steering wheel NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1 of 3066

MODEL T30 SERIES

2001 NISSAN EUROPE N.V.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe N.V., Paris, France.

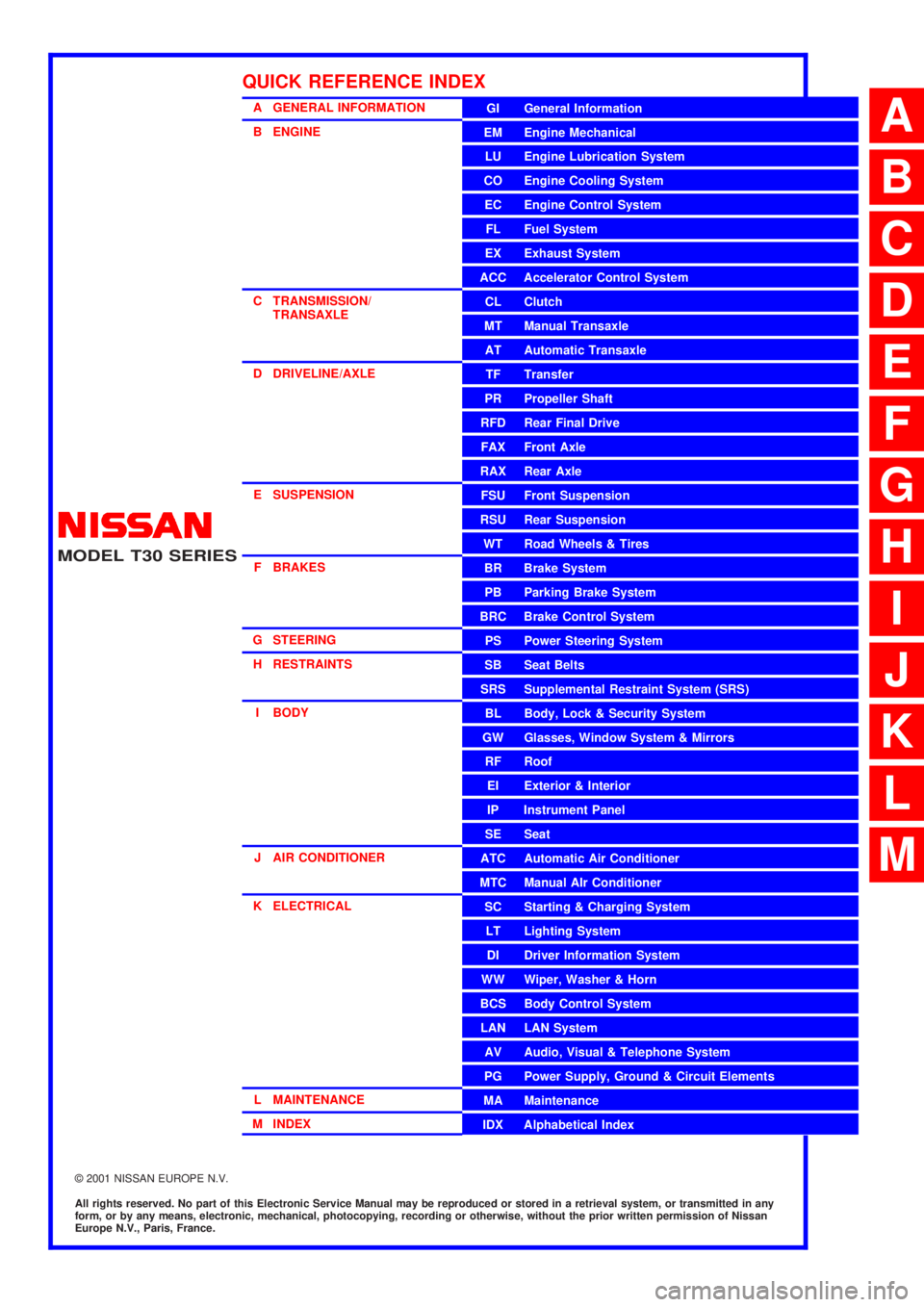

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 839 of 3066

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

BR-5

C

D

E

G

H

I

J

K

L

MA

B

BR

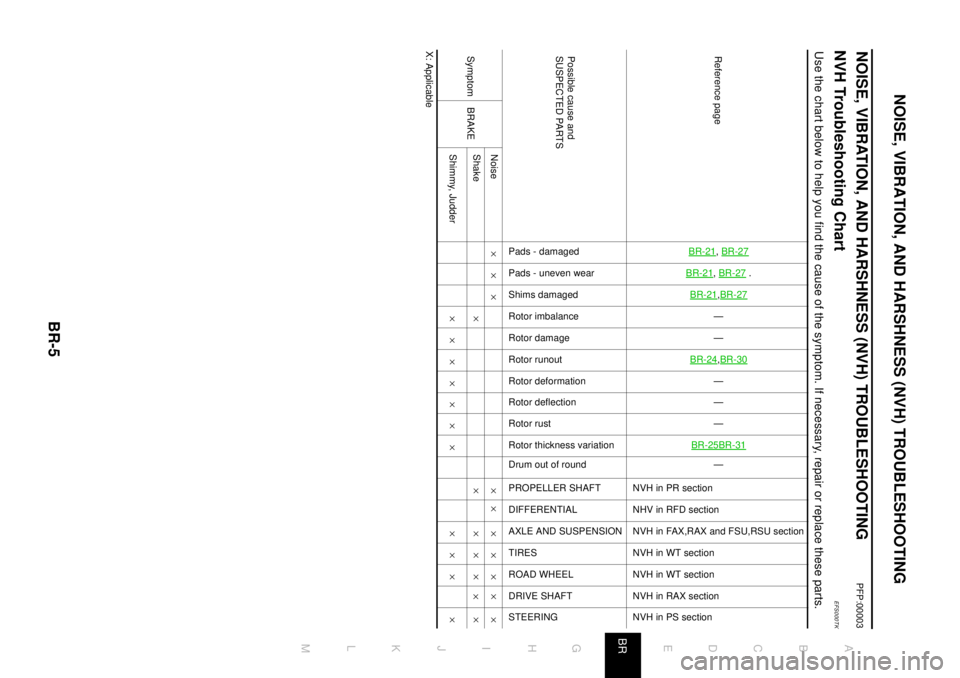

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEFS000TK

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

X: ApplicableReference page

BR-21

,BR-27

BR-21

,BR-27

.

BR-21

,BR-27—

—

BR-24,BR-30—

—

—

BR-25BR-31—

NVHinPRsection

NHV in RFD section

NVH in FAX,RAX and FSU,RSU section

NVH in WT section

NVH in WT section

NVH in RAX section

NVH in PS section

Possible cause and

SUSPECTED PARTS

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom BRAKENoise´´´ ´´ ´´´

´´

Shake´ ´ ´´´

´´

Shimmy, Judder´´´´´´´ ´´´ ´

Page 869 of 3066

BRC-1

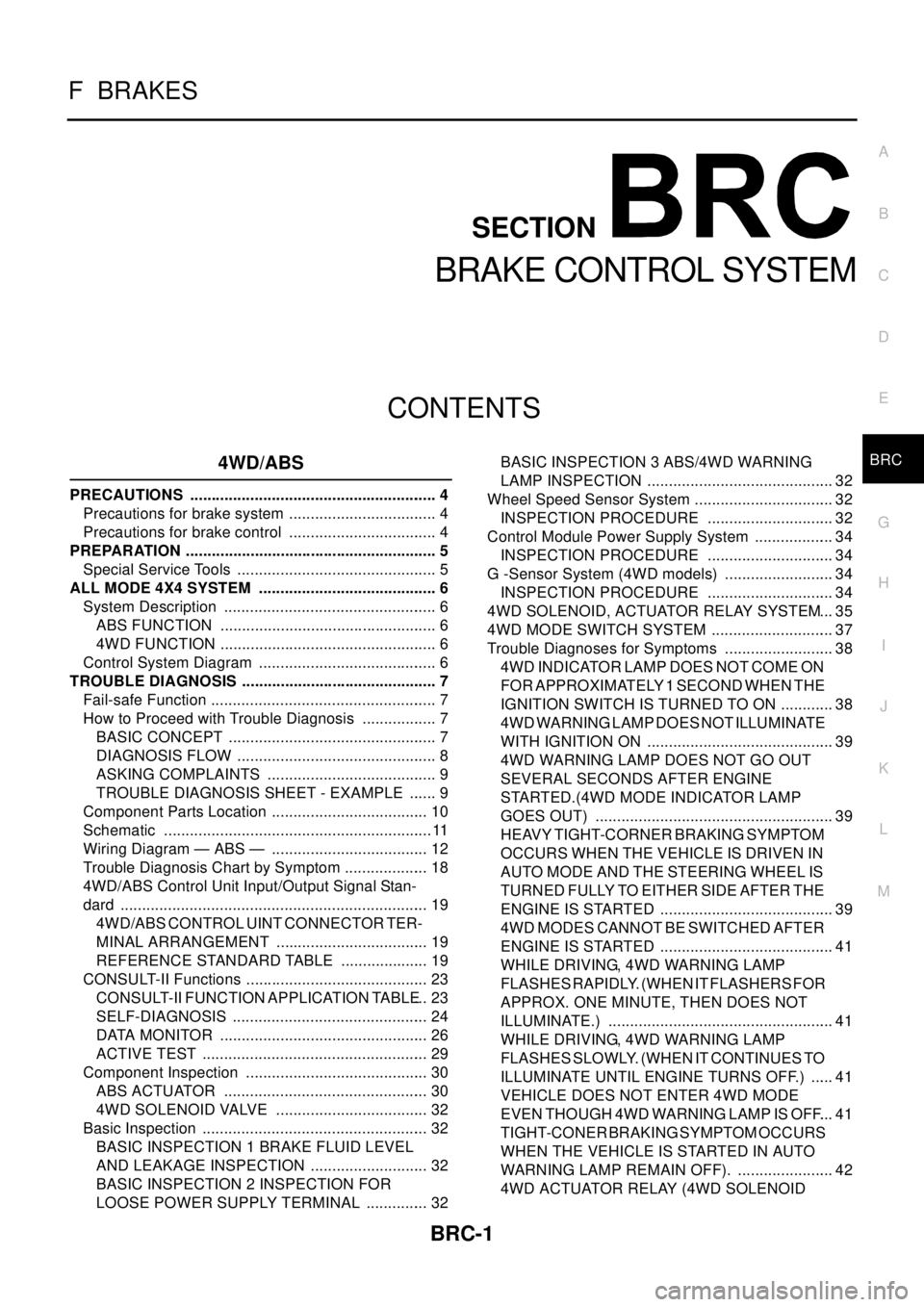

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTION

A

B

BRC

BRAKE CONTROL SYSTEM

4WD/ABS

PRECAUTIONS .......................................................... 4

Precautions for brake system ................................... 4

Precautions for brake control ................................... 4

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

ALL MODE 4X4 SYSTEM .......................................... 6

System Description .................................................. 6

ABS FUNCTION ................................................... 6

4WD FUNCTION ................................................... 6

Control System Diagram .......................................... 6

TROUBLE DIAGNOSIS .............................................. 7

Fail-safe Function ..................................................... 7

How to Proceed with Trouble Diagnosis .................. 7

BASIC CONCEPT ................................................. 7

DIAGNOSIS FLOW ............................................... 8

ASKING COMPLAINTS ........................................ 9

TROUBLE DIAGNOSIS SHEET - EXAMPLE ....... 9

Component Parts Location ..................................... 10

Schematic ...............................................................11

Wiring Diagram — ABS — ..................................... 12

Trouble Diagnosis Chart by Symptom .................... 18

4WD/ABS Control Unit Input/Output Signal Stan-

dard ........................................................................ 19

4WD/ABS CONTROL UINT CONNECTOR TER-

MINAL ARRANGEMENT .................................... 19

REFERENCE STANDARD TABLE ..................... 19

CONSULT-II Functions ........................................... 23

CONSULT-II FUNCTION APPLICATION TABLE... 23

SELF-DIAGNOSIS .............................................. 24

DATA MONITOR ................................................. 26

ACTIVE TEST ..................................................... 29

Component Inspection ........................................... 30

ABS ACTUATOR ................................................ 30

4WD SOLENOID VALVE .................................... 32

Basic Inspection ..................................................... 32

BASIC INSPECTION 1 BRAKE FLUID LEVEL

AND LEAKAGE INSPECTION ............................ 32

BASIC INSPECTION 2 INSPECTION FOR

LOOSE POWER SUPPLY TERMINAL ............... 32BASIC INSPECTION 3 ABS/4WD WARNING

LAMP INSPECTION ............................................ 32

Wheel Speed Sensor System ................................. 32

INSPECTION PROCEDURE .............................. 32

Control Module Power Supply System ................... 34

INSPECTION PROCEDURE .............................. 34

G -Sensor System (4WD models) .......................... 34

INSPECTION PROCEDURE .............................. 34

4WD SOLENOID, ACTUATOR RELAY SYSTEM... 35

4WD MODE SWITCH SYSTEM ............................. 37

Trouble Diagnoses for Symptoms .......................... 38

4WD INDICATOR LAMP DOES NOT COME ON

FORAPPROXIMATELY1SECONDWHENTHE

IGNITION SWITCH IS TURNED TO ON ............. 38

4WD WARNING LAMP DOES NOT ILLUMINATE

WITH IGNITION ON ............................................ 39

4WD WARNING LAMP DOES NOT GO OUT

SEVERAL SECONDS AFTER ENGINE

STARTED.(4WD MODE INDICATOR LAMP

GOES OUT) ........................................................ 39

HEAVY TIGHT-CORNER BRAKING SYMPTOM

OCCURS WHEN THE VEHICLE IS DRIVEN IN

AUTO MODE AND THE STEERING WHEEL IS

TURNED FULLY TO EITHER SIDE AFTER THE

ENGINE IS STARTED ......................................... 39

4WD MODES CANNOT BE SWITCHED AFTER

ENGINE IS STARTED ......................................... 41

WHILE DRIVING, 4WD WARNING LAMP

FLASHES RAPIDLY. (WHEN IT FLASHERSFOR

APPROX. ONE MINUTE, THEN DOES NOT

ILLUMINATE.) ..................................................... 41

WHILE DRIVING, 4WD WARNING LAMP

FLASHES SLOWLY. (WHEN IT CONTINUES TO

ILLUMINATE UNTIL ENGINE TURNS OFF.) ...... 41

VEHICLE DOES NOT ENTER 4WD MODE

EVEN THOUGH 4WD WARNING LAMP IS OFF.... 41

TIGHT-CONER BRAKING SYMPTOM OCCURS

WHEN THE VEHICLE IS STARTED IN AUTO

WARNING LAMP REMAIN OFF). ....................... 42

4WD ACTUATOR RELAY (4WD SOLENOID

Page 870 of 3066

BRC-2

ACTUATOR RELAY) TURNS ON/OFF FRE-

QUENTLY ............................................................ 42

ABS warning lamp does not illuminate. (ABS warn-

ing lamp does not come on when the ignition switch

is turned ON.) ......................................................... 42

ABS warning lamp illuminates with ignition ON, but

does not illuminates after a few seconds. (ABS

warning lamp has illuminated.) ............................... 42

4WD warning lamp does not illuminate with ignition

ON. ......................................................................... 43

4WD warning lamp does not go out several seconds

after engine is started. (Drive mode indicator lamp

goes out.) ................................................................ 43

Heavy tight-corner braking symptom occurs when

the vehicle is driven in AUTO mode and the steering

wheel is turned fully to either side after the engine

is started. ................................................................ 44

Drive modes cannot be switched after engine is

started. .................................................................... 45

Wheel driving, 4WD warning lamp flashes rapidly.

(When it flashes for Approx. one minute, then does

not illuminate.) ........................................................ 45

Wheel driving, 4WD warning lamp flashes slowly.

(When it continues to illuminate until engine turns

OFF.) ....................................................................... 45

Vehicle does not enter 4WD mode even though

4WD warning lamp is off. ........................................ 46

Tight-corner braking symptom occurs when the

vehicle is started in AUTO mode (4WD warning lamp

remain OFF). .......................................................... 46

E-TS actuator relay (4WD solenoid actuator relay)

turns ON/OFF frequently. ........................................ 46

Inspection of drive mode change-over switch path... 47

WHEEL SENSORS ................................................... 48

Removal and Installation ........................................ 48

G-SENSOR (4WD MODEL ONLY) ............................ 49

Removal and Installation ........................................ 49

SENSOR ROTOR ...................................................... 50

Removal and Installation ........................................ 50

REMOVAL ........................................................... 50

INSTALLATION .................................................... 50

ACTUATOR ............................................................... 51

Removal and Installation ........................................ 51

REMOVAL ........................................................... 51

INSTALLATION .................................................... 51

ESP/TCS/ABS

PRECAUTIONS ......................................................... 52

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................. 52

Precautions for Brake System ................................ 52

Precautions for Brake Control ................................ 52

Precautions for CAN System .................................. 53

FOR INSPECTION .............................................. 53

FOR HARNESS REPAIR .................................... 53ON-VEHICLE SERVICE ............................................54

Adjustment of Neutral Position of Steering Angle

Sensor .....................................................................54

GENERAL INFORMATION .......................................56

Fail-Safe ..................................................................56

ABS SYSTEM ......................................................56

ESP/TCS SYSTEM ..............................................56

Hydraulic Circuit ......................................................56

ABS Functions ........................................................56

TCS Functions ........................................................57

ESP Functions ........................................................57

System Diagram .....................................................58

CAN COMMUNICATION ...........................................59

System Description .................................................59

FOR M/T MODELS ..............................................59

TROUBLE DIAGNOSIS ............................................60

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ......................................................60

INTRODUCTION .................................................60

WORK FLOW ......................................................61

ASKING COMPLAINTS .......................................62

EXAMPLE OF DIAGNOSIS SHEET ....................62

Component Parts and Harness Connector Location... 63

Schematic ...............................................................64

Wiring Diagram —ESP/TCS/ABS— .....................65

Control Unit Input/Output Signal Standard ..............71

STANDARDS USING A CIRCUIT TESTER AND

OSCILLOSCOPE .................................................71

STANDARDS WITH CONSULT-II ........................75

Functions of CONSULT-II .......................................77

CONSULT-II MAINLY FUNCTION APPLICA-

TION TO ESP/TCS/ABS ......................................77

SELF-DIAGNOSIS ...............................................78

DATA MONITOR ..................................................81

ACTIVE TEST ......................................................84

For Correct and Quick Diagnosis ............................88

PRECAUTIONS FOR TROUBLE DIAGNOSIS ... 88

Basic Inspection ......................................................89

PRELIMINARY CHECK 1: (BRAKE FLUID

LEVEL AND LEAK INSPECTION) .......................89

PRELIMINARY CHECK 2: (INSPECTION FOR

LOOSE POWER SUPPLY TERMINAL) ...............89

PRELIMINARY CHECK 3: (INSPECTION FOR

ABS WARNING LAMP, ESP OFF INDICATOR

LAMP, AND SLIP INDICATOR LAMP) .................89

Inspection 1 Wheel Speed Sensor and Circuit .......90

Inspection 2 Engine System ...................................92

Inspection 3 ESP/TCS/ABS Control Unit System ...92

Inspection 4 Pressure Sensor and the Circuit

between Pressure Sensor and ESP/TCS/ABS Con-

trol Unit. ...................................................................93

Inspection 5 Steering Angle Sensor and the Circuit

between Steering Angle Sensor and ESP/TCS/ABS

Control Unit. ............................................................94

Inspection 6 Yaw Rate Sensor/ Side G sensor and

the Circuit between Yaw Rate Sensor/ Side G sen-

sor and ESP/TCS/ABS Control Unit. ......................95

Inspection 7 Solenoid Valve, ESP Switch-over Sole-

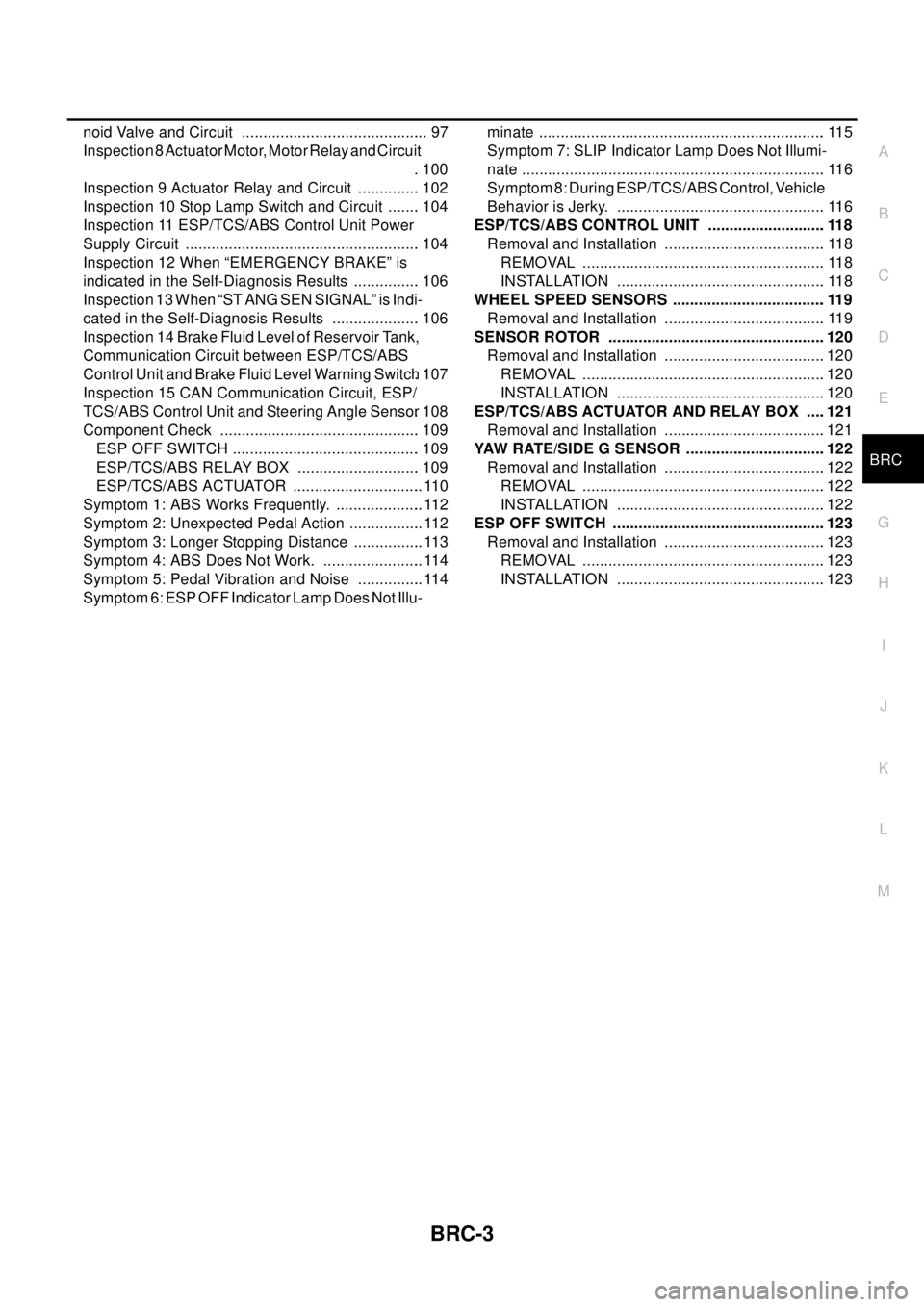

Page 871 of 3066

BRC-3

C

D

E

G

H

I

J

K

L

MA

B

BRC noid Valve and Circuit ............................................ 97

Inspection 8 Actuator Motor, Motor Relay and Circuit

. 100

Inspection 9 Actuator Relay and Circuit ............... 102

Inspection 10 Stop Lamp Switch and Circuit ........ 104

Inspection 11 ESP/TCS/ABS Control Unit Power

Supply Circuit ....................................................... 104

Inspection 12 When “EMERGENCY BRAKE” is

indicated in the Self-Diagnosis Results ................ 106

Inspection 13 When “ST ANG SEN SIGNAL” is Indi-

cated in the Self-Diagnosis Results ..................... 106

Inspection 14 Brake Fluid Level of Reservoir Tank,

Communication Circuit between ESP/TCS/ABS

Control Unit and Brake Fluid Level Warning Switch. 107

Inspection 15 CAN Communication Circuit, ESP/

TCS/ABS Control Unit and Steering Angle Sensor. 108

Component Check ............................................... 109

ESP OFF SWITCH ............................................ 109

ESP/TCS/ABS RELAY BOX ............................. 109

ESP/TCS/ABS ACTUATOR ............................... 110

Symptom 1: ABS Works Frequently. ..................... 112

Symptom 2: Unexpected Pedal Action .................. 112

Symptom 3: Longer Stopping Distance ................. 113

Symptom 4: ABS Does Not Work. ........................ 114

Symptom 5: Pedal Vibration and Noise ................ 114

Symptom 6: ESP OFF Indicator Lamp Does Not Illu-minate ...................................................................115

Symptom 7: SLIP Indicator Lamp Does Not Illumi-

nate .......................................................................116

Symptom 8: During ESP/TCS/ABS Control, Vehicle

Behavior is Jerky. .................................................116

ESP/TCS/ABS CONTROL UNIT ............................118

Removal and Installation ......................................118

REMOVAL .........................................................118

INSTALLATION .................................................118

WHEEL SPEED SENSORS ....................................119

Removal and Installation ......................................119

SENSOR ROTOR ...................................................120

Removal and Installation ......................................120

REMOVAL .........................................................120

INSTALLATION .................................................120

ESP/TCS/ABS ACTUATOR AND RELAY BOX .....121

Removal and Installation ......................................121

YAW RATE/SIDE G SENSOR .................................122

Removal and Installation ......................................122

REMOVAL .........................................................122

INSTALLATION .................................................122

ESP OFF SWITCH ..................................................123

Removal and Installation ......................................123

REMOVAL .........................................................123

INSTALLATION .................................................123

Page 872 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref](/img/5/57402/w960_57402-871.png)

BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

lTo clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing and installing brake tube.

lAlways torque brake lines when installing.

lBurnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-10, "

Brake Burnishing

Procedure".

lBefore working, turn OFF ignition switch. Disconnect connectors

for ABS actuator and control module or battery terminals.

WAR NIN G:

lClean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

Precautions for brake controlEFS001B7

lIf malfunction is indicated by 4WD warning lamp and/or ABS warning lamp, collect necessary information

from customer (what symptoms are present under what conditions). Find out possible causes before start-

ing service. Besides electrical system inspection, check operation of ABS actuator.

lIf malfunction is detected, proceed to trouble diagnosis after checking tire pressure and tire wear.

lStopping distance or steering stability may be deteriorated by the following conditions. Tire size and type

are in improper combination. Brake pads are not Nissan genuine parts.

lFitting tires of different size on vehicle can be cause of longitudinal vibration. Always use tires of the same

size and brand. Exchange front and rear tires on the following conditions: Longitudinal vibration occurs in

vehicle with tires of the same size and brand. After replacement, perform trouble diagnosis. 1580|None

l4WD/ABS function may have a failure or error under following condition: There is radio, antenna, or

antenna lead-in wire (including wiring) near control module.

lIf aftermarket parts (e.g. Car stereo equipment, CD player) have been installed, check electrical har-

nesses for pinches, open, and improper wiring.

SBR686C

Page 886 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-18

[4WD/ABS]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

EFS001BF

When ABS and 4WD warning lamps illuminate, perform self-diagnosis.

Symptom Condition Check items Reference page

When igni NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-18

[4WD/ABS]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

EFS001BF

When ABS and 4WD warning lamps illuminate, perform self-diagnosis.

Symptom Condition Check items Reference page

When igni](/img/5/57402/w960_57402-885.png)

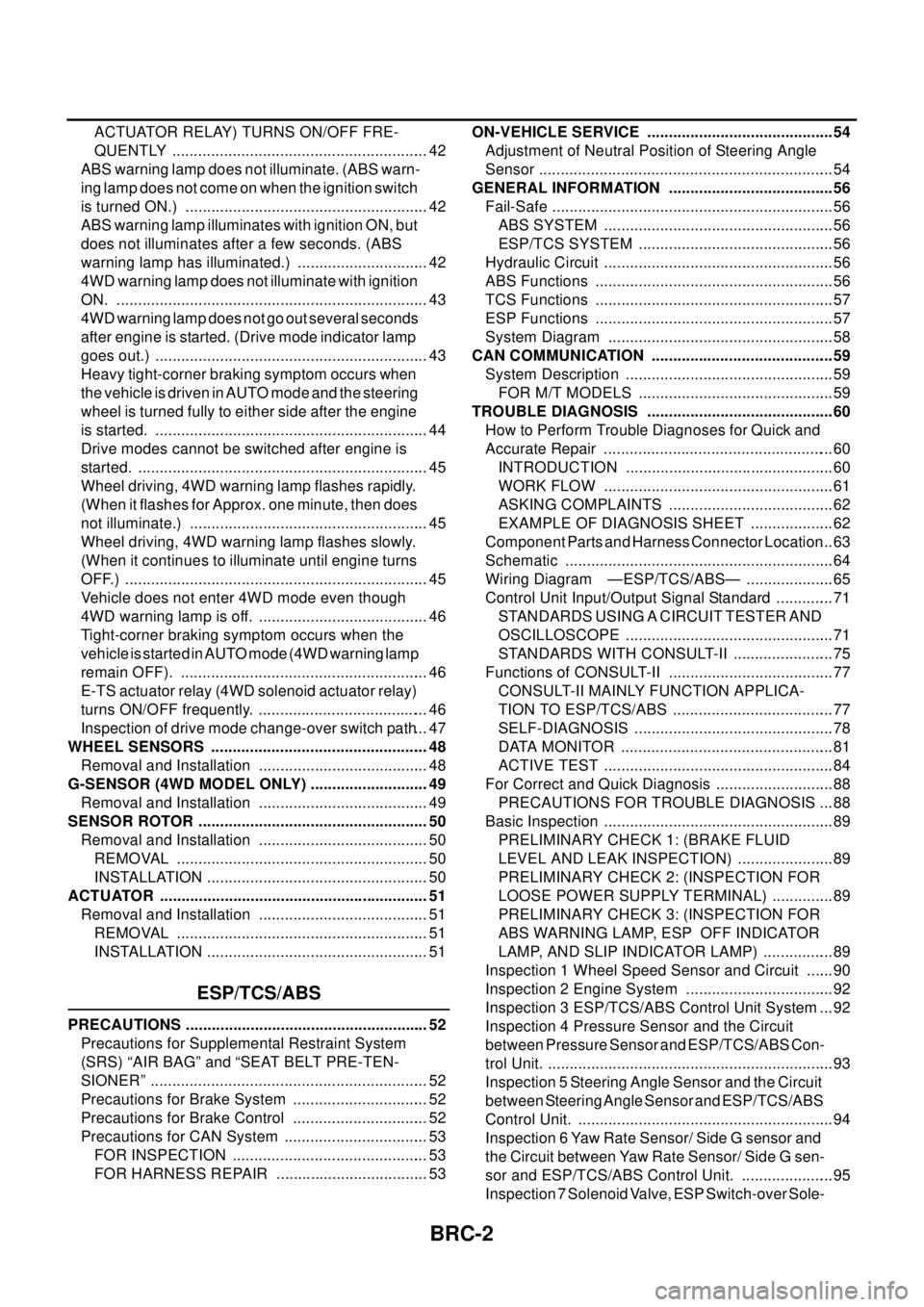

BRC-18

[4WD/ABS]

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

EFS001BF

When ABS and 4WD warning lamps illuminate, perform self-diagnosis.

Symptom Condition Check items Reference page

When ignition switch is turned ON,

drive mode indicator lamp does not illu-

minate for Approx. 1 second (drive

mode lamp check)IGN-ON

lBlown drive mode indicator lamp bulb

lBlown fuse between ignition and drive mode

indicator lamp

lOpen circuit of wiring between ignition and

drive mode indicator lampBRC-42

ABS warning lamp does not illuminate

with ignition ON. (ABS warning lamp

check)IGN-ON

lBlown ABS warning lamp bulb

lBlown fuse between ignition and ABS warning

lamp.

lOpen circuit of wiring between ignition and

ABS warning lamp.

lMalfunction in ABS systemBRC-42

ABS warning lamp illuminates with

ignition ON, but does not illuminates

after a few seconds. (ABS warning

lamp has not illuminated.)IGN-ONl4WD/ABS control unit connector discon-

nected

lMalfunction in ABS systemBRC-42

4WD warning lamp does not illuminate

with ignition ON.IGN-ON

lBlown 4WD warning lamp bulb

lBlown fuse between ignition and 4WD warn-

ing lamp

lOpen circuit in wire between ignition and 4WD

warning lamp

lOpen circuit in wire between 4WD warning

lamp and 4WD actuator relay

lDisconnected 4WD actuator relay

lOpen circuit in wire between 4WD actuator

relay and body groundBRC-43

4WD warning lamp does not go out

several seconds after engine is started.

(Drive mode indicator lamp goes out.)Engine runningl4WD/ABS control unit connector discon-

nected

lMalfunction present in 4WD systemBRC-43

Heavy tight-corner braking symptom

occurs when vehicle is driven in the fol-

lowing conditions: AUTO mode and

steering wheel is turned fully to either

sides after engine is started (Note 1,

Note 2).lEngine run-

ning

lAUTO mode

lSteering

wheel fully

turned

lOperation is not in AUTO mode (in 2WD or

LOCK mode).

lThrottle position signal error

lMechanical malfunction of electronically con-

trolled coupling

lMalfunction present in 4WD systemBRC-44

Drive modes cannot be switched after

engine is started.Engine running

lDrive mode change-over switch is discon-

nected.

lOpen circuit between drive mode change-over

switch and 4WD /ABS control unit

lOpen circuit between drive mode change-over

switch and body groundBRC-45

Vehicle running, 4WD warning lamp

flashes rapidly. (When it flashes for

Approx. One minute, then does not illu-

minate.) Rapid flashing: Two times

flashing per 1 secondEngine running

(to other than

2WD mode)Protection function was activated due to heavy

load to electronically controlled coupling. (4WD

system is not malfunctioning.)BRC-45

Page 887 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-19

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode.

This is not malfunction.

2. Heavy t NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-19

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode.

This is not malfunction.

2. Heavy t](/img/5/57402/w960_57402-886.png)

TROUBLE DIAGNOSIS

BRC-19

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode.

This is not malfunction.

2. Heavy tight-corner braking symptom occurs when vehicle is driven in the following conditions:

LOCK mode, steering wheel is turned fully to either sides, and accelerator pedal was depressed.

4WD/ABS Control Unit Input/Output Signal StandardEFS001BG

4WD/ABS CONTROL UINT CONNECTOR TERMINAL ARRANGEMENT

CAUTION:

When ignition switch is turned to ON with connectors of 4WD/ABS control unit and actuator con-

nected.

REFERENCE STANDARD TABLE

Specifications defined by circuit tester

Vehicle running, 4WD warning lamp

flashes slowly. (When it flashes for

Approx. One minute, then does not illu-

minate.)Slow flashing: One flashing

per 2 secondslEngine run-

ning

lDriving at

vehicle speed

30km/hTire size is different for front and rear of vehicle.BRC-45

Vehicle does not enter 4WD mode

even though 4WD warning lamp is off.Engine runningMechanical malfunction of electronically con-

trolled coupling (Mechanical engagement of

clutch is not possible.)BRC-46

Symptom Condition Check items Reference page

SFIA0351E

Terminal No.

Location Standard (note 1)(Note) Check

points when result

was malfunctioning +-

3.

109Power supply Ignition switch ONBattery voltage (Approx.

12V)Control unit power

supply circuit

Page 907 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-39

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

4WD WARNING LAMP DOES NOT ILLUMINATE WITH IGNITION ON

1.INSPECTION OF BLOWN FUSE BETWEEN IGNITION SWITCH AND COMBINATION METER

Check blown NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-39

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

4WD WARNING LAMP DOES NOT ILLUMINATE WITH IGNITION ON

1.INSPECTION OF BLOWN FUSE BETWEEN IGNITION SWITCH AND COMBINATION METER

Check blown](/img/5/57402/w960_57402-906.png)

TROUBLE DIAGNOSIS

BRC-39

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

4WD WARNING LAMP DOES NOT ILLUMINATE WITH IGNITION ON

1.INSPECTION OF BLOWN FUSE BETWEEN IGNITION SWITCH AND COMBINATION METER

Check blown fuse between ignition switch and combination meter.

OK or NG

OK >> GO TO 2 (No blown fuse)

NG >> Replace the fuse and perform the inspection again.

2.COMBINATION METER POWER SUPPLY CIRCUIT INSPECTION

1. Disconnect combination meter connector.

2. Check voltage between the combination meter harness connector M46 terminal No. LHD models: 46 (W/

L) RHD models: 59 (W/L) and body ground.

OK or NG

OK >> Malfunctioning combination meter.

NG >> Check fuse 10A [#11] to combination meter harness and connector.

4WD WARNING LAMP DOES NOT GO OUT SEVERAL SECONDS AFTER ENGINE

STARTED.(4WD MODE INDICATOR LAMP GOES OUT)

1.PERFORM SELF-DIAGNOSIS

Using CONSULT-II perform self-diagnosis.

OK or NG

OK >> No malfunction detected. Perform inspection again.

NG >>

lDetermine the location of the malfunction according to the result of Self-diagnosis using CON-

SULT-II. (Malfunction is present in the 4WD system.)

lCONSULT-II does not display 4WD system-related trouble codes. GO TO 2.

2.4WD CONTROL UNIT CONNECTOR CONNECTION INSPECTION

lCheck 4WD/ABS control unit connector for proper connection.

OK or NG

OK >> Reconnect the 4WD/ABS control unit connector properly and perform inspection again.

NG >> Repair or replace the connector.

HEAVY TIGHT-CORNER BRAKING SYMPTOM OCCURS WHEN THE VEHICLE IS DRIVEN IN

AUTO MODE AND THE STEERING WHEEL IS TURNED FULLY TO EITHER SIDE AFTER THE

ENGINE IS STARTED

1.PERFORM SELF-DIAGNOSIS.

Using CONSULT-II perform self-diagnosis.

OK or NG

OK >> GO TO 2. (No self-diagnosis malfunction indicated.)

NG >> Determine the location of the malfunction according to the result of Self-diagnosis using CON-

SULT-II. (Malfunction is present in the 4WD system.)

Page 912 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-44

[4WD/ABS]

TROUBLE DIAGNOSIS

2.4WD/ABS CONTROL UNIT CONNECTOR CONNECTION INSPECTION

lRemove glove box on the passenger side and check 4WD/ABS control unit connector for proper connec-

tion.

Is i NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-44

[4WD/ABS]

TROUBLE DIAGNOSIS

2.4WD/ABS CONTROL UNIT CONNECTOR CONNECTION INSPECTION

lRemove glove box on the passenger side and check 4WD/ABS control unit connector for proper connec-

tion.

Is i](/img/5/57402/w960_57402-911.png)

BRC-44

[4WD/ABS]

TROUBLE DIAGNOSIS

2.4WD/ABS CONTROL UNIT CONNECTOR CONNECTION INSPECTION

lRemove glove box on the passenger side and check 4WD/ABS control unit connector for proper connec-

tion.

Is inspection result OK?

YES >> 4WD/ABS control unit connector is properly connected.

NO >> Reconnect the 4WD/ABS control module connector properly and perform inspection again.

Heavy tight-corner braking symptom occurs when the vehicle is driven in AUTO

mode and the steering wheel is turned fully to either side after the engine is

started.

EFS001BT

1.USING CONSULT, PERFORM SELF-DIAGNOSIS.

Heavy tight-corner braking symptom occurs when the vehicle is driven in AUTO mode and the steering wheel

is turned fully to either side after the engine is started.

Is inspection result OK?

YES >> GO TO 2. (No self-diagnosis malfunction indicated.)

NO >> Determine the location of the malfunction according to the result of self-diagnosis using CON-

SULT. (Malfunction is present in the 4WD system.)

2.CHECK USING THE DATA MONITOR FUNCTION OF THE CONSULT.

lPerform inspection by the data monitor function of the CONSULT.

lCheck that the operation is in AUTO mode.

lMeasure voltage when the accelerator pedal is not depressed. (Accelerator pedal not depressed: Approx.

0.5V or lower)

lMeasure the current supplied to the E-TS solenoid valve. (Accelerator pedal not depressed: Approx. 0A)

Is inspection result OK?

YES >> GO TO 3. (No self-diagnosis malfunction indicated.)

NO >>

lNot in AUTO mode. GO TO 3.

lVoltage when accelerator pedal is not depressed is higher than approximately 0.5V.

lE-TS solenoid valve current when accelerator pedal is not depressed is other than 0A.

lCountermeasure: Keep the vehicle idling for approximately 15 minutes before checking again.

(Voltage when accelerator pedal is not depressed will be automatically reset to zero during this

period.)