NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3271 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MAINSHAFT AND GEARSMT-87

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

Check contact surface of baulk ring cam and insert key for exces-

sive wear, uneven wear, bend, and damage. NISSAN TIIDA 2010 Service Repair Manual MAINSHAFT AND GEARSMT-87

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

Check contact surface of baulk ring cam and insert key for exces-

sive wear, uneven wear, bend, and damage.](/img/5/57397/w960_57397-3270.png)

MAINSHAFT AND GEARSMT-87

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

Check contact surface of baulk ring cam and insert key for exces-

sive wear, uneven wear, bend, and damage. Replace if necessary.

Bearing

Check bearing for damage and unsmooth rotation. Replace if neces-

sary.

CAUTION:

• Replace mainshaft front bearing outer race and mainshaft front bearing inner race as a set.

• Replace mainshaft rear bearin g inner race and mainshaft rear

bearing outer race as a set.

ASSEMBLY

CAUTION:

• Select mainshaft rear bearing adjusting shim acco rding to the following procedures when replacing

mainshaft adjusting shim, 6th main gear , 5th main gear, or 4th main gear.

- Replace mainshaft adjusting shim.

• If new mainshaft adjusting shim is thinner than previous one, offset the thickness difference by

selecting thicker mainshaft r ear bearing adjusting shim.

• If new mainshaft adjusting shim is thicker th an previous one, offset the thickness difference by

selecting thinner mainshaft rear bearing adjusting shim.

- Replace 6th main gear, 5th main gear, or 4th main gear.

• Measure the thickness of the main gear used before and the new main gear

• Increase the thickness of the mainsh aft rear bearing adjusting shim, if the difference is smaller than

0.025 mm (0.0010 in).

• Replace transaxle assembly when replacing mainshaft.

1. Install mainshaft front bearing inner race (1) using the Tool (A).

CAUTION:

Replace mainshaft front bearing outer race and mainshaft

front bearing inner race as a set.

2. Apply gear oil to 1st inner baulk ring, 1st synchronizer cone, 1st outer baulk ring, 2nd inner baulk ring, 2nd synchronizer cone,

and 2nd outer baulk ring.

CAUTION:

• Replace 1st inner baulk ring, 1st synchronizer cone, and

1st outer baulk ring as a set.

• Replace 2nd inner baulk ring, 2nd synchronize r cone, and 2nd outer baulk ring as a set.

3. Install insert keys and 1st-2nd coupling sleeve to 1st-2nd synchronizer hub. CAUTION:

Replace 1st-2nd synchroni zer hub and 1st-2nd coupling sleeve as a set.

SCIA0608J

SPD715

Tool number A: ST36720030 ( — )

PCIB1733E

Revision: January 20102010 Versa

Page 3272 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-88

< SERVICE INFORMATION >[RS6F94R]

MAINSHAFT AND GEARS

4. Install 1st main gear (1), 1st inner baulk ring, 1st synchronizer

cone, 1st outer baulk ring, 1s t-2nd synchronizer hub assembly

(2), 2nd NISSAN TIIDA 2010 Service Repair Manual MT-88

< SERVICE INFORMATION >[RS6F94R]

MAINSHAFT AND GEARS

4. Install 1st main gear (1), 1st inner baulk ring, 1st synchronizer

cone, 1st outer baulk ring, 1s t-2nd synchronizer hub assembly

(2), 2nd](/img/5/57397/w960_57397-3271.png)

MT-88

< SERVICE INFORMATION >[RS6F94R]

MAINSHAFT AND GEARS

4. Install 1st main gear (1), 1st inner baulk ring, 1st synchronizer

cone, 1st outer baulk ring, 1s t-2nd synchronizer hub assembly

(2), 2nd inner baulk ring, 2nd synchronizer cone, and 2nd outer

baulk ring.

5. Install bushing (3) using the Tool (A).

6. Install 3rd main gear (1) and 2nd main gear (2) using Tool (A).

7. Measure dimension (L) as shown. Select mainshaft adjusting shim (1) according to the following list, and then install it to main-

shaft.

Unit: mm (in)

8. Install 4th main gear (1) using Tool (A). Tool number A: KV32102700 ( — )

PCIB1734E

Tool number A: ST32102700 ( — )

PCIB1735E

2: Mainshaft

3 : 3rd main gear

Dimension (L) Mainshaft adjusting shim thickness

147.690 – 147.666 (5.8146 – 5.8136) 1.500 (0.0591)

147.665 – 147.641 (5.8136 – 5.8126) 1.525 (0.0600)

147.640 – 147.616 (5.8126 – 5.8116) 1.550 (0.0610)

147.615 – 147.591 (5.8116 – 5.8107) 1.575 (0.0620)

147.590 – 147.566 (5.8106 – 5.8097) 1.600 (0.0630)

147.565 – 147.541 (5.8096 – 5.8087) 1.625 (0.0640)

147.540 – 147.516 (5.8086 – 5.8077) 1.650 (0.0650)

147.515 – 147.491 (5.8077 – 5.8067) 1.675 (0.0659)

147.490 – 147.466 (5.8067 – 5.8057) 1.700 (0.0669)

147.465 – 147.441 (5.8057 – 5.8048) 1.725 (0.0679)

147.440 – 147.416 (5.8047 – 5.8038) 1.750 (0.0689)

147.415 – 147.391 (5.8037 – 5.8028) 1.775 (0.0699)

Tool number A: KV32102700 ( — )

PCIB1736E

PCIB1737E

Revision: January 20102010 Versa

Page 3273 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MAINSHAFT AND GEARSMT-89

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

9. Install 5th main gear (1) using Tool (A).

10. Install 6th main gear (1) using Tool (A).

11. Install mains NISSAN TIIDA 2010 Service Repair Manual MAINSHAFT AND GEARSMT-89

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

9. Install 5th main gear (1) using Tool (A).

10. Install 6th main gear (1) using Tool (A).

11. Install mains](/img/5/57397/w960_57397-3272.png)

MAINSHAFT AND GEARSMT-89

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

9. Install 5th main gear (1) using Tool (A).

10. Install 6th main gear (1) using Tool (A).

11. Install mainshaft rear bearing inner race (1) usingTool (A).

CAUTION:

Replace mainshaft rear bearing inner race and mainshaft

rear bearing outer race as a set.

12. Install snap ring. CAUTION:

Never reuse snap ring.Tool number A: KV32102700 ( — )

PCIB1738E

Tool number A: KV32102700 ( — )

PCIB1739E

Tool number A: ST30901000 (J-26010-

01)

PCIB1740E

Revision: January 20102010 Versa

Page 3274 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-90

< SERVICE INFORMATION >[RS6F94R]

REVERSE IDLER SHAFT AND GEARS

REVERSE IDLER SHAFT AND GEARS

Disassembly and AssemblyINFOID:0000000005397203

DISASSEMBLY

1. Remove reverse output gear (1).

2. Rem NISSAN TIIDA 2010 Service Repair Manual MT-90

< SERVICE INFORMATION >[RS6F94R]

REVERSE IDLER SHAFT AND GEARS

REVERSE IDLER SHAFT AND GEARS

Disassembly and AssemblyINFOID:0000000005397203

DISASSEMBLY

1. Remove reverse output gear (1).

2. Rem](/img/5/57397/w960_57397-3273.png)

MT-90

< SERVICE INFORMATION >[RS6F94R]

REVERSE IDLER SHAFT AND GEARS

REVERSE IDLER SHAFT AND GEARS

Disassembly and AssemblyINFOID:0000000005397203

DISASSEMBLY

1. Remove reverse output gear (1).

2. Remove snap ring (1) using suitable tool.

3. Remove reverse baulk ring (1) and return spring (2).

4. Remove snap ring (1), lock washer (2), and reverse input gear

(3) using suitable tool.

PCIB1760E

PCIB1759E

PCIB1758E

PCIB1757E

Revision: January 20102010 Versa

Page 3275 of 3745

![NISSAN TIIDA 2010 Service Repair Manual REVERSE IDLER SHAFT AND GEARSMT-91

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

5. Remove needle bearings (1) and spacer.

INSPECTION AFTER DISASSEMBLY

Shaft and Gear

Check the fo NISSAN TIIDA 2010 Service Repair Manual REVERSE IDLER SHAFT AND GEARSMT-91

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

5. Remove needle bearings (1) and spacer.

INSPECTION AFTER DISASSEMBLY

Shaft and Gear

Check the fo](/img/5/57397/w960_57397-3274.png)

REVERSE IDLER SHAFT AND GEARSMT-91

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

5. Remove needle bearings (1) and spacer.

INSPECTION AFTER DISASSEMBLY

Shaft and Gear

Check the following items. Replace reverse output gear , snap ring, reverse baulk ring, return spring, needle

bearing, reverse idler shaft, spacer, reverse i nput gear, and lock washer as a set, if necessary.

• Damage, peeling, bend, uneven wear, and distortion of shaft

• Excessive wear, damage, and peeling of gear

Bearing

Check damage and rotation of bearing. Replace revers e output gear, snap ring, reverse baulk ring, return

spring, needle bearing, reverse idler shaft, spacer, reve rse input gear, and lock washer as a set, if necessary.

ASSEMBLY

Note the following procedures, and assemble in the reverse order of disassembly.

CAUTION:

• Never reuse snap ring.

• Check that snap ring is securely installed in a groove.

• Replace reverse output gear, snap ring, reverse baul k ring, return spring, needle bearing, reverse

idler shaft, spacer, reverse input gear, and lock washer as a set.

PCIB1761E

Revision: January 20102010 Versa

Page 3276 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-92

< SERVICE INFORMATION >[RS6F94R]

FINAL DRIVE

FINAL DRIVE

Disassembly and AssemblyINFOID:0000000005397204

DISASSEMBLY

1. Remove differential side bearing inner race (clutch housing side)

(1) acco NISSAN TIIDA 2010 Service Repair Manual MT-92

< SERVICE INFORMATION >[RS6F94R]

FINAL DRIVE

FINAL DRIVE

Disassembly and AssemblyINFOID:0000000005397204

DISASSEMBLY

1. Remove differential side bearing inner race (clutch housing side)

(1) acco](/img/5/57397/w960_57397-3275.png)

MT-92

< SERVICE INFORMATION >[RS6F94R]

FINAL DRIVE

FINAL DRIVE

Disassembly and AssemblyINFOID:0000000005397204

DISASSEMBLY

1. Remove differential side bearing inner race (clutch housing side)

(1) according to the following procedures.

a. Set a suitable toolto differential side bearing inner race (clutch housing side).

b. Remove differential side bearing inner race (clutch housing side) using Tool (A).

2. Remove speedometer drive gear.

3. Remove final gear bolts, and then remove final gear (1).

4. Remove differential side bearing inner race (transaxle case side) (1) according to the following procedures.

a. Set a suitable tool to differential side bearing inner race (tran- saxle case side).

b. Remove differential side bearing inner race (transaxle case side) using a suitable tool (A).

INSPECTION AFTER DISASSEMBLY

Gear and Case

Check final gear and differential case. Replace if necessary.

Bearing

Check bearing for damage and unsmooth rotation. Replace if neces-

sary.

CAUTION:

• Replace differential side bear ing outer race (clutch housing

side) and differential side bearing inner race (clutch housing

side) as a set.

• Replace differential side bearing inner race (transaxle case side) and differential side bearing outer race (transaxle case

side) as a set.

ASSEMBLY

Tool number A: ST33061000 (J-8107-2)

PCIB1767E

JPDIC0446ZZ

JPDIC0114ZZ

SPD715

Revision: January 20102010 Versa

Page 3277 of 3745

![NISSAN TIIDA 2010 Service Repair Manual FINAL DRIVEMT-93

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

1. Install final gear, and then tighten final gear bolts to the specified torque. Refer to MT-92, "Disassembly

and NISSAN TIIDA 2010 Service Repair Manual FINAL DRIVEMT-93

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

1. Install final gear, and then tighten final gear bolts to the specified torque. Refer to MT-92, "Disassembly

and](/img/5/57397/w960_57397-3276.png)

FINAL DRIVEMT-93

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

1. Install final gear, and then tighten final gear bolts to the specified torque. Refer to MT-92, "Disassembly

and Assembly".

CAUTION:

Replace final gear and differential case as a set.

2. Install speedometer drive gear.

3. Install differential side bearing inner race (clutch housing side) using a suitable tool (A).

CAUTION:

Replace differential side bear ing inner race (clutch housing

side) and differential side bearing outer race (clutch hous-

ing side) as a set.

4. Install differential side bearing inner race (transaxle case side) using a suitable tool (A).

CAUTION:

Replace differential side bearing inner race (transaxle case

side) and differential side bearing outer race (transaxle

case side) as a set.

JPDIC0115ZZ

JPDIC0116ZZ

Revision: January 20102010 Versa

Page 3278 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-94

< SERVICE INFORMATION >[RS6F94R]

SHIFT CONTROL

SHIFT CONTROL

InspectionINFOID:0000000005397205

FORK ROD AND SHIFT FORK

Check contact surface and sliding surface for excessive wear,

uneven wear, NISSAN TIIDA 2010 Service Repair Manual MT-94

< SERVICE INFORMATION >[RS6F94R]

SHIFT CONTROL

SHIFT CONTROL

InspectionINFOID:0000000005397205

FORK ROD AND SHIFT FORK

Check contact surface and sliding surface for excessive wear,

uneven wear,](/img/5/57397/w960_57397-3277.png)

MT-94

< SERVICE INFORMATION >[RS6F94R]

SHIFT CONTROL

SHIFT CONTROL

InspectionINFOID:0000000005397205

FORK ROD AND SHIFT FORK

Check contact surface and sliding surface for excessive wear,

uneven wear, bend, and damage. Replace if necessary.

SCIA7785E

Revision: January 20102010 Versa

Page 3279 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-95

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397206

Transax NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-95

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397206

Transax](/img/5/57397/w960_57397-3278.png)

SERVICE DATA AND SPECIFICATIONS (SDS)MT-95

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397206

Transaxle type RS6F94R

Engine type MR18DE

Number of speed 6

Synchromesh type Warner

Shift pattern

Gear ratio 1st 3.727

2nd 2.105

3rd 1.452

4th 1.171

5th 0.971

6th 0.811

Reverse 3.687

Final gear 3.933

Number of teeth Input gear 1st 11

2nd 19

3rd 31

4th 35

5th 35

6th 37

Reverse 11

Main gear 1st 41

2nd 40

3rd 45

4th 41

5th 34

6th 30

Reverse 42

Reverse idler gear Input/Output 28/29

Final gear Final gear/Pinion 59/15

Side gear/Pinion

mate gear 21/18

Oil capacity (Reference) (US pt, Imp pt)Approx. 2.0 (4-1/4, 3-1/2)

Remarks Reverse synchronizer Installed

Triple-cone synchronizer 1st and 2nd

PCIB1769E

Revision: January 20102010 Versa

Page 3280 of 3745

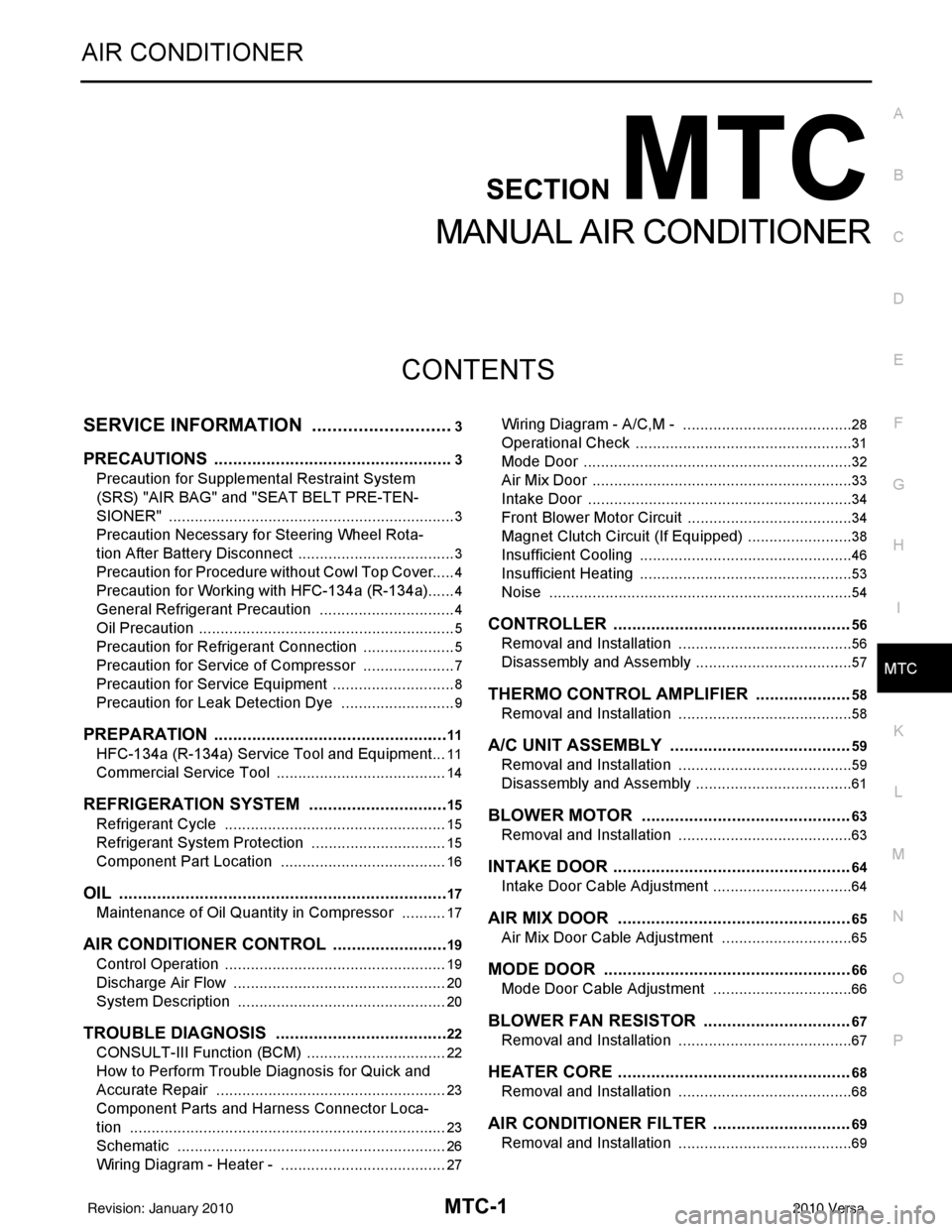

MTC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION MTC

A

B

MTC

N

O P

CONTENTS

MANUAL AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Working with HFC-134a (R-134a) ......4

General Refrigerant Precaution ................................4

Oil Precaution ............................................................5

Precaution for Refrigerant Connection ......................5

Precaution for Service of Compressor ................ ......7

Precaution for Service Equipment ....................... ......8

Precaution for Leak Detection Dye ...........................9

PREPARATION ..................................................11

HFC-134a (R-134a) Service Tool and Equipment ....11

Commercial Service Tool ........................................14

REFRIGERATION SYSTEM ..............................15

Refrigerant Cycle ................................................ ....15

Refrigerant System Protection ................................15

Component Part Location ................................... ....16

OIL ......................................................................17

Maintenance of Oil Quantity in Compressor ....... ....17

AIR CONDITIONER CONTROL .........................19

Control Operation ................................................ ....19

Discharge Air Flow ..................................................20

System Description .................................................20

TROUBLE DIAGNOSIS .....................................22

CONSULT-III Function (BCM) ............................. ....22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

23

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

23

Schematic ...............................................................26

Wiring Diagram - Heater - .......................................27

Wiring Diagram - A/C,M - .................................... ....28

Operational Check ...................................................31

Mode Door ...............................................................32

Air Mix Door .............................................................33

Intake Door ..............................................................34

Front Blower Motor Circuit .......................................34

Magnet Clutch Circuit (If Equipped) ..................... ....38

Insufficient Cooling ..................................................46

Insufficient Heating ..................................................53

Noise .......................................................................54

CONTROLLER ..................................................56

Removal and Installation .........................................56

Disassembly and Assembly .....................................57

THERMO CONTROL AMPLIFIER ....................58

Removal and Installation .........................................58

A/C UNIT ASSEMBLY ......................................59

Removal and Installation .........................................59

Disassembly and Assembly .....................................61

BLOWER MOTOR ............................................63

Removal and Installation .........................................63

INTAKE DOOR ..................................................64

Intake Door Cable Adjustment .................................64

AIR MIX DOOR .................................................65

Air Mix Door Cable Adjustment ...............................65

MODE DOOR ....................................................66

Mode Door Cable Adjustment .................................66

BLOWER FAN RESISTOR ...............................67

Removal and Installation .........................................67

HEATER CORE .................................................68

Removal and Installation .........................................68

AIR CONDITIONER FILTER .............................69

Removal and Installation .........................................69

Revision: January 20102010 Versa