heating NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 14 of 3066

AT-8

PRECAUTIONS

lVehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

lConverter is contaminated with engine coolant containing antifreeze.

lInternal failure of stator roller clutch.

lHeavy clutch debris due to overheating (blue converter).

lSteel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

lThe fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

lThe threads in one or more of the converter bolt holes are damaged.

lTransaxle failure did not display evidence of damaged or worn internal parts, steel particles or clutch plate

lining material in unit and inside the fluid filter.

lVehicle has been exposed to high mileage (only). The exception may be where the torque converter

clutch dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic,

such as taxi, delivery or police use.

EURO-OBD SELF-DIAGNOSIS — EURO-OBD —

lA/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the O/D OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the

table onAT-42, "

SELF-DIAGNOSTIC RESULT TEST MODE"for the indicator used to display each self-

diagnostic result.

lThe self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM mem-

ories.

Always perform the procedure “HOW TO ERASE DTC” onAT-39, "

HOW TO ERASE DTC"to com-

plete the repair and avoid unnecessary blinking of the MIL.

lThe following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when

the O/D OFF indicator lamp does not indicate any malfunctions.

–PNP switch

–A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of EURO-OBD, refer toAT - 3 7 , "

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION".

lCertain systems and components, especially those related to EURO-OBD, may use a new style

slide-locking type harness connector.

For description and how to disconnect, refer toPG-70, "

HARNESS CONNECTOR".

Wiring Diagrams and Trouble DiagnosisECS004Q4

When you read wiring diagrams, refer to the following:

lGI-14, "How to Read Wiring Diagrams".

lPG-2, "POWER SUPPLY ROUTING".

When you perform trouble diagnosis, refer to the following:

lGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

l"", “HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT”

Page 70 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-64

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS0 04 QQ

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for examp NISSAN X-TRAIL 2003 Electronic Repair Manual AT-64

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS0 04 QQ

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for examp](/img/5/57402/w960_57402-69.png)

AT-64

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS0 04 QQ

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for example, mating surface

of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in “D” posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

FLUID LEVEL CHECK

Refer to “Checking A/T Fluid”,AT-13, "A/T FLUID".

SAT767B

SAT288G

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination — Road water

entering through filler tube or breather

Varnished fluid, light to dark brown and

tackyOxidation — Over or under filling, —

Overheating

SAT638A

Page 292 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-286

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS004VR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for NISSAN X-TRAIL 2003 Electronic Repair Manual AT-286

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS004VR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for](/img/5/57402/w960_57402-291.png)

AT-286

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS004VR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for example, mating surface

of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in “D” posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

FLUID LEVEL CHECK

Refer to “Checking A/T Fluid”,AT-13, "A/T FLUID".

SAT767B

SAT288G

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination — Road water

entering through filler tube or breather

Varnished fluid, light to dark brown and

tackyOxidation — Over or under filling, —

Overheating

SAT638A

Page 580 of 3066

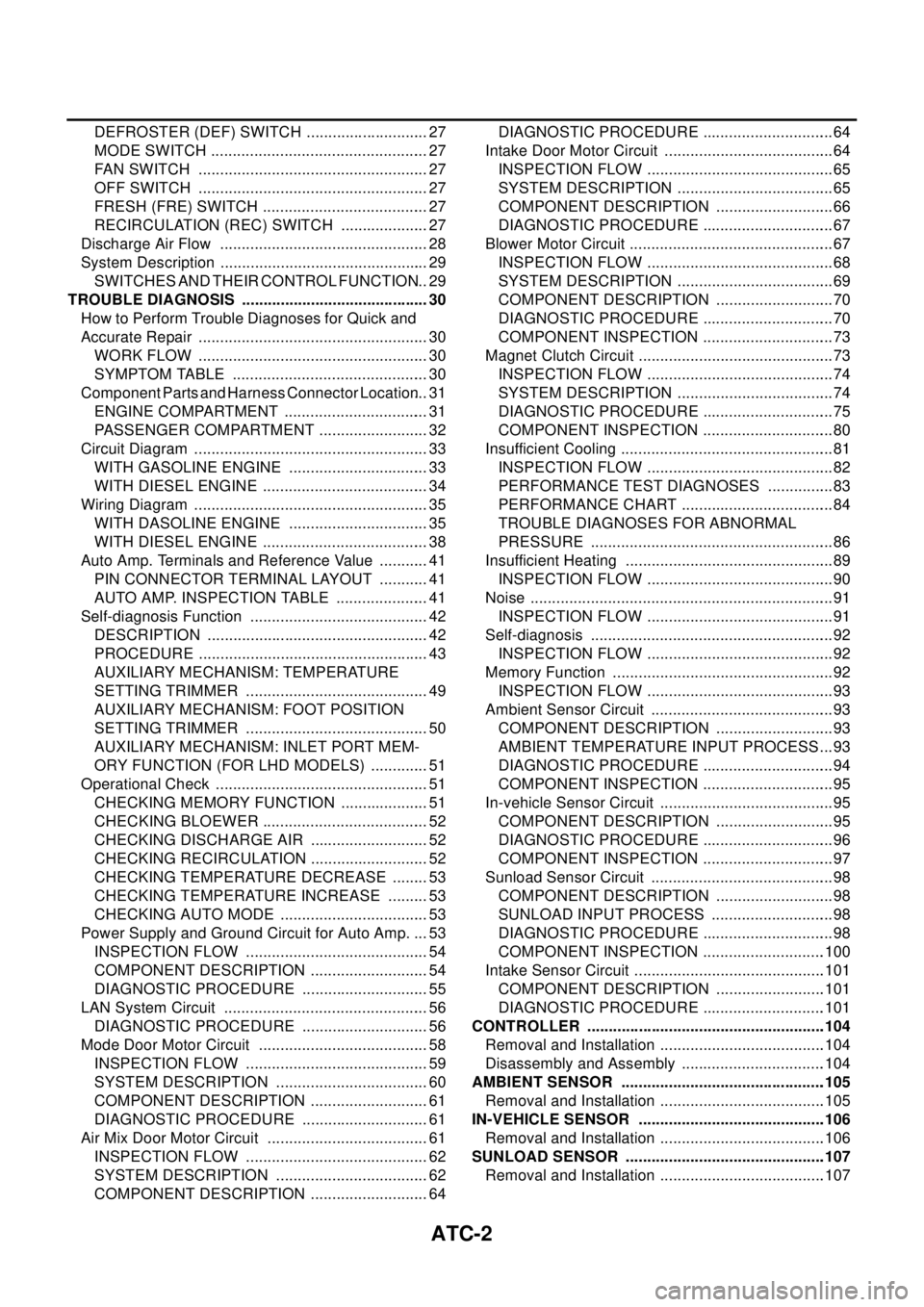

ATC-2

DEFROSTER (DEF) SWITCH ............................. 27

MODE SWITCH ................................................... 27

FAN SWITCH ...................................................... 27

OFF SWITCH ...................................................... 27

FRESH (FRE) SWITCH ....................................... 27

RECIRCULATION (REC) SWITCH ..................... 27

Discharge Air Flow ................................................. 28

System Description ................................................. 29

SWITCHES AND THEIR CONTROL FUNCTION... 29

TROUBLE DIAGNOSIS ............................................ 30

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ...................................................... 30

WORK FLOW ...................................................... 30

SYMPTOM TABLE .............................................. 30

Component Parts and Harness Connector Location... 31

ENGINE COMPARTMENT .................................. 31

PASSENGER COMPARTMENT .......................... 32

Circuit Diagram ....................................................... 33

WITH GASOLINE ENGINE ................................. 33

WITH DIESEL ENGINE ....................................... 34

Wiring Diagram ....................................................... 35

WITH DASOLINE ENGINE ................................. 35

WITH DIESEL ENGINE ....................................... 38

Auto Amp. Terminals and Reference Value ............ 41

PIN CONNECTOR TERMINAL LAYOUT ............ 41

AUTO AMP. INSPECTION TABLE ...................... 41

Self-diagnosis Function .......................................... 42

DESCRIPTION .................................................... 42

PROCEDURE ...................................................... 43

AUXILIARY MECHANISM: TEMPERATURE

SETTING TRIMMER ........................................... 49

AUXILIARY MECHANISM: FOOT POSITION

SETTING TRIMMER ........................................... 50

AUXILIARY MECHANISM: INLET PORT MEM-

ORY FUNCTION (FOR LHD MODELS) .............. 51

Operational Check .................................................. 51

CHECKING MEMORY FUNCTION ..................... 51

CHECKING BLOEWER ....................................... 52

CHECKING DISCHARGE AIR ............................ 52

CHECKING RECIRCULATION ............................ 52

CHECKING TEMPERATURE DECREASE ......... 53

CHECKING TEMPERATURE INCREASE .......... 53

CHECKING AUTO MODE ................................... 53

Power Supply and Ground Circuit for Auto Amp. ... 53

INSPECTION FLOW ........................................... 54

COMPONENT DESCRIPTION ............................ 54

DIAGNOSTIC PROCEDURE .............................. 55

LAN System Circuit ................................................ 56

DIAGNOSTIC PROCEDURE .............................. 56

Mode Door Motor Circuit ........................................ 58

INSPECTION FLOW ........................................... 59

SYSTEM DESCRIPTION .................................... 60

COMPONENT DESCRIPTION ............................ 61

DIAGNOSTIC PROCEDURE .............................. 61

Air Mix Door Motor Circuit ...................................... 61

INSPECTION FLOW ........................................... 62

SYSTEM DESCRIPTION .................................... 62

COMPONENT DESCRIPTION ............................ 64DIAGNOSTIC PROCEDURE ...............................64

Intake Door Motor Circuit ........................................64

INSPECTION FLOW ............................................65

SYSTEM DESCRIPTION .....................................65

COMPONENT DESCRIPTION ............................66

DIAGNOSTIC PROCEDURE ...............................67

Blower Motor Circuit ................................................67

INSPECTION FLOW ............................................68

SYSTEM DESCRIPTION .....................................69

COMPONENT DESCRIPTION ............................70

DIAGNOSTIC PROCEDURE ...............................70

COMPONENT INSPECTION ...............................73

Magnet Clutch Circuit ..............................................73

INSPECTION FLOW ............................................74

SYSTEM DESCRIPTION .....................................74

DIAGNOSTIC PROCEDURE ...............................75

COMPONENT INSPECTION ...............................80

Insufficient Cooling ..................................................81

INSPECTION FLOW ............................................82

PERFORMANCE TEST DIAGNOSES ................83

PERFORMANCE CHART ....................................84

TROUBLE DIAGNOSES FOR ABNORMAL

PRESSURE .........................................................86

Insufficient Heating .................................................89

INSPECTION FLOW ............................................90

Noise .......................................................................91

INSPECTION FLOW ............................................91

Self-diagnosis .........................................................92

INSPECTION FLOW ............................................92

Memory Function ....................................................92

INSPECTION FLOW ............................................93

Ambient Sensor Circuit ...........................................93

COMPONENT DESCRIPTION ............................93

AMBIENT TEMPERATURE INPUT PROCESS...93

DIAGNOSTIC PROCEDURE ...............................94

COMPONENT INSPECTION ...............................95

In-vehicle Sensor Circuit .........................................95

COMPONENT DESCRIPTION ............................95

DIAGNOSTIC PROCEDURE ...............................96

COMPONENT INSPECTION ...............................97

Sunload Sensor Circuit ...........................................98

COMPONENT DESCRIPTION ............................98

SUNLOAD INPUT PROCESS .............................98

DIAGNOSTIC PROCEDURE ...............................98

COMPONENT INSPECTION ............................. 100

Intake Sensor Circuit ............................................. 101

COMPONENT DESCRIPTION .......................... 101

DIAGNOSTIC PROCEDURE ............................. 101

CONTROLLER ........................................................ 104

Removal and Installation ....................................... 104

Disassembly and Assembly .................................. 104

AMBIENT SENSOR ................................................ 105

Removal and Installation ....................................... 105

IN-VEHICLE SENSOR ............................................ 106

Removal and Installation ....................................... 106

SUNLOAD SENSOR ............................................... 107

Removal and Installation ....................................... 107

Page 608 of 3066

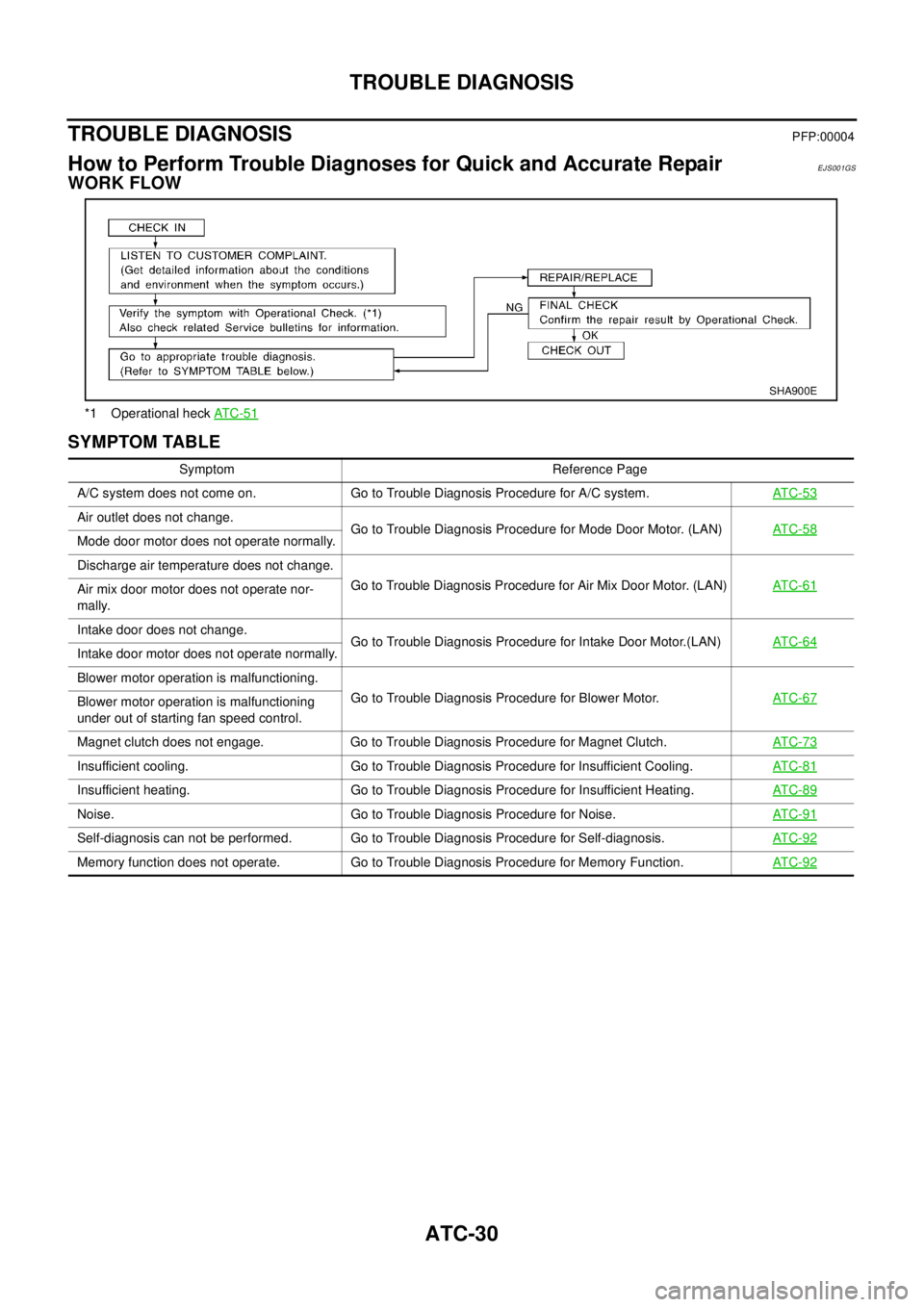

ATC-30

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

PFP:00004

How to Perform Trouble Diagnoses for Quick and Accurate RepairEJS001GS

WORK FLOW

SYMPTOM TABLE

*1 Operational heckAT C -5 1

SHA900E

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C system.AT C - 5 3

Air outlet does not change.

Go to Trouble Diagnosis Procedure for Mode Door Motor. (LAN)AT C - 5 8

Mode door motor does not operate normally.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor. (LAN)AT C - 6 1

Air mix door motor does not operate nor-

mally.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor.(LAN)AT C - 6 4

Intake door motor does not operate normally.

Blower motor operation is malfunctioning.

Go to Trouble Diagnosis Procedure for Blower Motor.AT C - 6 7

Blower motor operation is malfunctioning

under out of starting fan speed control.

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet Clutch.AT C - 7 3

Insufficient cooling. Go to Trouble Diagnosis Procedure for Insufficient Cooling.AT C - 8 1

Insufficient heating. Go to Trouble Diagnosis Procedure for Insufficient Heating.AT C - 8 9

Noise. Go to Trouble Diagnosis Procedure for Noise.AT C - 9 1

Self-diagnosis can not be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis.AT C - 9 2

Memory function does not operate. Go to Trouble Diagnosis Procedure for Memory Function.AT C - 9 2

Page 631 of 3066

TROUBLE DIAGNOSIS

ATC-53

C

D

E

F

G

H

I

K

L

MA

B

AT C

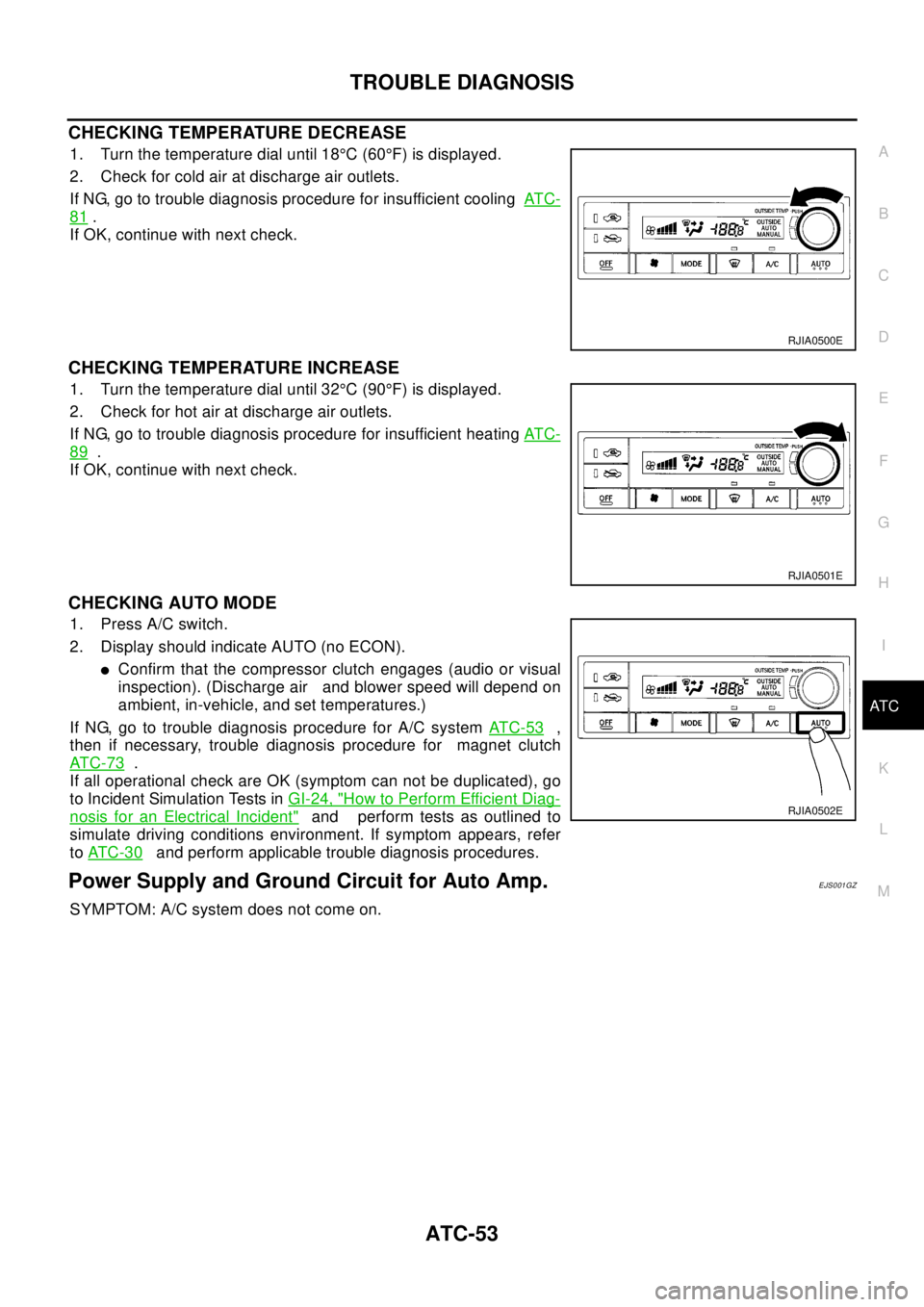

CHECKING TEMPERATURE DECREASE

1. Turn the temperature dial until 18°C(60°F) is displayed.

2. Check for cold air at discharge air outlets.

If NG, go to trouble diagnosis procedure for insufficient coolingAT C -

81.

If OK, continue with next check.

CHECKING TEMPERATURE INCREASE

1. Turn the temperature dial until 32°C(90°F) is displayed.

2. Check for hot air at discharge air outlets.

If NG, go to trouble diagnosis procedure for insufficient heatingAT C -

89.

If OK, continue with next check.

CHECKING AUTO MODE

1. Press A/C switch.

2. Display should indicate AUTO (no ECON).

lConfirm that the compressor clutch engages (audio or visual

inspection). (Discharge air and blower speed will depend on

ambient, in-vehicle, and set temperatures.)

If NG, go to trouble diagnosis procedure for A/C systemAT C - 5 3

,

then if necessary, trouble diagnosis procedure for magnet clutch

AT C - 7 3

.

If all operational check are OK (symptom can not be duplicated), go

to Incident Simulation Tests inGI-24, "

How to Perform Efficient Diag-

nosis for an Electrical Incident"and perform tests as outlined to

simulate driving conditions environment. If symptom appears, refer

toAT C - 3 0

and perform applicable trouble diagnosis procedures.

Power Supply and Ground Circuit for Auto Amp.EJS001GZ

SYMPTOM: A/C system does not come on.

RJIA0500E

RJIA0501E

RJIA0502E

Page 667 of 3066

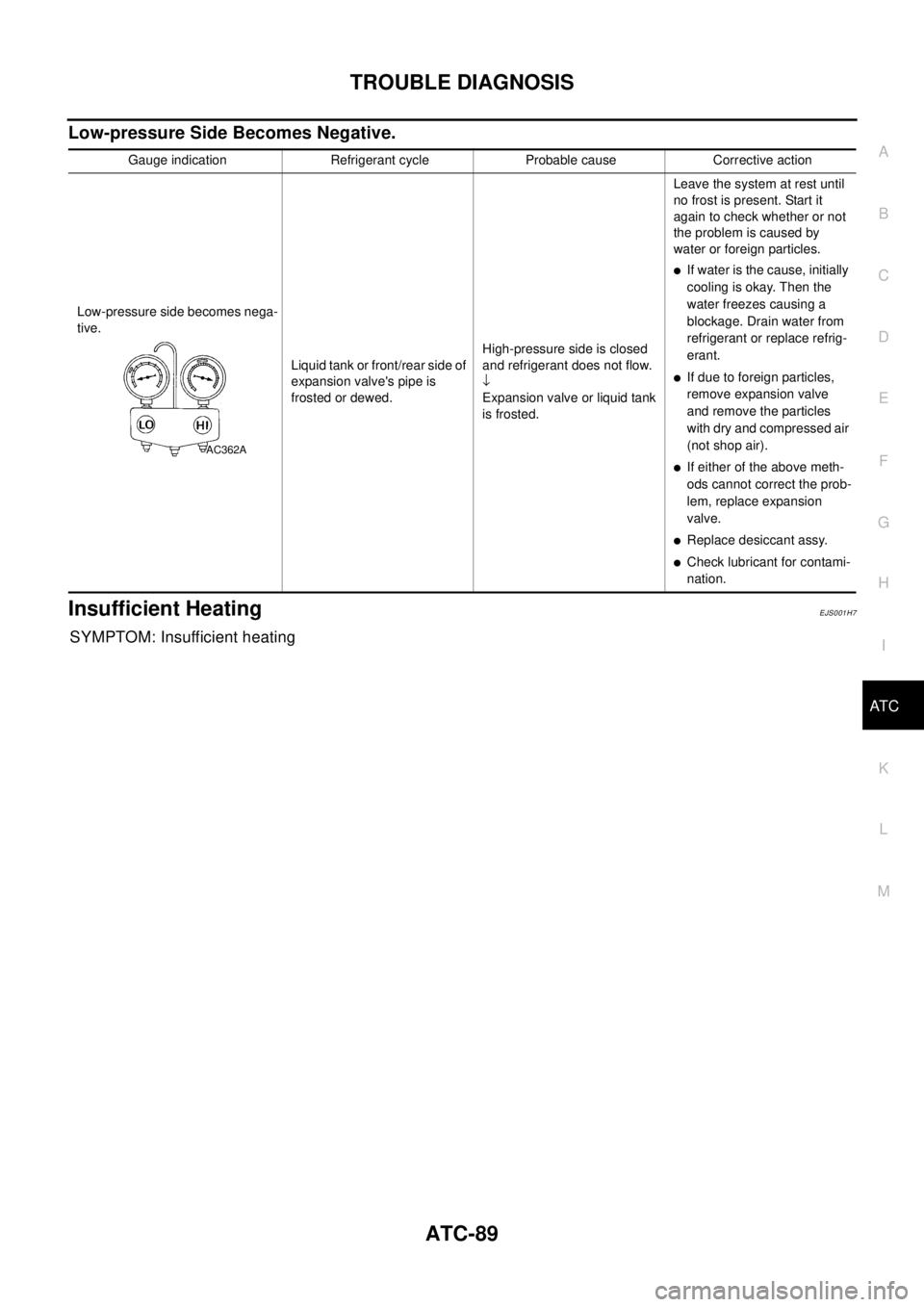

TROUBLE DIAGNOSIS

ATC-89

C

D

E

F

G

H

I

K

L

MA

B

AT C

Low-pressure Side Becomes Negative.

Insufficient HeatingEJS001H7

SYMPTOM: Insufficient heating

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side becomes nega-

tive.

Liquid tank or front/rear side of

expansion valve's pipe is

frosted or dewed.High-pressure side is closed

and refrigerant does not flow.

¯

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the problem is caused by

water or foreign particles.

lIf water is the cause, initially

cooling is okay. Then the

water freezes causing a

blockage. Drain water from

refrigerant or replace refrig-

erant.

lIf due to foreign particles,

remove expansion valve

and remove the particles

with dry and compressed air

(not shop air).

lIf either of the above meth-

ods cannot correct the prob-

lem, replace expansion

valve.

lReplace desiccant assy.

lCheck lubricant for contami-

nation.

AC362A

Page 899 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-31

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Continuity exists, resistance value

Insulation inspection

lCheck resistance value between each pair of ABS solenoid E70 and E71 terminals NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-31

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Continuity exists, resistance value

Insulation inspection

lCheck resistance value between each pair of ABS solenoid E70 and E71 terminals](/img/5/57402/w960_57402-898.png)

TROUBLE DIAGNOSIS

BRC-31

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Continuity exists, resistance value

Insulation inspection

lCheck resistance value between each pair of ABS solenoid E70 and E71 terminals (No.1 (L), 2 ((R/B) 3

(L/W), 12 (Y/G), 25 (L/Y), 26 (B/Y), 27 (L/R), 28 (W/G).

ABS motor operation inspection

1. Connect 2-pin connector on ABS actuator E69 terminals No. 9

(R/B) and No. 10 (Y).

2. Apply voltage of Approx. 12V voltage between terminals E70

No. 5 (G/R) and terminals E71 No. 7 (W/G) on ABS relay unit.

Measure motor voltage (terminal E70 No. 4 (R/Y) - Body

ground) using an oscilloscope and check motor counter electro-

motive force duration when operation stops.

CAUTION:

lBefore measuring time, check each part of ABS relay unit

and confirm motor relay is normal.

lTo prevent overheating, ABS motor should be driven no

longer than 4 seconds.

lMotor counter electromotive force duration is based on the

time at 20°C, in ambient temperatures, with 12V battery volt-

age. If battery voltage is low, time will be slightly shorter.

SFIA0353E

Standard : 5.8 - 21.2 (W)

Motor counter electromotive force duration:

0.1 second or longer

SFIA0354E

Page 980 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-112

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

Actuator operation check

1. Connect 19 and 21 terminals of actuator to 40 and 41 terminals

of relay box.

2. Measure the motor voltage (No.4 terminal to body ear NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-112

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

Actuator operation check

1. Connect 19 and 21 terminals of actuator to 40 and 41 terminals

of relay box.

2. Measure the motor voltage (No.4 terminal to body ear](/img/5/57402/w960_57402-979.png)

BRC-112

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

Actuator operation check

1. Connect 19 and 21 terminals of actuator to 40 and 41 terminals

of relay box.

2. Measure the motor voltage (No.4 terminal to body earth ) with

oscilloscope. Then check the motor reverse voltage occasioned

time.

The motor reverse voltage occasioned time is more than 0.1

sec.

CAUTION:

lPerform checking of motor relay unit .Then confirm that

relay functions.

lDriving actuator motor is with in 4 sec to prevent heating

up.

lStandard condition of the motor reverse voltage occa-

sioned time is: Battery voltage is 12V. temperature 20°.

when the battery voltage or temperature is lower than the

standard, the motor reverse voltage occasioned time

becomesslightlyshorter.

Symptom 1: ABS Works Frequently.EFS001AS

Inspection procedure

1.INSPECTION START

Check the wheel speed sensor system.

lSensor mounting inspection

lSensor pick-up inspection for iron chips

lSensor rotor inspection (e.g. number of teeth, damaged teeth)

lSensor connector engagement inspection

Is inspection result OK?

YES >> GO TO 2.

NO >> Refer to wheel speed sensor and rotor lines.

2.LOOSENESS INSPECTION

Check the front axle for looseness.

Is inspection result OK?

YES >>BRC-112, "Symptom 2: Unexpected Pedal Action"

NO >> Axle inspection and repair

Symptom 2: Unexpected Pedal ActionEFS001AT

Inspection procedure

1.BRAKE PEDAL STROKE INSPECTION

Check the brake pedal stroke.

Is stroke excessively long?

YES >> Check the bleeding and brake system.

NO >> GO TO 2.

SFIA0400E

Page 1011 of 3066

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

CO

ENGINE COOLING SYSTEM

QR20DE

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET .......................... 3

LIQUID GASKET APPLICATION PROCEDURE..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

OVERHEATING CAUSE ANALYSIS .......................... 5

Troubleshooting Chart .............................................. 5

COOLING SYSTEM .................................................... 7

Cooling Circuit .......................................................... 7

ENGINE COOLANT .................................................... 9

Inspection ................................................................. 9

LEVEL CHECK ..................................................... 9

LEAK CHECK ....................................................... 9

Changing Engine Coolant ........................................ 9

DRAINING ENGINE COOLANT ........................... 9

REFILLING ENGINE COOLANT ........................ 10

FLUSHING COOLING SYSTEM ......................... 10

RADIATOR ................................................................ 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

Disassembly and Assembly Radiator Fan ............. 13

DISASSEMBLY ................................................... 13

ASSEMBLY ......................................................... 13

INSPECTION ......................................................... 13

CHECKING RADIATOR CAP .............................. 13

CHECKING RADIATOR ...................................... 14

RADIATOR (ALUMINUM TYPE) .............................. 15

Disassembly and Assembly ................................... 15

PREPARATION ................................................... 15

DISASSEMBLY ................................................... 15

ASSEMBLY ......................................................... 16

INSPECTION ...................................................... 18WATER PUMP .......................................................... 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 20

INSTALLATION ................................................... 20

INSPECTION AFTER INSTALLATION ................ 20

THERMOSTAT AND WATER CONTROL VALVE .... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 23

Capacity .................................................................. 23

Thermostat ............................................................. 23

Water Control Valve ................................................ 23

Radiator .................................................................. 23

Tightening Torque ................................................... 23

YD22DDTi

PRECAUTIONS ........................................................ 24

Precautions For Liquid Gasket ............................... 24

REMOVAL AND LIQUID GASKET ...................... 24

LIQUID GASKET APPLICATION PROCEDURE... 24

PREPARATION ......................................................... 25

Special Service Tools ............................................. 25

OVERHEATING CAUSE ANALYSIS ........................ 26

Troubleshooting Chart ............................................ 26

COOLING SYSTEM .................................................. 28

Cooling Circuit ........................................................ 28

ENGINE COOLANT .................................................. 30

Inspection ............................................................... 30

LEVEL CHECK .................................................... 30

LEAK CHECK ...................................................... 30

Changing Engine Coolant ....................................... 30

DRAINING ENGINE COOLANT .......................... 30

REFILLING ENGINE COOLANT ......................... 31

FLUSHING COOLING SYSTEM ......................... 32

RADIATOR ................................................................ 33

Removal and Installation ........................................ 33