stop start NISSAN X-TRAIL 2003 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 454 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide AT-448

[ALL]

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00408

SYMPTOM 1:

lSelector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

lSelector lever can b NISSAN X-TRAIL 2003 Electronic User Guide AT-448

[ALL]

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00408

SYMPTOM 1:

lSelector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

lSelector lever can b](/img/5/57402/w960_57402-453.png)

AT-448

[ALL]

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

ECS00408

SYMPTOM 1:

lSelector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

lSelector lever can be moved from “P” position with key in ON position and brake pedal released.

lSelector lever can be moved from “P” position when key is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to “P” position. It can be removed when

selector lever is set to any position except “P”.

1.CHECKKEYINTERLOCKCABLE

Check key interlock cable for damage.

OK or NG

OK >> GO TO 2

NG >> Repair key interlock cable. Refer toAT - 4 5 2 , "

KEY INTERLOCK CABLE".

2.CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK >> GO TO 3

NG >> Check selector lever. Refer toAT - 4 5 6 , "

Park/Neutral Position (PNP) Switch Adjustment".

3.CHECK POWER SOURCE

1. Turn ignition switch to “ON” position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground.

OK or NG

OK >> GO TO 4

NG >> Check the following items:

1. Harness for short or open between battery and stop

lamp switch harness terminal 1

2. Fuse

3. Ignition switch (Refer toPG-2, "

POWER SUPPLY

ROUTING".) Voltage : Battery voltageSCIA0782E

Page 455 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide A/T SHIFT LOCK SYSTEM

AT-449

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to “ON” position.

(Do not start engine.)

lCheck voltage between A/T device harne NISSAN X-TRAIL 2003 Electronic User Guide A/T SHIFT LOCK SYSTEM

AT-449

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to “ON” position.

(Do not start engine.)

lCheck voltage between A/T device harne](/img/5/57402/w960_57402-454.png)

A/T SHIFT LOCK SYSTEM

AT-449

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to “ON” position.

(Do not start engine.)

lCheck voltage between A/T device harness terminal 7 and ground.

OK or NG

OK >> GO TO 5

NG >> Check the following items:

1. Harness for short and open between battery and stop

lamp switch harness connector 1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T device har-

ness connector 7.

3. Fuse

4. Stop lamp switch (Refer toAT- 4 5 0 , "

A/T DEVICE CHECK".)

5.CHECK GROUND CIRCUIT

1. Turn ignition switch to “OFF” position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 6 and ground.

If OK, check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6

NG >> Repair open circuit or short to ground or short to power

in harness or connectors. Voltage:

Brake pedal depressd:

Battery voltage

Brake pedal released:

0V

SCIA0783E

Continuity should exist.

SCIA0784E

Page 599 of 3066

LUBRICANT

ATC-21

C

D

E

F

G

H

I

K

L

MA

B

AT C

LUBRICANTPFP:KLG00

Maintenance of Lubricant Quantity in CompressorEJS000TH

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large gas leakage occurred. It is important to maintain the speci-

fied amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

LUBRICANT RETURN OPERATION

Adjust the lubricant quantity according to the test group shown below.

1.CHECK LUBRICANT RETURN OPERATION

Can lubricant return operation be performed?

lA/C system works properly.

lThere is no evidence of a large amount of lubricant leakage.

Ye s o r N o

Yes >>GOTO2.

No >> GO TO 3.

2.PERFORM LUBRICANT RETURN OPERATION, PROCEEDING AS FOLLOWS:

1. Start engine, and set the following conditions:

–Test condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to 30°C (77 to 86°F).]

Intake position: Recirculation (REC)

2. Perform lubricant return operation for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

>> GO TO 3.

3.CHECK COMPRESSOR

Should the compressor be replaced?

Ye s o r N o

Ye s > > G o t oAT C - 2 2 , "LUBRICANT ADJUSTING PROCEDURE FOR COMPRESSOR REPLACE-

MENT".

No >> GO TO 4.With gasoline engine

(CWV-615M Compressor)With diesel engine

(DKV-11G Compressor)

Name Nissan A/C System Oil Type S Nissan A/C System Oil Type R

Part number KLH00-PAGS0 KLH00-PAGR0

Page 603 of 3066

AIR CONDITIONER CONTROL

ATC-25

C

D

E

F

G

H

I

K

L

MA

B

AT C

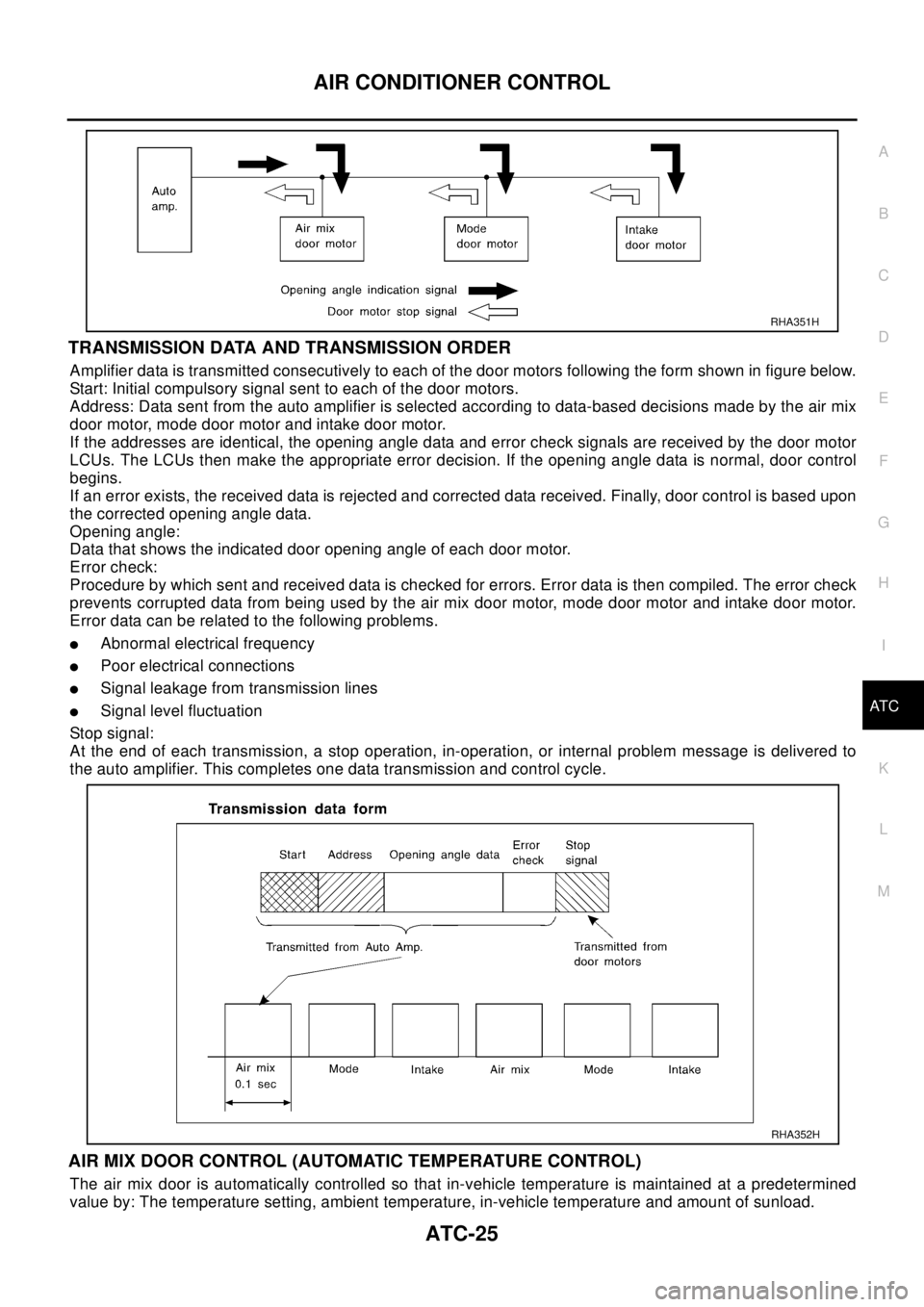

TRANSMISSION DATA AND TRANSMISSION ORDER

Amplifier data is transmitted consecutively to each of the door motors following the form shown in figure below.

Start: Initial compulsory signal sent to each of the door motors.

Address: Data sent from the auto amplifier is selected according to data-based decisions made by the air mix

door motor, mode door motor and intake door motor.

If the addresses are identical, the opening angle data and error check signals are received by the door motor

LCUs. The LCUs then make the appropriate error decision. If the opening angle data is normal, door control

begins.

If an error exists, the received data is rejected and corrected data received. Finally, door control is based upon

the corrected opening angle data.

Opening angle:

Data that shows the indicated door opening angle of each door motor.

Error check:

Procedure by which sent and received data is checked for errors. Error data is then compiled. The error check

prevents corrupted data from being used by the air mix door motor, mode door motor and intake door motor.

Error data can be related to the following problems.

lAbnormal electrical frequency

lPoor electrical connections

lSignal leakage from transmission lines

lSignal level fluctuation

Stop signal:

At the end of each transmission, a stop operation, in-operation, or internal problem message is delivered to

the auto amplifier. This completes one data transmission and control cycle.

AIR MIX DOOR CONTROL (AUTOMATIC TEMPERATURE CONTROL)

The air mix door is automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by: The temperature setting, ambient temperature, in-vehicle temperature and amount of sunload.

RHA351H

RHA352H

Page 666 of 3066

ATC-88

TROUBLE DIAGNOSIS

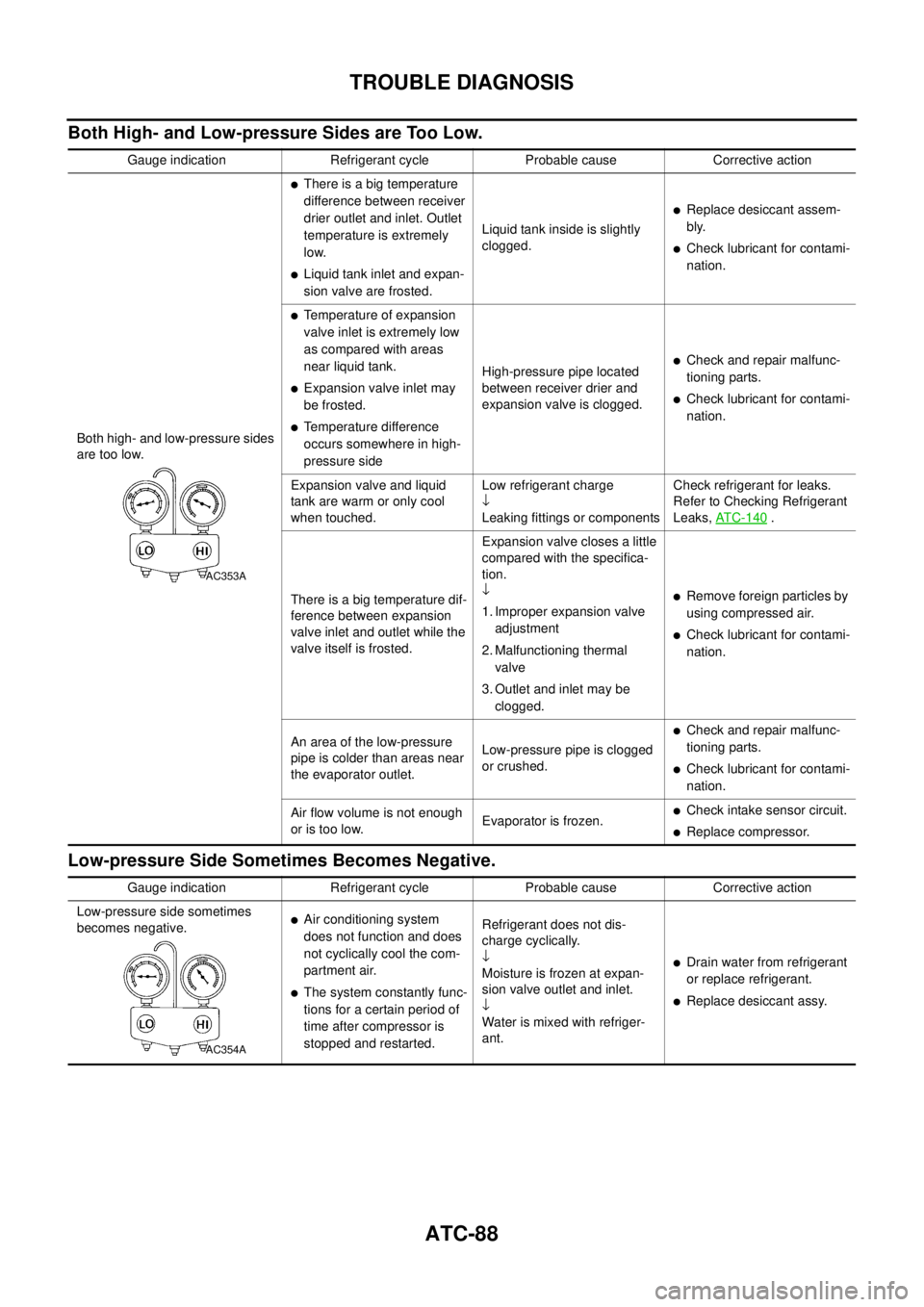

Both High- and Low-pressure Sides are Too Low.

Low-pressure Side Sometimes Becomes Negative.

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too low.

lThere is a big temperature

difference between receiver

drier outlet and inlet. Outlet

temperature is extremely

low.

lLiquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged.

lReplace desiccant assem-

bly.

lCheck lubricant for contami-

nation.

lTemperature of expansion

valve inlet is extremely low

as compared with areas

near liquid tank.

lExpansion valve inlet may

be frosted.

lTemperature difference

occurs somewhere in high-

pressure sideHigh-pressure pipe located

between receiver drier and

expansion valve is clogged.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Expansion valve and liquid

tank are warm or only cool

when touched.Low refrigerant charge

¯

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to Checking Refrigerant

Leaks,AT C - 1 4 0

.

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specifica-

tion.

¯

1. Improper expansion valve

adjustment

2. Malfunctioning thermal

valve

3. Outlet and inlet may be

clogged.

lRemove foreign particles by

using compressed air.

lCheck lubricant for contami-

nation.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet.Low-pressure pipe is clogged

or crushed.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Air flow volume is not enough

or is too low.Evaporator is frozen.

lCheck intake sensor circuit.

lReplace compressor.

AC353A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes

becomes negative.

lAir conditioning system

does not function and does

not cyclically cool the com-

partment air.

lThe system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not dis-

charge cyclically.

¯

Moisture is frozen at expan-

sion valve outlet and inlet.

¯

Water is mixed with refriger-

ant.

lDrain water from refrigerant

or replace refrigerant.

lReplace desiccant assy.

AC354A

Page 721 of 3066

REFRIGERANT LINES

ATC-143

C

D

E

F

G

H

I

K

L

MA

B

AT C

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on "High" for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer's recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. Face mode

c. Intake position: Recirculation

d. Max cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps 4 through 6 above.

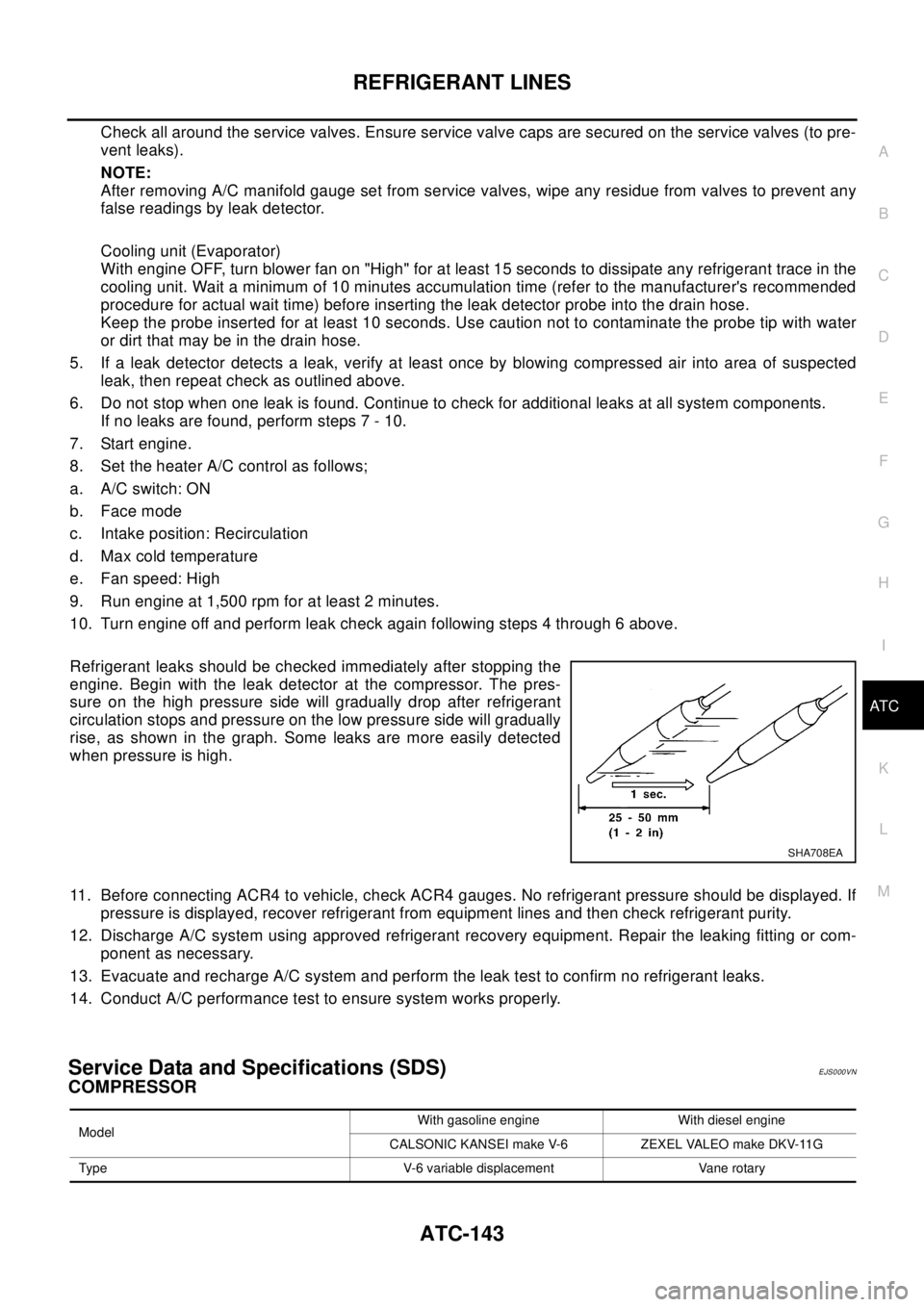

Refrigerant leaks should be checked immediately after stopping the

engine. Begin with the leak detector at the compressor. The pres-

sure on the high pressure side will gradually drop after refrigerant

circulation stops and pressure on the low pressure side will gradually

rise, as shown in the graph. Some leaks are more easily detected

when pressure is high.

11. Before connecting ACR4 to vehicle, check ACR4 gauges. No refrigerant pressure should be displayed. If

pressure is displayed, recover refrigerant from equipment lines and then check refrigerant purity.

12. Discharge A/C system using approved refrigerant recovery equipment. Repair the leaking fitting or com-

ponent as necessary.

13. Evacuate and recharge A/C system and perform the leak test to confirm no refrigerant leaks.

14. Conduct A/C performance test to ensure system works properly.

Service Data and Specifications (SDS)EJS000VN

COMPRESSOR

SHA708EA

ModelWith gasoline engine With diesel engine

CALSONIC KANSEI make V-6 ZEXEL VALEO make DKV-11G

Type V-6 variable displacement Vane rotary

Page 841 of 3066

BRAKE PEDAL

BR-7

C

D

E

G

H

I

J

K

L

MA

B

BR

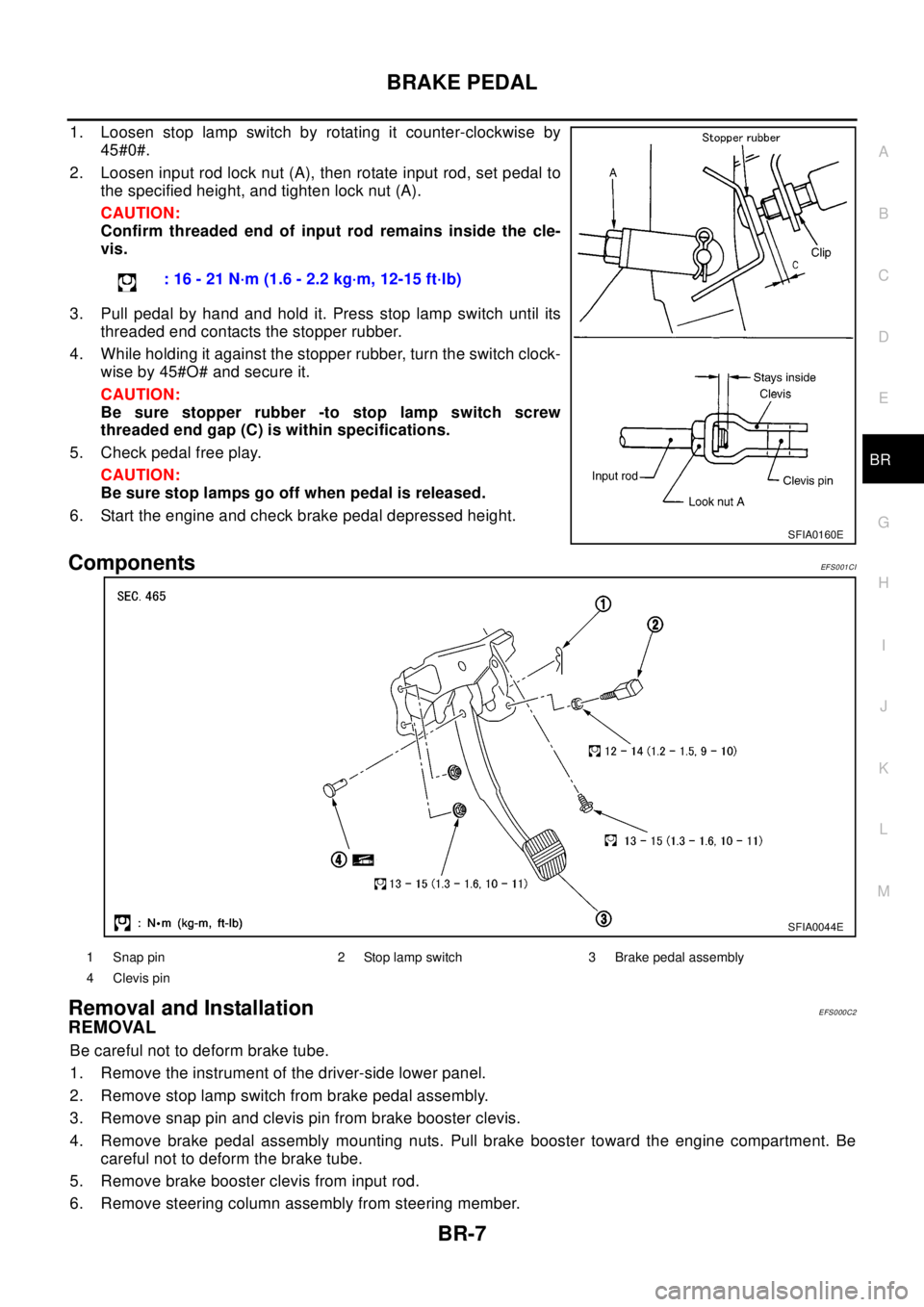

1. Loosen stop lamp switch by rotating it counter-clockwise by

45#0#.

2. Loosen input rod lock nut (A), then rotate input rod, set pedal to

the specified height, and tighten lock nut (A).

CAUTION:

Confirm threaded end of input rod remains inside the cle-

vis.

3. Pull pedal by hand and hold it. Press stop lamp switch until its

threaded end contacts the stopper rubber.

4. While holding it against the stopper rubber, turn the switch clock-

wise by 45#O# and secure it.

CAUTION:

Be sure stopper rubber -to stop lamp switch screw

threaded end gap (C) is within specifications.

5. Check pedal free play.

CAUTION:

Be sure stop lamps go off when pedal is released.

6. Start the engine and check brake pedal depressed height.

ComponentsEF S0 01 CI

Removal and InstallationEFS000C2

REMOVAL

Be careful not to deform brake tube.

1. Remove the instrument of the driver-side lower panel.

2. Remove stop lamp switch from brake pedal assembly.

3. Remove snap pin and clevis pin from brake booster clevis.

4. Remove brake pedal assembly mounting nuts. Pull brake booster toward the engine compartment. Be

careful not to deform the brake tube.

5. Remove brake booster clevis from input rod.

6. Remove steering column assembly from steering member.: 16 - 21 N·m (1.6 - 2.2 kg·m, 12-15 ft·lb)

SFIA0160E

SFIA0044E

1 Snap pin 2 Stop lamp switch 3 Brake pedal assembly

4 Clevis pin

Page 851 of 3066

BRAKE BOOSTER

BR-17

C

D

E

G

H

I

J

K

L

MA

B

BR

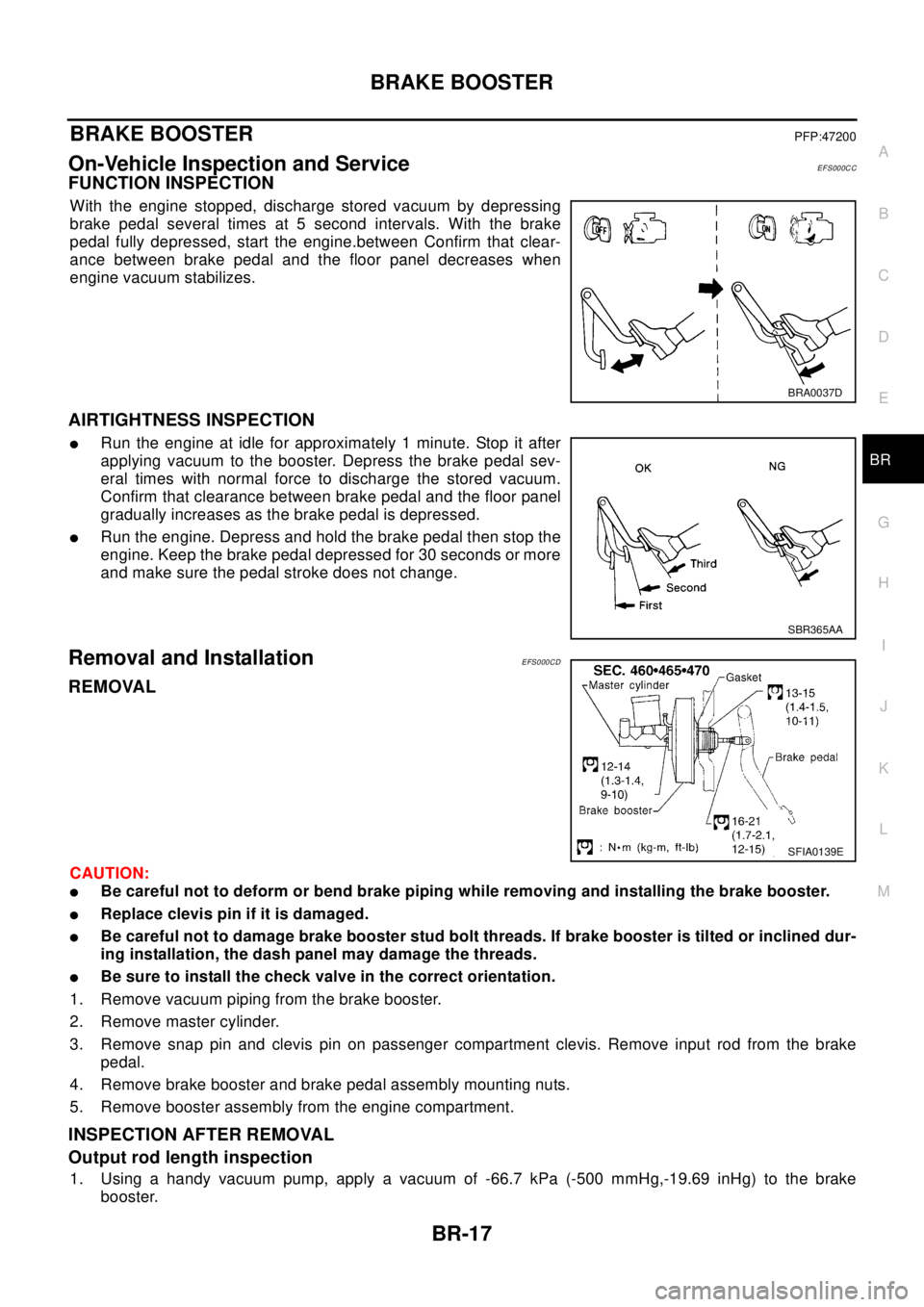

BRAKE BOOSTERPFP:47200

On-Vehicle Inspection and ServiceEFS000CC

FUNCTION INSPECTION

With the engine stopped, discharge stored vacuum by depressing

brake pedal several times at 5 second intervals. With the brake

pedal fully depressed, start the engine.between Confirm that clear-

ance between brake pedal and the floor panel decreases when

engine vacuum stabilizes.

AIRTIGHTNESS INSPECTION

lRun the engine at idle for approximately 1 minute. Stop it after

applying vacuum to the booster. Depress the brake pedal sev-

eral times with normal force to discharge the stored vacuum.

Confirm that clearance between brake pedal and the floor panel

gradually increases as the brake pedal is depressed.

lRun the engine. Depress and hold the brake pedal then stop the

engine. Keep the brake pedal depressed for 30 seconds or more

and make sure the pedal stroke does not change.

Removal and InstallationEFS000CD

REMOVAL

CAUTION:

lBe careful not to deform or bend brake piping while removing and installing the brake booster.

lReplace clevis pin if it is damaged.

lBe careful not to damage brake booster stud bolt threads. If brake booster is tilted or inclined dur-

ing installation, the dash panel may damage the threads.

lBe sure to install the check valve in the correct orientation.

1. Remove vacuum piping from the brake booster.

2. Remove master cylinder.

3. Remove snap pin and clevis pin on passenger compartment clevis. Remove input rod from the brake

pedal.

4. Remove brake booster and brake pedal assembly mounting nuts.

5. Remove booster assembly from the engine compartment.

INSPECTION AFTER REMOVAL

Output rod length inspection

1. Using a handy vacuum pump, apply a vacuum of -66.7 kPa (-500 mmHg,-19.69 inHg) to the brake

booster.

BRA0037D

SBR365AA

SFIA0139E

Page 872 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref NISSAN X-TRAIL 2003 Electronic User Guide BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref](/img/5/57402/w960_57402-871.png)

BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

lTo clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing and installing brake tube.

lAlways torque brake lines when installing.

lBurnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-10, "

Brake Burnishing

Procedure".

lBefore working, turn OFF ignition switch. Disconnect connectors

for ABS actuator and control module or battery terminals.

WAR NIN G:

lClean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

Precautions for brake controlEFS001B7

lIf malfunction is indicated by 4WD warning lamp and/or ABS warning lamp, collect necessary information

from customer (what symptoms are present under what conditions). Find out possible causes before start-

ing service. Besides electrical system inspection, check operation of ABS actuator.

lIf malfunction is detected, proceed to trouble diagnosis after checking tire pressure and tire wear.

lStopping distance or steering stability may be deteriorated by the following conditions. Tire size and type

are in improper combination. Brake pads are not Nissan genuine parts.

lFitting tires of different size on vehicle can be cause of longitudinal vibration. Always use tires of the same

size and brand. Exchange front and rear tires on the following conditions: Longitudinal vibration occurs in

vehicle with tires of the same size and brand. After replacement, perform trouble diagnosis. 1580|None

l4WD/ABS function may have a failure or error under following condition: There is radio, antenna, or

antenna lead-in wire (including wiring) near control module.

lIf aftermarket parts (e.g. Car stereo equipment, CD player) have been installed, check electrical har-

nesses for pinches, open, and improper wiring.

SBR686C

Page 874 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

lDuring ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. Thi NISSAN X-TRAIL 2003 Electronic User Guide BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

lDuring ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. Thi](/img/5/57402/w960_57402-873.png)

BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

lDuring ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. This is a nor-

mal condition.

lWhen starting engine, or just after starting vehicle, brake pedal may vibrate. Also motor operating noise

may be heard from engine compartment. This is a normal status of operation check.

lWhen vehicle drives on rough, gravel, or snowy (fresh deep snow) road, the following conditions occur.

Stopping distance may be longer than that of vehicles without ABS.

4WD FUNCTION

lElectronically controlled 4WD is controlled by the same control module as that for ABS (4WD/ABS control

unit). 4WD/ABS control unit controls both electronically-controlled 4WD and ABS, based on input signals

from several sensors.

lIf electrical system-related malfunction occurred in 4WD/ABS system, control unit illuminates the following

lamps: 4WD warning lamp and/or ABS warning lamp on meter control unit assembly. This notifies driver of

malfunction. At the same time, control unit indicates malfunctioning part detected by self-diagnosis with

flashing pattern of LED. Indication on electronic system diagnosis tester (CONSULT) corresponds to this

flashing pattern as shown below.

Control System DiagramEFS001CK

Self-diagnostic test mode Remarks

Result of self-diagnosis Conformable to 4WD/ABS

Data monitor Conformable to 4WD/ABS

Active testChecks ABS solenoid valve ON/OFF, ABS motor ON/OFF, 4WD sole-

noid

Control unit part No. 4WD/ABS control unit

SFIA0350E