air conditioning NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 582 of 3066

ATC-4

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EJS000T0

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WAR NIN G:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connectors.

Precautions for Working with HFC-134a (R-134a)EJS000T1

WAR NIN G:

lUse only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor failure is likely to occur.

lThe specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

–When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

–When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possi-

bletominimizetheentryofmoistureintosystem.

–Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

–Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Remove R-134a from the A/C system, using certified service equipment meeting require-

ments of SAE J2210 (R-134a recycling equipment), or J2209 (R-134a recovery equipment). If acci-

dental system discharge occurs, ventilate work area before resuming service. Additional health

and safety information may be obtained from refrigerant and lubricant manufacturers.

–Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

General Refrigerant PrecautionsEJS000T2

WAR NIN G:

lDo not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

lAlways wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

lDo not store or heat refrigerant containers above 52°C(125°F).

lDo not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

lDo not intentionally drop, puncture, or incinerate refrigerant containers.

lKeep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

lRefrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent

suffocation.

lDo not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and R-134a have been

shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

Page 595 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual REFRIGERATION SYSTEM

ATC-17

C

D

E

F

G

H

I

K

L

MA

B

AT C

cm2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

V-6 Variable Dis NISSAN X-TRAIL 2003 Electronic Repair Manual REFRIGERATION SYSTEM

ATC-17

C

D

E

F

G

H

I

K

L

MA

B

AT C

cm2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

V-6 Variable Dis](/img/5/57402/w960_57402-594.png)

REFRIGERATION SYSTEM

ATC-17

C

D

E

F

G

H

I

K

L

MA

B

AT C

cm2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

V-6 Variable Displacement Compressor (With Gasoline Engine: CWV-165M

Compressor)

EJS000TF

GENERAL INFORMATION

1. The V-6 variable compressor differs from previous units. The vent temperatures of the V-6 variable com-

pressor do not drop too far below 5°C(41°F) when:

Evaporator intake air temperature is less than 20°C(68°F).

Engine is running at speeds less than 1,500 rpm.

This is because the V-6 compressor provides a means of "capacity" control.

2. The V-6 variable compressor provides refrigerant control under varying conditions. During cold winters, it

may not produce high refrigerant pressure discharge (compared to previous units) when used with air

conditioning systems.

3. A "clanking" sound may occasionally be heard during refrigerant charge. The sound indicates that the tilt

angle of the swash plate has changed and is not a problem.

4. For air conditioning systems with the V-6 compressor, the clutch remains engaged unless: the system

main switch, fan switch or ignition switch is turned OFF. When ambient (outside) temperatures are low or

when the amount of refrigerant is insufficient, the clutch is disengaged to protect the compressor.

5. A constant range of suction pressure is maintained when engine speed is greater than a certain value. It

normally ranges from 147 to 177 kPa (1.5 to 1.8 kg/cm

2, 21 to 26 psi) under varying conditions.

In previous compressors, however, suction pressure was reduced with increases in engine speed.

DESCRIPTION

General

The variable compressor is basically a swash plate type that changes piston stroke in response to the required

cooling capacity.

RJIA0198E

Page 663 of 3066

TROUBLE DIAGNOSIS

ATC-85

C

D

E

F

G

H

I

K

L

MA

B

AT C

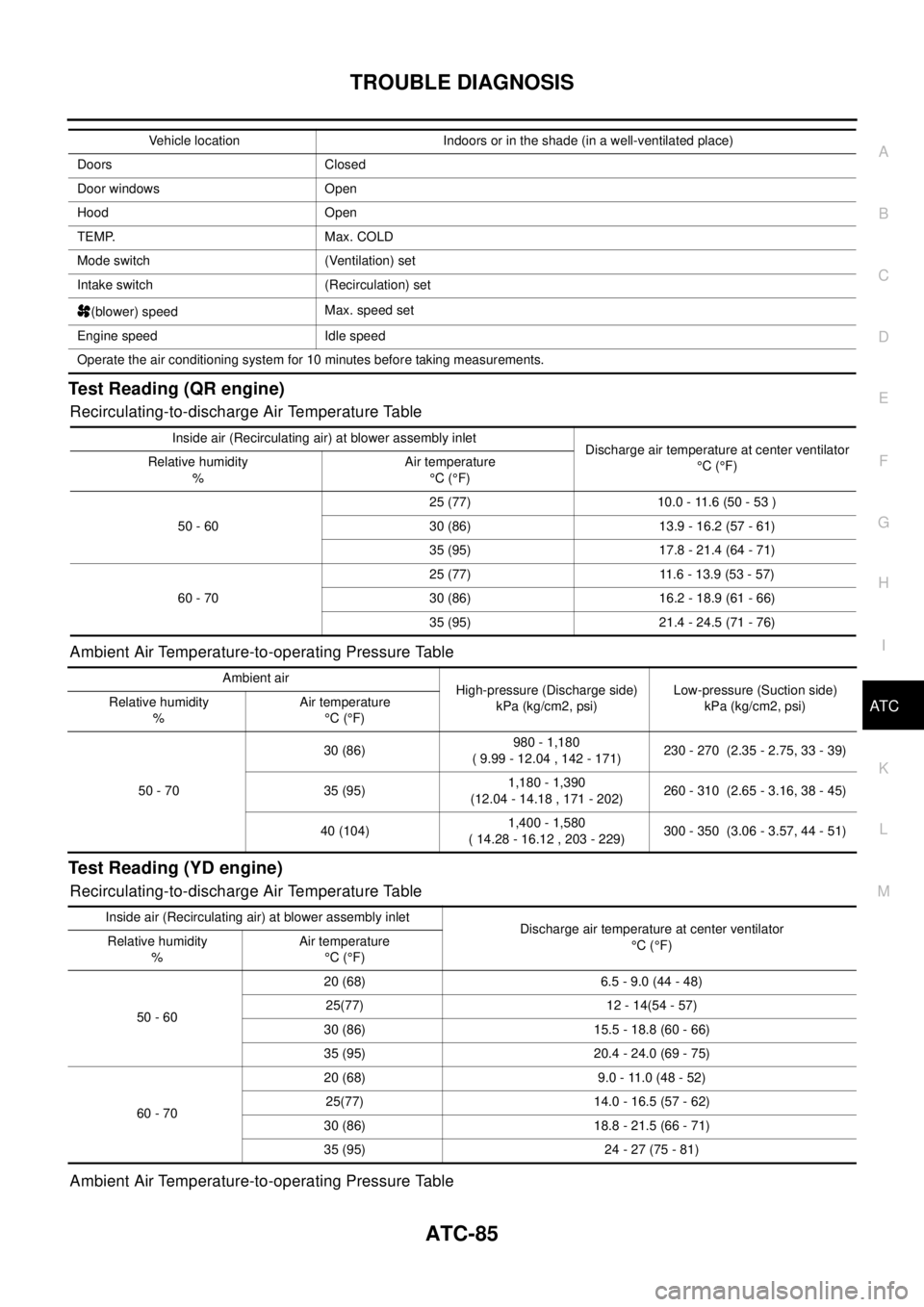

Test Reading (QR engine)

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Test Reading (YD engine)

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Vehicle location Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door windows Open

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Intake switch (Recirculation) set

(blower) speedMax. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C(°F) Relative humidity

%Air temperature

°C(°F)

50 - 6025 (77) 10.0 - 11.6 (50 - 53 )

30 (86) 13.9 - 16.2 (57 - 61)

35 (95) 17.8 - 21.4 (64 - 71)

60 - 7025 (77) 11.6 - 13.9 (53 - 57)

30 (86) 16.2 - 18.9 (61 - 66)

35 (95) 21.4 - 24.5 (71 - 76)

Ambient air

High-pressure (Discharge side)

kPa (kg/cm2, psi)Low-pressure (Suction side)

kPa (kg/cm2, psi) Relative humidity

%Air temperature

°C(°F)

50 - 7030 (86)980 - 1,180

( 9.99 - 12.04 , 142 - 171)230 - 270 (2.35 - 2.75, 33 - 39)

35 (95)1,180 - 1,390

(12.04 - 14.18 , 171 - 202)260 - 310 (2.65 - 3.16, 38 - 45)

40 (104)1,400 - 1,580

( 14.28 - 16.12 , 203 - 229)300 - 350 (3.06 - 3.57, 44 - 51)

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C(°F) Relative humidity

%Air temperature

°C(°F)

50 - 6020 (68) 6.5 - 9.0 (44 - 48)

25(77) 12 - 14(54 - 57)

30 (86) 15.5 - 18.8 (60 - 66)

35 (95) 20.4 - 24.0 (69 - 75)

60 - 7020 (68) 9.0 - 11.0 (48 - 52)

25(77) 14.0 - 16.5 (57 - 62)

30 (86) 18.8 - 21.5 (66 - 71)

35 (95) 24 - 27 (75 - 81)

Page 666 of 3066

ATC-88

TROUBLE DIAGNOSIS

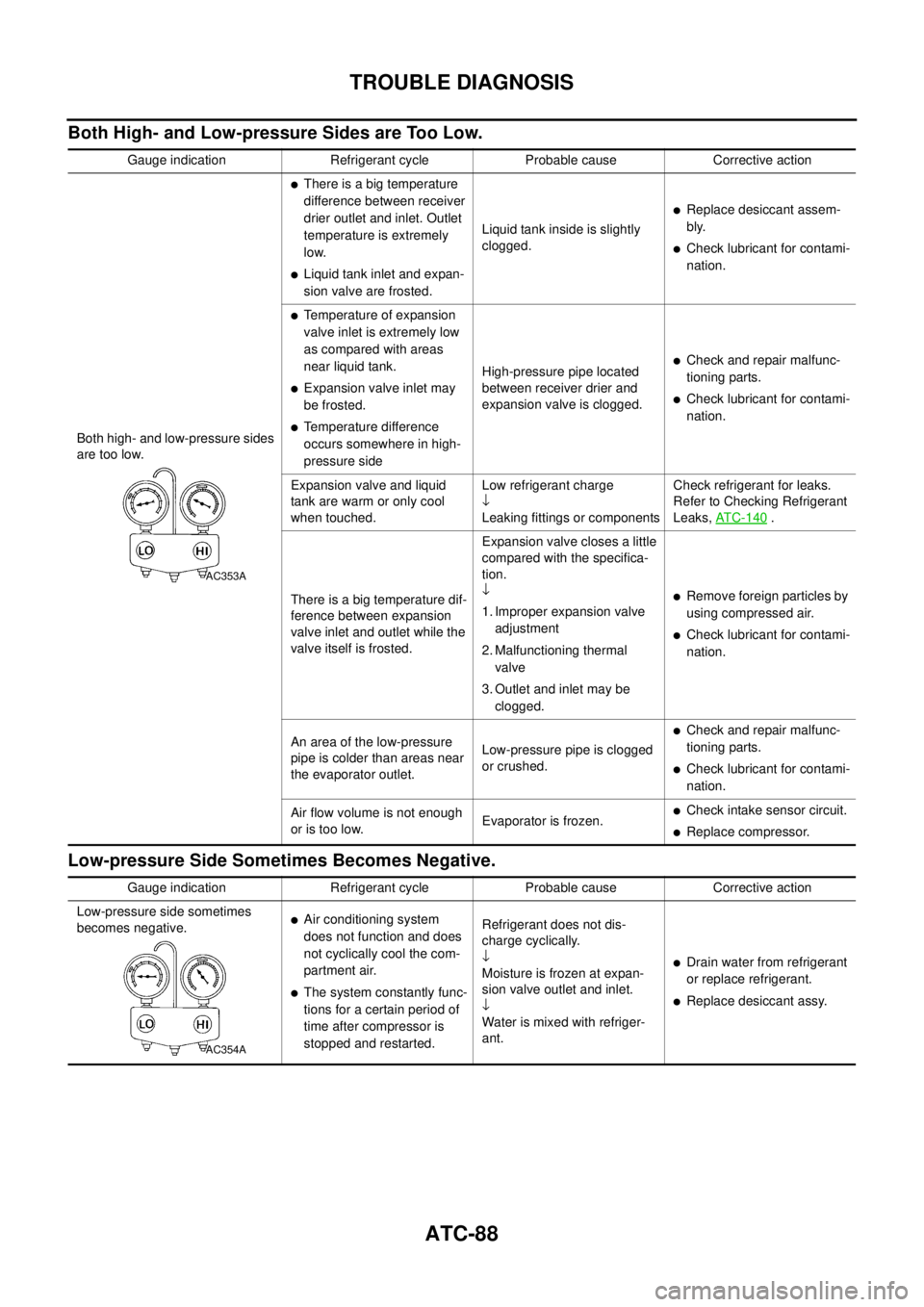

Both High- and Low-pressure Sides are Too Low.

Low-pressure Side Sometimes Becomes Negative.

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too low.

lThere is a big temperature

difference between receiver

drier outlet and inlet. Outlet

temperature is extremely

low.

lLiquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged.

lReplace desiccant assem-

bly.

lCheck lubricant for contami-

nation.

lTemperature of expansion

valve inlet is extremely low

as compared with areas

near liquid tank.

lExpansion valve inlet may

be frosted.

lTemperature difference

occurs somewhere in high-

pressure sideHigh-pressure pipe located

between receiver drier and

expansion valve is clogged.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Expansion valve and liquid

tank are warm or only cool

when touched.Low refrigerant charge

¯

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to Checking Refrigerant

Leaks,AT C - 1 4 0

.

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specifica-

tion.

¯

1. Improper expansion valve

adjustment

2. Malfunctioning thermal

valve

3. Outlet and inlet may be

clogged.

lRemove foreign particles by

using compressed air.

lCheck lubricant for contami-

nation.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet.Low-pressure pipe is clogged

or crushed.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Air flow volume is not enough

or is too low.Evaporator is frozen.

lCheck intake sensor circuit.

lReplace compressor.

AC353A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes

becomes negative.

lAir conditioning system

does not function and does

not cyclically cool the com-

partment air.

lThe system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not dis-

charge cyclically.

¯

Moisture is frozen at expan-

sion valve outlet and inlet.

¯

Water is mixed with refriger-

ant.

lDrain water from refrigerant

or replace refrigerant.

lReplace desiccant assy.

AC354A

Page 1115 of 3066

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EC

ENGINE CONTROL SYSTEM

QR (WITH EURO-OBD)

INDEX FOR DTC ...................................................... 12

Alphabetical Index .................................................. 12

DTC No. Index ....................................................... 14

PRECAUTIONS ........................................................ 16

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 16

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 16

Precaution .............................................................. 16

Wiring Diagrams and Trouble Diagnosis ................ 19

PREPARATION ......................................................... 20

Special Service Tools ............................................. 20

Commercial Service Tools ...................................... 20

ENGINE CONTROL SYSTEM .................................. 22

System Diagram ..................................................... 22

Vacuum Hose Drawing ........................................... 23

System Chart ......................................................... 24

Multiport Fuel Injection (MFI) System .................... 24

Electronic Ignition (EI) System ............................... 27

Air Conditioning Cut Control ................................... 27

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 28

CAN communication .............................................. 28

BASIC SERVICE PROCEDURE .............................. 30

Idle Speed and Ignition Timing Check .................... 30

Throttle Valve Closed Position Learning ................ 31

Accelerator Pedal Released Position Learning ...... 31

Idle Air Volume Learning ........................................ 31

Fuel Pressure Check .............................................. 34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 36

Introduction ............................................................ 36

Two Trip Detection Logic ........................................ 36

Emission-related Diagnostic Information ................ 37

NATS (Nissan Anti-theft System) ........................... 48

Malfunction Indicator (MI) ....................................... 48

OBD System Operation Chart ................................ 51

TROUBLE DIAGNOSIS ............................................ 57

Trouble Diagnosis Introduction ............................... 57DTC Inspection Priority Chart ................................. 61

Fail-safe Chart ........................................................ 62

Basic Inspection ..................................................... 64

Symptom Matrix Chart ............................................ 69

Engine Control Component Parts Location ............ 73

Circuit Diagram ....................................................... 77

ECM Harness Connector Terminal Layout ............. 79

ECM Terminals and Reference Value ..................... 79

CONSULT-II Function ............................................. 86

Generic Scan Tool (GST) Function ......................... 96

CONSULT-II Reference Value in Data Monitor ....... 97

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................100

TROUBLE DIAGNOSIS - SPECIFICATION VALUE. 103

Description ............................................................103

Testing Condition ..................................................103

Inspection Procedure ............................................103

Diagnostic Procedure ...........................................104

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................107

Description ............................................................107

Diagnostic Procedure ...........................................107

POWER SUPPLY CIRCUIT FOR ECM ...................108

Wiring Diagram .....................................................108

ECM Terminals and Reference Value ...................109

Diagnostic Procedure ...........................................109

Component Inspection ..........................................113

DTC U1000 CAN COMMUNICATION LINE ............114

Description ............................................................114

On Board Diagnosis Logic ....................................114

DTC Confirmation Procedure ...............................114

Wiring Diagram .....................................................115

Diagnostic Procedure ...........................................116

DTC P0011 IVT CONTROL .....................................117

Description ............................................................117

CONSULT-II Reference Value in Data Monitor Mode

.117

ECM Terminals and Reference Value ...................117

On Board Diagnosis Logic ....................................118

Page 1119 of 3066

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA DTC P1805 BRAKE SWITCH ................................ 329

Description ........................................................... 329

CONSULT-II Reference Value in Data Monitor Mode

. 329

ECM Terminals and Reference Value .................. 329

On Board Diagnosis Logic ................................... 329

DTC Confirmation Procedure ............................... 329

Wiring Diagram .................................................... 330

Diagnostic Procedure ........................................... 331

Component Inspection ......................................... 332

IGNITION SIGNAL .................................................. 334

Component Description ........................................ 334

ECM Terminals and Reference Value .................. 334

Wiring Diagram .................................................... 335

Diagnostic Procedure ........................................... 337

Component Inspection ......................................... 341

Removal and Installation ...................................... 342

INJECTOR CIRCUIT ............................................... 343

Component Description ........................................ 343

CONSULT-II Reference Value in Data Monitor Mode

. 343

ECM Terminals and Reference Value .................. 343

Wiring Diagram .................................................... 344

Diagnostic Procedure ........................................... 345

Component Inspection ......................................... 347

Removal and Installation ...................................... 347

START SIGNAL ...................................................... 348

CONSULT-II Reference Value in Data Monitor Mode

. 348

ECM Terminals and Reference Value .................. 348

Wiring Diagram .................................................... 349

Diagnostic Procedure ........................................... 350

FUEL PUMP CIRCUIT ............................................ 352

Description ........................................................... 352

CONSULT-II Reference Value in Data Monitor Mode

. 352

ECM Terminals and Reference Value .................. 352

Wiring Diagram .................................................... 354

Diagnostic Procedure ........................................... 355

Component Inspection ......................................... 357

Removal and Installation ...................................... 358

REFRIGERANT PRESSURE SENSOR ................. 359

Component Description ........................................ 359

ECM Terminals and Reference Value .................. 359

Wiring Diagram .................................................... 360

Diagnostic Procedure ........................................... 361

Removal and Installation ...................................... 362

ELECTRICAL LOAD SIGNAL ................................ 363

CONSULT-II Reference Value in Data Monitor Mode

. 363

ECM Terminals and Reference Value .................. 363

Wiring Diagram .................................................... 364

Diagnostic Procedure ........................................... 366

DATA LINK CONNECTOR ..................................... 371

Wiring Diagram .................................................... 371

EVAPORATIVE EMISSION SYSTEM ..................... 372

Description ........................................................... 372

Component Inspection ......................................... 374POSITIVE CRANKCASE VENTILATION ...............375

Description ............................................................375

Component Inspection ..........................................375

SERVICE DATA AND SPECIFICATIONS (SDS) ....377

Fuel Pressure .......................................................377

Idle Speed and Ignition Timing .............................377

Calculated Load Value ..........................................377

Mass Air Flow Sensor ...........................................377

Intake Air Temperature Sensor .............................377

Engine Coolant Temperature Sensor ...................377

Heated Oxygen Sensor 1 Heater .........................377

Heated Oxygen sensor 2 Heater ..........................377

Crankshaft Position Sensor (POS) .......................377

Camshaft Position Sensor (PHASE) ....................377

Throttle Control Motor ...........................................378

Injector ..................................................................378

Fuel Pump ............................................................378

QR (WITHOUT EURO-OBD)

INDEX FOR DTC .....................................................379

Alphabetical Index ................................................379

DTC No. Index ......................................................380

PRECAUTIONS ......................................................381

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................381

On Board Diagnostic (OBD) System of Engine and

A/T ........................................................................381

Precaution ............................................................381

Wiring Diagrams and Trouble Diagnosis ..............384

PREPARATION .......................................................385

Special Service Tools ...........................................385

Commercial Service Tools ....................................385

ENGINE CONTROL SYSTEM ................................387

System Diagram ...................................................387

Vacuum Hose Drawing .........................................388

System Chart ........................................................389

Multiport Fuel Injection (MFI) System ...................389

Electronic Ignition (EI) System .............................392

Air Conditioning Cut Control .................................392

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................393

CAN communication .............................................393

BASIC SERVICE PROCEDURE .............................395

Idle Speed and Ignition Timing Check ..................395

Throttle Valve Closed Position Learning ...............396

Accelerator Pedal Released Position Learning ....396

Idle Air Volume Learning ......................................396

Fuel Pressure Check ............................................399

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..........401

Introduction ...........................................................401

Two Trip Detection Logic ......................................401

Emission-related Diagnostic Information ..............401

NATS (Nissan Anti-theft System) .........................403

Malfunction Indicator (MI) .....................................404

TROUBLE DIAGNOSIS ..........................................407

Trouble Diagnosis Introduction .............................407

Page 1123 of 3066

EC-9

C

D

E

F

G

H

I

J

K

L

M

ECA ENGINE CONTROL SYSTEM ................................ 659

System Diagram ................................................... 659

System Chart ....................................................... 660

Fuel Injection Control System .............................. 660

Fuel Injection Timing Control System ................... 662

Air Conditioning Cut Control ................................. 662

Fuel Cut Control (At No Load & High Engine Speed). 662

Crankcase Ventilation System ............................. 663

BASIC SERVICE PROCEDURE ............................ 664

Fuel Filter ............................................................. 664

Accelerator Pedal Released Position Learning .... 664

Fuel Pressure Relief Valve ................................... 665

ON BOARD DIAGNOSTIC (OBD) SYSTEM .......... 666

DTC and MI Detection Logic ................................ 666

Diagnostic Trouble Code (DTC) ........................... 666

NATS (Nissan Anti-theft System) ......................... 666

Malfunction Indicator (MI) ..................................... 667

TROUBLE DIAGNOSIS .......................................... 669

Trouble Diagnosis Introduction ............................. 669

Basic Inspection ................................................... 672

Symptom Matrix Chart ......................................... 676

Engine Control Component Parts Location .......... 680

Circuit Diagram .................................................... 683

ECM Harness Connector Terminal Layout ........... 685

ECM Terminals And Reference Value .................. 685

CONSULT-II Function .......................................... 691

CONSULT-II Reference Value in Data Monitor Mode

. 696

Major Sensor Reference Graph in Data Monitor

Mode .................................................................... 698

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT ...................................................................... 699

Description ........................................................... 699

Diagnostic Procedure ........................................... 699

POWER SUPPLY CIRCUIT FOR ECM .................. 700

ECM Terminals and Reference Value .................. 700

Wiring Diagram .................................................... 701

Diagnostic Procedure ........................................... 702

Component Inspection ......................................... 705

DTCP0100MASSAIRFLOWSENSOR(MAFS).. 706

Component Description ........................................ 706

CONSULT-II Reference Value in Data Monitor Mode

. 706

ECM Terminals and Reference Value .................. 706

On Board Diagnosis Logic ................................... 707

DTC Confirmation Procedure ............................... 707

Wiring Diagram .................................................... 708

Diagnostic Procedure ........................................... 709

Component Inspection ......................................... 710

Removal and Installation ...................................... 710

DTC P0115 ENGINE COOLANT TEMPERATURE

(ECT) SENSOR (CIRCUIT) ...................................... 711

Description ............................................................ 711

On Board Diagnosis Logic .................................... 711

DTC Confirmation Procedure ................................ 711

Wiring Diagram .................................................... 712

Diagnostic Procedure ........................................... 713Component Inspection ..........................................714

Removal and Installation ......................................714

DTC P0120 ACCELERATOR PEDAL POSITION

SENSOR .................................................................715

Description ............................................................715

CONSULT-II Reference Value in Data Monitor Mode

.715

ECM Terminals and Reference Value ...................715

On Board Diagnosis Logic ....................................716

DTC Confirmation Procedure ...............................716

Wiring Diagram .....................................................717

Diagnostic Procedure ...........................................718

Component Inspection ..........................................721

Removal and Installation ......................................722

DTC P0190 COMMON RAIL FUEL PRESSURE

SENSOR .................................................................723

Description ............................................................723

CONSULT-II Reference Value in Data Monitor Mode

.723

ECM Terminals and Reference Value ...................723

On Board Diagnosis Logic ....................................723

DTC Confirmation Procedure ...............................723

Wiring Diagram .....................................................724

Diagnostic Procedure ...........................................725

Component Inspection ..........................................726

Removal and Installation ......................................726

DTC P0201 - P0204 FUEL INJECTOR ...................727

Description ............................................................727

CONSULT-II Reference Value in Data Monitor Mode

.727

ECM Terminals and Reference Value ...................727

On Board Diagnosis Logic ....................................728

DTC Confirmation Procedure ...............................729

Wiring Diagram .....................................................730

Diagnostic Procedure ...........................................732

Component Inspection ..........................................733

Removal and Installation ......................................733

DTC P0335 CRANKSHAFT POSISTION SENSOR

(TDC) .......................................................................734

Description ............................................................734

CONSULT-II Reference Value in Data Monitor Mode

.734

ECM Terminals and Reference Value ...................734

On Board Diagnosis Logic ....................................735

DTC Confirmation Procedure ...............................735

Wiring Diagram .....................................................736

Diagnostic Procedure ...........................................737

Component Inspection ..........................................737

Removal and Installation ......................................738

DTC P0340 CAMSHAFT POSITION SENSOR ......739

Description ............................................................739

ECM Terminals and Reference Value ...................739

On Board Diagnosis Logic ....................................739

DTC Confirmation Procedure ...............................739

Wiring Diagram .....................................................741

Diagnostic Procedure ...........................................742

Component Inspection ..........................................742

Removal and Installation ......................................743

Page 1138 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-24

[QR (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

System Chart

EBS00B0Q

*1: This sensor is not used to control the engine system under normal conditions.

*2: These signals are sent to the ECM through C NISSAN X-TRAIL 2003 Electronic Repair Manual EC-24

[QR (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

System Chart

EBS00B0Q

*1: This sensor is not used to control the engine system under normal conditions.

*2: These signals are sent to the ECM through C](/img/5/57402/w960_57402-1137.png)

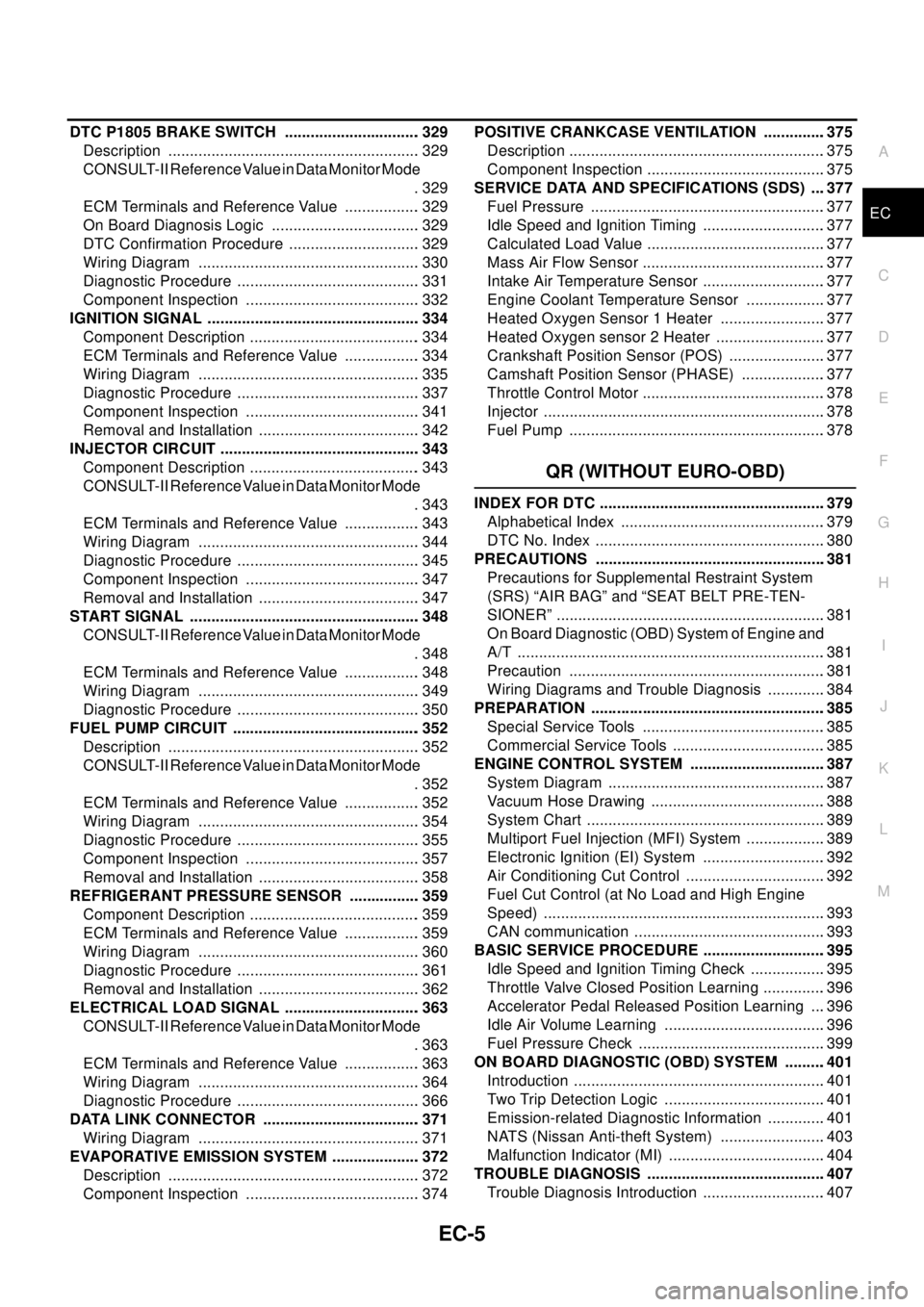

EC-24

[QR (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

System Chart

EBS00B0Q

*1: This sensor is not used to control the engine system under normal conditions.

*2: These signals are sent to the ECM through CAN communication line.

Multiport Fuel Injection (MFI) SystemEBS00B0R

INPUT/OUTPUT SIGNAL CHART

*1: Under normal conditions, this sensor is not for engine control operation.

*2: This signal is sent to the ECM through CAN communication line.Input (Sensor) ECM Function Output (Actuator)

lCamshaft position sensor (PHASE)

lCrankshaft position sensor (POS)

lMass air flow sensor

lEngine coolant temperature sensor

lHeated oxygen sensor 1

lThrottle position sensor

lAccelerator pedal position sensor

lPark/neutral position (PNP) switch

lIntake air temperature sensor

lPower steering pressure sensor

lIgnition switch

lBattery voltage

lKnock sensor

lRefrigerant pressure sensor

lHeated oxygen sensor 2 *1

lTCM (Transmission control module) *2

lESP/TCS/ABS control unit *2

lWheel sensor

lAir conditioner switch

lElectrical loadFuel injection & mixture ratio control Fuel injectors

Electronic ignition system Power transistors

Fuel pump control Fuel pump relay

On board diagnostic system MI (On the instrument panel)

Heated oxygen sensor 1 heater control Heated oxygen sensor 1 heater

Heated oxygen sensor 2 heater control Heated oxygen sensor 2 heater

EVAP canister purge flow controlEVAP canister purge volume control

solenoid valve

Air conditioning cut control Air conditioner relay

Cooling fan control Cooling fan relays

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS)

Engine speed

Piston position

Fuel injec-

tion & mix-

ture ratio

controlFuel injectors Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Ignition switch Start signal

Knock sensor Engine knocking condition

Battery Battery voltage

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2 *1 Density of oxygen in exhaust gas

ESP/TCS/ABS control unit *2 ESP/TCS operation command

Wheel sensor Vehicle speed

Air conditioner switch Air conditioner operation

Page 1141 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Electronic Ignition (EI) SystemEBS00B0S

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

The ignition timing is controlled by the NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Electronic Ignition (EI) SystemEBS00B0S

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

The ignition timing is controlled by the](/img/5/57402/w960_57402-1140.png)

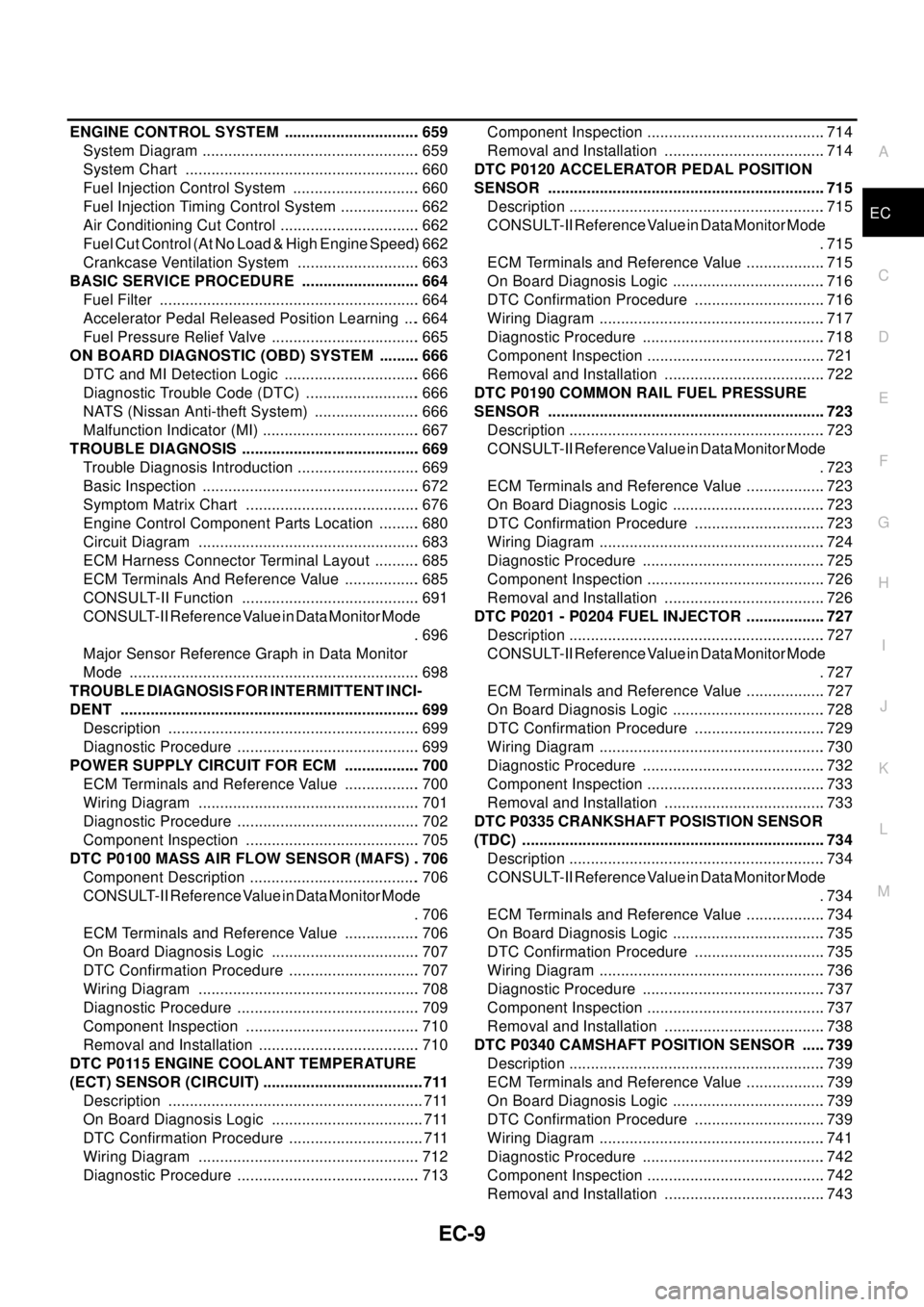

ENGINE CONTROL SYSTEM

EC-27

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Electronic Ignition (EI) SystemEBS00B0S

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

The ignition timing is controlled by the ECM to maintain the best air-

fuel ratio for every running condition of the engine. The ignition tim-

ing data is stored in the ECM. This data forms the map shown.

The ECM receives information such as the injection pulse width and

camshaft position sensor signal. Computing this information, ignition

signals are transmitted to the power transistor.

e.g.,N:1,800rpm,Tp:1.50msec

A°BTDC

During the following conditions, the ignition timing is revised by the

ECM according to the other data stored in the ECM.

lAt starting

lDuring warm-up

lAt idle

lAt low battery voltage

lDuring acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Air Conditioning Cut ControlEBS00B0T

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS)

Engine speed

Piston position

Ignition

timing con-

trolPower transistor Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Ignition switch Start signal

Knock sensor Engine knocking

Park/neutral position (PNP) switch Gear position

Battery Battery voltage

Wheel sensor Vehicle speed

SEF742M

Sensor Input Signal to ECM ECM function Actuator

Air conditioner switch Air conditioner “ON” signal

Air conditioner

cut controlAir conditioner relay Throttle position sensor Throttle valve opening angle

Crankshaft position sensor (POS) Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

Wheel sensor Vehicle speed

Page 1146 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-32

[QR (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelle NISSAN X-TRAIL 2003 Electronic Repair Manual EC-32

[QR (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelle](/img/5/57402/w960_57402-1145.png)

EC-32

[QR (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

lBattery voltage: More than 12.9V (At idle)

lEngine coolant temperature: 70 - 100°C (158 - 212°F)

lPNP switch: ON

lElectric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, set lighting switch to the 1st position to light

only small lamps.

lSteering wheel: Neutral (Straight-ahead position)

lVehicle speed: Stopped

lTransmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “A/

T” system indicates less than 0.9V.

For A/T models without CONSULT-II and M/T models, drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-II

1. PerformEC-31, "Accelerator Pedal Released Position Learning".

2. PerformEC-31, "

Throttle Valve Closed Position Learning".

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic “PRE-CONDITIONING” (previously mentioned) are in good

order.

5. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

SEF452Y

SEF454Y