lock NISSAN TIIDA 2007 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 527 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CO-46

< ON-VEHICLE REPAIR >[MR18DE]

THERMOSTAT

If out of the specification, replace thermostat.

INSTALLATION

Installation is in the reverse order of removal.

Thermostat

CAUTION:

Replace the rubber NISSAN TIIDA 2007 Service Manual PDF CO-46

< ON-VEHICLE REPAIR >[MR18DE]

THERMOSTAT

If out of the specification, replace thermostat.

INSTALLATION

Installation is in the reverse order of removal.

Thermostat

CAUTION:

Replace the rubber](/img/5/57395/w960_57395-526.png)

CO-46

< ON-VEHICLE REPAIR >[MR18DE]

THERMOSTAT

If out of the specification, replace thermostat.

INSTALLATION

Installation is in the reverse order of removal.

Thermostat

CAUTION:

Replace the rubber ring with a new one.

Install thermostat while making rubber ring (1) groove fit to thermo-

stat flange (A) around the whole circumference.

Install thermostat (1) into the thermostat housing (2) with jiggle

valve (A) facing upwards.

Thermostat Housing

CAUTION:

Replace the rubber ring with a new one.

Securely insert the rubber ring into the mating groove of thermostat housing and install it.

Install the thermostat housing to the cylinder block without displacing the gasket from the gasket position.

INSPECTION AFTER INSTALLATION

Check for leaks of engine coolant. Refer to CO-35, "Inspection".

Start and warm up the engine. Visually check for engine coolant leaks.

ItemsThermostat

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Maximum valve lift 8 mm/ 95°C (0.315 in/ 203°F)

Valve closing temperature 77°C (171°F)

PBIC3315J

PBIC3548J

Page 535 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CO-54

< SYMPTOM DIAGNOSIS >[K9K]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for ex-

NISSAN TIIDA 2007 Service Manual PDF CO-54

< SYMPTOM DIAGNOSIS >[K9K]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for ex-](/img/5/57395/w960_57395-534.png)

CO-54

< SYMPTOM DIAGNOSIS >[K9K]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator —

Blocked condenser

—

Installed large fog lamp Symptom Check items

Page 536 of 5883

![NISSAN TIIDA 2007 Service Manual PDF PRECAUTIONS

CO-55

< PRECAUTION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00000000 NISSAN TIIDA 2007 Service Manual PDF PRECAUTIONS

CO-55

< PRECAUTION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00000000](/img/5/57395/w960_57395-535.png)

PRECAUTIONS

CO-55

< PRECAUTION >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001534592

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001534593

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precaution for Liquid GasketINFOID:0000000001534594

REMOVAL OF LIQUID GASKET SEALING

After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

Page 539 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CO-58

< ON-VEHICLE MAINTENANCE >[K9K]

ENGINE COOLANT

ON-VEHICLE MAINTENANCE

ENGINE COOLANT

InspectionINFOID:0000000001381585

LEVEL CHECK

Check if the reservoir tank engine coolant level is within th NISSAN TIIDA 2007 Service Manual PDF CO-58

< ON-VEHICLE MAINTENANCE >[K9K]

ENGINE COOLANT

ON-VEHICLE MAINTENANCE

ENGINE COOLANT

InspectionINFOID:0000000001381585

LEVEL CHECK

Check if the reservoir tank engine coolant level is within th](/img/5/57395/w960_57395-538.png)

CO-58

< ON-VEHICLE MAINTENANCE >[K9K]

ENGINE COOLANT

ON-VEHICLE MAINTENANCE

ENGINE COOLANT

InspectionINFOID:0000000001381585

LEVEL CHECK

Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” range when engine is cool.

Adjust the engine coolant level as necessary.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leaks, apply pressure to the cooling system using suit-

able tool.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

DrainingINFOID:0000000001381586

WARNING:

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

Be careful not to allow engine coolant to contact drive belt.

1. Remove engine undercover using power tool.

2. Disconnect radiator hose (lower) from radiator and remove reservoir tank cap.

When draining all of engine coolant in the system, open water drain plug on cylinder block. Refer

to EM-314, "

Exploded View".

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belt.

3. Remove air relief plug from water outlet. Refer to EM-302, "

Exploded View".

4. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

5. Check drained coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush engine cooling system. Refer to CO-59, "

Flushing".

RefillingINFOID:0000000001381587

Before starting work, turn off the automatic air conditioner and the blower motor.

1. Install reservoir tank if removed, lower radiator hose and air relief plug.

If water drain plug on cylinder block is removed, install and tighten it. Refer to EM-314,

"Exploded View".

2. Fill reservoir tank slowly with coolant until coolant spills from the air relief hole.

SMA412B

Testing pressure

: 157 kPa (1.6 kg/cm2, 23 psi)

WBIA0568E

Page 540 of 5883

![NISSAN TIIDA 2007 Service Manual PDF ENGINE COOLANT

CO-59

< ON-VEHICLE MAINTENANCE >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Put a cloth under the air relief plug to prevent engine coolant from dampening the crankshaft

position sensor.

Po NISSAN TIIDA 2007 Service Manual PDF ENGINE COOLANT

CO-59

< ON-VEHICLE MAINTENANCE >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Put a cloth under the air relief plug to prevent engine coolant from dampening the crankshaft

position sensor.

Po](/img/5/57395/w960_57395-539.png)

ENGINE COOLANT

CO-59

< ON-VEHICLE MAINTENANCE >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Put a cloth under the air relief plug to prevent engine coolant from dampening the crankshaft

position sensor.

Pour coolant to the MAX level line of the reservoir tank at

a rate of 2 liter (1-3/4 lamp qt.)/min. or lower.

3. Close the air relief plug.

CAUTION:

If the filling rate is too fast, this could lead to air being

mixed in the coolant. Be sure to fill the coolant slowly

according to the rate indicated above.

Use Insane Genuine Engine Coolant or equivalent mixed

with water (distilled or demineralized). Refer to MA-21,

"Engine Coolant Mixture Ratio".

4. Start engine without closing reservoir tank cap and keep engine racing at 1,500 rpm for about 2-3 minutes.

If necessary, pour engine coolant up to MAX level.

If coolant overflows reservoir tank hole, install filler cap.

Watch engine coolant temperature gauge so as not overheat the engine.

WARNING:

Be careful not to be scaled with hot engine coolant or vacuum pump when operating.

Radiator fan blade can start at any time and cause personal injuries.

5. Turn off the engine and loosen air relief plug until coolant spills from air relief hole.

6. Close the air relief plug and run the engine at 2,000 rpm until the upper hose becomes hot and radiator

fan operates. Leave the engine running approximately 5 minutes at idle speed and check for sound of

coolant flow while running engine from idle up to 3,000 rpm.

Sound may be noticeable at heater water cock.

7. If sound is heard, bleed air from cooling system by repeating steps 4 to 6 until coolant level no longer

drops.

Check the radiator lower hose for any signs of leakage.

8. Turn off the engine and let it cool down.

Cool down using a fan to reduce the time.

9. After cooling period, loosen the air relief plug and check if coolant spills from the air relief hole. if not,

remove the air relief plug until the coolant spills, and then close the relief air plug. Bleed air from cooling

system by repeating steps 6 to 10 until the coolant spills immediately.

10. Check the engine coolant level when engine is cool and refill to MAX level line if the level is lower.

Clean excess coolant from engine.

11. Check that the reservoir tank cap is tightened.

FlushingINFOID:0000000001381588

1. Install reservoir tank if removed.

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-314, "

Exploded

View".

2. Fill reservoir tank with water until water spills from the air relief hole, then close air relief plug. Reinstall

reservoir tank cap.

3. Run engine and warm it up to normal operating temperature.

4. Rev engine two or three times under no-load.

5. Stop engine and wait until it cools down.

6. Drain water.

7. Repeat steps 1 through 6 until clear water begins to drain from radiator.

8. Blow compressed air into cooling circuit through the reservoir tank valve hole to drain all the water.

JPBIA0306ZZ

Engine coolant capacity

(With reservoir tank at MAX): Refer to MA-19, "Fluids and Lubricants".

Reservoir tank capacity : Refer to MA-19, "

Fluids and Lubricants".

Page 546 of 5883

![NISSAN TIIDA 2007 Service Manual PDF COOLING FAN

CO-65

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Disassembly and AssemblyINFOID:0000000001381596

DISASSEMBLY

1. Remove cooling fan control module from fan shroud.

CAUTION:

NISSAN TIIDA 2007 Service Manual PDF COOLING FAN

CO-65

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Disassembly and AssemblyINFOID:0000000001381596

DISASSEMBLY

1. Remove cooling fan control module from fan shroud.

CAUTION:](/img/5/57395/w960_57395-545.png)

COOLING FAN

CO-65

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Disassembly and AssemblyINFOID:0000000001381596

DISASSEMBLY

1. Remove cooling fan control module from fan shroud.

CAUTION:

Handle carefully to avoid dropping and shocks.

2. Remove cooling fan mounting nut, and then remove the cooling fan.

CAUTION:

Reverse nut is used for the fan attachment. When removing or attaching, turn the nut the opposite

direction from a normal nut.

3. Remove fan motor.

ASSEMBLY

Assembly is in the reverse order of disassembly.

Apply thread locking sealant on fan motor shaft.

InspectionINFOID:0000000001381597

INSPECTION AFTER DISASSEMBLY

Cooling Fan

Inspect cooling fan for crack or unusual bend.

If anything is found, replace cooling fan.

Page 547 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CO-66

< ON-VEHICLE REPAIR >[K9K]

WATER PUMP

WATER PUMP

Exploded ViewINFOID:0000000001381598

Removal and InstallationINFOID:0000000001381599

WARNING:

Never remove the radiator cap when the engine is ho NISSAN TIIDA 2007 Service Manual PDF CO-66

< ON-VEHICLE REPAIR >[K9K]

WATER PUMP

WATER PUMP

Exploded ViewINFOID:0000000001381598

Removal and InstallationINFOID:0000000001381599

WARNING:

Never remove the radiator cap when the engine is ho](/img/5/57395/w960_57395-546.png)

CO-66

< ON-VEHICLE REPAIR >[K9K]

WATER PUMP

WATER PUMP

Exploded ViewINFOID:0000000001381598

Removal and InstallationINFOID:0000000001381599

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator.

REMOVAL

1. Remove the following parts.

Battery ground cable

Engine undercover

RH front wheel

2. Remove fender protector RH. Refer to EXT-22, "

Removal and Installation".

3. Drain engine coolant. Refer to CO-58, "

Draining".

CAUTION:

Perform when engine is cold.

4. Remove drive belt. Refer to EM-263, "

Removal and Installation".

5. Remove timing belt and inner cover. Refer to EM-291, "

Removal and Installation".

6. Remove the water pump.

Coolant will leak from the cylinder block, so have a receptacle ready below.

CAUTION:

Handle the water pump vane so that it does not contact any other parts.

Water pump cannot be disassembled and should be replaced as a unit.

INSTALLATION

Installation is in the reverse order of removal.

InspectionINFOID:0000000001381600

INSPECTION AFTER REMOVAL

1. Water pump 2. Gasket 3. Cylinder block

E1BIA0026GB

Page 549 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CO-68

< ON-VEHICLE REPAIR >[K9K]

WATER OUTLET AND THERMOSTAT ASSEMBLY

WATER OUTLET AND THERMOSTAT ASSEMBLY

Exploded ViewINFOID:0000000001381601

Removal and InstallationINFOID:0000000001381602

REMOVAL

NISSAN TIIDA 2007 Service Manual PDF CO-68

< ON-VEHICLE REPAIR >[K9K]

WATER OUTLET AND THERMOSTAT ASSEMBLY

WATER OUTLET AND THERMOSTAT ASSEMBLY

Exploded ViewINFOID:0000000001381601

Removal and InstallationINFOID:0000000001381602

REMOVAL](/img/5/57395/w960_57395-548.png)

CO-68

< ON-VEHICLE REPAIR >[K9K]

WATER OUTLET AND THERMOSTAT ASSEMBLY

WATER OUTLET AND THERMOSTAT ASSEMBLY

Exploded ViewINFOID:0000000001381601

Removal and InstallationINFOID:0000000001381602

REMOVAL

1. Remove battery.

2. Remove engine undercover using power tool.

3. Drain engine coolant. Refer to CO-58, "

Draining".

CAUTION:

Perform when engine is cold.

4. Remove engine cover.

5. Remove air cleaner and air duct assembly. Refer to EM-269, "

Removal and Installation".

6. Remove rear engine slinger. Refer to EM-314, "

Exploded View".

7. Remove vacuum hose.

8. Remove vacuum pump. Refer to EM-280, "

Removal and Installation".

9. Remove radiator upper hose. Refer to CO-62, "

Exploded View".

10. Remove heater hose.

11. Disconnect reservoir tank hose.

12. Remove water outlet.

INSTALLATION

Installation is in the reverse order of removal.

InspectionINFOID:0000000001381603

INSPECTION AFTER REMOVAL

1. O-ring 2. EGR cooler cover 3. Clamp

4. Water pipe 5. Heater hose 6. Clamp

7. Engine coolant temperature sensor 8. O-ring 9. Lock plate

10. Clamp 11. Gasket 12. Water outlet and thermostat assembly

13. Air relief plug

A. To EGR volume control valve housing B. To radiator hose (upper) C. To heater core

E1BIA0027GB

Page 563 of 5883

DEF-12

< COMPONENT DIAGNOSIS >

REAR WINDOW DEFOGGER RELAY

REAR WINDOW DEFOGGER RELAY

DescriptionINFOID:0000000001697551

Power is supplied to the rear window defogger with BCM control.

Component Function CheckINFOID:0000000001697552

1. CHECK REAR WINDOW DEFOGGER RELAY POWER SUPPLY CIRCUIT

Check that an operation noise of rear window defogger relay [located in fuse block (J/B)] can be heard when

turning the rear window defogger switch ON.

Is the inspection result normal?

YES >> Rear window defogger relay power supply circuit is OK.

NO >> Refer to DEF-12, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001697553

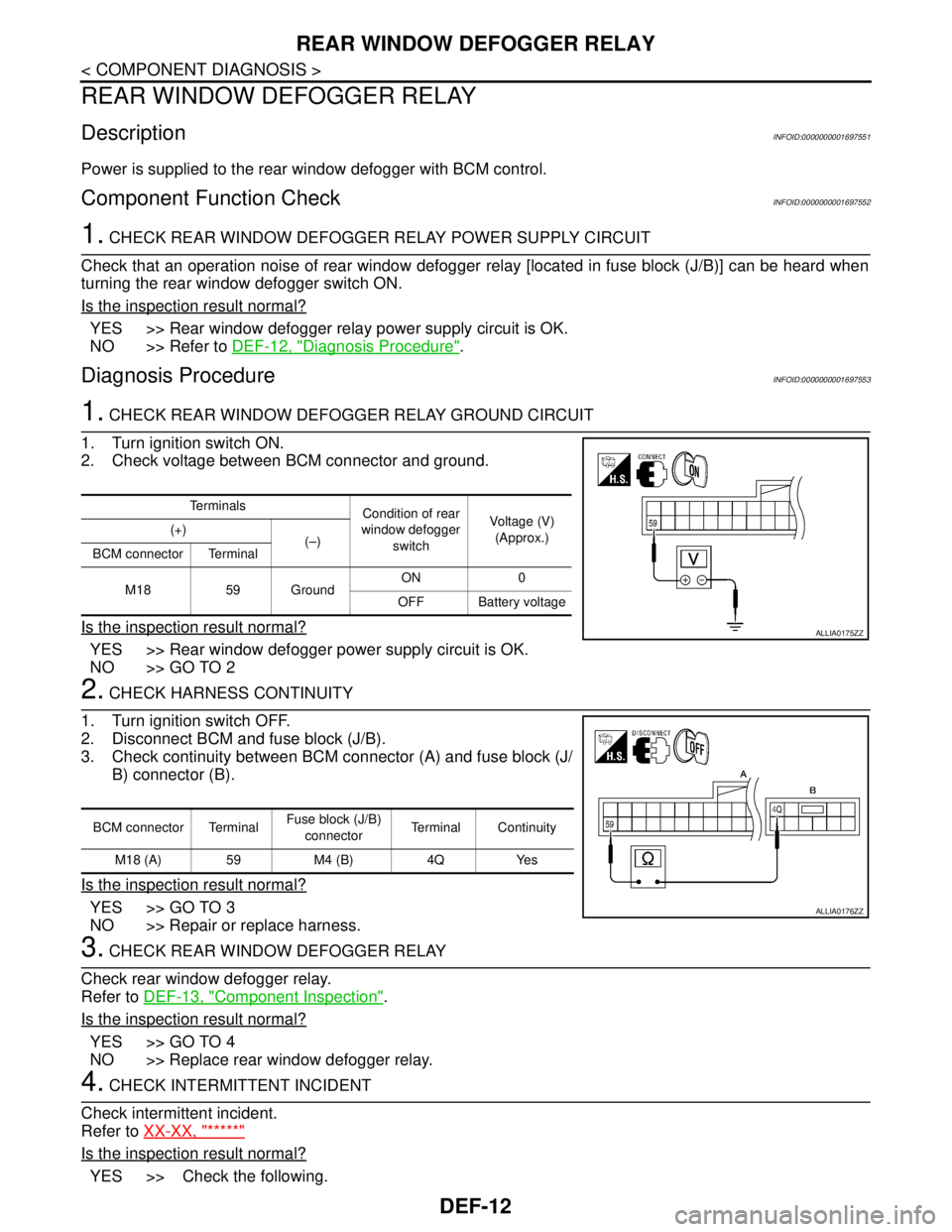

1. CHECK REAR WINDOW DEFOGGER RELAY GROUND CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between BCM connector and ground.

Is the inspection result normal?

YES >> Rear window defogger power supply circuit is OK.

NO >> GO TO 2

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM and fuse block (J/B).

3. Check continuity between BCM connector (A) and fuse block (J/

B) connector (B).

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK REAR WINDOW DEFOGGER RELAY

Check rear window defogger relay.

Refer to DEF-13, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4

NO >> Replace rear window defogger relay.

4. CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to XX-XX, "*****"

Is the inspection result normal?

YES >> Check the following.

Te r m i n a l s

Condition of rear

window defogger

switchVoltage (V)

(Approx.) (+)

(–)

BCM connector Terminal

M18 59 GroundON 0

OFF Battery voltage

ALLIA0175ZZ

BCM connector TerminalFuse block (J/B)

connectorTerminal Continuity

M18 (A) 59 M4 (B) 4Q Yes

ALLIA0176ZZ

Page 564 of 5883

REAR WINDOW DEFOGGER RELAY

DEF-13

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

DEF

N

O

P

Battery power supply circuit.

Fuse block (J/B).

NO >> Repair or replace the malfunctioning parts.

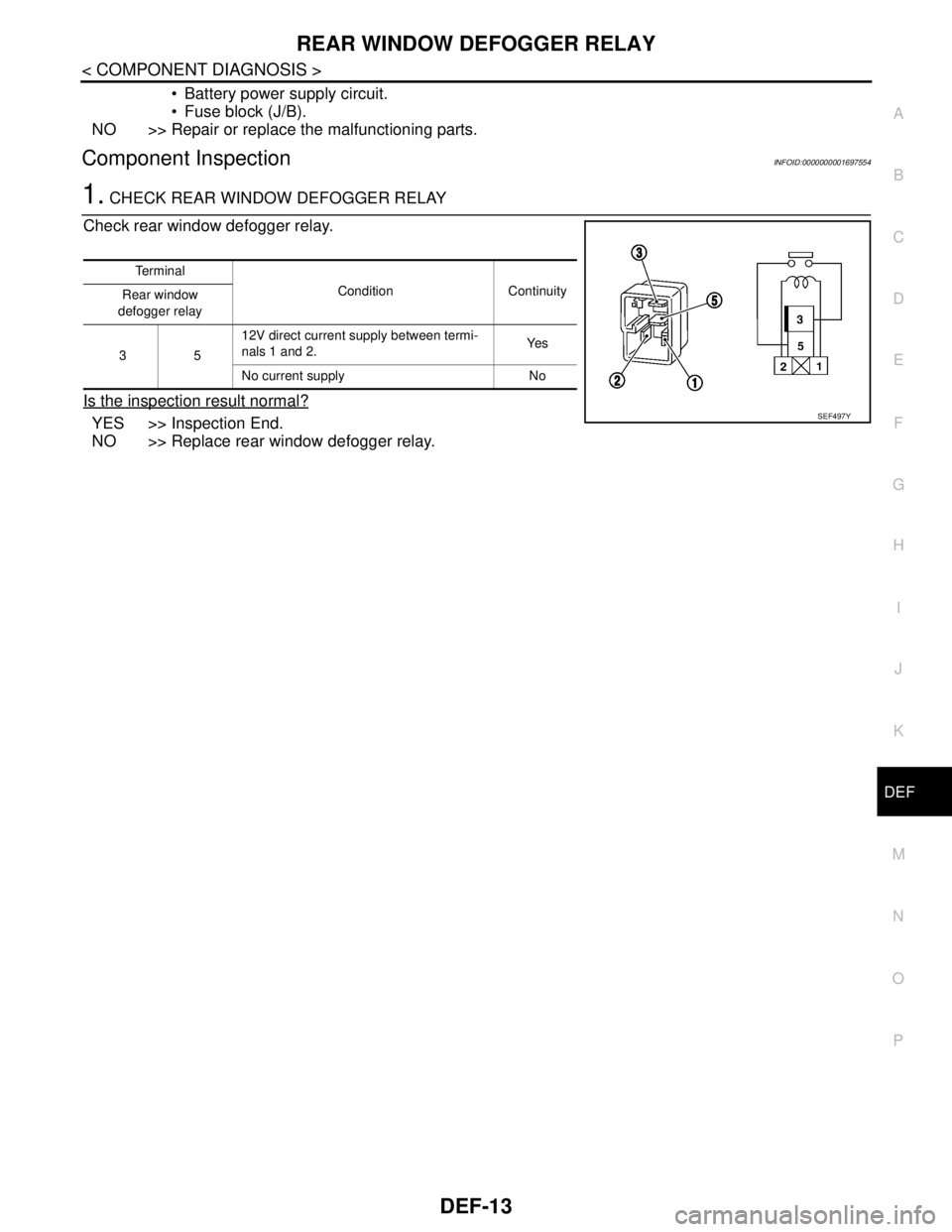

Component InspectionINFOID:0000000001697554

1. CHECK REAR WINDOW DEFOGGER RELAY

Check rear window defogger relay.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace rear window defogger relay.

Te r m i n a l

Condition Continuity

Rear window

defogger relay

3512V direct current supply between termi-

nals 1 and 2.Ye s

No current supply No

SEF497Y