NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 301 of 2771

REPAIR FOR COMPONENT PARTS

AT-289

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

DISASSEMBLY

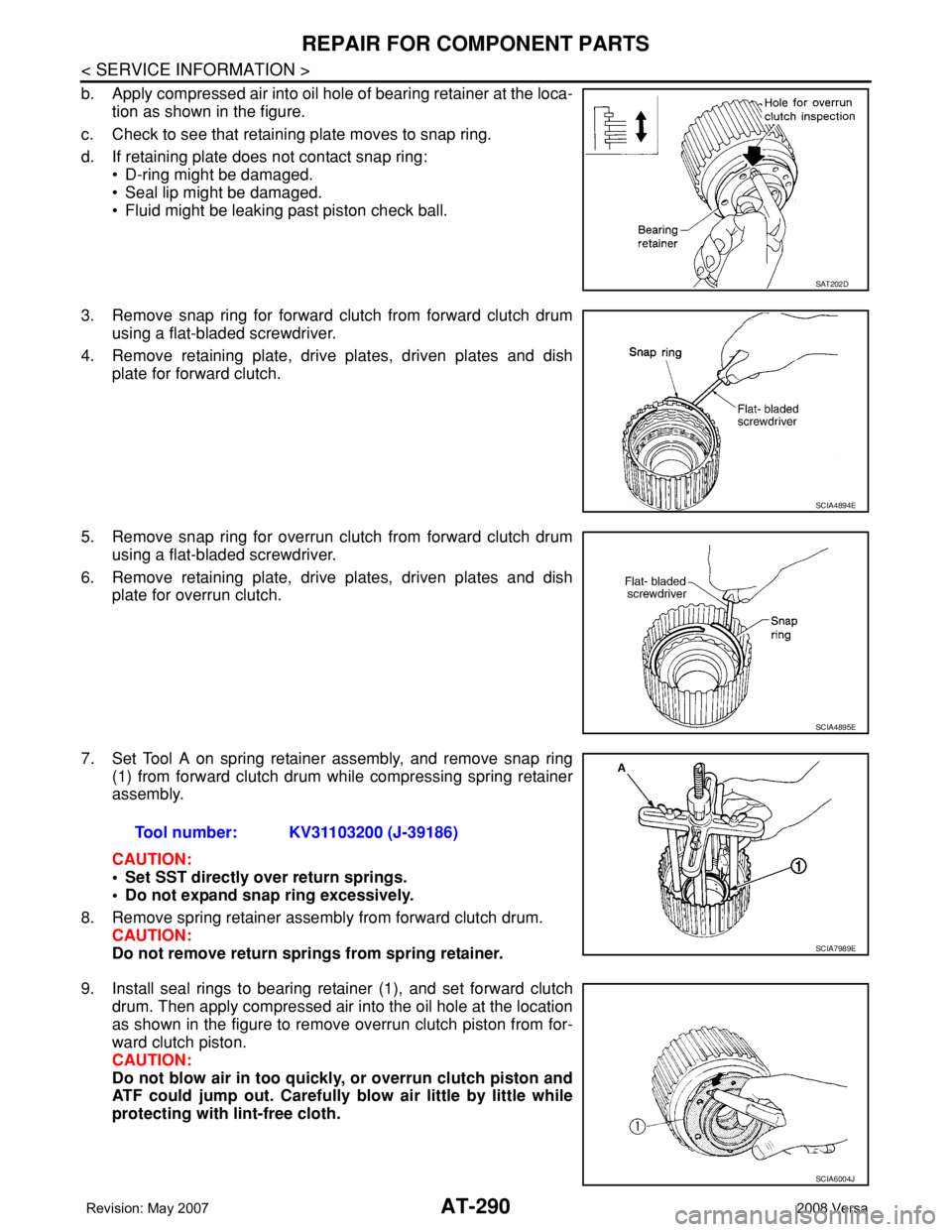

1. Check operation of forward clutch.

a. Install seal rings to bearing retainer, and set forward clutch drum.

b. Apply compressed air into oil hole of bearing retainer at the loca-

tion as shown in the figure.

c. Check to see that retaining plate moves to snap ring.

d. If retaining plate does not contact snap ring:

• D-ring might be damaged.

• Seal lip might be damaged.

• Fluid might be leaking past piston check ball.

2. Check operation of overrun clutch.

a. Install seal rings to bearing retainer, and set forward clutch drum.

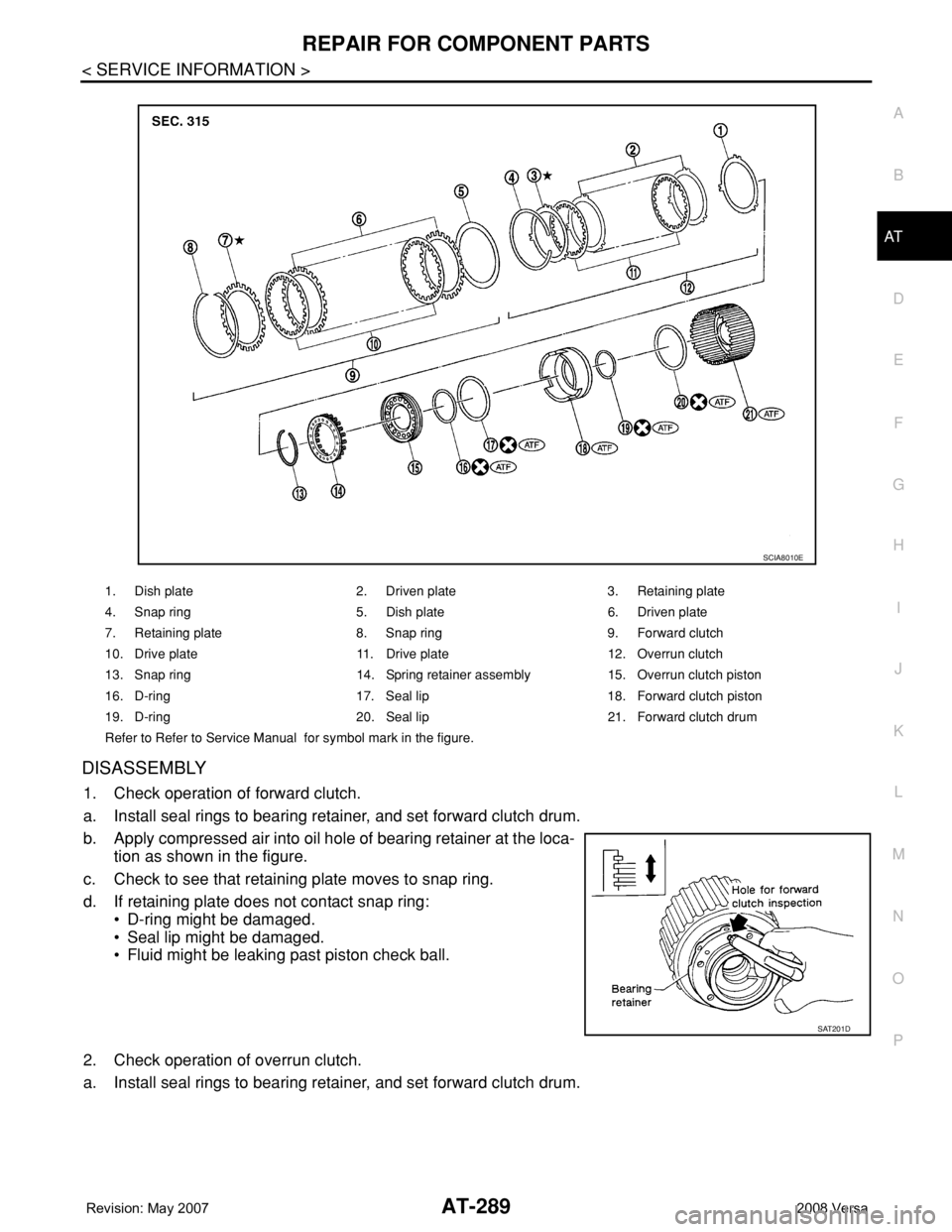

1. Dish plate 2. Driven plate 3. Retaining plate

4. Snap ring 5. Dish plate 6. Driven plate

7. Retaining plate 8. Snap ring 9. Forward clutch

10. Drive plate 11. Drive plate 12. Overrun clutch

13. Snap ring 14. Spring retainer assembly 15. Overrun clutch piston

16. D-ring 17. Seal lip 18. Forward clutch piston

19. D-ring 20. Seal lip 21. Forward clutch drum

Refer to Refer to Service Manual for symbol mark in the figure.

SCIA8010E

SAT201D

Page 302 of 2771

AT-290

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

b. Apply compressed air into oil hole of bearing retainer at the loca-

tion as shown in the figure.

c. Check to see that retaining plate moves to snap ring.

d. If retaining plate does not contact snap ring:

• D-ring might be damaged.

• Seal lip might be damaged.

• Fluid might be leaking past piston check ball.

3. Remove snap ring for forward clutch from forward clutch drum

using a flat-bladed screwdriver.

4. Remove retaining plate, drive plates, driven plates and dish

plate for forward clutch.

5. Remove snap ring for overrun clutch from forward clutch drum

using a flat-bladed screwdriver.

6. Remove retaining plate, drive plates, driven plates and dish

plate for overrun clutch.

7. Set Tool A on spring retainer assembly, and remove snap ring

(1) from forward clutch drum while compressing spring retainer

assembly.

CAUTION:

• Set SST directly over return springs.

• Do not expand snap ring excessively.

8. Remove spring retainer assembly from forward clutch drum.

CAUTION:

Do not remove return springs from spring retainer.

9. Install seal rings to bearing retainer (1), and set forward clutch

drum. Then apply compressed air into the oil hole at the location

as shown in the figure to remove overrun clutch piston from for-

ward clutch piston.

CAUTION:

Do not blow air in too quickly, or overrun clutch piston and

ATF could jump out. Carefully blow air little by little while

protecting with lint-free cloth.

SAT202D

SCIA4894E

SCIA4895E

Tool number: KV31103200 (J-39186)

SCIA7989E

SCIA6004J

Page 303 of 2771

REPAIR FOR COMPONENT PARTS

AT-291

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

10. Install seal rings to bearing retainer (1), and set forward clutch

drum. Then apply compressed air into the oil hole at the location

as shown in the figure to remove forward clutch piston from for-

ward clutch drum.

CAUTION:

Do not blow air in too quickly, or forward clutch piston and

ATF could jump out. Carefully blow air little by little while

protecting with lint-free cloth.

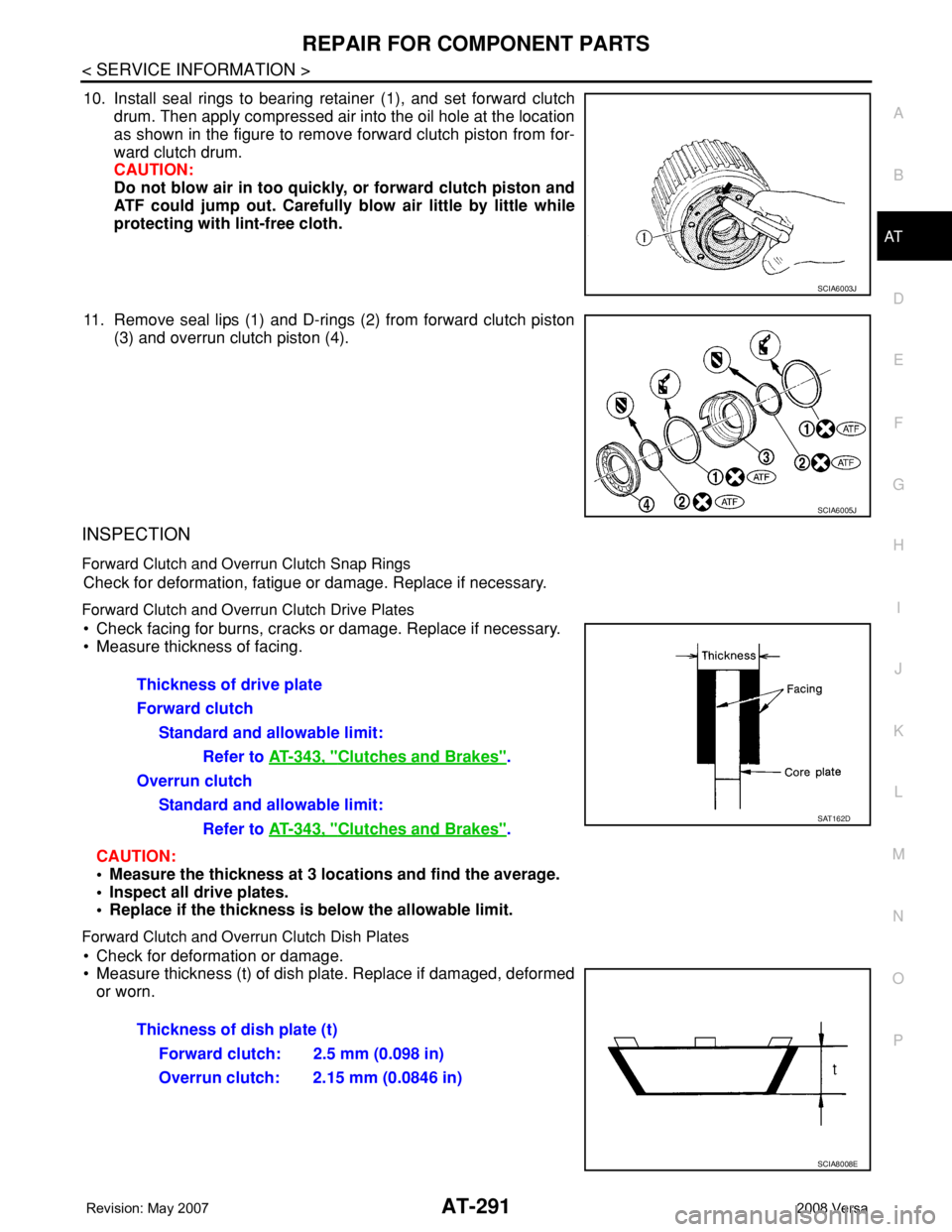

11. Remove seal lips (1) and D-rings (2) from forward clutch piston

(3) and overrun clutch piston (4).

INSPECTION

Forward Clutch and Overrun Clutch Snap Rings

Check for deformation, fatigue or damage. Replace if necessary.

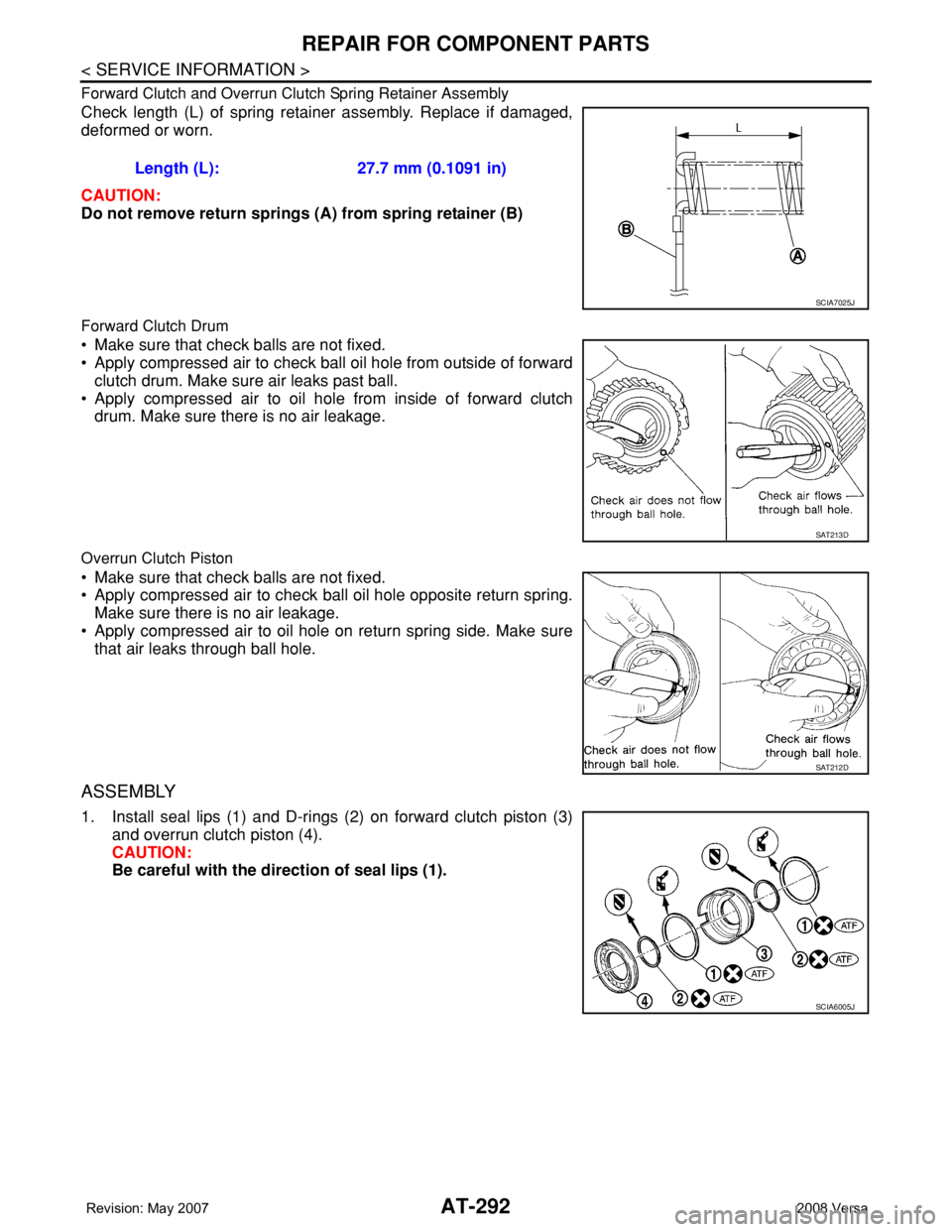

Forward Clutch and Overrun Clutch Drive Plates

• Check facing for burns, cracks or damage. Replace if necessary.

• Measure thickness of facing.

CAUTION:

• Measure the thickness at 3 locations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

Forward Clutch and Overrun Clutch Dish Plates

• Check for deformation or damage.

• Measure thickness (t) of dish plate. Replace if damaged, deformed

or worn.

SCIA6003J

SCIA6005J

Thickness of drive plate

Forward clutch

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

Overrun clutch

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".SAT162D

Thickness of dish plate (t)

Forward clutch: 2.5 mm (0.098 in)

Overrun clutch: 2.15 mm (0.0846 in)

SCIA8008E

Page 304 of 2771

AT-292

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

Forward Clutch and Overrun Clutch Spring Retainer Assembly

Check length (L) of spring retainer assembly. Replace if damaged,

deformed or worn.

CAUTION:

Do not remove return springs (A) from spring retainer (B)

Forward Clutch Drum

• Make sure that check balls are not fixed.

• Apply compressed air to check ball oil hole from outside of forward

clutch drum. Make sure air leaks past ball.

• Apply compressed air to oil hole from inside of forward clutch

drum. Make sure there is no air leakage.

Overrun Clutch Piston

• Make sure that check balls are not fixed.

• Apply compressed air to check ball oil hole opposite return spring.

Make sure there is no air leakage.

• Apply compressed air to oil hole on return spring side. Make sure

that air leaks through ball hole.

ASSEMBLY

1. Install seal lips (1) and D-rings (2) on forward clutch piston (3)

and overrun clutch piston (4).

CAUTION:

Be careful with the direction of seal lips (1).Length (L): 27.7 mm (0.1091 in)

SCIA7025J

SAT213D

SAT212D

SCIA6005J

Page 305 of 2771

REPAIR FOR COMPONENT PARTS

AT-293

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

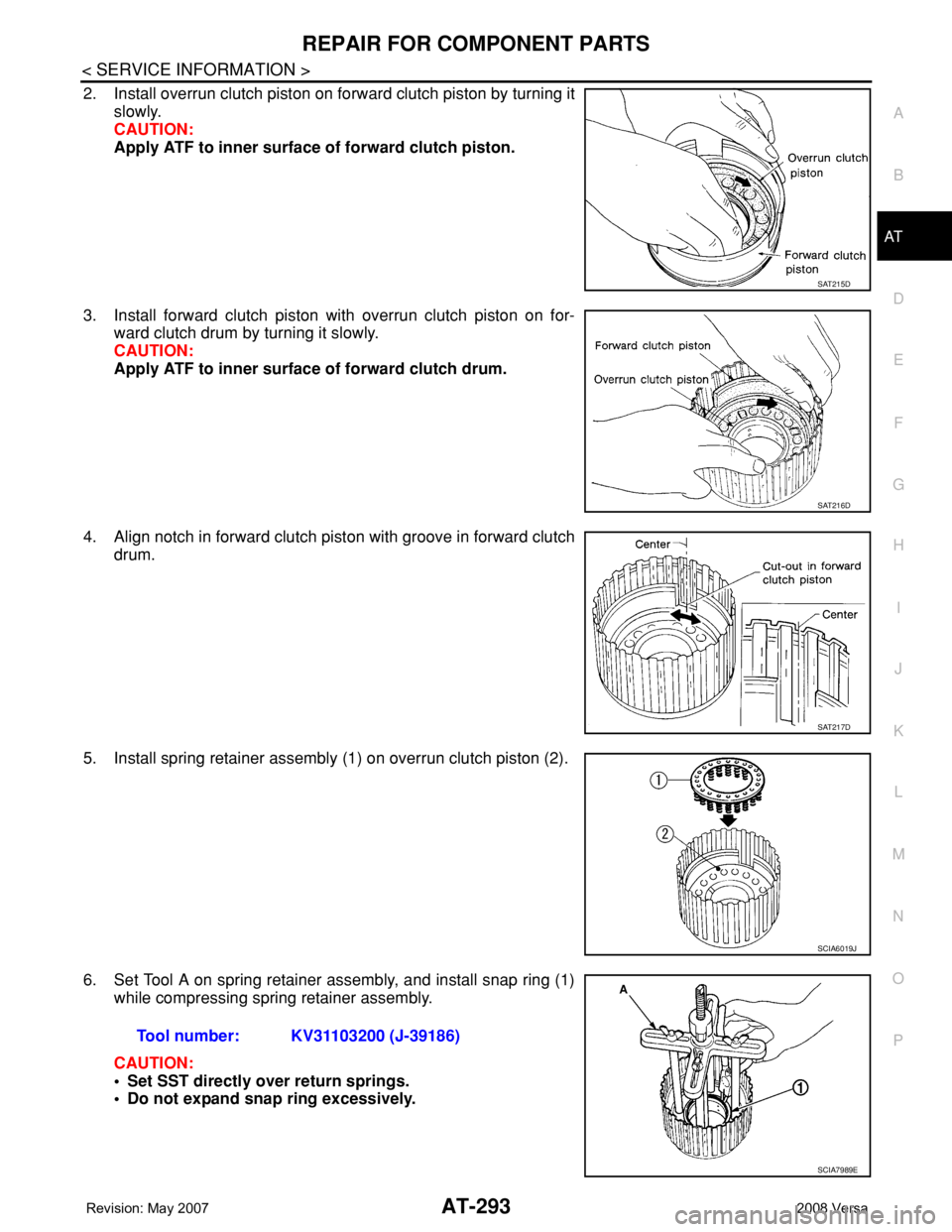

2. Install overrun clutch piston on forward clutch piston by turning it

slowly.

CAUTION:

Apply ATF to inner surface of forward clutch piston.

3. Install forward clutch piston with overrun clutch piston on for-

ward clutch drum by turning it slowly.

CAUTION:

Apply ATF to inner surface of forward clutch drum.

4. Align notch in forward clutch piston with groove in forward clutch

drum.

5. Install spring retainer assembly (1) on overrun clutch piston (2).

6. Set Tool A on spring retainer assembly, and install snap ring (1)

while compressing spring retainer assembly.

CAUTION:

• Set SST directly over return springs.

• Do not expand snap ring excessively.

SAT215D

SAT216D

SAT217D

SCIA6019J

Tool number: KV31103200 (J-39186)

SCIA7989E

Page 306 of 2771

AT-294

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

• Do not align snap ring gap with spring retainer assembly

stopper.

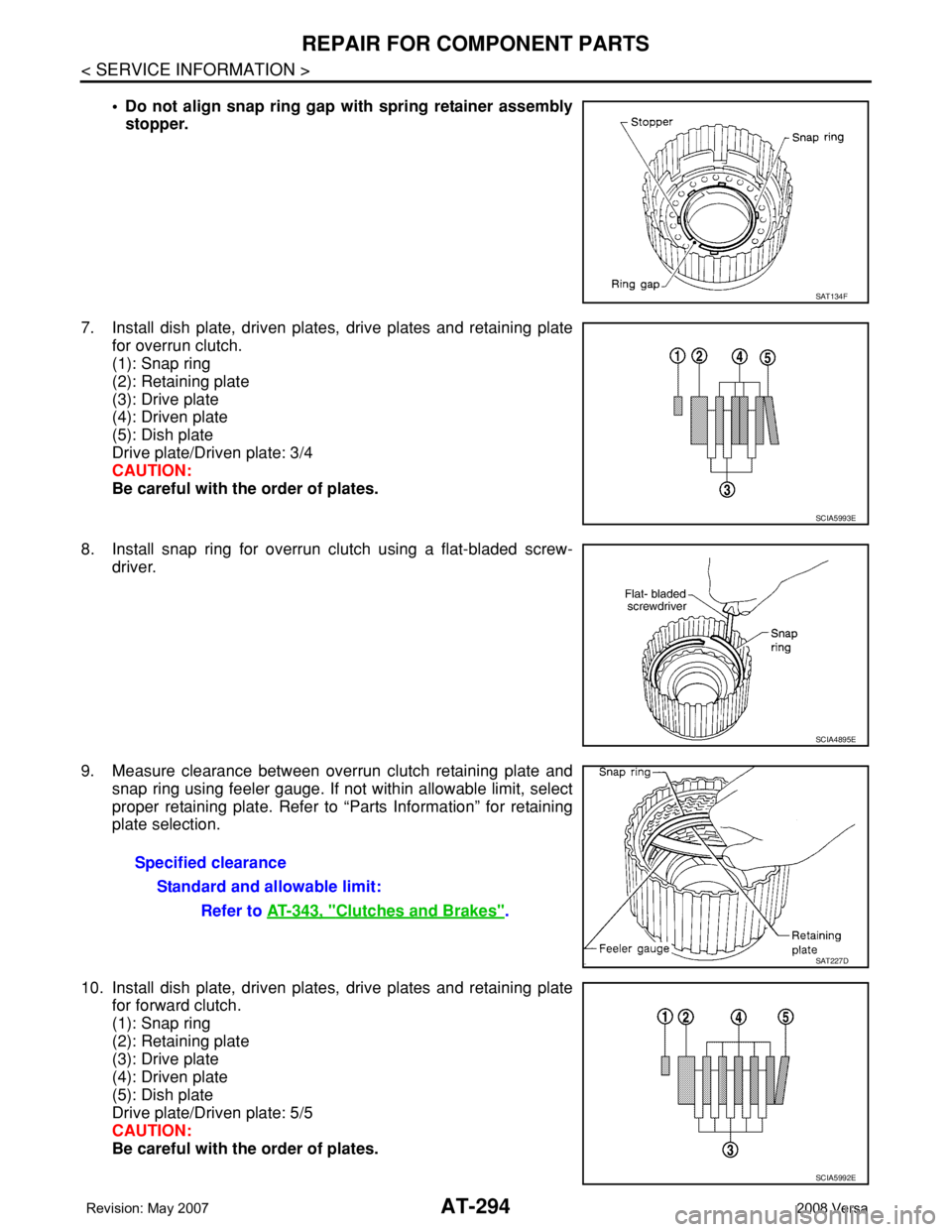

7. Install dish plate, driven plates, drive plates and retaining plate

for overrun clutch.

(1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Dish plate

Drive plate/Driven plate: 3/4

CAUTION:

Be careful with the order of plates.

8. Install snap ring for overrun clutch using a flat-bladed screw-

driver.

9. Measure clearance between overrun clutch retaining plate and

snap ring using feeler gauge. If not within allowable limit, select

proper retaining plate. Refer to “Parts Information” for retaining

plate selection.

10. Install dish plate, driven plates, drive plates and retaining plate

for forward clutch.

(1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Dish plate

Drive plate/Driven plate: 5/5

CAUTION:

Be careful with the order of plates.

SAT134F

SCIA5993E

SCIA4895E

Specified clearance

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SAT227D

SCIA5992E

Page 307 of 2771

REPAIR FOR COMPONENT PARTS

AT-295

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

11. Install snap ring for forward clutch using a flat-bladed screw-

driver.

12. Measure clearance between forward clutch retaining plate and

snap ring using feeler gauge. If not within allowable limit, select

proper retaining plate. Refer to “Parts Information” for retaining

plate selection.

13. Check operation of forward clutch and overrun clutch. Refer to

"DISASSEMBLY".

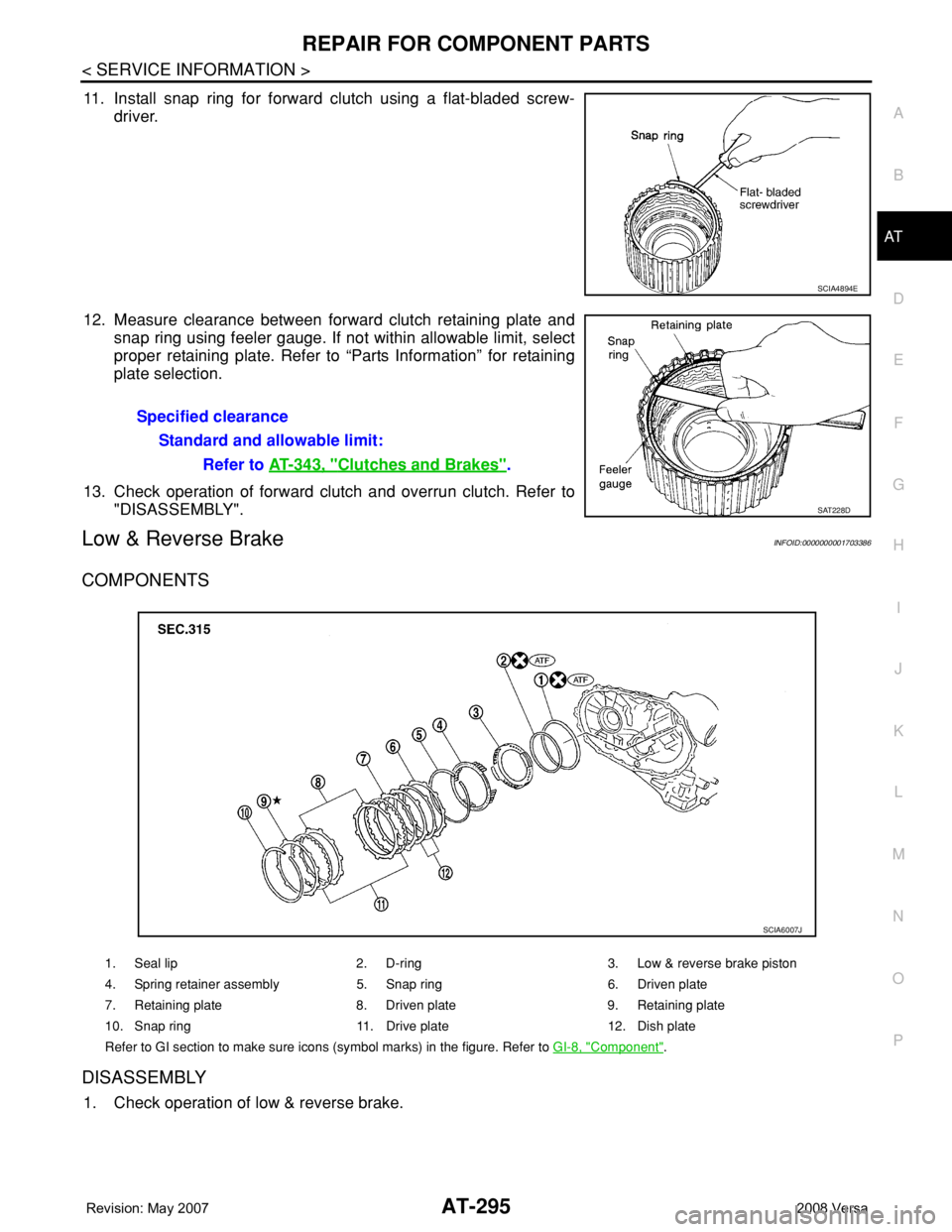

Low & Reverse BrakeINFOID:0000000001703386

COMPONENTS

DISASSEMBLY

1. Check operation of low & reverse brake.

SCIA4894E

Specified clearance

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SAT228D

1. Seal lip 2. D-ring 3. Low & reverse brake piston

4. Spring retainer assembly 5. Snap ring 6. Driven plate

7. Retaining plate 8. Driven plate 9. Retaining plate

10. Snap ring 11. Drive plate 12. Dish plate

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA6007J

Page 308 of 2771

AT-296

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

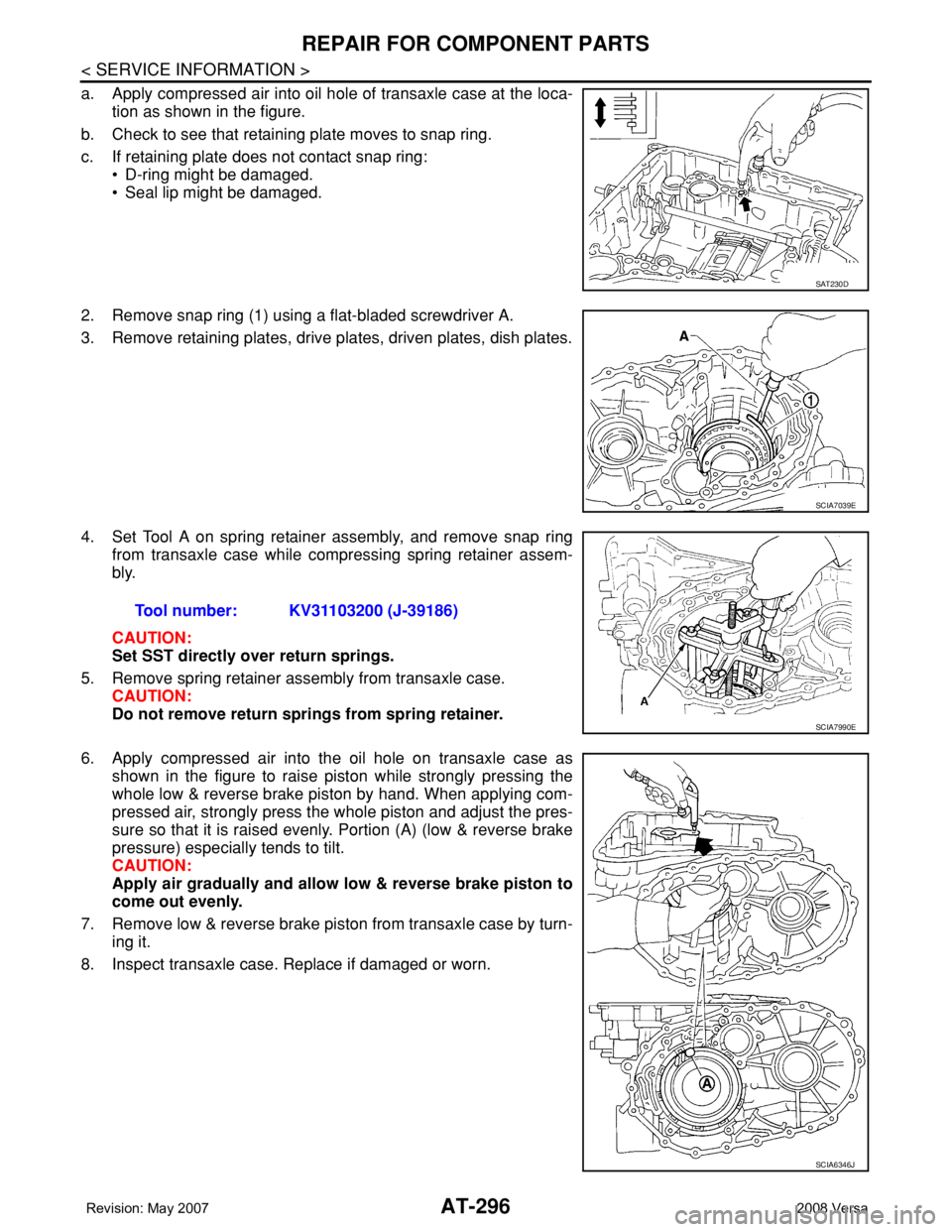

a. Apply compressed air into oil hole of transaxle case at the loca-

tion as shown in the figure.

b. Check to see that retaining plate moves to snap ring.

c. If retaining plate does not contact snap ring:

• D-ring might be damaged.

• Seal lip might be damaged.

2. Remove snap ring (1) using a flat-bladed screwdriver A.

3. Remove retaining plates, drive plates, driven plates, dish plates.

4. Set Tool A on spring retainer assembly, and remove snap ring

from transaxle case while compressing spring retainer assem-

bly.

CAUTION:

Set SST directly over return springs.

5. Remove spring retainer assembly from transaxle case.

CAUTION:

Do not remove return springs from spring retainer.

6. Apply compressed air into the oil hole on transaxle case as

shown in the figure to raise piston while strongly pressing the

whole low & reverse brake piston by hand. When applying com-

pressed air, strongly press the whole piston and adjust the pres-

sure so that it is raised evenly. Portion (A) (low & reverse brake

pressure) especially tends to tilt.

CAUTION:

Apply air gradually and allow low & reverse brake piston to

come out evenly.

7. Remove low & reverse brake piston from transaxle case by turn-

ing it.

8. Inspect transaxle case. Replace if damaged or worn.

SAT230D

SCIA7039E

Tool number: KV31103200 (J-39186)

SCIA7990E

SCIA6346J

Page 309 of 2771

REPAIR FOR COMPONENT PARTS

AT-297

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

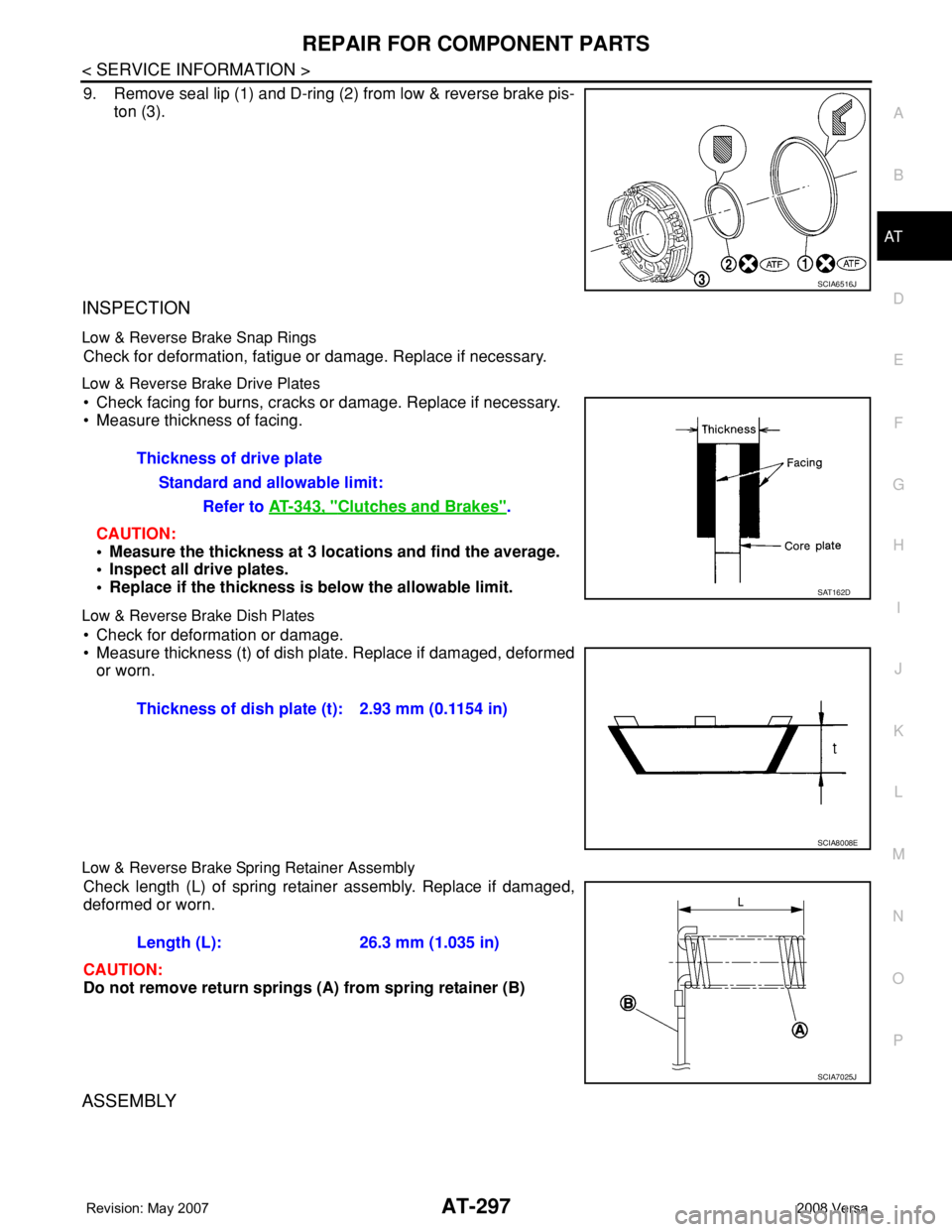

9. Remove seal lip (1) and D-ring (2) from low & reverse brake pis-

ton (3).

INSPECTION

Low & Reverse Brake Snap Rings

Check for deformation, fatigue or damage. Replace if necessary.

Low & Reverse Brake Drive Plates

• Check facing for burns, cracks or damage. Replace if necessary.

• Measure thickness of facing.

CAUTION:

• Measure the thickness at 3 locations and find the average.

• Inspect all drive plates.

• Replace if the thickness is below the allowable limit.

Low & Reverse Brake Dish Plates

• Check for deformation or damage.

• Measure thickness (t) of dish plate. Replace if damaged, deformed

or worn.

Low & Reverse Brake Spring Retainer Assembly

Check length (L) of spring retainer assembly. Replace if damaged,

deformed or worn.

CAUTION:

Do not remove return springs (A) from spring retainer (B)

ASSEMBLY

SCIA6516J

Thickness of drive plate

Standard and allowable limit:

Refer to AT-343, "

Clutches and Brakes".

SAT162D

Thickness of dish plate (t): 2.93 mm (0.1154 in)

SCIA8008E

Length (L): 26.3 mm (1.035 in)

SCIA7025J

Page 310 of 2771

AT-298

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

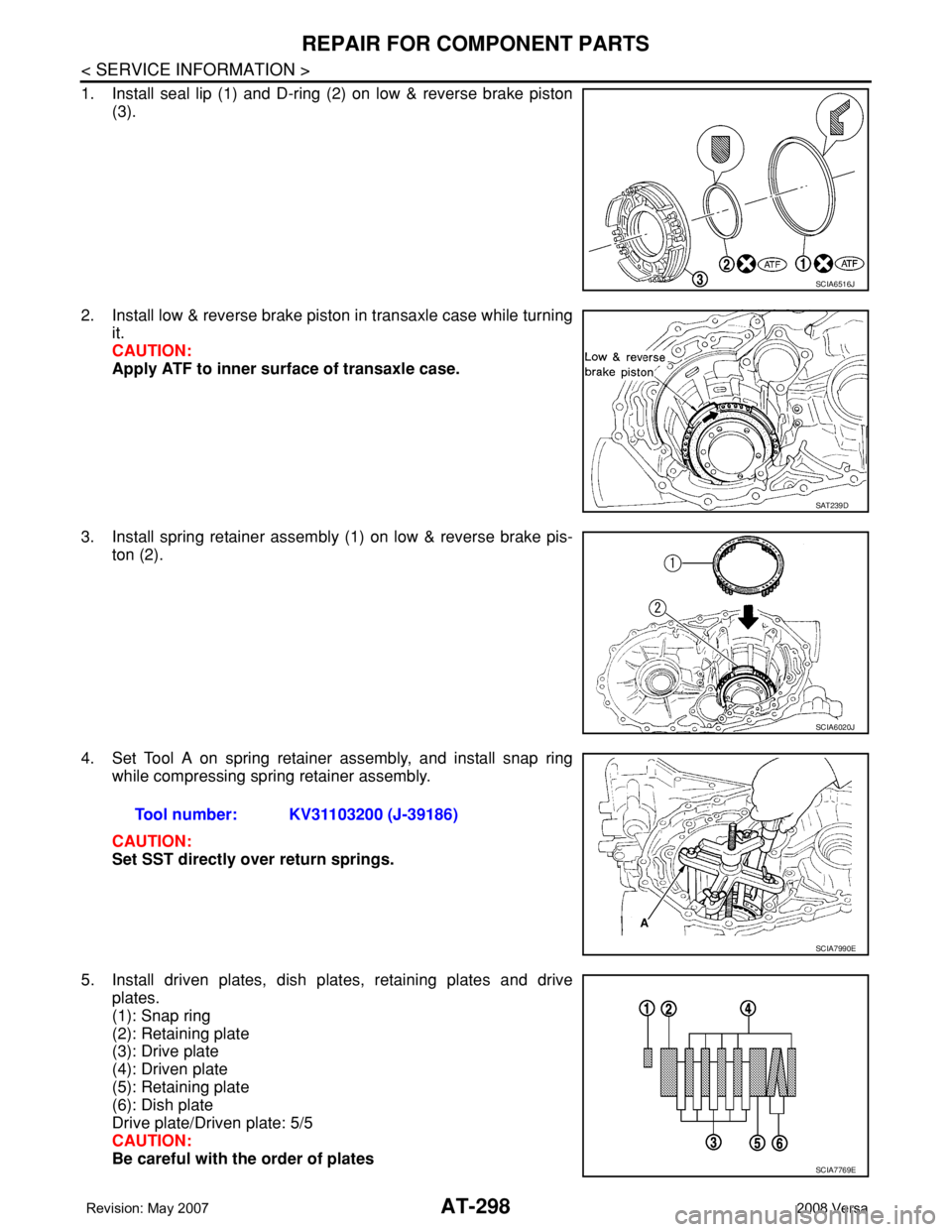

1. Install seal lip (1) and D-ring (2) on low & reverse brake piston

(3).

2. Install low & reverse brake piston in transaxle case while turning

it.

CAUTION:

Apply ATF to inner surface of transaxle case.

3. Install spring retainer assembly (1) on low & reverse brake pis-

ton (2).

4. Set Tool A on spring retainer assembly, and install snap ring

while compressing spring retainer assembly.

CAUTION:

Set SST directly over return springs.

5. Install driven plates, dish plates, retaining plates and drive

plates.

(1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Retaining plate

(6): Dish plate

Drive plate/Driven plate: 5/5

CAUTION:

Be careful with the order of plates

SCIA6516J

SAT239D

SCIA6020J

Tool number: KV31103200 (J-39186)

SCIA7990E

SCIA7769E