light NISSAN TIIDA 2007 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 411 of 5883

![NISSAN TIIDA 2007 Service Service Manual BRC-178

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000001731207

Symptom Result

Slight vibrations are felt on the brake pedal and the NISSAN TIIDA 2007 Service Service Manual BRC-178

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000001731207

Symptom Result

Slight vibrations are felt on the brake pedal and the](/img/5/57395/w960_57395-410.png)

BRC-178

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000001731207

Symptom Result

Slight vibrations are felt on the brake pedal and the operation noises occur, when VDC, TCS or ABS is acti-

vated.

This is a normal condi-

tion due to the VDC,

TCS or ABS activation. Stopping distance is longer than that of vehicles without ABS when the vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

The brake pedal moves and generates noises, when TCS or VDC is activated due to rapid acceleration or

sharp turn.

The brake pedal vibrates and motor operation noises occur from the engine room, after the engine starts and

just after the vehicle starts.This is normal, and it is

caused by the ABS op-

eration check.

Depending on the road conditions, the driver may experience a sluggish feel. This is normal, because

TCS places the highest

priority on the optimum

traction (stability). TCS may activate momentarily if wheel speed changes when driving over location where friction coefficient

varies, when downshifting, or when fully depressing accelerator pedal.

The ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp may turn ON when the vehicle is

subject to strong shaking or large vibration, such as when the vehicle is rotating on a turntable or located on

a ship while the engine is running. In this case, restart the

engine on a normal

road. If the normal con-

dition is restored, there

is no malfunction. At

that time, erase the self-

diagnosis memory. VDC may not operate normally or the ABS warning lamp, VDC OFF indicator lamp, and SLIP indicator lamp

may illuminate, when running on a special road that is extremely slanted (e.g. bank in a circuit course).

A malfunction may occur in the yaw rate/side/decel G sensor system, when the vehicle turns sharply, such

as during a spin turn, axle turn, or drift driving, while the VDC function is off (VDC OFF indicator lamp illumi-

nated).

The vehicle speed will not increase even though the accelerator pedal is depressed, when inspecting the

speedometer on a 2-wheel chassis dynamometer. Normal (Deactivate the

VDC/TCS function be-

fore performing an in-

spection on a chassis

dynamometer.)

VDC OFF indicator lamp and SLIP indicator lamp may simultaneously turn on when low tire pressure warn-

ing lamp turns on.This is not a VDC sys-

tem error but results

from characteristic

change of tire.

Page 412 of 5883

![NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

BRC-179

< PRECAUTION >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

BRC-179

< PRECAUTION >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO](/img/5/57395/w960_57395-411.png)

PRECAUTIONS

BRC-179

< PRECAUTION >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001691411

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001691412

Recommended fluid is Genuine NISSAN Fluid, DOT 3 or DOT 4 (US FMVSS No. 116).

Do not reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas such as body. If brake fluid is splashed, wipe it off and

flush area with water immediately.

Do not use mineral oils such as gasoline or kerosene to clean. They will ruin rubber parts and cause

improper operation.

Using a flare nut torque wrench, securely tighten brake tube flare

nuts.

Brake system is an important safety part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Before working, turn ignition switch OFF and disconnect electrical

connectors of ABS actuator and electric unit (control unit) or bat-

tery negative terminals.

When installing brake piping, be sure to check torque.

After removing/installing any hydraulic parts of the brake or ESP

system (such as actuator and piping parts, etc), bleed air from the

system.

Precaution for Brake ControlINFOID:0000000001691413

During ESP/TCS/ABS operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is

normal.

When starting engine, or just after starting vehicle, brake pedal may vibrate or motor operating noise may be

heard from engine room. This is a normal status of operation check.

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

When an error is indicated by ABS or another warning lamp, collect all necessary information from the cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting diag-

nostic servicing. Besides the electrical system inspection, check booster operation, brake fluid level, and

fluid leaks.

If tire size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

If there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, ESP/TCS/ABS

function may have a malfunction or error.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR820BA

Page 479 of 5883

CL-14

< SERVICE INFORMATION >

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

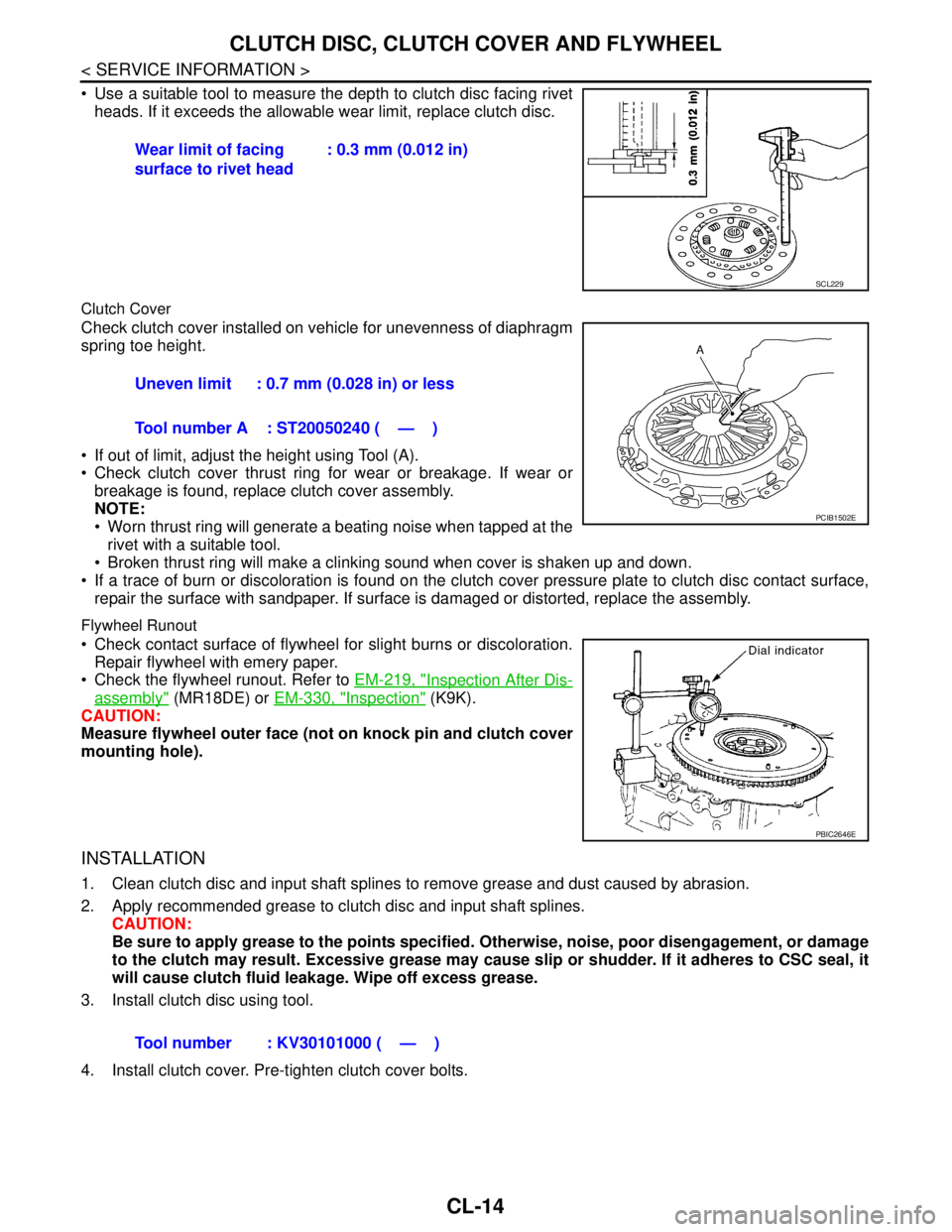

Use a suitable tool to measure the depth to clutch disc facing rivet

heads. If it exceeds the allowable wear limit, replace clutch disc.

Clutch Cover

Check clutch cover installed on vehicle for unevenness of diaphragm

spring toe height.

If out of limit, adjust the height using Tool (A).

Check clutch cover thrust ring for wear or breakage. If wear or

breakage is found, replace clutch cover assembly.

NOTE:

Worn thrust ring will generate a beating noise when tapped at the

rivet with a suitable tool.

Broken thrust ring will make a clinking sound when cover is shaken up and down.

If a trace of burn or discoloration is found on the clutch cover pressure plate to clutch disc contact surface,

repair the surface with sandpaper. If surface is damaged or distorted, replace the assembly.

Flywheel Runout

Check contact surface of flywheel for slight burns or discoloration.

Repair flywheel with emery paper.

Check the flywheel runout. Refer to EM-219, "

Inspection After Dis-

assembly" (MR18DE) or EM-330, "Inspection" (K9K).

CAUTION:

Measure flywheel outer face (not on knock pin and clutch cover

mounting hole).

INSTALLATION

1. Clean clutch disc and input shaft splines to remove grease and dust caused by abrasion.

2. Apply recommended grease to clutch disc and input shaft splines.

CAUTION:

Be sure to apply grease to the points specified. Otherwise, noise, poor disengagement, or damage

to the clutch may result. Excessive grease may cause slip or shudder. If it adheres to CSC seal, it

will cause clutch fluid leakage. Wipe off excess grease.

3. Install clutch disc using tool.

4. Install clutch cover. Pre-tighten clutch cover bolts.Wear limit of facing

surface to rivet head: 0.3 mm (0.012 in)

SCL229

Uneven limit : 0.7 mm (0.028 in) or less

Tool number A : ST20050240 ( — )

PCIB1502E

PBIC2646E

Tool number : KV30101000 ( — )

Page 490 of 5883

![NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

CO-9

< PRECAUTION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

CAUTION:

Be careful not to damage the mating surfaces.

Tap Tool to insert it (1), and then slide it by tapping on the side (2) NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

CO-9

< PRECAUTION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

CAUTION:

Be careful not to damage the mating surfaces.

Tap Tool to insert it (1), and then slide it by tapping on the side (2)](/img/5/57395/w960_57395-489.png)

PRECAUTIONS

CO-9

< PRECAUTION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

CAUTION:

Be careful not to damage the mating surfaces.

Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

In areas where Tool is difficult to use, use plastic hammer to lightly

tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica-

tion surface and the mating surface, using scraper.

Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-27, "

Recommended Chemical Prod-

ucts and Sealants".

4. Apply liquid gasket without breaks to the specified location with the specified dimensions.

If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

As for the bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

Within five minutes of liquid gasket application, install the mat-

ing component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten nuts or bolts after the installation.

After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them. Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

SEM159F

Page 514 of 5883

![NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

CO-33

< PRECAUTION >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

CAUTION:

Be careful not to damage the mating surfaces.

Tap Tool to insert it (1), and then slide it by tapping on the side (2 NISSAN TIIDA 2007 Service Service Manual PRECAUTIONS

CO-33

< PRECAUTION >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

CAUTION:

Be careful not to damage the mating surfaces.

Tap Tool to insert it (1), and then slide it by tapping on the side (2](/img/5/57395/w960_57395-513.png)

PRECAUTIONS

CO-33

< PRECAUTION >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

CAUTION:

Be careful not to damage the mating surfaces.

Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

In areas where Tool is difficult to use, use plastic hammer to lightly

tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica-

tion surface and the mating surface, using scraper.

Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-27, "

Recommended Chemical Prod-

ucts and Sealants".

4. Apply liquid gasket without breaks to the specified location with the specified dimensions.

If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

As for the bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

Within five minutes of liquid gasket application, install the mat-

ing component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten nuts or bolts after the installation.

After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them. Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

SEM159F

Page 537 of 5883

![NISSAN TIIDA 2007 Service Service Manual CO-56

< PRECAUTION >[K9K]

PRECAUTIONS

CAUTION:

Be careful not to damage the mating surfaces.

Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

In areas where Tool i NISSAN TIIDA 2007 Service Service Manual CO-56

< PRECAUTION >[K9K]

PRECAUTIONS

CAUTION:

Be careful not to damage the mating surfaces.

Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

In areas where Tool i](/img/5/57395/w960_57395-536.png)

CO-56

< PRECAUTION >[K9K]

PRECAUTIONS

CAUTION:

Be careful not to damage the mating surfaces.

Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

In areas where Tool is difficult to use, use plastic hammer to lightly

tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica-

tion surface and the mating surface, using scraper.

Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-27, "

Recommended Chemical Prod-

ucts and Sealants".

4. Apply liquid gasket without breaks to the specified location with the specified dimensions.

If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

As for the bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

Within five minutes of liquid gasket application, install the mat-

ing component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten nuts or bolts after the installation.

After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them. Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

SEM159F

Page 553 of 5883

DEF-2

PASSENGER SIDE DOOR MIRROR DEFOG-

GER DOES NOT OPERATE. ............................

33

Diagnosis Procedure ..............................................33

REAR WINDOW DEFOGGER SWITCH DOES

NOT LIGHT, BUT REAR WINDOW DEFOG-

GER OPERATES ...............................................

34

Diagnosis Procedure ..............................................34

PRECAUTION .............................................35

PRECAUTIONS .................................................35

Supplemental Restraint System (SRS) "AIR BAG"

and "SEAT BELT PRE-TENSIONER" ....................

35

ON-VEHICLE REPAIR ...............................36

FILAMENT .........................................................36

Inspection and Repair .............................................36

CONDENSER ....................................................38

Exploded View ........................................................38

Removal and Installation .........................................38

Page 585 of 5883

DEF-34

< SYMPTOM DIAGNOSIS >

REAR WINDOW DEFOGGER SWITCH DOES NOT LIGHT, BUT REAR WINDOW

DEFOGGER OPERATES

REAR WINDOW DEFOGGER SWITCH DOES NOT LIGHT, BUT REAR WIN-

DOW DEFOGGER OPERATES

Diagnosis ProcedureINFOID:0000000001697574

1.CHECK CONTROLLER (AUTO AMP.) (REAR WINDOW DEFOGGER SWITCH)

Check that the controller (auto amp.) (rear window defogger switch) is operating normally.

OK or NG

OK >> Refer to XX-XX, "*****".

NG >> Refer to DEF-11, "

Diagnosis Procedure".

Page 588 of 5883

FILAMENT

DEF-37

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

MA

B

DEF

N

O

P

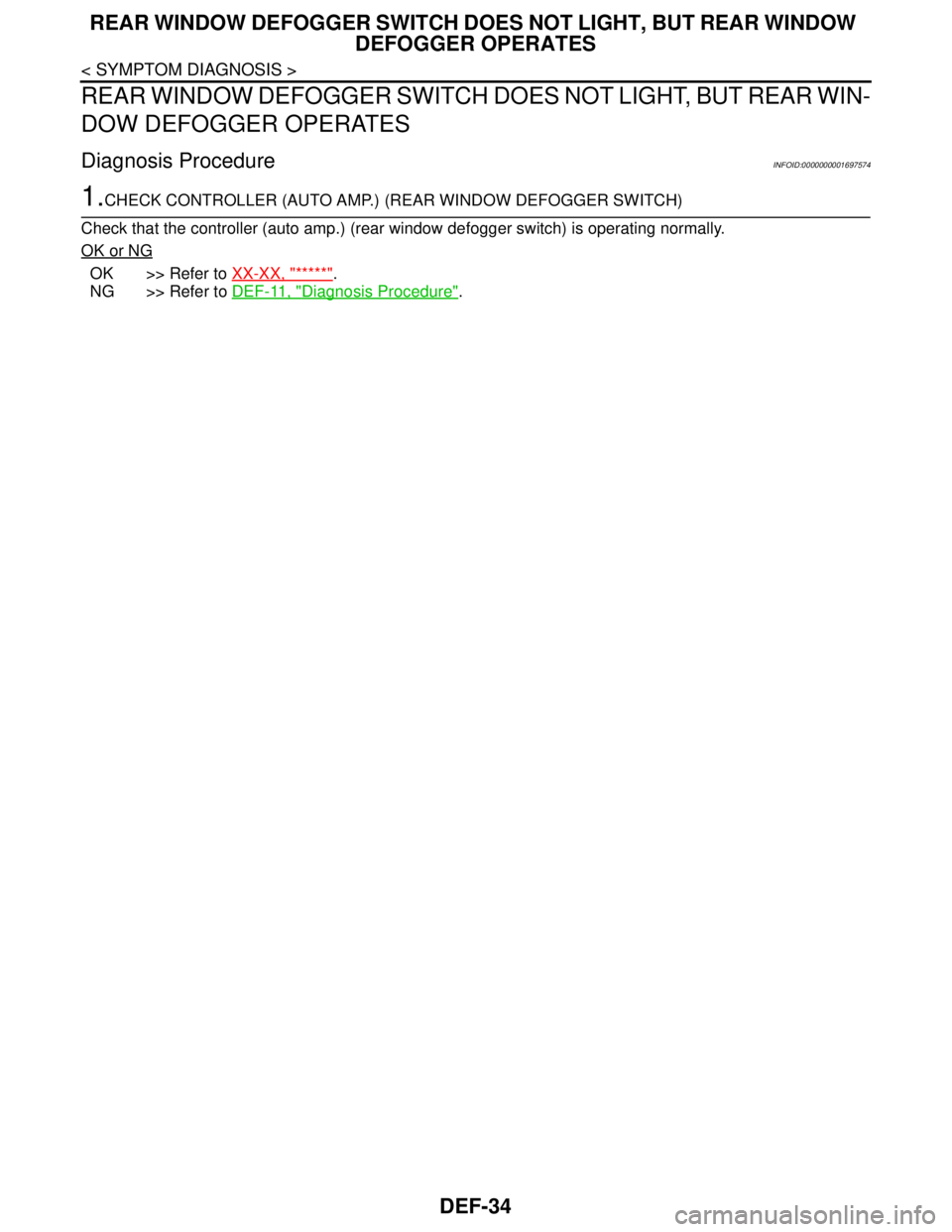

Ruler 30 cm (11.8 in) long

Drawing pen

Heat gun

Alcohol

Cloth

REPAIRING PROCEDURE

1. Wipe broken heat wire and its surrounding area clean with a

cloth dampened in alcohol.

2. Apply a small amount of conductive silver composition to tip of

drawing pen.

Shake silver composition container before use.

3. Place ruler on glass along broken line. Deposit conductive silver

composition on break with drawing pen. Slightly overlap existing

heat wire on both sides [preferably 5 mm (0.20 in)] of the break.

4. After repair has been completed, check repaired wire for conti-

nuity. This check should be conducted 10 minutes after silver

composition is deposited.

Do not touch repaired area while test is being conducted.

5. Apply a constant stream of hot air directly to the repaired area

for approximately 20 minutes with a heat gun. A minimum dis-

tance of 3 cm (1.2 in) should be kept between repaired area and

hot air outlet.

If a heat gun is not available, let the repaired area dry for 24

hours.

SPECIAL REPAIR REQUIREMENT

PIIA0215E

SEL012D

SEL013D

Page 630 of 5883

![NISSAN TIIDA 2007 Service Service Manual WARNING FUNCTION

DLK-41

< FUNCTION DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

KEY WARNING LAMP & LOCK WARNING LAMP

The key indicator and lock indicator indicates Inte NISSAN TIIDA 2007 Service Service Manual WARNING FUNCTION

DLK-41

< FUNCTION DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

KEY WARNING LAMP & LOCK WARNING LAMP

The key indicator and lock indicator indicates Inte](/img/5/57395/w960_57395-629.png)

WARNING FUNCTION

DLK-41

< FUNCTION DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

KEY WARNING LAMP & LOCK WARNING LAMP

The key indicator and lock indicator indicates Intelligent Key system status.

Operation Condition

BACK DOOR/TRUNK OPEN WARNING OPERATION

When back door (hatchback) or trunk lid (sedan) opener switch is operated, when door lock is locked with door

lock and unlock switch, speed sensing lock or only driver side is unlocked with anti-hijack function, the buzzer

(built in combination meter) will sound.

KEY REMINDER OPERATION

The buzzer (combination meter) will sound and the doors will not lock if the door lock and unlock switch is

pressed while the driver door is open and mechanical key is inserted into ignition key cylinder.

The buzzer (combination meter) will sound and the doors will not lock if the door lock and unlock switch is

pressed while any door other than the driver door is open.

Door lock op-

eration warn-

ingRequest

switch opera-

tionWhen request switch is pushed (lock op-

eration) under the following conditions.

Door switch: ON (Any door is open).

Ignition switch is in ACC or OFF posi-

tion or ignition knob is pressed in

LOCK position or mechanical key is

inserted into ignition key cylinder.

Intelligent Key is inside vehicle.——Active for 2

seconds

(pipipi···)

Intelligent Key

button opera-

tionWhen Intelligent Key button is pushed

(lock operation) under the following con-

ditions.

Door switch: ON (Any door is open).

Ignition switch is in ACC or OFF posi-

tion or ignition knob is pressed in

LOCK position or mechanical key is

inserted into ignition key cylinder.——Active for 2

seconds

(pipipi···)

Intelligent Key low battery

warningWhen Intelligent Key battery voltage is

low, Intelligent Key unit is detected after

ignition switch is turned ON.“KEY”

(GREEN blink-

ing for 30 sec-

onds)—— Warning/Information functions Operation conditions Warning lampWarning chime

Combination

meter buzzerIntelligent Key

warning buzz-

er(s)

Behavior of lamps Operation condition

KEYGREENLightingAll the following conditions are satisfied.

Ignition knob is pushed in LOCK position. (Ignition knob switch is ON)

Ignition key is removed from ignition key cylinder. (Key switch is OFF)

Intelligent Key is detected inside of the vehicle.

KEY RED lighting/blinking conditions are not satisfied.

Blinking while Intelligent Key low battery warning is operating.

REDLightingAll the following conditions are satisfied.

Ignition knob is pushed. (Ignition knob switch is ON)

Ignition key is removed from ignition key cylinder. (Key switch is OFF)

Intelligent Key is not detected inside of the vehicle.

BlinkingAll the following conditions are satisfied.

Take away warning is operating.

KEY RED lighting condition is not satisfied.

LOCK Blinking While OFF position warning is operating.

KEY(RED) and LOCK lightingAll the following conditions are satisfied.

Ignition switch is ON.

Steering lock ID is NG.