transmission oil NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 148 of 5883

BCS

SIGNAL BUFFER SYSTEM

BCS-13

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

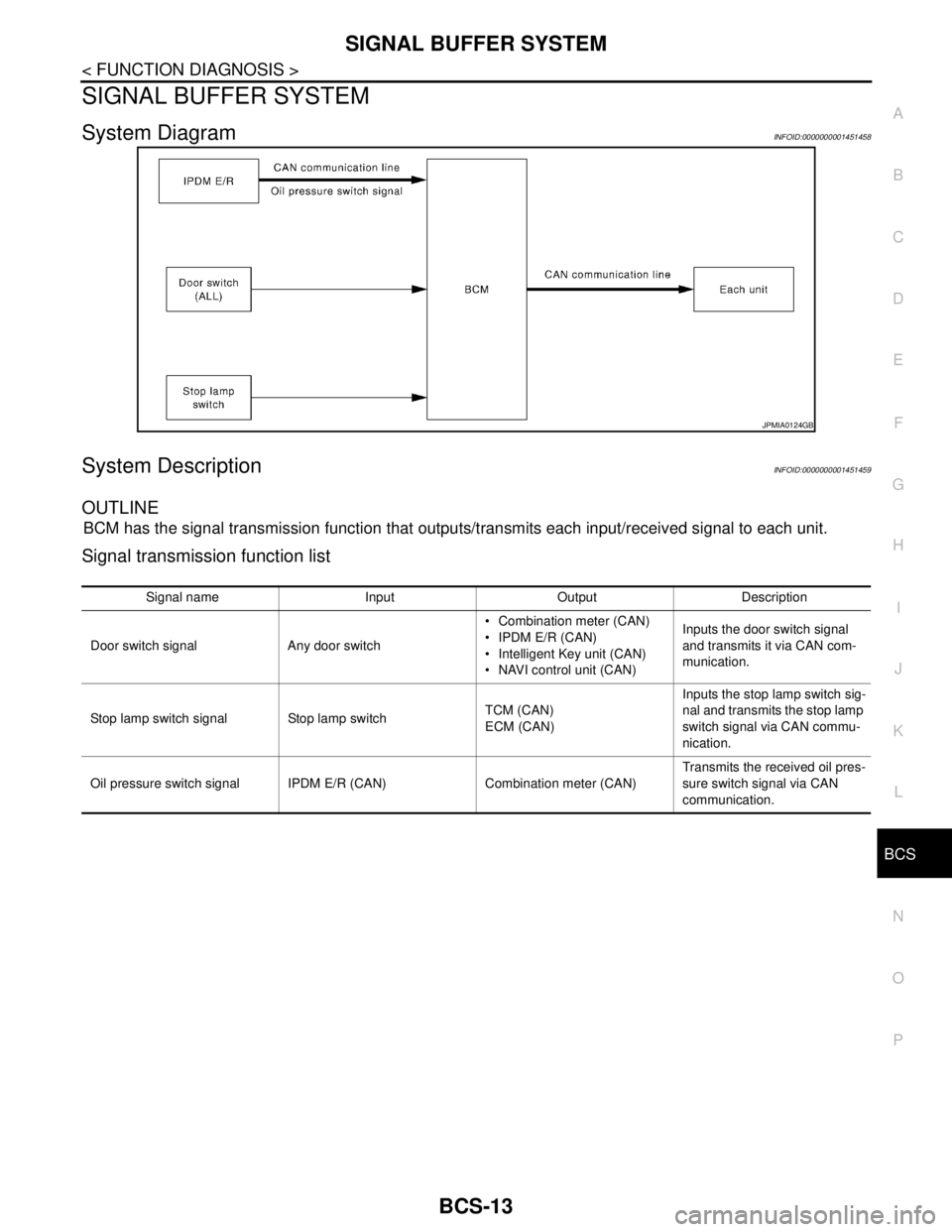

SIGNAL BUFFER SYSTEM

System DiagramINFOID:0000000001451458

System DescriptionINFOID:0000000001451459

OUTLINE

BCM has the signal transmission function that outputs/transmits each input/received signal to each unit.

Signal transmission function list

JPMIA0124GB

Signal name Input Output Description

Door switch signal Any door switch Combination meter (CAN)

IPDM E/R (CAN)

Intelligent Key unit (CAN)

NAVI control unit (CAN)Inputs the door switch signal

and transmits it via CAN com-

munication.

Stop lamp switch signal Stop lamp switchTCM (CAN)

ECM (CAN)Inputs the stop lamp switch sig-

nal and transmits the stop lamp

switch signal via CAN commu-

nication.

Oil pressure switch signal IPDM E/R (CAN) Combination meter (CAN)Transmits the received oil pres-

sure switch signal via CAN

communication.

Page 1470 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-121

< COMPONENT DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. NISSAN TIIDA 2007 Service Repair Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-121

< COMPONENT DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2.](/img/5/57395/w960_57395-1469.png)

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-121

< COMPONENT DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”

1. Start engine.

2. Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within

the SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO >> Detect malfunctioning part according to EC-366, "

Symptom Table".

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO-1 >> More than the SP value: GO TO 18.

NO-2 >> Less than the SP value: GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of alternator, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

Crushed air ducts

Malfunctioning seal of air cleaner element

Uneven dirt of air cleaner element

Improper specification of intake air system

Is the inspection result normal?

YES >> GO TO 21.

NO >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1” and “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

Is the measurement value within the SP value?

YES >>INSPECTION END

NO >> “B/FUEL SCHDL” is more, “A/F ALPHA-B1” is less than the SP value: GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it again.

Page 1823 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EC-474

< COMPONENT DIAGNOSIS >[HR16DE (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connec NISSAN TIIDA 2007 Service Repair Manual EC-474

< COMPONENT DIAGNOSIS >[HR16DE (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connec](/img/5/57395/w960_57395-1822.png)

EC-474

< COMPONENT DIAGNOSIS >[HR16DE (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”

1. Start engine.

2. Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within

the SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO >> Detect malfunctioning part according to EC-670, "

Symptom Table".

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO-1 >> More than the SP value: GO TO 18.

NO-2 >> Less than the SP value: GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of alternator, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

Crushed air ducts

Malfunctioning seal of air cleaner element

Uneven dirt of air cleaner element

Improper specification of intake air system

Is the inspection result normal?

YES >> GO TO 21.

NO >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1” and “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

Is the measurement value within the SP value?

YES >>INSPECTION END

NO >> “B/FUEL SCHDL” is more, “A/F ALPHA-B1” is less than the SP value: GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it again.

Page 2135 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EC-786

< COMPONENT DIAGNOSIS >[MR18DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin term NISSAN TIIDA 2007 Service Repair Manual EC-786

< COMPONENT DIAGNOSIS >[MR18DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin term](/img/5/57395/w960_57395-2134.png)

EC-786

< COMPONENT DIAGNOSIS >[MR18DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”

1. Start engine.

2. Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within

the SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO >> Detect malfunctioning part according to EC-1024, "

Symptom Table".

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO-1 >> More than the SP value: GO TO 18.

NO-2 >> Less than the SP value: GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of alternator, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

Crushed air ducts

Malfunctioning seal of air cleaner element

Uneven dirt of air cleaner element

Improper specification of intake air system

Is the inspection result normal?

YES >> GO TO 21.

NO >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1” and “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

Is the measurement value within the SP value?

YES >>INSPECTION END

NO >> “B/FUEL SCHDL” is more, “A/F ALPHA-B1” is less than the SP value: GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it again.

Page 2694 of 5883

![NISSAN TIIDA 2007 Service Repair Manual IGNITION COIL, SPARK PLUG AND ROCKER COVER

EM-47

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

IGNITION COIL, SPARK PLUG AND ROCKER COVER

Exploded ViewINFOID:0000000001381409

Removal a NISSAN TIIDA 2007 Service Repair Manual IGNITION COIL, SPARK PLUG AND ROCKER COVER

EM-47

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

IGNITION COIL, SPARK PLUG AND ROCKER COVER

Exploded ViewINFOID:0000000001381409

Removal a](/img/5/57395/w960_57395-2693.png)

IGNITION COIL, SPARK PLUG AND ROCKER COVER

EM-47

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

IGNITION COIL, SPARK PLUG AND ROCKER COVER

Exploded ViewINFOID:0000000001381409

Removal and InstallationINFOID:0000000001381410

REMOVAL

1. Remove intake manifold. Refer to EM-29, "Exploded View".

2. Remove ignition coil.

CAUTION:

Handle ignition coil carefully and avoid impacts.

Never disassemble.

3. Remove ground cable (RH).

4. Support the bottom surface of engine using a transmission jack, and then remove the engine mounting

bracket and insulator (RH). Refer to EM-89, "

Exploded View".

1. Ignition coil 2. Spark plug 3. PCV hose

4. Oil filler cap 5. Rocker cover 6. Gasket

7. Bracket 8. Grommet 9. PCV valve

10. PCV hose

A. To air duct

PBIC4257E

Page 2705 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM -58

< ON-VEHICLE REPAIR >[HR16DE]

TIMING CHAIN

Check for cracks and any excessive wear at link plates and roller

links of timing chain. Replace timing chain as necessary.

INSPECTION AFTER INSTALLAT NISSAN TIIDA 2007 Service Repair Manual EM -58

< ON-VEHICLE REPAIR >[HR16DE]

TIMING CHAIN

Check for cracks and any excessive wear at link plates and roller

links of timing chain. Replace timing chain as necessary.

INSPECTION AFTER INSTALLAT](/img/5/57395/w960_57395-2704.png)

EM -58

< ON-VEHICLE REPAIR >[HR16DE]

TIMING CHAIN

Check for cracks and any excessive wear at link plates and roller

links of timing chain. Replace timing chain as necessary.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-19, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside chain tensioner drops after removal/installation, slack in guide may generate a

pounding noise during and just after the engine start. However, this does not indicate an unusualness. Noise

will stop after hydraulic pressure rises.

Warm up engine thoroughly to make sure there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.A: Crack

B: Wear

JPBIA0091ZZ

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Page 2722 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-75

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, chec NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-75

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, chec](/img/5/57395/w960_57395-2721.png)

CAMSHAFT

EM-75

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-19, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

Warm up engine thoroughly to make sure there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

Perform this inspection only when DTC P0011 is detected in self-diagnostic results of CONSULT-III

and it is directed according to inspection procedure of EC section. Refer to EC-131, "

Diagnosis Pro-

cedure" (EURO-OBD), EC-484, "Diagnosis Procedure" (WITHOUT EURO-OBD).

Check when engine is cold so as to prevent burns from the splashing engine oil.

1. Check engine oil level. Refer to LU-6, "

Inspection".

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Release the fuel pressure. Refer to EC-377, "

Inspection" (EURO-OBD), EC-681, "Inspection" (WITHOUT

EURO-OBD).

b. Remove intake manifold. Refer to EM-29, "

Exploded View".

c. Disconnect ignition coil and injector harness connectors. Refer to EM-47, "

Exploded View".

3. Remove intake valve timing control solenoid valve. Refer to EM-50, "

Exploded View".

4. Crank engine, and then make sure that engine oil comes out

from intake valve timing control solenoid valve hole (A). End

crank after checking.

WARNING:

Be careful not to touch rotating parts (drive belts, idler pul-

ley, and crankshaft pulley, etc.).

CAUTION:

Prevent splashing by using a shop cloth so as to prevent

the worker from injury from engine oil and so as to prevent engine oil contamination.

Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to

engine and vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belts,

engine mounting insulator, etc. Wipe engine oil off immediately if it is splashed.

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

1: Plug

:Engine front

PBIC3706E

Page 2729 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-82

< ON-VEHICLE REPAIR >[HR16DE]

CYLINDER HEAD

In this step, loosen bolts in reverse order of that indicated.

d. Tighten all bolts.

e. Turn all bolts 75 degrees clockwise (angle tightening).

CAUTIO NISSAN TIIDA 2007 Service Repair Manual EM-82

< ON-VEHICLE REPAIR >[HR16DE]

CYLINDER HEAD

In this step, loosen bolts in reverse order of that indicated.

d. Tighten all bolts.

e. Turn all bolts 75 degrees clockwise (angle tightening).

CAUTIO](/img/5/57395/w960_57395-2728.png)

EM-82

< ON-VEHICLE REPAIR >[HR16DE]

CYLINDER HEAD

In this step, loosen bolts in reverse order of that indicated.

d. Tighten all bolts.

e. Turn all bolts 75 degrees clockwise (angle tightening).

CAUTION:

Check and confirm the tightening angle by using the angle

wrench [SST: KV10112100] (A) or protractor. Avoid judg-

ment by visual inspection without the tool.

f. Turn all bolts 75 degrees clockwise again (angle tightening).

3. Installation is in the reverse order of removal, for the remaining parts.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-19, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Disassembly and AssemblyINFOID:0000000001381422

: 40.0 N·m (4.1 kg-m, 30 ft-lb)

PBIC3733E

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2738 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-91

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Vehicle Underbody

1. Remove front wheel sensor (LH and RH) for ABS from steering knuckle. Refer to BRC-83, "R NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-91

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Vehicle Underbody

1. Remove front wheel sensor (LH and RH) for ABS from steering knuckle. Refer to BRC-83, "R](/img/5/57395/w960_57395-2737.png)

ENGINE ASSEMBLY

EM-91

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Vehicle Underbody

1. Remove front wheel sensor (LH and RH) for ABS from steering knuckle. Refer to BRC-83, "Removal and

Installation".

2. Remove brake caliper assembly with piping connected from steering knuckle. Temporarily secure it on the

vehicle side with a rope to avoid load on it. Refer to BR-24, "

Component".

3. Remove drive shafts (LH and RH) from steering knuckle. Refer to FAX-7, "

Removal and Installation".

4. Remove exhaust front tube. Refer to EX-5, "

Component".

5. Remove rear torque rod.

NOTE:

A/T models shown.

6. Remove A/T cooler hoses from transmission (A/T models).

7. Preparation for the separation work of transaxle is as follows:

Remove transaxle joint bolts which pierce at oil pan (upper) lower rear side. Refer to EM-89, "

Exploded

View".

Removal

1. Install engine slinger to cylinder head front left side (A) and rear

right side (B) and support the engine with a hoist.

2. Lift with a hoist and secure the engine in appropriate position.

3. Use a suitable tool to securely support bottom of the engine and

the transaxle assembly and simultaneously adjust hoist tension.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

PBIC3737E

PBIC3738E

PBIC3223J

Page 2740 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-93

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc. NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-93

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.](/img/5/57395/w960_57395-2739.png)

ENGINE ASSEMBLY

EM-93

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —