radiator cap NISSAN X-TRAIL 2003 Electronic Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1884 of 3066

![NISSAN X-TRAIL 2003 Electronic Service Manual EC-770

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E64, F5

lHarness for open or short between cooling fan relays-2 and -3 and ECM

>> NISSAN X-TRAIL 2003 Electronic Service Manual EC-770

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E64, F5

lHarness for open or short between cooling fan relays-2 and -3 and ECM

>>](/img/5/57402/w960_57402-1883.png)

EC-770

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E64, F5

lHarness for open or short between cooling fan relays-2 and -3 and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK COOLING FAN RELAYS-2 AND -3

Refer toEC-771, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace cooling fan relays.

7.CHECK COOLING FAN MOTORS

Refer toEC-771, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace cooling fan motors.

8.CHECK INTERMITTENT INCIDENT

PerformEC-699, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Main 12 Causes of OverheatingEBS004QY

Engine Step Inspection item Equipment Condition Reference page

OFF 1

lBlocked radiator

lBlocked radiator grille

lBlocked bumper

lVisual No blocking —

2

lCoolant mixturelCoolant tester 50 - 50% coolant mixture SeeMA-17, "RECOM-

MENDED FLUIDS AND

LUBRICANTS".

3

lCoolant levellVisual Coolant up to MAX level

in reservoir tank and radi-

ator filler neckSeeMA-27, "Changing

Engine Coolant".

4

lRadiator caplPressure tester 78 - 98 kPa (0.78 - 0.98

bar, 0.8 - 1.0 kg/cm2,11-

14 psi)SeeCO-34, "

Checking

Radiator Cap".

ON*

25lCoolant leakslVisual No leaks SeeCO-30, "LEAK

CHECK".

ON*

26lThermostatlTouch the upper and

lower radiator hosesBoth hoses should be hot SeeCO-42, "THERMO-

STAT AND WATER PIP-

ING".

ON*

17lCooling fanlCONSULT-II Operating See Trouble Diagnosis for

DTC P1217,EC-713

.

OFF 8

lCombustion gas leaklColor checker chemi-

cal tester 4 Gas ana-

lyzerNegative —

Page 2257 of 3066

GI-4

PRECAUTIONS

General Precautions

EAS000FQ

lDo not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

lBefore jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before working

on the vehicle.

These operations should be done on a level surface.

lWhen removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

lBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

lIf the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

lTo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

lDispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

lDo not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel

spray and possibly a fire.

lClean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

lReplace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new

ones.

lReplace inner and outer races of tapered roller bearings and needle bearings as a set.

lArrange the disassembled parts in accordance with their assembled locations and sequence.

lDo not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

lAfter disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

SGI285

SGI231

SEF289H

SGI233

Page 2493 of 3066

MA-1

MAINTENANCE

L MAINTENANCE

CONTENTS

C

D

E

F

G

H

I

J

K

M

SECTION

A

B

MA

MAINTENANCE

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

DESCRIPTION ............................................................ 4

Pre-delivery Inspection Items ................................... 4

GENERAL MAINTENANCE ....................................... 6

General Maintenance ............................................... 6

PERIODIC MAINTENANCE ....................................... 7

Periodic Maintenance ............................................... 7

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (QR20DE PETROL ENGINE) .................. 7

CHASSIS AND BODY MAINTENANCE

(QR20DE PETROL ENGINE) ............................... 7

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD22DDTI DIESEL ENGINE) ................ 8

CHASSIS AND BODY MAINTENANCE

(YD22DDTI DIESEL ENGINE) .............................. 9

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 10

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (QR20DE PETROL ENGINE) .................11

CHASSIS AND BODY MAINTENANCE

(QR20DE PETROL ENGINE) ............................. 12

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD22DDTI DIESEL ENGINE) .............. 13

CHASSIS AND BODY MAINTENANCE

(YD22DDTI DIESEL ENGINE) ............................ 14

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 15

RECOMMENDED FLUIDS AND LUBRICANTS ...... 17

Fluids and Lubricants ............................................. 17

SAE Viscosity Number ........................................... 18

GASOLINE ENGINE ........................................... 18

DISEL ENGINE ................................................... 18

Engine Coolant Mixture Ratio ................................ 19

ENGINE MAINTENANCE (QR20DE) ....................... 20

Checking Drive Belts .............................................. 20

Changing Engine Coolant ...................................... 20

DRAINING ENGINE COOLANT ......................... 20

REFILLING ENGINE COOLANT ........................ 21

FLUSHING COOLING SYSTEM ......................... 21Checking Cooling System ...................................... 22

CHECKING COOLING SYSTEM HOSES ........... 22

CHECKING RADIATOR ...................................... 22

CHECKING RADIATOR CAP ............................. 22

CHECKING COOLING SYSTEM FOR LEAKS ... 23

Checking Fuel Lines ............................................... 23

Changing Air Cleaner Filter .................................... 23

VISCOUS PAPER TYPE ..................................... 23

Changing Engine Oil ............................................... 24

Changing Oil Filter .................................................. 24

Checking and Changing Spark Plugs ..................... 25

Checking EVAP Vapor Lines .................................. 26

ENGINE MAINTENANCE (YD22DDTI) .................... 27

Checking Drive Belts .............................................. 27

Changing Engine Coolant ....................................... 27

DRAINING ENGINE COOLANT .......................... 27

REFILLING ENGINE COOLANT ......................... 28

FLUSHING COOLING SYSTEM ......................... 29

Checking Cooling System ...................................... 29

CHECKING COOLING SYSTEM HOSES ........... 29

CHECKING RADIATOR ...................................... 29

CHECKING RADIATOR CAP .............................. 29

CHECKING COOLING SYSTEM FOR LEAKS ... 30

Checking Fuel Lines ............................................... 30

Changing Fuel Filter ............................................... 30

REMOVAL ........................................................... 30

INSTALLATION ................................................... 31

Changing Air Cleaner Filter .................................... 31

VISCCOUS PAPER TYPE .................................. 31

Changing Engine Oil ............................................... 32

Changing Oil Filter .................................................. 33

REMOVAL ........................................................... 33

INSTALLATION ................................................... 34

Draining Water ........................................................ 34

CHASSIS AND BODY MAINTENANCE ................... 35

Checking Exhaust System ...................................... 35

Checking Clutch Fluid Level and Leaks ................. 35

Checking Clutch System ........................................ 35

Checking M/T Oil .................................................... 35

Changing M/T Oil .................................................... 35

Page 2511 of 3066

RECOMMENDED FLUIDS AND LUBRICANTS

MA-19

C

D

E

F

G

H

I

J

K

MA

B

MA

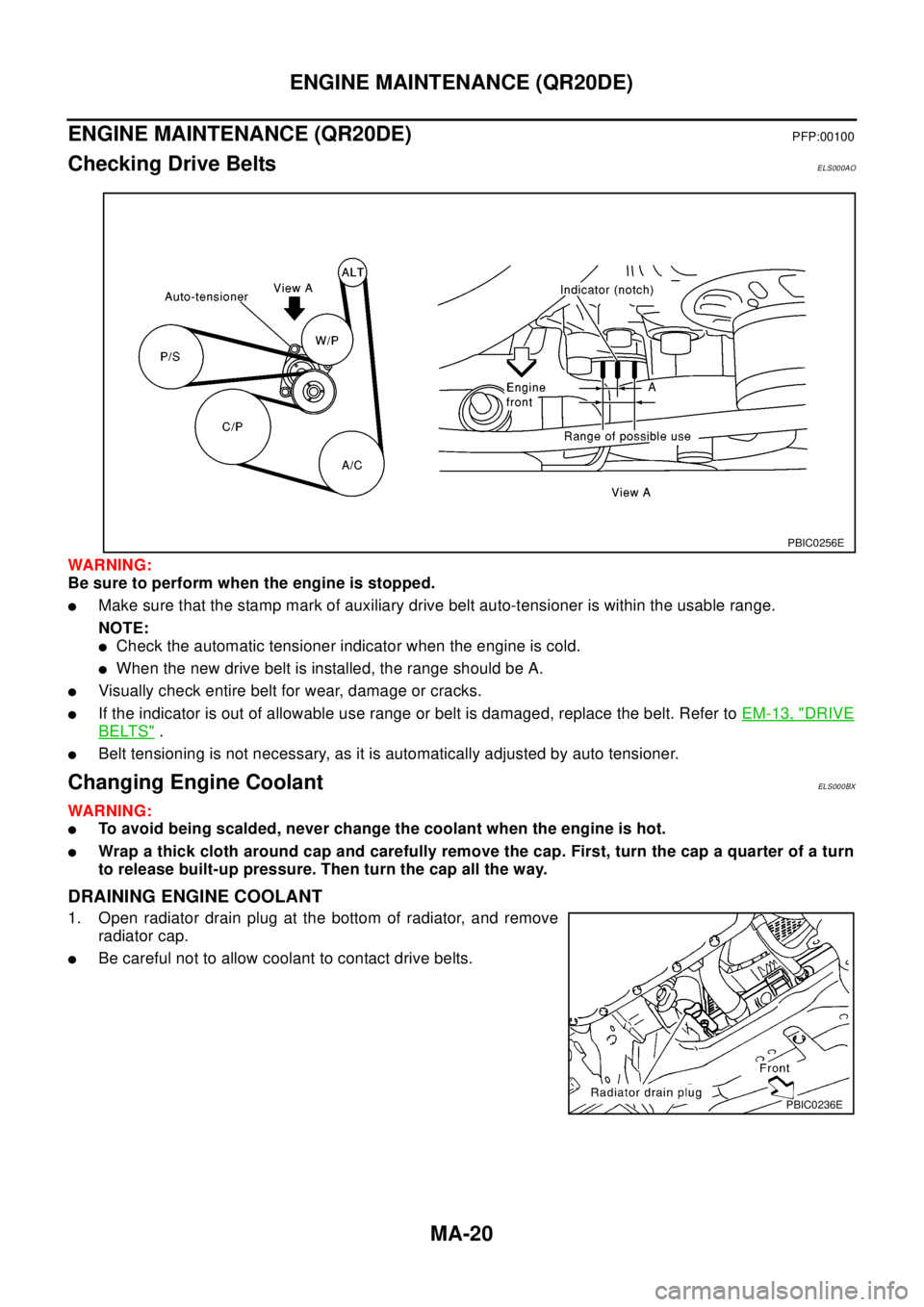

Engine Coolant Mixture RatioELS000AN

The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality engine

coolant contains the specific solutions effective for the anti-corrosion

and the anti-freeze function. Therefore, additional cooling system

additives are not necessary.

CAUTION:

lWhen adding or replacing coolant, be sure to use only Gen-

uine NISSAN Anti-freeze Coolant (L2N) or equivalent.

Because L2N is premixed type coolant.

The use of other types of engine coolant may damage your

cooling system.

lWhen checking the engine coolant mixture ratio by the coolant

hydrometer, use the chart below to correct your hydrometer reading (specific gravity) according to coolant

temperature.

Mixed coolant specific gravity

Unit: specific gravity

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the radiator. Wait until the engine and radiator cool down.

SMA089D

Engine coolant mixture

ratioCoolant temperature°C(°F)

15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

Page 2512 of 3066

MA-20

ENGINE MAINTENANCE (QR20DE)

ENGINE MAINTENANCE (QR20DE)

PFP:00100

Checking Drive BeltsELS000AO

WAR NIN G:

Be sure to perform when the engine is stopped.

lMake sure that the stamp mark of auxiliary drive belt auto-tensioner is within the usable range.

NOTE:

lCheck the automatic tensioner indicator when the engine is cold.

lWhen the new drive belt is installed, the range should be A.

lVisually check entire belt for wear, damage or cracks.

lIf the indicator is out of allowable use range or belt is damaged, replace the belt. Refer toEM-13, "DRIVE

BELTS".

lBelt tensioning is not necessary, as it is automatically adjusted by auto tensioner.

Changing Engine CoolantELS000BX

WAR NIN G:

lTo avoid being scalded, never change the coolant when the engine is hot.

lWrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove

radiator cap.

lBe careful not to allow coolant to contact drive belts.

PBIC0256E

PBIC0236E

Page 2513 of 3066

ENGINE MAINTENANCE (QR20DE)

MA-21

C

D

E

F

G

H

I

J

K

MA

B

MA

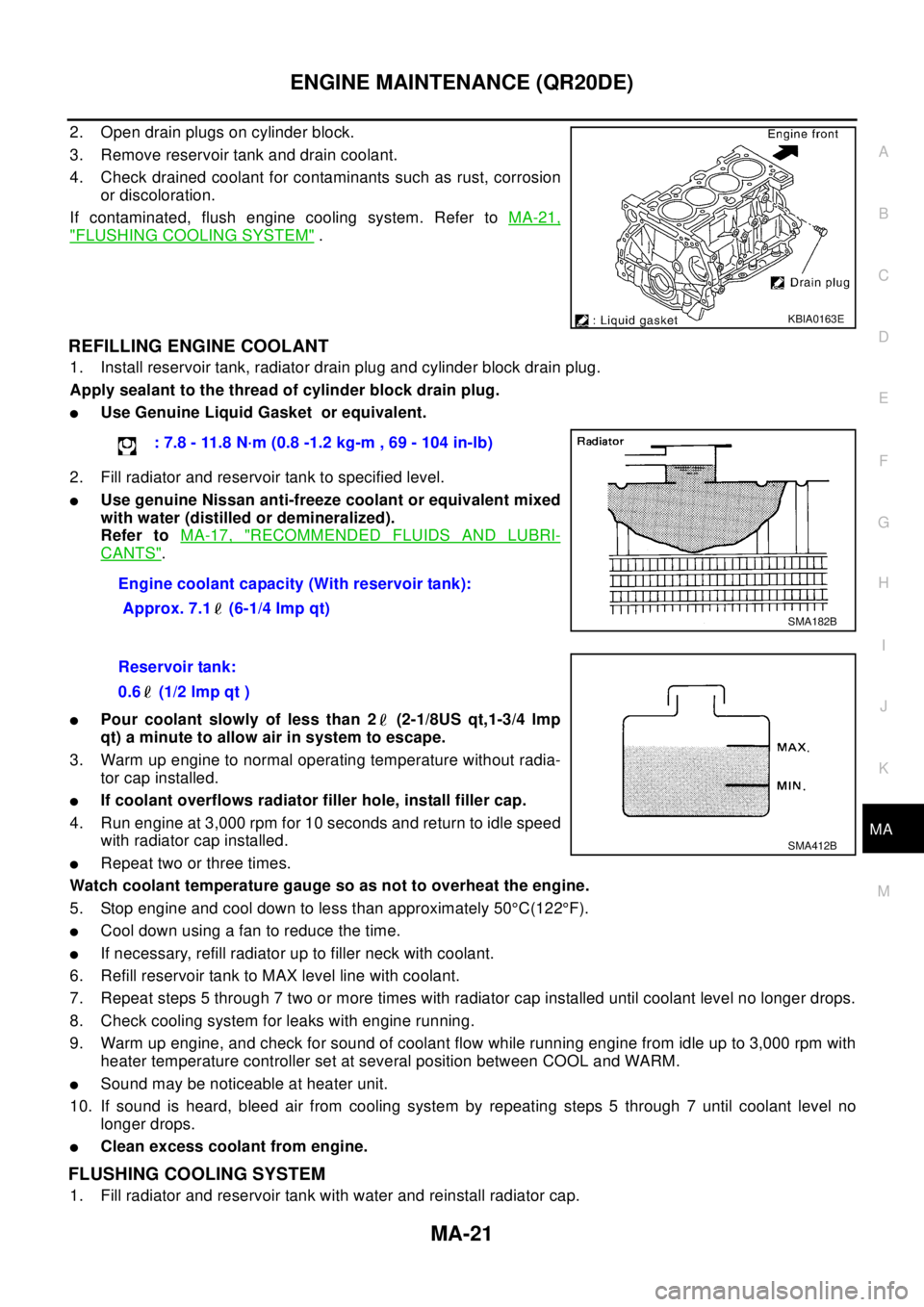

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If contaminated, flush engine cooling system. Refer toMA-21,

"FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plug.

lUse Genuine Liquid Gasket or equivalent.

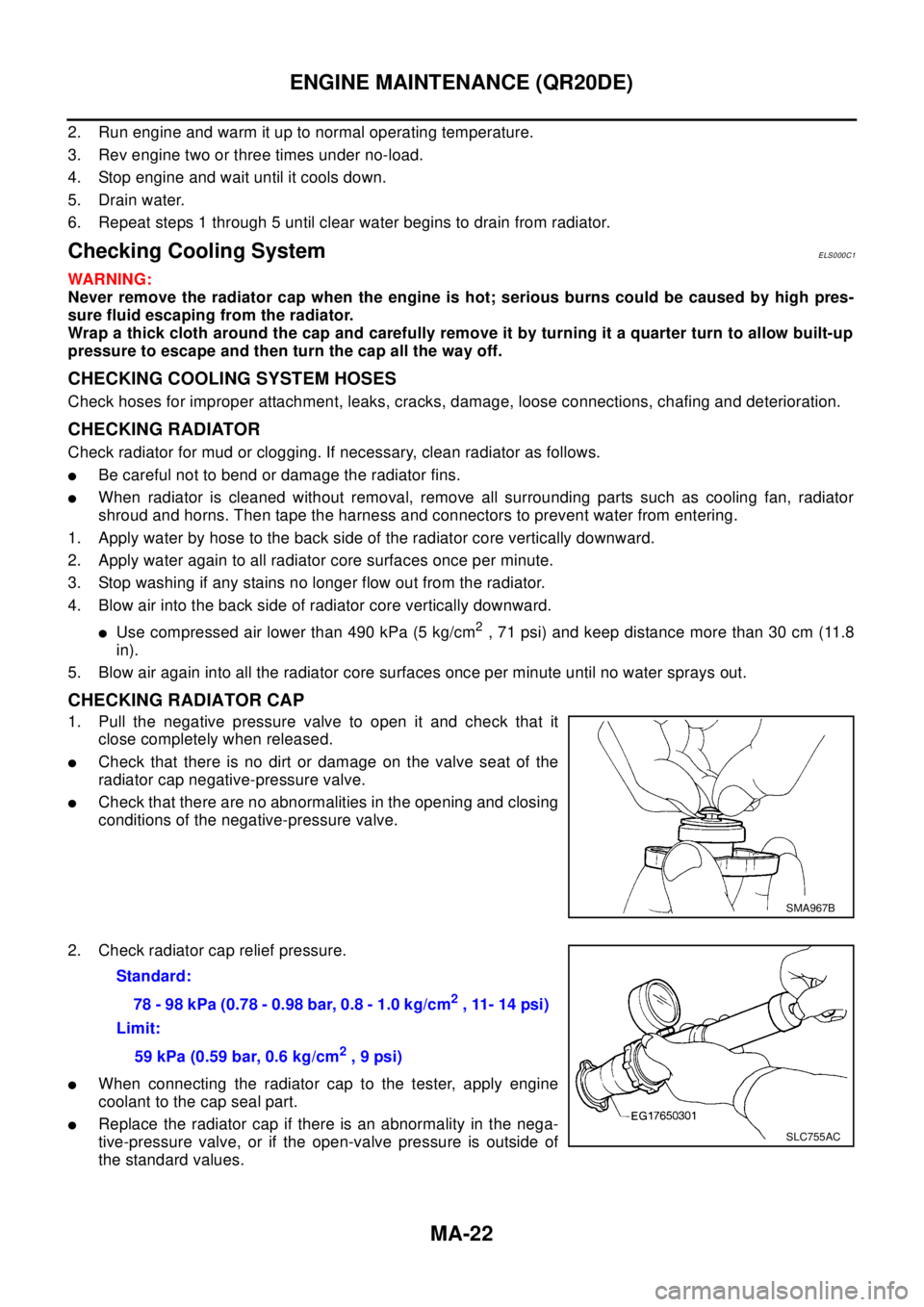

2. Fill radiator and reservoir tank to specified level.

lUse genuine Nissan anti-freeze coolant or equivalent mixed

with water (distilled or demineralized).

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS".

lPour coolant slowly of less than 2 (2-1/8US qt,1-3/4 lmp

qt) a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hole, install filler cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

lRepeat two or three times.

Watch coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with coolant.

6. Refill reservoir tank to MAX level line with coolant.

7. Repeat steps 5 through 7 two or more times with radiator cap installed until coolant level no longer drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

KBIA0163E

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank:

0.6 (1/2 lmp qt )

SMA412B

Page 2514 of 3066

MA-22

ENGINE MAINTENANCE (QR20DE)

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

Checking Cooling SystemELS000C1

WAR NIN G:

Never remove the radiator cap when the engine is hot; serious burns could be caused by high pres-

sure fluid escaping from the radiator.

Wrap a thick cloth around the cap and carefully remove it by turning it a quarter turn to allow built-up

pressure to escape and then turn the cap all the way off.

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surfaces once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downward.

lUsecompressedairlowerthan490kPa(5kg/cm2, 71 psi) and keep distance more than 30 cm (11.8

in).

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

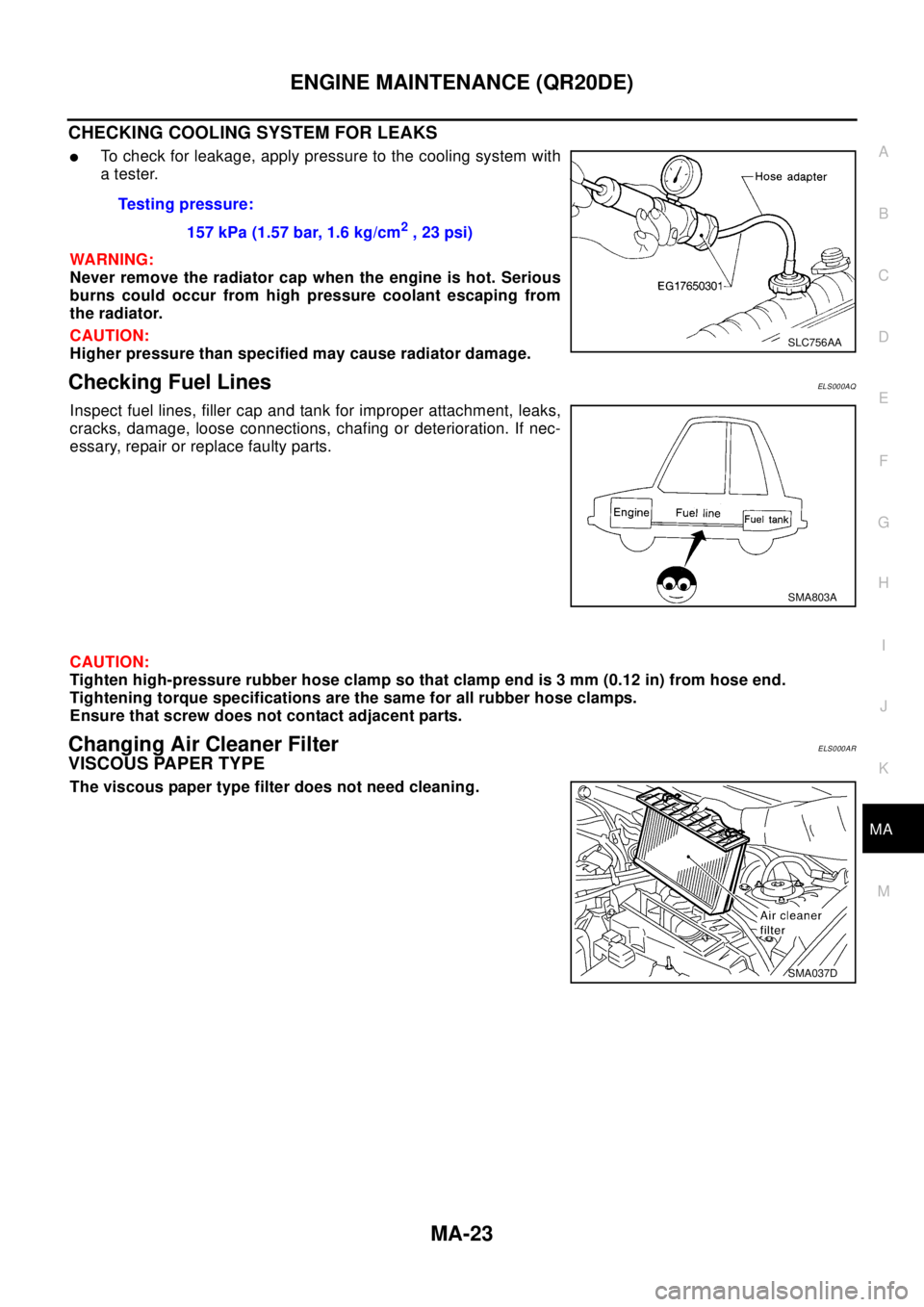

CHECKING RADIATOR CAP

1. Pull the negative pressure valve to open it and check that it

close completely when released.

lCheck that there is no dirt or damage on the valve seat of the

radiator cap negative-pressure valve.

lCheck that there are no abnormalities in the opening and closing

conditions of the negative-pressure valve.

2. Check radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply engine

coolant to the cap seal part.

lReplace the radiator cap if there is an abnormality in the nega-

tive-pressure valve, or if the open-valve pressure is outside of

the standard values.

SMA967B

Standard:

78-98kPa(0.78-0.98bar,0.8-1.0kg/cm

2, 11- 14 psi)

Limit:

59 kPa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC755AC

Page 2515 of 3066

ENGINE MAINTENANCE (QR20DE)

MA-23

C

D

E

F

G

H

I

J

K

MA

B

MA

CHECKING COOLING SYSTEM FOR LEAKS

lTo check for leakage, apply pressure to the cooling system with

atester.

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Checking Fuel LinesELS000AQ

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration. If nec-

essary, repair or replace faulty parts.

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is 3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber hose clamps.

Ensure that screw does not contact adjacent parts.

Changing Air Cleaner FilterELS000AR

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning.Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

SLC756AA

SMA803A

SMA037D

Page 2519 of 3066

ENGINE MAINTENANCE (YD22DDTI)

MA-27

C

D

E

F

G

H

I

J

K

MA

B

MA

ENGINE MAINTENANCE (YD22DDTI)PFP:00100

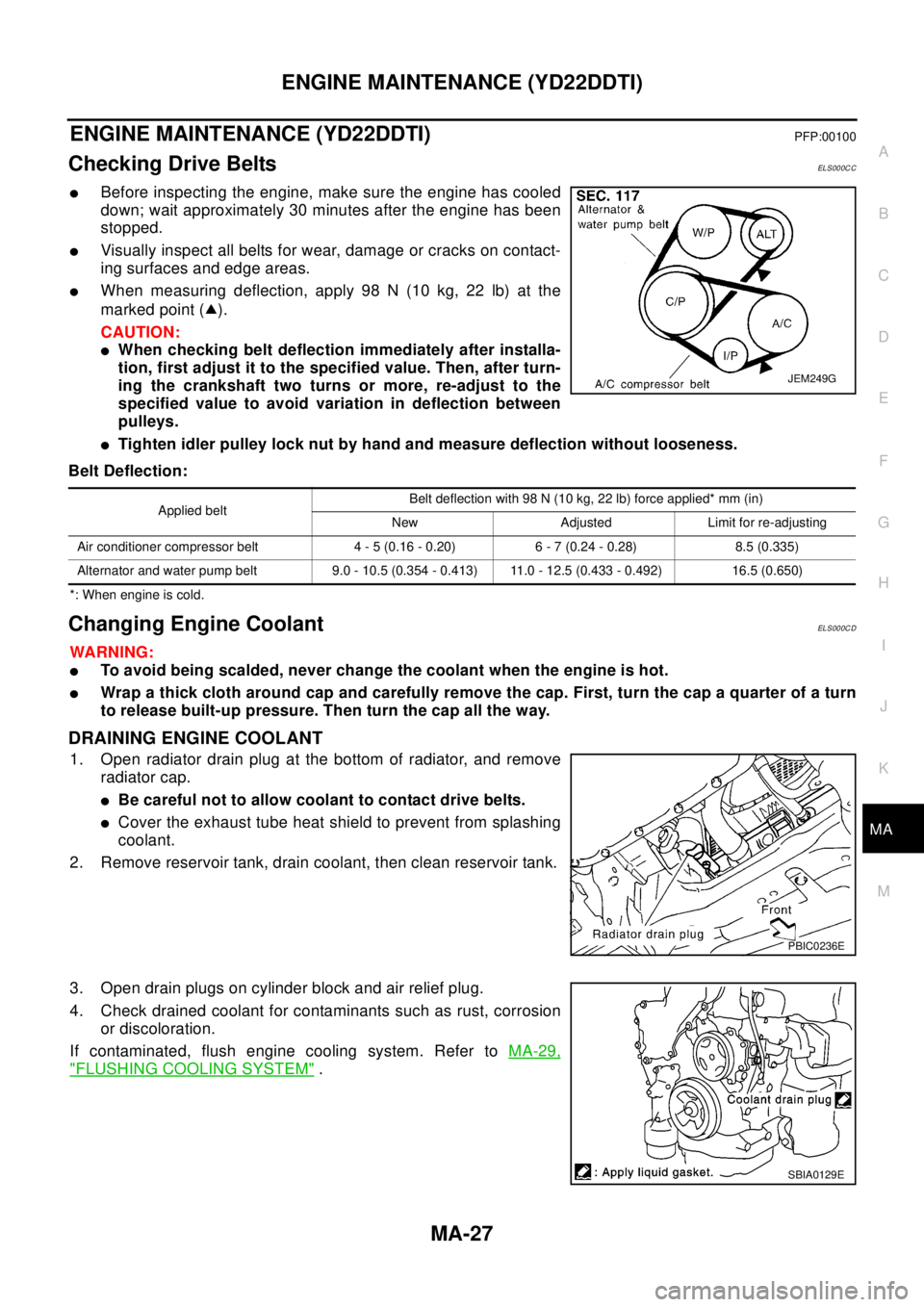

Checking Drive BeltsEL S00 0C C

lBefore inspecting the engine, make sure the engine has cooled

down; wait approximately 30 minutes after the engine has been

stopped.

lVisually inspect all belts for wear, damage or cracks on contact-

ing surfaces and edge areas.

lWhen measuring deflection, apply 98 N (10 kg, 22 lb) at the

marked point ( ).

CAUTION:

lWhen checking belt deflection immediately after installa-

tion, first adjust it to the specified value. Then, after turn-

ing the crankshaft two turns or more, re-adjust to the

specified value to avoid variation in deflection between

pulleys.

lTighten idler pulley lock nut by hand and measure deflection without looseness.

Belt Deflection:

*: When engine is cold.

Changing Engine CoolantEL S00 0C D

WA RN ING:

lTo avoid being scalded, never change the coolant when the engine is hot.

lWrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove

radiator cap.

lBe careful not to allow coolant to contact drive belts.

lCover the exhaust tube heat shield to prevent from splashing

coolant.

2. Remove reservoir tank, drain coolant, then clean reservoir tank.

3. Open drain plugs on cylinder block and air relief plug.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If contaminated, flush engine cooling system. Refer toMA-29,

"FLUSHING COOLING SYSTEM".

JEM249G

Applied beltBelt deflection with 98 N (10 kg, 22 lb) force applied* mm (in)

New Adjusted Limit for re-adjusting

Air conditioner compressor belt 4 - 5 (0.16 - 0.20) 6 - 7 (0.24 - 0.28) 8.5 (0.335)

Alternator and water pump belt 9.0 - 10.5 (0.354 - 0.413) 11.0 - 12.5 (0.433 - 0.492) 16.5 (0.650)

PBIC0236E

SBIA0129E

Page 2520 of 3066

MA-28

ENGINE MAINTENANCE (YD22DDTI)

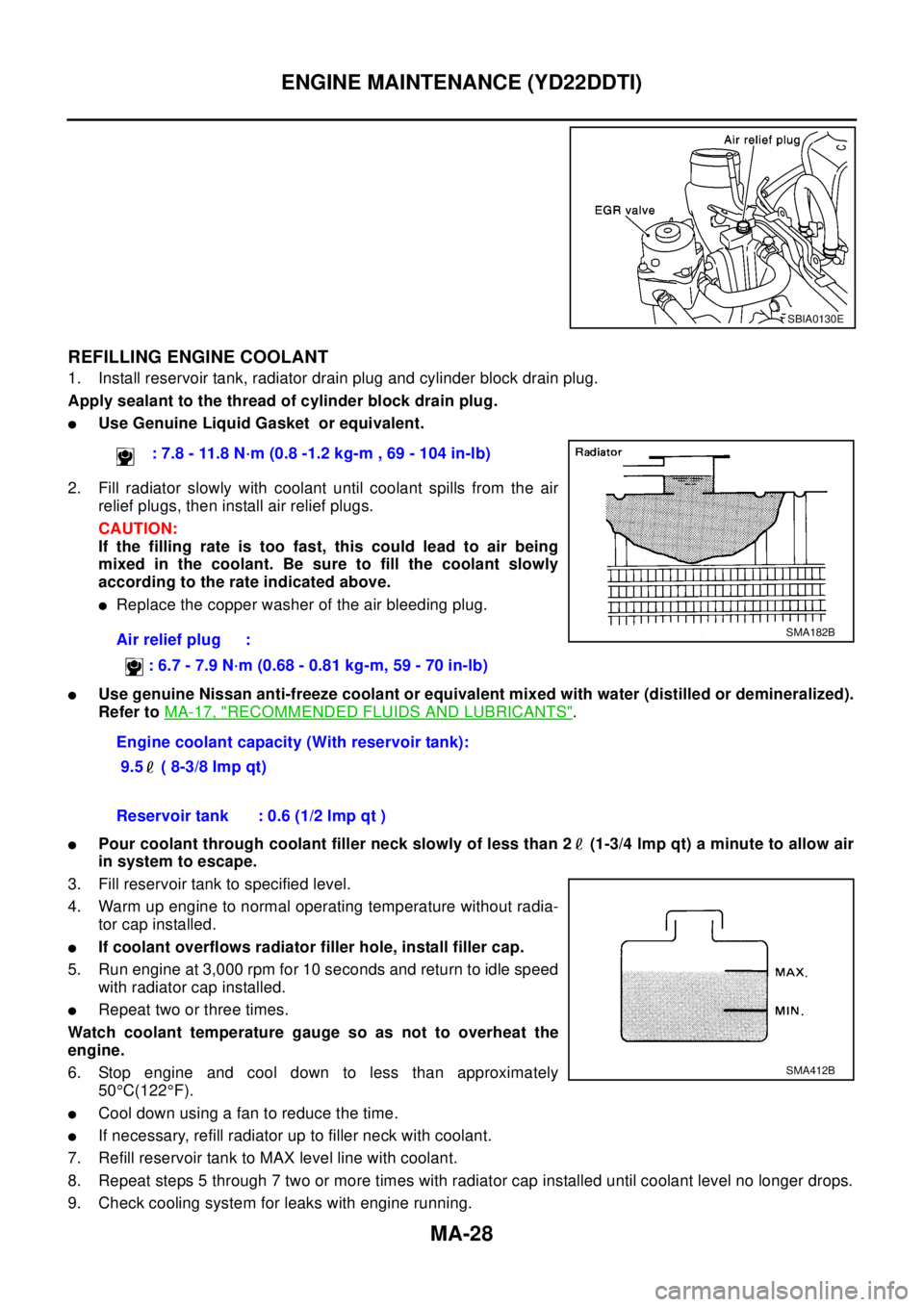

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plug.

lUse Genuine Liquid Gasket or equivalent.

2. Fill radiator slowly with coolant until coolant spills from the air

relief plugs, then install air relief plugs.

CAUTION:

If the filling rate is too fast, this could lead to air being

mixed in the coolant. Be sure to fill the coolant slowly

according to the rate indicated above.

lReplace the copper washer of the air bleeding plug.

lUse genuine Nissan anti-freeze coolant or equivalent mixed with water (distilled or demineralized).

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lPour coolant through coolant filler neck slowly of less than 2 (1-3/4 lmp qt) a minute to allow air

in system to escape.

3. Fill reservoir tank to specified level.

4. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hole, install filler cap.

5. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

lRepeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

6. Stop engine and cool down to less than approximately

50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with coolant.

7. Refill reservoir tank to MAX level line with coolant.

8. Repeat steps 5 through 7 two or more times with radiator cap installed until coolant level no longer drops.

9. Check cooling system for leaks with engine running.

SBIA0130E

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Air relief plug :

:6.7-7.9N·m(0.68-0.81kg-m,59-70in-lb)

Engine coolant capacity (With reservoir tank):

9.5 ( 8-3/8 Imp qt)

SMA182B

Reservoir tank : 0.6 (1/2 lmp qt )

SMA412B