checking oil NISSAN TIIDA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2903 of 5883

![NISSAN TIIDA 2007 Service Owners Guide EM-256

< PRECAUTION >[K9K]

PRECAUTIONS

SPECIAL FEATURES

CAUTION:

The engine must not operate with:

- Diesel engine fuel containing more than 10% diester,

- Petrol, even in tiny quantities.

The sys NISSAN TIIDA 2007 Service Owners Guide EM-256

< PRECAUTION >[K9K]

PRECAUTIONS

SPECIAL FEATURES

CAUTION:

The engine must not operate with:

- Diesel engine fuel containing more than 10% diester,

- Petrol, even in tiny quantities.

The sys](/img/5/57395/w960_57395-2902.png)

EM-256

< PRECAUTION >[K9K]

PRECAUTIONS

SPECIAL FEATURES

CAUTION:

The engine must not operate with:

- Diesel engine fuel containing more than 10% diester,

- Petrol, even in tiny quantities.

The system can inject the diesel into the engine at a pressure up to 1400 bars. Before carrying out

any work, check that the injector rail is not under pressure and that the fuel temperature is not too

high.

You must respect the cleaning and safety advice specified in this document for any work on the high

pressure injection system.

Removal of the interior of the pump and injectors is prohibited. Only the flow actuator, the fuel tem-

perature sensor and the venturi can be replaced.

For safety reasons, it is strictly forbidden to slacken a injection tube union when the engine is run-

ning.

It is not possible to remove the pressure sensor from the fuel rail because this may cause circuit

contamination malfunctions. If the pressure sensor fails, the pressure sensor, the rail and the five

injection tubes must be replaced.

It is strictly forbidden to remove any high pressure supply pump pulley marked number 070 575. If

the pump is being replaced, the pulley must be replaced.

It is forbidden to repair the wiring connecting the knock sensor (accelerometer) and the CKP sensor

(engine speed sensor). If the wiring should fail, it has to be replaced with new wiring.

Applying 12 volts directly to any component in the system is prohibited.

Ultrasonic carbon removal and cleaning are prohibited.

Never start the engine without the battery being connected correctly.

It is essential to replace all the disconnected air inlet plastic pipes.

INSTRUCTIONS FOR INJECTION TUBES

CAUTION:

All the injection tube removed must be systematically replaced along with the clips.

TIGHTENING THE INJECTION TUBES

NOTE:

fit the pump/rail pipe before the rail/injector pipes.

Rail-pump pipe

Undo the rail,

Grease the threads of the injection tube nuts,

Insert the injection tube olive into the taper of the high pressure pump outlet,

Insert the injection tube olive into the taper of the high pressure rail inlet.

Move the nut into position by hand, on the rail side then the pump side,

Tighten the rail,

Tighten the injection tube nuts on the rail side then on the pump side.

Rail/injector pipes

Undo the rail,

Grease the threads of the injection tube nuts,

Insert the injection tube olive into the taper of the high pressure injector inlet,

Insert the injection tube olive into the taper of the high pressure rail outlet,

Move the nuts into position by hand, on the injector side then the rail side,

Tighten the rail,

Ensure that the new clip, supplied with the new injection tube, is fitted,

Tighten the nuts of the injection tubes on the injector side first and then on the fuel rail side.

NOTE:

Before fitting a new injection tube, move back the nuts on the pipe then lightly lubricate the nut

threads with the oil from the sachet provided in the parts kit.

CHECKING SEALING AFTER REPAIR

CAUTION:

After any operation, check that there are no diesel leaks.

Reprime the circuit using the priming pump.

Start the engine and allow to warm up at idle speed, visually inspecting for any fuel leaks.

Apply tracing fluid around the high pressure connections of the pipe that has been replaced.

Once the engine coolant temperature is above 50°C and provided there are no malfunctions present, carry

out a road test, taking the engine speed up to 4000 rpm at least once to check that there are no leaks.

Perform a visual inspection after the road test to make sure that there are no high pressure leaks.

Clean off the tracing fluid.

Page 2914 of 5883

![NISSAN TIIDA 2007 Service Owners Guide COMPRESSION PRESSURE

EM-267

< ON-VEHICLE MAINTENANCE >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

COMPRESSION PRESSURE

InspectionINFOID:0000000001381466

1. Warm up engine thoroughly. Then stop.

2. Remove gl NISSAN TIIDA 2007 Service Owners Guide COMPRESSION PRESSURE

EM-267

< ON-VEHICLE MAINTENANCE >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

COMPRESSION PRESSURE

InspectionINFOID:0000000001381466

1. Warm up engine thoroughly. Then stop.

2. Remove gl](/img/5/57395/w960_57395-2913.png)

COMPRESSION PRESSURE

EM-267

< ON-VEHICLE MAINTENANCE >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

COMPRESSION PRESSURE

InspectionINFOID:0000000001381466

1. Warm up engine thoroughly. Then stop.

2. Remove glow plug.

3. Disconnect high-pressure supply pump harness connector to avoid fuel injection during measurement.

4. Connect compression gauge attachment hose [SST:

KV113B0400 (Mot. 1592)] (A) to the hole for glow plug.

5. Connect compression gauge (B) to attachment hose (A).

6. Turn ignition switch to START for cranking and check compres-

sion gauge.

7. Perform the same procedure for the other cylinders.

If compression pressure is below minimum value, check valve

clearances and parts associated with combustion chamber (valve, valve seat, piston, piston ring, cylin-

der bore, cylinder head, cylinder head gasket). After checking, measure compression pressure again.

If any cylinder has low compression pressure, pour a small amount of engine oil into the glow plug hole

of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check pis-

ton rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be mal-

functioning. Check valves for damage. Replace valve or valve seat accordingly.

If two adjacent cylinders have respectively low compression pressure and their compression remains

low even after the addition of engine oil, cylinder head gaskets are leaking. In this case, replace cylinder

head gaskets.

8. Disconnect compression gauge (B) and attachment hose (A).

9. After inspection is completed, install removed parts.

10. Start the engine, and make sure that the engine runs smoothly.

11. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-1043, "

BASIC INSPECTION : Descrip-

tion". Compres-

sion pres-

sure: Refer to EM-333,

"GeneralSpecification".

E1BIA0052ZZ

Page 3195 of 5883

GI-1

GENERAL INFORMATION

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION GI

N

O

P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANUAL ......................3

HOW TO USE THIS MANUAL ............................3

Description ................................................................3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Component ................................................................4

How to Follow Trouble Diagnosis ..............................5

How to Read Wiring Diagram ....................................9

Abbreviations ..........................................................16

HOW TO FOLLOW TROUBLE DIAGNOSES ....18

Description ..............................................................18

How to Follow Test Groups in Trouble Diagnosis ....18

Key to Symbols Signifying Measurements or Pro-

cedures ...................................................................

19

HOW TO READ WIRING DIAGRAMS ...............21

Connector symbols .................................................21

Sample/wiring diagram -example- ...........................22

Description ..............................................................23

ABBREVIATIONS ..............................................25

Abbreviation List ......................................................25

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

26

Tightening Torque Table .........................................26

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ................................................

27

Recommended Chemical Products and Sealants ....27

TERMINOLOGY .................................................28

SAE J1930 Terminology List ...................................28

FEATURES OF NEW MODEL .....................32

IDENTIFICATION INFORMATION .....................32

Model Variation .......................................................32

Dimensions ..............................................................41

Wheels & Tires ........................................................42

PRECAUTION ..............................................43

PRECAUTIONS .................................................43

Description ...............................................................43

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

43

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

43

General Precaution ..................................................44

Precaution for Three Way Catalyst ..........................45

Precaution for Fuel (Unleaded Regular Gasoline

Recommended) .......................................................

45

Precaution for Multiport Fuel Injection System or

Engine Control System ............................................

46

Precaution for Hoses ...............................................46

Precaution for Engine Oils .......................................47

Precaution for Air Conditioning ................................47

LIFTING POINT .................................................48

Special Service Tool ................................................48

Garage Jack and Safety Stand and 2-Pole Lift .......48

Board-On Lift ...........................................................49

TOW TRUCK TOWING .....................................50

Tow Truck Towing ...................................................50

Vehicle Recovery (Freeing a Stuck Vehicle) ...........50

BASIC INSPECTION ...................................51

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

51

Work Flow ................................................................51

Control Units and Electrical Parts ............................51

How to Check Terminal ...........................................52

Intermittent Incident .................................................55

Circuit Inspection .....................................................58

CONSULT-III CHECKING SYSTEM .................63

Page 3239 of 5883

PRECAUTIONS

GI-45

< PRECAUTION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

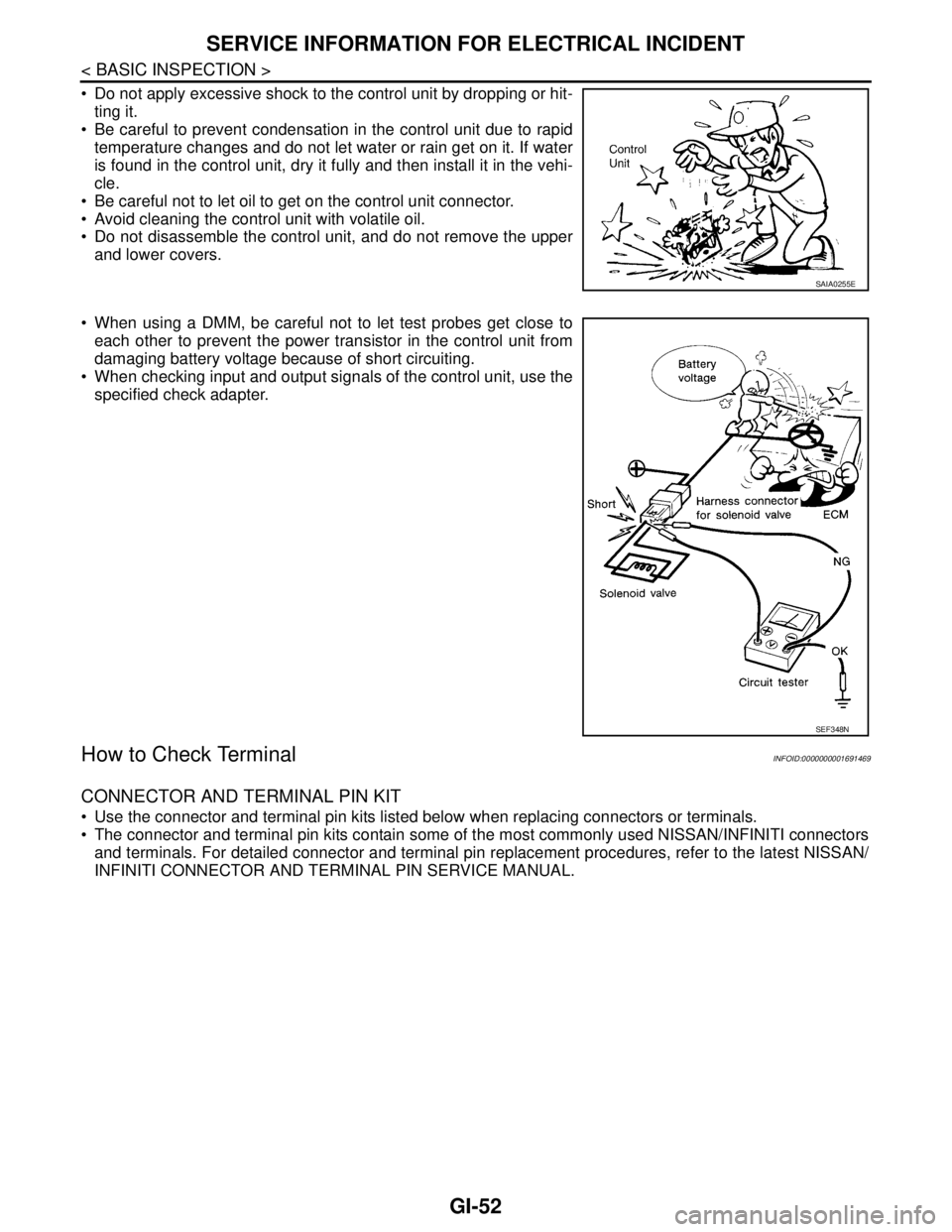

Use hand tools, power tools (disassembly only) and recommended

special tools where specified for safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precaution for Three Way CatalystINFOID:0000000001606119

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

When checking for ignition spark or measuring engine compression, make tests quickly and only when nec-

essary.

Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precaution for Fuel (Unleaded Regular Gasoline Recommended)INFOID:0000000001606120

Use unleaded regular gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research

octane number 91).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unleaded gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fuel other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

PBIC0190E

SGI234

Page 3246 of 5883

GI-52

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Do not apply excessive shock to the control unit by dropping or hit-

ting it.

Be careful to prevent condensation in the control unit due to rapid

temperature changes and do not let water or rain get on it. If water

is found in the control unit, dry it fully and then install it in the vehi-

cle.

Be careful not to let oil to get on the control unit connector.

Avoid cleaning the control unit with volatile oil.

Do not disassemble the control unit, and do not remove the upper

and lower covers.

When using a DMM, be careful not to let test probes get close to

each other to prevent the power transistor in the control unit from

damaging battery voltage because of short circuiting.

When checking input and output signals of the control unit, use the

specified check adapter.

How to Check TerminalINFOID:0000000001691469

CONNECTOR AND TERMINAL PIN KIT

Use the connector and terminal pin kits listed below when replacing connectors or terminals.

The connector and terminal pin kits contain some of the most commonly used NISSAN/INFINITI connectors

and terminals. For detailed connector and terminal pin replacement procedures, refer to the latest NISSAN/

INFINITI CONNECTOR AND TERMINAL PIN SERVICE MANUAL.

SAIA0255E

SEF348N

Page 3283 of 5883

HA-1

VENTILATION, HEATER & AIR CONDITIONER

C

D

E

F

G

H

J

K

L

M

SECTION HA

A

B

HA

N

O

P

CONTENTS

HEATER & AIR CONDITIONING SYSTEM

PRECAUTION ...............................................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Procedure without Cowl Top Cover ......3

Precaution for Working with HFC-134a (R-134a) ......3

General Refrigerant Precaution ................................4

Oil Precaution ............................................................4

Precaution for Refrigerant Connection ......................4

Precaution for Service of Compressor ......................8

Precaution for Service Equipment .............................9

Precaution for Leak Detection Dye .........................10

PREPARATION ...........................................12

PREPARATION ..................................................12

HFC-134a (R-134a) Service Tool and Equipment ....12

Commercial Service Tool ........................................14

FUNCTION DIAGNOSIS ..............................16

REFRIGERATION SYSTEM ..............................16

Refrigerant Cycle ....................................................16

Refrigerant System Protection ................................16

OIL ......................................................................18

Maintenance of Oil Quantity in Compressor ...........18

ON-VEHICLE MAINTENANCE ....................19

OIL ......................................................................19

Maintenance of Oil Quantity in Compressor ...........19

REFRIGERATION SYSTEM ..............................21

HFC-134a (R-134a) Service Procedure ..................21

Checking of Refrigerant Leaks ................................22

FLUORESCENT LEAK DETECTOR .................24

Checking System for Leaks Using the Fluorescent

Leak Detector ..........................................................

24

Dye Injection ............................................................24

ELECTRICAL LEAK DETECTOR ....................25

Electronic Refrigerant Leak Detector .......................25

ON-VEHICLE REPAIR .................................27

REFRIGERATION SYSTEM .............................27

Component ..............................................................27

HFC-134a (R-134a) Service Procedure ..................29

COMPRESSOR .................................................32

Removal and Installation of Compressor -

MR18DE ..................................................................

32

Removal and Installation of Compressor -

HR16DE ..................................................................

34

Removal and Installation of Compressor - K9K .......35

LOW-PRESSURE FLEXIBLE HOSE ................38

Removal and Installation of Low-Pressure Flexi-

ble Hose - MR18DE, HR16DE ................................

38

Removal and Installation of Low-Pressure Flexi-

ble Hose - K9K ........................................................

38

LOW-PRESSURE PIPE ....................................40

Removal and Installation of Low-Pressure Pipe -

K9K ..........................................................................

40

HIGH-PRESSURE FLEXIBLE HOSE ...............41

Removal and Installation of High-Pressure Flexi-

ble Hose - MR18DE, HR16DE ................................

41

Removal and Installation of High-Pressure Flexi-

ble Hose - K9K ........................................................

41

HIGH-PRESSURE PIPE ....................................43

Removal and Installation of High-Pressure Pipe -

MR18DE, HR16DE ..................................................

43

Removal and Installation of High-Pressure Pipe -

K9K ..........................................................................

43

CONDENSER ....................................................45

Removal and Installation of Condenser -

MR18DE, HR16DE ..................................................

45

Page 3304 of 5883

HA-22

< ON-VEHICLE MAINTENANCE >

REFRIGERATION SYSTEM

Checking of Refrigerant Leaks

INFOID:0000000001396447

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C oil leak-

age, damage and corrosion. A/C oil leakage may indicate an area of refrigerant leakage. Allow extra inspec-

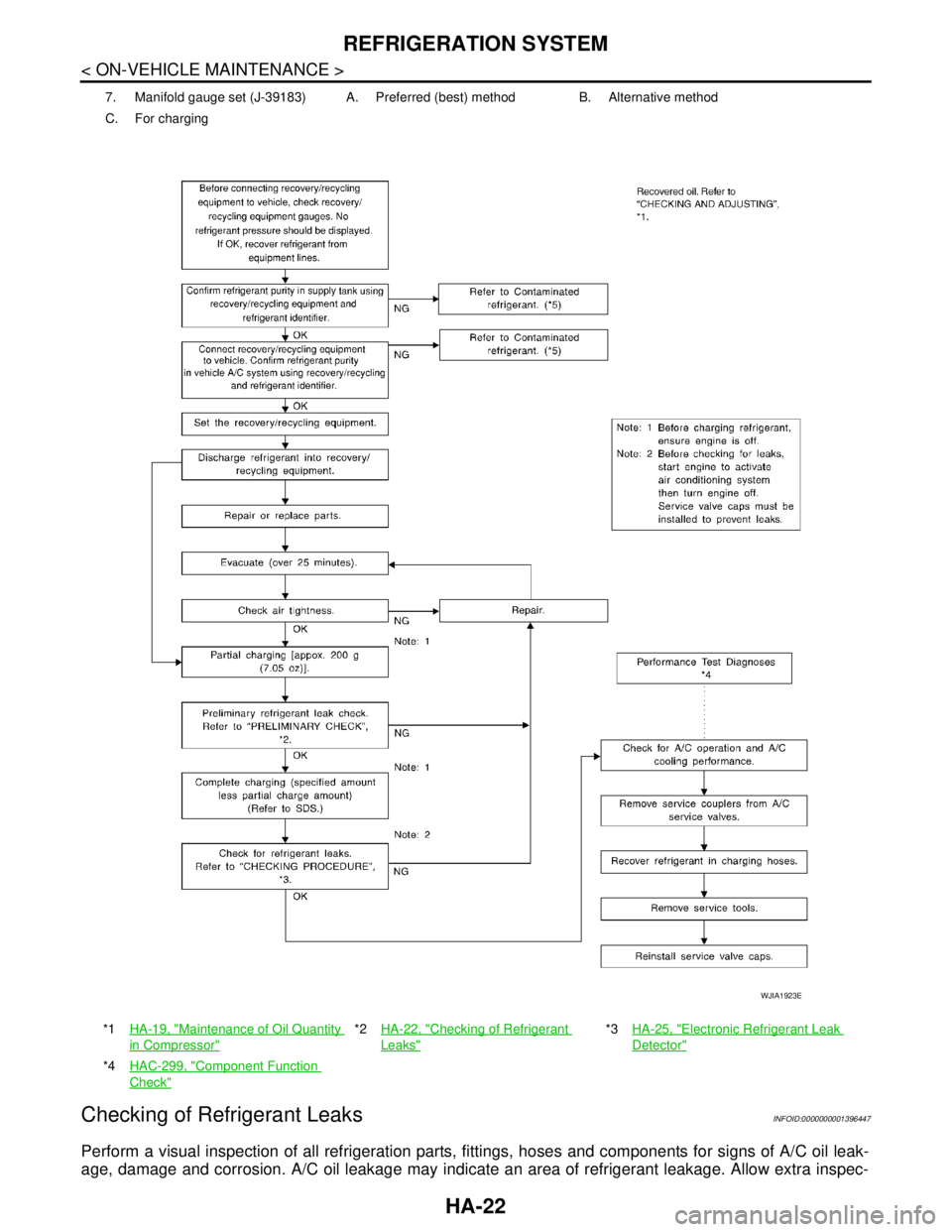

7. Manifold gauge set (J-39183) A. Preferred (best) method B. Alternative method

C. For charging

*1HA-19, "

Maintenance of Oil Quantity

in Compressor"

*2HA-22, "Checking of Refrigerant

Leaks"

*3HA-25, "Electronic Refrigerant Leak

Detector"

*4HAC-299, "Component Function

Check"

WJIA1923E

Page 3306 of 5883

HA-24

< ON-VEHICLE MAINTENANCE >

FLUORESCENT LEAK DETECTOR

FLUORESCENT LEAK DETECTOR

Checking System for Leaks Using the Fluorescent Leak DetectorINFOID:0000000001396445

1. Check A/C system for leaks using the UV lamp and safety goggles J-42220 in a low sunlight area (area

without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a bright

green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain opening indi-

cates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner J-43872 to prevent future misdiag-

nosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and oils, may falsely trigger the leak detector. Make sure the surfaces to be checked are

clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionINFOID:0000000001396446

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool J-41459.

3. Connect the injector tool to the A/C low-pressure side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture’s operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system

connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

Page 3313 of 5883

REFRIGERATION SYSTEM

HA-31

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

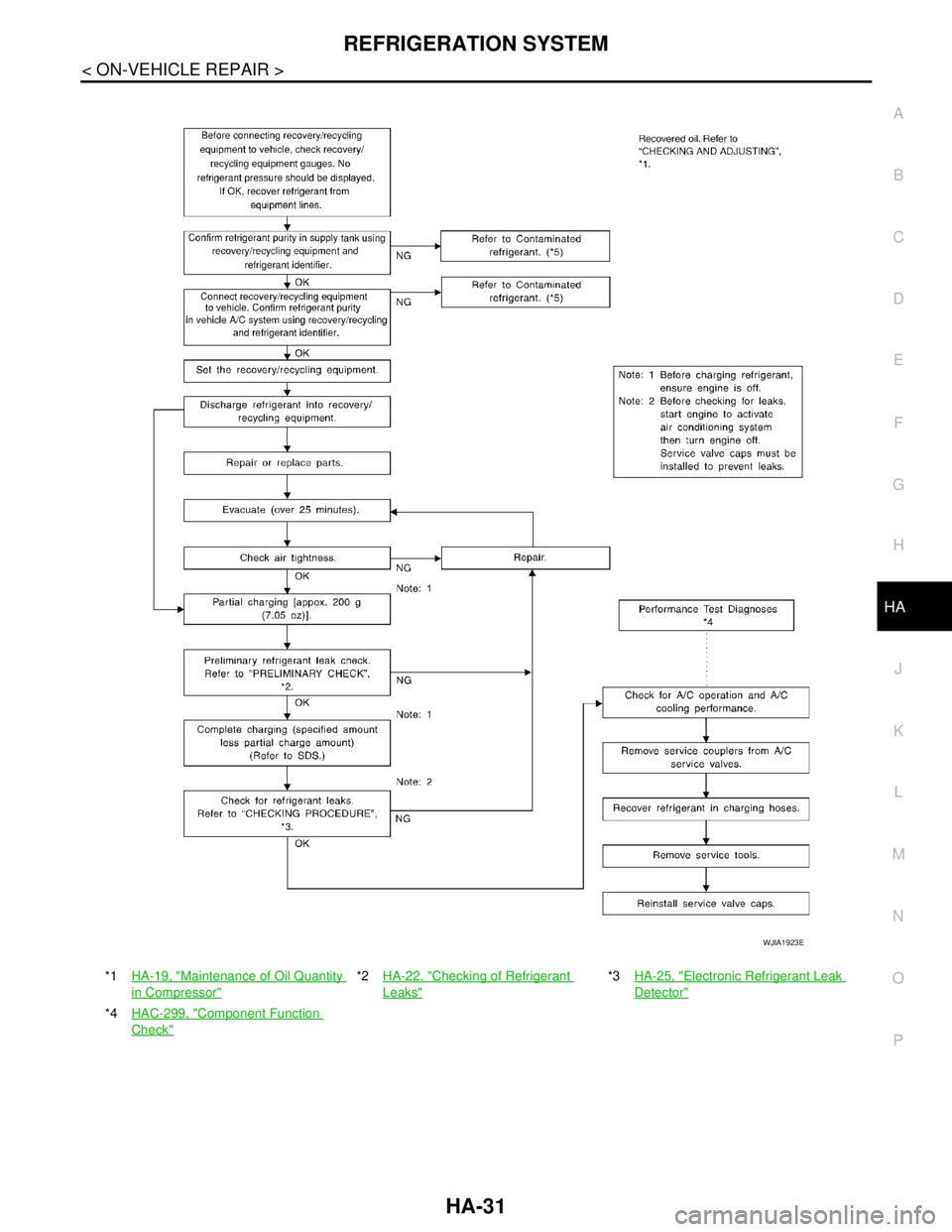

*1HA-19, "Maintenance of Oil Quantity

in Compressor"

*2HA-22, "Checking of Refrigerant

Leaks"

*3HA-25, "Electronic Refrigerant Leak

Detector"

*4HAC-299, "Component Function

Check"

WJIA1923E

Page 3315 of 5883

COMPRESSOR

HA-33

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

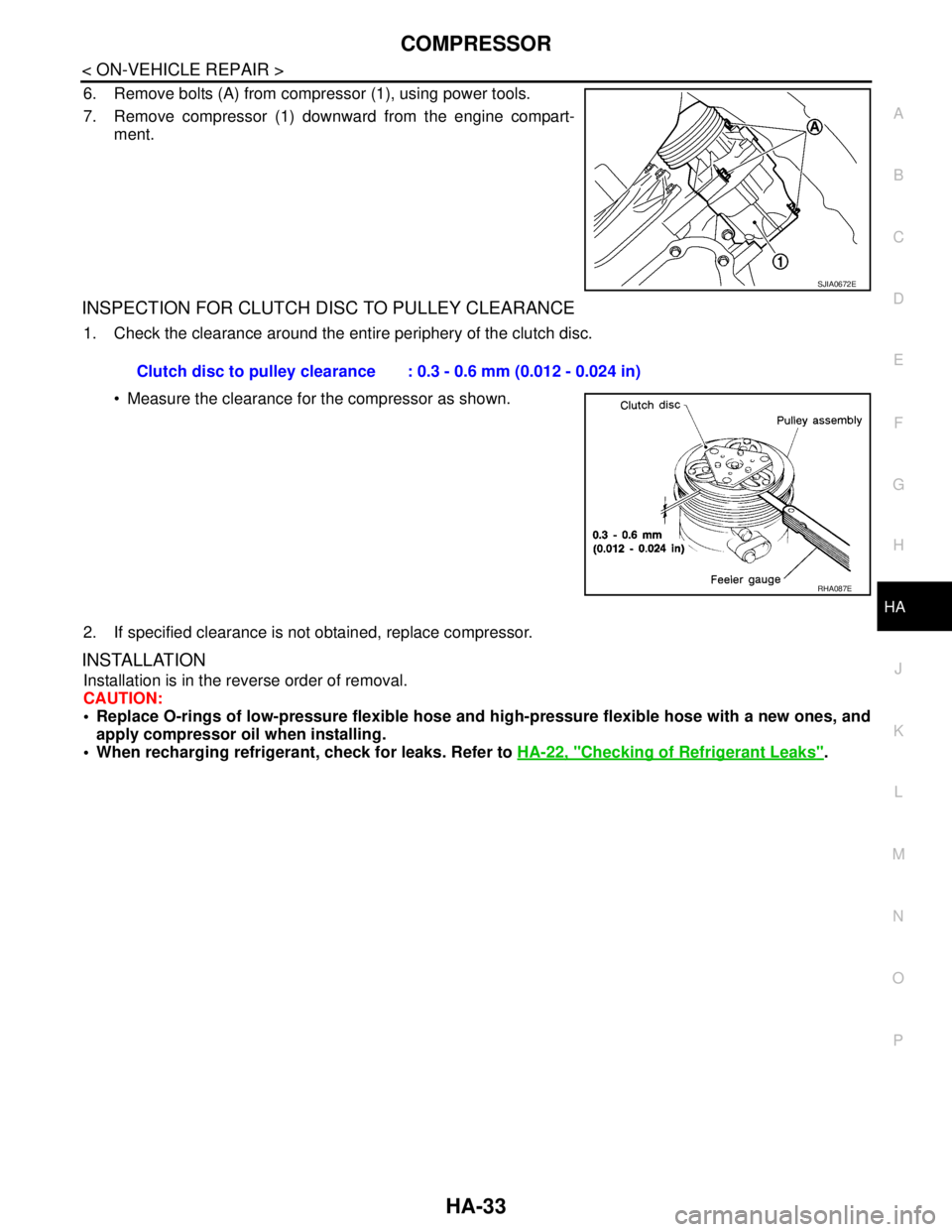

6. Remove bolts (A) from compressor (1), using power tools.

7. Remove compressor (1) downward from the engine compart-

ment.

INSPECTION FOR CLUTCH DISC TO PULLEY CLEARANCE

1. Check the clearance around the entire periphery of the clutch disc.

Measure the clearance for the compressor as shown.

2. If specified clearance is not obtained, replace compressor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of low-pressure flexible hose and high-pressure flexible hose with a new ones, and

apply compressor oil when installing.

When recharging refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

SJIA0672E

Clutch disc to pulley clearance : 0.3 - 0.6 mm (0.012 - 0.024 in)

RHA087E