system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3536 of 3787

TROUBLE DIAGNOSISRF-13

< FUNCTION DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

RF

N

O P

2. Release the UP/CLOSE switch.

3. Press the UP/CLOSE switch again and continuously hold. The sunroof will begin to move in about 10 sec- onds.

4. Continue to hold the UP/CLOSE switch while the sunroof moves in a jogging motion to the full tilt position.

When the sunroof reaches the full tilt positi on, it will back up a few millimeters and stop.

5. Release the UP/CLOSE switch.

6. Within 5 seconds of releasing the UP/CLOSE s witch, press and hold the UP/CLOSE switch again. The

sunroof will move to the full open pos ition and back to the closed position.

NOTE:

If the UP/CLOSE switch is released anytime during th is teaching process, all learned profile data will be dis-

carded and the procedure will have to be started over.

7. Release the UP/CLOSE switch. Do not disconnect power for at least two seconds. The sunroof is now re-

taught.

CAN Communication System DescriptionINFOID:0000000005929526

Refer to LAN-7 .

Revision: May 2010 2011 Versa

Page 3539 of 3787

RF-16

< FUNCTION DIAGNOSIS >

TROUBLE DIAGNOSIS

Terminal and Reference Valu e for Sunroof Motor Assembly

INFOID:0000000005929529

Work FlowINFOID:0000000005929530

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to RF-11, "

System Description" .

3. According to the trouble diagnosis chart, repa ir or replace the cause of the malfunction.

Refer to RF-17, "

Trouble Diagnosis Chart by Symptom" .

4. Does sunroof system operate normally? If Yes, GO TO 5. If No, GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM)INFOID:0000000005929531

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

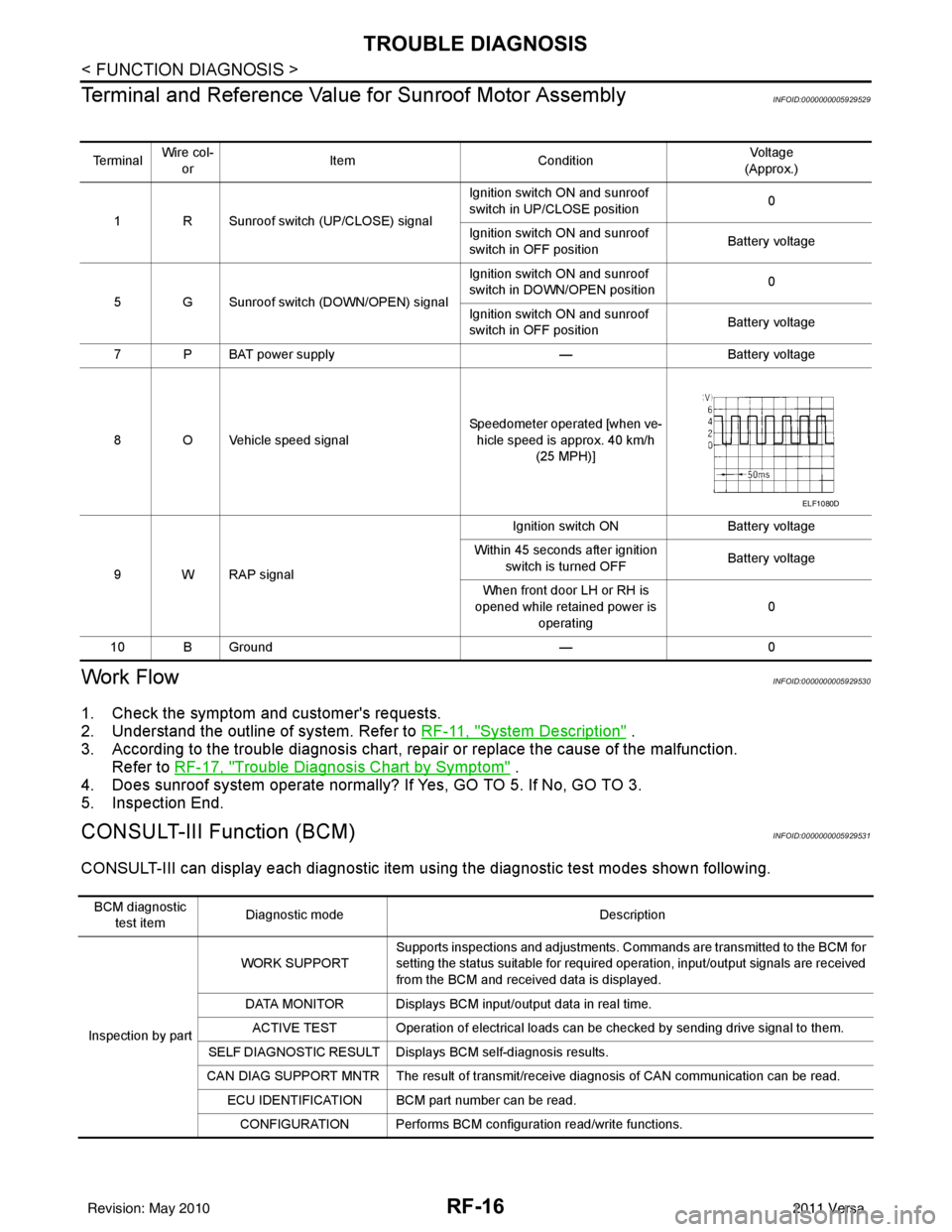

Te r m i n a lWire col-

or Item

Condition Vol tag e

(Approx.)

1 R Sunroof switch (UP/CLOSE) signal Ignition switch ON and sunroof

switch in UP/CLOSE position

0

Ignition switch ON and sunroof

switch in OFF position Battery voltage

5 G Sunroof switch (DOWN/OPEN) signal Ignition switch ON and sunroof

switch in DOWN/OPEN position

0

Ignition switch ON and sunroof

switch in OFF position Battery voltage

7 P BAT power supply —Battery voltage

8 O Vehicle speed signal Speedometer operated [when ve-

hicle speed is approx. 40 km/h (25 MPH)]

9 W RAP signal Ignition switch ON

Battery voltage

Within 45 seconds after ignition switch is turned OFF Battery voltage

When front door LH or RH is

opened while retained power is

operating 0

10 B Ground —0

ELF1080D

BCM diagnostic

test item Diagnostic mode

Description

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displa ys BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU IDENTIFICATION BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Revision: May 2010 2011 Versa

Page 3540 of 3787

TROUBLE DIAGNOSISRF-17

< FUNCTION DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

RF

N

O P

Work SupportINFOID:0000000005929532

Active TestINFOID:0000000005929533

Data MonitorINFOID:0000000005929534

Trouble Diagnosis Chart by SymptomINFOID:0000000005929535

BCM Power Supply and Gr ound Circuit InspectionINFOID:0000000005929536

Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspection" .

Sunroof Switch System InspectionINFOID:0000000005929537

1.SUNROOF SWITCH INPUT SIGNAL CHECK

Work item Description

RETAINED PWR SET RAP signal’s power supply period can be changed by mode setting. Selects RAP sig-

nal’s power supply period between the following three steps.

• MODE 1 (45 sec.) / MODE 2 (OFF) / MODE 3 (2 min.)

Test item

Description

RETAINED PWR This test is able to supply RAP signal (power) from BCM to power window system,

power sunroof system. Those systems can be operated when turning on "RETAINED

PWR" on CONSULT-III screen even if the ignition switch is turned OFF.

NOTE:

During this test, CONSULT-III can be operated with ignition switch in "OFF" po-

sition. "RETAINED PWR" should be turned "ON" or "OFF" on CONSULT-III

screen when ignition switch ON. Then turn ignition switch OFF for checking re-

tained power operation. CONSULT-III might be stuck if "RETAINED PWR" is

turned "ON" or "OFF" on CONSULT-III screen when ignition switch is OFF.

Monitored item

Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch LH.

DOOR SW-AS Indicates [ON/OFF] condition of front door switch RH.

SymptomDiagnostic procedure and repair order Refer to page

Sunroof does not operate. 1. BCM power supply and ground circuit check

BCS-16

2. Sunroof motor assembly power supply and ground

circuit check RF-19

3. Sunroof switch system check

RF-17

4. Replace sunroof motor assemblyRF-22

Motor does not stop at the sunroof fully-open or fully-closed

position. 1. Initialization procedure check

RF-11

2. Replace sunroof motor assemblyRF-22

Retained power operation does not operate properly. 1. Check the retained power operation mode setting

RF-112. BCM power supply and ground circuit checkBCS-16

3. Door switch check RF-20

4. Replace sunroof motor assemblyRF-22

Sunroof does not do the interruption detection. 1. Replace sunroof motor assemblyRF-22

Revision: May 2010 2011 Versa

Page 3550 of 3787

SUNROOFRF-27

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

RF

N

O P

CAUTION:

• Before installing the sunroof motor assembly, be su re the link assembly is in the symmetrical and

fully closed position.

• Align the link notch with the hole of the guide track (fully closed: RH and LH).

1. Place the sunroof motor assembly flat onto the sunroof unit assembly surface.

2. Laterally move the assembly little by little so that the gear is completely engaged into the wire and there is no gap between the sunroof unit assembly and sunroof motor assembly.

3. Install the sunroof motor assembly screws, then connect the harness connector.

4. After installing, perform the initialization procedure. Refer to RF-11, "

System Description" .

LINK ASSEMBLY

Removal

1. Remove sunroof unit assembly. Follow the SUNROOF UNIT ASSEMBLY procedure.

2. Remove screws, then remove rear drain assembly.

3. Remove sunroof motor assembly. Follow the SUNROOF MOTOR ASSEMBLY procedure.

4. Remove link assembly from the rear end of the sunroof frame.

Installation

Installation is in the reverse order of removal.

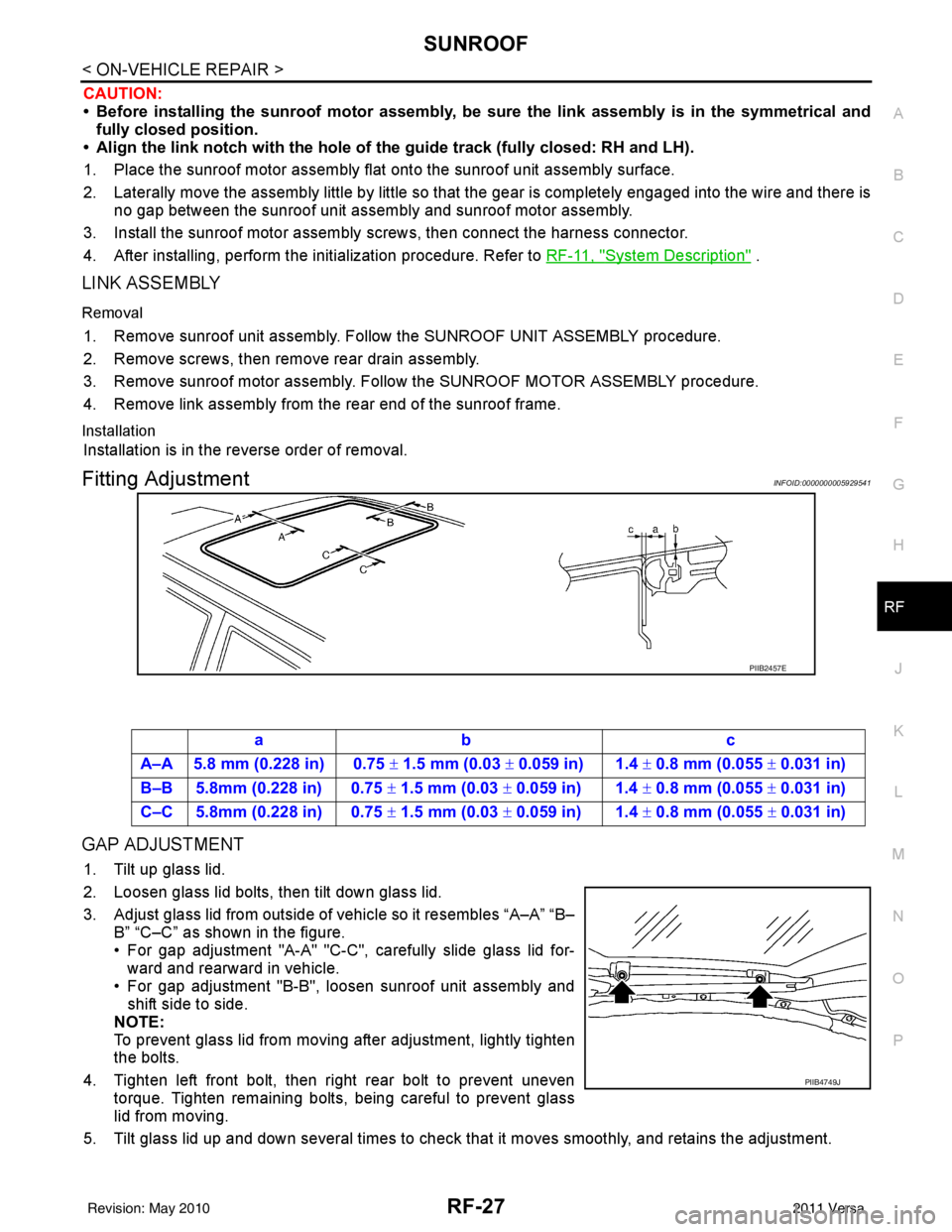

Fitting AdjustmentINFOID:0000000005929541

GAP ADJUSTMENT

1. Tilt up glass lid.

2. Loosen glass lid bolts, then tilt down glass lid.

3. Adjust glass lid from outside of vehicle so it resembles “A–A” “B–

B” “C–C” as shown in the figure.

• For gap adjustment "A-A" "C-C", carefully slide glass lid for-

ward and rearward in vehicle.

• For gap adjustment "B-B", loosen sunroof unit assembly and

shift side to side.

NOTE:

To prevent glass lid from moving after adjustment, lightly tighten

the bolts.

4. Tighten left front bolt, then right rear bolt to prevent uneven torque. Tighten remaining bolts, being careful to prevent glass

lid from moving.

5. Tilt glass lid up and down several times to check that it moves smoothly, and retains the adjustment.

PIIB2457E

ab c

A–A 5.8 mm (0.228 in) 0.75 ± 1.5 mm (0.03 ± 0.059 in) 1.4 ± 0.8 mm (0.055 ± 0.031 in)

B–B 5.8mm (0.228 in) 0.75 ± 1.5 mm (0.03 ± 0.059 in) 1.4 ± 0.8 mm (0.055 ± 0.031 in)

C–C 5.8mm (0.228 in) 0.75 ± 1.5 mm (0.03 ± 0.059 in) 1.4 ± 0.8 mm (0.055 ± 0.031 in)

PIIB4749J

Revision: May 2010 2011 Versa

Page 3554 of 3787

RSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION RSU

A

B

RSU

N

O PCONTENTS

REAR SUSPENSION

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Rear Suspension ......................... ......3

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ................................ ......5

REAR SUSPENSION ASSEMBLY .....................6

On-Vehicle Inspection and Service ..................... .....6

Wheel AlignmentInspection ......................................6

Component ...............................................................8

SHOCK ABSORBER .........................................9

Removal and Installation ..........................................9

Disposal ...................................................................10

COIL SPRING ...................................................11

Removal and Installation .........................................11

REAR SUSPENSION BEAM ............................12

Removal and Installation ..................................... ....12

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

13

Wheel Alignment (Unladen*) ...................................13

Wheelarch Height (Unladen*) ..................................13

Revision: May 2010 2011 Versa

Page 3555 of 3787

RSU-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005931079

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005931080

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3565 of 3787

RSU-12

< SERVICE INFORMATION >

REAR SUSPENSION BEAM

REAR SUSPENSION BEAM

Removal and InstallationINFOID:0000000005931090

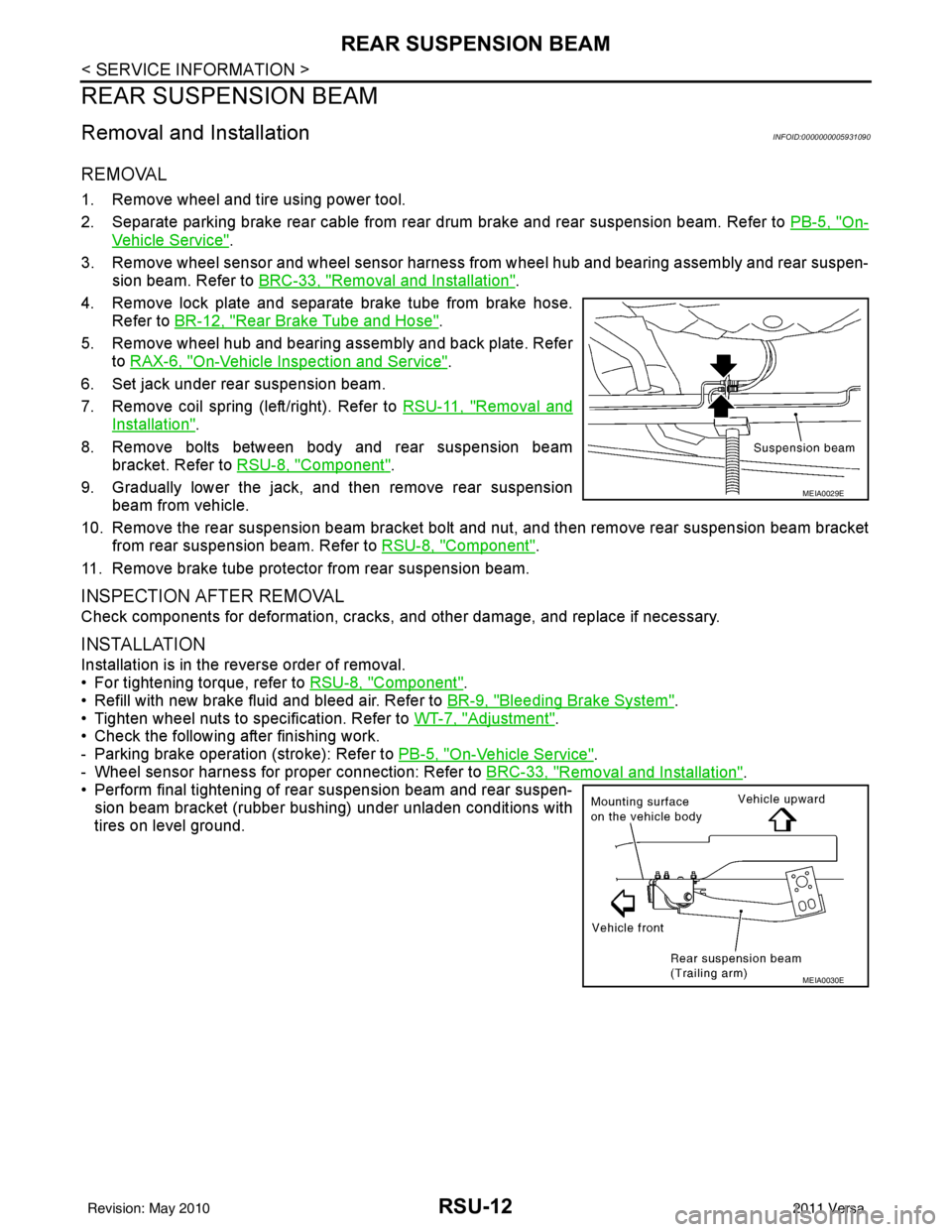

REMOVAL

1. Remove wheel and tire using power tool.

2. Separate parking brake rear cable from rear drum brake and rear suspension beam. Refer to PB-5, "

On-

Vehicle Service".

3. Remove wheel sensor and wheel sensor harness from wheel hub and bearing assembly and rear suspen-

sion beam. Refer to BRC-33, "

Removal and Installation".

4. Remove lock plate and separate brake tube from brake hose. Refer to BR-12, "

Rear Brake Tube and Hose".

5. Remove wheel hub and bearing assembly and back plate. Refer to RAX-6, "

On-Vehicle Inspection and Service".

6. Set jack under rear suspension beam.

7. Remove coil spring (left/right). Refer to RSU-11, "

Removal and

Installation".

8. Remove bolts between body and rear suspension beam bracket. Refer to RSU-8, "

Component".

9. Gradually lower the jack, and then remove rear suspension beam from vehicle.

10. Remove the rear suspension beam bracket bolt and nut, and then remove rear suspension beam bracket

from rear suspension beam. Refer to RSU-8, "

Component".

11. Remove brake tube protector from rear suspension beam.

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage, and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, "

Component".

• Refill with new brake fluid and bleed air. Refer to BR-9, "

Bleeding Brake System".

• Tighten wheel nuts to specification. Refer to WT-7, "

Adjustment".

• Check the following after finishing work.

- Parking brake operation (stroke): Refer to PB-5, "

On-Vehicle Service".

- Wheel sensor harness for proper connection: Refer to BRC-33, "

Removal and Installation".

• Perform final tightening of rear suspension beam and rear suspen-

sion beam bracket (rubber bushing) under unladen conditions with

tires on level ground.

MEIA0029E

MEIA0030E

Revision: May 2010 2011 Versa

Page 3567 of 3787

SB-1

RESTRAINTS

C

DE

F

G

I

J

K L

M

SECTION SB

A

B

SB

N

O P

CONTENTS

SEAT BELTS

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Seat Belt Service ...............................3

ON-VEHICLE REPAIR ..................................4

SEAT BELTS .....................................................4

Removal and Installation of Front Seat Belt ........ .....4

Removal and Installation of Rear Seat Belt ..............6

Seat Belt Inspection ............................................. .....8

LATCH (LOWER ANCHORS AND TETHER

FOR CHILDREN) SYSTEM ...............................

11

Removal and Installation .........................................11

TOP TETHER STRAP CHILD RESTRAINT .....12

Removal and Installation .........................................12

Revision: May 2010 2011 Versa

Page 3568 of 3787

SB-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929618

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005929619

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3569 of 3787

PRECAUTIONSSB-3

< PRECAUTION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Seat Belt ServiceINFOID:0000000005929620

CAUTION:

• Before removing the front seat belt pre-tensioner assembly, turn the ignition switch off, disconnect

the both battery cables and wait at least 3 minutes.

• After replacing or reinstalling front seat belt pre-tensioner assembly, or reconnecting front seat belt

pre-tensioner connector, check th e system function. Refer to SRS-19, "

SRS Operation Check".

• Do not disassemble buckle or seat belt assembly.

• Do not reuse seat belt anchor bolts after removal. Replace with new ones.

• Replace anchor bolts if th ey are deformed or worn out.

• Never oil tongue and buckle.

• If any component of seat belt assembly is questio nable, do not repair. Replace the whole seat belt

assembly.

• If webbing is cut, frayed, or damaged, replace seat belt assembly.

• When replacing seat belt assembly, u se a genuine NISSAN seat belt assembly.

AFTER A COLLISION

WARNING:

• Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

• NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an acci dent. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or im proper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly (including anchor bolts) if:

• The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and buckles show no damage and continue to operate properly).

• The seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide).

• The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage or distortion and repair as necessary before installing a new seat belt assembly.

• Anchor bolts are deformed or worn out.

• The seat belt pre-tensioner should be replaced even if t he seat belts are not in use during the collision in

which the air bags are deployed.

Revision: May 2010 2011 Versa