checking oil NISSAN TIIDA 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3330 of 5883

HA-48

< ON-VEHICLE REPAIR >

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

Removal and Installation of Refrigerant Pressure Sensor - MR18DE, HR16DE

INFOID:0000000001527644

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

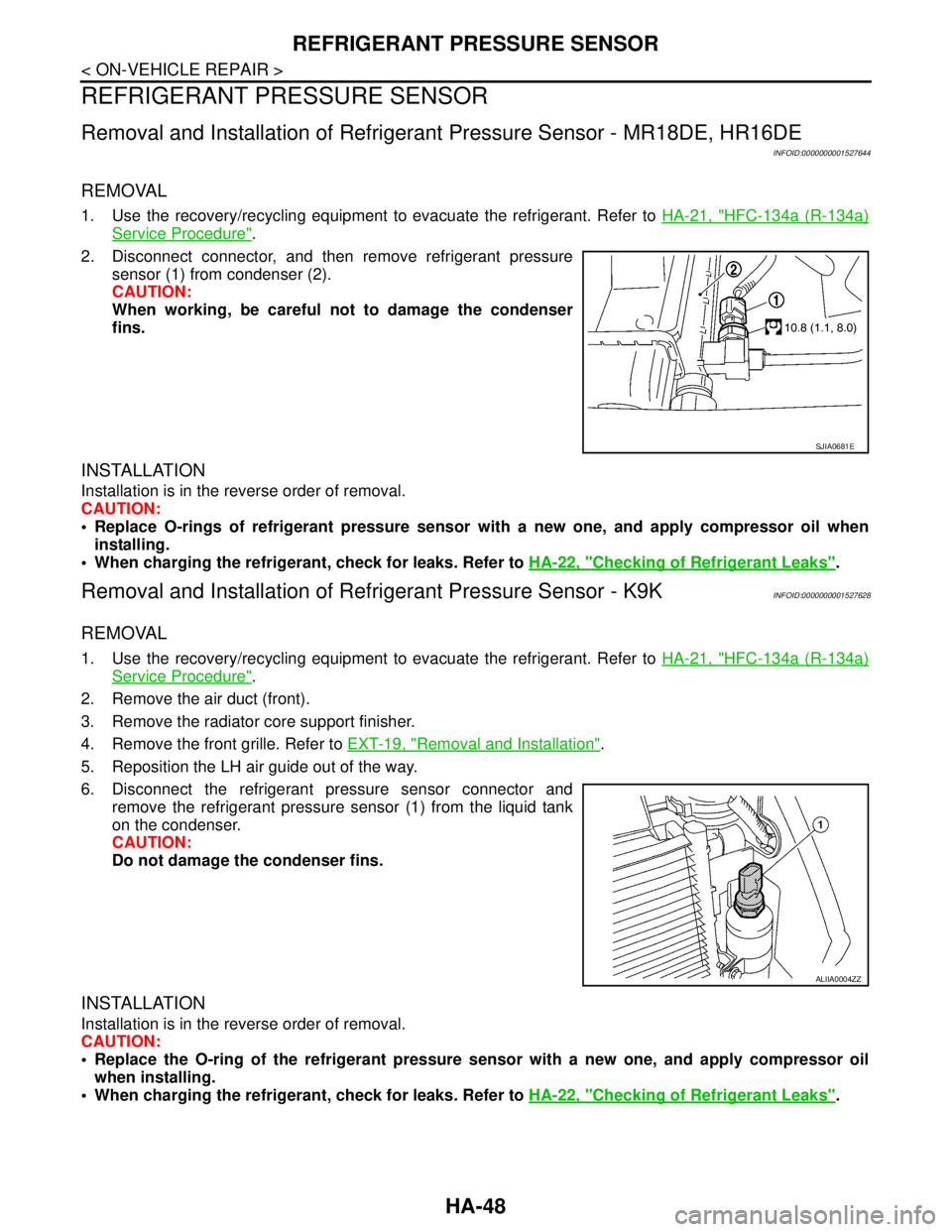

2. Disconnect connector, and then remove refrigerant pressure

sensor (1) from condenser (2).

CAUTION:

When working, be careful not to damage the condenser

fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of refrigerant pressure sensor with a new one, and apply compressor oil when

installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Removal and Installation of Refrigerant Pressure Sensor - K9KINFOID:0000000001527628

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove the air duct (front).

3. Remove the radiator core support finisher.

4. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

5. Reposition the LH air guide out of the way.

6. Disconnect the refrigerant pressure sensor connector and

remove the refrigerant pressure sensor (1) from the liquid tank

on the condenser.

CAUTION:

Do not damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the O-ring of the refrigerant pressure sensor with a new one, and apply compressor oil

when installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

SJIA0681E

ALIIA0004ZZ

Page 3331 of 5883

EXPANSION VALVE

HA-49

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

EXPANSION VALVE

Removal and Installation of Expansion Valve - MR18DE, HR16DE and K9K

INFOID:0000000001527645

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove cowl top cover. Refer to EXT-20, "

Removal and Installation".

3. Remove lower dash insulator.

4. Disconnect low-pressure flexible hose and high-pressure pipe from evaporator. Refer to HA-27, "

Compo-

nent".

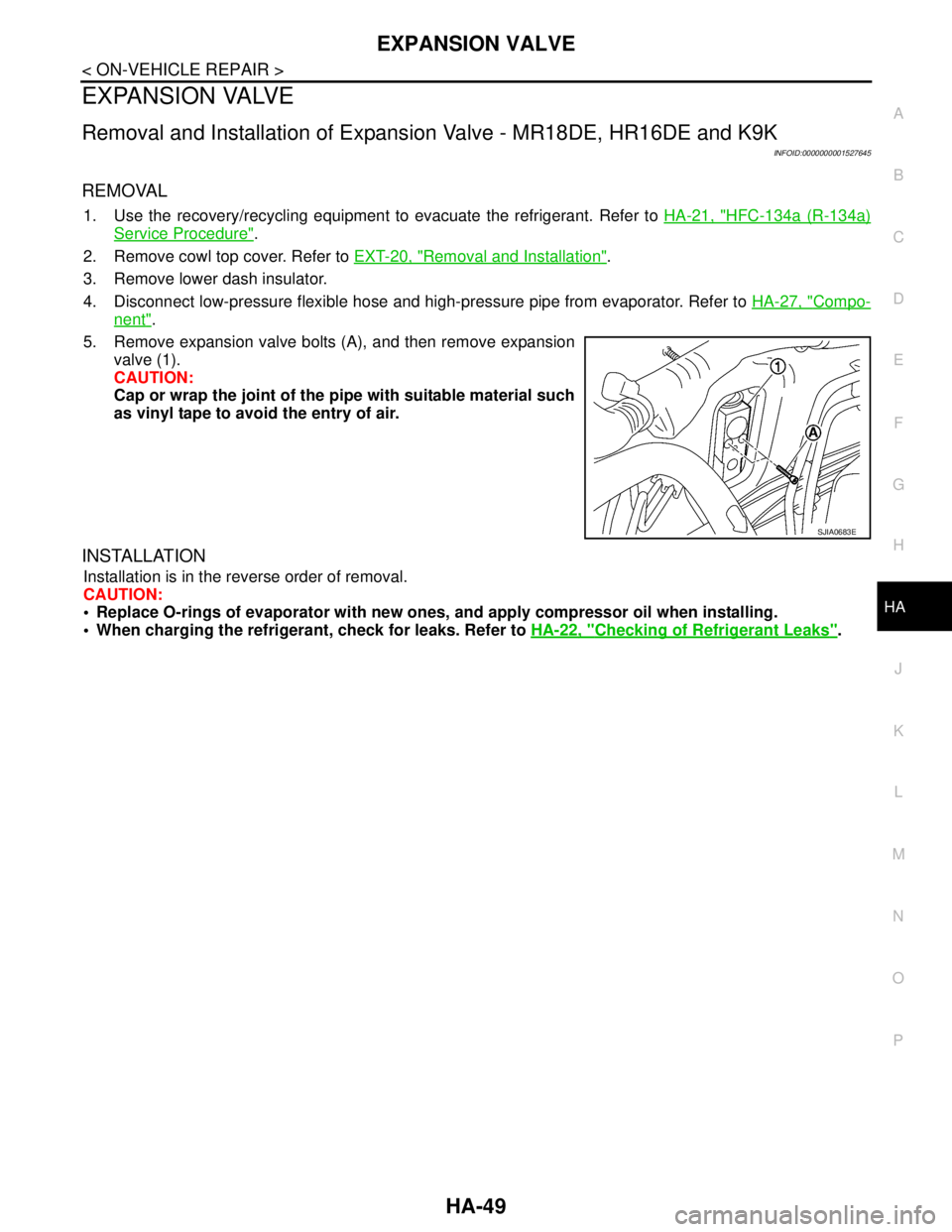

5. Remove expansion valve bolts (A), and then remove expansion

valve (1).

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings of evaporator with new ones, and apply compressor oil when installing.

When charging the refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

SJIA0683E

Page 3412 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual INSUFFICIENT COOLING

HAC-79

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indicat NISSAN TIIDA 2007 Service Workshop Manual INSUFFICIENT COOLING

HAC-79

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indicat](/img/5/57395/w960_57395-3411.png)

INSUFFICIENT COOLING

HAC-79

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low. There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

Liquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged. Replace liquid tank.

Check oil for contamination.

Temperature of expansion

valve inlet is extremely low as

compared with areas near liq-

uid tank.

Expansion valve inlet may be

frosted.

Temperature difference oc-

curs somewhere in high-pres-

sure side.High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched.Low refrigerant charge.

↓

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to XXXX CHECKING OF

REFRIG LEAKS .

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged. Remove foreign particles by

using compressed air.

Replace expansion valve.

Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet.Low-pressure pipe is clogged or

crushed. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Air flow volume is not enough or

is too low.Evaporator is frozen. Check thermo control amp.

Refer to XXXX MAG

CLUTCH CIR..

Replace compressor.

Repair evaporator fins.

Replace evaporator.

Refer to XXXX BLOWER

MOTOR CIR. .

AC353A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes be-

comes negative. Air conditioning system does

not function and does not cy-

clically cool the compart-

ment air.

The system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refrigerant. Drain water from refrigerant

or replace refrigerant.

Replace liquid tank.

AC354A

Page 3524 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual INSUFFICIENT COOLING

HAC-191

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes N NISSAN TIIDA 2007 Service Workshop Manual INSUFFICIENT COOLING

HAC-191

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes N](/img/5/57395/w960_57395-3523.png)

INSUFFICIENT COOLING

HAC-191

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low

and low-pressure side is too

high.High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

AC356A

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low. There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

Liquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged. Replace liquid tank.

Check oil for contamination.

Temperature of expansion

valve inlet is extremely low as

compared with areas near liq-

uid tank.

Expansion valve inlet may be

frosted.

Temperature difference oc-

curs somewhere in high-pres-

sure side.High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched.Low refrigerant charge.

↓

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to XXXX CHECKING OF

REFRIG LEAKS .

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged. Remove foreign particles by

using compressed air.

Replace expansion valve.

Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet.Low-pressure pipe is clogged or

crushed. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Air flow volume is not enough or

is too low.Evaporator is frozen. Check intake sensor circuit.

Refer to XXXX INTAKE

SENSOR CIR .

Replace compressor.

Repair evaporator fins.

Replace evaporator.

Refer to XXXX BLOWER

MOTOR CIR..

AC353A

Page 3638 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual INSUFFICIENT COOLING

HAC-305

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Neg NISSAN TIIDA 2007 Service Workshop Manual INSUFFICIENT COOLING

HAC-305

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Neg](/img/5/57395/w960_57395-3637.png)

INSUFFICIENT COOLING

HAC-305

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low

and low-pressure side is too

high.High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides.Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.Replace compressor.

AC356A

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low. There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

Liquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged. Replace liquid tank.

Check oil for contamination.

Temperature of expansion

valve inlet is extremely low as

compared with areas near liq-

uid tank.

Expansion valve inlet may be

frosted.

Temperature difference oc-

curs somewhere in high-pres-

sure side.High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched.Low refrigerant charge.

↓

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to HA-22, "

Checking of

Refrigerant Leaks".

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged. Remove foreign particles by

using compressed air.

Replace expansion valve.

Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet.Low-pressure pipe is clogged or

crushed. Check and repair malfunc-

tioning parts.

Check oil for contamination.

Air flow volume is not enough or

is too low.Evaporator is frozen. Check intake sensor circuit.

Refer to HAC-229, "

Intake

Door Motor Component

Function Check".

Replace compressor.

Repair evaporator fins.

Replace evaporator.

Refer to HAC-233, "

Front

Blower Motor Component

Function Check".

AC353A

Page 3643 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual HAC-310

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

NOISE

*1HA-32, "Removal and Installation of

Compressor - MR18DE" or HA-34,

"Removal and Installation of Com-

pressor - HR16DE" or HA-35, NISSAN TIIDA 2007 Service Workshop Manual HAC-310

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

NOISE

*1HA-32, "Removal and Installation of

Compressor - MR18DE" or HA-34,

"Removal and Installation of Com-

pressor - HR16DE" or HA-35,](/img/5/57395/w960_57395-3642.png)

HAC-310

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

NOISE

*1HA-32, "Removal and Installation of

Compressor - MR18DE" or HA-34,

"Removal and Installation of Com-

pressor - HR16DE" or HA-35, "Re-

moval and Installation of Compressor

- K9K"

*2HA-32, "Removal and Installation of

Compressor - MR18DE" or HA-34,

"Removal and Installation of Com-

pressor - HR16DE" or HA-35, "Re-

moval and Installation of Compressor

- K9K"

*3HA-19, "Maintenance of Oil Quantity

in Compressor"

*4HAC-202, "Operational Check"5.EM-15, "Checking" (HR16DE) or EM-

142, "Checking Drive Belts"

(HR18DE) or EM-263, "

Inspection

and Adjustment" (K9K)

Page 4213 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual LU-6

< ON-VEHICLE MAINTENANCE >[HR16DE]

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000001381527

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check NISSAN TIIDA 2007 Service Workshop Manual LU-6

< ON-VEHICLE MAINTENANCE >[HR16DE]

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000001381527

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check](/img/5/57395/w960_57395-4212.png)

LU-6

< ON-VEHICLE MAINTENANCE >[HR16DE]

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000001381527

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check the engine oil level. If engine is already started, stop

it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and make sure the engine oil level is within

the range (A) shown in the figure.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

Check engine oil for white turbidity or heavy contamination.

If engine oil becomes turbid and white, it is highly probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following area.

Oil pan (upper and lower)

Oil pan drain plug

Oil pressure switch

Oil level sensor

Oil filter

Intake valve timing control solenoid valve

Front cover

Mating surface between cylinder head and camshaft bracket

Mating surface between cylinder block and cylinder head

Mating surface between cylinder head and rocker cover

Crankshaft oil seals (front and rear)

Oil filter (for intake valve timing control)

OIL PRESSURE CHECK

WARNING:

Be careful not to get burned, as engine oil may be hot.

When checking engine oil pressure, shift position should be “Neutral”, and apply parking brake

securely.

1. Check engine oil level. Refer to LU-6, "

Inspection".

JPBIA0554ZZ

Page 4222 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual ENGINE OIL

LU-15

< ON-VEHICLE MAINTENANCE >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000001337827

ENGINE OIL LEVEL

NOTE:

Before starting engine, p NISSAN TIIDA 2007 Service Workshop Manual ENGINE OIL

LU-15

< ON-VEHICLE MAINTENANCE >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000001337827

ENGINE OIL LEVEL

NOTE:

Before starting engine, p](/img/5/57395/w960_57395-4221.png)

ENGINE OIL

LU-15

< ON-VEHICLE MAINTENANCE >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000001337827

ENGINE OIL LEVEL

NOTE:

Before starting engine, park vehicle on a level surface and check the engine oil level. If engine is already

started, stop it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and make sure the engine oil level is within

the range (A) as shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

Check engine oil for white turbidity or heavy contamination.

If engine oil becomes turbid and white, it is highly probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following areas:

Oil pan (upper and lower)

Oil pan drain plug

Oil pressure switch

Oil filter

Intake valve timing control solenoid valve

Front cover

Mating surface between cylinder block and cylinder head

Mating surface between cylinder head and rocker cover

Crankshaft oil seals (front and rear)

Oil filter (for intake valve timing control)

OIL PRESSURE CHECK

WARNING:

Be careful not to burn yourself, as engine oil may be hot.

For engine oil pressure check the transaxle should be in “Neutral position”, and apply the parking

brake securely.

1. Disconnect harness connector at oil pressure switch (1), and

remove oil pressure switch using a suitable tool.

Oil pan (lower) (2)

⇐ Front

WBIA0776E

PBIC3310E

Page 4233 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual LU-26

< ON-VEHICLE MAINTENANCE >[K9K]

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000001381537

OIL LEVEL AND MUDDINESS

Before starting the engine, check the oil level placing t NISSAN TIIDA 2007 Service Workshop Manual LU-26

< ON-VEHICLE MAINTENANCE >[K9K]

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000001381537

OIL LEVEL AND MUDDINESS

Before starting the engine, check the oil level placing t](/img/5/57395/w960_57395-4232.png)

LU-26

< ON-VEHICLE MAINTENANCE >[K9K]

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000001381537

OIL LEVEL AND MUDDINESS

Before starting the engine, check the oil level placing the vehicle

on a level surface. If the engine is already started, stop it and allow

10 minutes before checking.

Make sure the oil level is within the range shown.

If it is out of range, adjust it.

Check the oil for white turbidity or remarkable contamination.

If the oil becomes turbid and white, it is highly probable that it is

contaminated with coolant. Find the cause and repair.

OIL LEAKAGE

Check for oil leakage around the following area.

Oil pan

Oil pan drain plug

Oil pressure switch

Oil filter bracket

Vacuum pump

Oil pump housing

Mating surface between cylinder block and cylinder head

Mating surface between cylinder head and rocker cover

Oil cooler

Crankshaft oil seals

OIL PRESSURE CHECK

WARNING:

Be careful not to burn yourself, as the engine oil is hot.

Oil pressure check should be done in Neutral “N” position.

1. Check the engine oil level.

2. Remove engine undercover using power tool.

3. Disconnect the electrical connector (A) and remove the oil pres-

sure switch (1) to connect the oil pressure gauge [SST:

KV113E0020 (Mot. 836-05)].

4. After warming up the engine, make sure oil pressure corre-

sponding to the engine speed is produced.

5. After checking, install the oil pressure switch (1) as follows.

a. Remove old sealant adhering to the oil pressure switch (1) and

engine.

b. Apply thread sealant.

Use Genuine Liquid Gasket or equivalent.

6. Start engine and check for oil leakage.

MBIB0548E

Idle speed : Refer to LU-33, "EngineOilPressure".

3000 rpm : Refer to LU-33, "

EngineOilPressure".

Oil pressure switch:

: 25 N·m (2.55 kg-m, 18.4 ft-lb)

ALBIA0418ZZ

Page 4241 of 5883

MA-1

MAINTENANCE

C

D

E

F

G

H

I

J

K

L

MB

MA

SECTION MA

N

OA

CONTENTS

MAINTENANCE

PRECAUTION ...............................................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

PREPARATION ............................................4

PREPARATION ...................................................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

Pre-Delivery Inspection Item .....................................5

ON-VEHICLE MAINTENANCE .....................6

GENERAL MAINTENANCE ................................6

General Maintenance ................................................6

PERIODIC MAINTENANCE ................................7

Periodic Maintenance ................................................7

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

19

Fluids and Lubricants ..............................................19

SAE Viscosity Number ............................................20

Engine Coolant Mixture Ratio .................................21

ENGINE MAINTENANCE (HR16DE) .................22

DRIVE BELTS ...........................................................22

DRIVE BELTS : Checking .......................................22

DRIVE BELTS : Tension Adjustment ......................22

ENGINE COOLANT ...................................................23

ENGINE COOLANT : Inspection .............................23

ENGINE COOLANT : Changing Engine Coolant ....23

RADIATOR ................................................................25

RADIATOR : Checking Radiator .............................25

FUEL LINES ..............................................................25

FUEL LINES : Inspection ........................................25

AIR CLEANER FILTER .............................................25

AIR CLEANER FILTER : Removal and Installation

....

26

ENGINE OIL ...............................................................26

ENGINE OIL : Draining ............................................27

ENGINE OIL : Refilling ............................................27

OIL FILTER ................................................................27

OIL FILTER : Removal and Installation ...................27

OIL FILTER : Inspection ..........................................28

SPARK PLUG ............................................................28

SPARK PLUG : Removal and Installation ...............28

SPARK PLUG : Inspection ......................................29

EVAP VAPOR LINES ................................................30

EVAP VAPOR LINES : Inspection ...........................30

ENGINE MAINTENANCE (MR18DE) ...............31

DRIVE BELTS ............................................................31

DRIVE BELTS : Component ....................................31

DRIVE BELTS : Checking Drive Belts .....................31

DRIVE BELTS : Tension Adjustment ......................31

ENGINE COOLANT ...................................................31

ENGINE COOLANT : Inspection .............................31

ENGINE COOLANT : Changing Engine Coolant ....32

RADIATOR .................................................................33

RADIATOR : Checking Radiator Cap ......................34

RADIATOR : Checking Radiator .............................34

FUEL LINES ...............................................................34

FUEL LINES : Inspection .........................................35

AIR CLEANER FILTER .............................................35

AIR CLEANER FILTER : Removal and Installation

....

35

ENGINE OIL ...............................................................36

ENGINE OIL : Inspection .........................................36

ENGINE OIL : Changing Engine Oil ........................37