NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2671 of 3066

PARKING BRAKE SHOE

PB-5

C

D

E

G

H

I

J

K

L

MA

B

PB

PARKING BRAKE SHOEPFP:44060

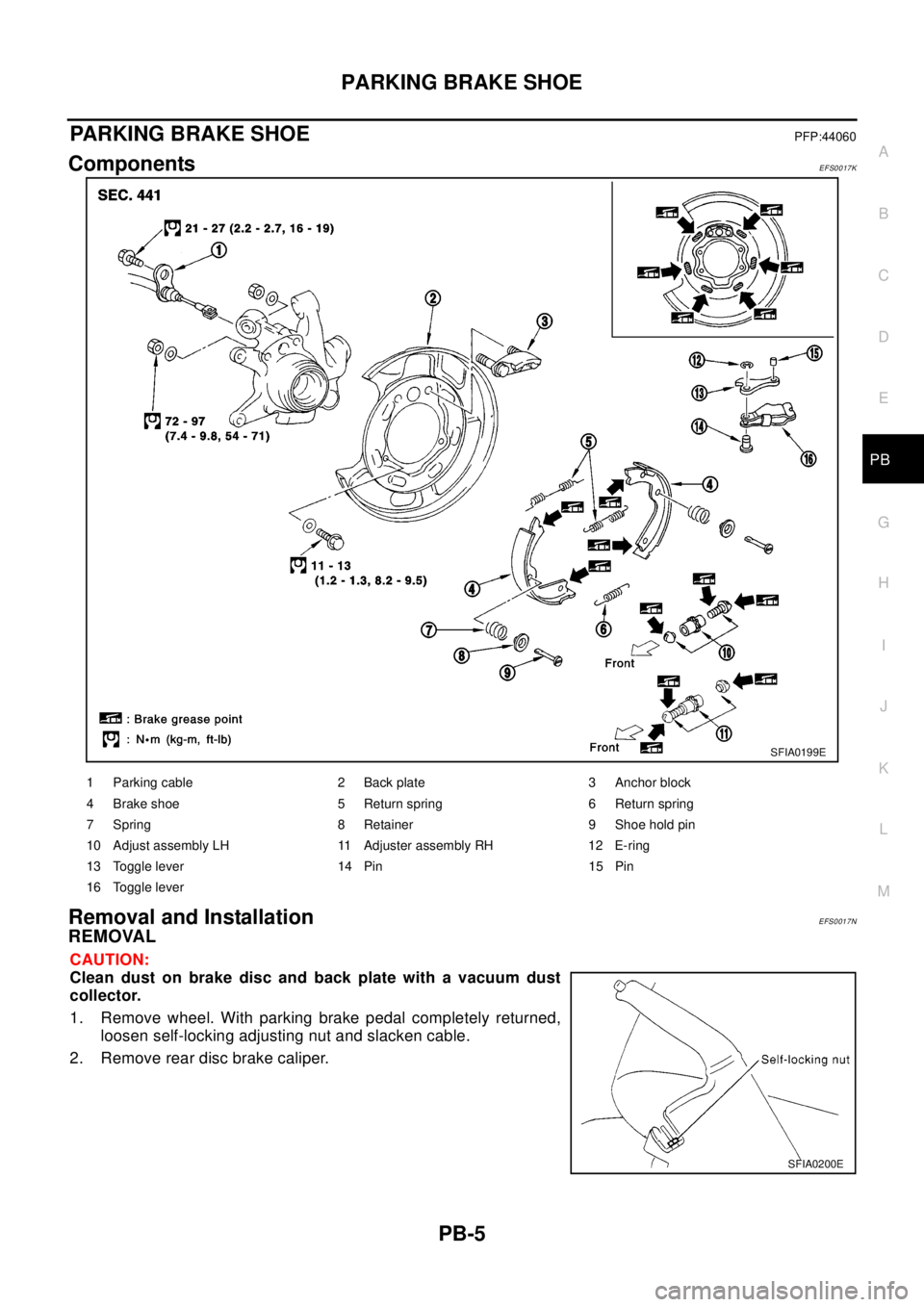

ComponentsEFS0017K

Removal and InstallationEFS0017N

REMOVAL

CAUTION:

Clean dust on brake disc and back plate with a vacuum dust

collector.

1. Remove wheel. With parking brake pedal completely returned,

loosen self-locking adjusting nut and slacken cable.

2. Remove rear disc brake caliper.

SFIA0199E

1 Parking cable 2 Back plate 3 Anchor block

4 Brake shoe 5 Return spring 6 Return spring

7 Spring 8 Retainer 9 Shoe hold pin

10 Adjust assembly LH 11 Adjuster assembly RH 12 E-ring

13 Toggle lever 14 Pin 15 Pin

16 Toggle lever

SFIA0200E

Page 2672 of 3066

PB-6

PARKING BRAKE SHOE

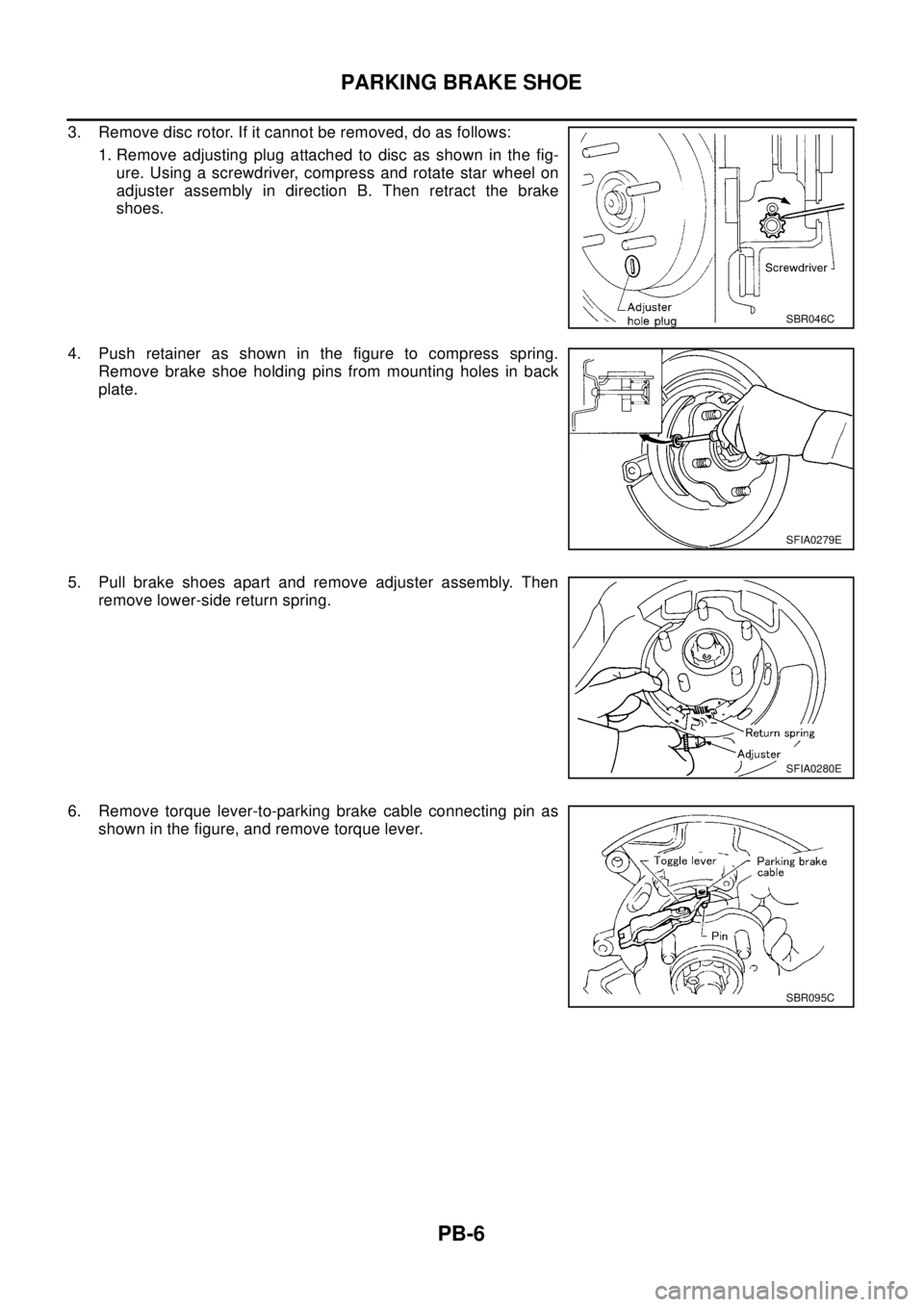

3. Remove disc rotor. If it cannot be removed, do as follows:

1.Removeadjustingplugattachedtodiscasshowninthefig-

ure. Using a screwdriver, compress and rotate star wheel on

adjuster assembly in direction B. Then retract the brake

shoes.

4. Push retainer as shown in the figure to compress spring.

Remove brake shoe holding pins from mounting holes in back

plate.

5. Pull brake shoes apart and remove adjuster assembly. Then

remove lower-side return spring.

6. Remove torque lever-to-parking brake cable connecting pin as

shown in the figure, and remove torque lever.

SBR046C

SFIA0279E

SFIA0280E

SBR095C

Page 2673 of 3066

PARKING BRAKE SHOE

PB-7

C

D

E

G

H

I

J

K

L

MA

B

PB

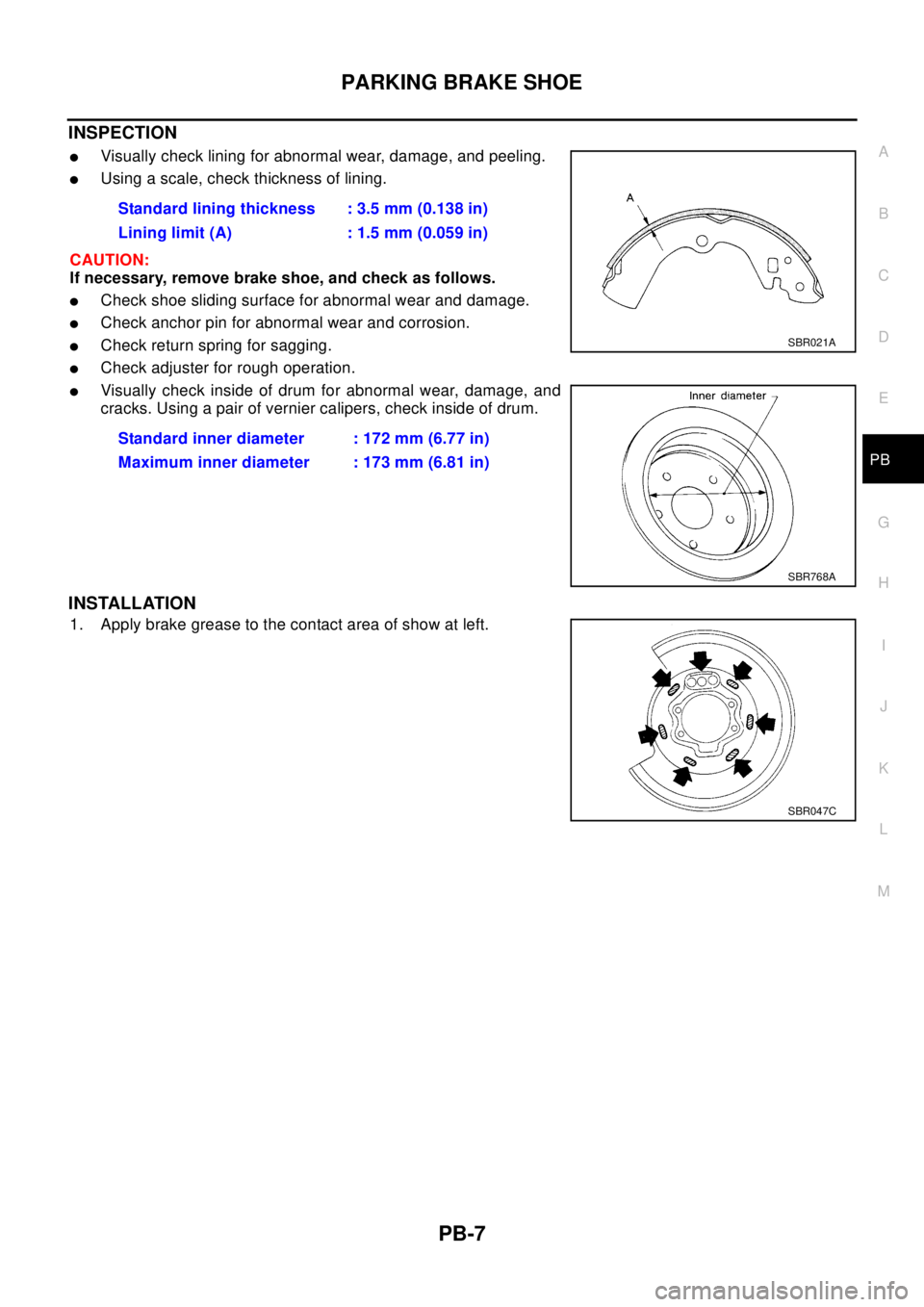

INSPECTION

lVisually check lining for abnormal wear, damage, and peeling.

lUsing a scale, check thickness of lining.

CAUTION:

If necessary, remove brake shoe, and check as follows.

lCheck shoe sliding surface for abnormal wear and damage.

lCheck anchor pin for abnormal wear and corrosion.

lCheck return spring for sagging.

lCheck adjuster for rough operation.

lVisually check inside of drum for abnormal wear, damage, and

cracks. Using a pair of vernier calipers, check inside of drum.

INSTALLATION

1. Apply brake grease to the contact area of show at left.Standard lining thickness : 3.5 mm (0.138 in)

Lining limit (A) : 1.5 mm (0.059 in)

Standard inner diameter : 172 mm (6.77 in)

Maximum inner diameter : 173 mm (6.81 in)

SBR021A

SBR768A

SBR047C

Page 2674 of 3066

PB-8

PARKING BRAKE SHOE

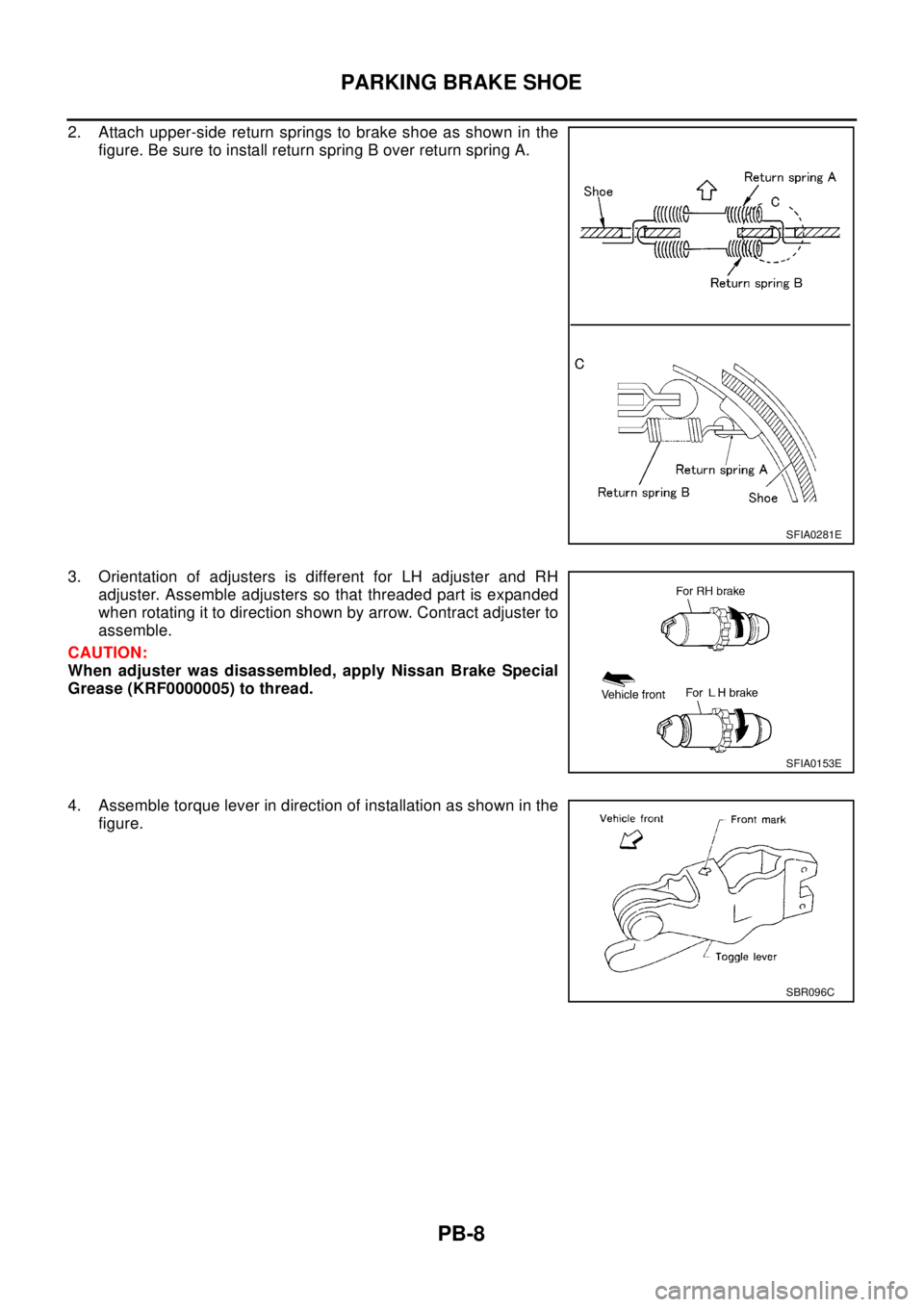

2. Attach upper-side return springs to brake shoe as shown in the

figure. Be sure to install return spring B over return spring A.

3. Orientation of adjusters is different for LH adjuster and RH

adjuster. Assemble adjusters so that threaded part is expanded

when rotating it to direction shown by arrow. Contract adjuster to

assemble.

CAUTION:

When adjuster was disassembled, apply Nissan Brake Special

Grease (KRF0000005) to thread.

4. Assemble torque lever in direction of installation as shown in the

figure.

SFIA0281E

SFIA0153E

SBR096C

Page 2675 of 3066

PARKING BRAKE SHOE

PB-9

C

D

E

G

H

I

J

K

L

MA

B

PB

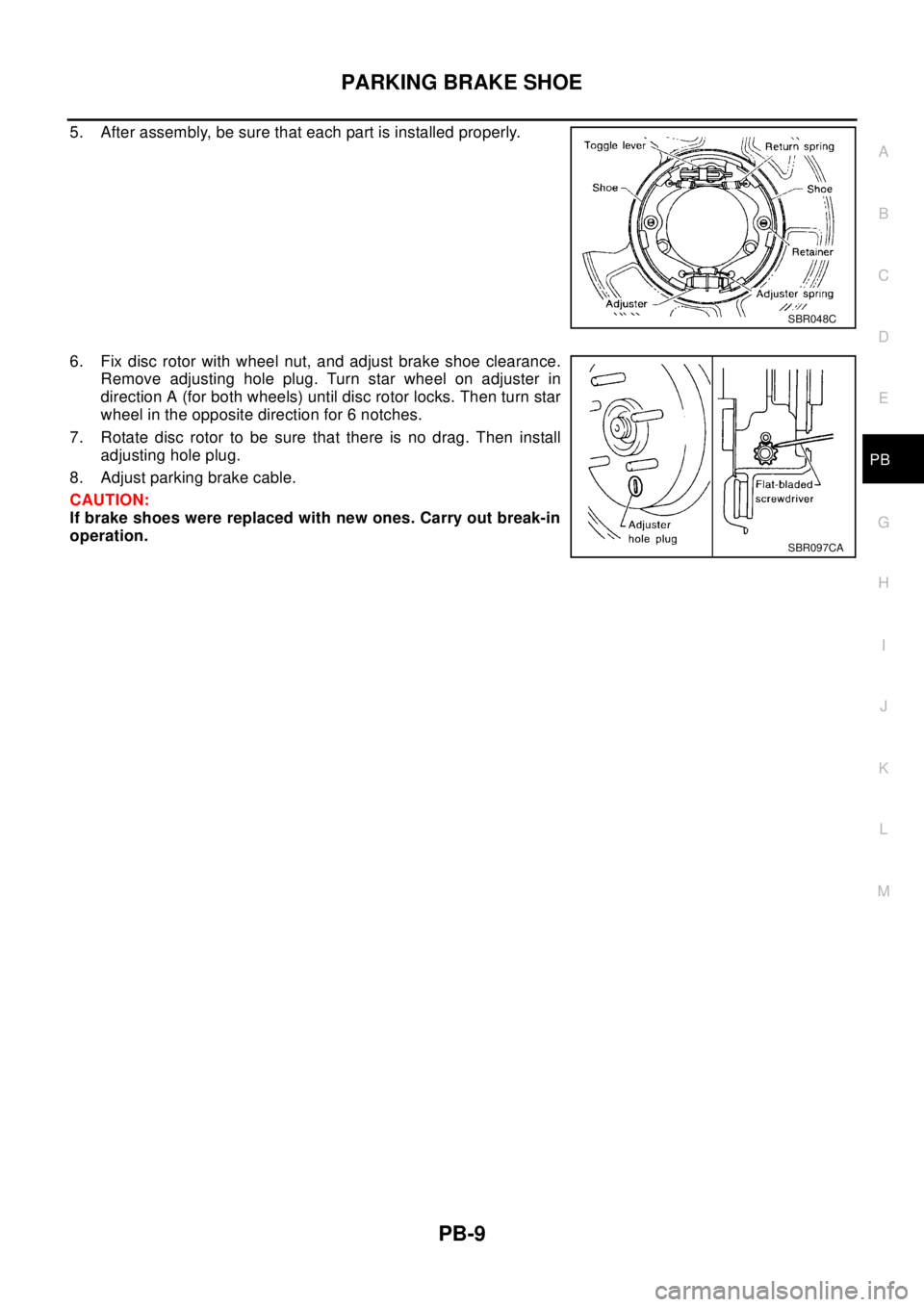

5. After assembly, be sure that each part is installed properly.

6. Fix disc rotor with wheel nut, and adjust brake shoe clearance.

Remove adjusting hole plug. Turn star wheel on adjuster in

direction A (for both wheels) until disc rotor locks. Then turn star

wheel in the opposite direction for 6 notches.

7. Rotate disc rotor to be sure that there is no drag. Then install

adjusting hole plug.

8. Adjust parking brake cable.

CAUTION:

If brake shoes were replaced with new ones. Carry out break-in

operation.

SBR048C

SBR097CA

Page 2676 of 3066

PB-10

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

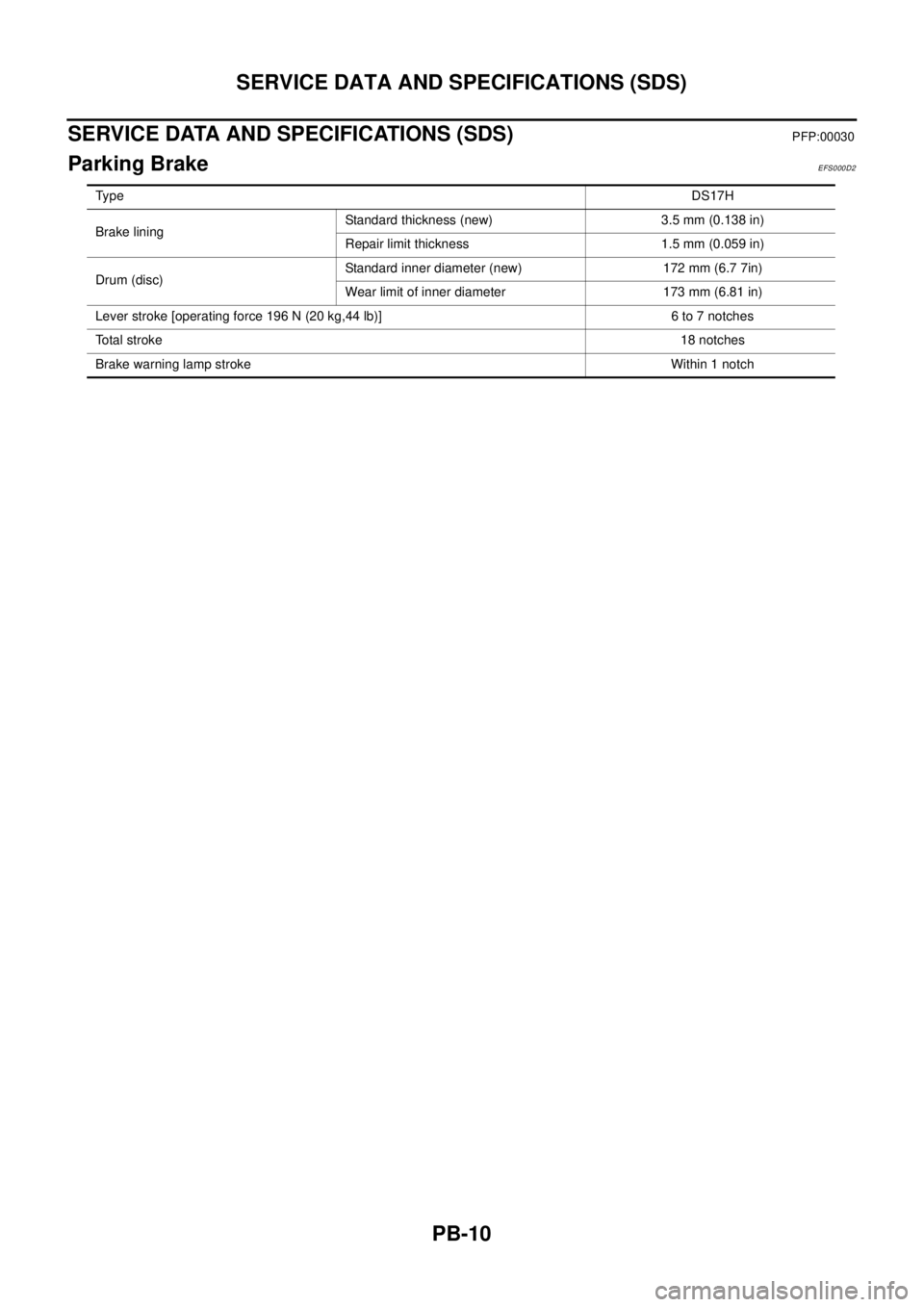

Parking BrakeEFS000D2

Ty p eDS17H

Brake liningStandard thickness (new) 3.5 mm (0.138 in)

Repair limit thickness 1.5 mm (0.059 in)

Drum (disc)Standard inner diameter (new) 172 mm (6.7 7in)

Wear limit of inner diameter 173 mm (6.81 in)

Lever stroke [operating force 196 N (20 kg,44 lb)] 6 to 7 notches

To t a l s t r o k e18 notches

Brake warning lamp strokeWithin 1 notch

Page 2677 of 3066

PG-1

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION

A

B

PG

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

POWER SUPPLY ROUTING ...................................... 2

Schematic ................................................................ 2

Wiring Diagram — POWER — ................................. 3

BATTERY POWER SUPPLY — IGNITION SW.

IN ANY POSITION ................................................ 3

ACCESSORY POWER SUPPLY — IGNITION

SW. IN “ACC” OR “ON” ......................................... 7

IGNITION POWER SUPPLY — IGNITION SW.

IN “ON” AND/OR “START” .................................... 8

Fuse ....................................................................... 12

Fusible Link ............................................................ 12

Circuit Breaker ....................................................... 12

GROUND .................................................................. 13

Ground Distribution ................................................ 13

MAIN HARNESS/LHD MODELS ........................ 14

MAIN HARNESS/RHD MODELS ........................ 16

ENGINE ROOM HARNESS/LHD MODELS ....... 18

ENGINE ROOM HARNESS/RHD MODELS ....... 19

ENGINE ROOM HARNESS ................................ 20

ENGINE CONTROL HARNESS/GASOLINE

ENGINE MODELS .............................................. 21

ENGINE CONTROL HARNESS/DIESEL

ENGINE MODELS .............................................. 22

BODY HARNESS/LHD MODELS ....................... 23

BODY HARNESS/RHD MODELS ....................... 24

BODY NO.2 HARNESS/LHD MODELS .............. 25

BODY NO.2 HARNESS/RHD MODELS ............. 26

BODY NO.2 HARNESS ...................................... 27

BACK DOOR SUB HARNESS/REAR WINDOW

DEFOGGER HARNESS ..................................... 28

HARNESS ................................................................. 29

Harness Layout ...................................................... 29

HOW TO READ HARNESS LAYOUTS ............... 29

OUTLINE/LHD MODELS .................................... 30

OUTLINE/RHD MODELS .................................... 31

MAIN HARNESS/LHD MODELS ........................ 32

MAIN HARNESS/RHD MODELS ........................ 34ENGINE ROOM HARNESS/LHD MODELS ........ 36

ENGINE ROOM HARNESS/RHD MODELS ....... 41

ENGINE CONTROL HARNESS .......................... 46

BODY HARNESS/LHD MODELS ....................... 49

BODY HARNESS/RHD MODELS ....................... 50

BODY NO.2 HARNESS/LHD MODELS .............. 51

BODY NO.2 HARNESS/RHD MODELS .............. 52

ROOM LAMP HARNESS .................................... 53

FRONT DOOR HARNESS/LHD MODELS .......... 54

FRONT DOOR HARNESS/RHD MODELS ......... 56

REAR DOOR HARNESS .................................... 58

BACK DOOR HARNESS .................................... 60

Wiring Diagram Codes (Cell Codes) ...................... 61

ELECTRICAL UNITS LOCATION ............................ 64

Electrical Units Location ......................................... 64

ENGINE COMPARTMENT .................................. 65

PASSENGER COMPARTMENT/LHD MODELS... 66

PASSENGER COMPARTMENT/RHD MODELS... 68

HARNESS CONNECTOR ......................................... 70

Description .............................................................. 70

HARNESS CONNECTOR (TAB-LOCKING

TYPE) .................................................................. 70

HARNESS CONNECTOR (SLIDE-LOCKING

TYPE) .................................................................. 71

JOINT CONNECTOR (J/C) ....................................... 72

Terminal Arrangement ............................................ 72

ELECTRICAL UNITS ................................................ 73

Terminal Arrangement ............................................ 73

STANDARDIZED RELAY .......................................... 74

Description .............................................................. 74

NORMAL OPEN, NORMAL CLOSED AND

MIXED TYPE RELAYS ........................................ 74

TYPE OF STANDARDIZED RELAYS ................. 74

FUSE BLOCK-JUNCTION BOX(J/B) ....................... 76

Terminal Arrangement ............................................ 76

FUSE AND FUSIBLE LINK BOX .............................. 77

Terminal Arrangement ............................................ 77

Page 2678 of 3066

PG-2

POWER SUPPLY ROUTING

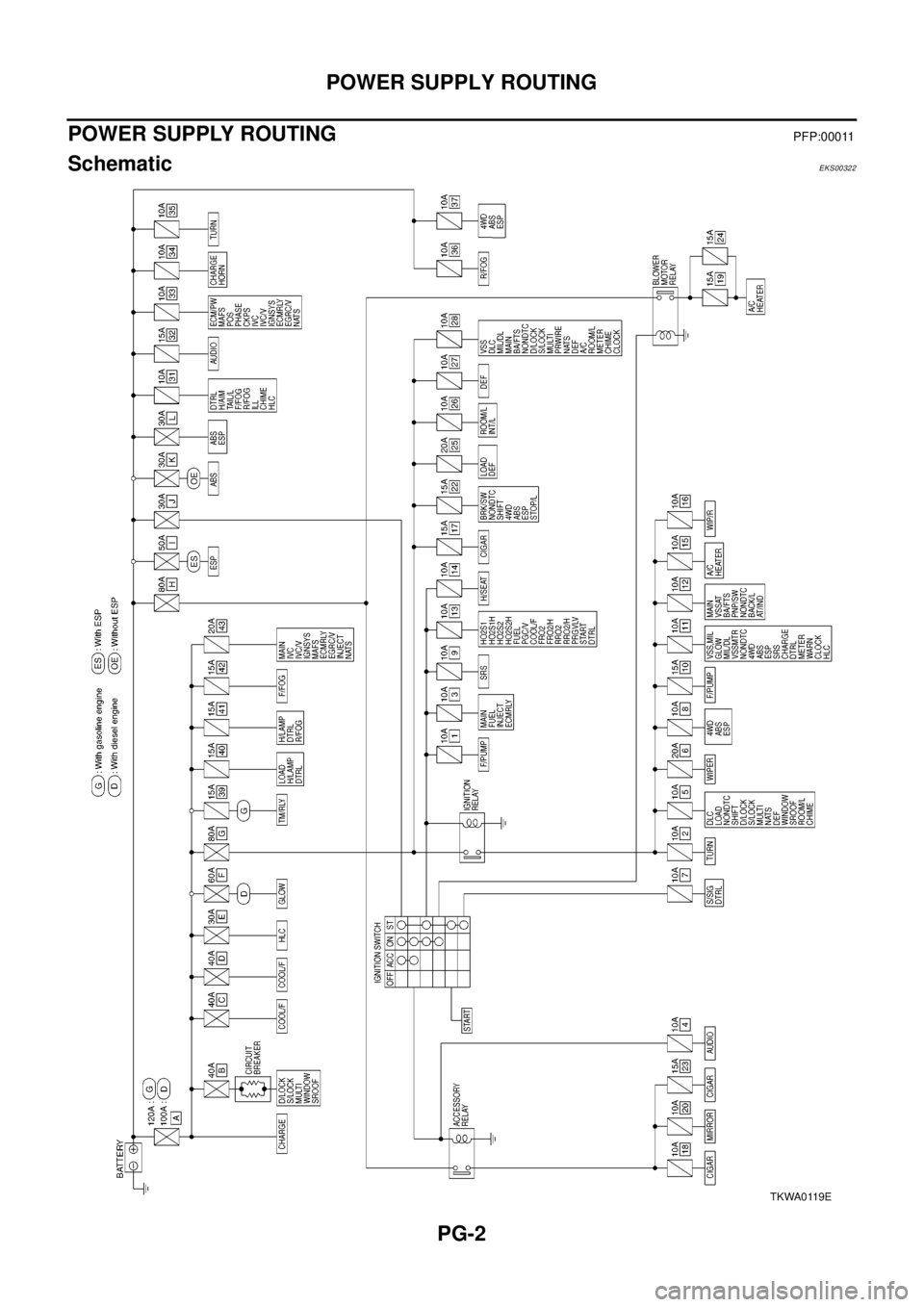

POWER SUPPLY ROUTING

PFP:00011

SchematicEKS00322

TKWA0119E

Page 2679 of 3066

POWER SUPPLY ROUTING

PG-3

C

D

E

F

G

H

I

J

L

MA

B

PG

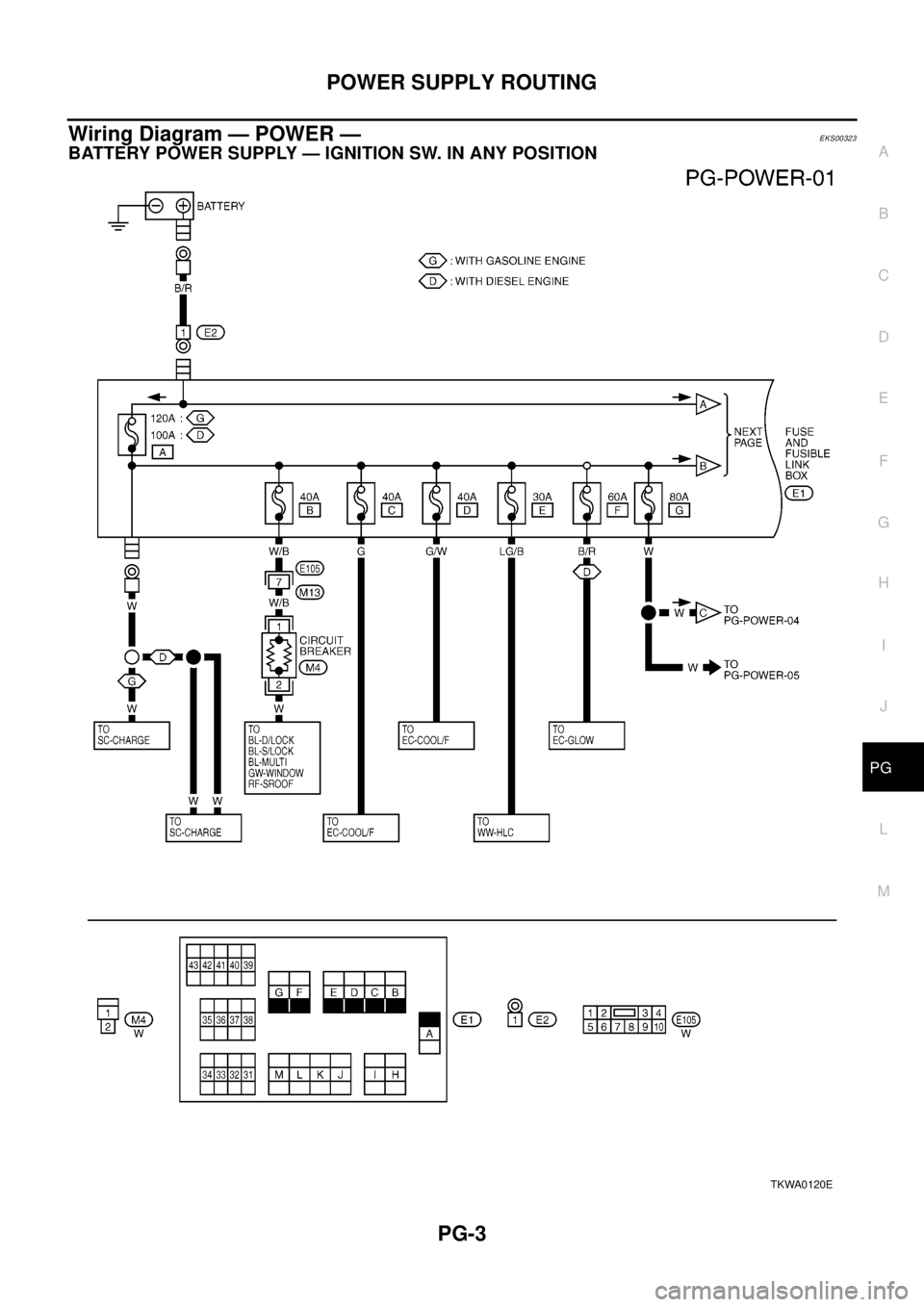

Wiring Diagram — POWER —EKS00323

BATTERY POWER SUPPLY — IGNITION SW. IN ANY POSITION

TKWA0120E

Page 2680 of 3066

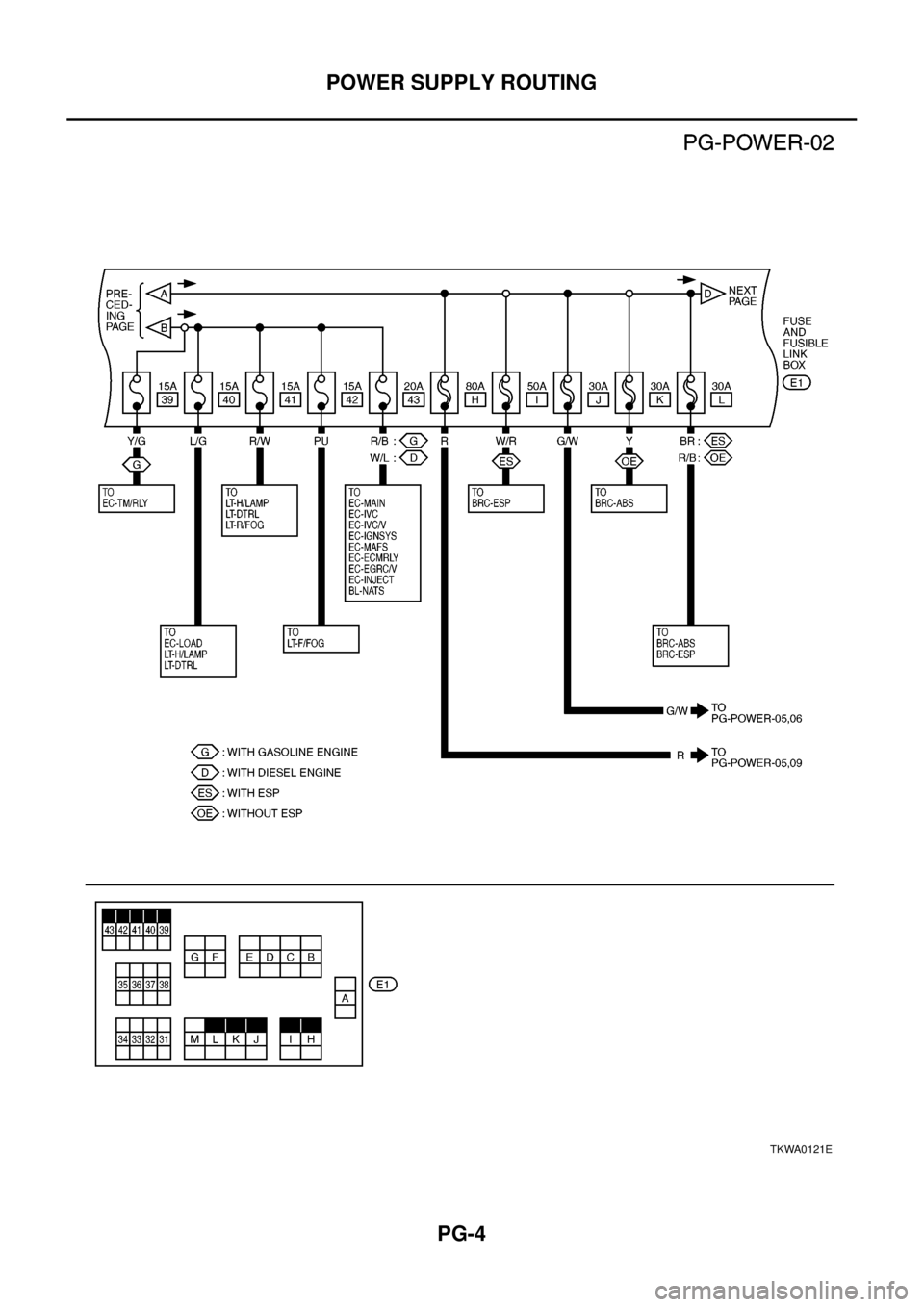

PG-4

POWER SUPPLY ROUTING

TKWA0121E