coolant capacity NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 307 of 3833

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

CO

ENGINE COOLING SYSTEM

QR

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET .......................... 3

LIQUID GASKET APPLICATION PROCEDURE ..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

OVERHEATING CAUSE ANALYSIS .......................... 5

Troubleshooting Chart .............................................. 5

COOLING SYSTEM .................................................... 7

Cooling Circuit .......................................................... 7

System Drawing ....................................................... 8

ENGINE COOLANT .................................................... 9

Inspection ................................................................. 9

LEVEL CHECK ..................................................... 9

CHECKING RADIATOR SYSTEM FOR LEAKS ..... 9

Changing Engine Coolant ........................................ 9

DRAINING ENGINE COOLANT ........................... 9

REFILLING ENGINE COOLANT ........................ 10

FLUSHING COOLING SYSTEM ......................... 10

RADIATOR .................................................................11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSTALLATION .................................................... 11

Disassembly and Assembly Radiator Fan ............. 12

DISASSEMBLY ................................................... 12

ASSEMBLY ......................................................... 12

Checking Radiator Cap .......................................... 12

Checking Radiator .................................................. 13

RADIATOR (ALUMINUM TYPE) .............................. 14

Disassembly and Assembly ................................... 14

PREPARATION ................................................... 14

DISASSEMBLY ................................................... 14

ASSEMBLY ......................................................... 15

INSPECTION ...................................................... 17WATER PUMP .......................................................... 18

Removal and Installation ........................................ 18

REMOVAL ........................................................... 18

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ................ 19

THERMOSTAT AND WATER CONTROL VALVE .... 20

Removal and Installation ........................................ 20

REMOVAL ........................................................... 20

INSPECTION AFTER REMOVAL ....................... 21

INSTALLATION ................................................

... 21

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 22

Standard and Limit .................................................. 22

CAPACITY ........................................................... 22

THERMOSTAT .................................................... 22

WATER CONTROL VALVE ................................. 22

RADIATOR ....................................................... ... 22

Tightening Torque ................................................... 22

YD22DDTi

PRECAUTIONS ........................................................ 23

Precautions For Liquid Gasket ............................... 23

REMOVAL OF LIQUID GASKET ......................... 23

LIQUID GASKET APPLICATION PROCEDURE ... 23

PREPARATION ......................................................... 24

Special Service Tools ............................................. 24

OVERHEATING CAUSE ANALYSIS ........................ 25

Troubleshooting Chart ............................................ 25

COOLING SYSTEM .................................................. 27

Cooling Circuit ........................................................ 27

System Drawing ..................................................... 28

ENGINE COOLANT .................................................. 29

Inspection ............................................................... 29

LEVEL CHECK .................................................... 29

CHECKING RADIATOR SYSTEM FOR LEAKS ... 29

Changing Engine Coolant ....................................... 29

DRAINING ENGINE COOLANT .......................... 29

REFILLING ENGINE COOLANT ......................... 30

FLUSHING COOLING SYSTEM ......................... 31

Page 316 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CO-10

[QR]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genui NISSAN X-TRAIL 2001 Service Repair Manual CO-10

[QR]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genui](/img/5/57405/w960_57405-315.png)

CO-10

[QR]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

●Use genuine Nissan engine coolant or equivalent in its

quality. Refer to MA-16, "

RECOMMENDED FLUIDS AND

LUBRICANTS" .

●Pour engine coolant slowly of less than 2 (1-3/4 lmp qt)

a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

●If engine coolant overflows radiator filler hole, install

radiator cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

●Repeat two or three times.

Watch engine coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

●Cool down using a fan to reduce the time.

●If necessary, refill radiator up to filler neck with engine coolant.

6. Refill reservoir tank to MAX level line with engine coolant.

7. Repeat steps 4 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

●Sound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 4 through 6 until engine coolant level

no longer drops.

●Clean excess engine coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator. Cylinder block drain plug:

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank: 0.6 (1/2 lmp qt)

SMA412B

Page 328 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CO-22

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00KOP

CAPACITY

Unit: (lmp qt)

THERMOSTAT

WATER CONTROL VALVE

RADIATOR

Unit: kPa NISSAN X-TRAIL 2001 Service Repair Manual CO-22

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00KOP

CAPACITY

Unit: (lmp qt)

THERMOSTAT

WATER CONTROL VALVE

RADIATOR

Unit: kPa](/img/5/57405/w960_57405-327.png)

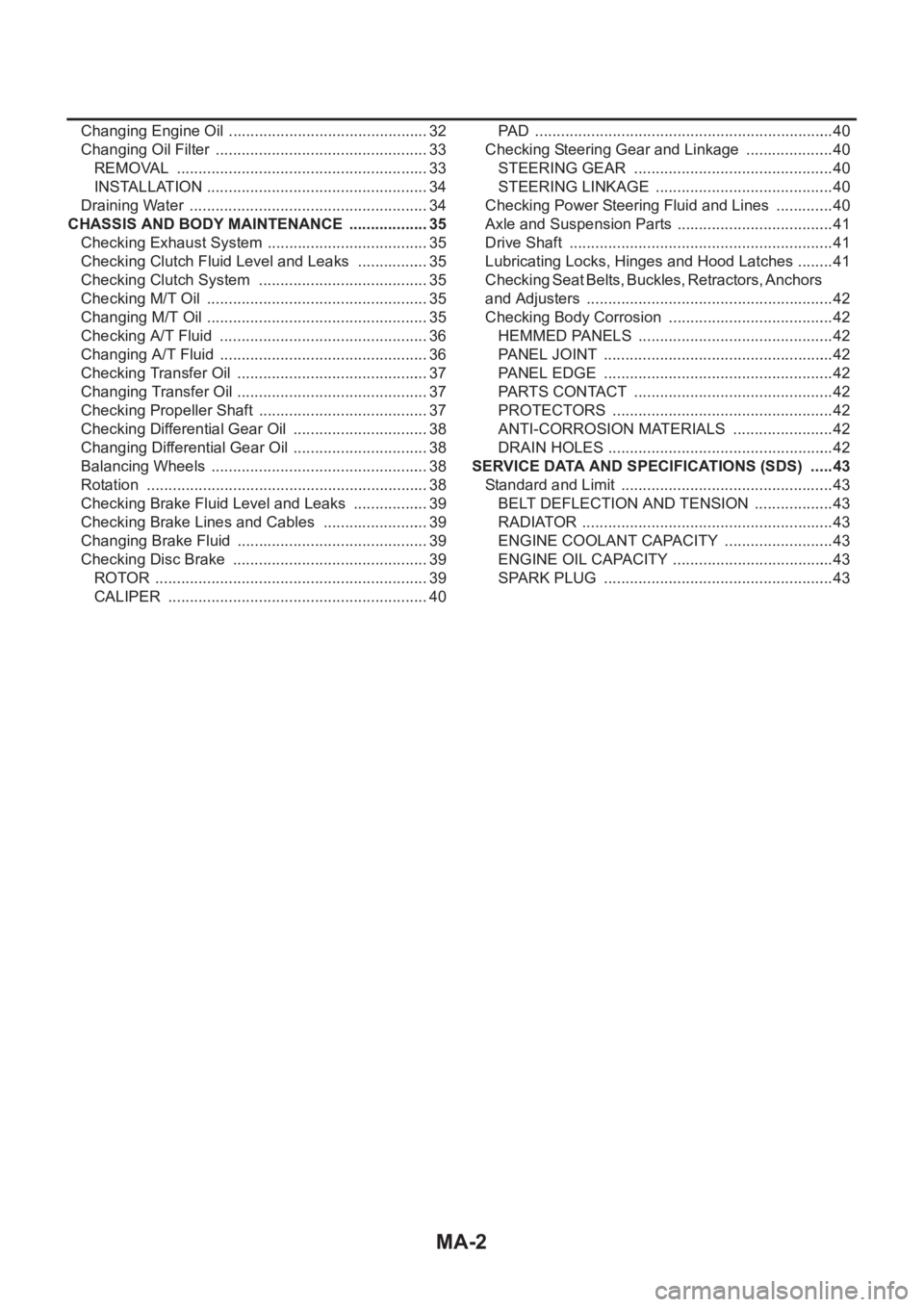

CO-22

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00KOP

CAPACITY

Unit: (lmp qt)

THERMOSTAT

WATER CONTROL VALVE

RADIATOR

Unit: kPa (bar, kg/cm2 , psi)

Tightening TorqueEBS00KOQ

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*

Engine coolant capacity [With reservoir tank (MAX level)] Approximately 7.1 (6-1/4)

Reservoir tank0.6 (1/2)

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Valve liftMore than 8 mm/ 95°C (0.315 in/203°F)

Valve closing temperature 77°C (171°F)

Valve opening temperature 93.5 - 96.5°C (200 - 206°F)

Valve liftMore than 8 mm/108°C (0.315 in/226°F)

Valve closing temperature 90°C (194° F)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11- 14)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Cylinder block drain plug 7.8 - 11.8 (0.8 - 1.2, 69 - 104)*

Radiator mounting bracket 3.8 - 4.5 (0.39 - 0.46, 34 - 39)*

Radiator fan assembly 3.8 - 4.5 (0.39 - 0.46, 34 - 39)*

Radiator fan2.9 - 3.9 (0.30 - 0.40, 26 - 34)*

Radiator fan motor 3.9 - 4.9 (0.40 - 0.50, 35 - 43)*

Water pump20.8 - 28.2 (2.1 - 2.9, 16 - 20)

Water pump housing 20.8 - 28.2 (2.1 - 2.9, 16 - 20)

Water inlet20.8 - 28.2 (2.1 - 2.9, 16 - 20)

Water outlet20.8 - 28.2 (2.1 - 2.9, 16 - 20)

Water pipe20.8 - 28.2 (2.1 - 2.9, 16 - 20)

Hater pipe20.8 - 28.2 (2.1 - 2.9, 16 - 20)

Engine coolant temperature sensor 19.6 - 29.4 (2.0 - 3.0, 15 - 21)

Page 336 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CO-30

[YD22DDTi]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use NISSAN X-TRAIL 2001 Service Repair Manual CO-30

[YD22DDTi]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use](/img/5/57405/w960_57405-335.png)

CO-30

[YD22DDTi]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genuine Liquid Gasket or equivalent.

2. Fill radiator slowly with engine coolant until engine coolant spills

from the air relief plugs, then install air relief plugs.

CAUTION:

If the filling rate is too fast, this could lead to air being

mixed in the engine coolant. Be sure to fill the engine cool-

ant slowly according to the rate indicated above.

●Replace the copper washer of the air bleeding plug.

●Use genuine Nissan anti-freeze engine coolant or equiva-

lent mixed with water (distilled or demineralized).

Refer to MA-16, "

RECOMMENDED FLUIDS AND LUBRICANTS".

●Pour engine coolant through engine coolant filler neck slowly of less than 2 (1-3/4 lmp qt) a

minute to allow air in system to escape.

3. Fill reservoir tank to specified level.

4. Warm up engine to normal operating temperature without radia-

tor cap installed.

●If engine coolant overflows radiator filler hole, install

radiator cap.

5. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

●Repeat two or three times.

Watch engine coolant temperature gauge so as not to overheat

the engine.

6. Stop engine and cool down to less than approximately

50°C(122°F).

●Cool down using a fan to reduce the time.

●If necessary, refill radiator up to filler neck with engine coolant.

7. Refill reservoir tank to MAX level line with engine coolant.

SBIA0130E

Cylinder block drain plug:

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Air relief plug:

: 6.7 - 7.9 N·m (0.68 - 0.81 kg-m, 59 - 70 in-lb)

Engine coolant capacity (With reservoir tank):

9.5 (8-3/8 Imp qt)

SMA182B

Reservoir tank

: 0.6 (1/2 lmp qt)

SMA412B

Page 349 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

CO-43

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitEBS00CU0

CAPACITY

Unit: (lmp qt)

THERMOSTAT

RADIATOR NISSAN X-TRAIL 2001 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

CO-43

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitEBS00CU0

CAPACITY

Unit: (lmp qt)

THERMOSTAT

RADIATOR](/img/5/57405/w960_57405-348.png)

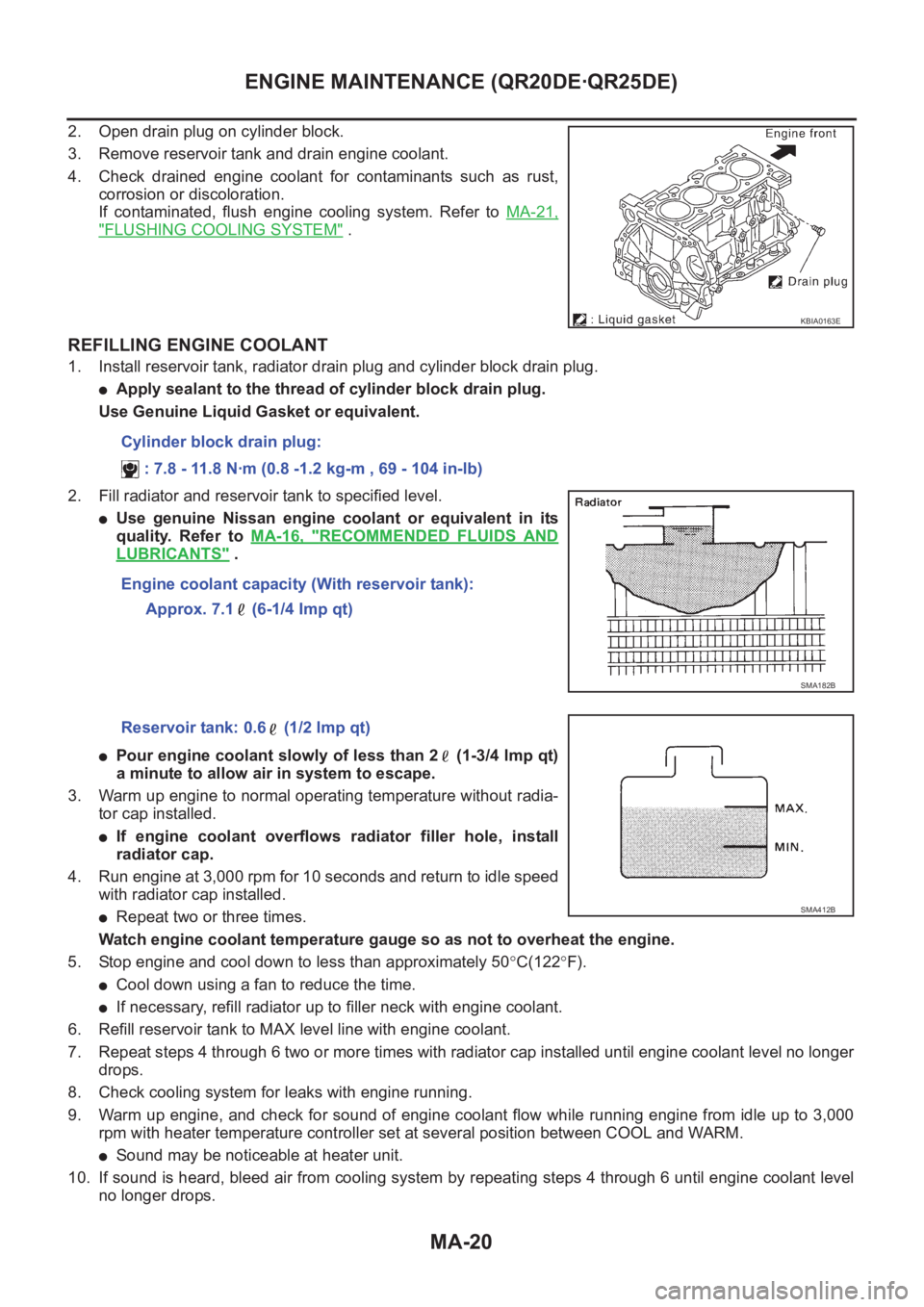

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-43

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitEBS00CU0

CAPACITY

Unit: (lmp qt)

THERMOSTAT

RADIATOR

Unit: kPa (bar, kg/cm2 , psi)

Tightening TorqueEBS00BKE

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*

Engine coolant capacity [With reservoir tank (MAX level)] 9.5 (8-3/8)

Reservoir tank0.6 (1/2)

Valve opening temperature 80 - 84°C (176 - 183°F)

Va l v e l i f tMore than 10 mm/ 95°C (0.39 in/203°F)

Valve closing temperature Approximately 77°C (171°F)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Cylinder block drain plug 7.8 - 11.8 (0.8 - 1.2, 69 - 104)*

Air relief plug6.7 - 7.9 (0.68 - 0.81, 59 - 70)*

Radiator mounting bracket

Radiator fan assembly

Radiator fan

Radiator fan motor3.8 - 4.5 (0.39 - 0.45, 34 - 39)*

3.8 - 4.5 (0.39 - 0.45, 34 - 39)*

2.9 - 3.9 (0.30 - 0.40, 26 - 34)*

3.9 - 4.9 (0.40 - 0.50, 35 - 43)*

Water pump

Water pump pulley

Water inlet

Thermostat housing

Water inlet pipe

Hater return pipe23.0 - 30.0 (2.3 - 3.1, 17 - 22)

7.3 - 9.6 (0.74 - 0.98, 65 - 85)*

21.0 - 28.0 (2.1 - 2.9, 16 - 20)

21.0 - 28.0 (2.1 - 2.9, 16 - 20)

21.0 - 28.0 (2.1 - 2.9, 16 - 20)

21.0 - 28.0 (2.1 - 2.9, 16 - 20)

Page 3782 of 3833

MA-2

Changing Engine Oil ............................................ ... 32

Changing Oil Filter .................................................. 33

REMOVAL ........................................................... 33

INSTALLATION .................................................... 34

Draining Water ........................................................ 34

CHASSIS AND BODY MAINTENANCE ................... 35

Checking Exhaust System ...................................... 35

Checking Clutch Fluid Level and Leaks ................. 35

Checking Clutch System ........................................ 35

Checking M/T Oil .................................................... 35

Changing M/T Oil .................................................... 35

Checking A/T Fluid ................................................. 36

Changing A/T Fluid ................................................. 36

Checking Transfer Oil ............................................. 37

Changing Transfer Oil .......................................... ... 37

Checking Propeller Shaft ........................................ 37

Checking Differential Gear Oil ................................ 38

Changing Differential Gear Oil ................................ 38

Balancing Wheels ................................................... 38

Rotation .................................................................. 38

Checking Brake Fluid Level and Leaks .................. 39

Checking Brake Lines and Cables ......................... 39

Changing Brake Fluid ............................................. 39

Checking Disc Brake .............................................. 39

ROTOR ................................................................ 39

CALIPER ............................................................. 40PAD ...................................................................... 40

Checking Steering Gear and Linkage ..................... 40

STEERING GEAR ............................................... 40

STEERING LINKAGE .......................................... 40

Checking Power Steering Fluid and Lines .............. 40

Axle and Suspension Parts ..................................... 41

Drive Shaft .............................................................. 41

Lubricating Locks, Hinges and Hood Latches ......... 41

Checking Seat Belts, Buckles, Retractors, Anchors

and Adjusters .......................................................... 42

Checking Body Corrosion ....................................... 42

HEMMED PANELS .............................................. 42

PANEL JOINT ...................................................... 42

PANEL EDGE ...................................................... 42

PARTS CONTACT ............................................... 42

PROTECTORS .................................................... 42

ANTI-CORROSION MATERIALS ........................ 42

DRAIN HOLES ..................................................... 42

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 43

Standard and Limit .................................................. 43

BELT DEFLECTION AND TENSION ................... 43

RADIATOR ........................................................... 43

ENGINE COOLANT CAPACITY .......................... 43

ENGINE OIL CAPACITY ...................................... 43

SPARK PLUG ...................................................... 43

Page 3796 of 3833

MA-16

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

PFP:00000

Fluids and LubricantsELS000C8

*1: For further details, see “SAE Viscosity Number”.

*2: Never use API CG-4.

*3: Use Genuine Nissan Anti-freeze Coolant (L2N)] or equivalent in its quality, in order to avoid possible aluminum corrosion within the

engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Contact a Nissan dealership for more information regarding suitable fluids, including recommended brand(s) of Dexron

TM III/Mer-

conTM Automatic Transmission Fluid.

*5: Never mix different types of fluids (DOT 3 and DOT 4).Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp measure

Engine oil

Drain and refillWith oil filter

changeQR20DE,

QR25DE3.9 3-3/8 qt

●Gasoline engine

API SG, SH, SJ or SL *1

ILSAC grade GF-I, GF-II or GF-III *1

ACEA 96-A2

●Diesel engine

API CF-4*1, *2

ACEA B1, B3, B4, B5*1, *2 YD22DDTi 5.2 4-5/8 qt

Without oil filter

changeQR20DE,

QR25DE3.5 3-1/8 qt

YD22DDTi 4.9 4-3/8 qt

Dry engine (engine overhaul)QR20DE,

QR25DE4.5 4 qt

YD22DDTi 6.3 5-1/2 qt

Cooling system (with reservoir)QR20DE,

QR25DE 7.1 6-1/4 qt

●Genuine Nissan Anti-freeze Coolant (L2N) or

equivalent in its quality*3 YD22DDTi 9.5 8-3/8 qt

Reservoir tankQR20DE,

QR25DE0.6 1/2 qt

YD22DDTi 0.6 1/2 qt

Manual transaxle gear oil

2.3 4pt

●Genuine Nissan gear oil or API GL-4, Viscos-

ity SAE 75W-85

Transfer gear oil 0.31 1/2 pt

●API GL-5*1, Viscosity SAE 80W-90

Differential gear oil 0.55 1 pt

●API GL-5*1, Viscosity SAE 80W-90

Automatic transaxle fluid 8.5 7-1/2 qt Genuine Nissan ATF or equivalent*4

Power steering fluid — —

Type Dexron

TM III or equivalent

Brake and clutch fluid — —

●DOT 3 or DOT 4 (US FMVSS No. 116)*5

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)

Page 3800 of 3833

MA-20

ENGINE MAINTENANCE (QR20DE·QR25DE)

2. Open drain plug on cylinder block.

3. Remove reservoir tank and drain engine coolant.

4. Check drained engine coolant for contaminants such as rust,

corrosion or discoloration.

If contaminated, flush engine cooling system. Refer to MA-21,

"FLUSHING COOLING SYSTEM" .

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

●Use genuine Nissan engine coolant or equivalent in its

quality. Refer to MA-16, "

RECOMMENDED FLUIDS AND

LUBRICANTS" .

●Pour engine coolant slowly of less than 2 (1-3/4 lmp qt)

a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

●If engine coolant overflows radiator filler hole, install

radiator cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

●Repeat two or three times.

Watch engine coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

●Cool down using a fan to reduce the time.

●If necessary, refill radiator up to filler neck with engine coolant.

6. Refill reservoir tank to MAX level line with engine coolant.

7. Repeat steps 4 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

●Sound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 4 through 6 until engine coolant level

no longer drops.

KBIA0163E

Cylinder block drain plug:

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank: 0.6 (1/2 lmp qt)

SMA412B

Page 3808 of 3833

MA-28

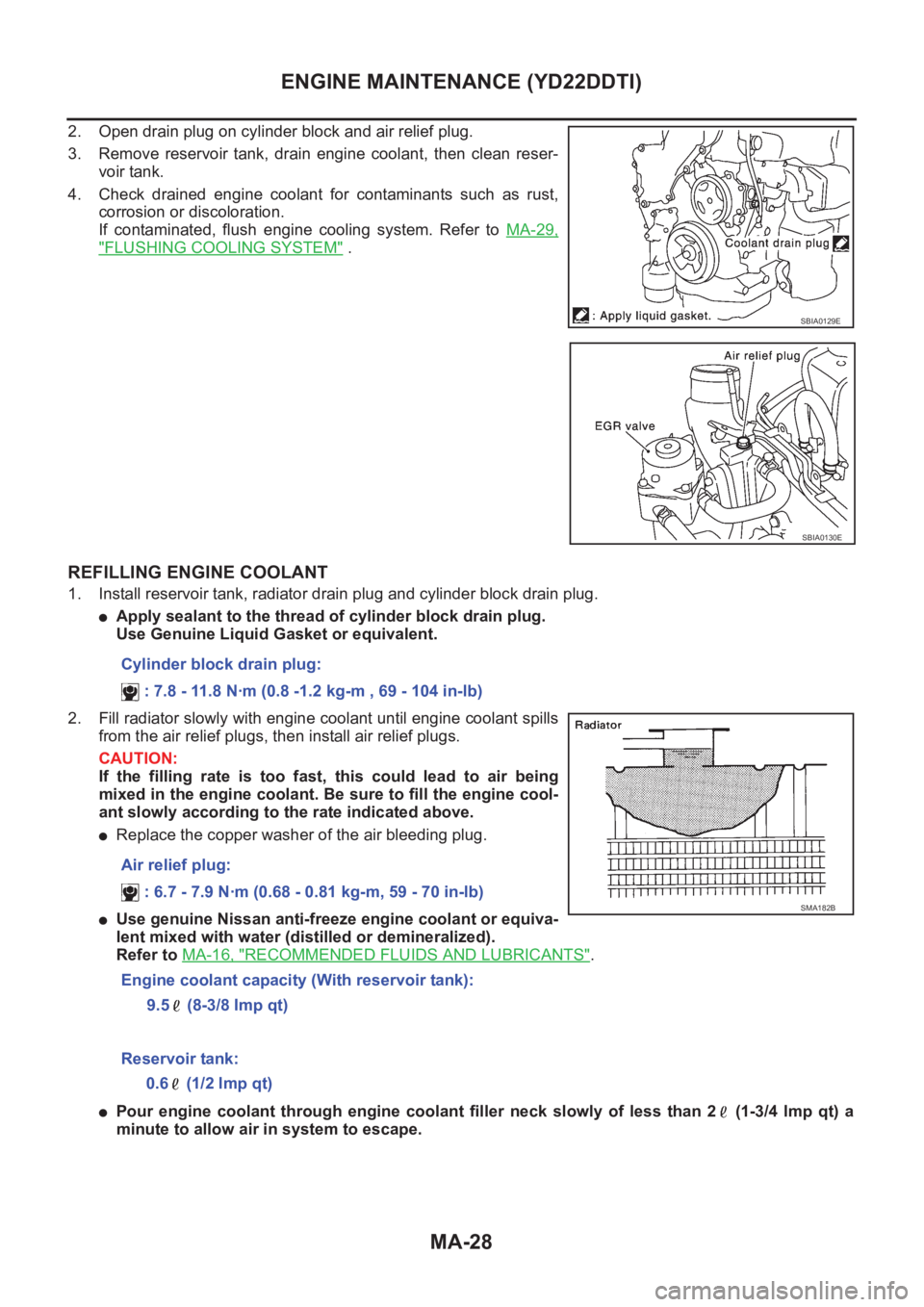

ENGINE MAINTENANCE (YD22DDTI)

2. Open drain plug on cylinder block and air relief plug.

3. Remove reservoir tank, drain engine coolant, then clean reser-

voir tank.

4. Check drained engine coolant for contaminants such as rust,

corrosion or discoloration.

If contaminated, flush engine cooling system. Refer to MA-29,

"FLUSHING COOLING SYSTEM" .

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genuine Liquid Gasket or equivalent.

2. Fill radiator slowly with engine coolant until engine coolant spills

from the air relief plugs, then install air relief plugs.

CAUTION:

If the filling rate is too fast, this could lead to air being

mixed in the engine coolant. Be sure to fill the engine cool-

ant slowly according to the rate indicated above.

●Replace the copper washer of the air bleeding plug.

●Use genuine Nissan anti-freeze engine coolant or equiva-

lent mixed with water (distilled or demineralized).

Refer to MA-16, "

RECOMMENDED FLUIDS AND LUBRICANTS".

●Pour engine coolant through engine coolant filler neck slowly of less than 2 (1-3/4 lmp qt) a

minute to allow air in system to escape.

SBIA0129E

SBIA0130E

Cylinder block drain plug:

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Air relief plug:

: 6.7 - 7.9 N·m (0.68 - 0.81 kg-m, 59 - 70 in-lb)

Engine coolant capacity (With reservoir tank):

9.5 (8-3/8 Imp qt)

SMA182B

Reservoir tank:

0.6 (1/2 lmp qt)

Page 3823 of 3833

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-43

C

D

E

F

G

H

I

J

K

MA

B

MA

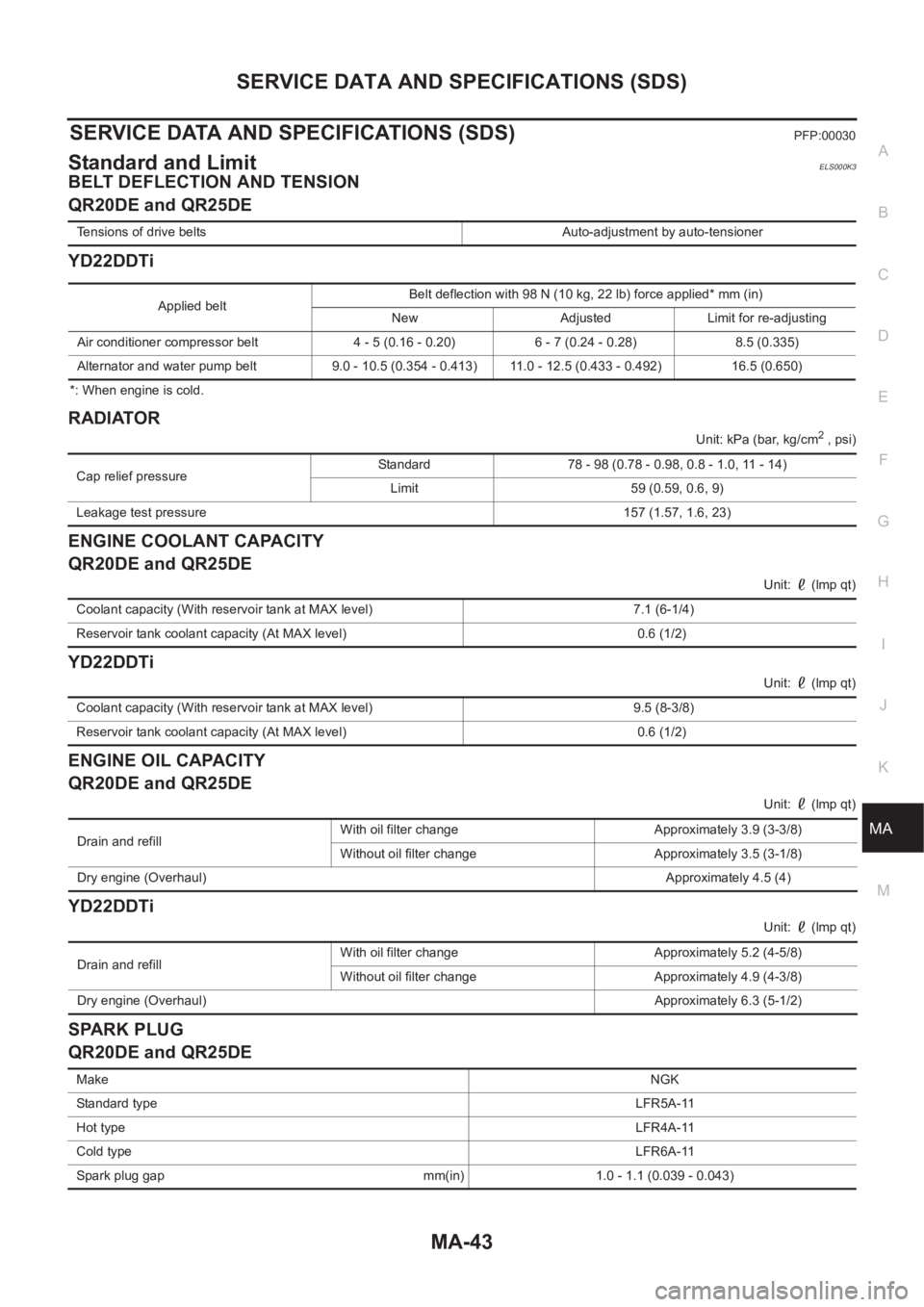

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitELS000K3

BELT DEFLECTION AND TENSION

QR20DE and QR25DE

YD22DDTi

*: When engine is cold.

RADIATOR

Unit: kPa (bar, kg/cm2 , psi)

ENGINE COOLANT CAPACITY

QR20DE and QR25DE

Unit: (lmp qt)

YD22DDTi

Unit: (lmp qt)

ENGINE OIL CAPACITY

QR20DE and QR25DE

Unit: (lmp qt)

YD22DDTi

Unit: (lmp qt)

SPARK PLUG

QR20DE and QR25DE

Tensions of drive belts Auto-adjustment by auto-tensioner

Applied beltBelt deflection with 98 N (10 kg, 22 lb) force applied* mm (in)

New Adjusted Limit for re-adjusting

Air conditioner compressor belt 4 - 5 (0.16 - 0.20) 6 - 7 (0.24 - 0.28) 8.5 (0.335)

Alternator and water pump belt 9.0 - 10.5 (0.354 - 0.413) 11.0 - 12.5 (0.433 - 0.492) 16.5 (0.650)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Coolant capacity (With reservoir tank at MAX level) 7.1 (6-1/4)

Reservoir tank coolant capacity (At MAX level) 0.6 (1/2)

Coolant capacity (With reservoir tank at MAX level) 9.5 (8-3/8)

Reservoir tank coolant capacity (At MAX level) 0.6 (1/2)

Drain and refill With oil filter change Approximately 3.9 (3-3/8)

Without oil filter change Approximately 3.5 (3-1/8)

Dry engine (Overhaul)Approximately 4.5 (4)

Drain and refill With oil filter change Approximately 5.2 (4-5/8)

Without oil filter change Approximately 4.9 (4-3/8)

Dry engine (Overhaul)Approximately 6.3 (5-1/2)

MakeNGK

Standard typeLFR5A-11

Hot typeLFR4A-11

Cold typeLFR6A-11

Spark plug gap mm(in) 1.0 - 1.1 (0.039 - 0.043)