Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3143 of 3745

MA-8

< SERVICE INFORMATION >

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-48

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Clutch pedal Make sure the pedal operates smoothly and check that it has the proper free play. CL-6

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

floor mats away from the pedal. BR-6

and

BR-20

Parking brake Check that the lever has the proper travel and make sure that the vehicle is held

securely on a fairly steep hill when only the parking brake is applied. PB-5

Automatic transaxle

“Park” mechanismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the se-

lector lever in the “P” position without applying any brakes. —

CVT P (Park) position

mechanism On a fairly steep hill check that the vehicle is held securely with the selector lever

in the “P” position without applying any brakes.

—

Item

Reference page

ItemReference page

Windshield wash-

er fluid Check that there is adequate fluid in the tank.

—

Engine coolant

level Check the coolant level when the engine is cold. CO-12

(HR)

CO-36

(MR)

A/C condenser,

radiator and hos-

es Check the front of the condenser and radiator and clean off any dirt, insects, leaves,

etc., that may have accumulated. Make sure the radiator hoses have no cracks, de-

formation, deterioration or loose connections.

—

Brake and clutch

fluid levels Make sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs.

BR-9

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require frequent

checks of the battery fluid level. —

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. EM-14

(HR)

EM-132

(MR)

Engine oil level Check the level on the dipstick after parking the vehicle on a level spot and turning

off the engine. MA-20

(HR)

MA-30

(MR)

CVT and Automat-

ic transaxle fluid

level Check the level on the dipstick after putting the selector lever in “P” with the engine

idling.

MA-38

MA-43

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the exhaust

seems unusual or there is a smell of exhaust fumes, immediately locate the trouble

and correct it. MA-37, "EXHAUST SYS-

TEM : Checking Exhaust

System HR16DE", MA-38,

"EXHAUST SYSTEM :

Checking Exhaust System

MR18DE"

Underbody

The underbody is frequently exposed to corrosive substances such as those used

on icy roads or to control dust. It is very important to remove these substances, oth-

erwise rust will form on the floor pan, frame, fuel lines and around the exhaust sys-

tem. At the end of winter, the underbody should be thoroughly flushed with plain

water, being careful to clean those areas where mud and dirt can easily accumu-

late. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has

been parked for a while. Water dripping from the air conditioner after use is normal.

If you should notice any leaks or gasoline fumes are evident, check for the cause

and correct it immediately. —

Revision: January 20102010 Versa

Page 3146 of 3745

PERIODIC MAINTENANCEMA-11

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

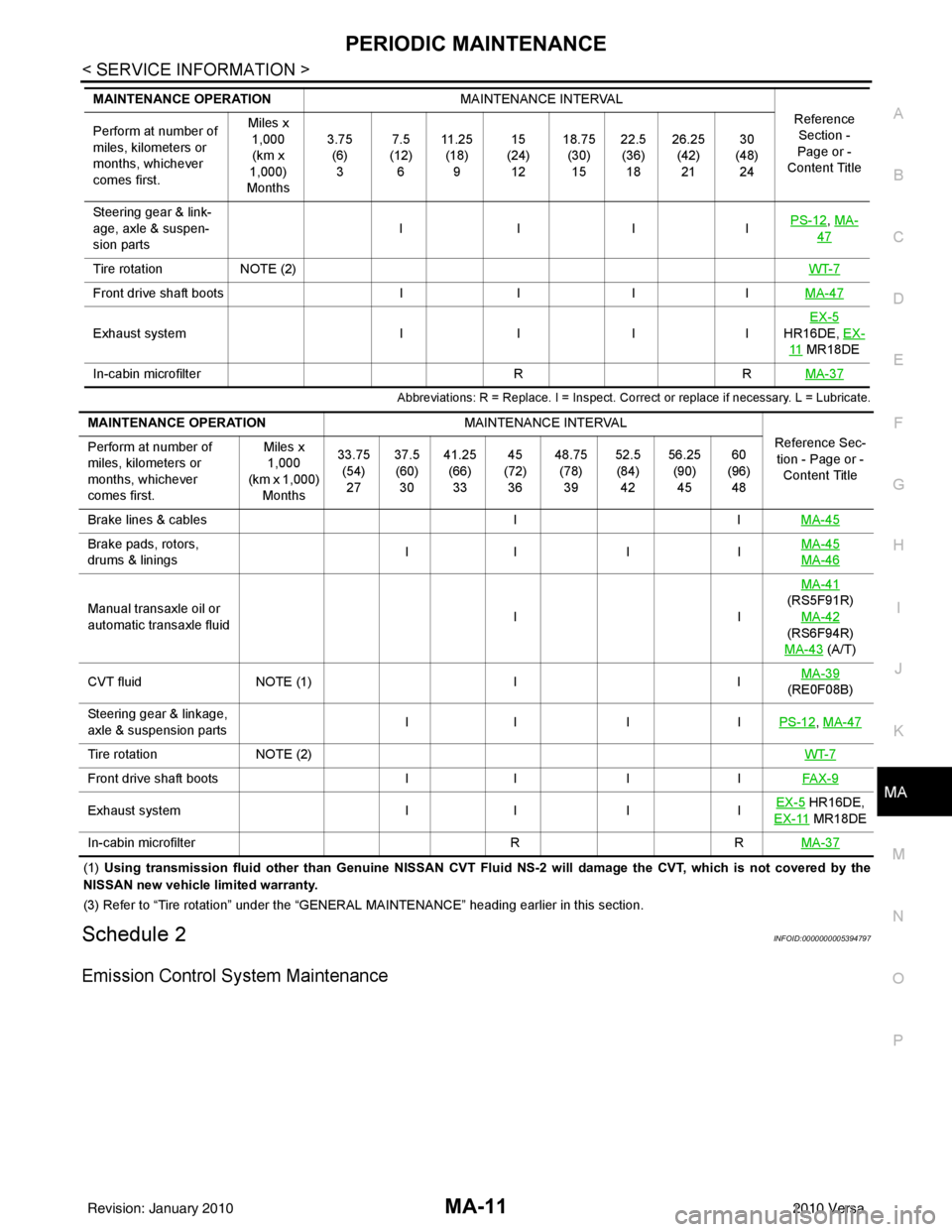

Abbreviations: R = Replace. I = Inspect. Corr ect or replace if necessary. L = Lubricate.

(1) Using transmission fluid other than Genuine NISSAN CVT Fluid NS-2 will damage the CVT, which is not covered by the

NISSAN new vehicle limited warranty.

(3) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section.

Schedule 2INFOID:0000000005394797

Emission Control System Maintenance

Steering gear & link-

age, axle & suspen-

sion parts IIII

PS-12, MA-

47

Tire rotation

NOTE (2) WT-7

Front drive shaft bootsIIIIMA-47

Exhaust system IIIIEX-5

HR16DE, EX-

11 MR18DE

In-cabin microfilter RRMA-37

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Section -

Page or -

Content Title

Perform at number of

miles, kilometers or

months, whichever

comes first. Miles x

1,000

(km x

1,000)

Months 3.75

(6)3 7.5

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-tion - Page or - Content Title

Perform at number of

miles, kilometers or

months, whichever

comes first. Miles x

1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Brake lines & cables IIMA-45

Brake pads, rotors,

drums & linings II I I MA-45

MA-46

Manual transaxle oil or

automatic transaxle fluid IIMA-41

(RS5F91R) MA-42

(RS6F94R)

MA-43

(A/T)

CVT fluid NOTE (1) IIMA-39

(RE0F08B)

Steering gear & linkage,

axle & suspension parts II I I

PS-12

, MA-47

Tire rotationNOTE (2) WT-7

Front drive shaft bootsII IIFAX-9

Exhaust system II IIEX-5 HR16DE,

EX-11

MR18DE

In-cabin microfilter RRMA-37

Revision: January 20102010 Versa

Page 3150 of 3745

RECOMMENDED FLUIDS AND LUBRICANTSMA-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

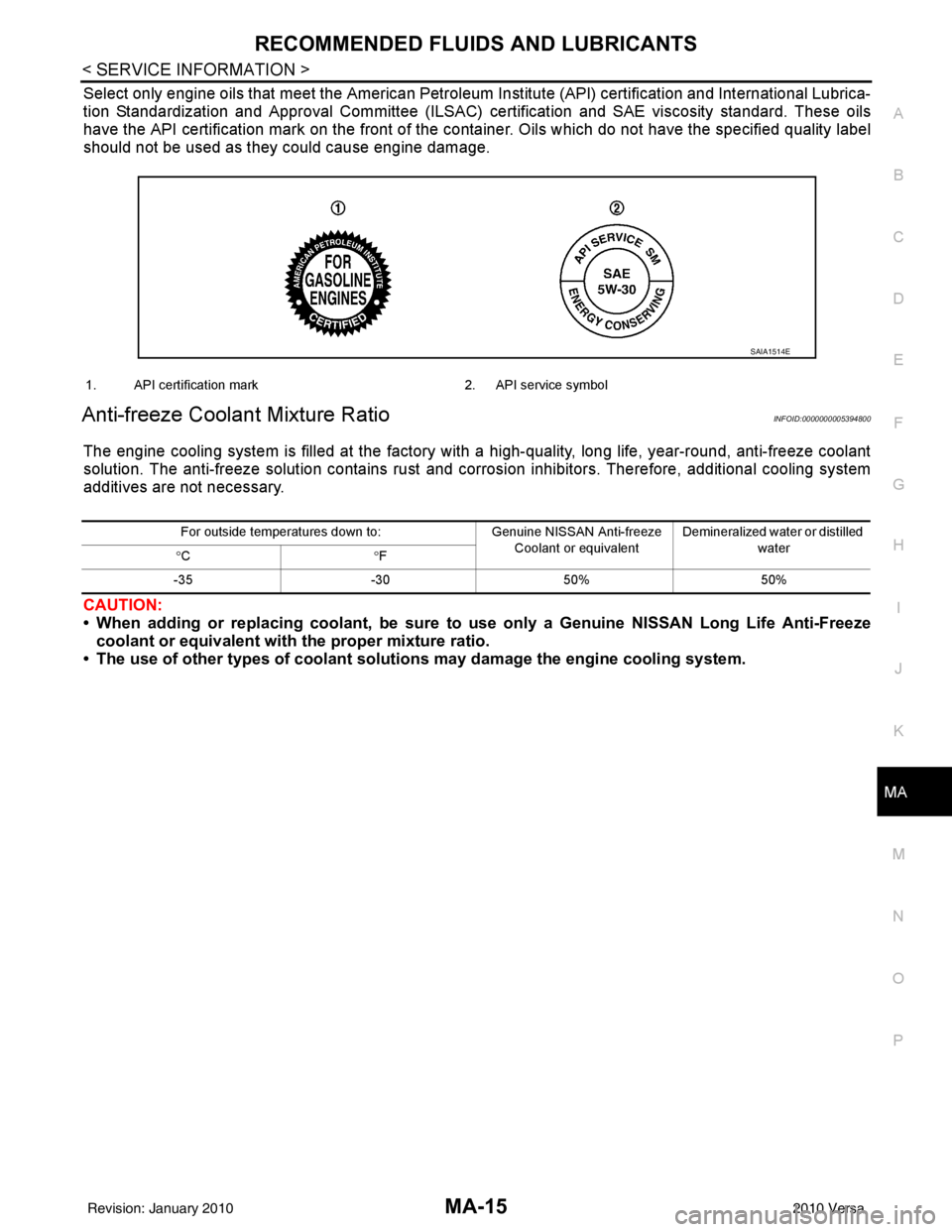

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubrica-

tion Standardization and Approval Committee (ILSAC) ce rtification and SAE viscosity standard. These oils

have the API certification mark on the front of the container. Oils which do not have the specified quality label

should not be used as they could cause engine damage.

Anti-freeze Coolant Mixture RatioINFOID:0000000005394800

The engine cooling system is filled at the factory wit h a high-quality, long life, year-round, anti-freeze coolant

solution. The anti-freeze solution contains rust and corrosion inhibitors. Therefore, additional cooling system

additives are not necessary.

CAUTION:

• When adding or replacing coolant, be sure to use only a Genuine NISSAN Long Life Anti-Freeze

coolant or equivalent with the proper mixture ratio.

• The use of other types of coolant soluti ons may damage the engine cooling system.

SAIA1514E

1. API certification mark 2. API service symbol

For outside temperatures down to: Genuine NISSAN Anti-freeze

Coolant or equivalent Demineralized water or distilled

water

° C °F

-35 -3050% 50%

Revision: January 20102010 Versa

Page 3153 of 3745

MA-18

< SERVICE INFORMATION >

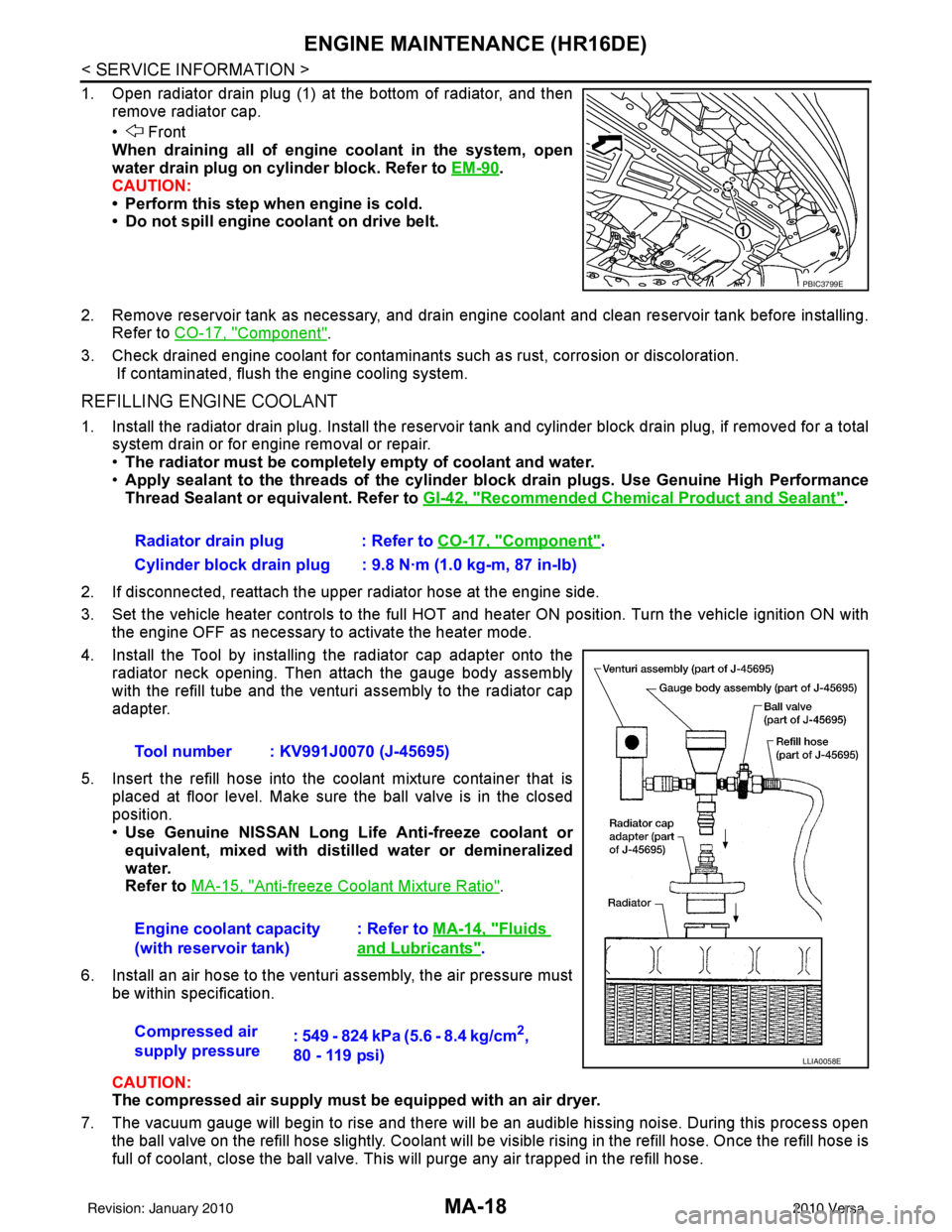

ENGINE MAINTENANCE (HR16DE)

1. Open radiator drain plug (1) at the bottom of radiator, and thenremove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-90

.

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing. Refer to CO-17, "

Component".

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, "

Recommended Chemical Product and Sealant".

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

•Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, "

Anti-freeze Coolant Mixture Ratio".

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

PBIC3799E

Radiator drain plug : Refer to CO-17, "Component".

Cylinder block drain plug : 9.8 N·m (1.0 kg-m, 87 in-lb)

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, "

Fluids

and Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)

LLIA0058E

Revision: January 20102010 Versa

Page 3156 of 3745

ENGINE MAINTENANCE (HR16DE)MA-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

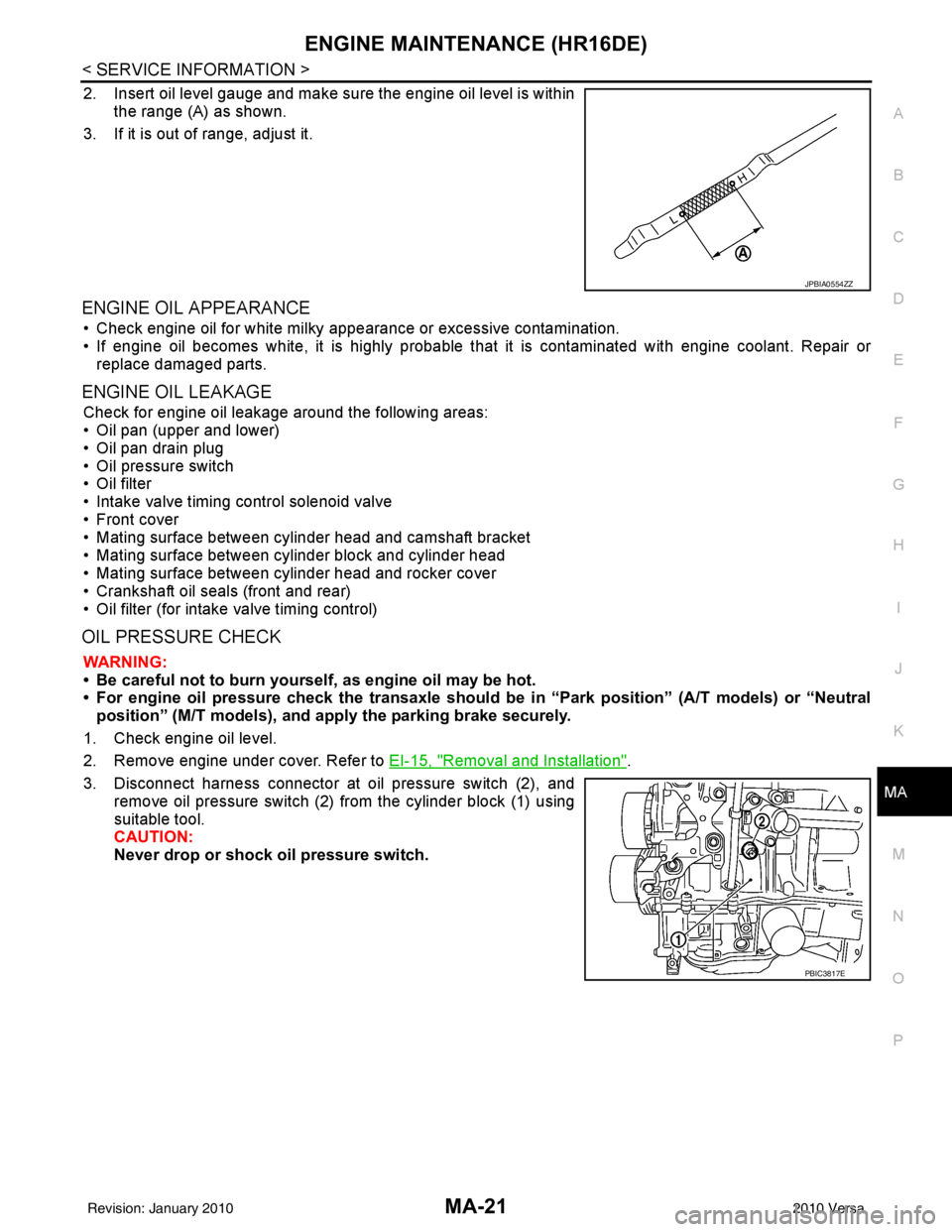

2. Insert oil level gauge and make sure the engine oil level is within the range (A) as shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

• Check engine oil for white milky appearance or excessive contamination.

• If engine oil becomes white, it is highly probable t hat it is contaminated with engine coolant. Repair or

replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following areas:

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder head and camshaft bracket

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

• Oil filter (for intake valve timing control)

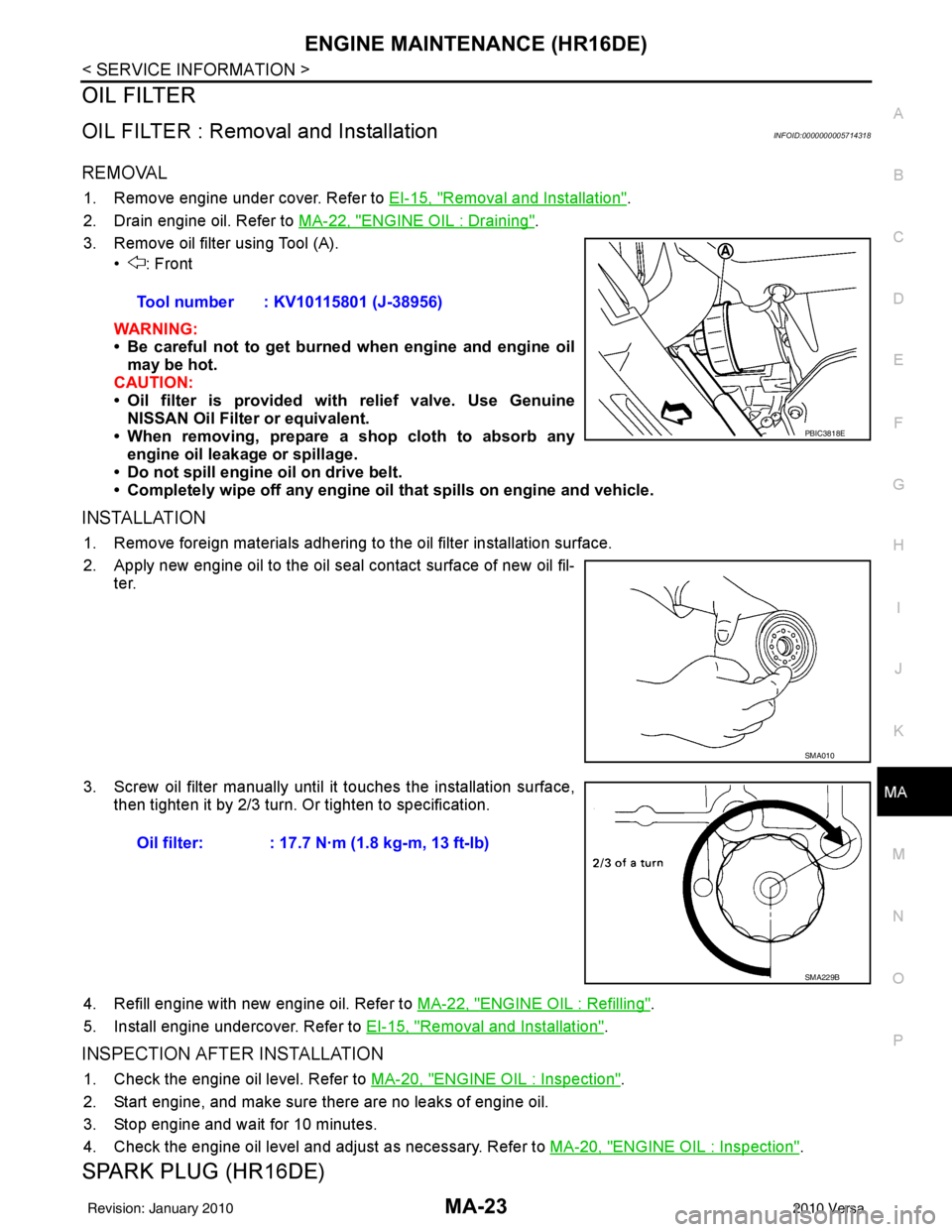

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• For engine oil pressure check the transaxle should be in “Park position” (A/T models) or “Neutral

position” (M/T models), and apply the parking brake securely.

1. Check engine oil level.

2. Remove engine under cover. Refer to EI-15, "

Removal and Installation".

3. Disconnect harness connector at oil pressure switch (2), and remove oil pressure switch (2) from the cylinder block (1) using

suitable tool.

CAUTION:

Never drop or shock oil pressure switch.

JPBIA0554ZZ

PBIC3817E

Revision: January 20102010 Versa

Page 3158 of 3745

ENGINE MAINTENANCE (HR16DE)MA-23

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

OIL FILTER

OIL FILTER : Remova l and InstallationINFOID:0000000005714318

REMOVAL

1. Remove engine under cover. Refer to EI-15, "Removal and Installation".

2. Drain engine oil. Refer to MA-22, "

ENGINE OIL : Draining".

3. Remove oil filter using Tool (A). • : Front

WARNING:

• Be careful not to get burned when engine and engine oil

may be hot.

CAUTION:

• Oil filter is provided with relief valve. Use Genuine

NISSAN Oil Filter or equivalent.

• When removing, prepare a s hop cloth to absorb any

engine oil leakage or spillage.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil that spills on engine and vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

4. Refill engine with new engine oil. Refer to MA-22, "

ENGINE OIL : Refilling".

5. Install engine undercover. Refer to EI-15, "

Removal and Installation".

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to MA-20, "ENGINE OIL : Inspection".

2. Start engine, and make sure there are no leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and adjust as necessary. Refer to MA-20, "

ENGINE OIL : Inspection".

SPARK PLUG (HR16DE)

Tool number : KV10115801 (J-38956)

PBIC3818E

SMA010

Oil filter: : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

Revision: January 20102010 Versa

Page 3162 of 3745

ENGINE MAINTENANCE (MR18DE)MA-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

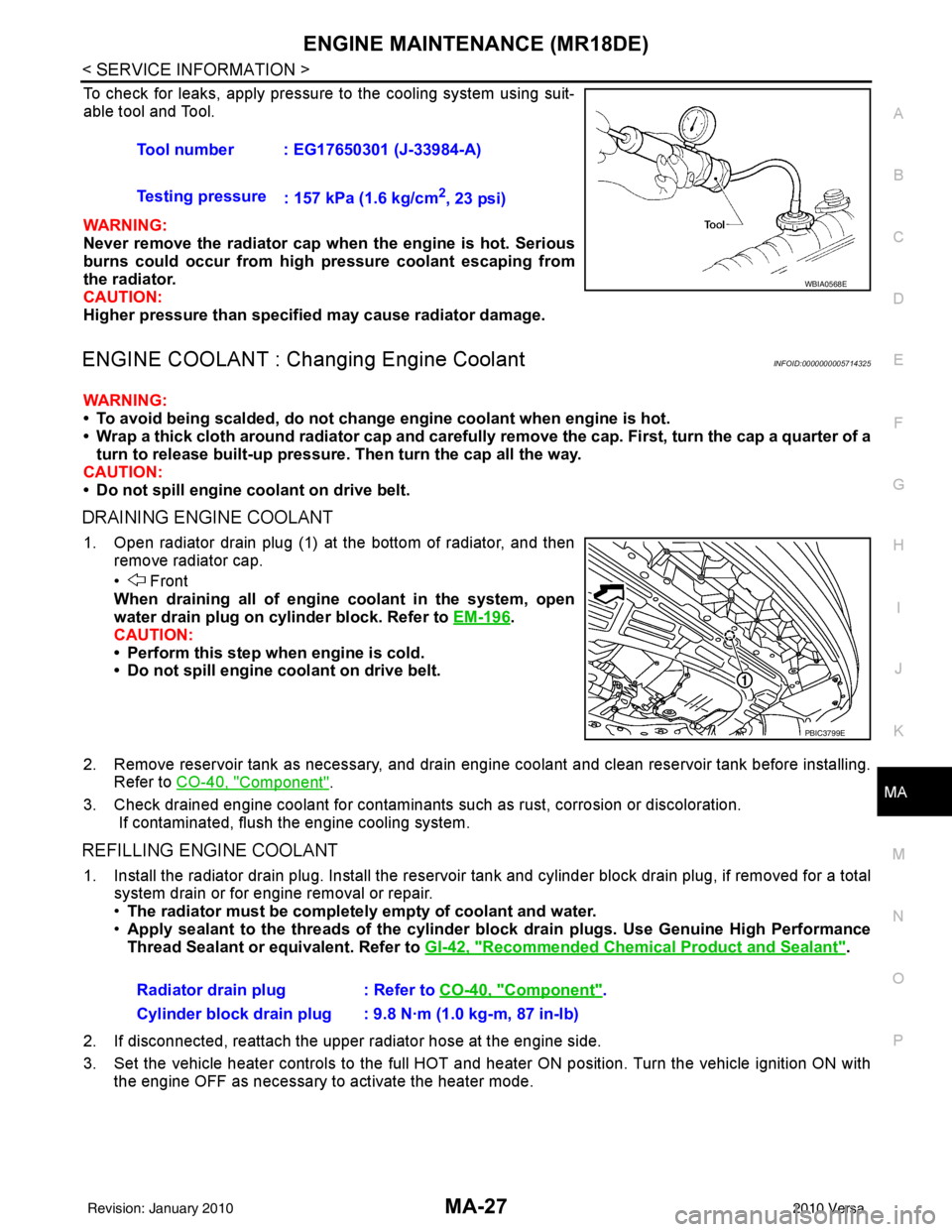

To check for leaks, apply pressure to the cooling system using suit-

able tool and Tool.

WARNING:

Never remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : Chang ing Engine CoolantINFOID:0000000005714325

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

CAUTION:

• Do not spill engine coolant on drive belt.

DRAINING ENGINE COOLANT

1. Open radiator drain plug (1) at the bottom of radiator, and then remove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-196

.

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engi ne coolant and clean reservoir tank before installing.

Refer to CO-40, "

Component".

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder blo ck drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, "

Recommended Chemical Product and Sealant".

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode. Tool number : EG17650301 (J-33984-A)

Testing pressure

: 157 kPa (1.6 kg/cm

2, 23 psi)

WBIA0568E

PBIC3799E

Radiator drain plug : Refer to CO-40, "Component".

Cylinder block drain plug : 9.8 N·m (1.0 kg-m, 87 in-lb)

Revision: January 20102010 Versa

Page 3164 of 3745

ENGINE MAINTENANCE (MR18DE)MA-29

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-40, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system.

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

FUEL LINES

FUEL LINES : Checking Fuel LineINFOID:0000000005714326

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loos e connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

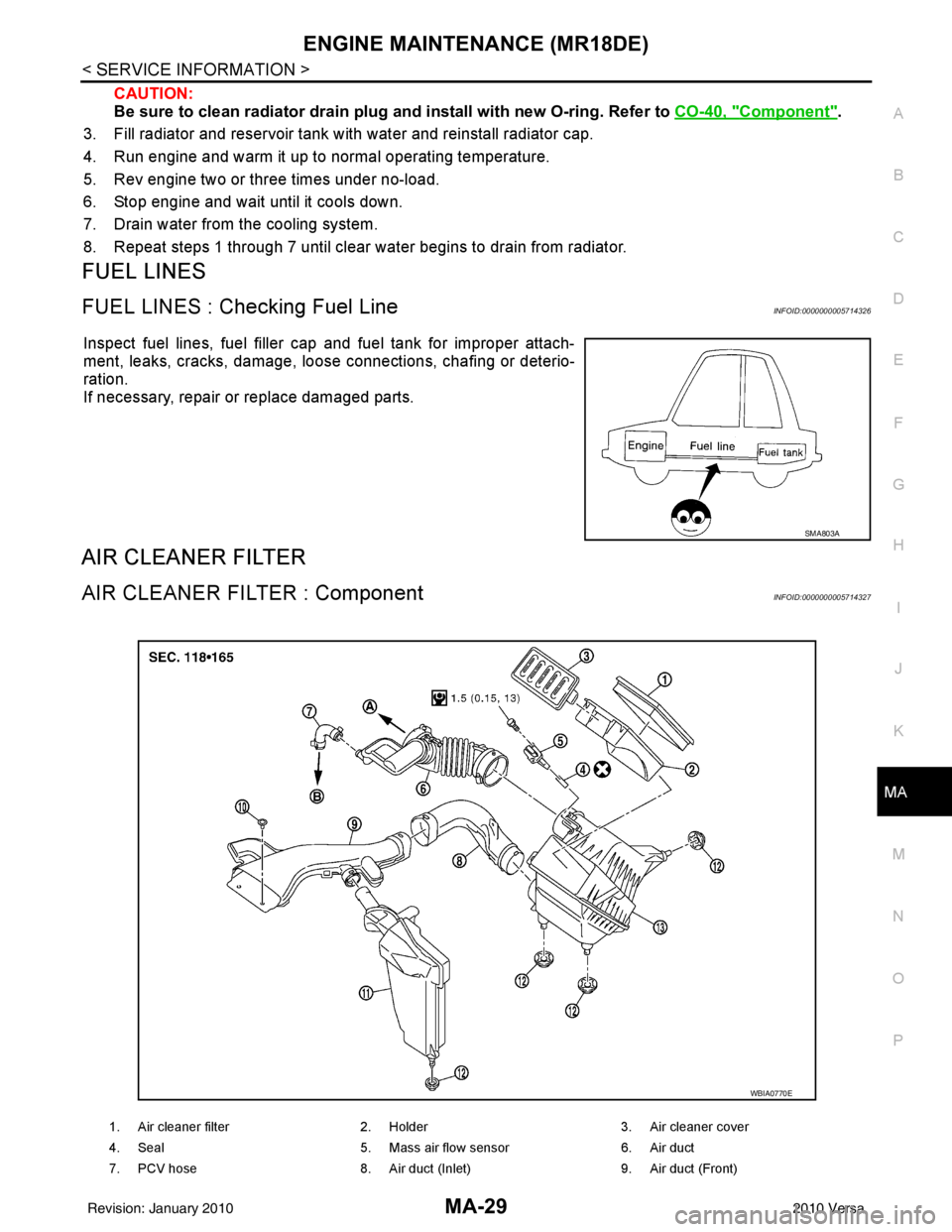

AIR CLEANER FILTER

AIR CLEANER FILTER : ComponentINFOID:0000000005714327

SMA803A

1. Air cleaner filter 2. Holder 3. Air cleaner cover

4. Seal 5. Mass air flow sensor 6. Air duct

7. PCV hose 8. Air duct (Inlet) 9. Air duct (Front)

WBIA0770E

Revision: January 20102010 Versa

Page 3166 of 3745

ENGINE MAINTENANCE (MR18DE)MA-31

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

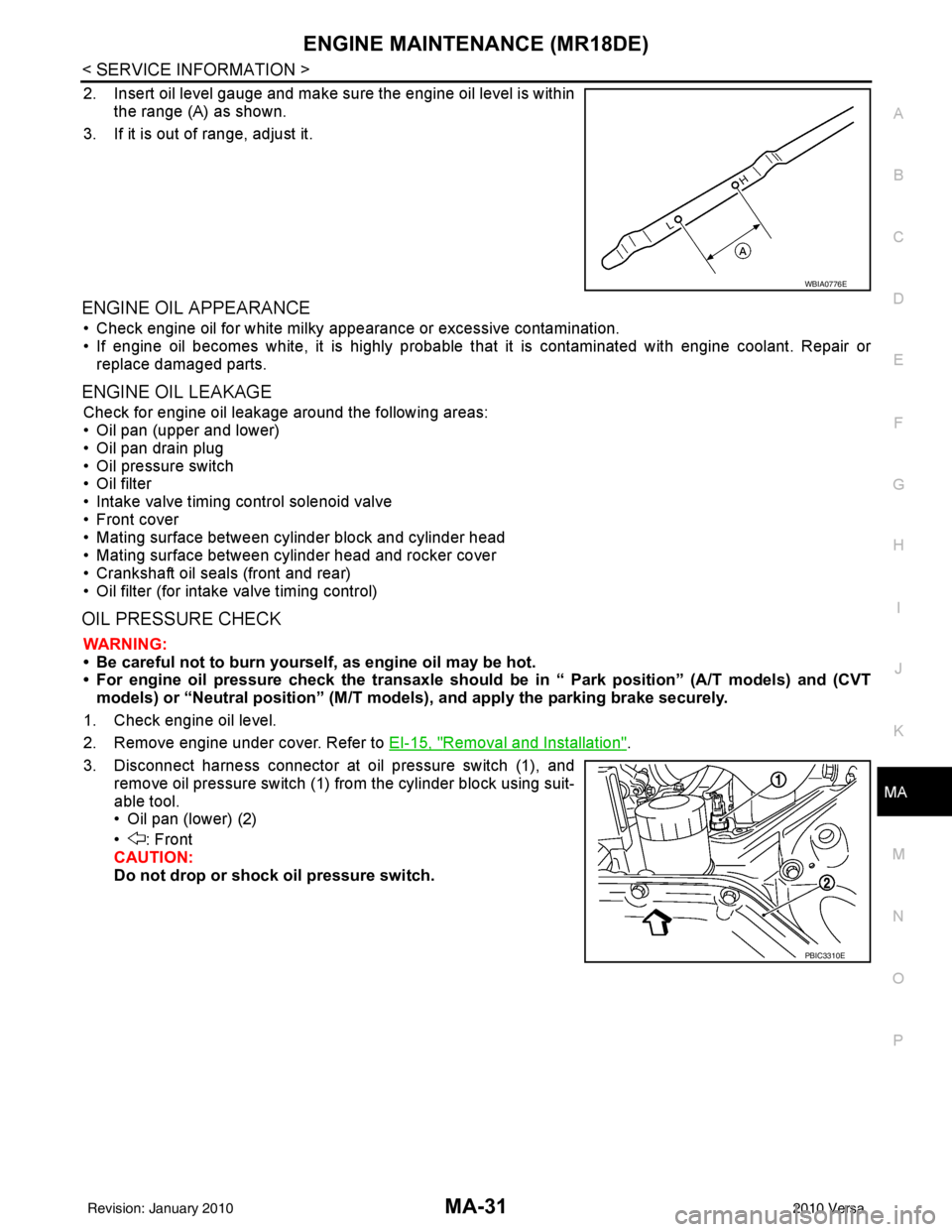

2. Insert oil level gauge and make sure the engine oil level is within the range (A) as shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

• Check engine oil for white milky appearance or excessive contamination.

• If engine oil becomes white, it is highly probable t hat it is contaminated with engine coolant. Repair or

replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following areas:

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

• Oil filter (for intake valve timing control)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• For engine oil pressure check the transaxle should be in “ Park position” (A/T models) and (CVT

models) or “Neutral position” (M/T mode ls), and apply the parking brake securely.

1. Check engine oil level.

2. Remove engine under cover. Refer to EI-15, "

Removal and Installation".

3. Disconnect harness connector at oil pressure switch (1), and remove oil pressure switch (1) from the cylinder block using suit-

able tool.

• Oil pan (lower) (2)

• : Front

CAUTION:

Do not drop or shock oil pressure switch.

WBIA0776E

PBIC3310E

Revision: January 20102010 Versa

Page 3168 of 3745

ENGINE MAINTENANCE (MR18DE)MA-33

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

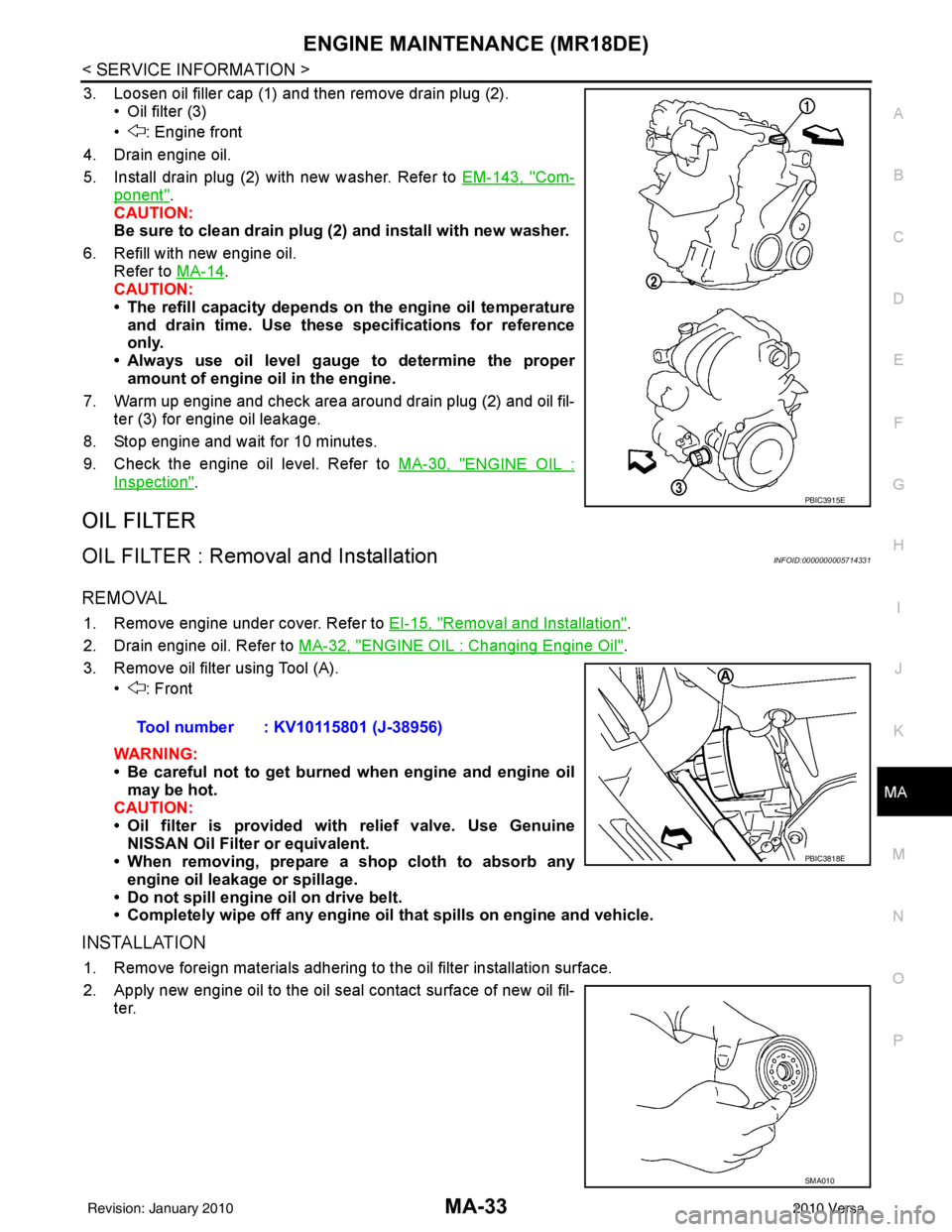

3. Loosen oil filler cap (1) and then remove drain plug (2). • Oil filter (3)

• : Engine front

4. Drain engine oil.

5. Install drain plug (2) with new washer. Refer to EM-143, "

Com-

ponent".

CAUTION:

Be sure to clean drain plug (2 ) and install with new washer.

6. Refill with new engine oil. Refer to MA-14

.

CAUTION:

• The refill capacity depends on the engine oil temperature

and drain time. Use these specifications for reference

only.

• Always use oil level gauge to determine the proper amount of engine oil in the engine.

7. Warm up engine and check area around drain plug (2) and oil fil- ter (3) for engine oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer to MA-30, "

ENGINE OIL :

Inspection".

OIL FILTER

OIL FILTER : Removal and InstallationINFOID:0000000005714331

REMOVAL

1. Remove engine under cover. Refer to EI-15, "Removal and Installation".

2. Drain engine oil. Refer to MA-32, "

ENGINE OIL : Changing Engine Oil".

3. Remove oil filter using Tool (A). • : Front

WARNING:

• Be careful not to get burned when engine and engine oil

may be hot.

CAUTION:

• Oil filter is provided with relief valve. Use Genuine

NISSAN Oil Filter or equivalent.

• When removing, prepare a s hop cloth to absorb any

engine oil leakage or spillage.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil that spills on engine and vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

PBIC3915E

Tool number : KV10115801 (J-38956)

PBIC3818E

SMA010

Revision: January 20102010 Versa