lock NISSAN TIIDA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 223 of 5883

![NISSAN TIIDA 2007 Service Owners Guide BRAKE MASTER CYLINDER

BR-31

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Using a pin-punch [commercial service tool: diameter approx. 4

mm (0.16 in)], remove pin from reservoir tank NISSAN TIIDA 2007 Service Owners Guide BRAKE MASTER CYLINDER

BR-31

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Using a pin-punch [commercial service tool: diameter approx. 4

mm (0.16 in)], remove pin from reservoir tank](/img/5/57395/w960_57395-222.png)

BRAKE MASTER CYLINDER

BR-31

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Using a pin-punch [commercial service tool: diameter approx. 4

mm (0.16 in)], remove pin from reservoir tank.

3. Remove master cylinder assembly from vise.

4. Remove reservoir tank and grommet from cylinder body.

5. While pushing primary piston, remove piston stopper through

secondary tank boss hole in the cylinder body.

6. Remove snap ring with pushing primary piston.

CAUTION:

Be careful not to pop out piston.

7. Holding rod of primary piston, remove primary piston assembly,

plate and guide assembly by pulling straight to prevent piston

cup from being caught by the inner wall of cylinder.

8. Remove plate and guide assembly from primary piston.

CAUTION:

Be careful not to damage rod from the inner wall of plate.

9. Tap flange using a soft block such as wood, and carefully pull

secondary piston assembly straight out to prevent cylinder inner

wall from being damaged.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for damage, wear, corrosion, and pin holes. Replace cylinder body if neces-

sary.

ASSEMBLY

CAUTION:

Never use mineral oils such as kerosene or gasoline during the cleaning and assembly processes.

Make sure that there is no foreign material such as dirt and dust on the inner wall of cylinder, piston,

and piston cup. Be careful not to damage parts with a service tool when assembling.

Do not drop parts. If a part is dropped, do not use it.

WFIA0515E

WFIA0516E

BRA0561DWFIA0517E

WFIA0518E

Page 226 of 5883

BR-34

< DISASSEMBLY AND ASSEMBLY >

FRONT DISC BRAKE

FRONT DISC BRAKE

Disassembly and Assembly of Brake Caliper AssemblyINFOID:0000000001717023

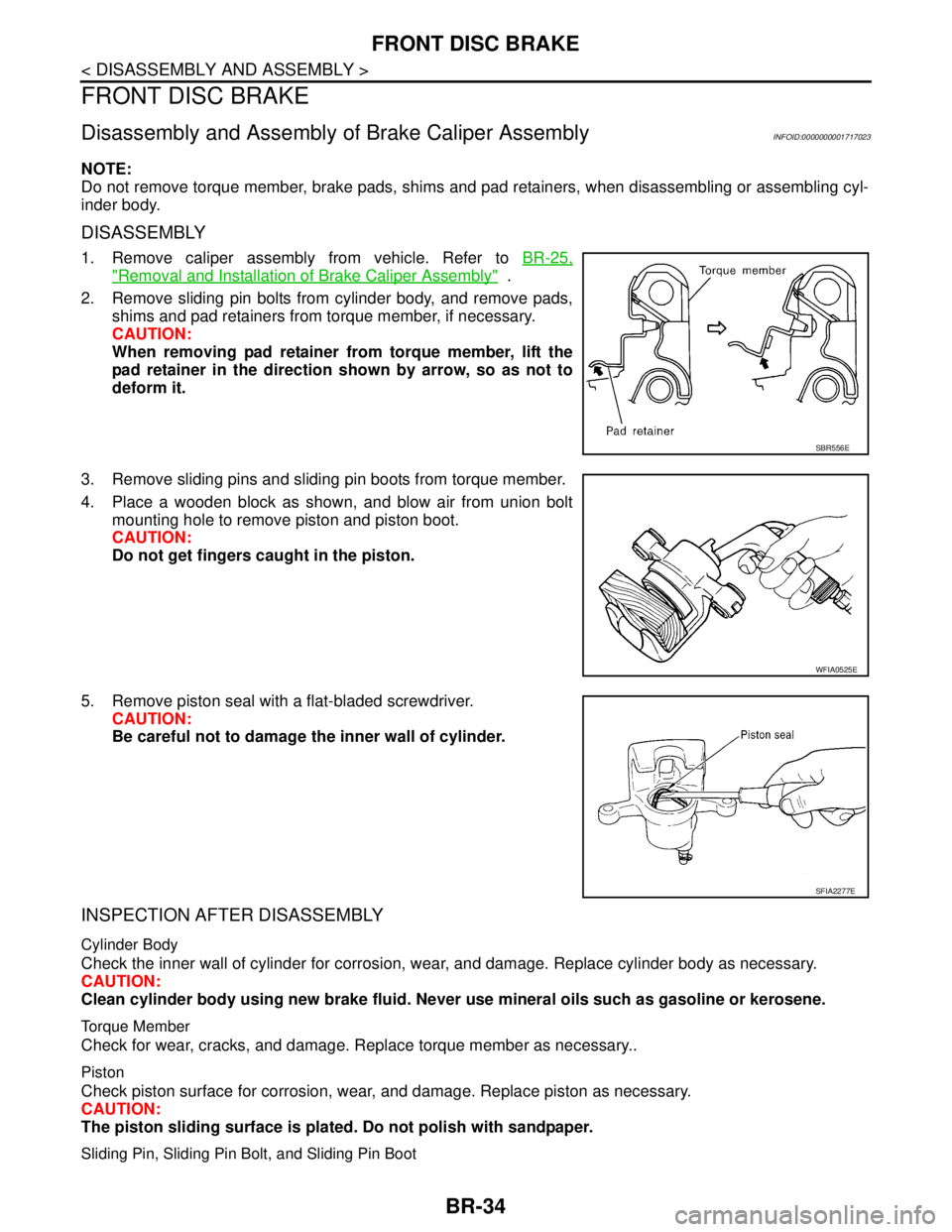

NOTE:

Do not remove torque member, brake pads, shims and pad retainers, when disassembling or assembling cyl-

inder body.

DISASSEMBLY

1. Remove caliper assembly from vehicle. Refer to BR-25,

"Removal and Installation of Brake Caliper Assembly" .

2. Remove sliding pin bolts from cylinder body, and remove pads,

shims and pad retainers from torque member, if necessary.

CAUTION:

When removing pad retainer from torque member, lift the

pad retainer in the direction shown by arrow, so as not to

deform it.

3. Remove sliding pins and sliding pin boots from torque member.

4. Place a wooden block as shown, and blow air from union bolt

mounting hole to remove piston and piston boot.

CAUTION:

Do not get fingers caught in the piston.

5. Remove piston seal with a flat-bladed screwdriver.

CAUTION:

Be careful not to damage the inner wall of cylinder.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for corrosion, wear, and damage. Replace cylinder body as necessary.

CAUTION:

Clean cylinder body using new brake fluid. Never use mineral oils such as gasoline or kerosene.

Torque Member

Check for wear, cracks, and damage. Replace torque member as necessary..

Piston

Check piston surface for corrosion, wear, and damage. Replace piston as necessary.

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Sliding Pin, Sliding Pin Bolt, and Sliding Pin Boot

SBR556E

WFIA0525E

SFIA2277E

Page 229 of 5883

REAR DISC BRAKE

BR-37

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

REAR DISC BRAKE

Disassembly and AssemblyINFOID:0000000001724669

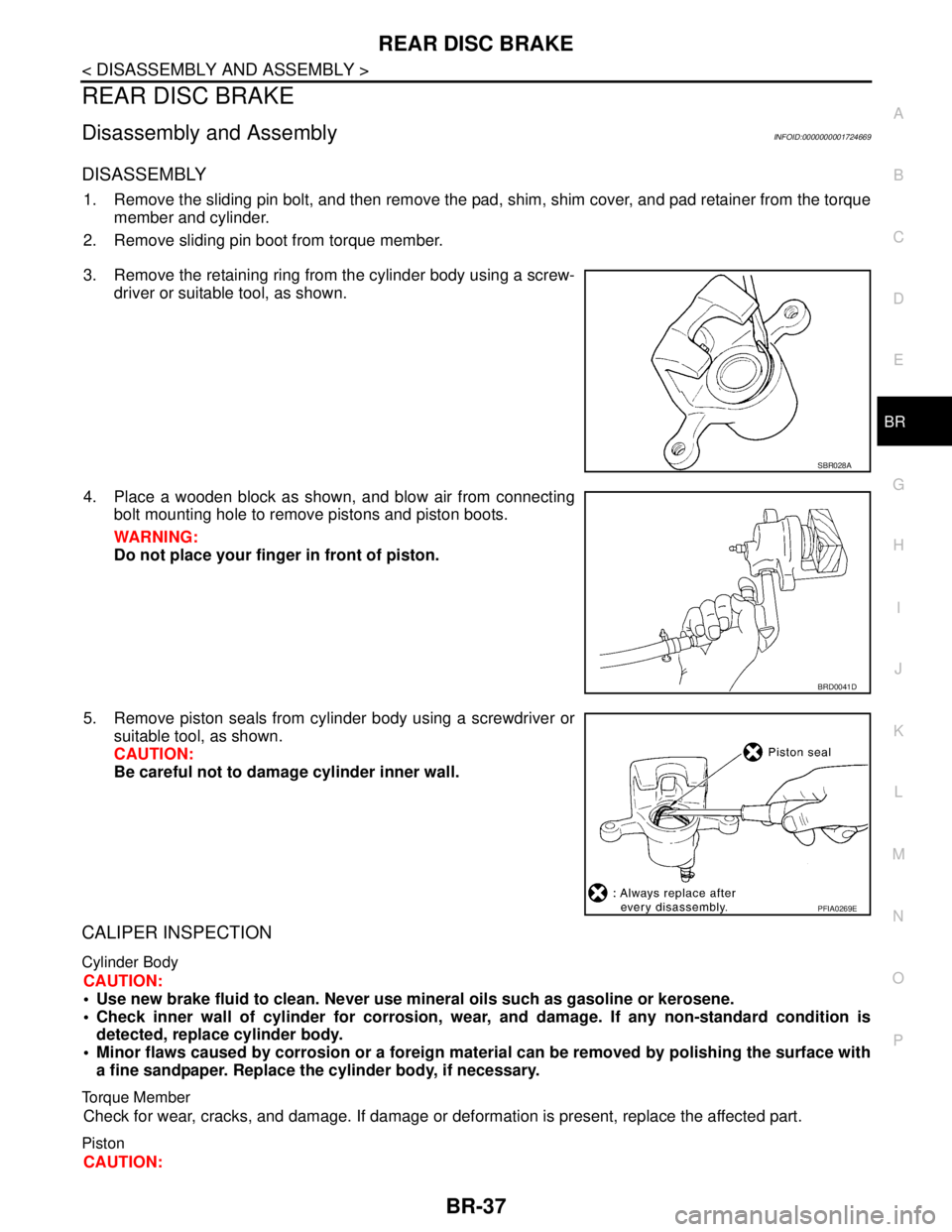

DISASSEMBLY

1. Remove the sliding pin bolt, and then remove the pad, shim, shim cover, and pad retainer from the torque

member and cylinder.

2. Remove sliding pin boot from torque member.

3. Remove the retaining ring from the cylinder body using a screw-

driver or suitable tool, as shown.

4. Place a wooden block as shown, and blow air from connecting

bolt mounting hole to remove pistons and piston boots.

WARNING:

Do not place your finger in front of piston.

5. Remove piston seals from cylinder body using a screwdriver or

suitable tool, as shown.

CAUTION:

Be careful not to damage cylinder inner wall.

CALIPER INSPECTION

Cylinder Body

CAUTION:

Use new brake fluid to clean. Never use mineral oils such as gasoline or kerosene.

Check inner wall of cylinder for corrosion, wear, and damage. If any non-standard condition is

detected, replace cylinder body.

Minor flaws caused by corrosion or a foreign material can be removed by polishing the surface with

a fine sandpaper. Replace the cylinder body, if necessary.

Torque Member

Check for wear, cracks, and damage. If damage or deformation is present, replace the affected part.

Piston

CAUTION:

SBR028A

BRD0041D

PFIA0269E

Page 252 of 5883

![NISSAN TIIDA 2007 Service Owners Guide ABS

BRC-19

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ABS

System DiagramINFOID:0000000001731216

System DescriptionINFOID:0000000001731217

Anti-Lock Braking System is a function tha NISSAN TIIDA 2007 Service Owners Guide ABS

BRC-19

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ABS

System DiagramINFOID:0000000001731216

System DescriptionINFOID:0000000001731217

Anti-Lock Braking System is a function tha](/img/5/57395/w960_57395-251.png)

ABS

BRC-19

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ABS

System DiagramINFOID:0000000001731216

System DescriptionINFOID:0000000001731217

Anti-Lock Braking System is a function that detects wheel revolution while braking, electronically controls

braking force, and prevents wheel locking during sudden braking. It improves handling stability and maneu-

verability for avoiding obstacles.

Electrical system diagnosis by CONSULT-III is available.

AWFIA0014GB

Page 316 of 5883

![NISSAN TIIDA 2007 Service Owners Guide WHEEL SENSORS

BRC-83

< REMOVAL AND INSTALLATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

REMOVAL AND INSTALLATION

WHEEL SENSORS

Removal and InstallationINFOID:0000000001691408

REMOVAL

Be careful of the NISSAN TIIDA 2007 Service Owners Guide WHEEL SENSORS

BRC-83

< REMOVAL AND INSTALLATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

REMOVAL AND INSTALLATION

WHEEL SENSORS

Removal and InstallationINFOID:0000000001691408

REMOVAL

Be careful of the](/img/5/57395/w960_57395-315.png)

WHEEL SENSORS

BRC-83

< REMOVAL AND INSTALLATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

REMOVAL AND INSTALLATION

WHEEL SENSORS

Removal and InstallationINFOID:0000000001691408

REMOVAL

Be careful of the following.

CAUTION:

When removing the sensor, do not rotate it if possible, and not forcibly pull the sensor harness.

Before removing front or rear wheel hub, remove wheel sensor to avoid sensor wiring damage.

INSTALLATION

Be certain to tighten bolts to the specified torque. Be careful of the following:

Check the inside of the sensor mounting hole for foreign material, the rotor surface for iron chips and other

foreign material, and if anything is non-standard, clean it before installation, or replace it.

When installing the front sensor, completely push in the strut bracket and body bracket rubber grommets

until they lock so that the sensor harness does not become twisted. In addition, there should be no twists in

the harness when installed. Install the harness so that the painted part faces the outside of the vehicle.

When installing the rear sensor, completely push in the rubber bracket of the suspension arm bracket and

lock the marking area of the side member harness mount so that the sensor harness will not be twisted. In

addition, there should be no twists in the harness when installed.

MFIB9029E

Page 318 of 5883

![NISSAN TIIDA 2007 Service Owners Guide ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

BRC-85

< REMOVAL AND INSTALLATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001691410

RE NISSAN TIIDA 2007 Service Owners Guide ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

BRC-85

< REMOVAL AND INSTALLATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001691410

RE](/img/5/57395/w960_57395-317.png)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

BRC-85

< REMOVAL AND INSTALLATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001691410

REMOVAL

Be careful of the following.

CAUTION:

Before servicing, disconnect the battery cables.

To remove brake tube, use a flare nut wrench to prevent flare nuts and brake tube from being dam-

aged. To install, use a flare nut torque wrench and tighten to the specified torque.

Do not apply excessive impact to the actuator, such as dropping it.

INSTALLATION

Be careful of the following.

When setting the actuator in the bracket, push it in until it locks.

Tighten the mounting bolts and nuts to the specified torque.

After the work, breed the air from the brake piping. Refer to BR-8, "

Bleeding Brake System".

After installing the vehicle harness connector in the actuator, make sure the connector is securely locked.

SFIA1183E

Page 332 of 5883

![NISSAN TIIDA 2007 Service Owners Guide ABS

BRC-99

< FUNCTION DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ABS

System DiagramINFOID:0000000001731073

System DescriptionINFOID:0000000001731074

Anti-Lock Braking System is a func NISSAN TIIDA 2007 Service Owners Guide ABS

BRC-99

< FUNCTION DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ABS

System DiagramINFOID:0000000001731073

System DescriptionINFOID:0000000001731074

Anti-Lock Braking System is a func](/img/5/57395/w960_57395-331.png)

ABS

BRC-99

< FUNCTION DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ABS

System DiagramINFOID:0000000001731073

System DescriptionINFOID:0000000001731074

Anti-Lock Braking System is a function that detects wheel revolution while braking, electronically controls

braking force, and prevents wheel locking during sudden braking. It improves handling stability and maneu-

verability for avoiding obstacles.

Electrical system diagnosis by CONSULT-III is available.

AWFIA0014GB

Page 415 of 5883

![NISSAN TIIDA 2007 Service Owners Guide BRC-182

< REMOVAL AND INSTALLATION >[ESP/TCS/ABS]

WHEEL SENSORS

REMOVAL AND INSTALLATION

WHEEL SENSORS

Removal and InstallationINFOID:0000000001691451

REMOVAL

Be careful of the following.

CAUTION:

W NISSAN TIIDA 2007 Service Owners Guide BRC-182

< REMOVAL AND INSTALLATION >[ESP/TCS/ABS]

WHEEL SENSORS

REMOVAL AND INSTALLATION

WHEEL SENSORS

Removal and InstallationINFOID:0000000001691451

REMOVAL

Be careful of the following.

CAUTION:

W](/img/5/57395/w960_57395-414.png)

BRC-182

< REMOVAL AND INSTALLATION >[ESP/TCS/ABS]

WHEEL SENSORS

REMOVAL AND INSTALLATION

WHEEL SENSORS

Removal and InstallationINFOID:0000000001691451

REMOVAL

Be careful of the following.

CAUTION:

When removing the sensor, do not rotate it if possible, and not forcibly pull the sensor harness.

Before removing front or rear wheel hub, remove wheel sensor to avoid sensor wiring damage.

INSTALLATION

Be certain to tighten bolts to the specified torque. Be careful of the following: Check the inside of the sensor mounting hole for foreign material, the rotor surface for iron chips and other

foreign material, and if anything is non-standard, clean it before installation, or replace it.

When installing the front sensor, completely push in the strut bracket and body bracket rubber grommets

until they lock so that the sensor harness does not become twisted. In addition, there should be no twists in

the harness when installed. Install the harness so that the painted part faces the outside of the vehicle.

When installing the rear sensor, completely push in the rubber bracket of the suspension arm bracket and

lock the marking area of the side member harness mount so that the sensor harness will not be twisted. In

addition, there should be no twists in the harness when installed.

MFIB9030E

Page 417 of 5883

![NISSAN TIIDA 2007 Service Owners Guide BRC-184

< REMOVAL AND INSTALLATION >[ESP/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001691453

REMOVAL

1. Disconnect ABS NISSAN TIIDA 2007 Service Owners Guide BRC-184

< REMOVAL AND INSTALLATION >[ESP/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001691453

REMOVAL

1. Disconnect ABS](/img/5/57395/w960_57395-416.png)

BRC-184

< REMOVAL AND INSTALLATION >[ESP/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001691453

REMOVAL

1. Disconnect ABS actuator and electric unit (control unit) connector.

2. Loosen brake tube flare nuts, then remove brake tubes from ABS actuator and electric unit (control unit).

3. Remove ABS actuator and electric unit (control unit) mounting nuts.

4. Remove ABS actuator and electric unit (control unit) from vehicle.

CAUTION:

Be careful of the following when removing ABS actuator and electric unit (control unit).

If the part number on the part number label (pasted on actuator upper surface) is the same, ABS

actuator and electric unit (control unit) cannot be used on another vehicle.

If it is used on another vehicle, ABS warning lamp, SLIP indicator lamp and ESP OFF indicator lamp

may turn ON or ESP/TCS/ABS may not operate normally.

When replacing ABS actuator and electric unit (control unit), must use new service parts.

Before servicing, disconnect battery cables.

To remove brake tube, use a flare nut wrench to prevent flare nuts and brake tube from being dam-

aged. To install, use a flare nut torque wrench (commercial service tool) and tighten to the specified

torque.

Do not apply excessive impact to actuator, such as dropping it.

Do not remove and install ABS actuator and electric unit (control unit) by holding harness.

INSTALLATION

To install, follow procedure for removal in reverse order.

CAUTION:

Be careful of the following when installing ABS actuator and electric unit (control unit).

Tighten the mounting bolts and nuts to the specified torque.

After the work, bleed air from brake piping. Refer to BR-8, "

Bleeding Brake System".

After installing vehicle harness connector in the actuator, make sure connector is securely locked.

MFIA0015E

Page 470 of 5883

CLUTCH PEDAL

CL-5

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

CL

N

O

P

CLUTCH PEDAL

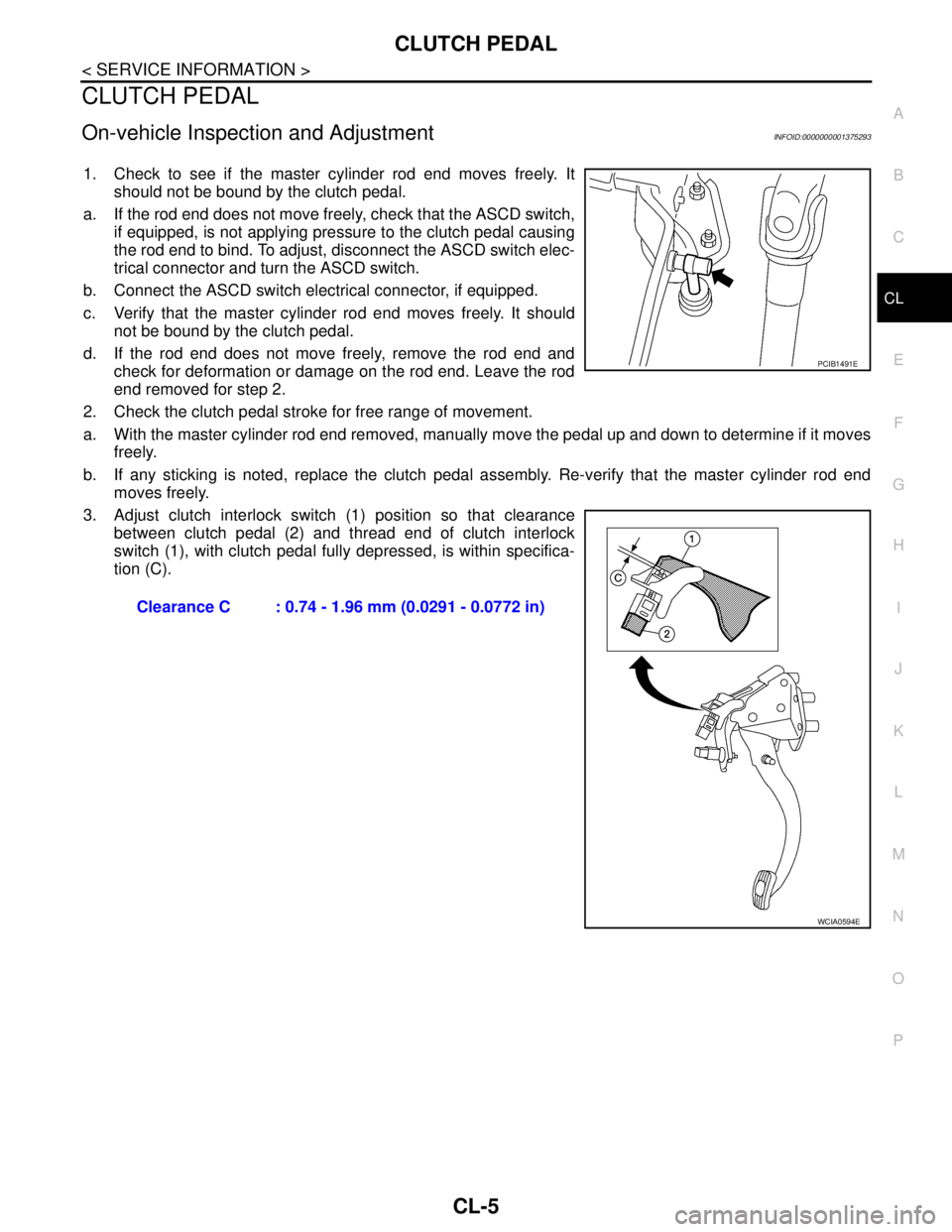

On-vehicle Inspection and AdjustmentINFOID:0000000001375293

1. Check to see if the master cylinder rod end moves freely. It

should not be bound by the clutch pedal.

a. If the rod end does not move freely, check that the ASCD switch,

if equipped, is not applying pressure to the clutch pedal causing

the rod end to bind. To adjust, disconnect the ASCD switch elec-

trical connector and turn the ASCD switch.

b. Connect the ASCD switch electrical connector, if equipped.

c. Verify that the master cylinder rod end moves freely. It should

not be bound by the clutch pedal.

d. If the rod end does not move freely, remove the rod end and

check for deformation or damage on the rod end. Leave the rod

end removed for step 2.

2. Check the clutch pedal stroke for free range of movement.

a. With the master cylinder rod end removed, manually move the pedal up and down to determine if it moves

freely.

b. If any sticking is noted, replace the clutch pedal assembly. Re-verify that the master cylinder rod end

moves freely.

3. Adjust clutch interlock switch (1) position so that clearance

between clutch pedal (2) and thread end of clutch interlock

switch (1), with clutch pedal fully depressed, is within specifica-

tion (C).

Clearance C : 0.74 - 1.96 mm (0.0291 - 0.0772 in)

PCIB1491E

WCIA0594E