alignment NISSAN TIIDA 2007 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4569 of 5883

SUNROOF SYSTEM

RF-35

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

RF

N

O

P

Removal and InstallationINFOID:0000000001724429

CAUTION:

After installation or any adjustment, check clearances for sunroof operation and glass lid alignment.

Handle glass lid with care to prevent damage.

Fully close the glass lid before removal, then do not operate sunroof motor assembly after removal.

When removing sunroof unit assembly, use shop cloths to protect the seats and trim from damage.

Always work with a helper.

NOTE:

For easy installation, mark each point before removal.

SUNROOF UNIT ASSEMBLY

Removal

1. Tilt glass lid up, then remove. Refer to RF-35, "Removal and Installation".

2. Position sunroof unit assembly to the fully closed position.

3. Remove the headlining. Refer to INT-29, "

Component".

4. Disconnect drain hoses.

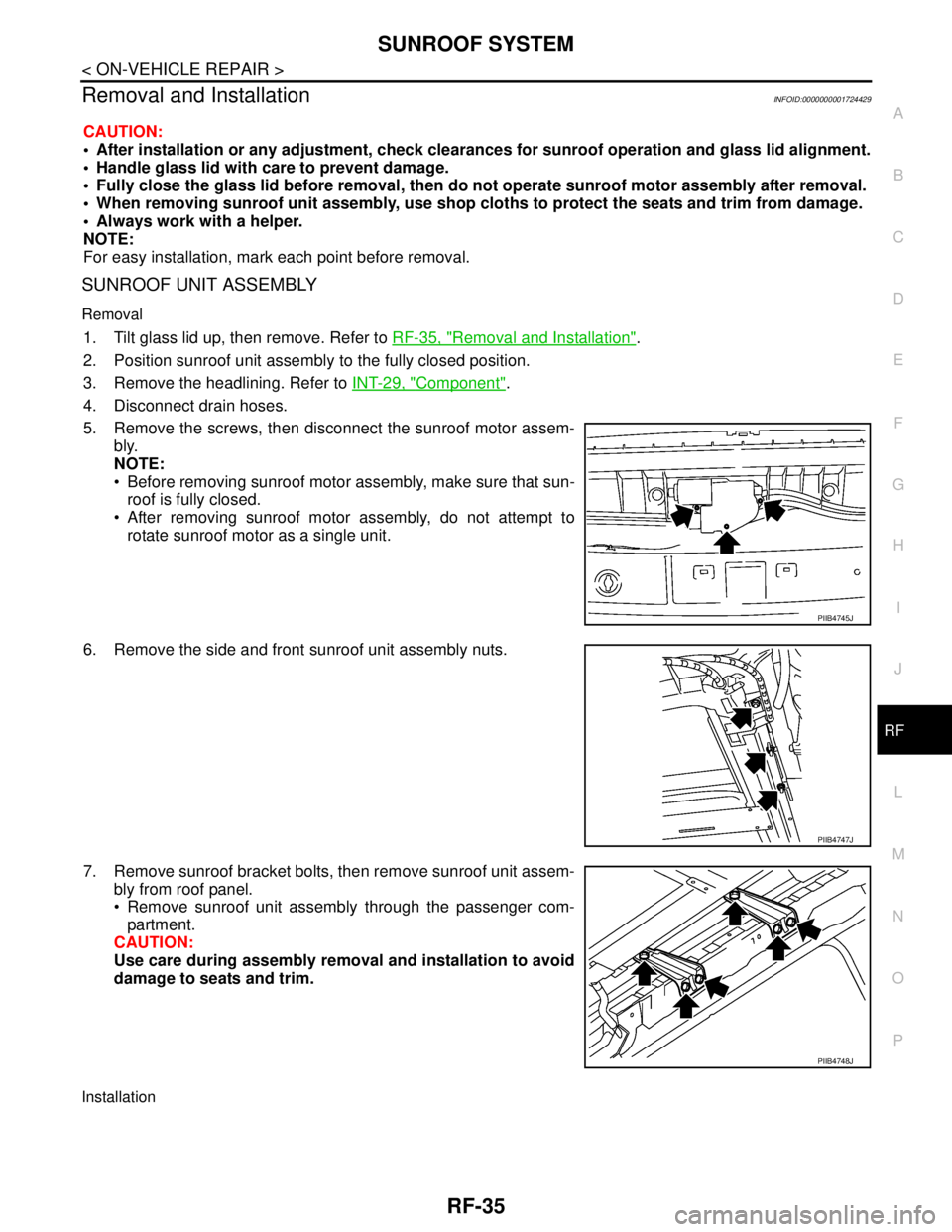

5. Remove the screws, then disconnect the sunroof motor assem-

bly.

NOTE:

Before removing sunroof motor assembly, make sure that sun-

roof is fully closed.

After removing sunroof motor assembly, do not attempt to

rotate sunroof motor as a single unit.

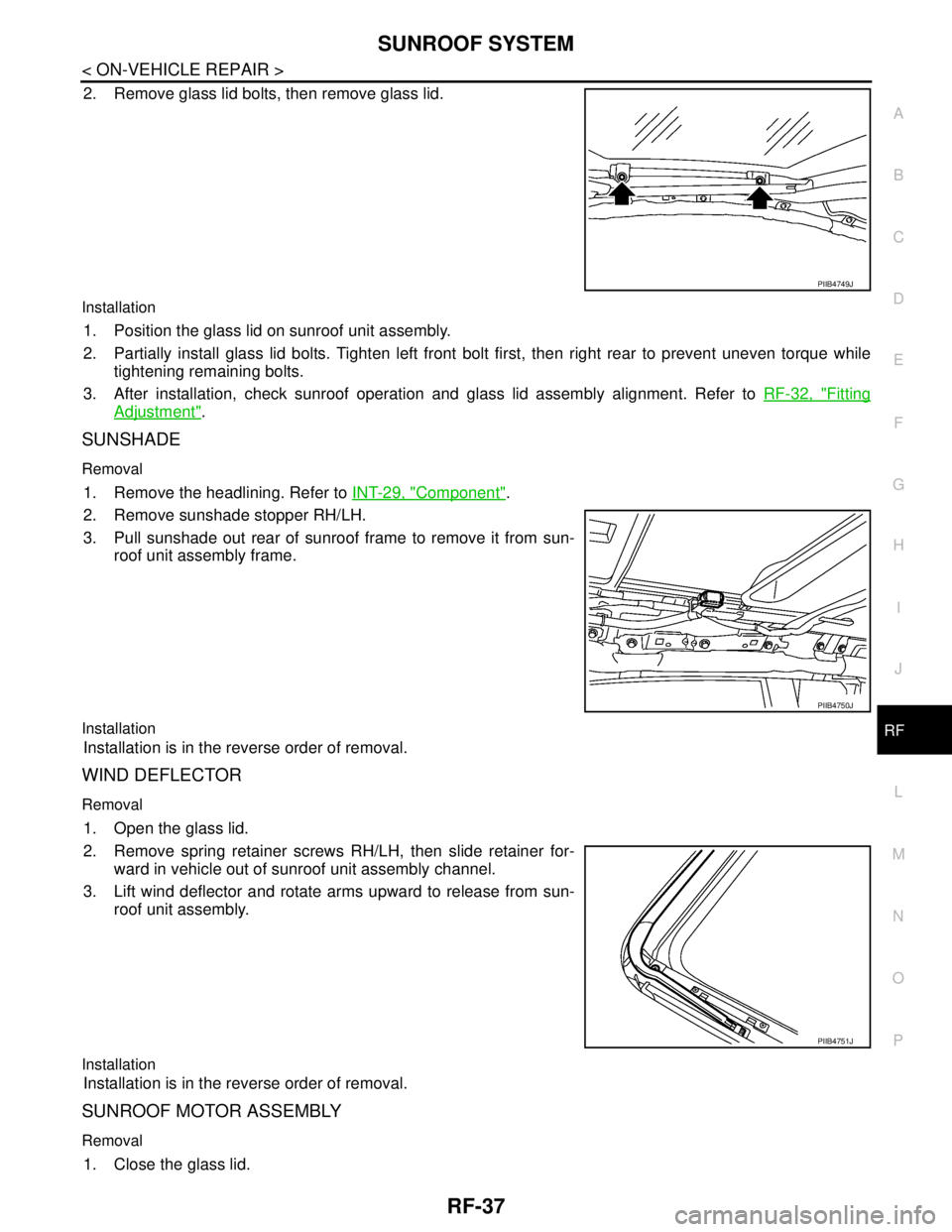

6. Remove the side and front sunroof unit assembly nuts.

7. Remove sunroof bracket bolts, then remove sunroof unit assem-

bly from roof panel.

Remove sunroof unit assembly through the passenger com-

partment.

CAUTION:

Use care during assembly removal and installation to avoid

damage to seats and trim.

Installation

PIIB4745J

PIIB4747J

PIIB4748J

Page 4571 of 5883

SUNROOF SYSTEM

RF-37

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

RF

N

O

P

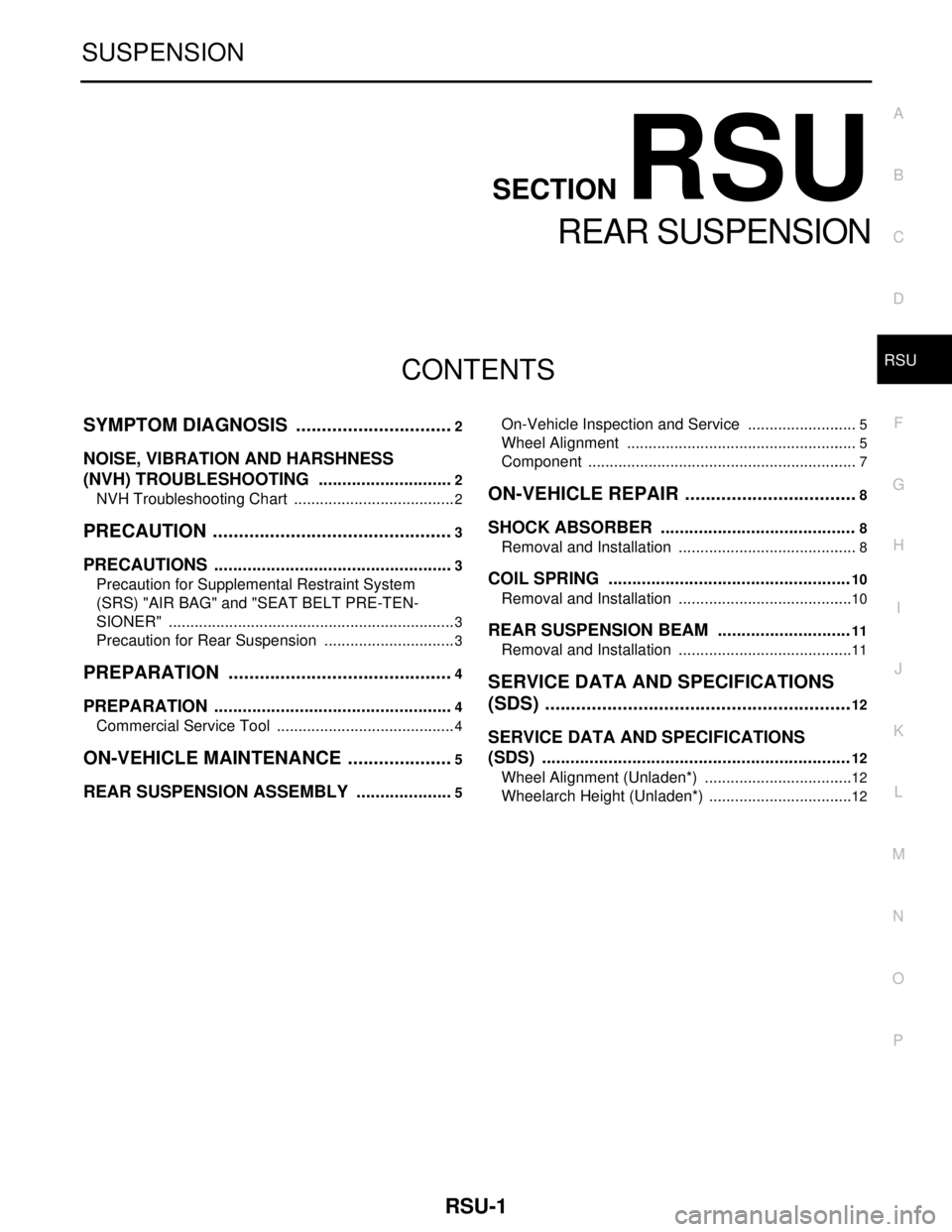

2. Remove glass lid bolts, then remove glass lid.

Installation

1. Position the glass lid on sunroof unit assembly.

2. Partially install glass lid bolts. Tighten left front bolt first, then right rear to prevent uneven torque while

tightening remaining bolts.

3. After installation, check sunroof operation and glass lid assembly alignment. Refer to RF-32, "

Fitting

Adjustment".

SUNSHADE

Removal

1. Remove the headlining. Refer to INT-29, "Component".

2. Remove sunshade stopper RH/LH.

3. Pull sunshade out rear of sunroof frame to remove it from sun-

roof unit assembly frame.

Installation

Installation is in the reverse order of removal.

WIND DEFLECTOR

Removal

1. Open the glass lid.

2. Remove spring retainer screws RH/LH, then slide retainer for-

ward in vehicle out of sunroof unit assembly channel.

3. Lift wind deflector and rotate arms upward to release from sun-

roof unit assembly.

Installation

Installation is in the reverse order of removal.

SUNROOF MOTOR ASSEMBLY

Removal

1. Close the glass lid.

PIIB4749J

PIIB4750J

PIIB4751J

Page 4573 of 5883

RSU-1

SUSPENSION

C

D

F

G

H

I

J

K

L

M

SECTION RSU

A

B

RSU

N

O

PCONTENTS

REAR SUSPENSION

SYMPTOM DIAGNOSIS ...............................2

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

2

NVH Troubleshooting Chart ......................................2

PRECAUTION ...............................................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Rear Suspension ...............................3

PREPARATION ............................................4

PREPARATION ...................................................4

Commercial Service Tool ..........................................4

ON-VEHICLE MAINTENANCE .....................5

REAR SUSPENSION ASSEMBLY .....................5

On-Vehicle Inspection and Service ..........................5

Wheel Alignment ......................................................5

Component ...............................................................7

ON-VEHICLE REPAIR ..................................8

SHOCK ABSORBER .........................................8

Removal and Installation ..........................................8

COIL SPRING ...................................................10

Removal and Installation .........................................10

REAR SUSPENSION BEAM ............................11

Removal and Installation .........................................11

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................

12

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

12

Wheel Alignment (Unladen*) ...................................12

Wheelarch Height (Unladen*) ..................................12

Page 4574 of 5883

RSU-2

< SYMPTOM DIAGNOSIS >

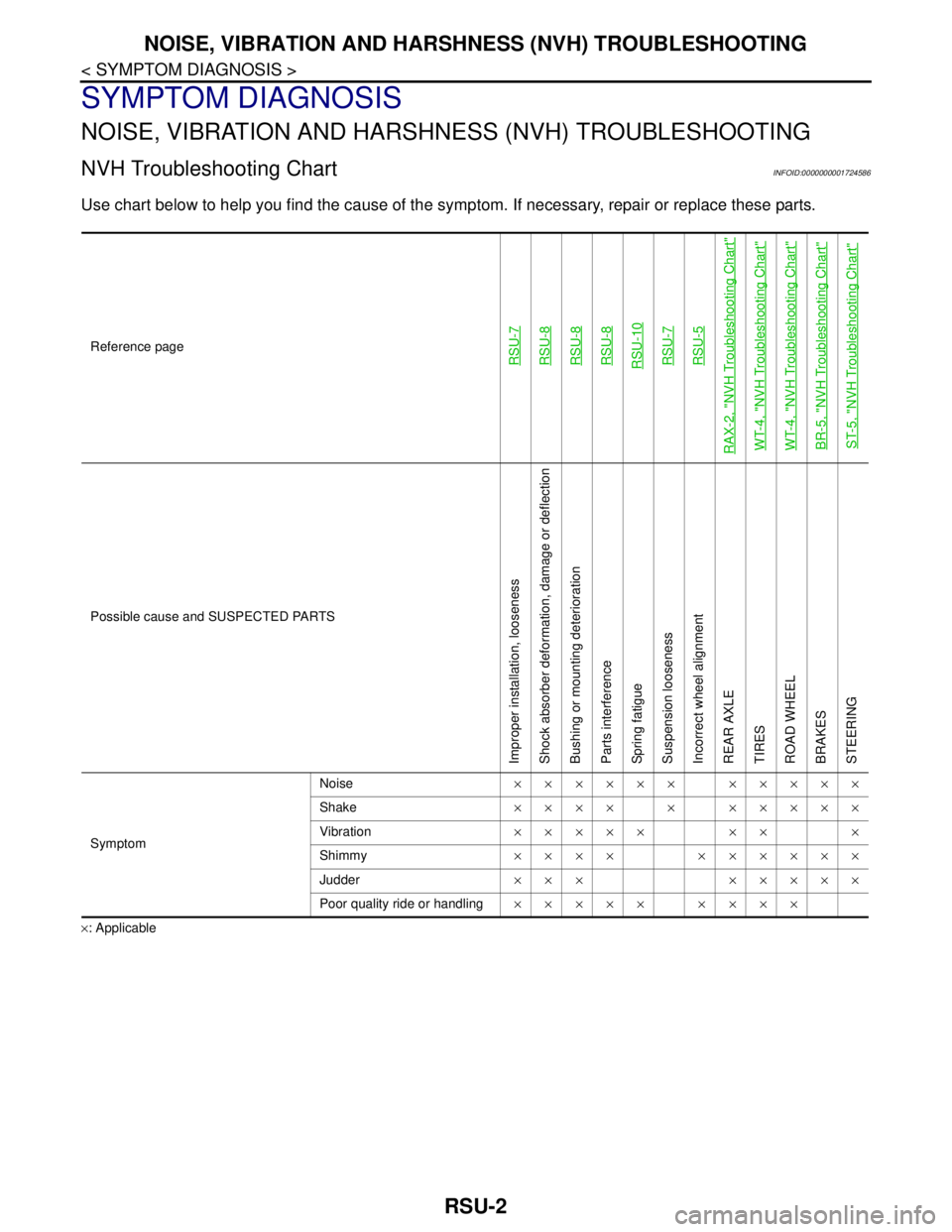

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001724586

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

RSU-7RSU-8RSU-8RSU-8RSU-10RSU-7RSU-5

RAX-2, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

ST-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

REAR AXLE

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomNoise×××××× ×××××

Shake×××× × ×××××

Vibration××××× ×× ×

Shimmy×××× ××××××

Judder ××× ×××××

Poor quality ride or handling××××× ××××

Page 4575 of 5883

PRECAUTIONS

RSU-3

< PRECAUTION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001724583

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Rear SuspensionINFOID:0000000001724584

When installing the rubber bushings, the final tightening must be done under unladen condition and with the

tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

After installing suspension components, check the wheel alignment.

Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre-

oiled, do not apply any additional lubrication.

Page 4577 of 5883

REAR SUSPENSION ASSEMBLY

RSU-5

< ON-VEHICLE MAINTENANCE >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

ON-VEHICLE MAINTENANCE

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001724575

Make sure the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are within specifications.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace it if necessary.

Wheel AlignmentINFOID:0000000001724576

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-5, "

Inspection" .

3. Wheel bearing axial end play. Refer to RAX-5, "

On-Vehicle Inspection and Service" .

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

This type of alignment is recommended for any NISSAN vehicle.

The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

The alignment machine itself should be capable of accepting any NISSAN vehicle.

The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

Your alignment machine should be regularly calibrated in order to give correct information.

Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-5, "Wheel

Alignment" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.

This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

Use the “Jacking Compensation” method. After installing the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

See Instructions in the alignment machine you are using for more information.

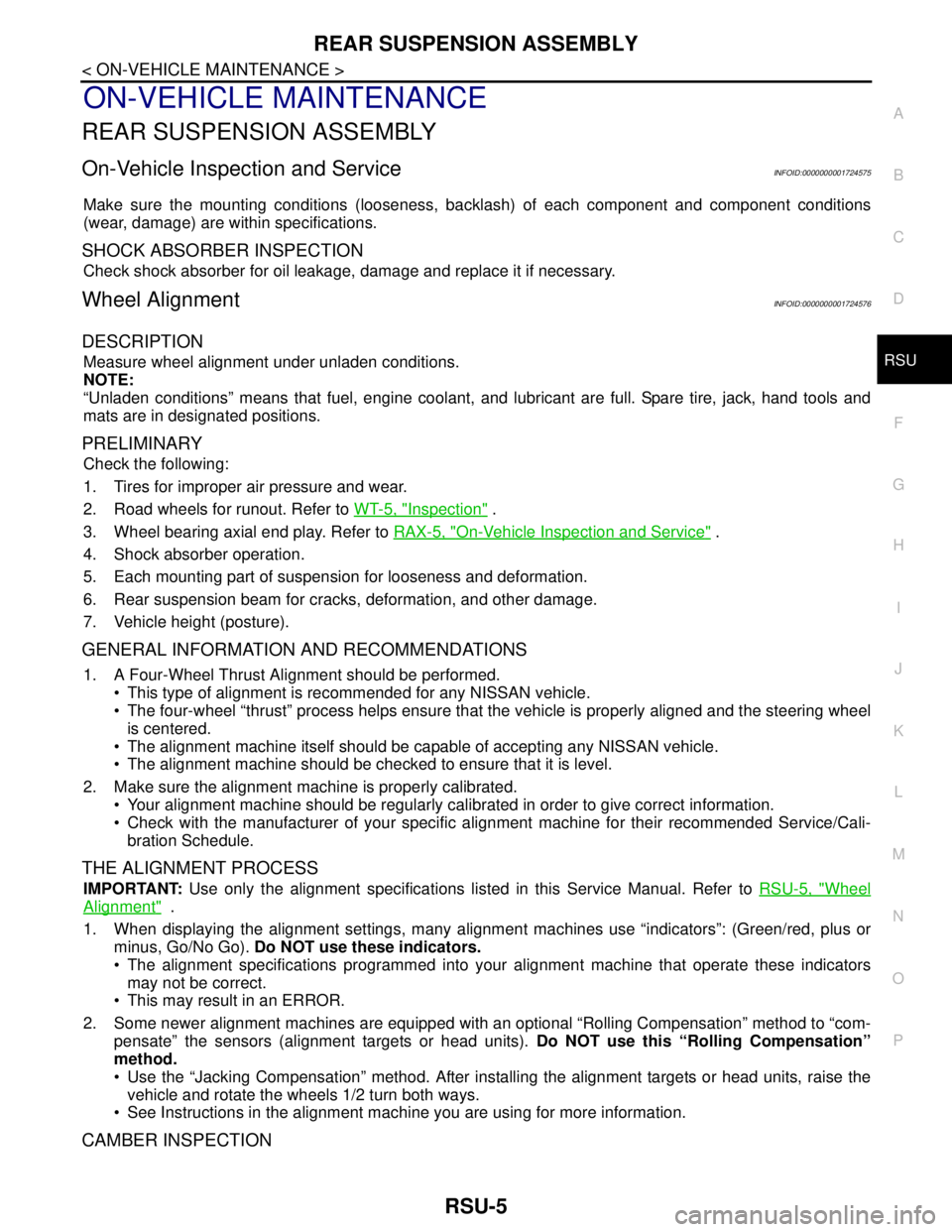

CAMBER INSPECTION

Page 4578 of 5883

RSU-6

< ON-VEHICLE MAINTENANCE >

REAR SUSPENSION ASSEMBLY

Measure camber of both right and left wheels with a suitable align-

ment gauge.

If it is out of the specification value, inspect and replace any dam-

aged or worn rear suspension parts.

TOE-IN INSPECTION

Measure toe-in using following procedure. If it is out of the specification, inspect and replace any damaged or

worn rear suspension parts.

WARNING:

Always perform the following procedure on a flat surface.

Make sure that no person is in front of vehicle before pushing it.

1. Bounce the rear of vehicle up and down to stabilize the vehicle height (posture).

2. Push vehicle straight ahead about 5 m (16 ft).

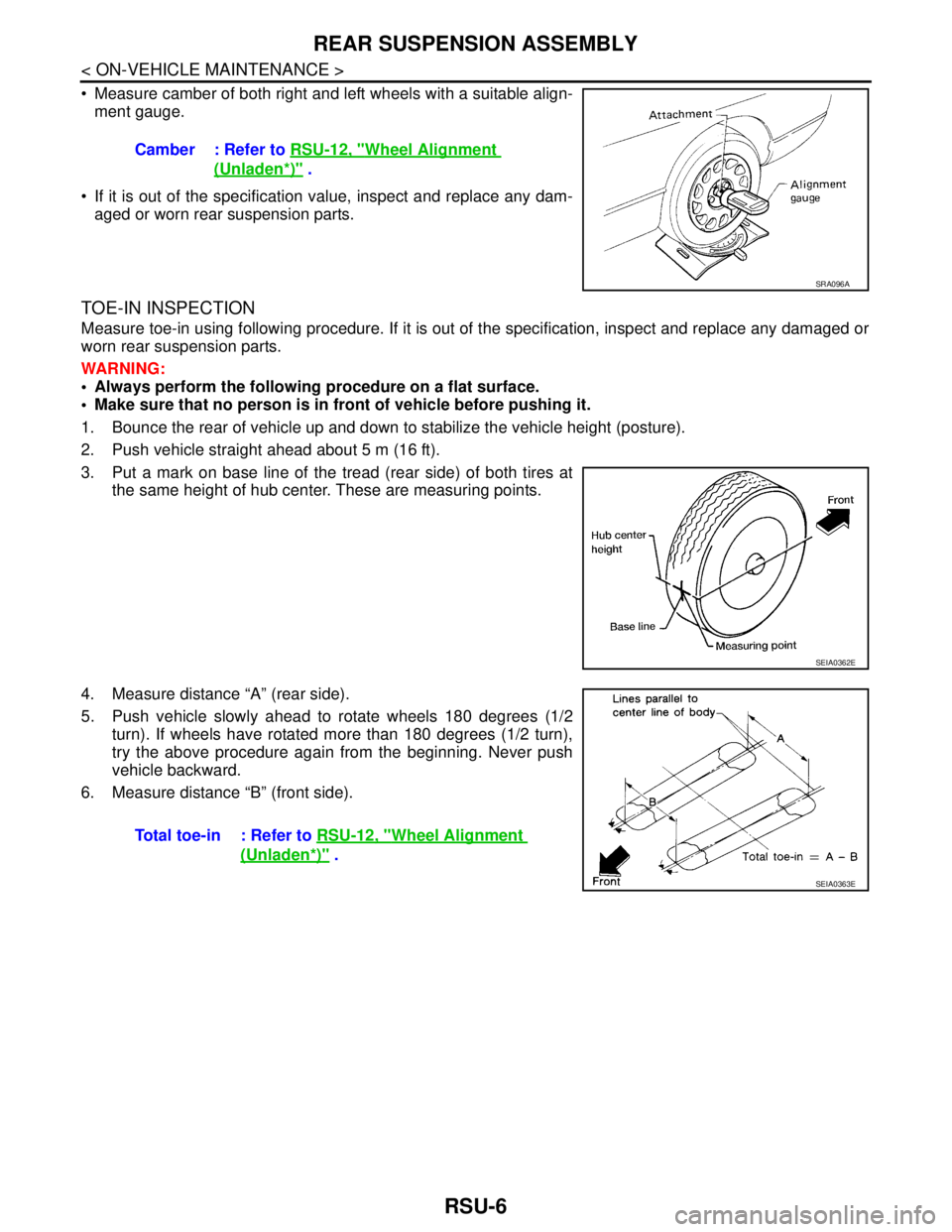

3. Put a mark on base line of the tread (rear side) of both tires at

the same height of hub center. These are measuring points.

4. Measure distance “A” (rear side).

5. Push vehicle slowly ahead to rotate wheels 180 degrees (1/2

turn). If wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance “B” (front side).Camber : Refer to RSU-12, "

Wheel Alignment

(Unladen*)" .

SRA096A

SEIA0362E

Total toe-in : Refer to RSU-12, "Wheel Alignment

(Unladen*)" .

SEIA0363E

Page 4584 of 5883

RSU-12

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Alignment (Unladen*)INFOID:0000000001724581

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Wheelarch Height (Unladen*)INFOID:0000000001724582

Unit: mm (in)

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Camber

Degree minute (Decimal degree)Minimum – 2° 01′ (– 2.02°)

Nominal – 1° 31′ (– 1.52°)

Maximum – 1° 01′ (– 1.02°)

Total toe-inDistance (A - B)Minimum – 1.0 mm (– 0.039 in)

Nominal 3.0 mm (0.118 in)

Maximum 7.0 mm (0.276 in)

Angle (A - B)

Degree minute

(Decimal degree)Minimum – 0° 5′ (0.08°)

Nominal 0° 13′ (0.22°)

Maximum 0° 31 (0.52)

Tire sizeP195/65R15

Engine model K9K HR16DE, MR18DE

Front (Hf) 689 (27.13) 692 (27.24)

Rear (Hr) 689 (27.13) 689 (27.13)

LEIA0085E

Page 4603 of 5883

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-7

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

68370-4B000: 15×25 mm (0.59×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000001710923

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

Page 4751 of 5883

SR-8

< ON-VEHICLE REPAIR >

SPIRAL CABLE

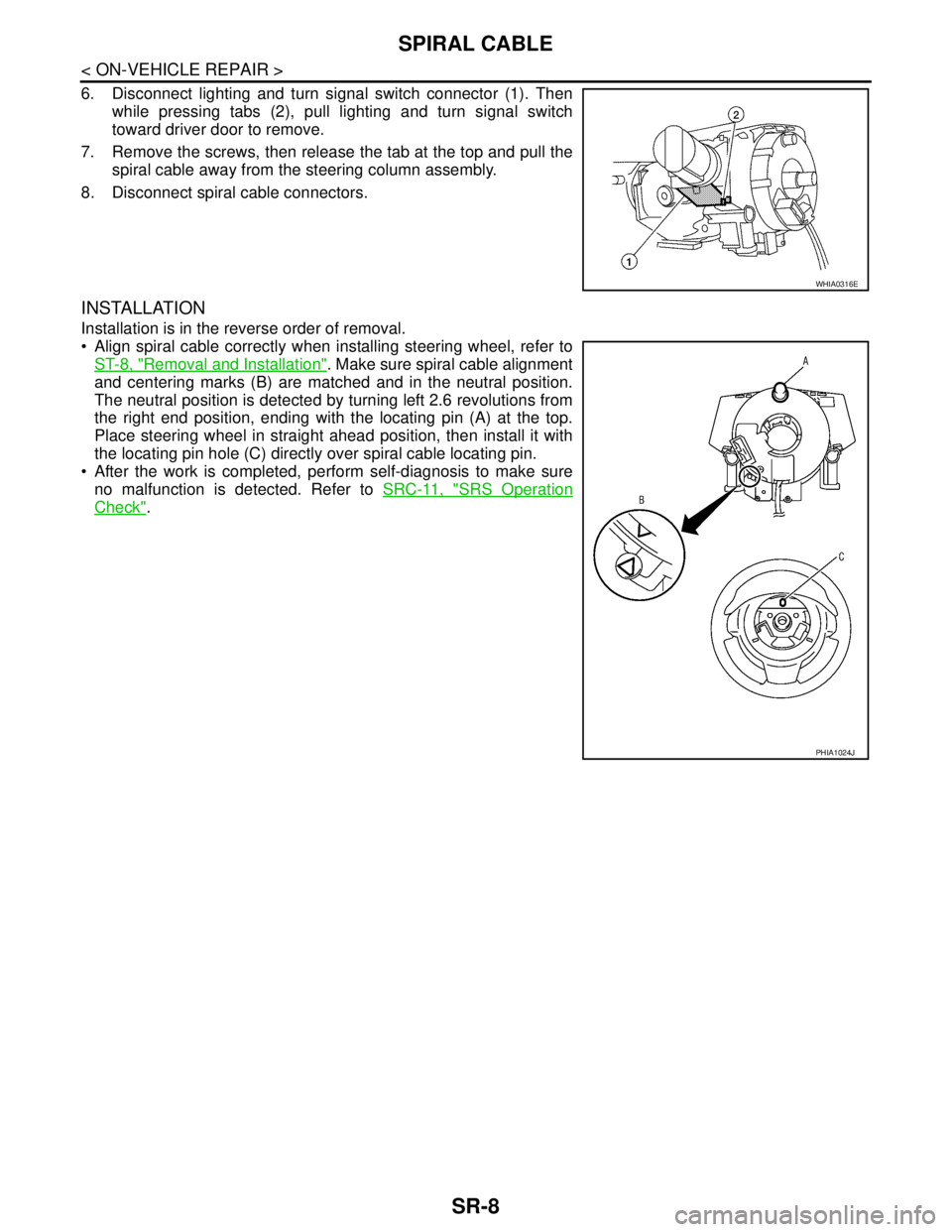

6. Disconnect lighting and turn signal switch connector (1). Then

while pressing tabs (2), pull lighting and turn signal switch

toward driver door to remove.

7. Remove the screws, then release the tab at the top and pull the

spiral cable away from the steering column assembly.

8. Disconnect spiral cable connectors.

INSTALLATION

Installation is in the reverse order of removal.

Align spiral cable correctly when installing steering wheel, refer to

ST-8, "

Removal and Installation". Make sure spiral cable alignment

and centering marks (B) are matched and in the neutral position.

The neutral position is detected by turning left 2.6 revolutions from

the right end position, ending with the locating pin (A) at the top.

Place steering wheel in straight ahead position, then install it with

the locating pin hole (C) directly over spiral cable locating pin.

After the work is completed, perform self-diagnosis to make sure

no malfunction is detected. Refer to SRC-11, "

SRS Operation

Check".

WHIA0316E

PHIA1024J