clock spring NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2710 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-63

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

If the lock pin is not released by hands, tap the camshaft

sprocket (INT) lightly with a plastic hammer (A).

If the cam NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-63

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

If the lock pin is not released by hands, tap the camshaft

sprocket (INT) lightly with a plastic hammer (A).

If the cam](/img/5/57395/w960_57395-2709.png)

CAMSHAFT

EM-63

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

If the lock pin is not released by hands, tap the camshaft

sprocket (INT) lightly with a plastic hammer (A).

If the camshaft sprocket (INT) is not rotated counterclockwise

even if the above procedures are performed, check the air

pressure and the oil hole position.

d. While doing the above, once you hear a click (the sound of the

internal lock pin disengaging) from inside the camshaft sprocket

(INT), start turning the camshaft sprocket (INT) in the counter-

clockwise direction in the most advanced angle position.

Keep the air pressure on.

If there is no click, as soon as the vane-side (camshaft side)

starts moving independently of the sprocket, the lock pin has

become disengaged.

Make sure that it is in the most advanced angle position by

seeing if the stopper pin groove (A) and the stopper pin hole (B) are matched up as shown.

e. Complete the applying procedure of air pressure and the holding procedure of camshaft (INT).

f. Insert the stopper pin (A) into the stopper pin holes in the cam-

shaft sprocket (INT) and lock in the most advanced angle posi-

tion.

CAUTION:

No load is exerted on the stopper pin (spring reaction, etc.).

Since it comes out easily, secure it with tape (B) to prevent

it from coming out.

NOTE:

The stopper pin shows one example of a hexagonal wrench for

2.5 mm (0.098 in) [length of inserted section: approximately15

mm (0.59 in)].

13. Remove camshaft brackets (No. 2 to 5).

Loosen bolts in several steps in the reverse of the order

shown.

NOTE:

The camshaft bracket (No. 1) has been already removed.

14. Remove camshaft (EXH).

AWBIA0106ZZ

C : Most retarded angle (lock pin engaged)

D : Most advanced angle

PBIC3684E

AWBIA0107ZZ

A : EXH side

B : INT side

: Engine front

PBIC3686E

Page 2752 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CYLINDER BLOCK

EM-105

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

c. Turn main bearing cap bolts 60 degrees clockwise (angle tight-

ening) in numerical order shown in the figu NISSAN TIIDA 2007 Service Repair Manual CYLINDER BLOCK

EM-105

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

c. Turn main bearing cap bolts 60 degrees clockwise (angle tight-

ening) in numerical order shown in the figu](/img/5/57395/w960_57395-2751.png)

CYLINDER BLOCK

EM-105

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

c. Turn main bearing cap bolts 60 degrees clockwise (angle tight-

ening) in numerical order shown in the figure.

CAUTION:

Check and confirm the tightening angle by using the angle

wrench [SST: KV10112100] (A) or protractor. Avoid judg-

ment by visual inspection without the tool.

After installing the mounting bolts, make sure that crankshaft can be rotated smoothly by hand.

Check crankshaft end play. Refer to EM-108, "

Inspection".

8. Install piston to connecting rod with the following procedure:

a. Set so that the front mark (A) on the piston head and the cylin-

der number (C) are in the position shown in the figure.

NOTE:

The symbols without notes are for management.

b. Press-fit the piston pin using the piston pin press stand (SST).

CAUTION:

Press-fit the piston so as not to damage it.

NOTE:

The joint between the connecting rod and the piston pin is a

press fit.

PBIC3750E

B: Oil hole

D : Connecting rod big end grade

JPBIA0537ZZ

A : Drift [KV10109730]

B : Center cap [KV10110310]

C : Press stand [ST13030020]

D : Center shaft [KV10114120]

E : Spring [ST13030030]

F: For detail

PBIC5271J

Page 3085 of 5883

EXL-84

< ON-VEHICLE REPAIR >

HEADLAMP

ON-VEHICLE REPAIR

HEADLAMP

Bulb ReplacementINFOID:0000000001529252

HEADLAMP - HALOGEN (HIGH/LOW)

CAUTION:

After installing the halogen bulb, install the back cover and bulb socket securely to ensure a water

tight seal.

1. Turn lighting switch OFF.

2. Disconnect the battery negative terminal.

3. Remove the back cover.

4. Unlock the retaining spring and remove the bulb from the combination lamp.

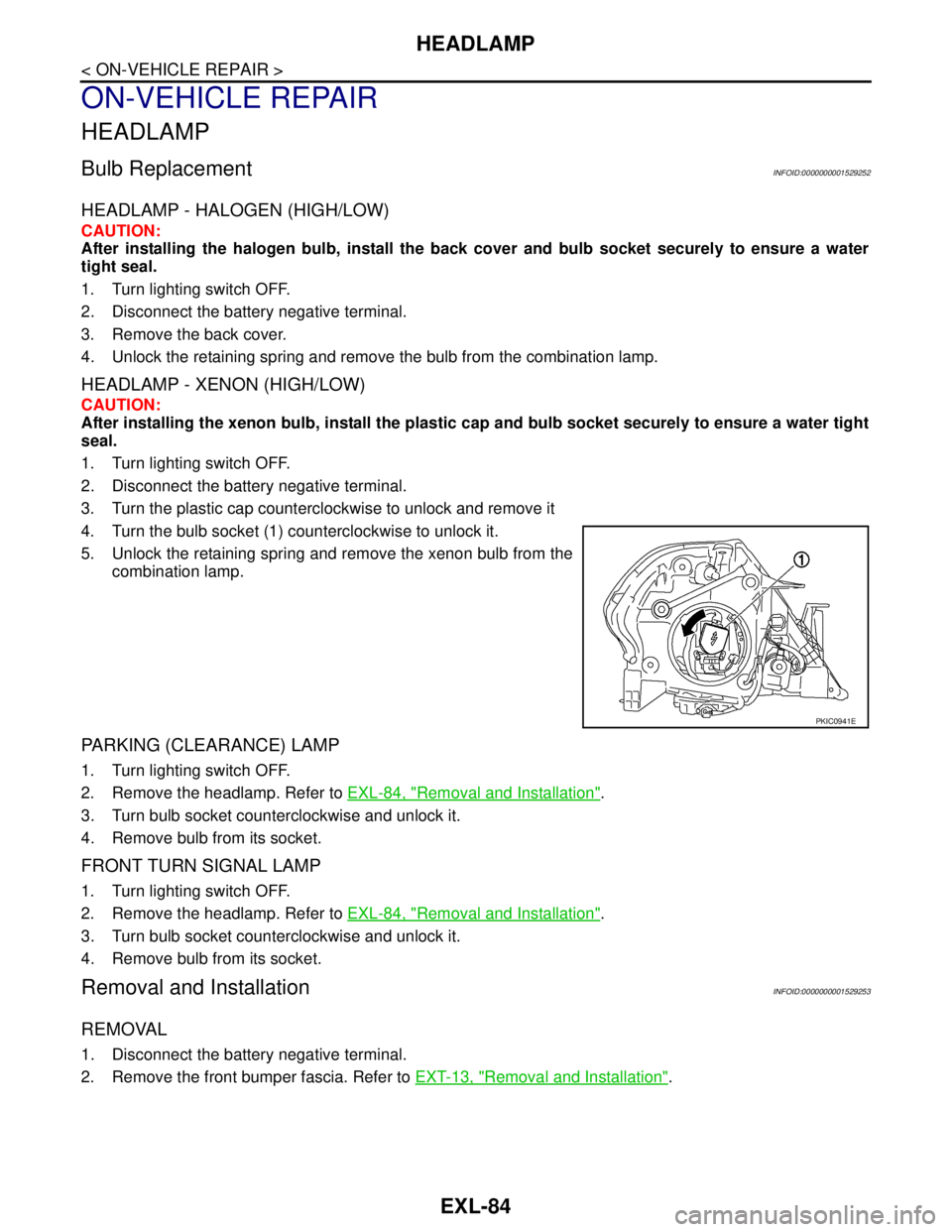

HEADLAMP - XENON (HIGH/LOW)

CAUTION:

After installing the xenon bulb, install the plastic cap and bulb socket securely to ensure a water tight

seal.

1. Turn lighting switch OFF.

2. Disconnect the battery negative terminal.

3. Turn the plastic cap counterclockwise to unlock and remove it

4. Turn the bulb socket (1) counterclockwise to unlock it.

5. Unlock the retaining spring and remove the xenon bulb from the

combination lamp.

PARKING (CLEARANCE) LAMP

1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to EXL-84, "

Removal and Installation".

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

FRONT TURN SIGNAL LAMP

1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to EXL-84, "

Removal and Installation".

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

Removal and InstallationINFOID:0000000001529253

REMOVAL

1. Disconnect the battery negative terminal.

2. Remove the front bumper fascia. Refer to EXT-13, "

Removal and Installation".

PKIC0941E

Page 3086 of 5883

HEADLAMP

EXL-85

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

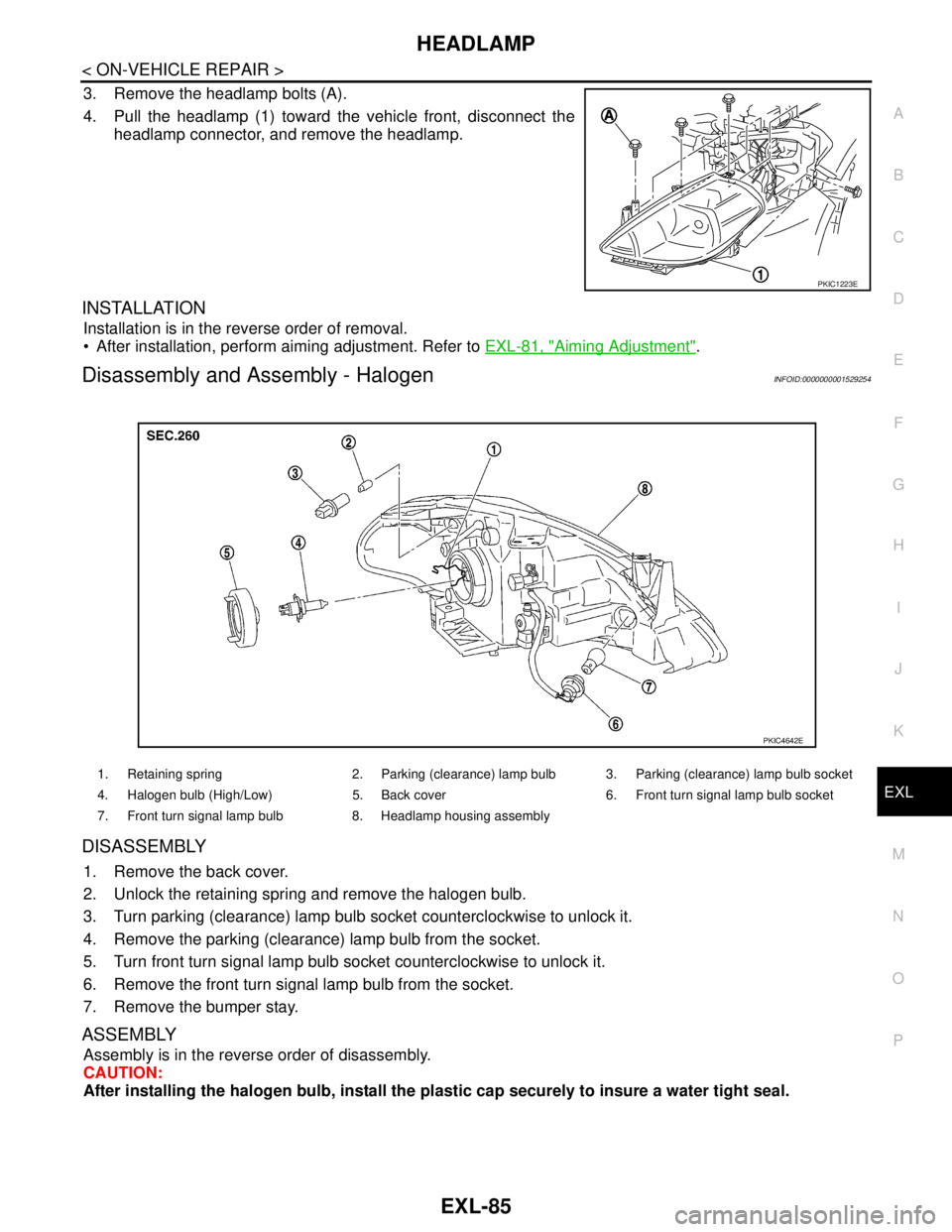

3. Remove the headlamp bolts (A).

4. Pull the headlamp (1) toward the vehicle front, disconnect the

headlamp connector, and remove the headlamp.

INSTALLATION

Installation is in the reverse order of removal.

After installation, perform aiming adjustment. Refer to EXL-81, "

Aiming Adjustment".

Disassembly and Assembly - HalogenINFOID:0000000001529254

DISASSEMBLY

1. Remove the back cover.

2. Unlock the retaining spring and remove the halogen bulb.

3. Turn parking (clearance) lamp bulb socket counterclockwise to unlock it.

4. Remove the parking (clearance) lamp bulb from the socket.

5. Turn front turn signal lamp bulb socket counterclockwise to unlock it.

6. Remove the front turn signal lamp bulb from the socket.

7. Remove the bumper stay.

ASSEMBLY

Assembly is in the reverse order of disassembly.

CAUTION:

After installing the halogen bulb, install the plastic cap securely to insure a water tight seal.

PKIC1223E

1. Retaining spring 2. Parking (clearance) lamp bulb 3. Parking (clearance) lamp bulb socket

4. Halogen bulb (High/Low) 5. Back cover 6. Front turn signal lamp bulb socket

7. Front turn signal lamp bulb 8. Headlamp housing assembly

PKIC4642E

Page 3087 of 5883

EXL-86

< ON-VEHICLE REPAIR >

HEADLAMP

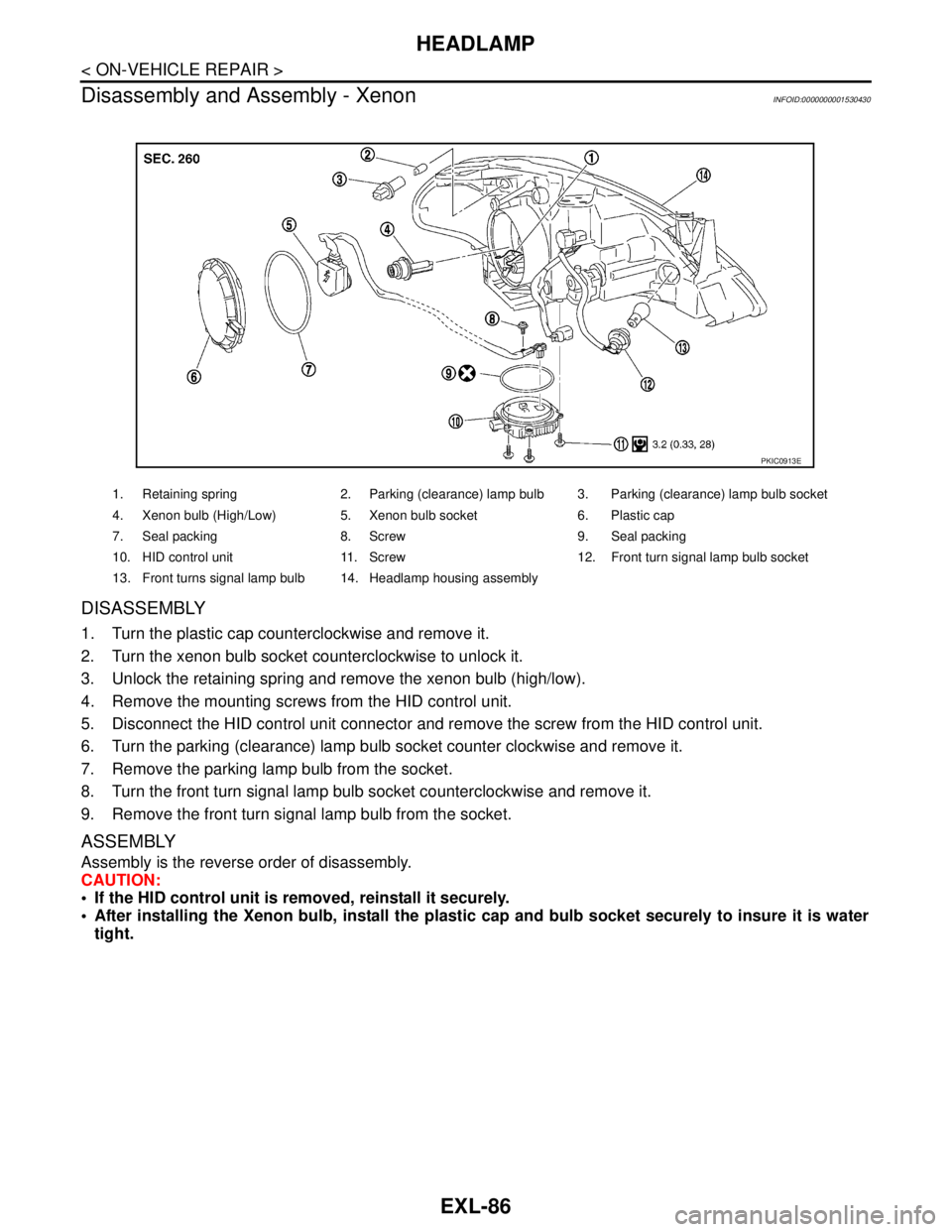

Disassembly and Assembly - Xenon

INFOID:0000000001530430

DISASSEMBLY

1. Turn the plastic cap counterclockwise and remove it.

2. Turn the xenon bulb socket counterclockwise to unlock it.

3. Unlock the retaining spring and remove the xenon bulb (high/low).

4. Remove the mounting screws from the HID control unit.

5. Disconnect the HID control unit connector and remove the screw from the HID control unit.

6. Turn the parking (clearance) lamp bulb socket counter clockwise and remove it.

7. Remove the parking lamp bulb from the socket.

8. Turn the front turn signal lamp bulb socket counterclockwise and remove it.

9. Remove the front turn signal lamp bulb from the socket.

ASSEMBLY

Assembly is the reverse order of disassembly.

CAUTION:

If the HID control unit is removed, reinstall it securely.

After installing the Xenon bulb, install the plastic cap and bulb socket securely to insure it is water

tight.

1. Retaining spring 2. Parking (clearance) lamp bulb 3. Parking (clearance) lamp bulb socket

4. Xenon bulb (High/Low) 5. Xenon bulb socket 6. Plastic cap

7. Seal packing 8. Screw 9. Seal packing

10. HID control unit 11. Screw 12. Front turn signal lamp bulb socket

13. Front turns signal lamp bulb 14. Headlamp housing assembly

PKIC0913E

Page 5596 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-650

< DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

27. Shift the shift lever (1) of control shaft assembly to 3rd gear posi-

tion.

NOTE:

If not, the transaxle case cannot be remove NISSAN TIIDA 2007 Service Repair Manual TM-650

< DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

27. Shift the shift lever (1) of control shaft assembly to 3rd gear posi-

tion.

NOTE:

If not, the transaxle case cannot be remove](/img/5/57395/w960_57395-5595.png)

TM-650

< DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

27. Shift the shift lever (1) of control shaft assembly to 3rd gear posi-

tion.

NOTE:

If not, the transaxle case cannot be removed from clutch hous-

ing.

3rd gear position means that the shift lever of control shaft

assembly is fully rotated clockwise and it is returned approxi-

mately 10°.

28. Install oil gutter to transaxle case.

29. Apply recommended sealant to mating surface of clutch hous-

ing.

CAUTION:

Remove old sealant adhering to the mating surfaces. Also remove any moisture, oil, or foreign

material adhering to both mating surfaces.

Check for damage on the mounting surface.

Apply a continuous bead of liquid gasket to the mounting surface.

30. Install transaxle case to clutch housing.

(1): Selector

(2): Shift fork

CAUTION:

Do not allow sealant to contact the transaxle case so as

not to break the bead when installing.

Be careful to align the lever of 5th-reverse fork rod with

reverse gear assembly sleeve.

NOTE:

If installation is difficult, gently return shift lever of control shaft

assembly counterclockwise slightly.

31. Fit shaft with bearing by rotating input shaft. Then, tighten bolts

to the specified torque. Refer to TM-635, "

Exploded View".

32. Apply recommended sealant to threads of position switch and

check ball plug. Then install them to transaxle case and tighten

to the specified torque. Refer to TM-635, "

Exploded View".

33. Apply gear oil to spline of mainshaft and then press in 5th main

gear (1) to mainshaft using a suitable bolt (A) [M10 x 1.0] and

nut (B).

34. Install spread springs to 5th-reverse synchronizer hub.

PCIB1524E

PCIB1553E

PCIB1528E

PCIB1554E