dimensions NISSAN TIIDA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3195 of 5883

GI-1

GENERAL INFORMATION

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION GI

N

O

P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANUAL ......................3

HOW TO USE THIS MANUAL ............................3

Description ................................................................3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Component ................................................................4

How to Follow Trouble Diagnosis ..............................5

How to Read Wiring Diagram ....................................9

Abbreviations ..........................................................16

HOW TO FOLLOW TROUBLE DIAGNOSES ....18

Description ..............................................................18

How to Follow Test Groups in Trouble Diagnosis ....18

Key to Symbols Signifying Measurements or Pro-

cedures ...................................................................

19

HOW TO READ WIRING DIAGRAMS ...............21

Connector symbols .................................................21

Sample/wiring diagram -example- ...........................22

Description ..............................................................23

ABBREVIATIONS ..............................................25

Abbreviation List ......................................................25

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

26

Tightening Torque Table .........................................26

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ................................................

27

Recommended Chemical Products and Sealants ....27

TERMINOLOGY .................................................28

SAE J1930 Terminology List ...................................28

FEATURES OF NEW MODEL .....................32

IDENTIFICATION INFORMATION .....................32

Model Variation .......................................................32

Dimensions ..............................................................41

Wheels & Tires ........................................................42

PRECAUTION ..............................................43

PRECAUTIONS .................................................43

Description ...............................................................43

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

43

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

43

General Precaution ..................................................44

Precaution for Three Way Catalyst ..........................45

Precaution for Fuel (Unleaded Regular Gasoline

Recommended) .......................................................

45

Precaution for Multiport Fuel Injection System or

Engine Control System ............................................

46

Precaution for Hoses ...............................................46

Precaution for Engine Oils .......................................47

Precaution for Air Conditioning ................................47

LIFTING POINT .................................................48

Special Service Tool ................................................48

Garage Jack and Safety Stand and 2-Pole Lift .......48

Board-On Lift ...........................................................49

TOW TRUCK TOWING .....................................50

Tow Truck Towing ...................................................50

Vehicle Recovery (Freeing a Stuck Vehicle) ...........50

BASIC INSPECTION ...................................51

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

51

Work Flow ................................................................51

Control Units and Electrical Parts ............................51

How to Check Terminal ...........................................52

Intermittent Incident .................................................55

Circuit Inspection .....................................................58

CONSULT-III CHECKING SYSTEM .................63

Page 3235 of 5883

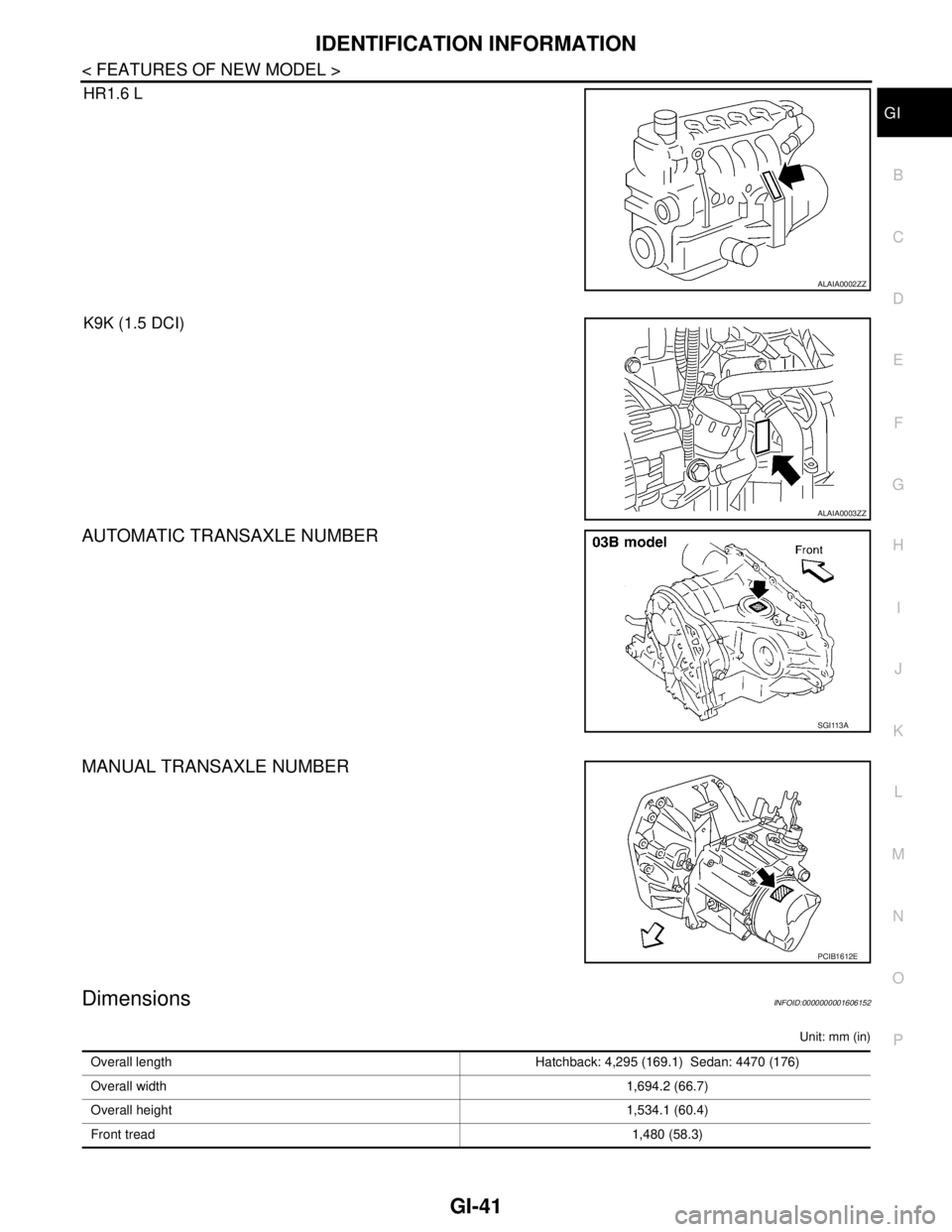

IDENTIFICATION INFORMATION

GI-41

< FEATURES OF NEW MODEL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

HR1.6 L

K9K (1.5 DCI)

AUTOMATIC TRANSAXLE NUMBER

MANUAL TRANSAXLE NUMBER

DimensionsINFOID:0000000001606152

Unit: mm (in)

ALAIA0002ZZ

ALAIA0003ZZ

SGI113A

PCIB1612E

Overall length Hatchback: 4,295 (169.1) Sedan: 4470 (176)

Overall width1,694.2 (66.7)

Overall height1,534.1 (60.4)

Front tread1,480 (58.3)

Page 4231 of 5883

![NISSAN TIIDA 2007 Service Owners Guide LU-24

< PRECAUTION >[K9K]

PRECAUTIONS

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

If there is a groove for the liquid gasket application, apply the

ga NISSAN TIIDA 2007 Service Owners Guide LU-24

< PRECAUTION >[K9K]

PRECAUTIONS

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

If there is a groove for the liquid gasket application, apply the

ga](/img/5/57395/w960_57395-4230.png)

LU-24

< PRECAUTION >[K9K]

PRECAUTIONS

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

If there is a groove for the liquid gasket application, apply the

gasket to the groove.

As for the bolt holes, normally apply the gasket inside the

holes. If specified, it should be applied outside the holes. Make

sure to read the instruction in this manual.

Within five minutes of gasket application, install the mating

component.

If the liquid gasket protrudes, wipe it off immediately.

Do not retighten after the installation.

After 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are instructions in this manual, observe them.

EMA0622D

SEM159F

Page 5243 of 5883

![NISSAN TIIDA 2007 Service Owners Guide ASSEMBLY

TM-297

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

ASSEMBLY

Assembly (1)INFOID:0000000001730996

1. Drive transaxle case side oil seal (1) using Tools, NISSAN TIIDA 2007 Service Owners Guide ASSEMBLY

TM-297

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

ASSEMBLY

Assembly (1)INFOID:0000000001730996

1. Drive transaxle case side oil seal (1) using Tools,](/img/5/57395/w960_57395-5242.png)

ASSEMBLY

TM-297

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

ASSEMBLY

Assembly (1)INFOID:0000000001730996

1. Drive transaxle case side oil seal (1) using Tools, and converter

housing side oil seal (2) using suitable tool, to the dimensions as

shown

(A): Transaxle case side

(B): Converter housing side

NOTE:

Differential side oil seal pulling direction is used as the reference.

2. Install O-ring on governor cap.

CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

3. Install governor cap in transaxle case.

4. Install snap ring in transaxle case.

5. Install parking actuator support (1) on transaxle case.

(A): Inside

(B): Outside

CAUTION:

Be careful with the direction of parking actuator support (1).

6. Tighten parking actuator support bolts to the specified torque.

7. Install parking pawl (2) on transaxle case, and secure it with

parking shaft (1).Tool numbers : ST35325000 ( — )

: KV31103000 ( — )

Dimension "C" : 0 ±±

Dimension "D" : 1.1 ± 0.5 mm (0.043 ± 0.020 in)

SCIA7226E

SCIA5910J

SCIA6997E

Page 5244 of 5883

![NISSAN TIIDA 2007 Service Owners Guide TM-298

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

8. Install return spring (2) on parking shaft (3) and parking pawl (1)

using suitable tool.

Adjustment (1)INFOID:0000000001730997

RE NISSAN TIIDA 2007 Service Owners Guide TM-298

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

8. Install return spring (2) on parking shaft (3) and parking pawl (1)

using suitable tool.

Adjustment (1)INFOID:0000000001730997

RE](/img/5/57395/w960_57395-5243.png)

TM-298

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

8. Install return spring (2) on parking shaft (3) and parking pawl (1)

using suitable tool.

Adjustment (1)INFOID:0000000001730997

REDUCTION PINION GEAR BEARING PRELOAD

1. Select proper thickness of reduction pinion gear adjusting shim using the following procedures.

a. Place reduction pinion gear on transaxle case as shown.

b. Install idler gear bearing outer race on transaxle case.

c. Place idler gear bearing inner race on outer race.

d. Measure dimensions “B”, “C” and “D”, and calculate dimension

“A”.

Measure dimension “B” between the end of reduction pinion

gear and the surface of transaxle case.

Measure dimension “B” in at least two places, and take

the average.

SCIA6996E

SCIA3623E

“A”: Distance between the surface of idler gear bear-

ing inner race and the adjusting shim mating

surface of reduction pinion gear.

A = D − (B + C)

SCIA3624E

SCIA3625E

Page 5246 of 5883

![NISSAN TIIDA 2007 Service Owners Guide TM-300

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

7. Measure turning torque of reduction pinion gear.

When measuring turning torque, turn reduction pinion

gear in both directions se NISSAN TIIDA 2007 Service Owners Guide TM-300

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

7. Measure turning torque of reduction pinion gear.

When measuring turning torque, turn reduction pinion

gear in both directions se](/img/5/57395/w960_57395-5245.png)

TM-300

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

7. Measure turning torque of reduction pinion gear.

When measuring turning torque, turn reduction pinion

gear in both directions several times to seat bearing roll-

ers correctly.

If turning torque is out of specification, decrease or

increase thickness of reduction pinion gear adjusting

shim.

OUTPUT SHAFT BEARING PRELOAD

1. Select proper thickness of output gear adjusting spacer using the following procedures.

a. Remove paper rolled around output shaft.

b. Install output gear bearing outer race on bearing retainer.

c. Place bearing retainer on output shaft.

d. Place output gear bearing inner race on bearing retainer.

e. Measure dimensions “G” and “H”, and calculate dimension “F”.

Measure dimension “G” between end of output shaft and sur-

face of output gear bearing inner race.

Measure dimension “G” in at least two places, and take

the average.Turning torque of reduction pinion gear:

Refer to TM-323, "

Reduction Pinion Gear".

SAT190FB

SAT682D

“F”: Distance between the surface of output gear

bearing inner race and adjusting spacer mating

surface of output shaft.

F = H − G

SAT683D

SAT684D

Page 5254 of 5883

![NISSAN TIIDA 2007 Service Owners Guide TM-308

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

Measure clearance between reverse clutch drum and needle bear-

ing for oil pump cover.

Select proper thickness of bearing race s NISSAN TIIDA 2007 Service Owners Guide TM-308

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

Measure clearance between reverse clutch drum and needle bear-

ing for oil pump cover.

Select proper thickness of bearing race s](/img/5/57395/w960_57395-5253.png)

TM-308

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

Measure clearance between reverse clutch drum and needle bear-

ing for oil pump cover.

Select proper thickness of bearing race so that end play is within

specifications.

1. Measure dimensions “K” and “L”, and then calculate dimension

“J”.

a. Measure dimension “K”.

b. Measure dimension “L”.

c. Calculate dimension “J”.

2. Measure dimension “M”.

a. Place bearing race and needle bearing on oil pump assembly.

SCIA3661E

SCIA3662E

SCIA3663E

“J”: Distance between oil pump fitting surface of

transaxle case and needle bearing mating sur-

face of input shaft assembly (high clutch drum).

J = K – L

SCIA3664E

SAT378D

Page 5255 of 5883

![NISSAN TIIDA 2007 Service Owners Guide ASSEMBLY

TM-309

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

b. Measure dimension “M”.

c. Measure thickness of straightedge “t”.

3. Adjust total end play NISSAN TIIDA 2007 Service Owners Guide ASSEMBLY

TM-309

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

b. Measure dimension “M”.

c. Measure thickness of straightedge “t”.

3. Adjust total end play](/img/5/57395/w960_57395-5254.png)

ASSEMBLY

TM-309

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

b. Measure dimension “M”.

c. Measure thickness of straightedge “t”.

3. Adjust total end play “T

1”.

Select proper thickness of bearing race so that total end play

is within specifications.

REVERSE CLUTCH END PLAY

Measure clearance between oil pump cover and thrust washer for

reverse clutch drum.

Select proper thickness of thrust washer so that end play is within

specification.

1. Measure dimensions “O” and “P”, and then calculate dimension

“N”.“M”: Distance between transaxle case fitting surface

of oil pump cover and needle bearing on oil

pump cover.

“M

1”: Indication of gauge

SAT379D

M = M1– t

T

1 = J – M

Total end play “T

1”:

Refer to TM-324, "

Total End Play".

SAT443D

SCIA3665E

SCIA3666E

Page 5256 of 5883

![NISSAN TIIDA 2007 Service Owners Guide TM-310

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

a. Place thrust washer on reverse clutch drum.

b. Measure dimension “O”.

c. Measure dimension “P”.

d. Calculate dimension � NISSAN TIIDA 2007 Service Owners Guide TM-310

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

a. Place thrust washer on reverse clutch drum.

b. Measure dimension “O”.

c. Measure dimension “P”.

d. Calculate dimension �](/img/5/57395/w960_57395-5255.png)

TM-310

< DISASSEMBLY AND ASSEMBLY >[TYPE 1 (4AT: RE4F03B)]

ASSEMBLY

a. Place thrust washer on reverse clutch drum.

b. Measure dimension “O”.

c. Measure dimension “P”.

d. Calculate dimension “N”.

2. Measure dimensions “R” and “S”, and then calculate dimension

“Q”.

a. Measure dimension “R”.

b. Measure dimension “S”.

c. Calculate dimension “Q”.

SCIA3667E

“N”: Distance between oil pump fitting surface of

transaxle case and thrust washer on reverse

clutch drum.

N = O – P

SCIA3668E

SAT384D

SAT385D

“Q”: Distance between transaxle case fitting surface

and thrust washer mating surface.

Q = R – S

SAT386D

Page 5536 of 5883

![NISSAN TIIDA 2007 Service Owners Guide TM-590

< DISASSEMBLY AND ASSEMBLY >[TYPE 2 (4AT: RE4F03B)]

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000001731448

1. Drive transaxle case side oil seal (1) using Tools, and converter

housing side oil s NISSAN TIIDA 2007 Service Owners Guide TM-590

< DISASSEMBLY AND ASSEMBLY >[TYPE 2 (4AT: RE4F03B)]

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000001731448

1. Drive transaxle case side oil seal (1) using Tools, and converter

housing side oil s](/img/5/57395/w960_57395-5535.png)

TM-590

< DISASSEMBLY AND ASSEMBLY >[TYPE 2 (4AT: RE4F03B)]

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000001731448

1. Drive transaxle case side oil seal (1) using Tools, and converter

housing side oil seal (2) using suitable tool, to the dimensions as

shown

(A): Transaxle case side

(B): Converter housing side

NOTE:

Differential side oil seal pulling direction is used as the reference.

2. Install O-ring on governor cap.

CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

3. Install governor cap in transaxle case.

4. Install snap ring in transaxle case.

5. Install parking actuator support (1) on transaxle case.

(A): Inside

(B): Outside

CAUTION:

Be careful with the direction of parking actuator support (1).

6. Tighten parking actuator support bolts to the specified torque.

7. Install parking pawl (2) on transaxle case, and secure it with

parking shaft (1).Tool numbers : ST35325000 ( — )

: KV31103000 ( — )

Dimension "C" : 0 ±±

Dimension "D" : 1.1 ± 0.5 mm (0.043 ± 0.020 in)

SCIA7226E

SCIA5910J

SCIA6997E