code NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 910 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-42

[4WD/ABS]

TROUBLE DIAGNOSIS

2. Check using the active test function of the CONSULT-II.

Using active test mode of CONSULT-II, supply current to the 4WD solenoid valve and check that the mon-

ito NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-42

[4WD/ABS]

TROUBLE DIAGNOSIS

2. Check using the active test function of the CONSULT-II.

Using active test mode of CONSULT-II, supply current to the 4WD solenoid valve and check that the mon-

ito](/img/5/57402/w960_57402-909.png)

BRC-42

[4WD/ABS]

TROUBLE DIAGNOSIS

2. Check using the active test function of the CONSULT-II.

Using active test mode of CONSULT-II, supply current to the 4WD solenoid valve and check that the mon-

itor current becomes close to this supply current.

lThe 4WDcontrol unit is normal when the difference between 4WD solenoid valve current and the monitor

current is within±10%.

It is necessary to inspect the electronically controlled coupling assembly.

TIGHT-CONER BRAKING SYMPTOM OCCURS WHEN THE VEHICLE IS STARTED IN AUTO

WARNING LAMP REMAIN OFF).

1.THROTTLE POSITION SENSOR AND HARNESS INSPECTION

Check accelerator pedal stroke.

OK or NG

OK >> Perform self-diagnosis again.

NG >> Malfunctioning throttle position sensor harness

4WD ACTUATOR RELAY (4WD SOLENOID ACTUATOR RELAY) TURNS ON/OFF FREQUENTLY

1.SELF-DIAGNOSIS RESULT IS 4WD ACTUATOR RELAY (4WD SOLENOID ACTUATOR RELAY) ON

ERROR AND OFF ERROR.

Is self-diagnosis result [ON error and OFF error]?

OK or NG

OK >> GO TO 2.

NG >> Repair or replace as necessary.

2.4WD ACTUATOR RELAY (4WD SOLENOID ACTUATOR RELAY) AND HARNESS INSPECTION

Is self-diagnosis result [ON error and OFF error]?

OK or NG

OK >> Perform self-diagnosis again.

NG >> Malfunctioning 4WD actuator relay (4WD solenoid actuator relay) harness

ABS warning lamp does not illuminate. (ABS warning lamp does not come on

when the ignition switch is turned ON.)

EFS001BP

lReplace the combination meter control unit.

ABS warning lamp illuminates with ignition ON, but does not illuminates after a

few seconds. (ABS warning lamp has illuminated.)

EFS001BQ

1.4WD/ABS CONTROL MODULE CONNECTOR CONNECTION INSPECTION

lRemove glove box on the passenger side and check 4WD/ABS control module connector for proper con-

nection.

Is inspection result OK?

YES >> Proceed to 2. (4WD/ABS control unit connector is properly connected.)

NO >>

lConnect the 4WD/ABS control unit connector and perform inspection again.

2.USING CONSULT, PERFORM SELF-DIAGNOSIS.

lConnect the CONSULT and perform self-diagnosis.

Is inspection result OK?

YES >> GO TO 3. (No self-diagnosis malfunction indicated.)

NO >> Perform inspection according to the trouble codes displayed on the CONSULT. Refer to the “DTC

chart”. Example) Monitor value becomes Approx. 1 A for 4WD solenoid current 1 A setting.

Page 911 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-43

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.CHECK CONTINUITY BETWEEN IGNITION SWITCH AND ABS WARNING LAMP.

lDisconnect 4WD/ABS control unit connector.

lCheck continuity between ign NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-43

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.CHECK CONTINUITY BETWEEN IGNITION SWITCH AND ABS WARNING LAMP.

lDisconnect 4WD/ABS control unit connector.

lCheck continuity between ign](/img/5/57402/w960_57402-910.png)

TROUBLE DIAGNOSIS

BRC-43

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.CHECK CONTINUITY BETWEEN IGNITION SWITCH AND ABS WARNING LAMP.

lDisconnect 4WD/ABS control unit connector.

lCheck continuity between ignition switch and 4WD/ABS control module terminal No. 4. (Open circuit

check)

Is inspection result OK?

YES >> Continuity exists. Connect 4WD/ABS control module connector, check again.

NO >> Continuity does not exist. Check ABS warning lamp path.

4.CHECK FUSE.

lCheck if Fuse No.8 is working normally.

Is the check result OK?

YES >> Repair or replace the harness in between 4WD/ABS control unit and IGN.

NO >> Replace the fuse and replace again.

lIf the figure of the monitor is with in±10% of the set value of E-TS solenoid electric current, 4WD/ABS C/

U is operating normally.Check for electric control coupling ASSY is required.

4WD warning lamp does not illuminate with ignition ON.EFS001BR

1.INSPECTION OF BLOWN 4WD WARNING LAMP BULB

lRemove glove box on the passenger side and disconnect the 4WD/ABS control unit connector.

lConfirm continuity between 4WD/ABS control unit connector terminals No. 3 (IGN) and No. 4 (ABS warn-

ing lamp).

Is inspection result OK?

YES >> GO TO 3. (Continuity exists.)

NO >>

lCheck 4WD warning lamp harness.

lRemove meter control module assembly and check for blown 4WD warning lamp bulb.

2.4WD ACTUATOR RELAY HARNESS INSPECTION

lOpen the hood and check that the 4WD relay is properly installed in the relay box.

lConfirm continuity between 4WD/ABS control unit connector terminals No. 7 (4WD warning lamp) and No.

104 (ground).

lConfirm continuity between 4WD/ABS control unit connector terminals No. 3 (IGN) and No. 18 (4WD

actuator relay).

Is inspection result OK?

YES >> Continuity exists. Connect 4WD/ABS control unit connector, check again.

NO >> Check ABS warning lamp harness.

4WD warning lamp does not go out several seconds after engine is started.

(Drive mode indicator lamp goes out.)

EFS001BS

1.USING CONSULT, PERFORM SELF-DIAGNOSIS.

4WD warning lamp does not go out several seconds after the engine is started. (Drive mode indicator lamp

goes out.)

Is inspection result OK?

YES >> No malfunction detected. Perform inspection again.

NO >>

lDetermine the location of the malfunction according to the result of self-diagnosis using CON-

SULT. (Malfunction is present in the 4WD system.)

lCONSULT-II does not display ABS -related trouble codes. Proceed to 2.

Page 1123 of 3066

EC-9

C

D

E

F

G

H

I

J

K

L

M

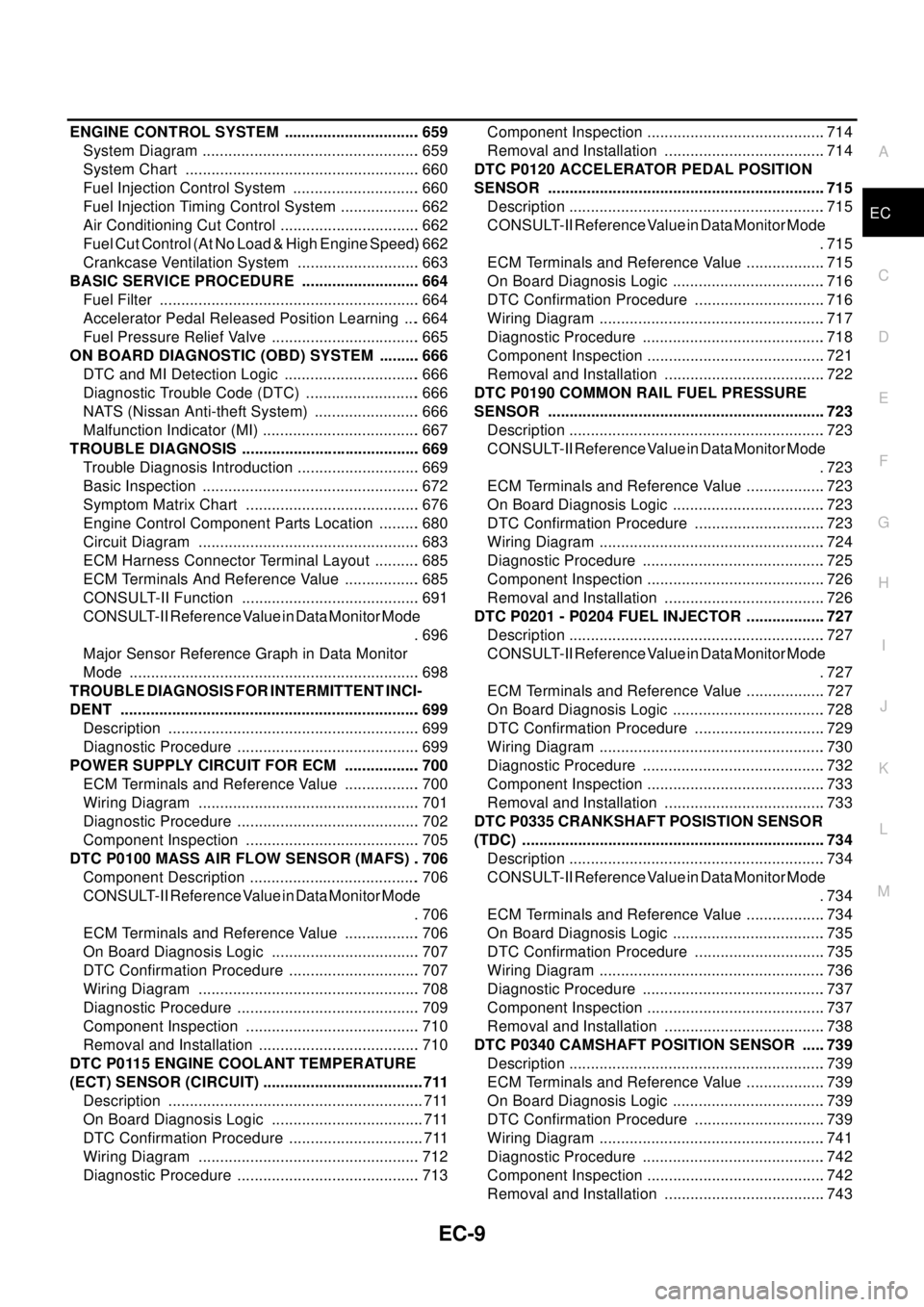

ECA ENGINE CONTROL SYSTEM ................................ 659

System Diagram ................................................... 659

System Chart ....................................................... 660

Fuel Injection Control System .............................. 660

Fuel Injection Timing Control System ................... 662

Air Conditioning Cut Control ................................. 662

Fuel Cut Control (At No Load & High Engine Speed). 662

Crankcase Ventilation System ............................. 663

BASIC SERVICE PROCEDURE ............................ 664

Fuel Filter ............................................................. 664

Accelerator Pedal Released Position Learning .... 664

Fuel Pressure Relief Valve ................................... 665

ON BOARD DIAGNOSTIC (OBD) SYSTEM .......... 666

DTC and MI Detection Logic ................................ 666

Diagnostic Trouble Code (DTC) ........................... 666

NATS (Nissan Anti-theft System) ......................... 666

Malfunction Indicator (MI) ..................................... 667

TROUBLE DIAGNOSIS .......................................... 669

Trouble Diagnosis Introduction ............................. 669

Basic Inspection ................................................... 672

Symptom Matrix Chart ......................................... 676

Engine Control Component Parts Location .......... 680

Circuit Diagram .................................................... 683

ECM Harness Connector Terminal Layout ........... 685

ECM Terminals And Reference Value .................. 685

CONSULT-II Function .......................................... 691

CONSULT-II Reference Value in Data Monitor Mode

. 696

Major Sensor Reference Graph in Data Monitor

Mode .................................................................... 698

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT ...................................................................... 699

Description ........................................................... 699

Diagnostic Procedure ........................................... 699

POWER SUPPLY CIRCUIT FOR ECM .................. 700

ECM Terminals and Reference Value .................. 700

Wiring Diagram .................................................... 701

Diagnostic Procedure ........................................... 702

Component Inspection ......................................... 705

DTCP0100MASSAIRFLOWSENSOR(MAFS).. 706

Component Description ........................................ 706

CONSULT-II Reference Value in Data Monitor Mode

. 706

ECM Terminals and Reference Value .................. 706

On Board Diagnosis Logic ................................... 707

DTC Confirmation Procedure ............................... 707

Wiring Diagram .................................................... 708

Diagnostic Procedure ........................................... 709

Component Inspection ......................................... 710

Removal and Installation ...................................... 710

DTC P0115 ENGINE COOLANT TEMPERATURE

(ECT) SENSOR (CIRCUIT) ...................................... 711

Description ............................................................ 711

On Board Diagnosis Logic .................................... 711

DTC Confirmation Procedure ................................ 711

Wiring Diagram .................................................... 712

Diagnostic Procedure ........................................... 713Component Inspection ..........................................714

Removal and Installation ......................................714

DTC P0120 ACCELERATOR PEDAL POSITION

SENSOR .................................................................715

Description ............................................................715

CONSULT-II Reference Value in Data Monitor Mode

.715

ECM Terminals and Reference Value ...................715

On Board Diagnosis Logic ....................................716

DTC Confirmation Procedure ...............................716

Wiring Diagram .....................................................717

Diagnostic Procedure ...........................................718

Component Inspection ..........................................721

Removal and Installation ......................................722

DTC P0190 COMMON RAIL FUEL PRESSURE

SENSOR .................................................................723

Description ............................................................723

CONSULT-II Reference Value in Data Monitor Mode

.723

ECM Terminals and Reference Value ...................723

On Board Diagnosis Logic ....................................723

DTC Confirmation Procedure ...............................723

Wiring Diagram .....................................................724

Diagnostic Procedure ...........................................725

Component Inspection ..........................................726

Removal and Installation ......................................726

DTC P0201 - P0204 FUEL INJECTOR ...................727

Description ............................................................727

CONSULT-II Reference Value in Data Monitor Mode

.727

ECM Terminals and Reference Value ...................727

On Board Diagnosis Logic ....................................728

DTC Confirmation Procedure ...............................729

Wiring Diagram .....................................................730

Diagnostic Procedure ...........................................732

Component Inspection ..........................................733

Removal and Installation ......................................733

DTC P0335 CRANKSHAFT POSISTION SENSOR

(TDC) .......................................................................734

Description ............................................................734

CONSULT-II Reference Value in Data Monitor Mode

.734

ECM Terminals and Reference Value ...................734

On Board Diagnosis Logic ....................................735

DTC Confirmation Procedure ...............................735

Wiring Diagram .....................................................736

Diagnostic Procedure ...........................................737

Component Inspection ..........................................737

Removal and Installation ......................................738

DTC P0340 CAMSHAFT POSITION SENSOR ......739

Description ............................................................739

ECM Terminals and Reference Value ...................739

On Board Diagnosis Logic ....................................739

DTC Confirmation Procedure ...............................739

Wiring Diagram .....................................................741

Diagnostic Procedure ...........................................742

Component Inspection ..........................................742

Removal and Installation ......................................743

Page 1150 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-36

[QR (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

PFP:00028

IntroductionEBS00BM5

The ECM has an on board diagnostic system, which detects malfunctions relate NISSAN X-TRAIL 2003 Electronic Repair Manual EC-36

[QR (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

PFP:00028

IntroductionEBS00BM5

The ECM has an on board diagnostic system, which detects malfunctions relate](/img/5/57402/w960_57402-1149.png)

EC-36

[QR (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

PFP:00028

IntroductionEBS00BM5

The ECM has an on board diagnostic system, which detects malfunctions related to engine sensors or actua-

tors. The ECM also records various emission-related diagnostic information including:

The above information can be checked using procedures listed in the table below.

´: Applicable —: Not applicable

*1: 1st trip DTCs for self-diagnoses concerning SRT items cannot be shown on the GST display.

*2: When DTC and 1st trip DTC simultaneously appear on the display, they cannot be clearly distinguished from each other.

The malfunction indicator (MI) on the instrument panel lights up when the same malfunction is detected in two

consecutive trips (Two trip detection logic), or when the ECM enters fail-safe mode. (Refer toEC-62

.)

Two Trip Detection LogicEBS00BM6

When a malfunction is detected for the first time, 1st trip DTC and 1st trip Freeze Frame data are stored in the

ECM memory. The MI will not light up at this stage. <1st trip>

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored in

the ECM memory, and the MI lights up. The MI lights up at the same time when the DTC is stored. <2nd trip>

The “trip” in the “Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed during

vehicle operation. Specific on board diagnostic items will cause the ECM to light up or blink the MI, and store

DTC and Freeze Frame data, even in the 1st trip, as shown below.

´: Applicable —: Not applicable

*1: Except “ECM”Emission-related diagnostic information ISO Standard

Diagnostic Trouble Code (DTC) Mode 3 of ISO 15031-5

Freeze Frame data Mode 2 of ISO 15031-5

System Readiness Test (SRT) code Mode 1 of ISO 15031-5

1st Trip Diagnostic Trouble Code (1st Trip DTC) Mode 7 of ISO 15031-5

1st Trip Freeze Frame data

Test values and Test limits Mode 6 of ISO 15031-5

Calibration ID Mode 9 of ISO 15031-5

DTC 1st trip DTCFreeze Frame

data1st trip Freeze

Frame dataSRT code Test value

CONSULT-II´´ ´ ´ ´—

GST´´*1´—´´

ECM´´*2 — — — —

ItemsMI DTC 1st trip DTC

1st trip 2nd trip

1st trip

displaying2nd trip

displaying1st trip

displaying2nd trip

display-

ing BlinkingLighting

upBlinkingLighting

up

Misfire (Possible three way cata-

lyst damage) — DTC: P0300 -

P0304 is being detected´———— —´—

Misfire (Possible three way cata-

lyst damage) — DTC: P0300 -

P0304 is being detected——´——´——

Fail-safe items (Refer toEC-62

.) —´——´*1 —´*1 —

Except above — — —´—´´—

Page 1151 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-37

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Emission-related Diagnostic InformationEBS00BM7

EMISSION-RELATED DIAGNOSTIC INFORMATION ITEMS

´: Applicable —: NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-37

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Emission-related Diagnostic InformationEBS00BM7

EMISSION-RELATED DIAGNOSTIC INFORMATION ITEMS

´: Applicable —:](/img/5/57402/w960_57402-1150.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-37

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Emission-related Diagnostic InformationEBS00BM7

EMISSION-RELATED DIAGNOSTIC INFORMATION ITEMS

´: Applicable —: Not applicable

DTC*1

Items

(CONSULT-II screen terms)SRT codeTest value/

Te s t l i m i t

(GST only)1st trip

DTC*1Reference page

CONSULT-II

GST*2ECM*3

U1000 1000*6 CAN COMM CIRCUIT*7 — —EC-114

P0000 0000NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.————

P0011 0011 INT/V TIM CONT-B1 — —´EC-117

P0031 0031 HO2S1 HTR (B1)´´´*4EC-120

P0032 0032 HO2S1 HTR (B1)´´´*4EC-120

P0037 0037 HO2S2 HTR (B1)´´´*4EC-125

P0038 0038 HO2S2 HTR (B1)´´´*4EC-125

P0102 0102 MAF SEN/CIRCUIT*5 — —´EC-130

P0103 0103 MAF SEN/CIRCUIT*5 — —´EC-130

P0112 0112 IAT SEN/CIRCUIT — —´EC-136

P0113 0113 IAT SEN/CIRCUIT — —´EC-136

P0117 0117 ECT SEN/CIRCUIT*5 — —´EC-141

P0118 0118 ECT SEN/CIRCUIT*5 — —´EC-141

P0120 0120 THRTL POS SEN/CIRC*5 — —´EC-146

P0121 0121 APP SEN/CIRCUIT — —´EC-154

P0132 0132 HO2S1 (B1)´´´*4EC-160

P0133 0133 HO2S1 (B1)´´´*4EC-166

P0134 0134 HO2S1 (B1)´´´*4EC-174

P0138 0138 HO2S2 (B1)´´´*4EC-181

P0139 0139 HO2S2 (B1)´´´*4EC-187

P0171 0171 FUEL SYS-LEAN-B1 — —´EC-194

P0172 0172 FUEL SYS-RICH-B1 — —´EC-200

P0300 0300 MULTI CYL MISFIRE — —´EC-206

P0301 0301 CYL 1 MISFIRE — —´EC-206

P0302 0302 CYL 2 MISFIRE — —´EC-206

P0303 0303 CYL 3 MISFIRE — —´EC-206

P0304 0304 CYL 4 MISFIRE — —´EC-206

P0327 0327 KNOCK SEN/CIRC-B1 — —´EC-212

P0328 0328 KNOCK SEN/CIRC-B1 — —´EC-212

P0335 0335 CKP SEN/CIRCUIT — —´EC-217

P0340 0340 CMP SEN/CIRCUIT — —´EC-223

P0420 0420 TW CATALYST SYS-B1´´´*4EC-229

P0444 0444 PURG VOLUME CONT/V — —´EC-233

P0445 0445 PURG VOLUME CONT/V — —´EC-233

P0500 0500 VEH SPEED SEN/CIRC*9 — —´EC-239

P0550 0550 PW ST P SEN/CIRC — —´EC-244

P0605 0605 ECM — —´EC-249

P0650 0650 MIL/CIRC — —´EC-252

Page 1152 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-38

[QR (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic NISSAN X-TRAIL 2003 Electronic Repair Manual EC-38

[QR (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic](/img/5/57402/w960_57402-1151.png)

EC-38

[QR (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these numbers are controlled by NISSAN.

*4: These are not displayed with GST.

*5: When the fail-safe operation occurs, the MI illuminates.

*6: The trouble shooting for this DTC needs CONSULT-II.

*7: Except for M/T models without ESP/TCS/ABS system.

*8: For M/T models with ESP/TCS/ABS system.

*9: When the fail-safe operations for both self-diagnoses occur at the same time, the MI illuminates.

DTC AND 1ST TRIP DTC

The 1st trip DTC (whose number is the same as the DTC number) is displayed for the latest self-diagnostic

result obtained. If the ECM memory was cleared previously, and the 1st trip DTC did not reoccur, the 1st trip

DTC will not be displayed.

If a malfunction is detected during the 1st trip, the 1st trip DTC is stored in the ECM memory. The MI will not

light up (two trip detection logic). If the same malfunction is not detected in the 2nd trip (meeting the required

driving pattern), the 1st trip DTC is cleared from the ECM memory. If the same malfunction is detected in the

2nd trip, both the 1st trip DTC and DTC are stored in the ECM memory and the MI lights up. In other words,

the DTC is stored in the ECM memory and the MI lights up when the same malfunction occurs in two consec-

P0705 0705 PNP SW/CIRC — —´AT- 1 3 0

P0710 0710 ATF TEMP SEN/CIRC — —´AT- 1 3 6

P0720 0720 VEH SPD SEN/CIR AT*9 — —´AT- 1 4 2

P0731 0731 A/T 1ST GR FNCTN — —´AT- 1 5 1

P0732 0732 A/T 2ND GR FNCTN — —´AT- 1 5 8

P0733 0733 A/T 3RD GR FNCTN — —´AT- 1 6 5

P0734 0734 A/T 4TH GR FNCTN — —´AT- 1 7 2

P0740 0740 TCC SOLENOID/CIRC — —´AT- 1 8 1

P0745 0745 L/PRESS SOL/CIRC — —´AT- 1 8 6

P0750 0750 SFT SOL A/CIRC*5 — —´AT- 1 9 3

P0755 0755 SFT SOL B/CIRC*5 — —´AT- 1 9 8

P1065 1065 ECM BACK UP/CIRC — —´EC-256

P1102 1102 MAF SENSOR — —´EC-260

P 1111 1111 I N T / V T IM V / C I R - B 1 — —´EC-266

P1121 1121 ETC ACTR — —´EC-271

P1122 1122 ETC FUNCTION/CIRC — —´EC-273

P1123 1123 ETC MOT RLY/CIRC — —´EC-279

P1143 1143 HO2S1 (B1) — —´*4EC-284

P1144 1144 HO2S1 (B1) — —´*4EC-290

P1146 1146 HO2S2 (B1) — —´*4EC-296

P1147 1147 HO2S2 (B1) — —´*4EC-303

P1212 1212 TCS/CIRC*8 — —´EC-310

P1217 1217 ENG OVER TEMP — —´EC-311

P1610 - P1615 1610 - 1615 NATS MALFUNCTION — —´EC-48

P1705 1705 TP SEN/CIRC A/T*5 — —´AT- 2 0 3

P1706 1706 P-N POS SW/CIRCUIT — —´EC-325

P1760 1760 O/R CLTCH SOL/CIRC — —´AT- 2 0 8

P1805 1805 BRAKE SW/CIRCUIT — —´EC-329

DTC*1

Items

(CONSULT-II screen terms)SRT codeTe s t v a l u e /

Test limit

(GST only)1st trip

DTC*1Reference page

CONSULT-II

GST*2ECM*3

Page 1154 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-40

[QR (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

freeze frame data (2nd trip detection/MI on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one NISSAN X-TRAIL 2003 Electronic Repair Manual EC-40

[QR (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

freeze frame data (2nd trip detection/MI on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one](/img/5/57402/w960_57402-1153.png)

EC-40

[QR (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

freeze frame data (2nd trip detection/MI on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

For example, the EGR malfunction (Priority: 2) was detected and the freeze frame data was stored in the 2nd

trip. After that when the misfire (Priority: 1) is detected in another trip, the freeze frame data will be updated

from the EGR malfunction to the misfire. The 1st trip freeze frame data is updated each time a different mal-

function is detected. There is no priority for 1st trip freeze frame data. However, once freeze frame data is

stored in the ECM memory, 1st trip freeze data is no longer stored (because only one freeze frame data or 1st

trip freeze frame data can be stored in the ECM). If freeze frame data is stored in the ECM memory and freeze

frame data with the same priority occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Both 1st trip freeze frame data and freeze frame data (along with the DTCs) are cleared when the ECM mem-

ory is erased. Procedures for clearing the ECM memory are described inEC-46, "

HOW TO ERASE EMIS-

SION-RELATED DIAGNOSTIC INFORMATION".

SYSTEM READINESS TEST (SRT) CODE

System Readiness Test (SRT) code is specified in Mode 1 of ISO 15031-5.

As part of an enhanced emissions test for Inspection & Maintenance (I/M), certain states require the status of

SRT be used to indicate whether the ECM has completed self-diagnosis of major emission systems and com-

ponents. Completion must be verified in order for the emissions inspection to proceed.

If a vehicle is rejected for a State emissions inspection due to one or more SRT items indicating “INCMP”, use

the information in this Service Manual to set the SRT to “CMPLT”.

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate “CMPLT” for each application system. Once set as “CMPLT”, the SRT status remains

“CMPLT” until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate “INCMP” for these items.

NOTE:

The SRT will also indicate “INCMP” if the self-diagnosis memory is erased for any reason or if the ECM mem-

ory power supply is interrupted for several hours.

If, during the state emissions inspection, the SRT indicates “CMPLT” for all test items, the inspector will con-

tinue with the emissions test. However, if the SRT indicates “INCMP” for one or more of the SRT items the

vehicle is returned to the customer untested.

NOTE:

If MI is “ON” during the state emissions inspection, the vehicle is also returned to the customer untested even

though the SRT indicates “CMPLT” for all test items. Therefore, it is important to check SRT (“CMPLT”) and

DTC (No DTCs) before the inspection.

SRT Item

The table below shows required self-diagnostic items to set the SRT to “CMPLT”.

Priority Items

1Freezeframedata Misfire—DTC:P0300-P0304

Fuel Injection System Function — DTC: P0171, P0172

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

SRT item

(CONSULT-II

indication)Performance

Priority*1Required self-diagnostic items to set the SRT to “CMPLT” Corresponding DTC No.

CATALYST 2 Three way catalyst function P0420

Page 1157 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-43

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

How to Display SRT Code

WITH CONSULT-II

Selecting “SRT STATUS” in “DTC CONFIRMATION” mode with

CONSULT-II. NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-43

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

How to Display SRT Code

WITH CONSULT-II

Selecting “SRT STATUS” in “DTC CONFIRMATION” mode with

CONSULT-II.](/img/5/57402/w960_57402-1156.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-43

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

How to Display SRT Code

WITH CONSULT-II

Selecting “SRT STATUS” in “DTC CONFIRMATION” mode with

CONSULT-II.

For items whose SRT codes are set, a “CMPLT” is displayed on the

CONSULT-II screen; for items whose SRT codes are not set,

“INCMP” is displayed.

A sample of CONSULT-II display for SRT code is shown at right.

“INCMP” means the self-diagnosis is incomplete and SRT is not set.

“CMPLT” means the self-diagnosis is complete and SRT is set.

WITH GST

Selecting Mode 1 with GST (Generic Scan Tool)

HowtoSetSRTCode

To set all SRT codes, self-diagnosis for the items indicated above must be performed one or more times. Each

diagnosis may require a long period of actual driving under various conditions.

WITH CONSULT-II

Perform corresponding DTC Confirmation Procedure one by one based on “Performance Priority” in the

table onEC-40

.

WITHOUT CONSULT-II

The most efficient driving pattern in which SRT codes can be properly set is explained on the next page.

The driving pattern should be performed one or more times to set all SRT codes.

*1EC-39*2EC-43*3EC-41

PBIB0666E

Page 1159 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-45

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

lThe time required for each diagnosis varies with road surface conditions, weather, altitude, individual driv-

ing NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-45

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

lThe time required for each diagnosis varies with road surface conditions, weather, altitude, individual driv-

ing](/img/5/57402/w960_57402-1158.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-45

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

lThe time required for each diagnosis varies with road surface conditions, weather, altitude, individual driv-

ing habits, etc.

Zone A refers to the range where the time, required for the diagnosis under normal conditions*, is the

shortest.

Zone B refers to the range where the diagnosis can still be performed if the diagnosis is not completed

within zone A.

*: Normal conditions refer to the following:

lSea level

lFlat road

lAmbient air temperature: 20 - 30°C(68-86°F)

lDiagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30°C(68-86°F)], diag-

nosis may also be performed.

Pattern 1:

lThe engine is started at the engine coolant temperature of-10 to 35°C (14 to 95°F)

(where the voltage between the ECM terminal 93 and ground is 3.0 - 4.3V).

lThe engine must be operated at idle speed until the engine coolant temperature is greater than

70°C(158°F) (where the voltage between the ECM terminal 93 and ground is lower than 1.4V).

Pattern 2:

lWhen steady-state driving is performed again even after it is interrupted, each diagnosis can be con-

ducted. In this case, the time required for diagnosis may be extended.

Pattern 3:

lThe driving pattern outlined in *2 must be repeated at least 3 times.

Pattern 4:

lTests are performed after the engine has been operated for at least 17 minutes.

lThe accelerator pedal must be held very steady during steady-state driving.

lIf the accelerator pedal is moved, the test must be conducted all over again.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56 MPH), then release the accelerator pedal

and keep it released for more than 10 seconds. Depress the accelerator pedal until vehicle speed is 90 km/h

(56 MPH) again.

*2: Operate the vehicle in the following driving pattern.

1. Decelerate vehicle to 0 km/h (0 MPH) and let engine idle.

2. Repeat driving pattern shown at right at least 10 times.

–During acceleration, hold the accelerator pedal as steady as

possible.

*3: Checking the vehicle speed with GST is advised.

Suggested Transmission Gear Position for A/T Models

Set the selector lever in the “D” position with the overdrive switch turned ON.

TEST VALUE AND TEST LIMIT (GST ONLY — NOT APPLICABLE TO CONSULT-II)

The following is the information specified in Mode 6 of ISO 15031-5.

The test value is a parameter used to determine whether a system/circuit diagnostic test is “OK” or “NG” while

being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored.

Items for which these data (test value and test limit) are displayed are the same as SRT code items (14 test

items).

These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be dis-

played on the GST screen.

SEF414S

Page 1161 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-47

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

How to Erase DTC ( With GST)

The emission related diagn NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-47

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

How to Erase DTC ( With GST)

The emission related diagn](/img/5/57402/w960_57402-1160.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-47

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

How to Erase DTC ( With GST)

The emission related diagnostic information in the ECM can be erased by selecting Mode 4 with GST.

NOTE:

If the DTC is not for A/T related items (seeEC-12

),skipstep2.

1. If the ignition switch stays “ON” after repair work, be sure to turn ignition switch “OFF” once. Wait at least

10 seconds and then turn it “ON” (engine stopped) again.

2. Perform “SELF-DIAGNOSTIC PROCEDURE (Without CONSULT-II)” in AT section titled “TROUBLE

DIAGNOSIS”, “Self-diagnosis”. (The engine warm-up step can be skipped when performing the diagnosis

only to erase the DTC.)

3. Select Mode 4 with GST (Generic Scan Tool).

How to Erase DTC ( No Tools)

1. If the ignition switch stays "ON" after repair work, be sure to turn ignition switch "OFF" once.

2. Wait at least 10 seconds and then turn it "ON" (engine stopped) again.

3. Change the diagnostic test mode from Mode II to Mode I by depressing the accelerator pedal. Refer to

EC-49, "

HOW TO SWITCH DIAGNOSTIC TEST MODE".

lIf the battery is disconnected, the emission-related diagnostic information will be lost after

approx. 24 hours.

lThe following data are cleared when the ECM memory is erased.

1. Diagnostic trouble codes

2. 1st trip diagnostic trouble codes

3. Freeze frame data

4. 1st trip freeze frame data

SEF966X