checking oil NISSAN TIIDA 2007 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4242 of 5883

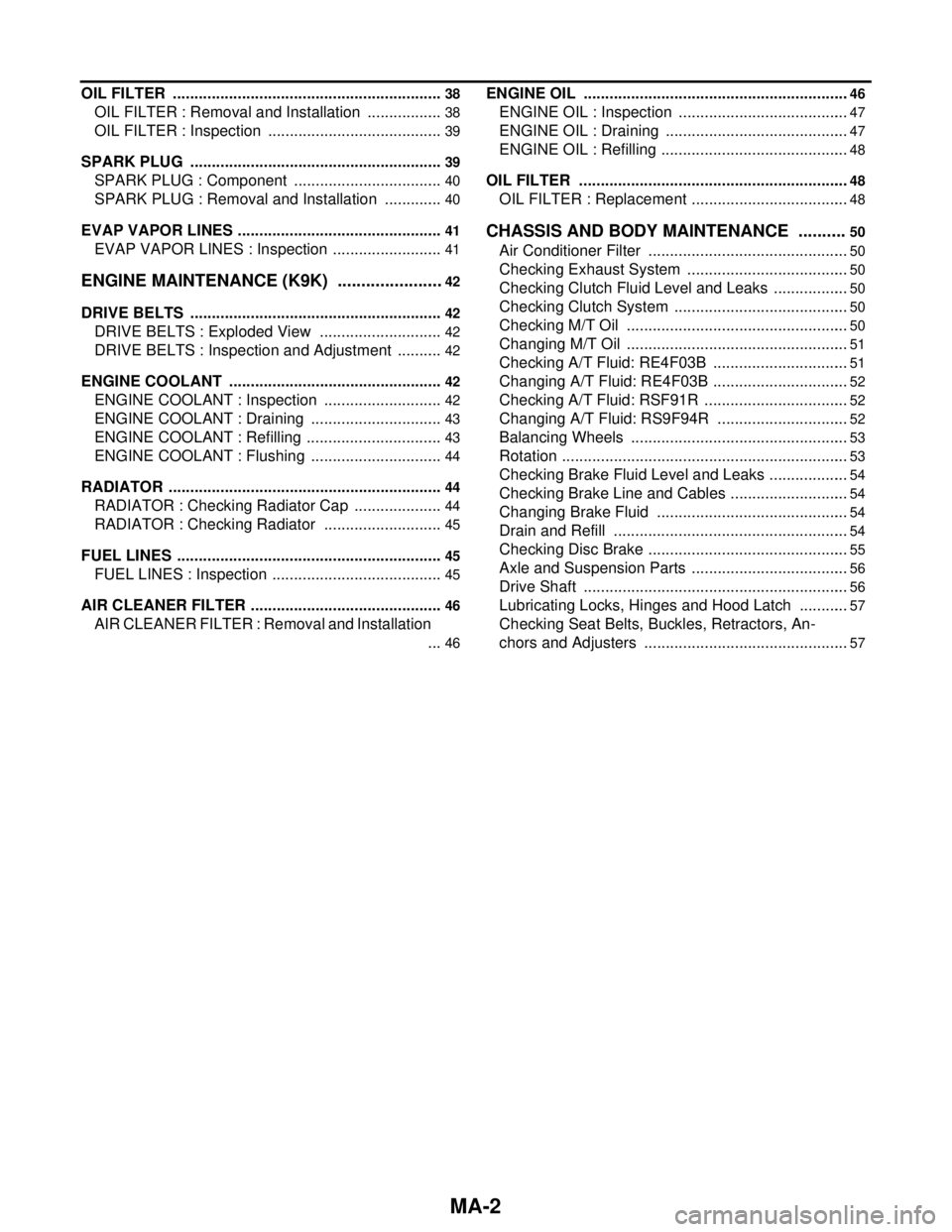

MA-2

OIL FILTER ...............................................................38

OIL FILTER : Removal and Installation ..................38

OIL FILTER : Inspection .........................................39

SPARK PLUG ...........................................................39

SPARK PLUG : Component ...................................40

SPARK PLUG : Removal and Installation ..............40

EVAP VAPOR LINES ................................................41

EVAP VAPOR LINES : Inspection ..........................41

ENGINE MAINTENANCE (K9K) .......................42

DRIVE BELTS ...........................................................42

DRIVE BELTS : Exploded View .............................42

DRIVE BELTS : Inspection and Adjustment ...........42

ENGINE COOLANT ..................................................42

ENGINE COOLANT : Inspection ............................42

ENGINE COOLANT : Draining ...............................43

ENGINE COOLANT : Refilling ................................43

ENGINE COOLANT : Flushing ...............................44

RADIATOR ................................................................44

RADIATOR : Checking Radiator Cap .....................44

RADIATOR : Checking Radiator ............................45

FUEL LINES ..............................................................45

FUEL LINES : Inspection ........................................45

AIR CLEANER FILTER .............................................46

AIR CLEANER FILTER : Removal and Installation

...

46

ENGINE OIL ..............................................................46

ENGINE OIL : Inspection ........................................47

ENGINE OIL : Draining ...........................................47

ENGINE OIL : Refilling ............................................48

OIL FILTER ...............................................................48

OIL FILTER : Replacement .....................................48

CHASSIS AND BODY MAINTENANCE ...........50

Air Conditioner Filter ...............................................50

Checking Exhaust System ......................................50

Checking Clutch Fluid Level and Leaks ..................50

Checking Clutch System .........................................50

Checking M/T Oil ....................................................50

Changing M/T Oil ....................................................51

Checking A/T Fluid: RE4F03B ................................51

Changing A/T Fluid: RE4F03B ................................52

Checking A/T Fluid: RSF91R ..................................52

Changing A/T Fluid: RS9F94R ...............................52

Balancing Wheels ...................................................53

Rotation ...................................................................53

Checking Brake Fluid Level and Leaks ...................54

Checking Brake Line and Cables ............................54

Changing Brake Fluid .............................................54

Drain and Refill .......................................................54

Checking Disc Brake ...............................................55

Axle and Suspension Parts .....................................56

Drive Shaft ..............................................................56

Lubricating Locks, Hinges and Hood Latch ............57

Checking Seat Belts, Buckles, Retractors, An-

chors and Adjusters ................................................

57

Page 4250 of 5883

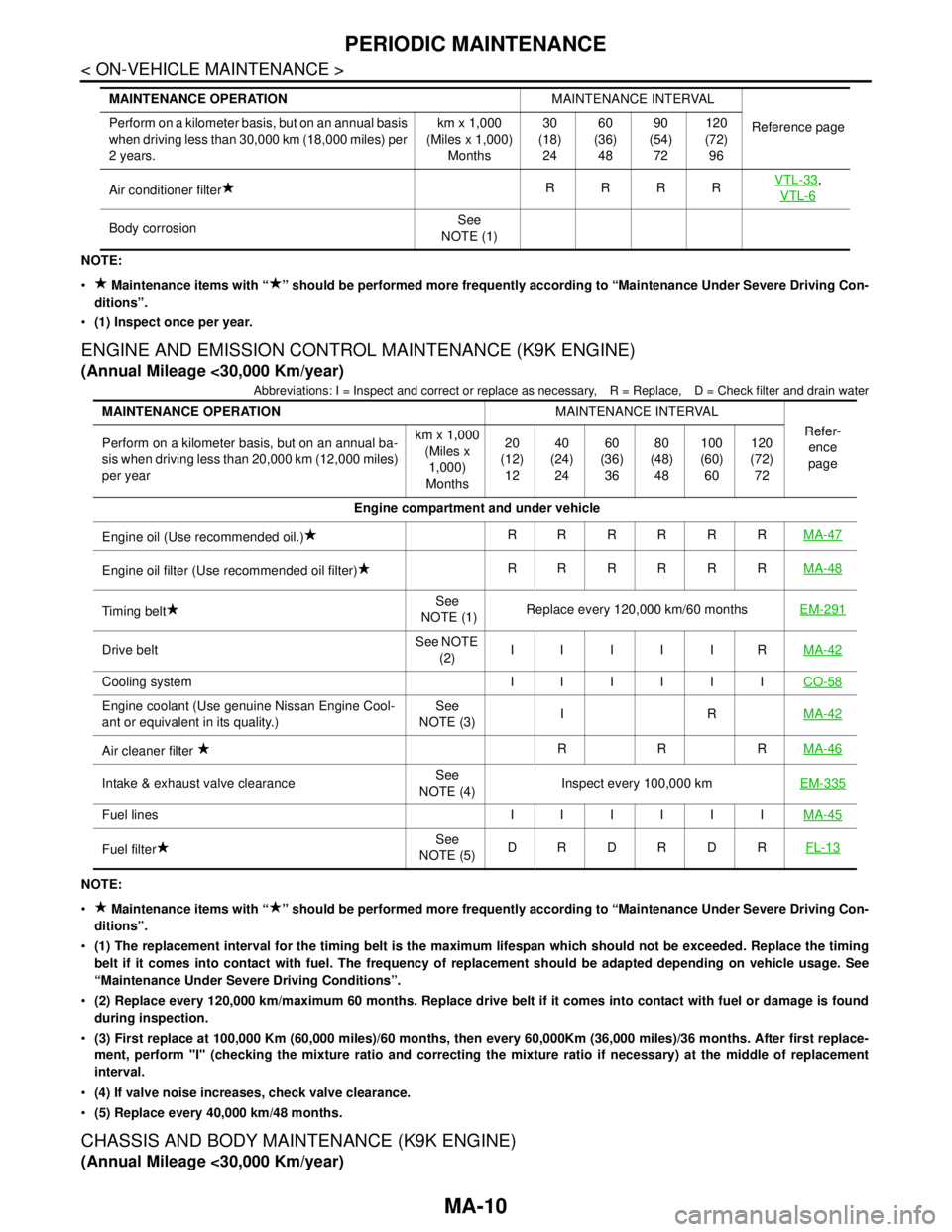

MA-10

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1) Inspect once per year.

ENGINE AND EMISSION CONTROL MAINTENANCE (K9K ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, D = Check filter and drain water

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1) The replacement interval for the timing belt is the maximum lifespan which should not be exceeded. Replace the timing

belt if it comes into contact with fuel. The frequency of replacement should be adapted depending on vehicle usage. See

“Maintenance Under Severe Driving Conditions”.

(2) Replace every 120,000 km/maximum 60 months. Replace drive belt if it comes into contact with fuel or damage is found

during inspection.

(3) First replace at 100,000 Km (60,000 miles)/60 months, then every 60,000Km (36,000 miles)/36 months. After first replace-

ment, perform "I" (checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement

interval.

(4) If valve noise increases, check valve clearance.

(5) Replace every 40,000 km/48 months.

CHASSIS AND BODY MAINTENANCE (K9K ENGINE)

(Annual Mileage <30,000 Km/year)

Air conditioner filterRRRRVTL-33,

VTL-6

Body corrosionSee

NOTE (1) MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per

2 years.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual ba-

sis when driving less than 20,000 km (12,000 miles)

per yearkm x 1,000

(Miles x

1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

Engine compartment and under vehicle

Engine oil (Use recommended oil.)RRRRRRMA-47

Engine oil filter (Use recommended oil filter)RRRRRRMA-48

Timing beltSee

NOTE (1)Replace every 120,000 km/60 monthsEM-291

Drive beltSee NOTE

(2)IIIIIRMA-42

Cooling system IIIIIICO-58

Engine coolant (Use genuine Nissan Engine Cool-

ant or equivalent in its quality.)See

NOTE (3)IRMA-42

Air cleaner filter RRRMA-46

Intake & exhaust valve clearanceSee

NOTE (4)Inspect every 100,000 kmEM-335

Fuel lines IIIIIIMA-45

Fuel filterSee

NOTE (5)DRDRDRFL-13

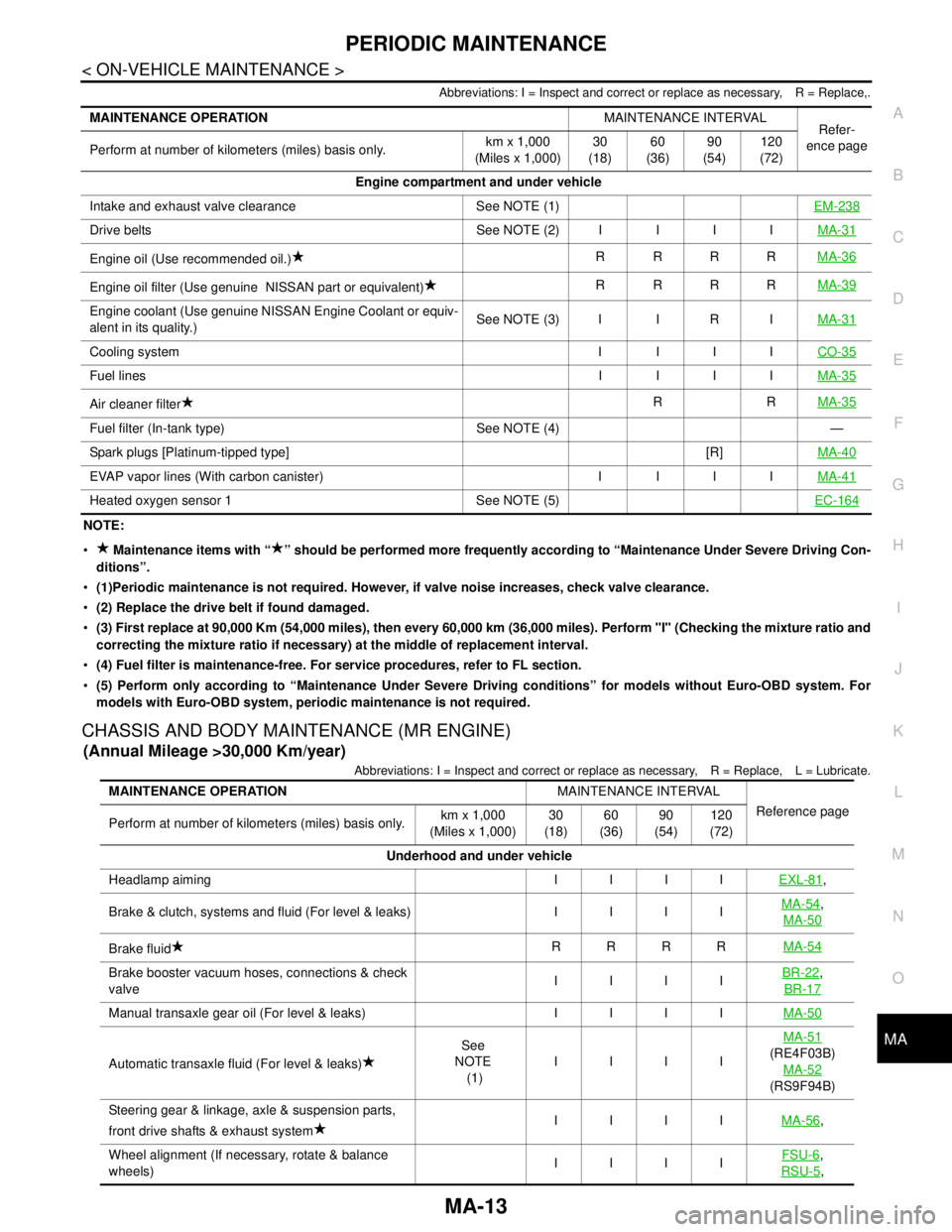

Page 4253 of 5883

PERIODIC MAINTENANCE

MA-13

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged.

(3) First replace at 90,000 Km (54,000 miles), then every 60,000 km (36,000 miles). Perform "I" (Checking the mixture ratio and

correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Perform only according to “Maintenance Under Severe Driving conditions” for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (MR ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x 1,000)30

(18)60

(36)90

(54)120

(72)

Engine compartment and under vehicle

Intake and exhaust valve clearance See NOTE (1)EM-238

Drive belts See NOTE (2) I I I IMA-31

Engine oil (Use recommended oil.)RRRRMA-36

Engine oil filter (Use genuine NISSAN part or equivalent)RRRRMA-39

Engine coolant (Use genuine NISSAN Engine Coolant or equiv-

alent in its quality.)See NOTE (3) I I R IMA-31

Cooling system I I I ICO-35

Fuel linesI IIIMA-35

Air cleaner filterRRMA-35

Fuel filter (In-tank type) See NOTE (4) —

Spark plugs [Platinum-tipped type] [R]MA-40

EVAP vapor lines (With carbon canister) I I I IMA-41

Heated oxygen sensor 1 See NOTE (5)EC-164

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x 1,000)30

(18)60

(36)90

(54)120

(72)

Underhood and under vehicle

Headlamp aiming I I I IEXL-81

,

Brake & clutch, systems and fluid (For level & leaks) I I I IMA-54

,

MA-50

Brake fluidRRRRMA-54

Brake booster vacuum hoses, connections & check

valveIIIIBR-22,

BR-17

Manual transaxle gear oil (For level & leaks) I I I IMA-50

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIMA-51(RE4F03B)

MA-52

(RS9F94B)

Steering gear & linkage, axle & suspension parts,

front drive shafts & exhaust systemIIIIMA-56

,

Wheel alignment (If necessary, rotate & balance

wheels)IIIIFSU-6

,

RSU-5

,

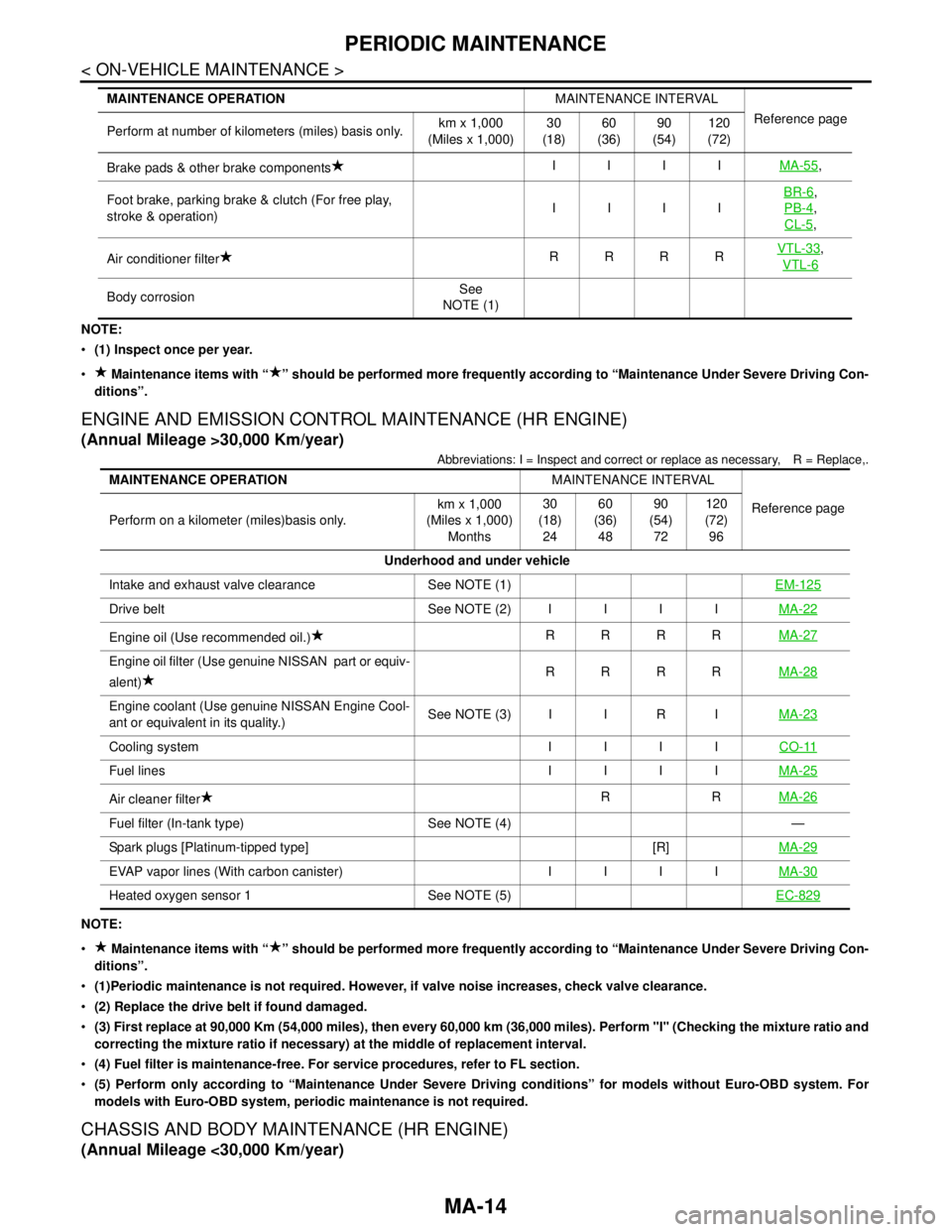

Page 4254 of 5883

MA-14

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

(1) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

ENGINE AND EMISSION CONTROL MAINTENANCE (HR ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged.

(3) First replace at 90,000 Km (54,000 miles), then every 60,000 km (36,000 miles). Perform "I" (Checking the mixture ratio and

correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Perform only according to “Maintenance Under Severe Driving conditions” for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (HR ENGINE)

(Annual Mileage <30,000 Km/year)

Brake pads & other brake componentsIIIIMA-55,

Foot brake, parking brake & clutch (For free play,

stroke & operation)IIIIBR-6

,

PB-4

,

CL-5

,

Air conditioner filterRRRRVTL-33

,

VTL-6

Body corrosionSee

NOTE (1) MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x 1,000)30

(18)60

(36)90

(54)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page

Perform on a kilometer (miles)basis only.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Underhood and under vehicle

Intake and exhaust valve clearance See NOTE (1)EM-125

Drive belt See NOTE (2)IIIIMA-22

Engine oil (Use recommended oil.)RRRRMA-27

Engine oil filter (Use genuine NISSAN part or equiv-

alent)RRRRMA-28

Engine coolant (Use genuine NISSAN Engine Cool-

ant or equivalent in its quality.)See NOTE (3) I I R IMA-23

Cooling system IIIICO-11

Fuel lines IIIIMA-25

Air cleaner filterRRMA-26

Fuel filter (In-tank type) See NOTE (4) —

Spark plugs [Platinum-tipped type] [R]MA-29

EVAP vapor lines (With carbon canister) IIIIMA-30

Heated oxygen sensor 1 See NOTE (5)EC-829

Page 4256 of 5883

MA-16

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

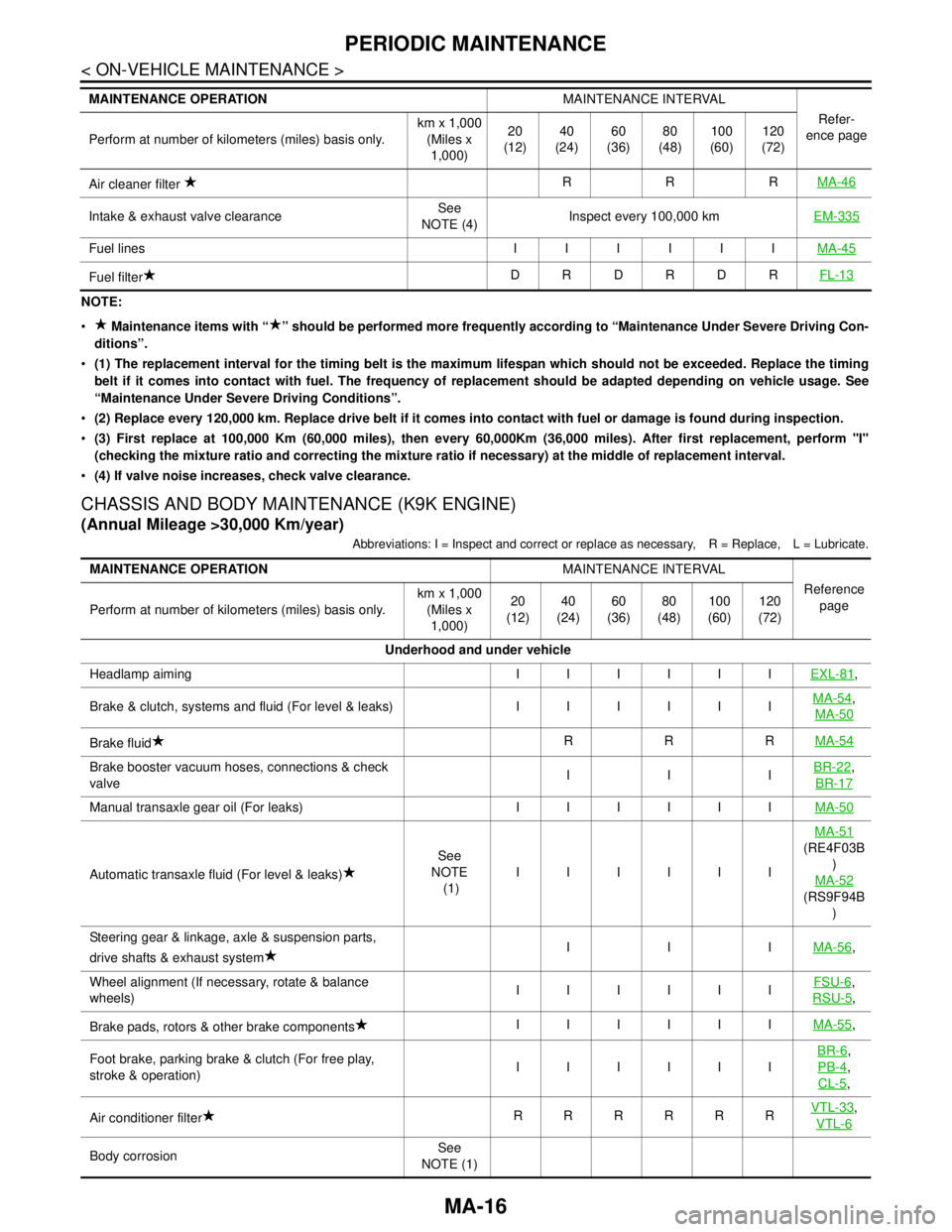

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1) The replacement interval for the timing belt is the maximum lifespan which should not be exceeded. Replace the timing

belt if it comes into contact with fuel. The frequency of replacement should be adapted depending on vehicle usage. See

“Maintenance Under Severe Driving Conditions”.

(2) Replace every 120,000 km. Replace drive belt if it comes into contact with fuel or damage is found during inspection.

(3) First replace at 100,000 Km (60,000 miles), then every 60,000Km (36,000 miles). After first replacement, perform "I"

(checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) If valve noise increases, check valve clearance.

CHASSIS AND BODY MAINTENANCE (K9K ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

Air cleaner filter RRRMA-46

Intake & exhaust valve clearanceSee

NOTE (4)Inspect every 100,000 kmEM-335

Fuel lines IIIIIIMA-45

Fuel filterDRDRDRFL-13

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x

1,000)20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x

1,000)20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

Underhood and under vehicle

Headlamp aiming IIIIIIEXL-81

,

Brake & clutch, systems and fluid (For level & leaks) I I I I I IMA-54

,

MA-50

Brake fluidRRRMA-54

Brake booster vacuum hoses, connections & check

valveIIIBR-22,

BR-17

Manual transaxle gear oil (For leaks) I I I I I IMA-50

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIIIMA-51

(RE4F03B

)

MA-52

(RS9F94B

)

Steering gear & linkage, axle & suspension parts,

drive shafts & exhaust systemIIIMA-56

,

Wheel alignment (If necessary, rotate & balance

wheels)IIIIIIFSU-6

,

RSU-5

,

Brake pads, rotors & other brake componentsIIIIIIMA-55

,

Foot brake, parking brake & clutch (For free play,

stroke & operation)IIIIIIBR-6

,

PB-4

,

CL-5

,

Air conditioner filterRRRRRRVTL-33

,

VTL-6

Body corrosionSee

NOTE (1)

Page 4262 of 5883

MA-22

< ON-VEHICLE MAINTENANCE >

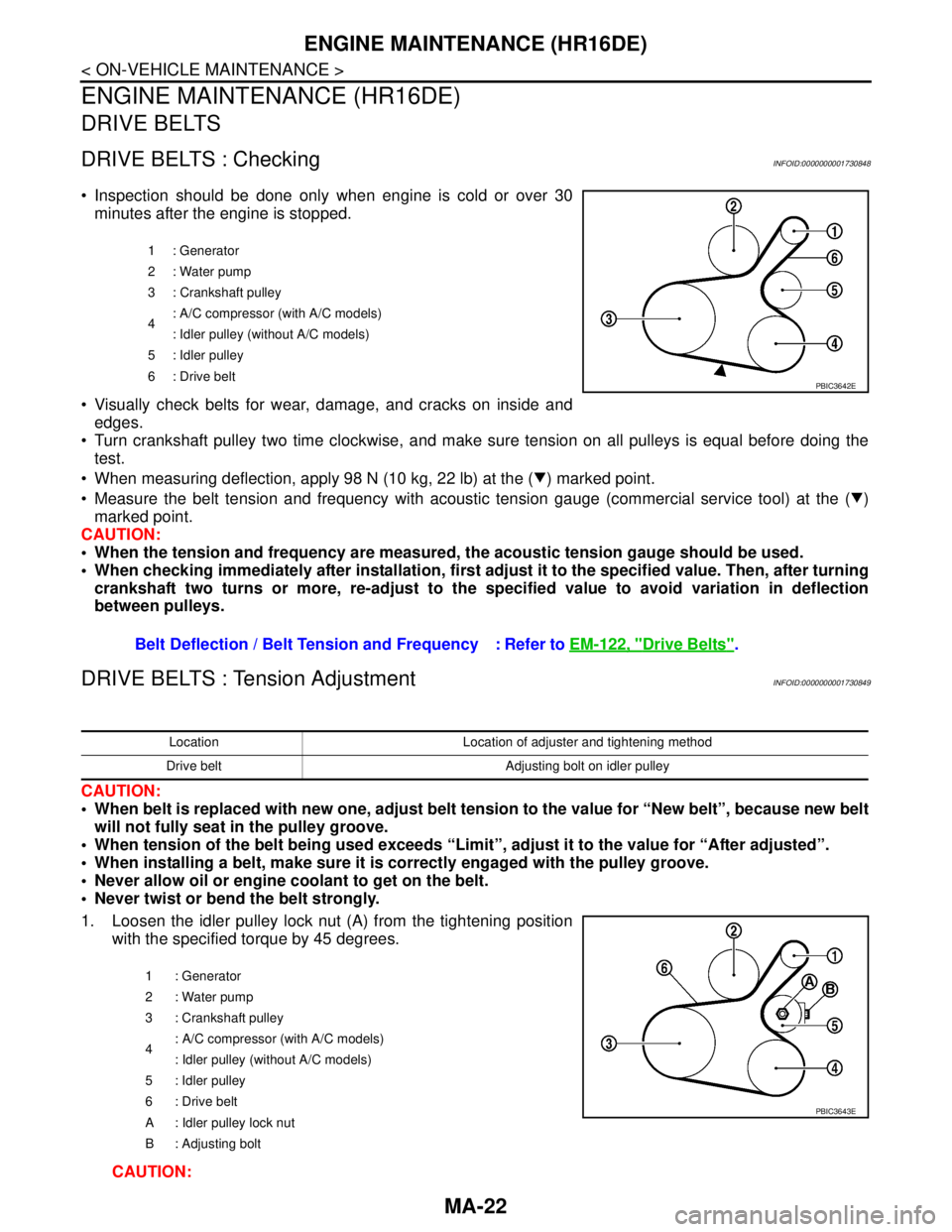

ENGINE MAINTENANCE (HR16DE)

ENGINE MAINTENANCE (HR16DE)

DRIVE BELTS

DRIVE BELTS : CheckingINFOID:0000000001730848

Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

Visually check belts for wear, damage, and cracks on inside and

edges.

Turn crankshaft pulley two time clockwise, and make sure tension on all pulleys is equal before doing the

test.

When measuring deflection, apply 98 N (10 kg, 22 lb) at the ( ) marked point.

Measure the belt tension and frequency with acoustic tension gauge (commercial service tool) at the ( )

marked point.

CAUTION:

When the tension and frequency are measured, the acoustic tension gauge should be used.

When checking immediately after installation, first adjust it to the specified value. Then, after turning

crankshaft two turns or more, re-adjust to the specified value to avoid variation in deflection

between pulleys.

DRIVE BELTS : Tension AdjustmentINFOID:0000000001730849

CAUTION:

When belt is replaced with new one, adjust belt tension to the value for “New belt”, because new belt

will not fully seat in the pulley groove.

When tension of the belt being used exceeds “Limit”, adjust it to the value for “After adjusted”.

When installing a belt, make sure it is correctly engaged with the pulley groove.

Never allow oil or engine coolant to get on the belt.

Never twist or bend the belt strongly.

1. Loosen the idler pulley lock nut (A) from the tightening position

with the specified torque by 45 degrees.

CAUTION:

1 : Generator

2: Water pump

3 : Crankshaft pulley

4: A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6: Drive belt

Belt Deflection / Belt Tension and Frequency : Refer to EM-122, "Drive Belts".

PBIC3642E

Location Location of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

1 : Generator

2: Water pump

3 : Crankshaft pulley

4: A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6 : Drive belt

A : Idler pulley lock nut

B : Adjusting bolt

PBIC3643E

Page 4274 of 5883

MA-34

< ON-VEHICLE MAINTENANCE >

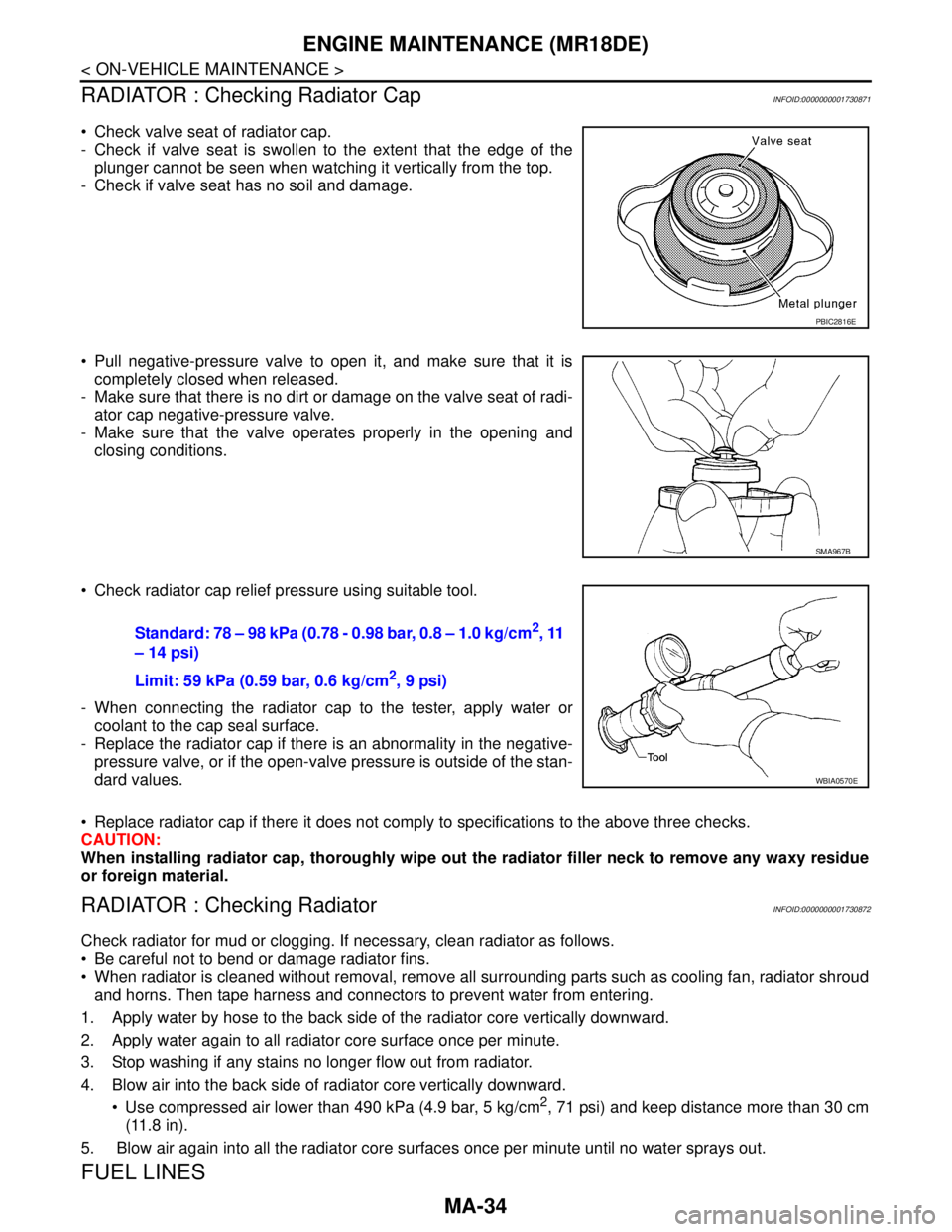

ENGINE MAINTENANCE (MR18DE)

RADIATOR : Checking Radiator Cap

INFOID:0000000001730871

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

Pull negative-pressure valve to open it, and make sure that it is

completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and

closing conditions.

Check radiator cap relief pressure using suitable tool.

- When connecting the radiator cap to the tester, apply water or

coolant to the cap seal surface.

- Replace the radiator cap if there is an abnormality in the negative-

pressure valve, or if the open-valve pressure is outside of the stan-

dard values.

Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

RADIATOR : Checking RadiatorINFOID:0000000001730872

Check radiator for mud or clogging. If necessary, clean radiator as follows.

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud

and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.8 in).

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

FUEL LINES

PBIC2816E

SMA967B

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E

Page 4276 of 5883

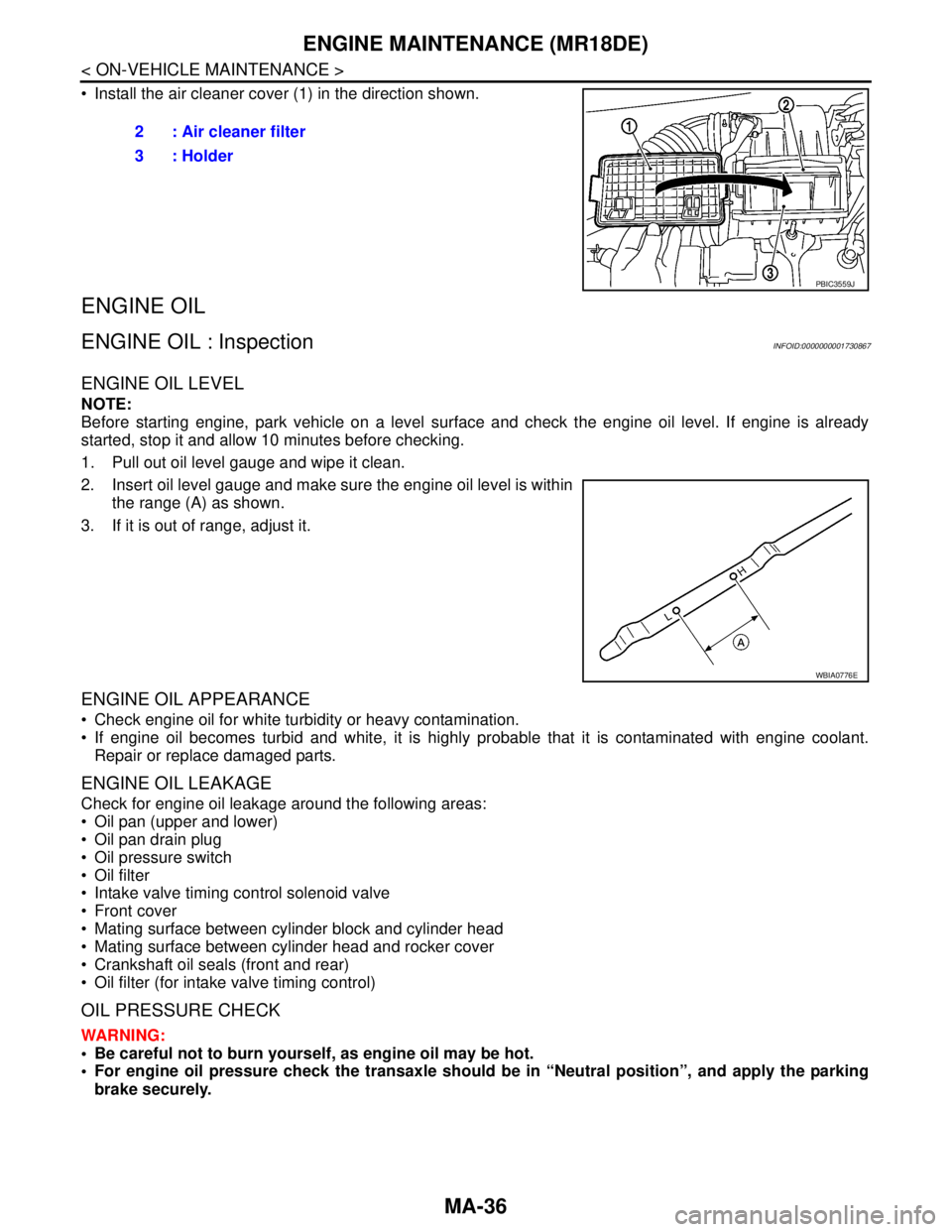

MA-36

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (MR18DE)

Install the air cleaner cover (1) in the direction shown.

ENGINE OIL

ENGINE OIL : InspectionINFOID:0000000001730867

ENGINE OIL LEVEL

NOTE:

Before starting engine, park vehicle on a level surface and check the engine oil level. If engine is already

started, stop it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and make sure the engine oil level is within

the range (A) as shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

Check engine oil for white turbidity or heavy contamination.

If engine oil becomes turbid and white, it is highly probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following areas:

Oil pan (upper and lower)

Oil pan drain plug

Oil pressure switch

Oil filter

Intake valve timing control solenoid valve

Front cover

Mating surface between cylinder block and cylinder head

Mating surface between cylinder head and rocker cover

Crankshaft oil seals (front and rear)

Oil filter (for intake valve timing control)

OIL PRESSURE CHECK

WARNING:

Be careful not to burn yourself, as engine oil may be hot.

For engine oil pressure check the transaxle should be in “Neutral position”, and apply the parking

brake securely.2 : Air cleaner filter

3 : Holder

PBIC3559J

WBIA0776E

Page 4281 of 5883

ENGINE MAINTENANCE (MR18DE)

MA-41

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

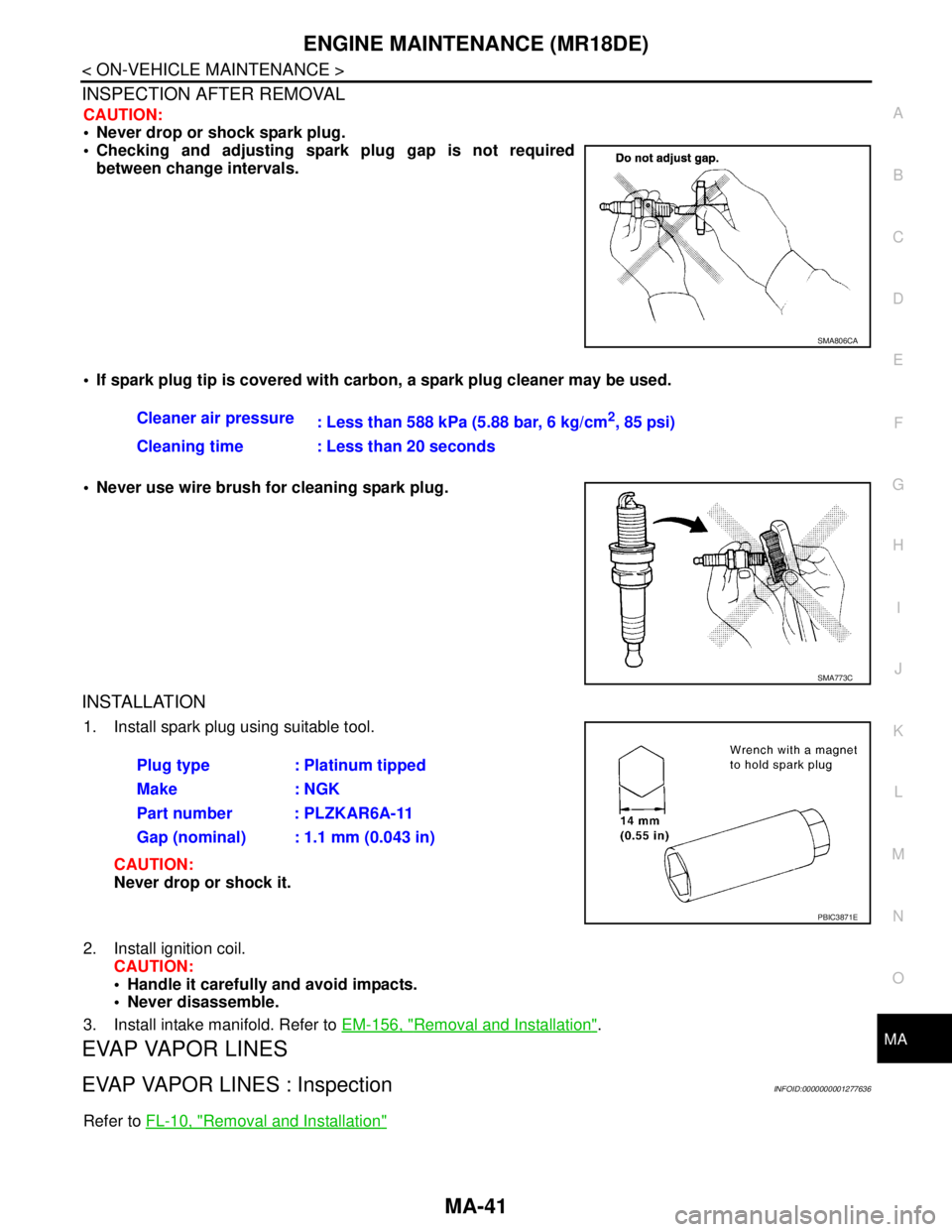

INSPECTION AFTER REMOVAL

CAUTION:

Never drop or shock spark plug.

Checking and adjusting spark plug gap is not required

between change intervals.

If spark plug tip is covered with carbon, a spark plug cleaner may be used.

Never use wire brush for cleaning spark plug.

INSTALLATION

1. Install spark plug using suitable tool.

CAUTION:

Never drop or shock it.

2. Install ignition coil.

CAUTION:

Handle it carefully and avoid impacts.

Never disassemble.

3. Install intake manifold. Refer to EM-156, "

Removal and Installation".

EVAP VAPOR LINES

EVAP VAPOR LINES : InspectionINFOID:0000000001277636

Refer to FL-10, "Removal and Installation"

SMA806CA

Cleaner air pressure

: Less than 588 kPa (5.88 bar, 6 kg/cm2, 85 psi)

Cleaning time : Less than 20 seconds

SMA773C

Plug type : Platinum tipped

Make : NGK

Part number : PLZKAR6A-11

Gap (nominal) : 1.1 mm (0.043 in)

PBIC3871E

Page 4282 of 5883

MA-42

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (K9K)

ENGINE MAINTENANCE (K9K)

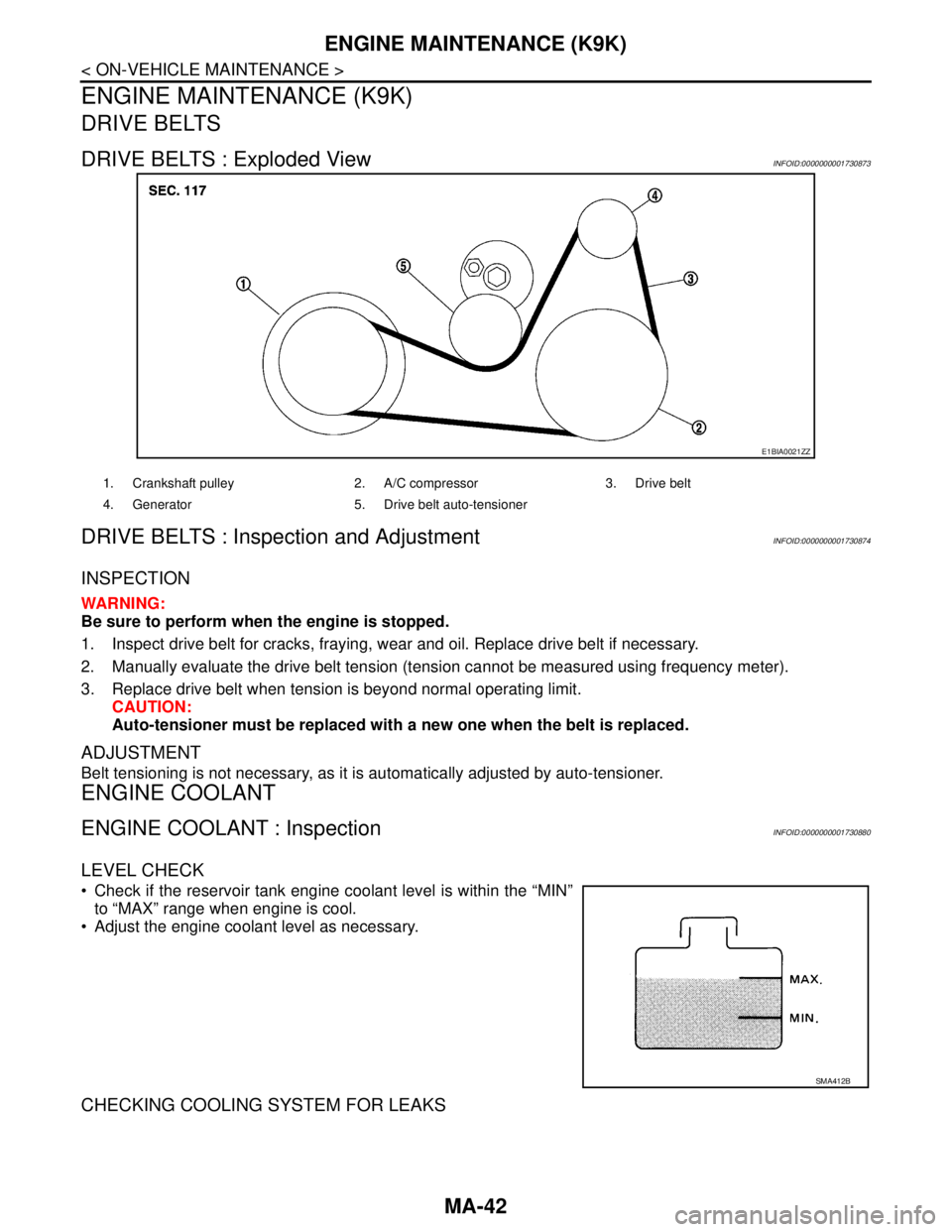

DRIVE BELTS

DRIVE BELTS : Exploded ViewINFOID:0000000001730873

DRIVE BELTS : Inspection and AdjustmentINFOID:0000000001730874

INSPECTION

WARNING:

Be sure to perform when the engine is stopped.

1. Inspect drive belt for cracks, fraying, wear and oil. Replace drive belt if necessary.

2. Manually evaluate the drive belt tension (tension cannot be measured using frequency meter).

3. Replace drive belt when tension is beyond normal operating limit.

CAUTION:

Auto-tensioner must be replaced with a new one when the belt is replaced.

ADJUSTMENT

Belt tensioning is not necessary, as it is automatically adjusted by auto-tensioner.

ENGINE COOLANT

ENGINE COOLANT : InspectionINFOID:0000000001730880

LEVEL CHECK

Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” range when engine is cool.

Adjust the engine coolant level as necessary.

CHECKING COOLING SYSTEM FOR LEAKS

E1BIA0021ZZ

1. Crankshaft pulley 2. A/C compressor 3. Drive belt

4. Generator 5. Drive belt auto-tensioner

SMA412B