NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2611 of 3833

TF-1

TRANSFER

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION

A

B

TF

TRANSFER

PRECAUTIONS .......................................................... 3

Caution ..................................................................... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Troubleshooting Chart ..................................... 7

TRANSFER FLUID ..................................................... 8

Replacement ............................................................ 8

DRAINING ............................................................. 8

FILLING ................................................................. 8

Inspection ................................................................. 8

OIL LEAKAGE AND OIL LEVEL ........................... 8

SIDE OIL SEAL .......................................................... 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ..................................................... 9

AIR BREATHER HOSE ............................................ 10

Removal and Installation ........................................ 10

TRANSFER ASSEMBLY ...........................................11

Removal and Installation from Vehicle .................... 11

REMOVAL ............................................................ 11

INSTALLATION .................................................... 11

Component Parts Drawing ..................................... 13

Assembly Inspection .............................................. 14

BACKLASH ......................................................... 14

TOOTH CONTACT .............................................. 14

PRELOAD TORQUE ........................................... 16

COMPANION FLANGE RUNOUT ...................... 17

Disassembly and Assembly ................................... 18

DISASSEMBLY ................................................... 18

INSPECTION AFTER DISASSEMBLY ............... 22

SELECTIONG ADJUSTING SHIMS ................... 23

ASSEMBLY ......................................................... 24

ALL MODE 4X4 SYSTEM ........................................ 30

Precautions ............................................................ 30

System Component ................................................ 30

System Description ................................................ 30

ELECTRONIC COUPLING ................................. 30

4WD CONTROL UNIT ........................................ 304WD MODE SWITCH ......................................... 31

4WD WARNING LAMP ....................................... 31

FAIL- SAFE FUNCTION ...................................... 32

System Diagram ..................................................... 32

CAN Communication ...........................................

... 32

SYSTEM DESCRIPTION .................................... 32

SYSTEM DIAGRAM ............................................ 32

INPUT/OUTPUT SIGNAL .................................... 33

Circuit Diagram ....................................................... 34

Wiring Diagram ....................................................... 35

TROUBLE DIAGNOSIS ............................................ 40

Fail-safe function .................................................... 40

How to proceed with trouble diagnosis ................... 40

BASIC CONCEPT ............................................... 40

Trouble diagnosis chart by symptom ...................... 41

4WD control unit input/output signal standard ........ 42

4WD CONTROL UNIT CONNECTOR TERMI-

NAL ARRANGEMENT ........................................ 42

REFERENCE STANDARD TABLE ...................... 43

CONSULT-II functions ............................................ 45

CONSULT-II FUNCTION APPLICATION TABLE ... 45

SELF-DIAGNOSIS .............................................. 45

DATA MONITOR ................................................. 46

ACTIVE TEST ..................................................... 48

ECU PART NUMBER .......................................... 49

Component Inspection ............................................ 49

4WD SOLENOID VALVE ..................................... 49

System Inspection .................................................. 49

CONTROL UNIT POWER SUPPLY SYSTEM .... 49

G-SENSOR SYSTEM ......................................... 50

4WD SOLENOID, ACTUATOR RELAY SYSTEM ... 52

CAN COMMUNICATION SYSTEM ..................... 53

4WD MODE SWITCH SYSTEM .......................... 54

Trouble Diagnoses for Symptoms .......................... 55

4WD INDICATOR LAMP DOSE NOT COME ON

FOR APPROXIMATELY 1 SECOND WHEN THE

IGNITION SWITCH IS TURNED TO ON ............. 55

4WD WARNING LAMP DOES NOT ILLUMINATE

WITH IGNITION ON ............................................ 55

4WD WARNING LAMP DOES NOT GO OUT

Page 2612 of 3833

TF-2

SEVERAL SECONDS AFTER ENGINE

STARTED.(4WD MODE INDICATOR LAMP

GOES OUT) ........................................................ 56

HEAVY TIGHT-CORNER BRAKING SYMPTOM

OCCURS WHEN THE VEHICLE IS DRIVEN IN

AUTO MODE AND THE STEERING WHEEL IS

TURNED FULLY TO EITHER SIDE AFTER THE

ENGINE IS STARTED ......................................... 56

4WD MODES CANNOT BE SWITCHED AFTER

ENGINE IS STARTED ......................................... 57

WHILE DRIVING, 4WD WARNING LAMP

FLASHES RAPIDLY. (WHEN IT FLASHERS FOR

APPROX. ONE MINUTE, THEN DOES NOT

ILLUMINATE.) ..................................................... 57

WHILE DRIVING, 4WD WARNING LAMP

FLASHES SLOWLY. (WHEN IT CONTINUES TO

ILLUMINATE UNTIL ENGINE TURNS OFF.) ...... 57

VEHICLE DOES NOT ENTER 4WD MODE EVEN THOUGH 4WD WARNING LAMP IS OFF. ... 58

TIGHT-CONER BRAKING SYMPTOM OCCURS

WHEN THE VEHICLE IS STARTED IN AUTO

WARNING LAMP REMAIN OFF). ....................... 58

4WD ACTUATOR RELAY (4WD SOLENOID

ACTUATOR RELAY) TURNS ON/OFF FRE-

QUENTLY ............................................................ 58

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 59

General Specifications ......................................... ... 59

Inspection and Adjustment ...................................... 59

PRELOAD TORQUE BEFORE DISASSEMBLY ... 59

PRELOAD TORQUE AFTER DISASSEMBLY

AND REASSEMBLY ............................................ 59

BACKLSH ............................................................ 59

COMPANION FLANGE RUNOUT ....................... 59

SELECTIVE PARTS ............................................ 59

PINION SLEEVE SHIM ........................................ 60

Page 2613 of 3833

PRECAUTIONS

TF-3

C

E

F

G

H

I

J

K

L

MA

B

TF

PRECAUTIONSPFP:00001

CautionEDS0004O

●Do not reuse the drained transfer oil.

●Check the oil level with the vehicle on the level ground.

●During removal and installation, be careful not to allow foreign material such as dust or dirt to enter into

the transfer unit.

●Before starting diagnosis of the vehicle, understand trouble symptoms well. Perform correct and system-

atic operations.

●Check for the correct installation status prior to removal or disassembly. If mating marks are required, be

certain they do not interfere with the function of the parts they are applied to.

●Carry out the work in a clean work place. Using a dust proof room is recommended.

●Before disassembly, using steam or white gasoline, completely remove sand and mud from the exterior of

the unit, preventing them from entering into the unit during disassembly or assembly.

●Check appearance of the disassembled parts for damage, deformation, and abnormal wear. If a malfunc-

tion is detected, replace it with a new one.

●Normally replace O-rings, oil seals, bearings, and lock nuts with new ones every time they are removed.

●In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, observe it.

●Clean and flush the parts sufficiently and blow them dry.

●Be careful not to damage sliding surfaces and mating surfaces.

●Always use shop paper for cleaning the inside of components.

●Do not use cotton gloves or a shop cloth. Using them may leave lint on the surface of the parts.

●During assembly always tighten bolts and screws to specified torque. New transfer oil a petroleum jelly

such as "Vaseline", or multi-purpose grease as appropriate.

●Discard waste oil after oil changes or part treatment in accordance with local laws and regulations.

Page 2614 of 3833

TF-4

PREPARATION

PREPARATION

PFP:00002

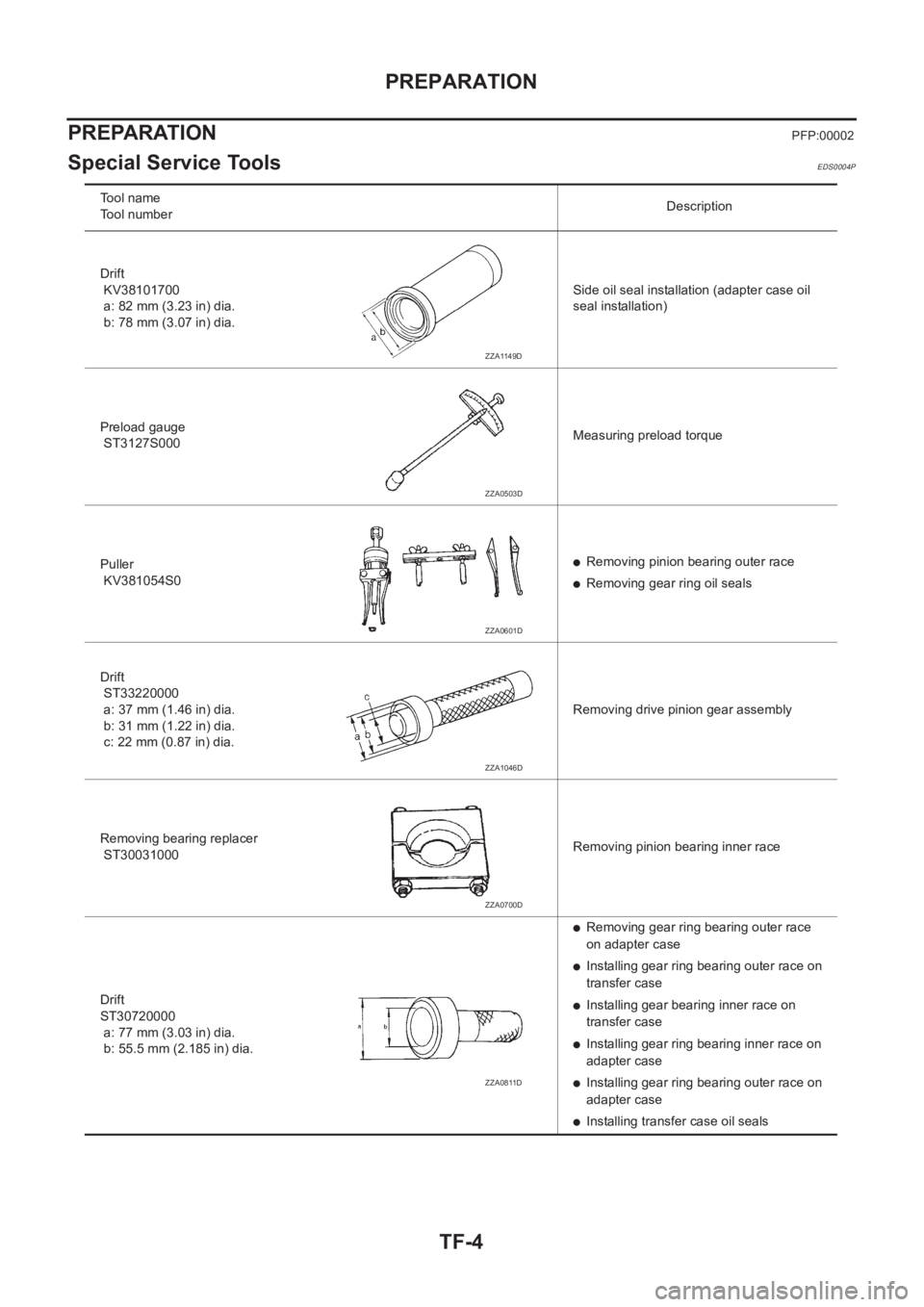

Special Service ToolsEDS0004P

Tool name

Tool numberDescription

Drift

KV38101700

a: 82 mm (3.23 in) dia.

b: 78 mm (3.07 in) dia.Side oil seal installation (adapter case oil

seal installation)

Preload gauge

ST3127S000Measuring preload torque

Puller

KV381054S0

●Removing pinion bearing outer race

●Removing gear ring oil seals

Drift

ST33220000

a: 37 mm (1.46 in) dia.

b: 31 mm (1.22 in) dia.

c: 22 mm (0.87 in) dia.Removing drive pinion gear assembly

Removing bearing replacer

ST30031000Removing pinion bearing inner race

Drift

ST30720000

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

●Removing gear ring bearing outer race

on adapter case

●Installing gear ring bearing outer race on

transfer case

●Installing gear bearing inner race on

transfer case

●Installing gear ring bearing inner race on

adapter case

●Installing gear ring bearing outer race on

adapter case

●Installing transfer case oil seals

ZZA1149D

ZZA0503D

ZZA0601D

ZZA1046D

ZZA0700D

ZZA0811D

Page 2615 of 3833

PREPARATION

TF-5

C

E

F

G

H

I

J

K

L

MA

B

TF

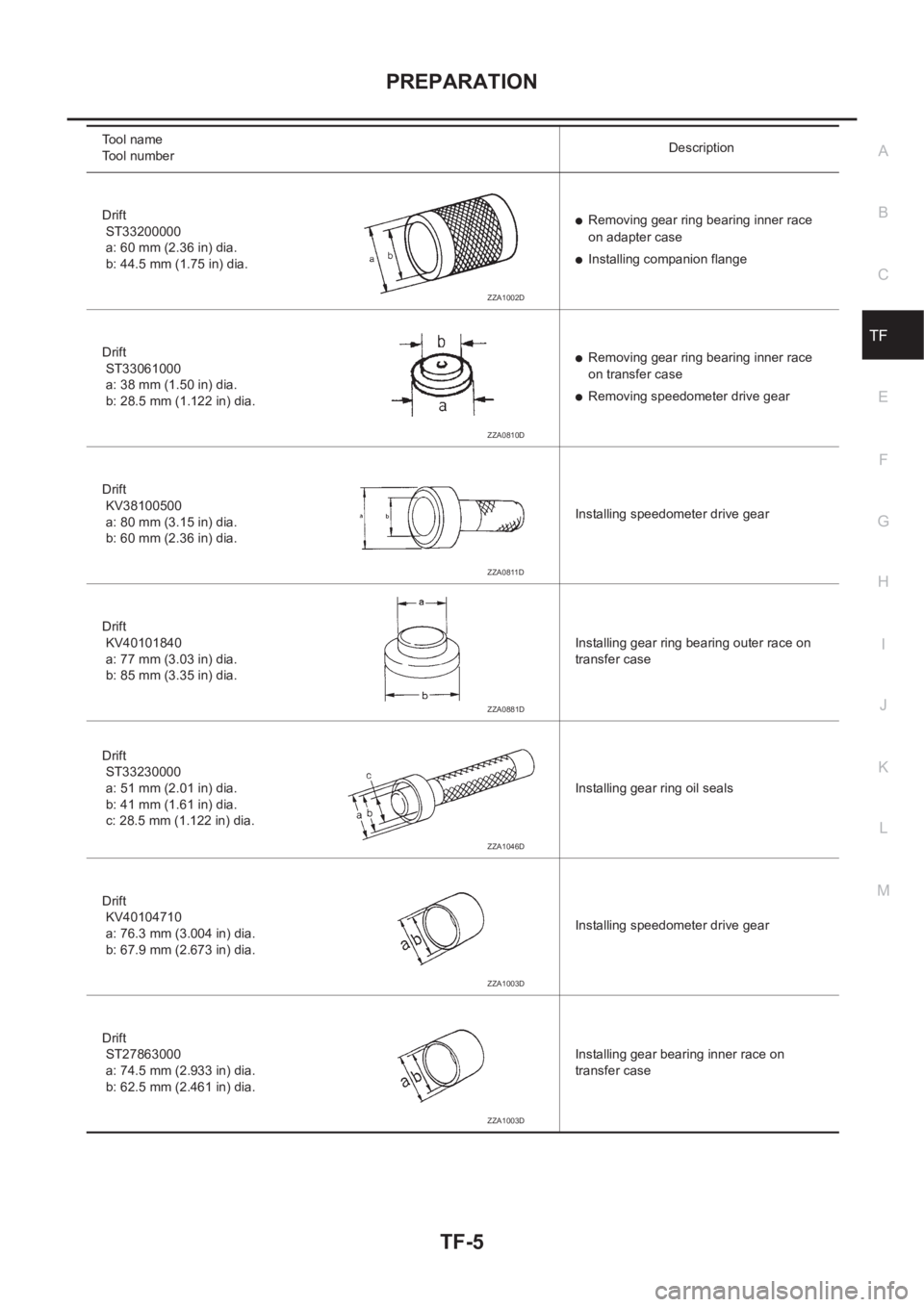

Drift

ST33200000

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.75 in) dia.●Removing gear ring bearing inner race

on adapter case

●Installing companion flange

Drift

ST33061000

a: 38 mm (1.50 in) dia.

b: 28.5 mm (1.122 in) dia.

●Removing gear ring bearing inner race

on transfer case

●Removing speedometer drive gear

Drift

KV38100500

a: 80 mm (3.15 in) dia.

b: 60 mm (2.36 in) dia.Installing speedometer drive gear

Drift

KV40101840

a: 77 mm (3.03 in) dia.

b: 85 mm (3.35 in) dia.Installing gear ring bearing outer race on

transfer case

Drift

ST33230000

a: 51 mm (2.01 in) dia.

b: 41 mm (1.61 in) dia.

c: 28.5 mm (1.122 in) dia.Installing gear ring oil seals

Drift

KV40104710

a: 76.3 mm (3.004 in) dia.

b: 67.9 mm (2.673 in) dia.Installing speedometer drive gear

Drift

ST27863000

a: 74.5 mm (2.933 in) dia.

b: 62.5 mm (2.461 in) dia.Installing gear bearing inner race on

transfer case Tool name

Tool numberDescription

ZZA1002D

ZZA0810D

ZZA0811D

ZZA0881D

ZZA1046D

ZZA1003D

ZZA1003D

Page 2616 of 3833

TF-6

PREPARATION

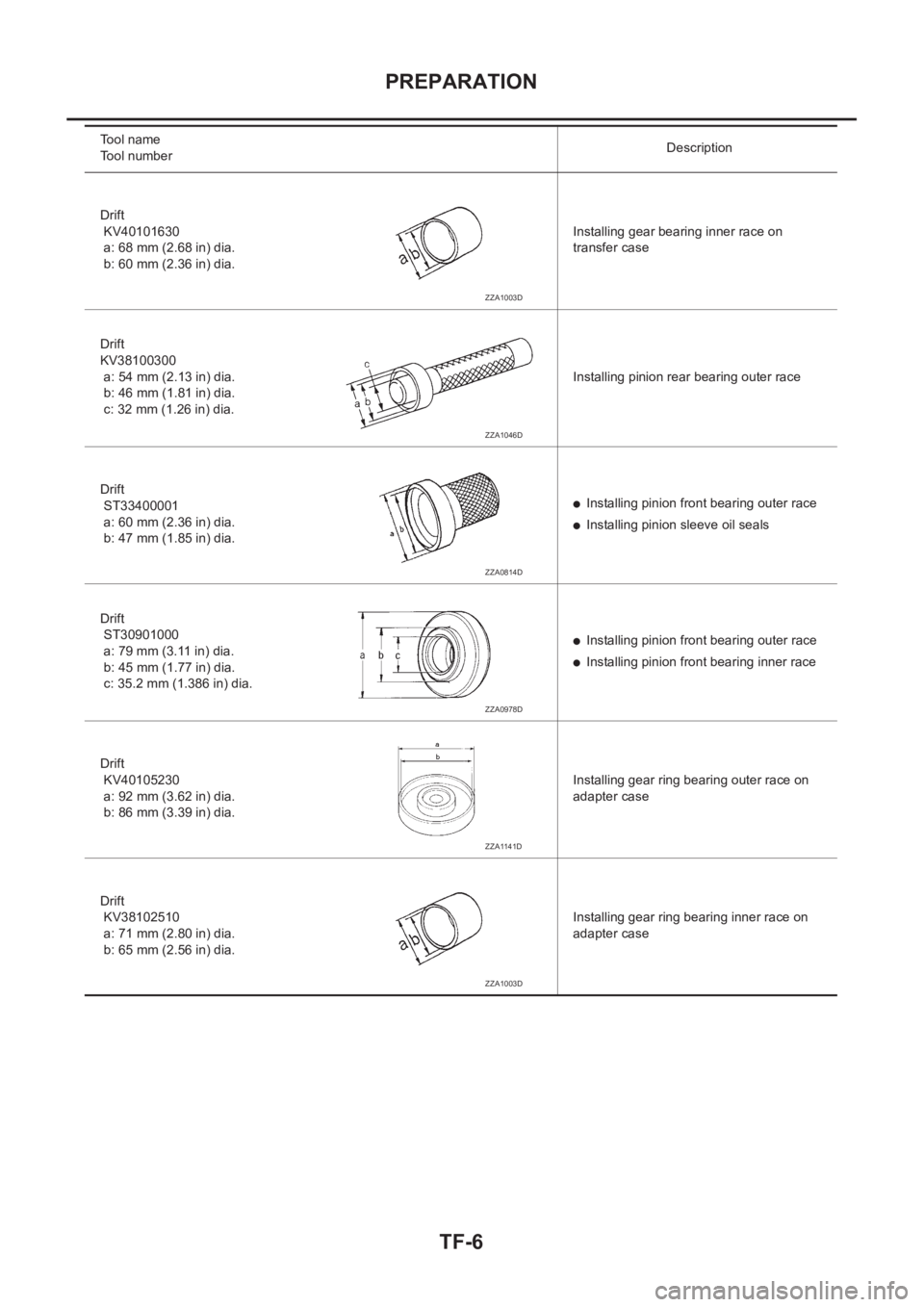

Drift

KV40101630

a: 68 mm (2.68 in) dia.

b: 60 mm (2.36 in) dia.Installing gear bearing inner race on

transfer case

Drift

KV38100300

a: 54 mm (2.13 in) dia.

b: 46 mm (1.81 in) dia.

c: 32 mm (1.26 in) dia.Installing pinion rear bearing outer race

Drift

ST33400001

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

●Installing pinion front bearing outer race

●Installing pinion sleeve oil seals

Drift

ST30901000

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35.2 mm (1.386 in) dia.

●Installing pinion front bearing outer race

●Installing pinion front bearing inner race

Drift

KV40105230

a: 92 mm (3.62 in) dia.

b: 86 mm (3.39 in) dia.Installing gear ring bearing outer race on

adapter case

Drift

KV38102510

a: 71 mm (2.80 in) dia.

b: 65 mm (2.56 in) dia.Installing gear ring bearing inner race on

adapter case Tool name

Tool numberDescription

ZZA1003D

ZZA1046D

ZZA0814D

ZZA0978D

ZZA1141D

ZZA1003D

Page 2617 of 3833

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

TF-7

C

E

F

G

H

I

J

K

L

MA

B

TF

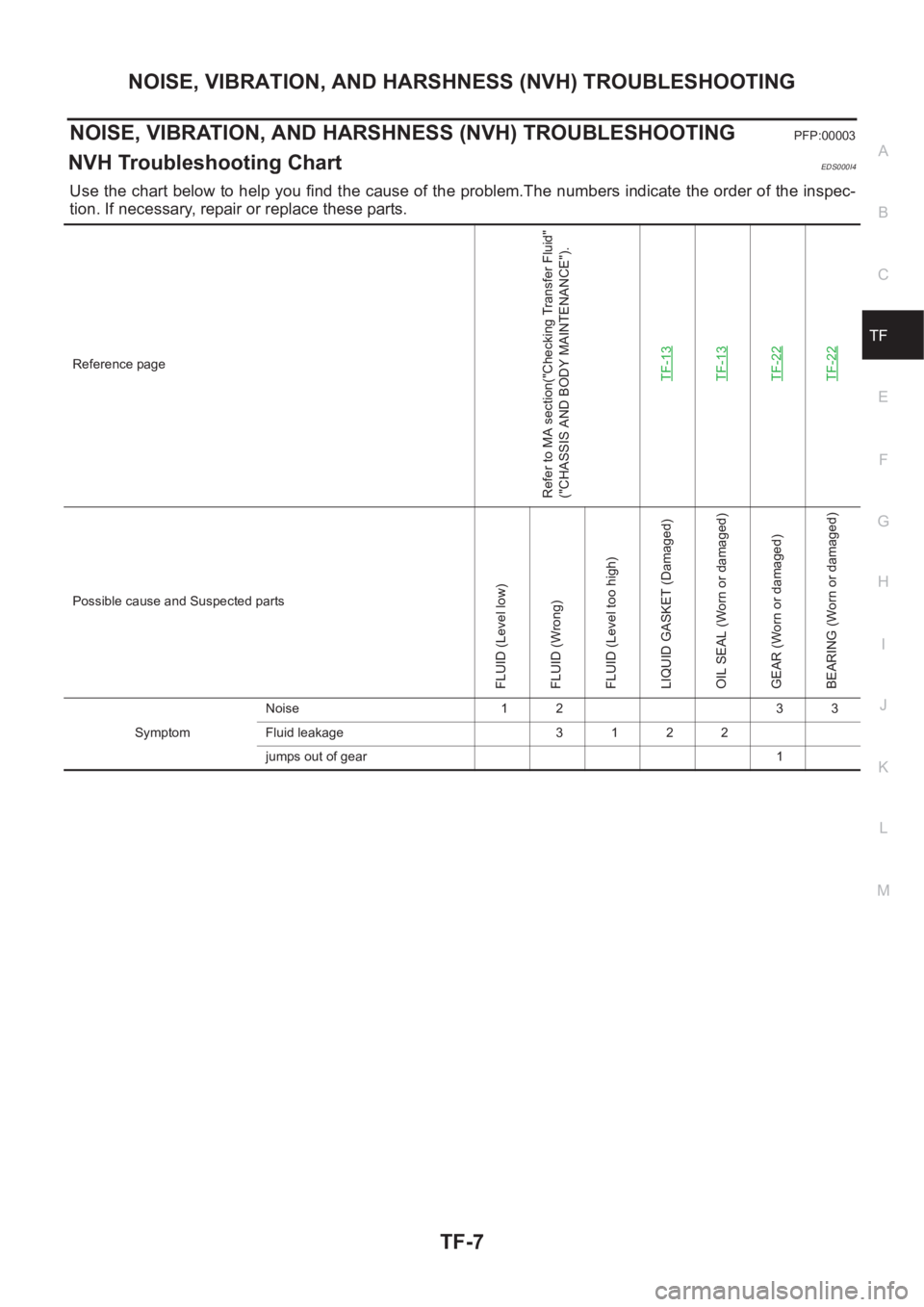

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEDS000I4

Use the chart below to help you find the cause of the problem.The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference page

Refer to MA section("Checking Transfer Fluid"

("CHASSIS AND BODY MAINTENANCE").

TF-13

TF-13TF-22TF-22

Possible cause and Suspected parts

FLUID (Level low)

FLUID (Wrong)

FLUID (Level too high)

LIQUID GASKET (Damaged)

OIL SEAL (Worn or damaged)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

SymptomNoise 1 2 3 3

Fluid leakage 3 1 2 2

jumps out of gear 1

Page 2618 of 3833

TF-8

TRANSFER FLUID

TRANSFER FLUID

PFP:KLD30

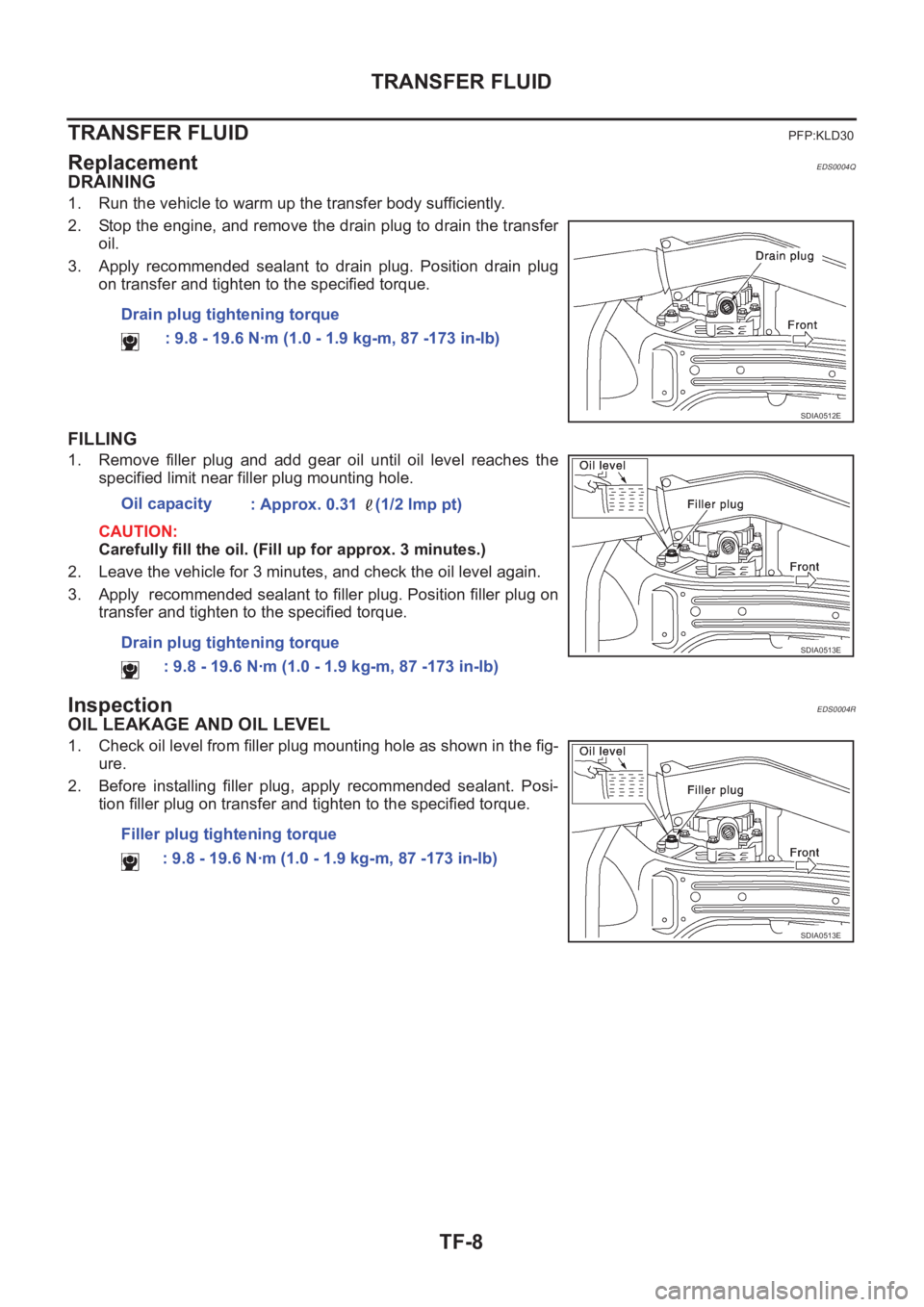

ReplacementEDS0004Q

DRAINING

1. Run the vehicle to warm up the transfer body sufficiently.

2. Stop the engine, and remove the drain plug to drain the transfer

oil.

3. Apply recommended sealant to drain plug. Position drain plug

on transfer and tighten to the specified torque.

FILLING

1. Remove filler plug and add gear oil until oil level reaches the

specified limit near filler plug mounting hole.

CAUTION:

Carefully fill the oil. (Fill up for approx. 3 minutes.)

2. Leave the vehicle for 3 minutes, and check the oil level again.

3. Apply recommended sealant to filler plug. Position filler plug on

transfer and tighten to the specified torque.

InspectionEDS0004R

OIL LEAKAGE AND OIL LEVEL

1. Check oil level from filler plug mounting hole as shown in the fig-

ure.

2. Before installing filler plug, apply recommended sealant. Posi-

tion filler plug on transfer and tighten to the specified torque. Drain plug tightening torque

: 9.8 - 19.6 N·m (1.0 - 1.9 kg-m, 87 -173 in-lb)

SDIA0512E

Oil capacity

: Approx. 0.31 (1/2 lmp pt)

Drain plug tightening torque

: 9.8 - 19.6 N·m (1.0 - 1.9 kg-m, 87 -173 in-lb)

SDIA0513E

Filler plug tightening torque

: 9.8 - 19.6 N·m (1.0 - 1.9 kg-m, 87 -173 in-lb)

SDIA0513E

Page 2619 of 3833

SIDE OIL SEAL

TF-9

C

E

F

G

H

I

J

K

L

MA

B

TF

SIDE OIL SEALPFP:33142

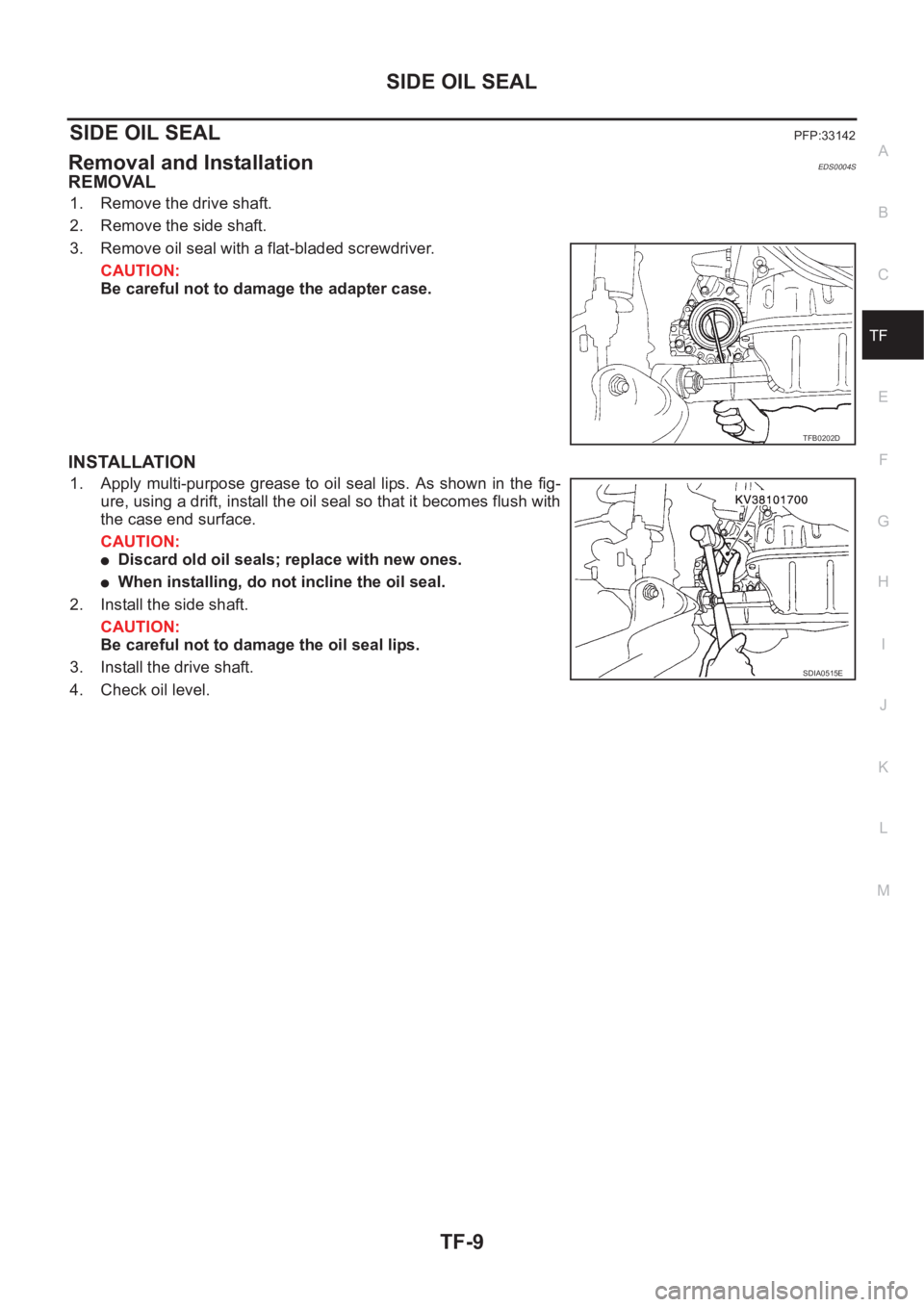

Removal and InstallationEDS0004S

REMOVAL

1. Remove the drive shaft.

2. Remove the side shaft.

3. Remove oil seal with a flat-bladed screwdriver.

CAUTION:

Be careful not to damage the adapter case.

INSTALLATION

1. Apply multi-purpose grease to oil seal lips. As shown in the fig-

ure, using a drift, install the oil seal so that it becomes flush with

the case end surface.

CAUTION:

●Discard old oil seals; replace with new ones.

●When installing, do not incline the oil seal.

2. Install the side shaft.

CAUTION:

Be careful not to damage the oil seal lips.

3. Install the drive shaft.

4. Check oil level.

TFB0202D

SDIA0515E

Page 2620 of 3833

TF-10

AIR BREATHER HOSE

AIR BREATHER HOSE

PFP:31098

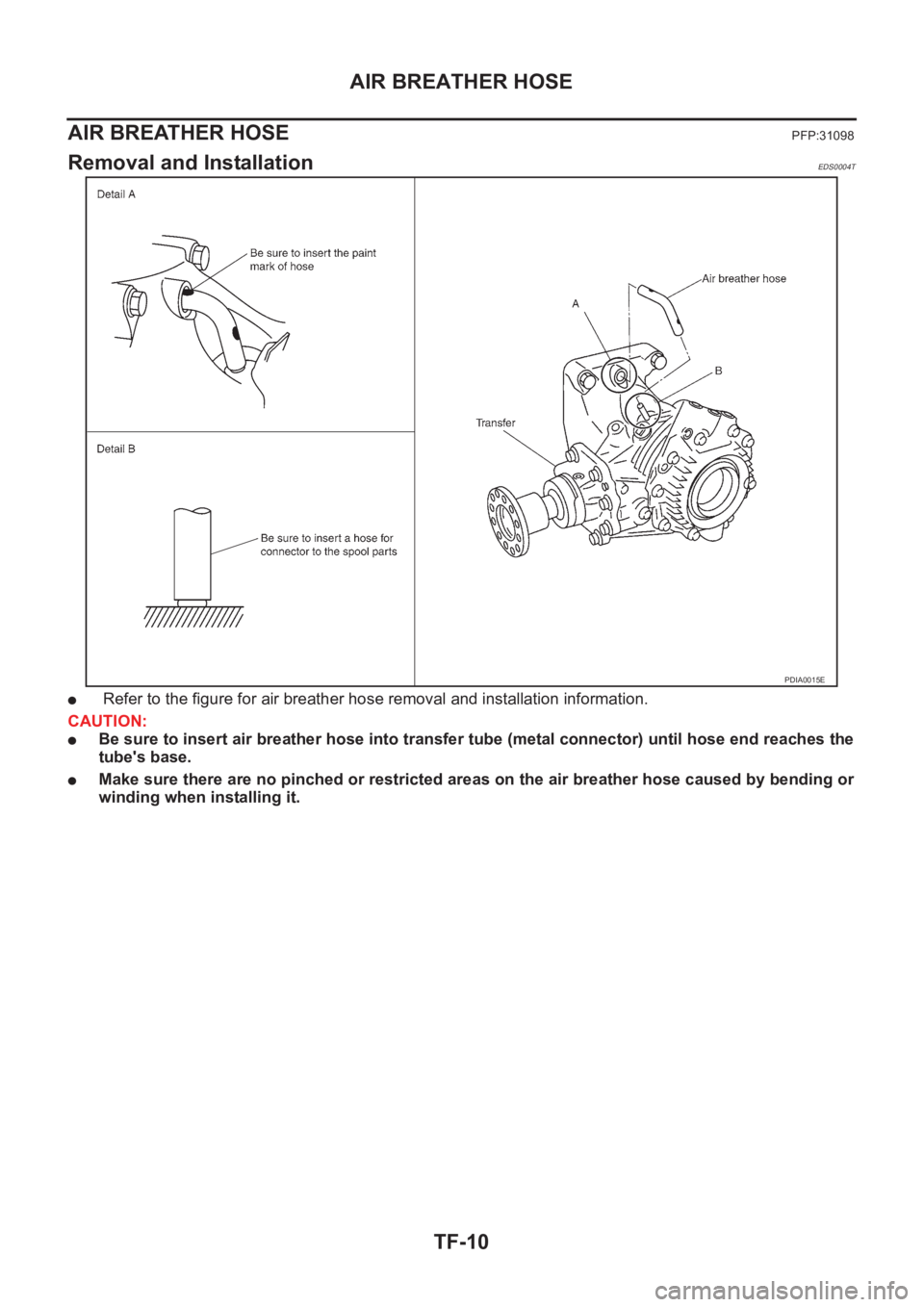

Removal and InstallationEDS0004T

● Refer to the figure for air breather hose removal and installation information.

CAUTION:

●Be sure to insert air breather hose into transfer tube (metal connector) until hose end reaches the

tube's base.

●Make sure there are no pinched or restricted areas on the air breather hose caused by bending or

winding when installing it.

PDIA0015E