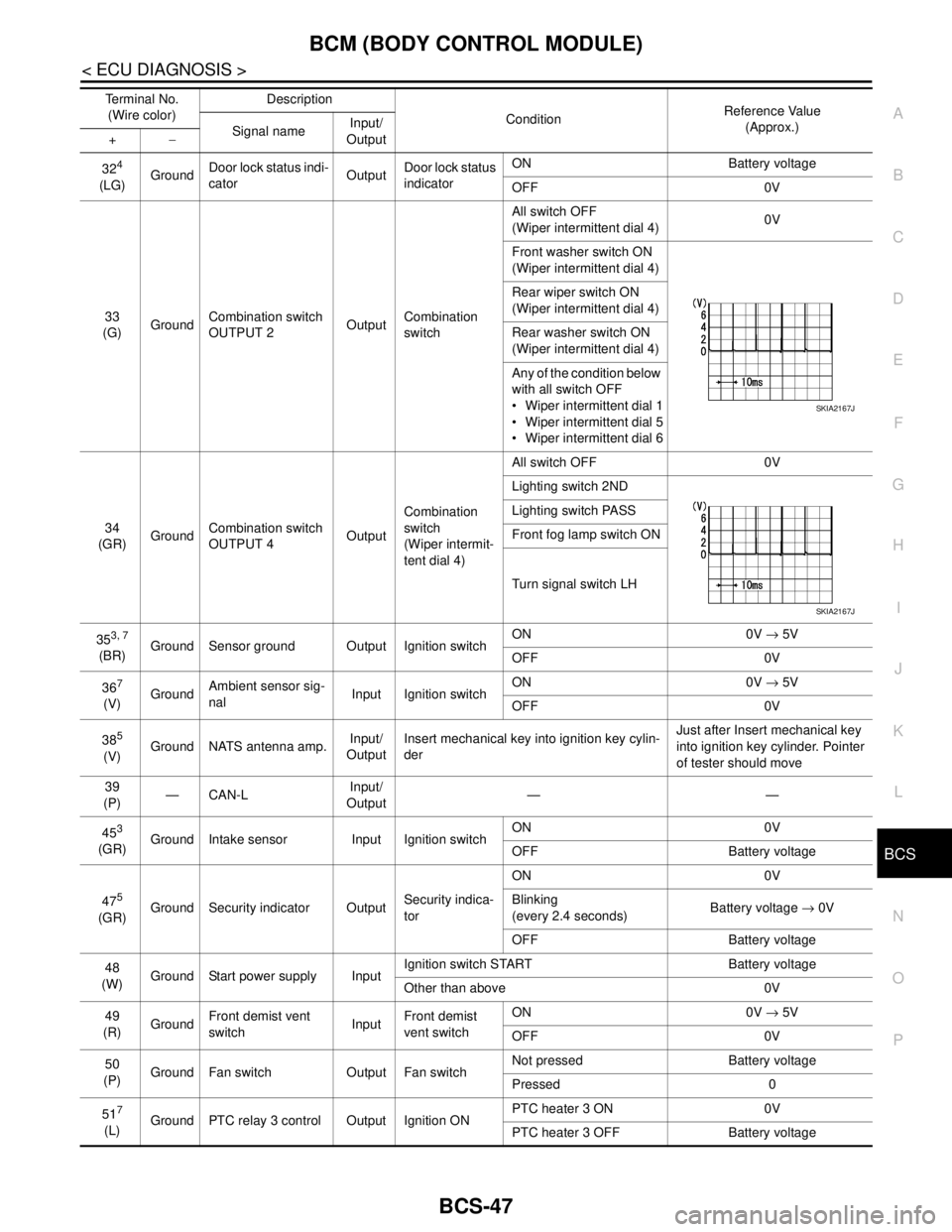

324

(LG)GroundDoor lock status indi-

catorOutputDoor lock status

indicatorON Battery voltage

OFF 0V

33

(G)GroundCombination switch

OUTPUT 2OutputCombination

switchAll switch OFF

(Wiper intermittent dial 4)0V

Front washer switch ON

(Wiper intermittent dial 4)

Rear wiper switch ON

(Wiper intermittent dial 4)

Rear washer switch ON

(Wiper intermittent dial 4)

Any of the condition below

with all switch OFF

Wiper intermittent dial 1

Wiper intermittent dial 5

Wiper intermittent dial 6

34

(GR)GroundCombination switch

OUTPUT 4OutputCombination

switch

(Wiper intermit-

tent dial 4)All switch OFF 0V

Lighting switch 2ND

Lighting switch PASS

Front fog lamp switch ON

Turn signal switch LH

35

3, 7

(BR)Ground Sensor ground Output Ignition switchON 0V → 5V

OFF 0V

36

7

(V)GroundAmbient sensor sig-

nalInput Ignition switchON 0V → 5V

OFF 0V

38

5

(V)Ground NATS antenna amp.Input/

OutputInsert mechanical key into ignition key cylin-

derJust after Insert mechanical key

into ignition key cylinder. Pointer

of tester should move

39

(P)—CAN-LInput/

Output——

45

3

(GR)Ground Intake sensor Input Ignition switchON 0V

OFF Battery voltage

47

5

(GR)Ground Security indicator OutputSecurity indica-

torON 0V

Blinking

(every 2.4 seconds)Battery voltage → 0V

OFF Battery voltage

48

(W)Ground Start power supply InputIgnition switch START Battery voltage

Other than above 0V

49

(R)GroundFront demist vent

switchInputFront demist

vent switchON 0V → 5V

OFF 0V

50

(P)Ground Fan switch Output Fan switchNot pressed Battery voltage

Pressed 0

51

7

(L)Ground PTC relay 3 control Output Ignition ONPTC heater 3 ON 0V

PTC heater 3 OFF Battery voltage Terminal No.

(Wire color)Description

ConditionReference Value

(Approx.)

Signal nameInput/

Output +−

SKIA2167J

SKIA2167J

Page 183 of 5883

BCS-48

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

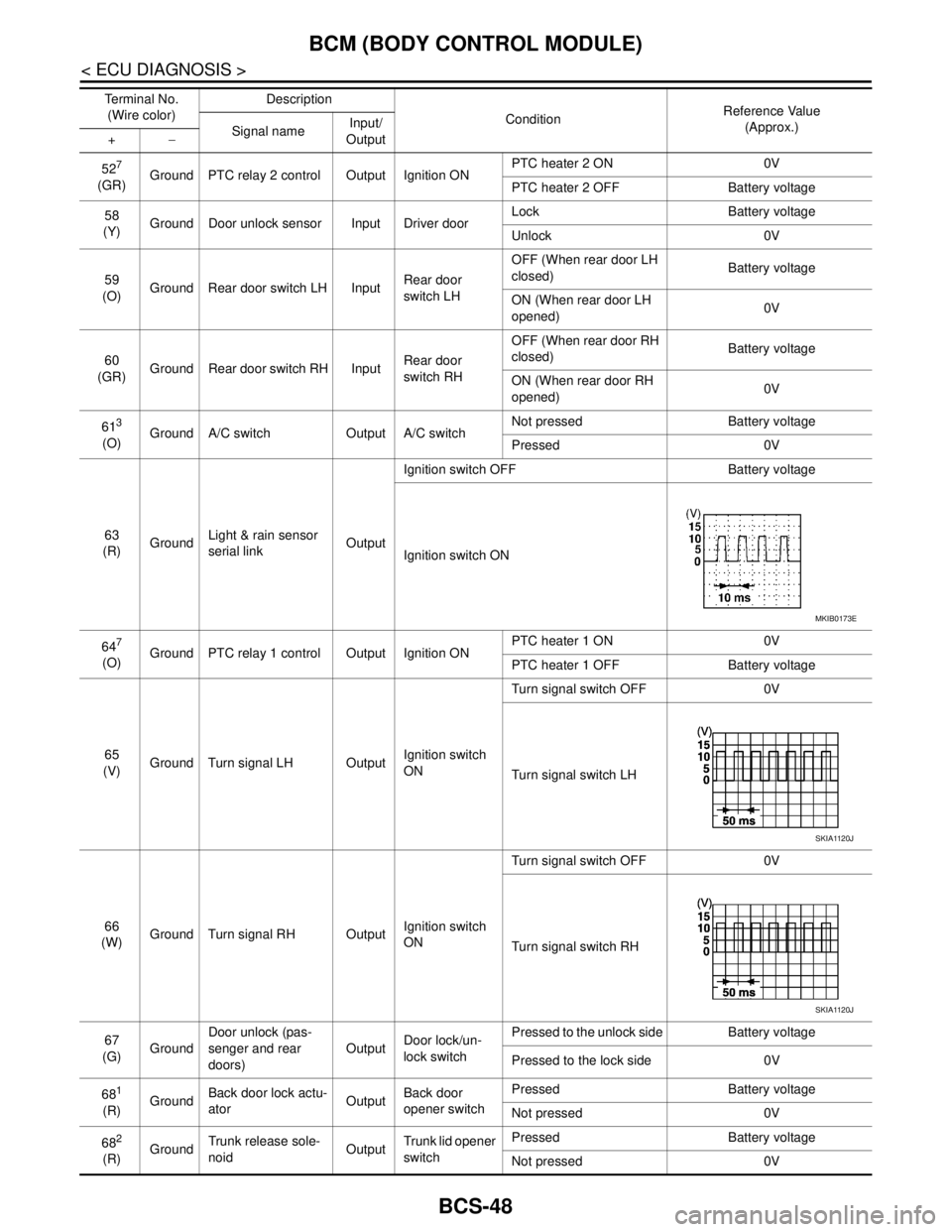

527

(GR)Ground PTC relay 2 control Output Ignition ONPTC heater 2 ON 0V

PTC heater 2 OFF Battery voltage

58

(Y)Ground Door unlock sensor Input Driver doorLock Battery voltage

Unlock 0V

59

(O)Ground Rear door switch LH InputRear door

switch LHOFF (When rear door LH

closed) Battery voltage

ON (When rear door LH

opened)0V

60

(GR)Ground Rear door switch RH InputRear door

switch RHOFF (When rear door RH

closed) Battery voltage

ON (When rear door RH

opened)0V

61

3

(O)Ground A/C switch Output A/C switchNot pressed Battery voltage

Pressed 0V

63

(R)GroundLight & rain sensor

serial linkOutputIgnition switch OFF Battery voltage

Ignition switch ON

64

7

(O)Ground PTC relay 1 control Output Ignition ONPTC heater 1 ON 0V

PTC heater 1 OFF Battery voltage

65

(V)Ground Turn signal LH OutputIgnition switch

ONTurn signal switch OFF 0V

Turn signal switch LH

66

(W)Ground Turn signal RH OutputIgnition switch

ONTurn signal switch OFF 0V

Turn signal switch RH

67

(G)GroundDoor unlock (pas-

senger and rear

doors)OutputDoor lock/un-

lock switchPressed to the unlock side Battery voltage

Pressed to the lock side 0V

68

1

(R)GroundBack door lock actu-

atorOutputBack door

opener switchPressed Battery voltage

Not pressed 0V

68

2

(R)GroundTrunk release sole-

noidOutputTrunk lid opener

switchPressed Battery voltage

Not pressed 0V Te r m i n a l N o .

(Wire color)Description

ConditionReference Value

(Approx.)

Signal nameInput/

Output +−

MKIB0173E

SKIA1120J

SKIA1120J

Page 204 of 5883

BR-12

< ON-VEHICLE REPAIR >

BRAKE PEDAL

ON-VEHICLE REPAIR

BRAKE PEDAL

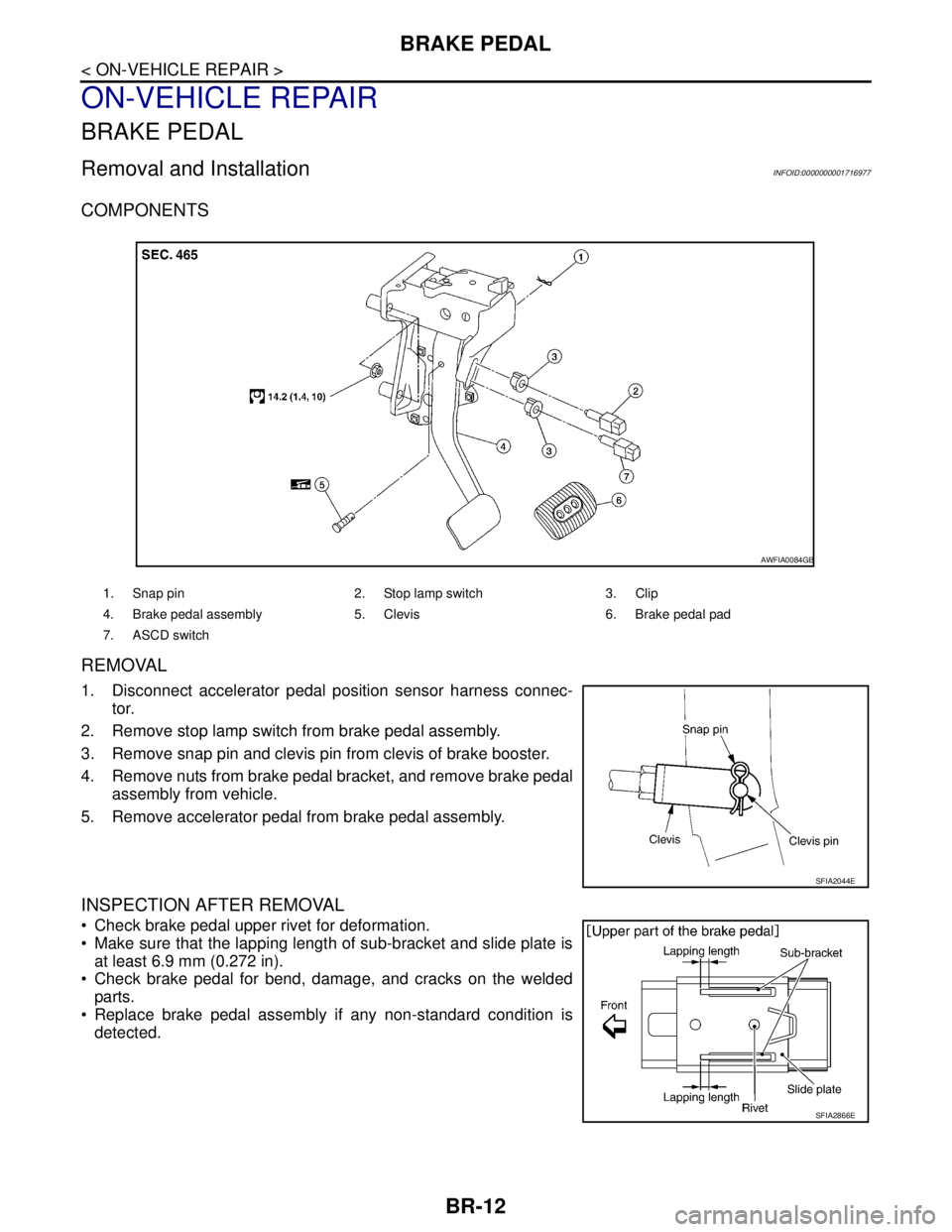

Removal and InstallationINFOID:0000000001716977

COMPONENTS

REMOVAL

1. Disconnect accelerator pedal position sensor harness connec-

tor.

2. Remove stop lamp switch from brake pedal assembly.

3. Remove snap pin and clevis pin from clevis of brake booster.

4. Remove nuts from brake pedal bracket, and remove brake pedal

assembly from vehicle.

5. Remove accelerator pedal from brake pedal assembly.

INSPECTION AFTER REMOVAL

Check brake pedal upper rivet for deformation.

Make sure that the lapping length of sub-bracket and slide plate is

at least 6.9 mm (0.272 in).

Check brake pedal for bend, damage, and cracks on the welded

parts.

Replace brake pedal assembly if any non-standard condition is

detected.

1. Snap pin 2. Stop lamp switch 3. Clip

4. Brake pedal assembly 5. Clevis 6. Brake pedal pad

7. ASCD switch

AWFIA0084GB

SFIA2044E

SFIA2866E

Page 216 of 5883

BR-24

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

FRONT DISC BRAKE

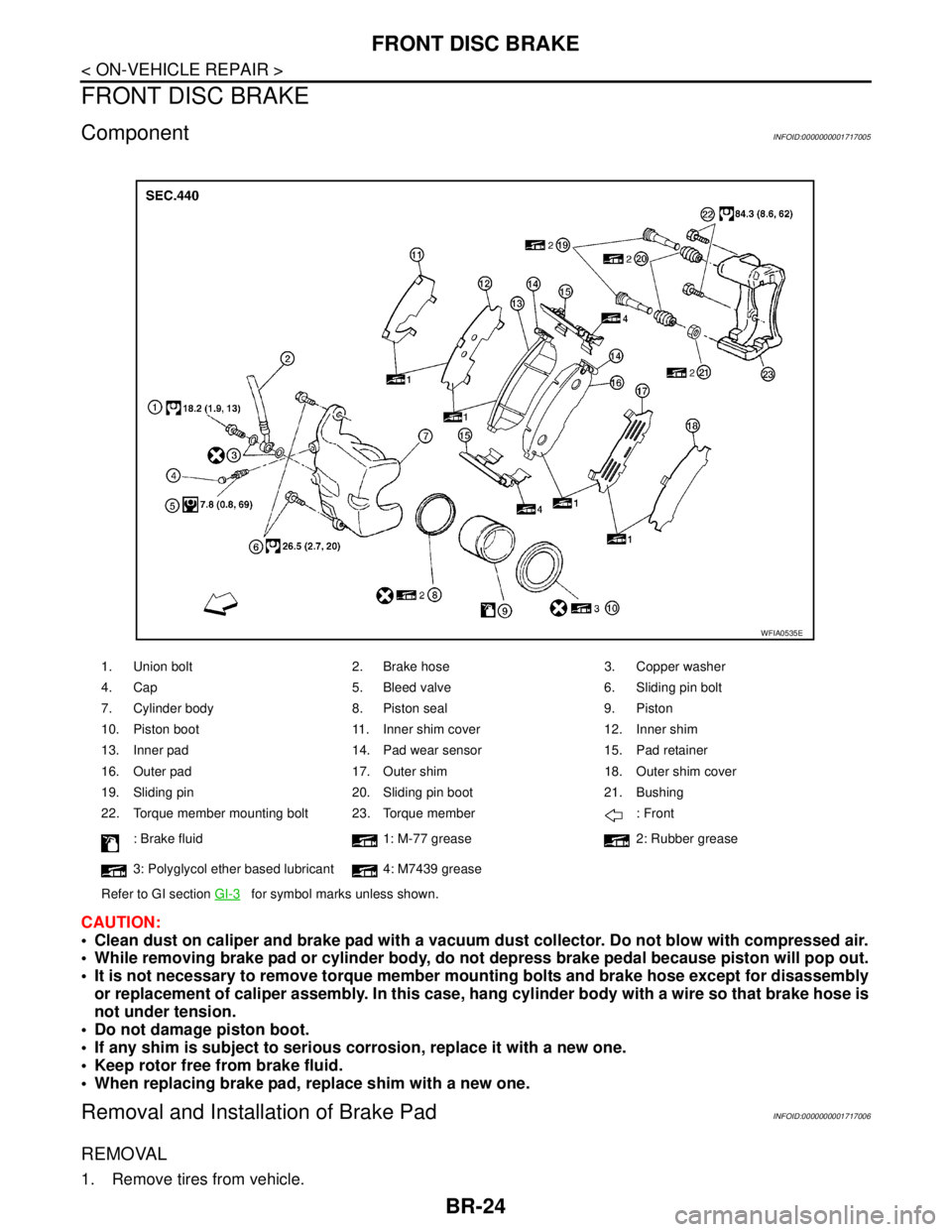

ComponentINFOID:0000000001717005

CAUTION:

Clean dust on caliper and brake pad with a vacuum dust collector. Do not blow with compressed air.

While removing brake pad or cylinder body, do not depress brake pedal because piston will pop out.

It is not necessary to remove torque member mounting bolts and brake hose except for disassembly

or replacement of caliper assembly. In this case, hang cylinder body with a wire so that brake hose is

not under tension.

Do not damage piston boot.

If any shim is subject to serious corrosion, replace it with a new one.

Keep rotor free from brake fluid.

When replacing brake pad, replace shim with a new one.

Removal and Installation of Brake PadINFOID:0000000001717006

REMOVAL

1. Remove tires from vehicle.

1. Union bolt 2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Inner shim cover 12. Inner shim

13. Inner pad 14. Pad wear sensor 15. Pad retainer

16. Outer pad 17. Outer shim 18. Outer shim cover

19. Sliding pin 20. Sliding pin boot 21. Bushing

22. Torque member mounting bolt 23. Torque member : Front

: Brake fluid 1: M-77 grease 2: Rubber grease

3: Polyglycol ether based lubricant 4: M7439 grease

Refer to GI section GI-3

for symbol marks unless shown.

WFIA0535E

Page 234 of 5883

BRC-1

BRAKES

C

D

E

G

H

I

J

K

L

M

SECTION BRC

A

B

BRC

N

O

P

CONTENTS

BRAKE CONTROL SYSTEM

ABS

BASIC INSPECTION ....................................

6

DIAGNOSIS AND REPAIR WORKFLOW ..........6

Work Flow .................................................................6

Diagnostic Work Sheet ..............................................9

INSPECTION AND ADJUSTMENT ....................10

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ........................................................

10

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

10

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

10

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION ................................................

10

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Description ........................

10

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Special Repair Require-

ment ........................................................................

10

CALIBRATION OF DECEL G SENSOR ...................11

CALIBRATION OF DECEL G SENSOR : Descrip-

tion ..........................................................................

11

CALIBRATION OF DECEL G SENSOR : Special

Repair Requirement ................................................

12

FUNCTION DIAGNOSIS ..............................13

VDC ....................................................................13

System Diagram ......................................................13

System Description .................................................13

Component Parts Location ......................................14

Component Description ...........................................15

TCS .....................................................................16

System Diagram ......................................................16

System Description .................................................16

Component Parts Location ......................................17

Component Description ...........................................18

ABS ...................................................................19

System Diagram ......................................................19

System Description ..................................................19

Component Parts Location ......................................20

Component Description ...........................................21

EBD ...................................................................22

System Diagram ......................................................22

System Description ..................................................22

Component Parts Location ......................................23

Component Description ...........................................24

DIAGNOSIS SYSTEM [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)] .......

25

CONSULT-III Function (ABS) ..................................25

COMPONENT DIAGNOSIS .........................30

C1101, C1102, C1103, C1104 WHEEL SEN-

SOR-1 ................................................................

30

Description ...............................................................30

DTC Logic ................................................................30

Diagnosis Procedure ...............................................30

Component Inspection .............................................32

Special Repair Requirement ....................................32

C1105, C1106, C1107, C1108 WHEEL SEN-

SOR-2 ................................................................

33

Description ...............................................................33

DTC Logic ................................................................33

Diagnosis Procedure ...............................................33

Component Inspection .............................................35

Special Repair Requirement ....................................35

C1109 POWER AND GROUND SYSTEM ........36

Description ...............................................................36

DTC Logic ................................................................36

Diagnosis Procedure ...............................................36

Special Repair Requirement ....................................37