NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3291 of 3745

MTC-12

< SERVICE INFORMATION >

PREPARATION

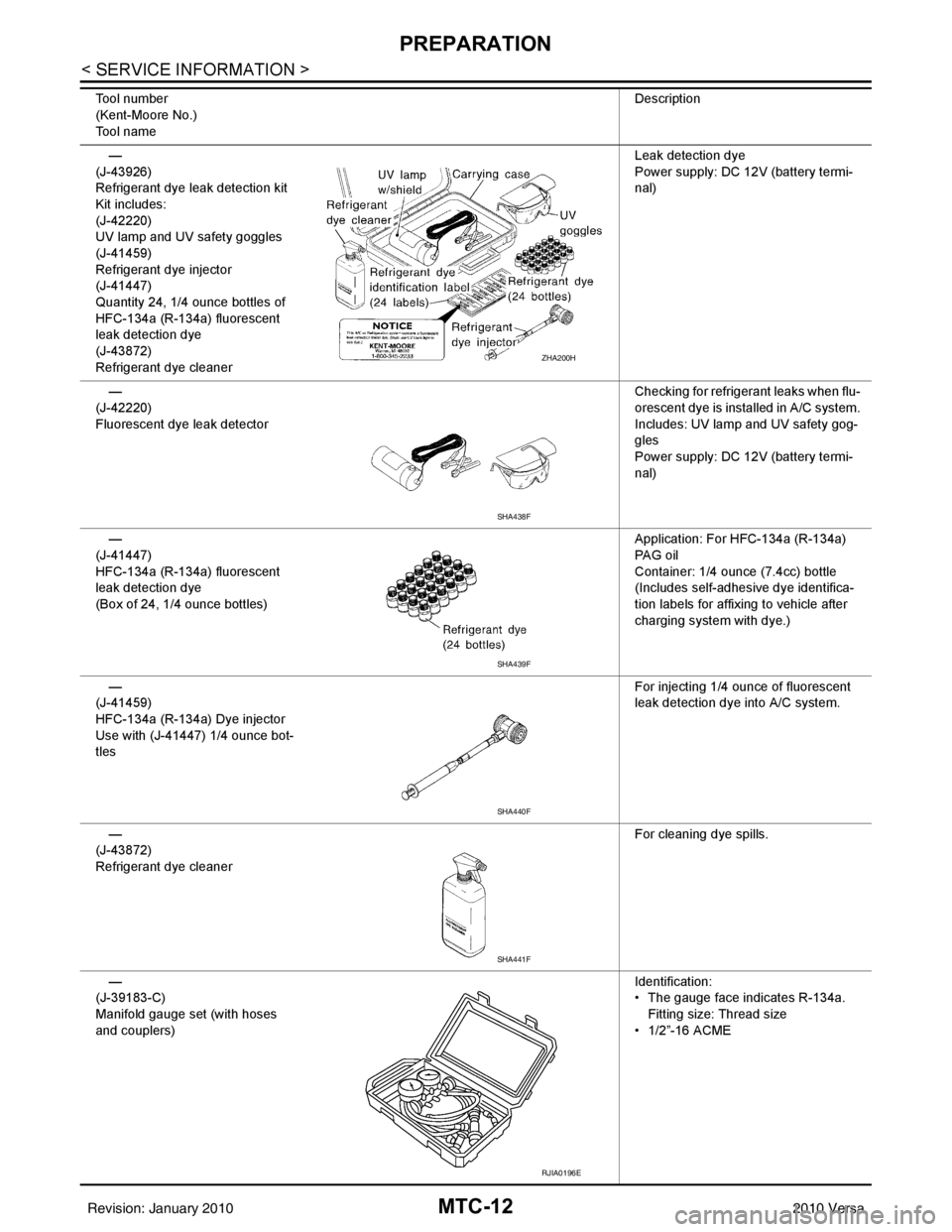

—

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

Refrigerant dye injector

(J-41447)

Quantity 24, 1/4 ounce bottles of

HFC-134a (R-134a) fluorescent

leak detection dye

(J-43872)

Refrigerant dye cleaner Leak detection dye

Power supply: DC 12

V (battery termi-

nal)

—

(J-42220)

Fluorescent dye leak detector Checking for refrigerant leaks when flu-

orescent dye is installed in A/C system.

Includes: UV lamp and UV safety gog-

gles

Power supply: DC 12

V (battery termi-

nal)

—

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles) Application: For HFC-134a (R-134a)

PA G o i l

Container: 1/4 ounce (7.4cc) bottle

(Includes self-adhesive dye identifica-

tion labels for affixing to vehicle after

charging system with dye.)

—

(J-41459)

HFC-134a (R-134a) Dye injector

Use with (J-41447) 1/4 ounce bot-

tles For injecting 1/4 ounce of fluorescent

leak detection dye into A/C system.

—

(J-43872)

Refrigerant dye cleaner For cleaning dye spills.

—

(J-39183-C)

Manifold gauge set (with hoses

and couplers) Identification:

• The gauge face indicates R-134a.

Fitting size: Thread size

• 1/2”-16 ACME

Tool number

(Kent-Moore No.)

Tool name

Description

ZHA200H

SHA438F

SHA439F

SHA440F

SHA441F

RJIA0196E

Revision: January 20102010 Versa

Page 3292 of 3745

PREPARATIONMTC-13

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

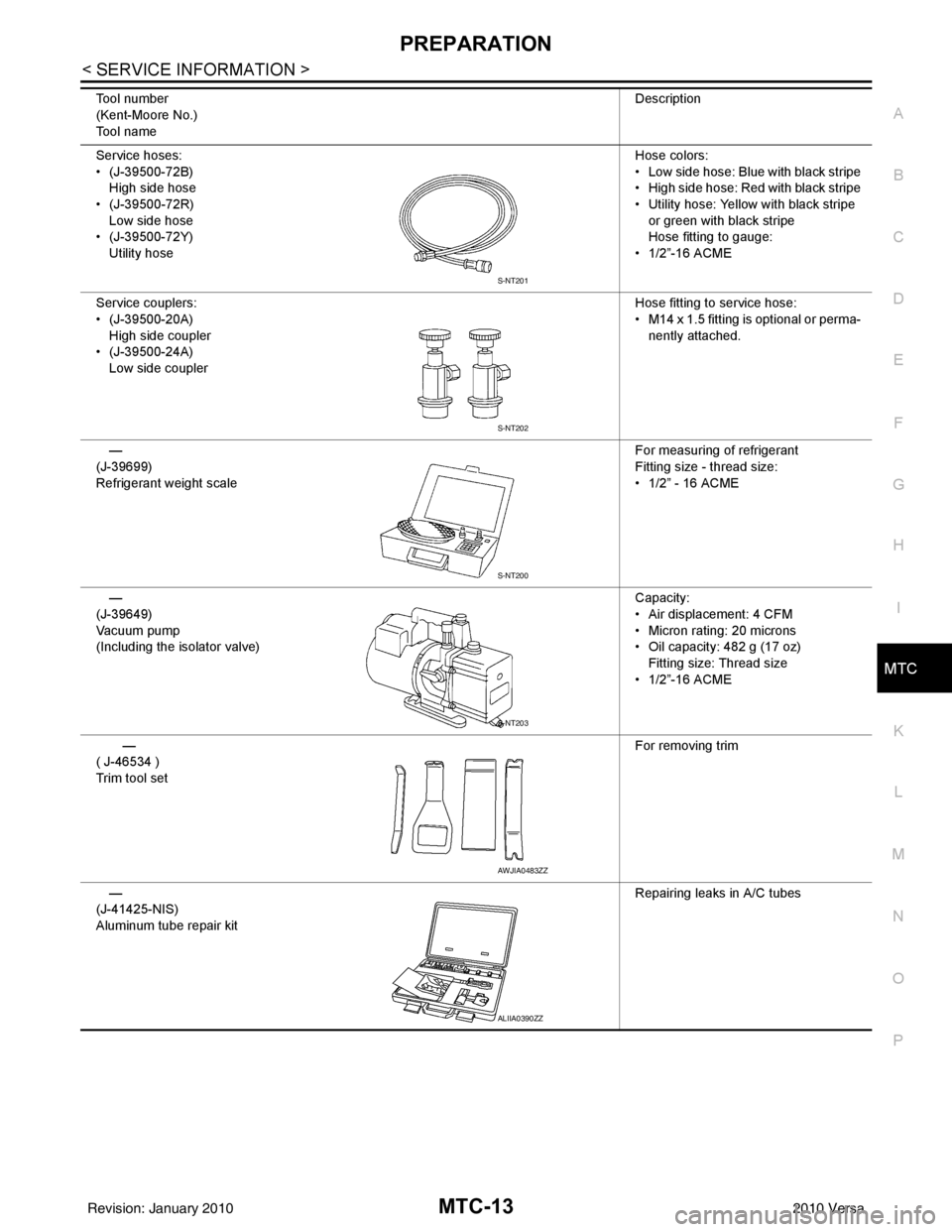

Service hoses:

• (J-39500-72B) High side hose

• (J-39500-72R) Low side hose

• (J-39500-72Y)

Utility hose Hose colors:

• Low side hose: Blue with black stripe

• High side hose: Red with black stripe

• Utility hose: Yellow with black stripe

or green with black stripe

Hose fitting to gauge:

• 1/2”-16 ACME

Service couplers:

• (J-39500-20A) High side coupler

• (J-39500-24A)

Low side coupler Hose fitting to service hose:

• M14 x 1.5 fitting is optional or perma-

nently attached.

—

(J-39699)

Refrigerant weight scale For measuring of refrigerant

Fitting size - thread size:

• 1/2” - 16 ACME

—

(J-39649)

Va c u u m p u m p

(Including the isolator valve) Capacity:

• Air displacement: 4 CFM

• Micron rating: 20 microns

• Oil capacity: 482 g (17 oz)

Fitting size: Thread size

• 1/2”-16 ACME

—

( J-46534 )

Trim tool set For removing trim

—

(J-41425-NIS)

Aluminum tube repair kit Repairing leaks in A/C tubes

Tool number

(Kent-Moore No.)

Tool name

Description

S-NT201

S-NT202

S-NT200

S-NT203

AWJIA0483ZZ

ALIIA0390ZZ

Revision: January 20102010 Versa

Page 3293 of 3745

MTC-14

< SERVICE INFORMATION >

PREPARATION

Commercial Service Tool

INFOID:0000000005396483

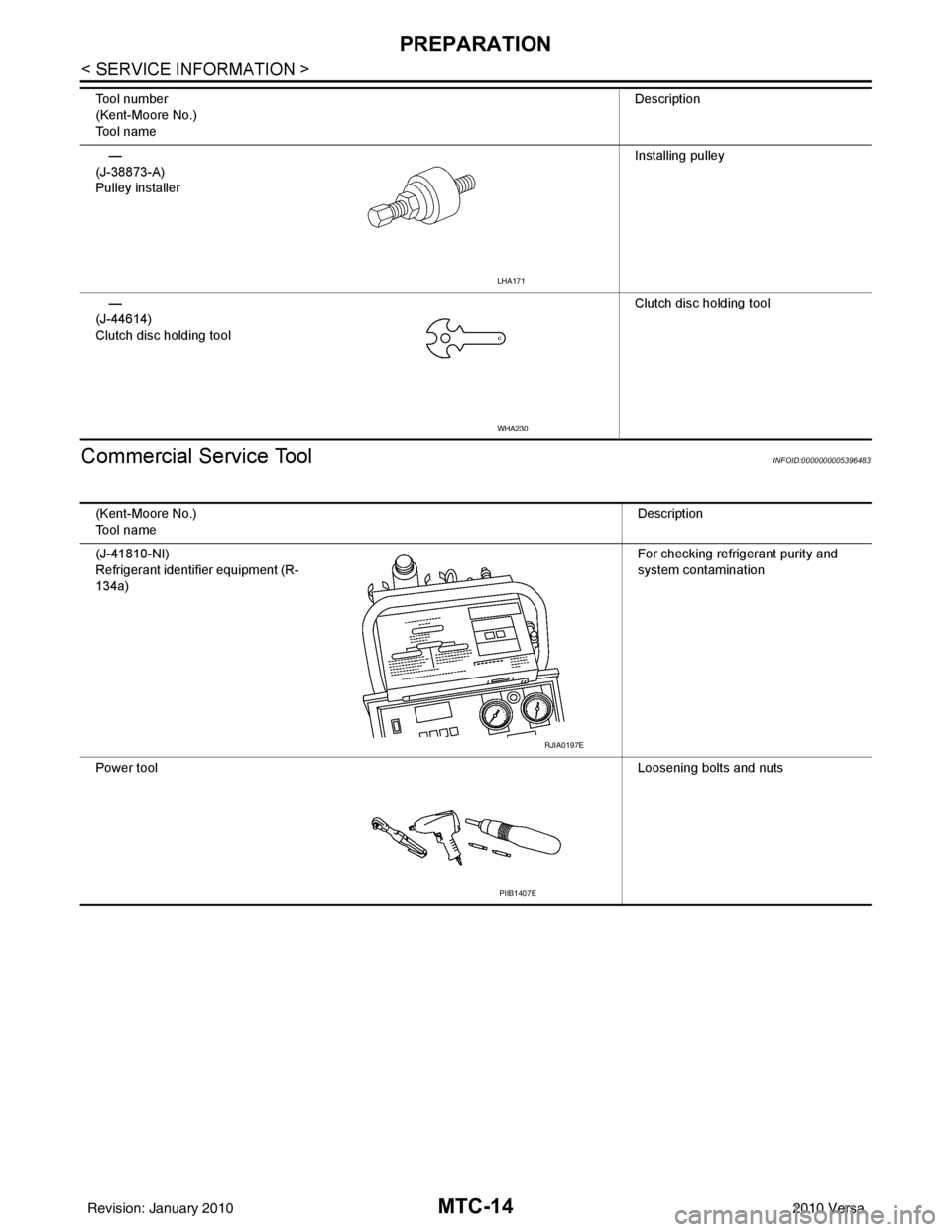

—

(J-38873-A)

Pulley installer Installing pulley

—

(J-44614)

Clutch disc holding tool Clutch disc holding tool

Tool number

(Kent-Moore No.)

Tool name

Description

LHA171

WHA230

(Kent-Moore No.)

Tool name

Description

(J-41810-NI)

Refrigerant identifier equipment (R-

134a) For checking refrigerant purity and

system contamination

Power tool Loosening bolts and nuts

RJIA0197E

PIIB1407E

Revision: January 20102010 Versa

Page 3294 of 3745

REFRIGERATION SYSTEMMTC-15

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000005396484

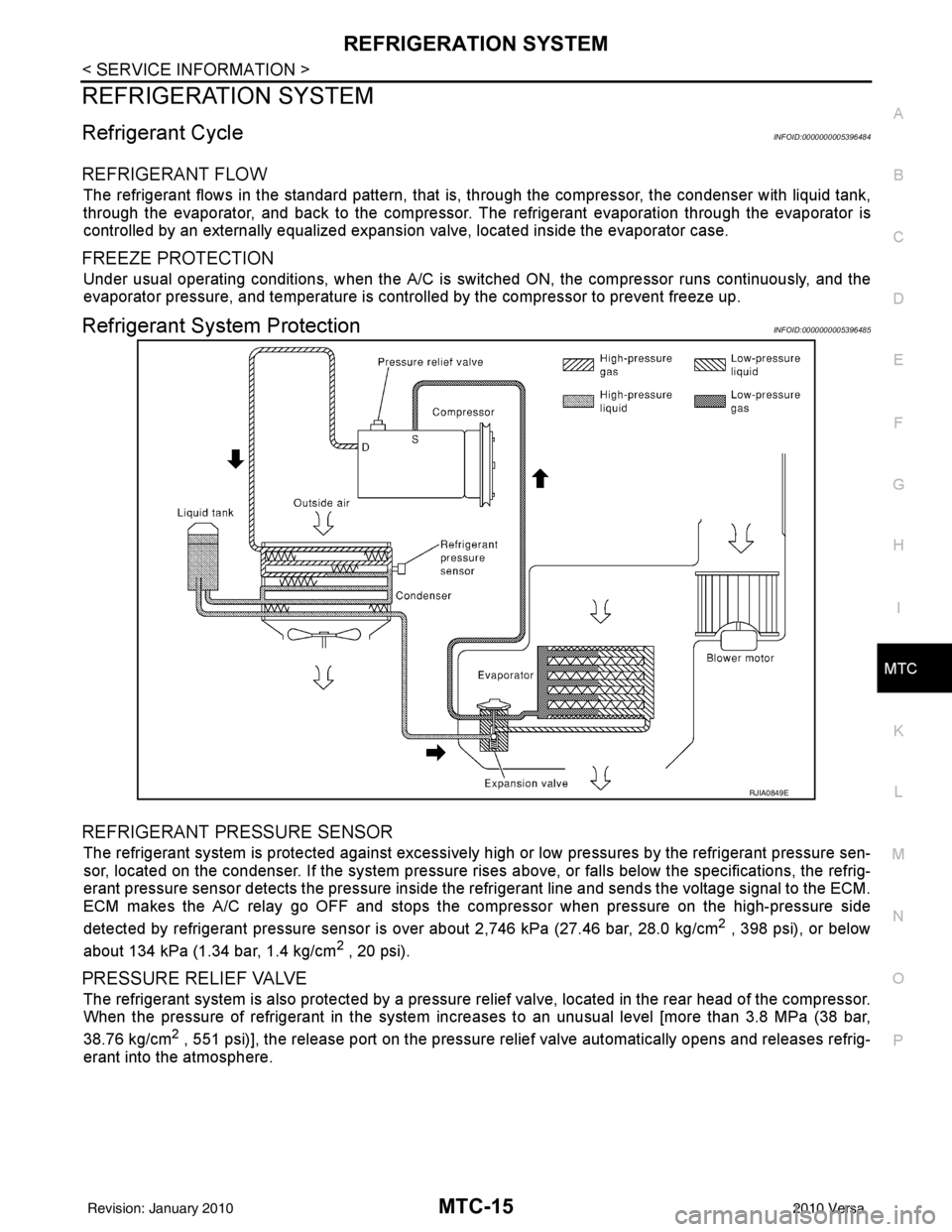

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the evaporator, and back to the compressor. T he refrigerant evaporation through the evaporator is

controlled by an externally equalized expansion valve, located inside the evaporator case.

FREEZE PROTECTION

Under usual operating conditions, when the A/C is s witched ON, the compressor runs continuously, and the

evaporator pressure, and temperature is controlled by the compressor to prevent freeze up.

Refrigerant System ProtectionINFOID:0000000005396485

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above, or falls below the specifications, the refrig-

erant pressure sensor detects the pressure inside t he refrigerant line and sends the voltage signal to the ECM.

ECM makes the A/C relay go OFF and stops the compressor when pressure on the high-pressure side

detected by refrigerant pressure sensor is over about 2,746 kPa (27.46 bar, 28.0 kg/cm

2 , 398 psi), or below

about 134 kPa (1.34 bar, 1.4 kg/cm

2 , 20 psi).

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system in creases to an unusual level [more than 3.8 MPa (38 bar,

38.76 kg/cm

2 , 551 psi)], the release port on the pressure relief valve automatically opens and releases refrig-

erant into the atmosphere.

RJIA0849E

Revision: January 20102010 Versa

Page 3295 of 3745

MTC-16

< SERVICE INFORMATION >

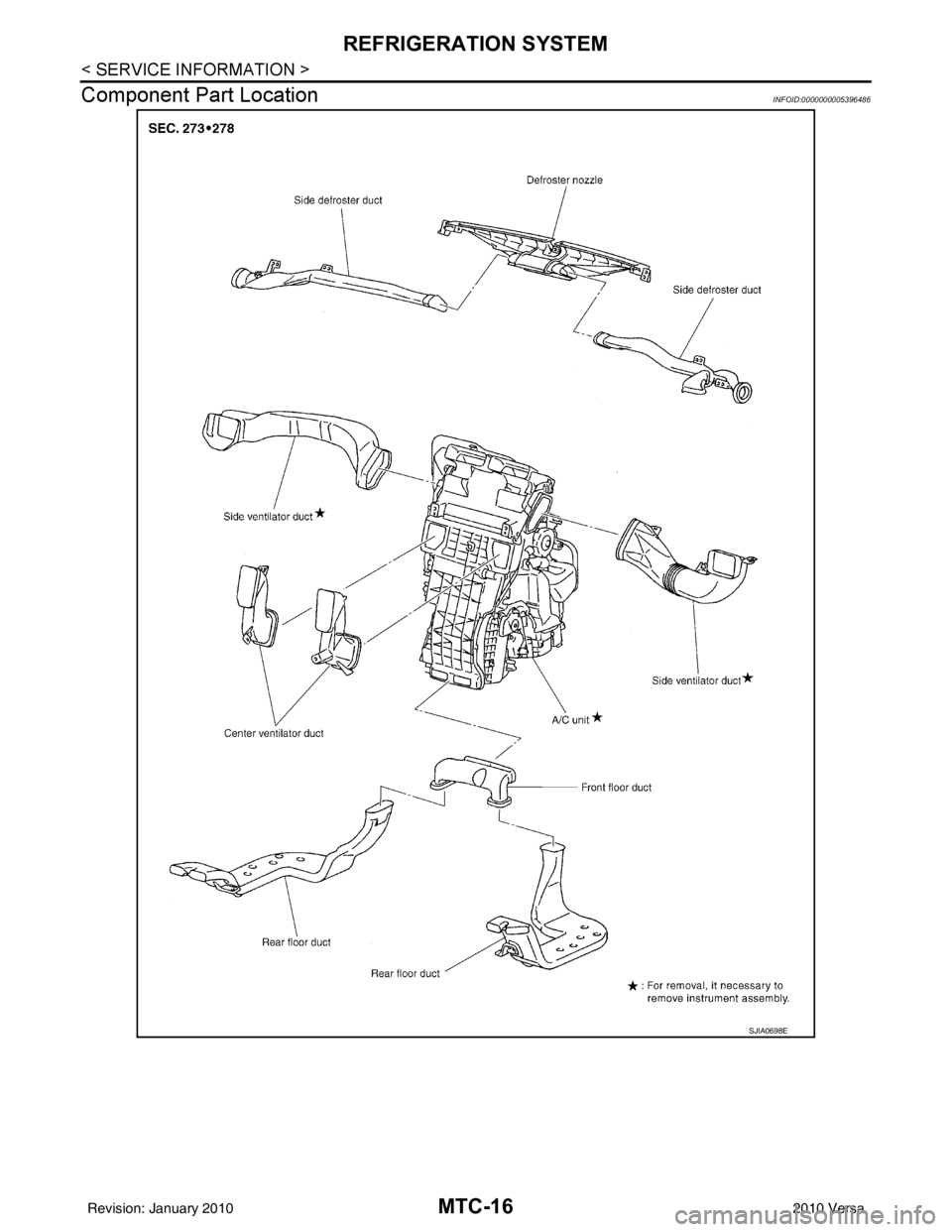

REFRIGERATION SYSTEM

Component Part Location

INFOID:0000000005396486

SJIA0698E

Revision: January 20102010 Versa

Page 3296 of 3745

OIL

MTC-17

< SERVICE INFORMATION >

C

D E

F

G H

I

K L

M A

B

MTC

N

O P

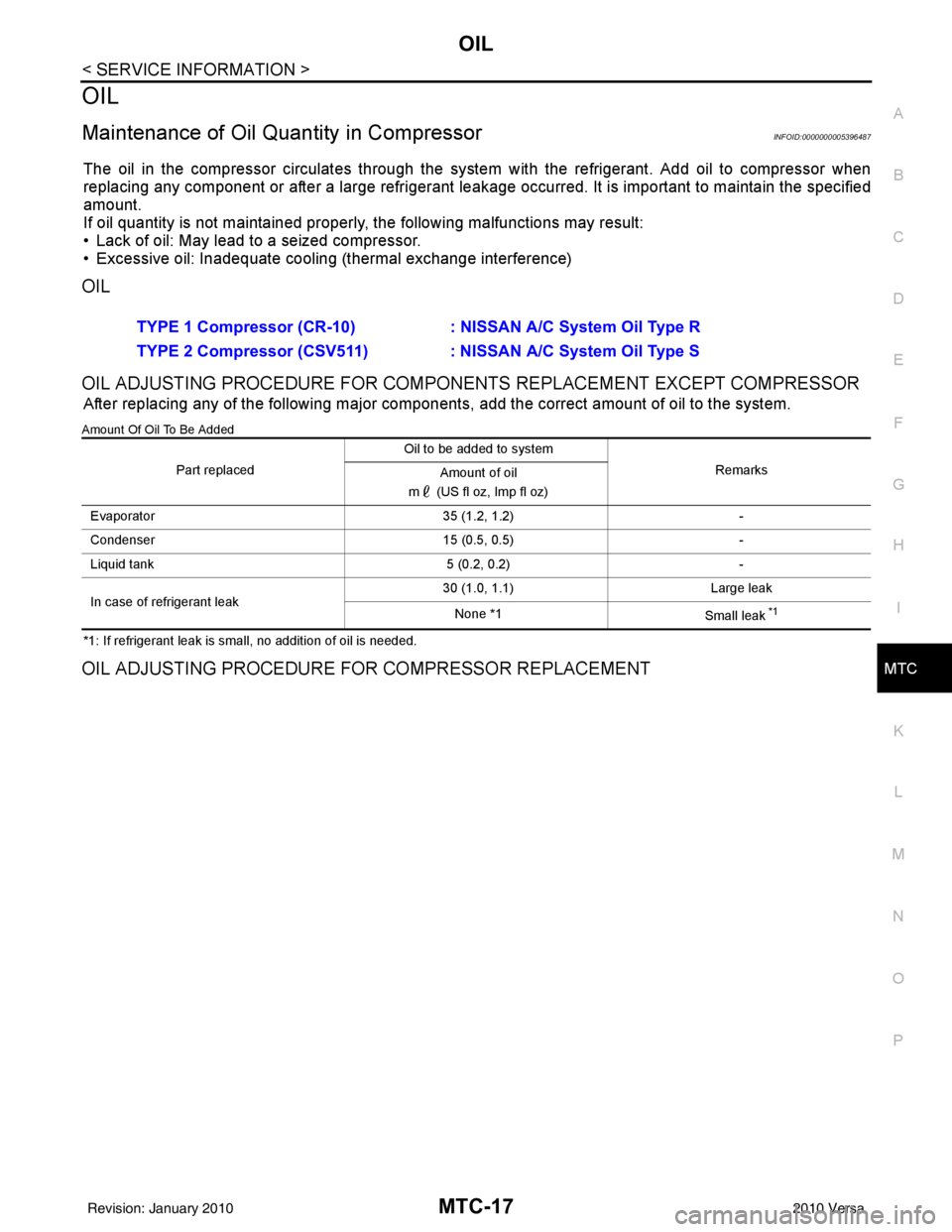

OIL

Maintenance of Oil Qu antity in CompressorINFOID:0000000005396487

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage occurred. It is important to maintain the specified

amount.

If oil quantity is not maintained properly , the following malfunctions may result:

• Lack of oil: May lead to a seized compressor.

• Excessive oil: Inadequate cooling (thermal exchange interference)

OIL

OIL ADJUSTING PROCEDURE FOR COMPONENTS REPLACEMENT EXCEPT COMPRESSOR

After replacing any of the following major components, add the correct amount of oil to the system.

Amount Of Oil To Be Added

*1: If refrigerant leak is small, no addition of oil is needed.

OIL ADJUSTING PROCEDURE FOR COMPRESSOR REPLACEMENT

TYPE 1 Compressor (CR-10) : NISSAN A/C System Oil Type R

TYPE 2 Compressor (CSV511) : NISSAN A/C System Oil Type S

Part replaced Oil to be added to system

Remarks

Amount of oil

m (US fl oz, Imp fl oz)

Evaporator 35 (1.2, 1.2)-

Condenser 15 (0.5, 0.5)-

Liquid tank 5 (0.2, 0.2)-

In case of refrigerant leak 30 (1.0, 1.1)

Large leak

None *1 Small leak

*1

Revision: January 20102010 Versa

Page 3297 of 3745

MTC-18

< SERVICE INFORMATION >

OIL

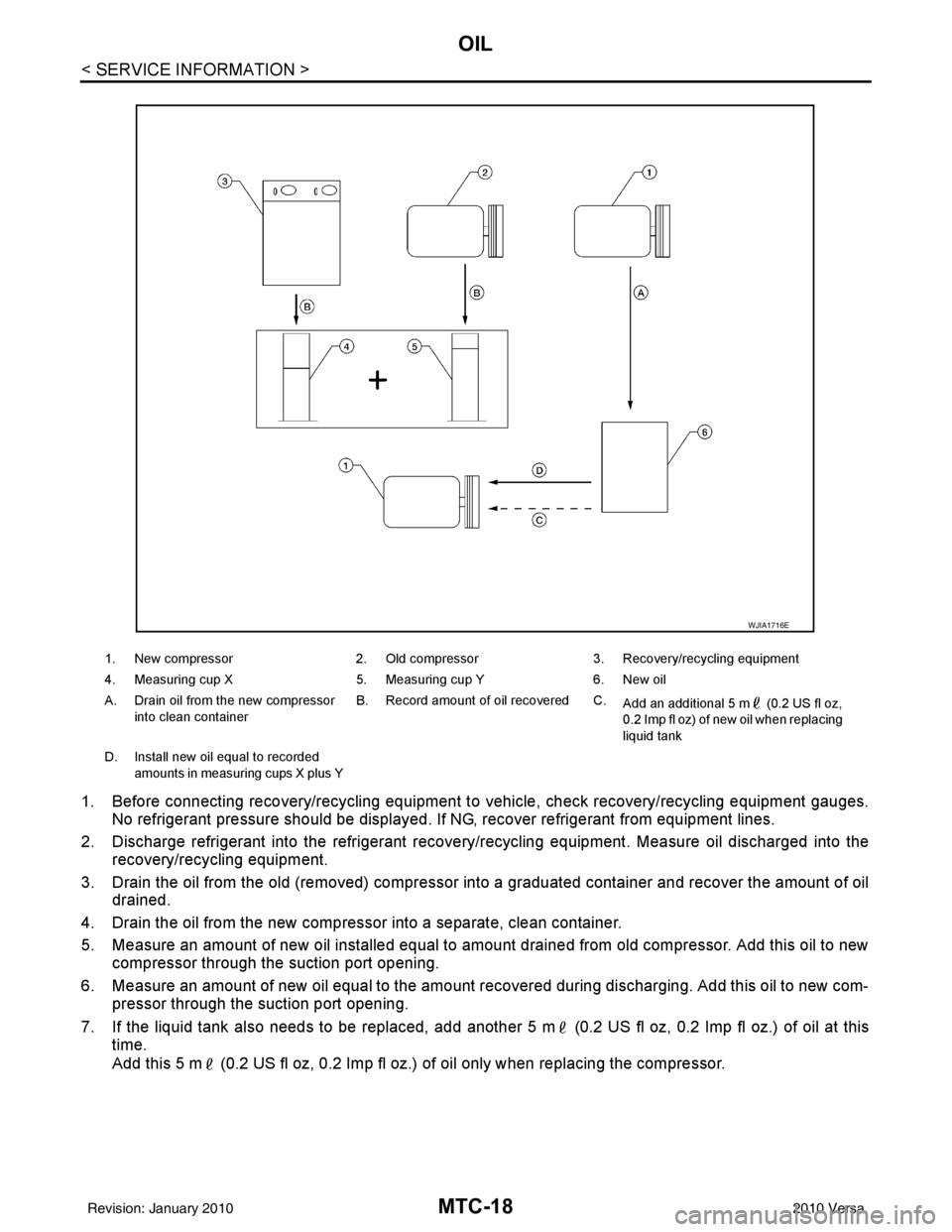

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Discharge refrigerant into the refrigerant recove ry/recycling equipment. Measure oil discharged into the

recovery/recycling equipment.

3. Drain the oil from the old (removed) compressor into a graduated container and recover the amount of oil drained.

4. Drain the oil from the new compressor into a separate, clean container.

5. Measure an amount of new oil installed equal to amount drained from old compressor. Add this oil to new compressor through the suction port opening.

6. Measure an amount of new oil equal to the amount recovered during discharging. Add this oil to new com- pressor through the suction port opening.

7. If the liquid tank also needs to be replaced, add another 5 m (0.2 US fl oz, 0.2 Imp fl oz.) of oil at this

time.

Add this 5 m (0.2 US fl oz, 0.2 Imp fl oz.) of oil only when replacing the compressor.

1. New compressor 2. Old compressor3. Recovery/recycling equipment

4. Measuring cup X 5. Measuring cup Y6. New oil

A. Drain oil from the new compressor into clean container B. Record amount of oil recovered C.

Add an additional 5 m (0.2 US fl oz,

0.2 Imp fl oz) of new oil when replacing

liquid tank

D. Install new oil equal to recorded amounts in measuring cups X plus Y

WJIA1716E

Revision: January 20102010 Versa

Page 3298 of 3745

AIR CONDITIONER CONTROLMTC-19

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

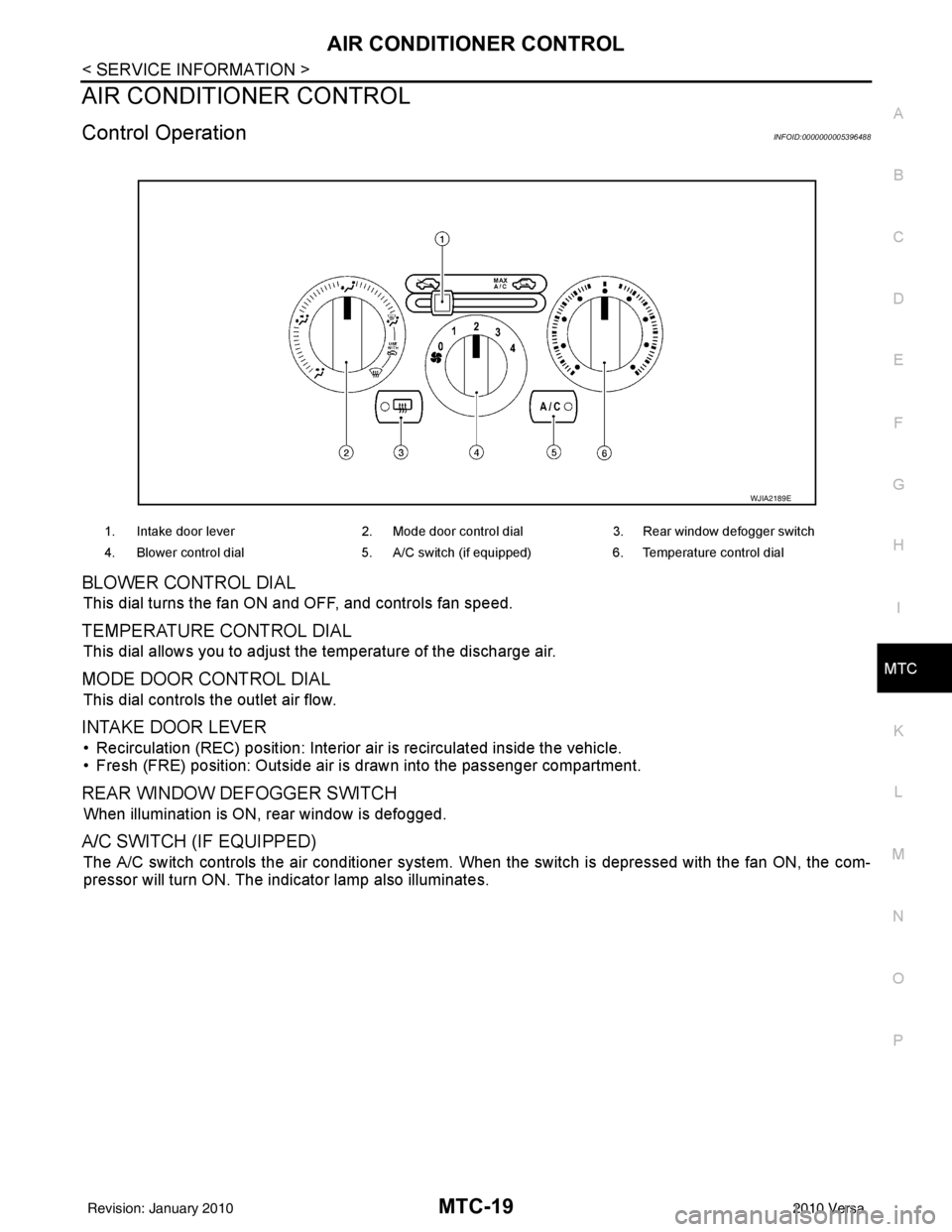

AIR CONDITIONER CONTROL

Control OperationINFOID:0000000005396488

BLOWER CONTROL DIAL

This dial turns the fan ON and OFF, and controls fan speed.

TEMPERATURE CONTROL DIAL

This dial allows you to adjust the temperature of the discharge air.

MODE DOOR CONTROL DIAL

This dial controls the outlet air flow.

INTAKE DOOR LEVER

• Recirculation (REC) position: Interior air is recirculated inside the vehicle.

• Fresh (FRE) position: Outside air is drawn into the passenger compartment.

REAR WINDOW DEFOGGER SWITCH

When illumination is ON, rear window is defogged.

A/C SWITCH (IF EQUIPPED)

The A/C switch controls the air conditioner system. When the switch is depressed with the fan ON, the com-

pressor will turn ON. The indicator lamp also illuminates.

1. Intake door lever 2. Mode door control dial 3. Rear window defogger switch

4. Blower control dial 5. A/C switch (if equipped)6. Temperature control dial

WJIA2189E

Revision: January 20102010 Versa

Page 3299 of 3745

MTC-20

< SERVICE INFORMATION >

AIR CONDITIONER CONTROL

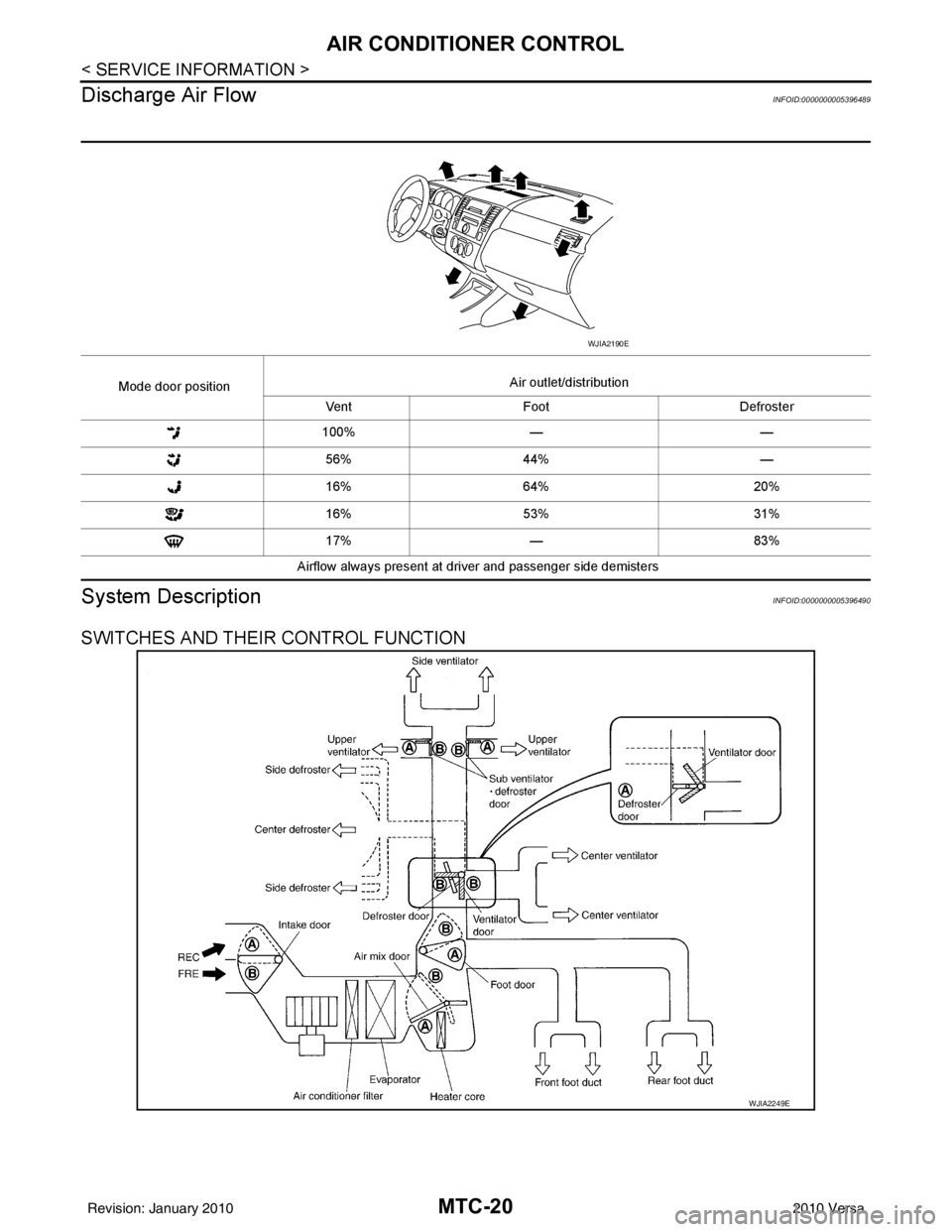

Discharge Air Flow

INFOID:0000000005396489

System DescriptionINFOID:0000000005396490

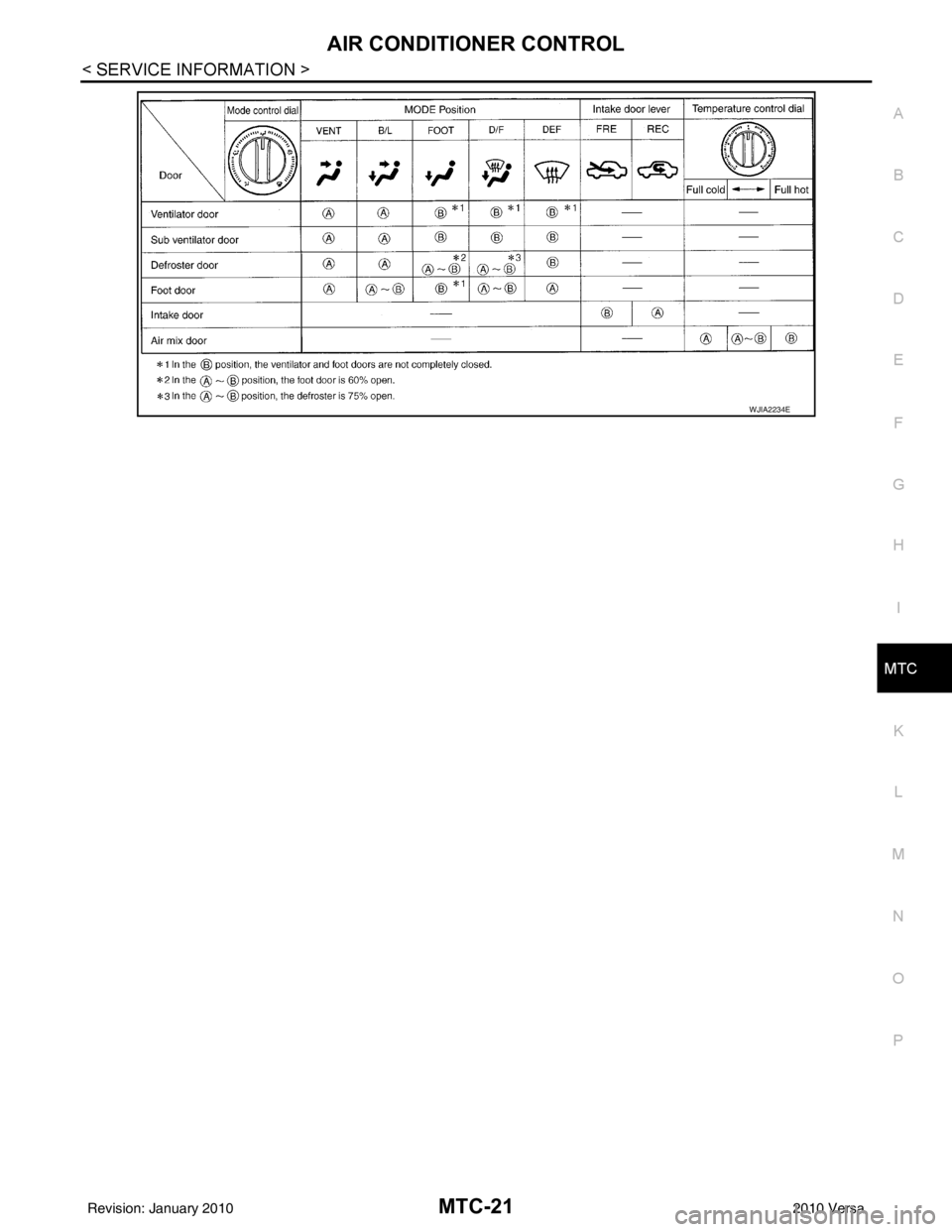

SWITCHES AND THEIR CONTROL FUNCTION

Mode door position Air outlet/distribution

Vent Foot Defroster

100% — —

56% 44% —

16% 64% 20%

16% 53% 31%

17% — 83%

Airflow always present at driver and passenger side demisters

WJIA2190E

WJIA2249E

Revision: January 20102010 Versa

Page 3300 of 3745

AIR CONDITIONER CONTROLMTC-21

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

WJIA2234E

Revision: January 20102010 Versa