air filter NISSAN X-TRAIL 2003 Electronic Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2362 of 3066

IDX-5

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Front washer ......................................................WW-4

Front wiper .........................................................WW-4

FTS - Wiring diagram ......................................EC-752

Fuel check valve ..............................................EC-372

Fuel cut control (at no load high engine speed)EC-28,

EC-393

,EC-662

Fuel filler lid ........................................................BL-64

Fuel filter ..........................................................EC-664

Fuel filter replacement(QR20DE) .........................FL-4

Fuel filter replacement(YD22DDTi) .......FL-15,MA-30

Fuel gauge ..................................................DI-4,DI-22

Fuel injection control system ...........................EC-660

Fuel injection system .........................EC-194,EC-200

Fuel injector .....................................................EC-727

Fuel injector adjustment resistor ......................EC-777

Fuel injector and fuel tube(QR20DE) ................EM-29

Fuel injector and fuel tube(YD22DDTi) ............EM-135

Fuel leak ..........................................................EC-781

Fuel line inspection(QR20DE) .................FL-3,MA-23

Fuel line inspection(YD22DDTi) ............FL-14,MA-30

Fuel pressure check ............................EC-34,EC-399

Fuel pressure release ..........................EC-34,EC-399

Fuel pressure relief valve ................................EC-665

Fuel pump ..........................................EC-352,EC-627

Fuel pump and gauge(QR20DE) ..........................FL-4

Fuel system(QR20DE) .........................................FL-3

Fuel system(YD22DDTi) .....................................FL-14

Fuel tank(QR20DE) ..............................................FL-9

Fuel tank(YD22DDTi) .........................................FL-21

Fuel temperature sensor .................................EC-751

Fuse ...................................................................PG-12

Fuse and fusible link box ...................................PG-77

Fusible link .........................................................PG-12

G

Gear components (M/T) .......................MT-19

,MT-24

Generator ..........................................................SC-12

Generator - See Alternator ................................SC-12

Generic scan tool (GST) ....................................EC-96

Glass ..................................................GW-41,GW-43

GLOW - Wiring diagram ..................................EC-797

Glow plug .........................................................EC-796

Glow plug(YD22DDTi) .....................................EM-130

Glow relay ........................................................EC-796

Grease ...............................................................MA-17

Grille - See Exterior .............................................EI-11

Ground distribution ............................................PG-13

G-sensor .............................................................TF-50

H

H/AIM - Wiring diagram ......................................LT-15

H/LAMP - Wiring diagram ...........................LT-4,LT-5

H/MIRROR - Wiring diagram ............................GW-10

Harness connector ............................................PG-70

Harness layout ...................................................PG-29

Headlamp .............................................................LT-4

Headlamp aiming control ....................................LT-15

Headlamp leveler - See Headlamp aiming control .......

LT-15

Headlamp washer ............................................WW-19

Headlining - See Roof trim ..................................EI-29

Heated oxygen sensor 1 ....EC-160,EC-166,EC-174,

EC-284

,EC-290,EC-490,EC-581

Heated oxygen sensor 1 heater .........EC-120,EC-568

Heated oxygen sensor 2 ....EC-181,EC-187,EC-296,

EC-303

,EC-587

Heated oxygen sensor 2 heater .........EC-125,EC-573

Heated seat ...............................................SE-3,SE-5

HEATER - Wiring diagram ................................MTC-6

Heater and cooling unit (Heater core) ............ATC-115

Heater mirror .....................................................GW-10

Heater system - Wiring diagram .......................MTC-6

Heater unit (heater core) ..ATC-120,MTC-23,MTC-26

HFC134a (R134a) system precaution ...............ATC-4

HFC134a (R134a) system service procedureATC-123

HFC134a (R134a) system service tools ..........ATC-12

HFC134a system service equipment precautionATC-8

HO2S1 - Wiring diaram ......EC-122,EC-162,EC-169,

EC-177

,EC-492

HO2S2 - Wiring diagram ....EC-183,EC-190,EC-299,

EC-306

HO2S2H - Wiring diagram ...............................EC-127

Hood ....................................................................BL-4

Horn .................................................................WW-23

HORN - Wiring diagram ...................................WW-23

How to erase DTC ...........................................EC-666

HowtoeraseDTCforOBDsystem .....EC-46,EC-402

I

IATS - Wiring diagram .....................................EC-138

IATSEN - Wiring diagram ................................EC-578

Identification .....................................................ATC-10

Idle air volume learning ........................EC-31,EC-396

Idle speed .............................EC-64,EC-412,EC-672

IGN/SG - Wiring diagram .................................EC-335

Ignition coil .........................................EC-334,EC-592

Ignition coil(QR20DE) .......................................EM-27

Ignition control system .......................EC-334,EC-592

Ignition timing .......................................EC-64,EC-412

IGNSYS - Wiring diagram ................................EC-593

ILL - Wiring diagram ...........................................LT-45

Illumination ..........................................................LT-45

In vehicle sensor ...............ATC-95,ATC-97,ATC-106

INJECT - Wiring diagram ....EC-344,EC-619,EC-730

Injection nozzle(YD22DDTi) ...........................EM-135

Injector ...............................................EC-343,EC-618

Input shaft (FF M/T) ..............................MT-19,MT-24

Instrument panel ...................................................IP-3

INT/L - Wiring diagram ........................................LT-65

Intake air temparature sensor ............EC-136,EC-577

Intake door control linkage adjustment ............ATC-66

Intake door motorATC-64,ATC-112,MTC-10,MTC-22

Intake manifold(QR20DE) .................................EM-17

Page 2363 of 3066

IDX-6

ALPHABETICAL INDEX

Intake manifold(YD22DDTi) ............................EM-115

Intake sensor ................................ATC-101,ATC-108

Intake valve timing control .................EC-117,EC-608

Intake valve timing control solenoid valve ......EC-266,

EC-608

Interior .......................EI-23,EI-25,EI-26,EI-28,EI-29

Interior lamp ........................................................LT-55

Interior lamp on-off control ......................LT-55,LT-56

ISO 15031-5 Mode 1 - 9 ....................................EC-36

IVC - Wiring diagram .......................................EC-268

IVC/V - Wiring diagram ....................................EC-610

J

Joint connector (J/C) .............................PG-72

,PG-76

K

Keyless entry system - See Multi-remote control system

BL-45

Knock sensor (KS) .............................EC-212,EC-496

KS - Wiring diagram ...........................EC-214,EC-498

L

LAN system circuit ...........................................ATC-56

License lamp .......................................................LT-30

Line pressure solenoid valve ...........................AT-179

Line pressure test (A/T) .......................AT-68,AT-290

Liquid gasket application(QR20DE) ....................EM-6

Liquid gasket application(YD22DDTi) .............EM-103

LOAD - Wiring diagram ......................EC-363,EC-638

Location of electrical units .................................PG-64

Lock, door ...............................................BL-54,BL-57

Lubricant (R134a) A/C ........................ATC-5,ATC-21

Lubricants .........................................................MA-17

Lubrication circuit (engine)(QR20DE) ..................LU-5

Lubrication circuit (engine)(YD22DDTi) .............LU-17

Lubrication-locks, hinges and hood latches ......MA-42

M

M/T major overhaul ...............................MT-27

,MT-35

M/T oil replacement ...........................................MT-11

M/T removal and installation ..............................MT-16

MAFS - Wiring diagram .....EC-132,EC-262,EC-466,

EC-708

Magnet clutch .................................ATC-73,ATC-129

MAIN - Wiring diagram .......EC-108,EC-454,EC-701

Mainshaft (M/T) .....................................MT-19,MT-24

Major overhaul (Transfer) ..................................TF-14

Malfunction indicator (MI) ...EC-252,EC-526,EC-667

Malfunction indicator lamp (MIL) ..........EC-48,EC-404

Mass air flow sensor (MAFS) ............EC-130,EC-260,

EC-463

,EC-706

Master cylinder (brake) ......................................BR-13

Master cylinder (clutch) ........................................CL-9

METER - Wiring diagram ...........................DI-8,DI-26

MIL - Wiring diagram ........................EC-253,EC-527

MIL/DL - Wiring diagram ..................................EC-825

MIRROR - Wiring diagram ...............................GW-47

Mirror defogger ................................................GW-10

Mirror, door ......................................................GW-46

Mirror, out side .................................................GW-46

Misfire ..............................................................EC-206

Mode door control linkage adjustment ...........ATC-61,

ATC-118

,MTC-8,MTC-27

Mode door motor ............................ATC-58,ATC-118

Molding - See Exterior ........GW-3,EI-14,EI-16,EI-17

Mud guard - See Exterior ....................................EI-16

MULTI - Wiring diagram .....................................BL-47

Multiport fuel injection (MFI) system ...EC-24,EC-389

Multi-remote control system ...............................BL-45

N

NATS - Wiring diagram ......................................BL-72

NATS (Nissan anti-theft system) .......................BL-70

NVH troubleshooting (BR) .........................BR-5,PB-2

NVH troubleshooting (CL) ....................................CL-4

NVH troubleshooting (EM)(QR20DE) ...............EM-11

NVH troubleshooting (EM)(YD22DDTi) ..........EM-108

NVH troubleshooting (FSU) ..............................FSU-4

NVH troubleshooting (M/T) .................................MT-8

NVH troubleshooting (PR) .................................FAX-6

NVH troubleshooting (RA) ................................RAX-5

NVH troubleshooting (RAX) ..............................RAX-5

NVH troubleshooting (RSU) ..............................RSU-4

NVH troubleshooting (ST) ....................................PS-4

NVH troubleshooting (Transfer) ...........................TF-7

NVH troubleshooting (WT) ..................................WT-2

O

Oil cooler (engine)(QR20DE) .............................LU-13

Oil cooler (engine)(YD22DDTi) ..........................LU-25

Oil filter(QR20DE) ................................................LU-9

Oil filter(YD22DDTi) ...........................................LU-20

Oil pan (engine)(QR20DE) ...............................EM-24

Oil pan (engine)(YD22DDTi) ...........................EM-125

Oil pressure (engine)(QR20DE) ..........................LU-7

Oil pressure (engine)(YD22DDTi) ......................LU-18

Oil pump (engine)(QR20DE) .............................LU-10

Oil pump (engine)(YD22DDTi) ...........................LU-23

Oil pump regulator valve (engine)(QR20DE) .....LU-11

Oil pump regulator valve (engine)(YD22DDTi) ..LU-24

On board diagnostic system ...............EC-36,EC-401

Operating cylinder (clutch) .................................CL-11

Out side mirror .................................................GW-46

Overdrive control switch ....................AT-265,AT-387

Overheat ..........................................................EC-761

Oversize piston(QR20DE) ................................EM-85

Oversize piston(YD22DDTi) ...........................EM-204

Page 2365 of 3066

IDX-8

ALPHABETICAL INDEX

SRS - See Supplemental Restraint System .....SRS-5

SRS - Wiring diagram/LHD .............................SRS-10

SRS - Wiring diagram/RHD ............................SRS-12

SRS Trouble diagnoses ....................................SRS-7

Stall test (A/T) ......................................AT-65,AT-287

Standardized relay .............................................PG-74

START - Wiring diagram ........................SC-22,SC-23

Start signal ..........................EC-348,EC-623,EC-818

Starter ................................................................SC-21

Starting system ..................................................SC-21

Steering gear and linkage inspection ................MA-40

Steering knuckle ................................................FAX-7

Steering linkage .................................................PS-12

Steering wheel and column .......................PS-6,PS-9

Stop lamp ................................................LT-26,LT-42

Stop lamp switch ................................EC-329,EC-562

STOP/L - Wiring diagram ........................LT-26,LT-42

Strut (rear) ........................................................RSU-8

Suction control valve ........................................EC-772

Sunload sensor ...............ATC-98,ATC-100,ATC-107

Sunroof ................................................................RF-2

Super lock ..........................................................BL-24

Supplemental Restraint System .......................SRS-5

Supplemental restraint system - Wiring diagram/LHD ..

SRS-10

Supplemental restraint system - Wiring diagram/RHD .

SRS-12

Suspension .......................................................MA-41

Symbols and abbreviations .................................GI-22

Symptom matrix chart ...........EC-69,EC-417,EC-676

Synchronizer (M/T) ...............................MT-19,MT-24

System readiness test (SRT) code ....................EC-40

T

T/MTR - Wiring diagram ....................EC-275

,EC-538

Tachometer ................................................DI-4,DI-22

Tail lamp .................................................LT-30,LT-40

TAIL/L - Wiring diagram ......................................LT-30

Tailgate lamp ......................................................LT-30

TCM circuit diagram ...........................................AT-16

TCM inspection table .........................AT-126,AT-348

THEFT - Wiring diagram ....................................BL-65

Theft warning system .........................................BL-65

Thermal protector ............................................ATC-81

Thermostat(QR20DE) .......................................CO-21

Thermostat(YD22DDTi) ....................................CO-43

Three way catalyst function .............................EC-229

Three way catalyst(QR20DE) ...........................EM-22

Throttle control motor relay ................EC-279,EC-542

Throttle position sensor (TPS) ...........EC-146,EC-475

Throttle position switch ......................AT-266,AT-388

Time control system ..........................................BCS-3

Timing chain(QR20DE) .....................................EM-43

Timing chain(YD22DDTi) ..................EM-158,EM-163

TM/RLY - Wiring diagram ..................EC-281,EC-544

Torque converter installation .............AT-459,AT-556

TPS - Wiring diagram ........................EC-149,EC-479

Transfer case .....................................................TF-23

Transfer control unit inspection table ......TF-42,TF-49

Transmission case (M/T) ......................MT-18,MT-23

Trouble diagnoses ..............................................GI-10

Turbocharger charge air cooler(YD22DDTi) ...EM-114

Turbocharger(YD22DDTi) ...............................EM-119

TURN - Wiring diagram ..........................LT-17,LT-19

Turn signal lamp .....................................LT-17,LT-42

Two trip detection logic .......................EC-36,EC-401

V

Vacuum hose (brake system) ............................BR-19

Vacuum hose drawing (Engine control)EC-23,EC-388

Vacuum pump(YD22DDTi) .............................EM-131

Valve clearance(QR20DE) ...............................EM-40

Valve clearance(YD22DDTi) ...........................EM-154

Valve guide(QR20DE) ......................................EM-57

Valve guide(YD22DDTi) .................................EM-180

Valve lifter(QR20DE) ........................................EM-33

Valve lifter(YD22DDTi) ...................................EM-152

Valve seat(QR20DE) ........................................EM-58

Valve seat(YD22DDTi) ...................................EM-181

Valve spring(QR20DE) .....................................EM-60

Valve spring(YD22DDTi) ................................EM-183

VDC -Wiring diagram ......................................BRC-65

Vehicle speed sensor (VSS)EC-239,EC-513,EC-744

Ventilation air filter ........................................ATC-114

Viscosity number (SAE) ....................................MA-18

VSS - Wiring diagram .........EC-241,EC-515,EC-745

W

Warning chime ....................................................DI-52

Warning lamps ....................................................DI-39

Washer, front .....................................................WW-4

Washer, rear ....................................................WW-13

Water control valve(QR20DE) ..........................CO-21

Water pump(QR20DE) .....................................CO-19

Water pump(YD22DDTi) ...................................CO-40

Water temperature gauge ..........................DI-4,DI-22

Weatherstrip - See Exterior ...............................BL-10

Wheel alignment (front) ....................................FSU-6

Wheel alignment (rear) .....................................RSU-6

Wheel balance ..................................................MA-38

Wheel bearing (front axle) .................................FAX-7

Wheel bearing (rear) .........................................RAX-6

Wheel hub (front) ...............................................FAX-7

Wheel hub (rear) ...............................................RAX-6

Wheel sensor(VDC) ......................................BRC-119

Wheel sensors (ABS) .....................................BRC-48

WINDOW - Wiring diagram ..............................GW-24

Window, back ....................................................GW-7

Window, back door ............................................GW-7

Window, door ......................................GW-41,GW-43

Window, rear side ..............................................GW-5

Window, side - See Rear side window ..............GW-5

Windshield .........................................................GW-3

Page 2473 of 3066

![NISSAN X-TRAIL 2003 Electronic Service Manual ENGINE OIL

LU-7

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

ENGINE OILPFP:KLA92

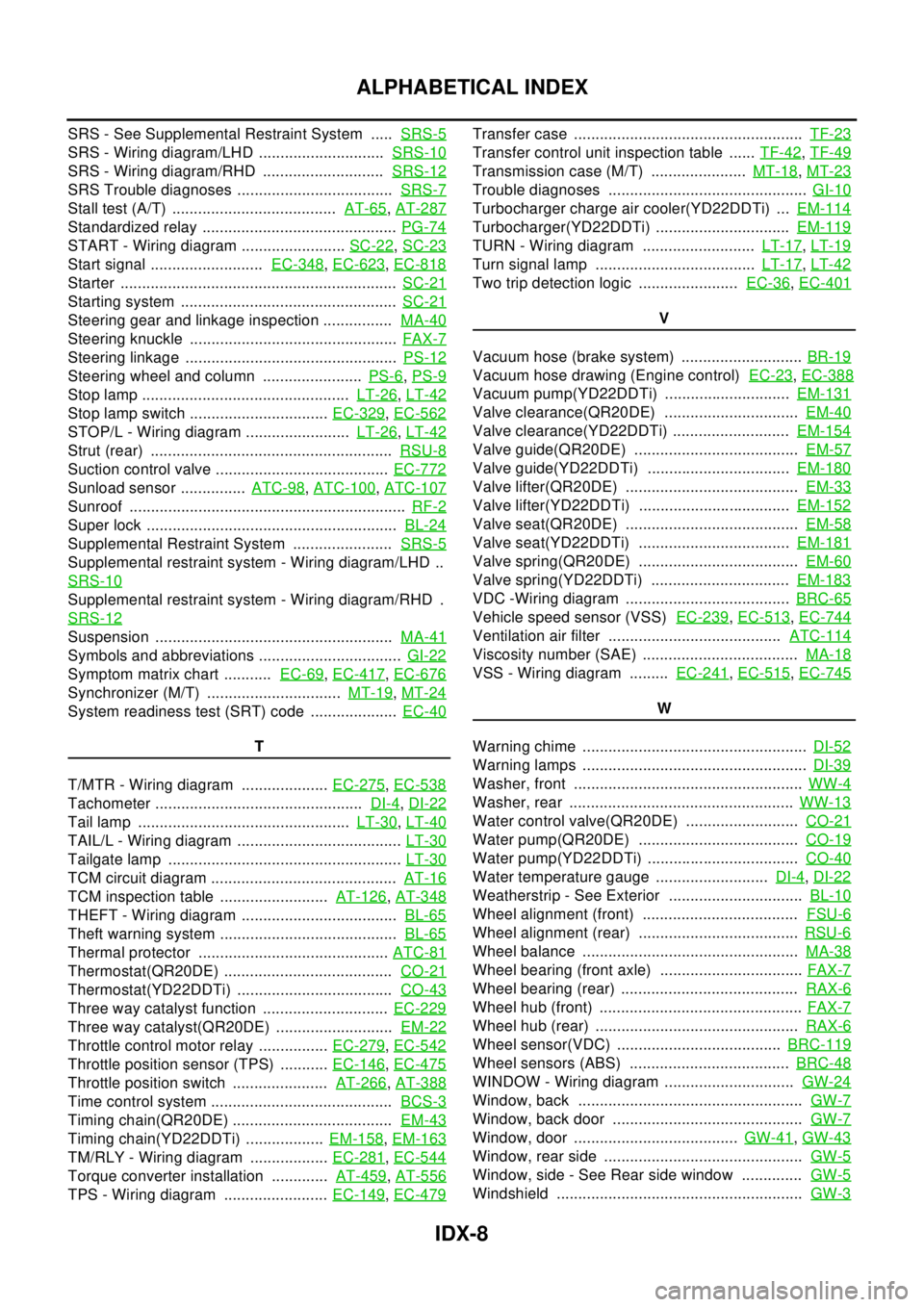

InspectionEBS009SU

OIL LEVEL AND MUDDINESS

lBefore starting the engine, check the oil level. If the engine is

already started, st NISSAN X-TRAIL 2003 Electronic Service Manual ENGINE OIL

LU-7

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

ENGINE OILPFP:KLA92

InspectionEBS009SU

OIL LEVEL AND MUDDINESS

lBefore starting the engine, check the oil level. If the engine is

already started, st](/img/5/57402/w960_57402-2472.png)

ENGINE OIL

LU-7

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

ENGINE OILPFP:KLA92

InspectionEBS009SU

OIL LEVEL AND MUDDINESS

lBefore starting the engine, check the oil level. If the engine is

already started, stop it and allow 10 minutes before checking.

lCheck that the oil level is within the range shown in the figure.

lIf it is out of range, adjust it.

lCheck the oil for white turbidity or remarkable contamination.

lIf the oil becomes turbid and white, it is highly probable that it is

contaminated with coolant. Find the cause and repair.

OIL LEAKAGE

Check for oil leakage around the following area.

lOil pan

lOil pan drain plug

lOil pressure switch

lOil filter

lIntake valve timing control cover

lFront cover

lMating surface between cylinder block and cylinder head

lMating surface between cylinder head and rocker cover

lCrankshaft oil seal.

OIL PRESSURE CHECK

WA RN ING:

lBe careful not to burn yourself, as the engine oil is hot.

lOil pressure check should be done in “ Parking position”.

1. Check the oil level.

2. Remove the under cover.

3. Remove the oil pressure switch to connect the oil pressure

gauge.

4. After warming up the engine, check that oil pressure corre-

sponding to the engine speed is produced.

Engine oil pressure [Oil temperature is 80°C (176°F)]

5. After checking, install the oil pressure switch as follows.

a. Remove old sealant adhering to the switch and engine.

b. Apply thread sealant.

Use Genuine Liquid Gasket or equivalent.

PBIC0249E

KBIA0275E

Engine speed (rpm) Idle speed 2,000 6,000

Engine pressure

kPa (bar.kg/cm

2,psi)Approx. 98 (0.98, 1.0, 14) or more Approx. 294 (2.9, 3.0, 43) or more Approx. 392 (3.9, 4.0, 57) or more

: 12.3 - 17.2 N·m (1.25 - 1.75 kg-m, 10 - 12 ft-lb)

Page 2484 of 3066

![NISSAN X-TRAIL 2003 Electronic Service Manual LU-18

[YD22DDTi]

ENGINE OIL

ENGINE OIL

PFP:KLA92

InspectionEBS00B03

OIL LEVEL AND MUDDINESS

lBefore starting the engine, check the oil level. If the engine is

already started, stop it and allow 10 min NISSAN X-TRAIL 2003 Electronic Service Manual LU-18

[YD22DDTi]

ENGINE OIL

ENGINE OIL

PFP:KLA92

InspectionEBS00B03

OIL LEVEL AND MUDDINESS

lBefore starting the engine, check the oil level. If the engine is

already started, stop it and allow 10 min](/img/5/57402/w960_57402-2483.png)

LU-18

[YD22DDTi]

ENGINE OIL

ENGINE OIL

PFP:KLA92

InspectionEBS00B03

OIL LEVEL AND MUDDINESS

lBefore starting the engine, check the oil level. If the engine is

already started, stop it and allow 10 minutes before checking.

lCheck that the oil level is within the range shown in the figure.

lIf it is out of range, adjust it.

lCheck the oil for white turbidity or remarkable contamination.

lIf the oil becomes turbid and white, it is highly probable that it is

contaminated with coolant. Find the cause and repair.

OIL LEAKAGE

Check for oil leakage around the following area.

lOil pan

lOil pan drain plug

lOil pressure switch

lOil filter bracket

lVacuum pump

lCylinder head rear cover assembly

lChain case

lOil pump housing

lMating surface between cylinder block and cylinder head

lMating surface between cylinder head and rocker cover

lOil cooler.

lCrankshaft oil seal

OIL PRESSURE CHECK

WAR NIN G:

lBe careful not to burn yourself, as the engine oil is hot.

lOil pressure check should be done in “ Parking position”.

1. Check the oil level.

2. Remove the under cover.

3. Remove the oil pressure switch to connect the oil pressure

gauge.

4. After warming up the engine, check that oil pressure corre-

sponding to the engine speed is produced.

Engine oil pressure [Oil temperature is 80°C (176°F)]

5. After checking, install the oil pressure switch as follows.

a. Remove old sealant adhering to the switch and engine.

b. Apply thread sealant.

Use Genuine Liquid Gasket or equivalent.

SBIA0122E

SBIA0123E

Engine speed (rpm) Idle speed 2,000 4,000

Engine pressure

kPa (bar, kg/cm

2,psi)Approx. 140 (1.40, 1.43, 20.3) or

moreApprox. 270 (2.69, 2.75, 39.1) or

moreApprox. 430 (4.29, 4.38, 62.3) or

more

Page 2493 of 3066

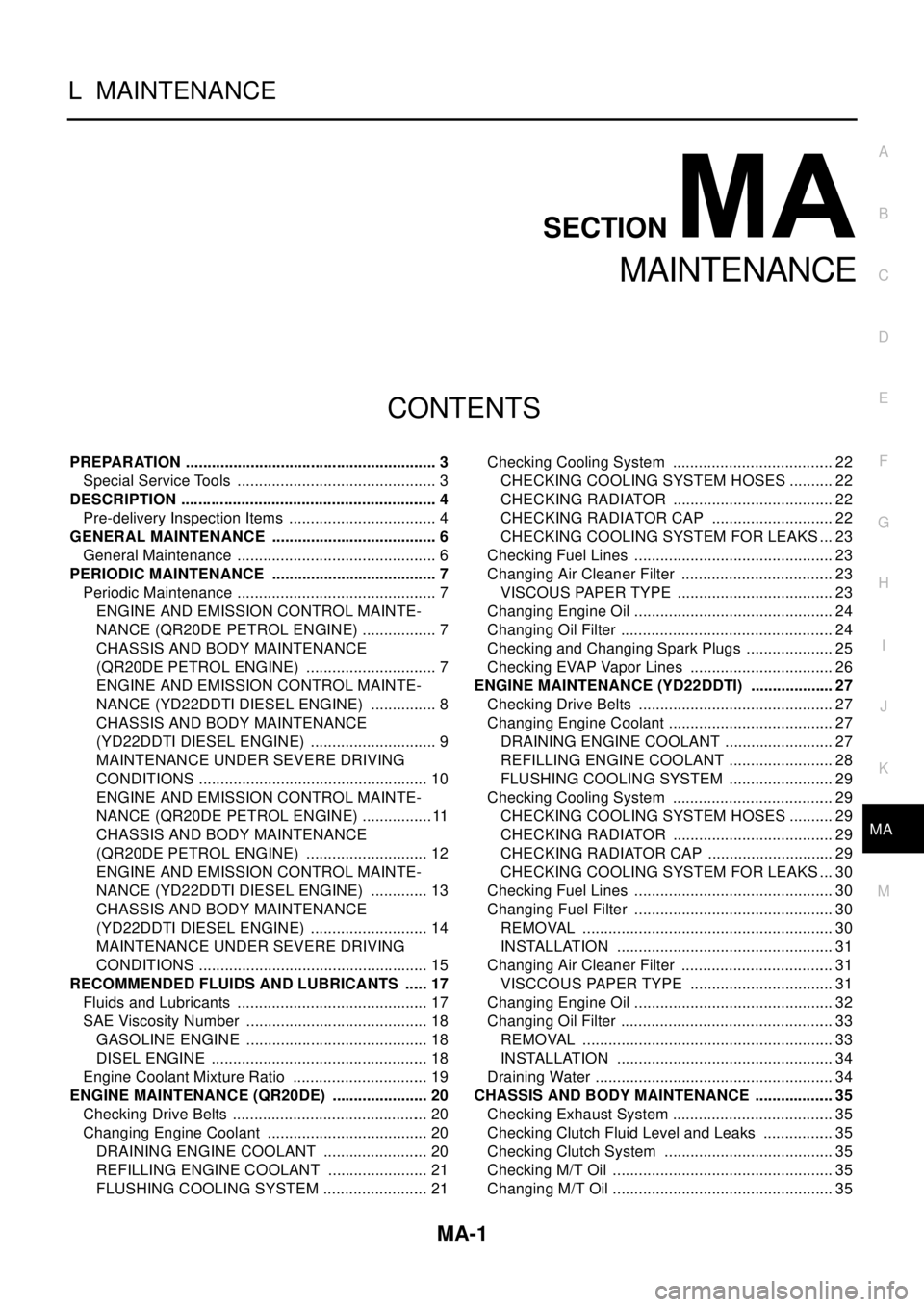

MA-1

MAINTENANCE

L MAINTENANCE

CONTENTS

C

D

E

F

G

H

I

J

K

M

SECTION

A

B

MA

MAINTENANCE

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

DESCRIPTION ............................................................ 4

Pre-delivery Inspection Items ................................... 4

GENERAL MAINTENANCE ....................................... 6

General Maintenance ............................................... 6

PERIODIC MAINTENANCE ....................................... 7

Periodic Maintenance ............................................... 7

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (QR20DE PETROL ENGINE) .................. 7

CHASSIS AND BODY MAINTENANCE

(QR20DE PETROL ENGINE) ............................... 7

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD22DDTI DIESEL ENGINE) ................ 8

CHASSIS AND BODY MAINTENANCE

(YD22DDTI DIESEL ENGINE) .............................. 9

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 10

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (QR20DE PETROL ENGINE) .................11

CHASSIS AND BODY MAINTENANCE

(QR20DE PETROL ENGINE) ............................. 12

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD22DDTI DIESEL ENGINE) .............. 13

CHASSIS AND BODY MAINTENANCE

(YD22DDTI DIESEL ENGINE) ............................ 14

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 15

RECOMMENDED FLUIDS AND LUBRICANTS ...... 17

Fluids and Lubricants ............................................. 17

SAE Viscosity Number ........................................... 18

GASOLINE ENGINE ........................................... 18

DISEL ENGINE ................................................... 18

Engine Coolant Mixture Ratio ................................ 19

ENGINE MAINTENANCE (QR20DE) ....................... 20

Checking Drive Belts .............................................. 20

Changing Engine Coolant ...................................... 20

DRAINING ENGINE COOLANT ......................... 20

REFILLING ENGINE COOLANT ........................ 21

FLUSHING COOLING SYSTEM ......................... 21Checking Cooling System ...................................... 22

CHECKING COOLING SYSTEM HOSES ........... 22

CHECKING RADIATOR ...................................... 22

CHECKING RADIATOR CAP ............................. 22

CHECKING COOLING SYSTEM FOR LEAKS ... 23

Checking Fuel Lines ............................................... 23

Changing Air Cleaner Filter .................................... 23

VISCOUS PAPER TYPE ..................................... 23

Changing Engine Oil ............................................... 24

Changing Oil Filter .................................................. 24

Checking and Changing Spark Plugs ..................... 25

Checking EVAP Vapor Lines .................................. 26

ENGINE MAINTENANCE (YD22DDTI) .................... 27

Checking Drive Belts .............................................. 27

Changing Engine Coolant ....................................... 27

DRAINING ENGINE COOLANT .......................... 27

REFILLING ENGINE COOLANT ......................... 28

FLUSHING COOLING SYSTEM ......................... 29

Checking Cooling System ...................................... 29

CHECKING COOLING SYSTEM HOSES ........... 29

CHECKING RADIATOR ...................................... 29

CHECKING RADIATOR CAP .............................. 29

CHECKING COOLING SYSTEM FOR LEAKS ... 30

Checking Fuel Lines ............................................... 30

Changing Fuel Filter ............................................... 30

REMOVAL ........................................................... 30

INSTALLATION ................................................... 31

Changing Air Cleaner Filter .................................... 31

VISCCOUS PAPER TYPE .................................. 31

Changing Engine Oil ............................................... 32

Changing Oil Filter .................................................. 33

REMOVAL ........................................................... 33

INSTALLATION ................................................... 34

Draining Water ........................................................ 34

CHASSIS AND BODY MAINTENANCE ................... 35

Checking Exhaust System ...................................... 35

Checking Clutch Fluid Level and Leaks ................. 35

Checking Clutch System ........................................ 35

Checking M/T Oil .................................................... 35

Changing M/T Oil .................................................... 35

Page 2496 of 3066

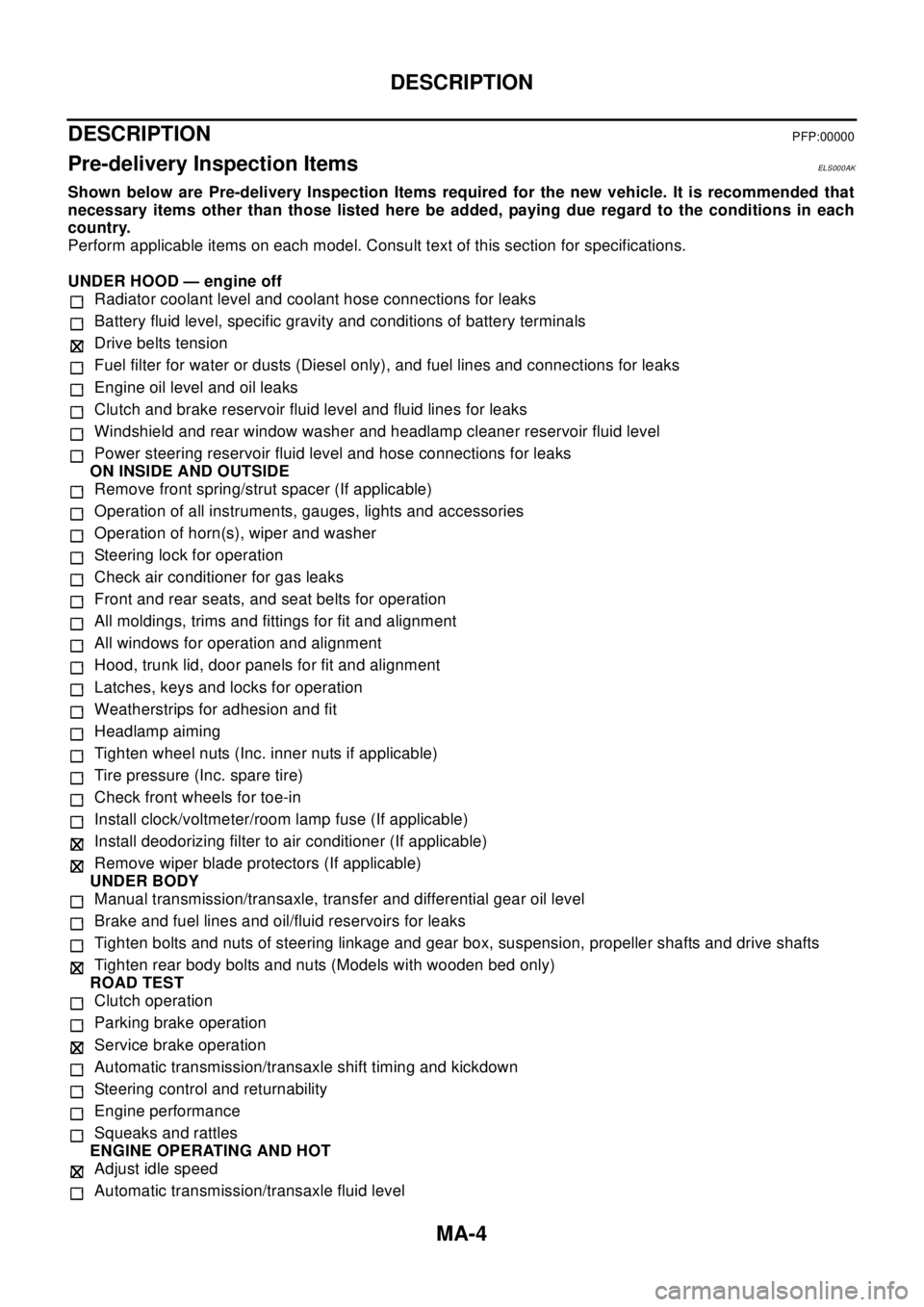

MA-4

DESCRIPTION

DESCRIPTION

PFP:00000

Pre-delivery Inspection ItemsELS000AK

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Page 2499 of 3066

PERIODIC MAINTENANCE

MA-7

C

D

E

F

G

H

I

J

K

MA

B

MA

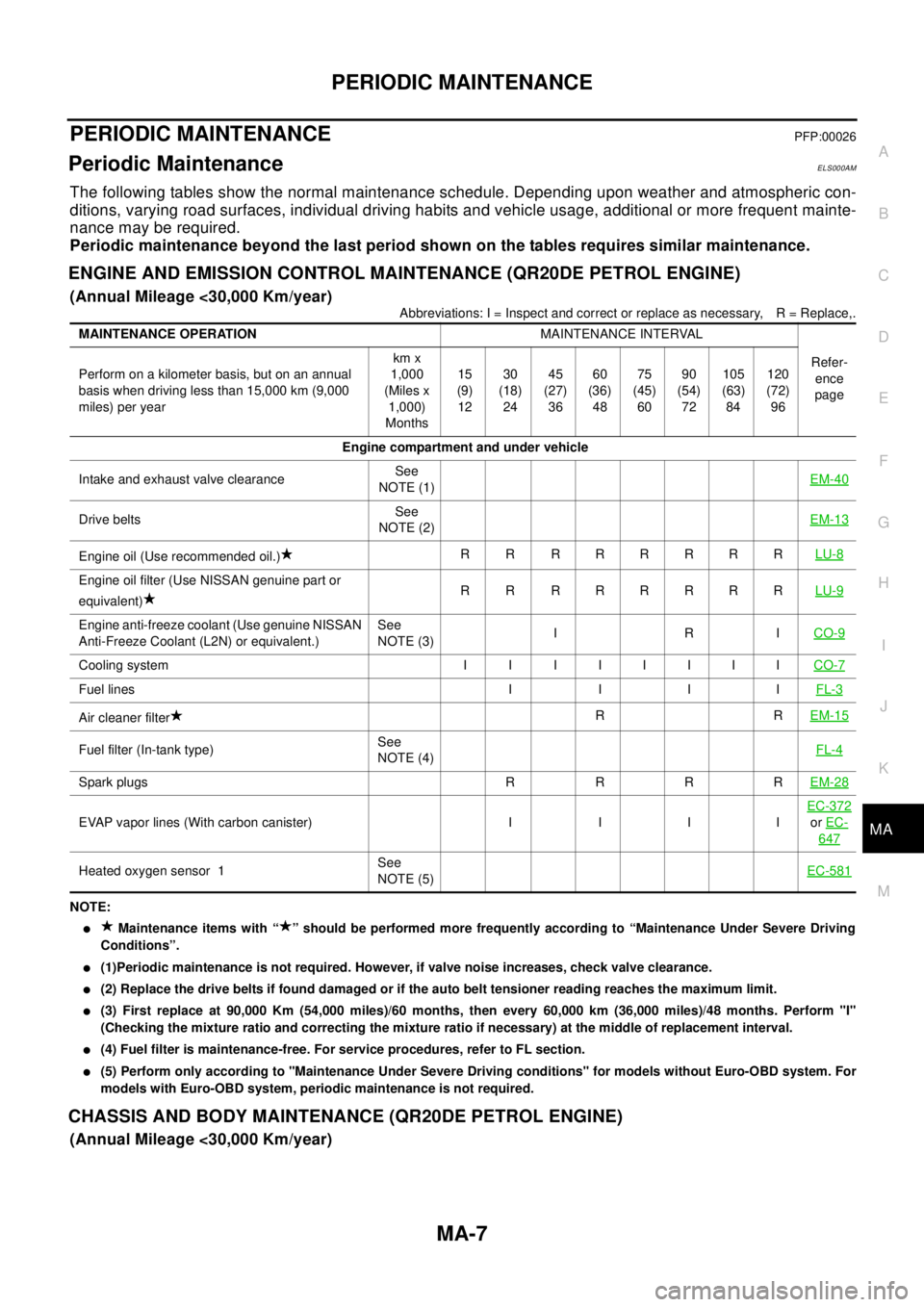

PERIODIC MAINTENANCEPFP:00026

Periodic MaintenanceELS000AM

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

ENGINE AND EMISSION CONTROL MAINTENANCE (QR20DE PETROL ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,.

NOTE:

lMaintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

l(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

l(2) Replace the drive belts if found damaged or if the auto belt tensioner reading reaches the maximum limit.

l(3) First replace at 90,000 Km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform "I"

(Checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

l(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

l(5) Perform only according to "Maintenance Under Severe Driving conditions" for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (QR20DE PETROL ENGINE)

(Annual Mileage <30,000 Km/year)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual

basis when driving less than 15,000 km (9,000

miles) per yearkm x

1,000

(Miles x

1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Engine compartment and under vehicle

Intake and exhaust valve clearanceSee

NOTE (1)EM-40

Drive beltsSee

NOTE (2)EM-13

Engine oil (Use recommended oil.)R R RRRRRRLU-8

Engine oil filter (Use NISSAN genuine part or

equivalent)R R RRRRRRLU-9

Engine anti-freeze coolant (Use genuine NISSAN

Anti-Freeze Coolant (L2N) or equivalent.)See

NOTE (3)IRICO-9

Coolingsystem I I IIIIIICO-7

Fuel lines I I I IFL-3

Air cleaner filterRREM-15

Fuel filter (In-tank type)See

NOTE (4)FL-4

Spark plugs R R R REM-28

EVAP vapor lines (With carbon canister) I I I IEC-372orEC-

647

Heated oxygen sensor 1See

NOTE (5)EC-581

Page 2500 of 3066

MA-8

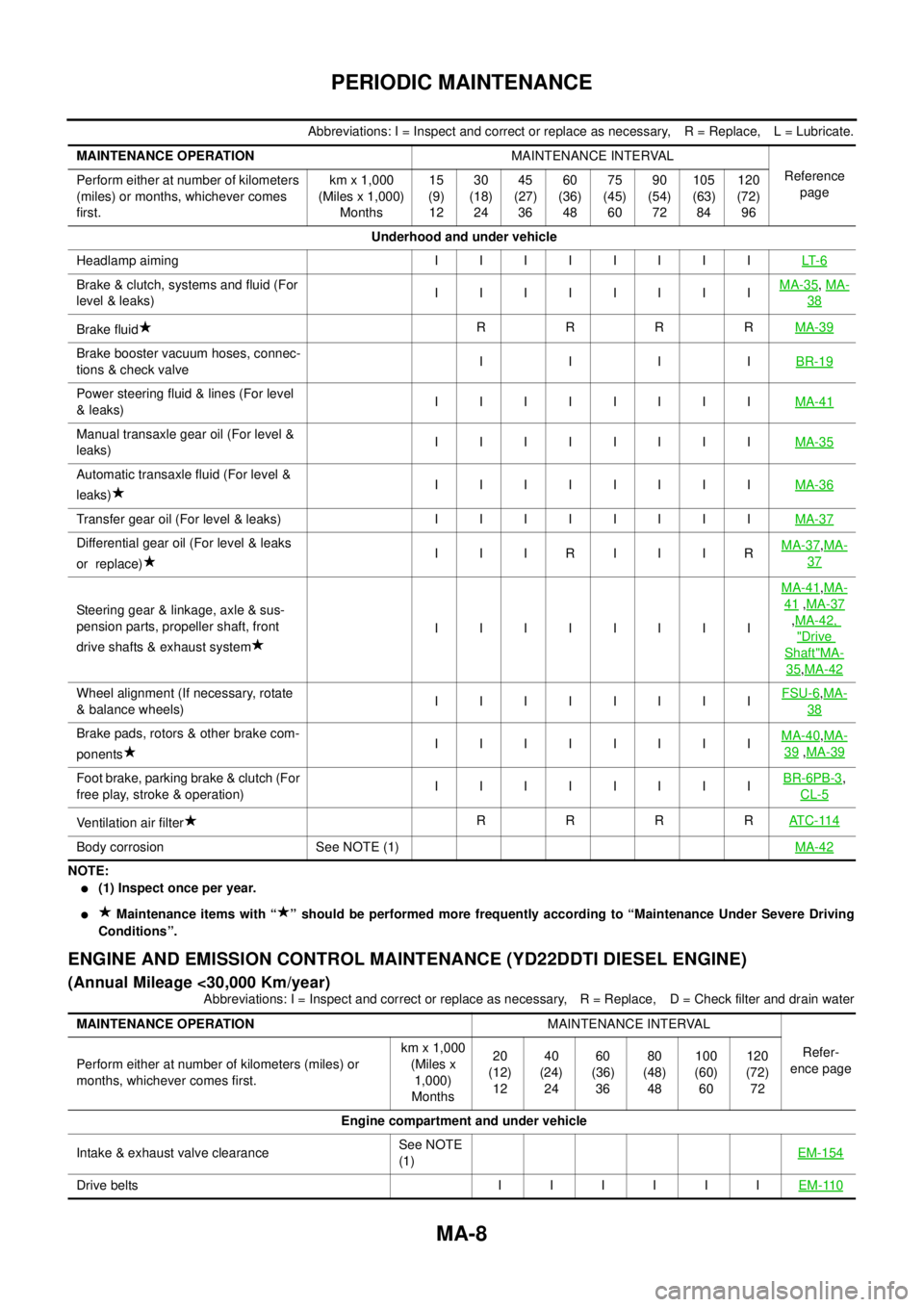

PERIODIC MAINTENANCE

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

NOTE:

l(1) Inspect once per year.

lMaintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

ENGINE AND EMISSION CONTROL MAINTENANCE (YD22DDTI DIESEL ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, D = Check filter and drain water MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers

(miles) or months, whichever comes

first.km x 1,000

(Miles x 1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Underhood and under vehicle

Headlampaiming IIIIIIIILT- 6

Brake & clutch, systems and fluid (For

level & leaks)IIIIIIIIMA-35,MA-

38

Brake fluidRRRRMA-39

Brake booster vacuum hoses, connec-

tions & check valveIIIIBR-19

Power steering fluid & lines (For level

&leaks)IIIIIIIIMA-41

Manual transaxle gear oil (For level &

leaks)IIIIIIIIMA-35

Automatic transaxle fluid (For level &

leaks)IIIIIIIIMA-36

Transfer gear oil (For level & leaks) I I I I I I I IMA-37

Differential gear oil (For level & leaks

or replace)I I IRI I IRMA-37,MA-

37

Steering gear & linkage, axle & sus-

pension parts, propeller shaft, front

drive shafts & exhaust systemIIIIIIIIMA-41

,MA-

41,MA-37

,MA-42,

"Drive

Shaft"MA-

35,MA-42

Wheel alignment (If necessary, rotate

& balance wheels)IIIIIIIIFSU-6,MA-

38

Brake pads, rotors & other brake com-

ponentsIIIIIIIIMA-40,MA-

39,MA-39

Foot brake, parking brake & clutch (For

free play, stroke & operation)IIIIIIIIBR-6PB-3,

CL-5

Ventilation air filterRRRRAT C - 11 4

Body corrosion See NOTE (1)MA-42

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence page Perform either at number of kilometers (miles) or

months, whichever comes first.km x 1,000

(Miles x

1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

Engine compartment and under vehicle

Intake & exhaust valve clearanceSee NOTE

(1)EM-154

Drivebelts IIIIIIEM-110

Page 2501 of 3066

PERIODIC MAINTENANCE

MA-9

C

D

E

F

G

H

I

J

K

MA

B

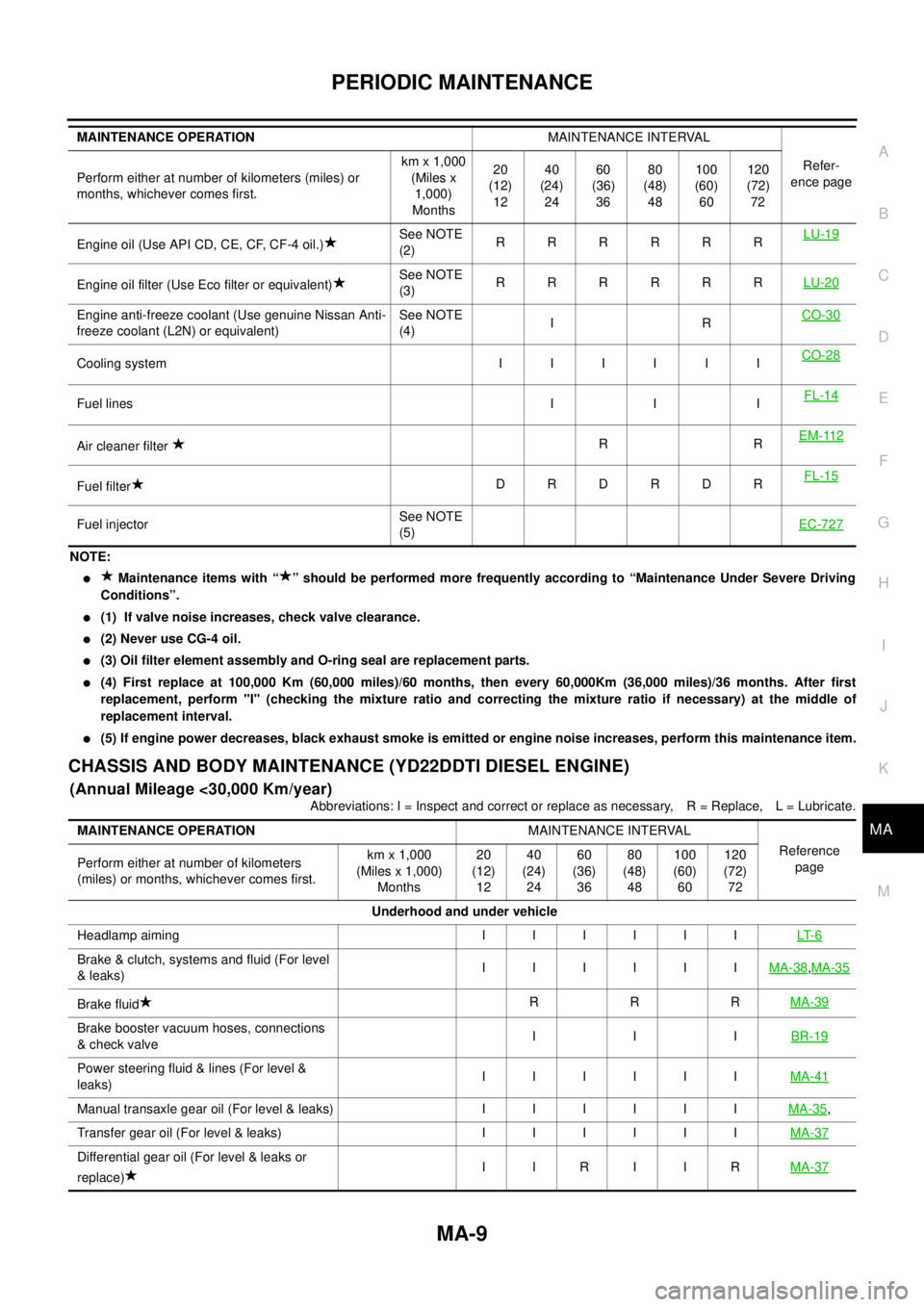

MA

NOTE:

lMaintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

l(1) If valve noise increases, check valve clearance.

l(2) Never use CG-4 oil.

l(3) Oil filter element assembly and O-ring seal are replacement parts.

l(4) First replace at 100,000 Km (60,000 miles)/60 months, then every 60,000Km (36,000 miles)/36 months. After first

replacement, perform "I" (checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of

replacement interval.

l(5) If engine power decreases, black exhaust smoke is emitted or engine noise increases, perform this maintenance item.

CHASSIS AND BODY MAINTENANCE (YD22DDTI DIESEL ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate. Engine oil (Use API CD, CE, CF, CF-4 oil.)See NOTE

(2)RRRRRRLU-19

Engine oil filter (Use Eco filter or equivalent)See NOTE

(3)RRRRRRLU-20

Engine anti-freeze coolant (Use genuine Nissan Anti-

freeze coolant (L2N) or equivalent)See NOTE

(4)IRCO-30

Coolingsystem IIIIIICO-28

Fuel lines I I IFL-14

Air cleaner filterRREM-112

Fuel filterDRDRDRFL-15

Fuel injectorSee NOTE

(5)EC-727

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence page Perform either at number of kilometers (miles) or

months, whichever comes first.km x 1,000

(Miles x

1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers

(miles) or months, whichever comes first.km x 1,000

(Miles x 1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

Underhood and under vehicle

Headlampaiming IIIIIILT- 6

Brake & clutch, systems and fluid (For level

& leaks)IIIIIIMA-38,MA-35

Brake fluidRRRMA-39

Brake booster vacuum hoses, connections

& check valveIIIBR-19

Power steering fluid & lines (For level &

leaks)IIIIIIMA-41

Manualtransaxlegearoil(Forlevel&leaks) IIIIIIMA-35,

Transfergearoil(Forlevel&leaks) IIIIIIMA-37

Differential gear oil (For level & leaks or

replace)IIRIIRMA-37