radiator cap NISSAN X-TRAIL 2003 Electronic Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2521 of 3066

ENGINE MAINTENANCE (YD22DDTI)

MA-29

C

D

E

F

G

H

I

J

K

MA

B

MA

10. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

11. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief flag. Fill radiator and

reservoir tank with water and reinstall radiator cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

Checking Cooling SystemELS000C4

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter turn to

allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUse compressed air lower than 490 kpa (5 kg/cm2, 71psi) and keep distance more than 30 cm(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.

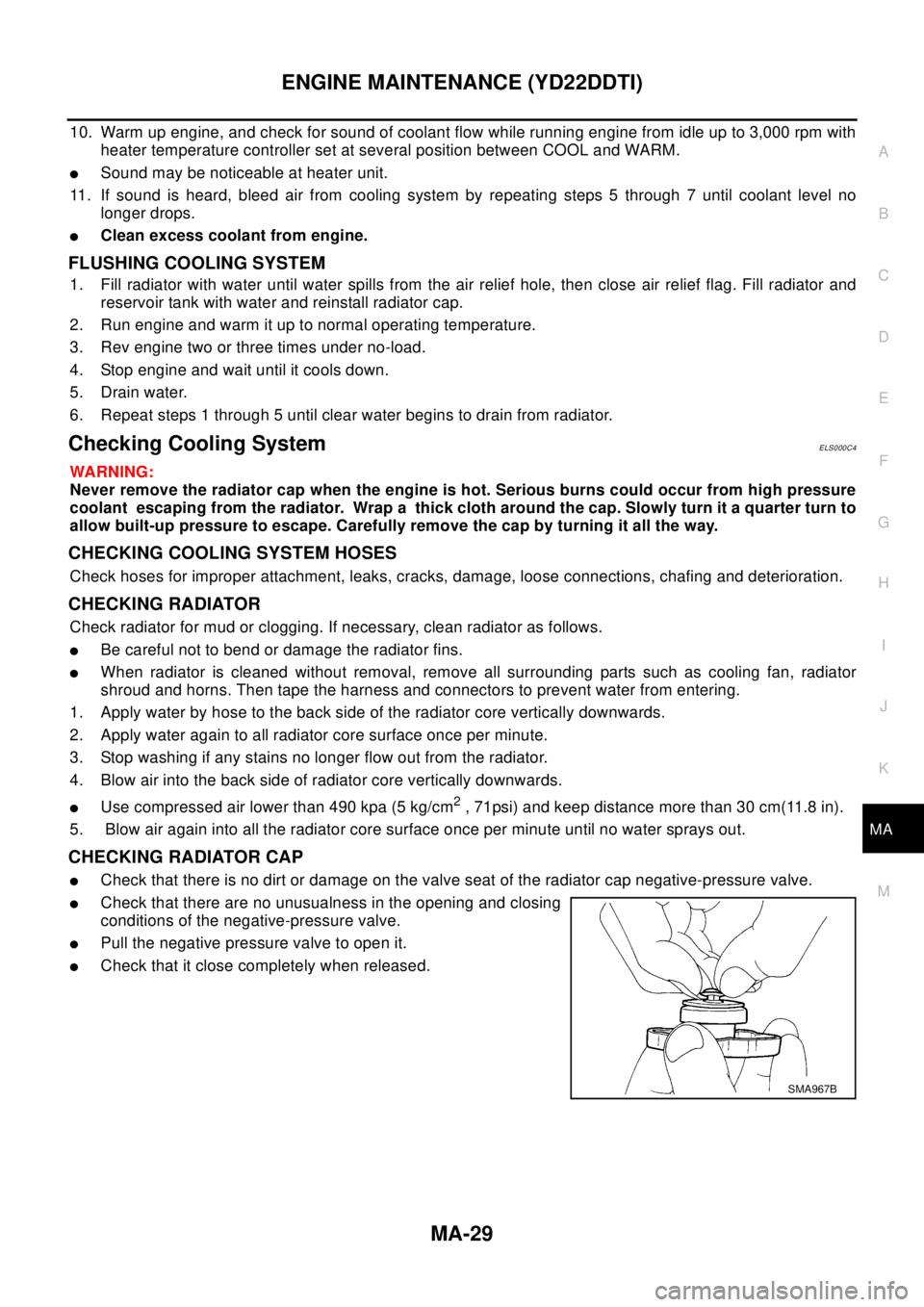

CHECKING RADIATOR CAP

lCheck that there is no dirt or damage on the valve seat of the radiator cap negative-pressure valve.

lCheck that there are no unusualness in the opening and closing

conditions of the negative-pressure valve.

lPull the negative pressure valve to open it.

lCheck that it close completely when released.

SMA967B

Page 2522 of 3066

MA-30

ENGINE MAINTENANCE (YD22DDTI)

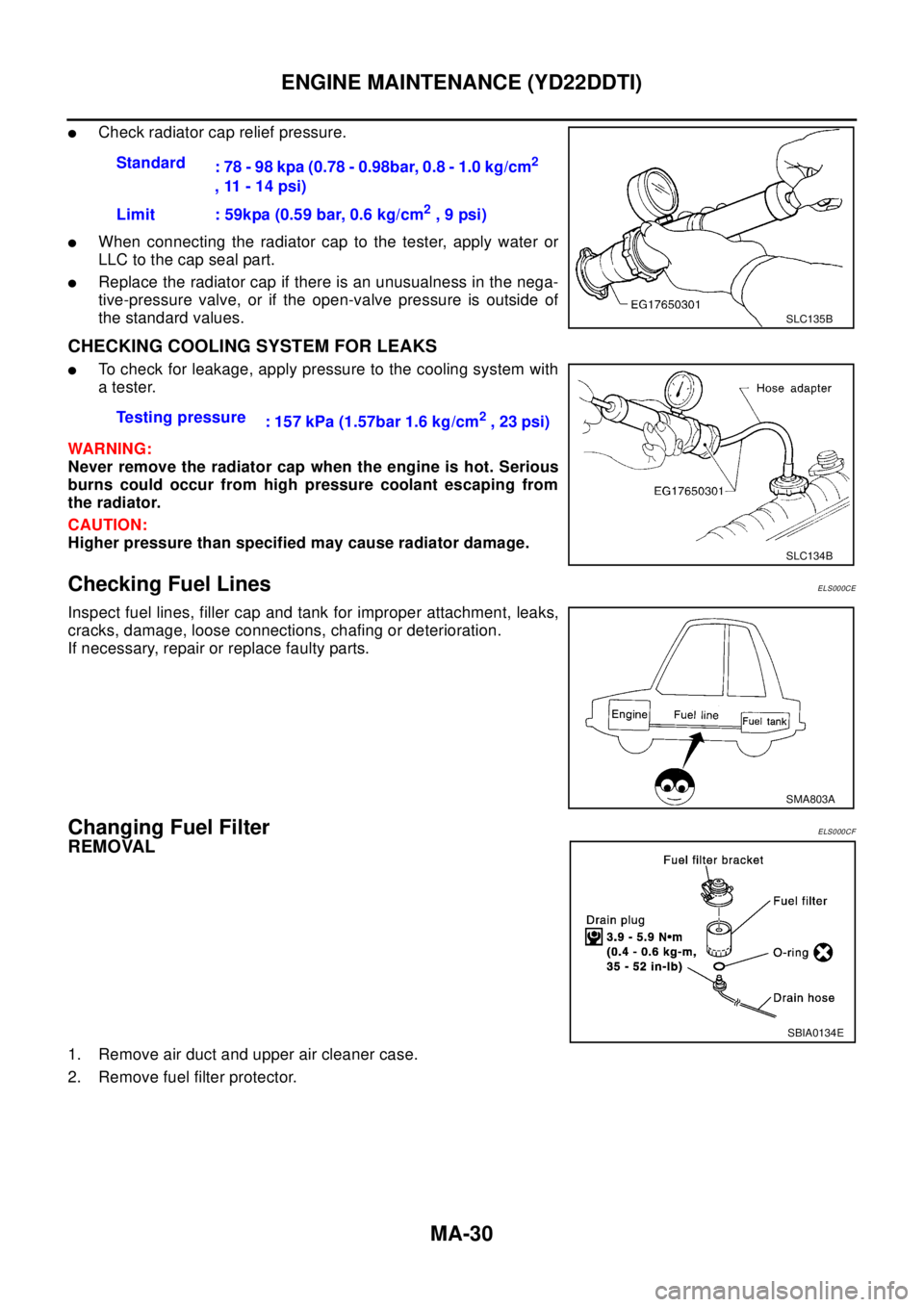

lCheck radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply water or

LLC to the cap seal part.

lReplace the radiator cap if there is an unusualness in the nega-

tive-pressure valve, or if the open-valve pressure is outside of

the standard values.

CHECKING COOLING SYSTEM FOR LEAKS

lTo check for leakage, apply pressure to the cooling system with

atester.

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Checking Fuel LinesELS000CE

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

Changing Fuel FilterELS000CF

REMOVAL

1. Remove air duct and upper air cleaner case.

2. Remove fuel filter protector.Standard

: 78 - 98 kpa (0.78 - 0.98bar, 0.8 - 1.0 kg/cm

2

,11-14psi)

Limit : 59kpa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC135B

Testing pressure

: 157 kPa (1.57bar 1.6 kg/cm2,23psi)

SLC134B

SMA803A

SBIA0134E

Page 2528 of 3066

MA-36

CHASSIS AND BODY MAINTENANCE

2. Check oil level.

CAUTION:

Do not reuse gasket.

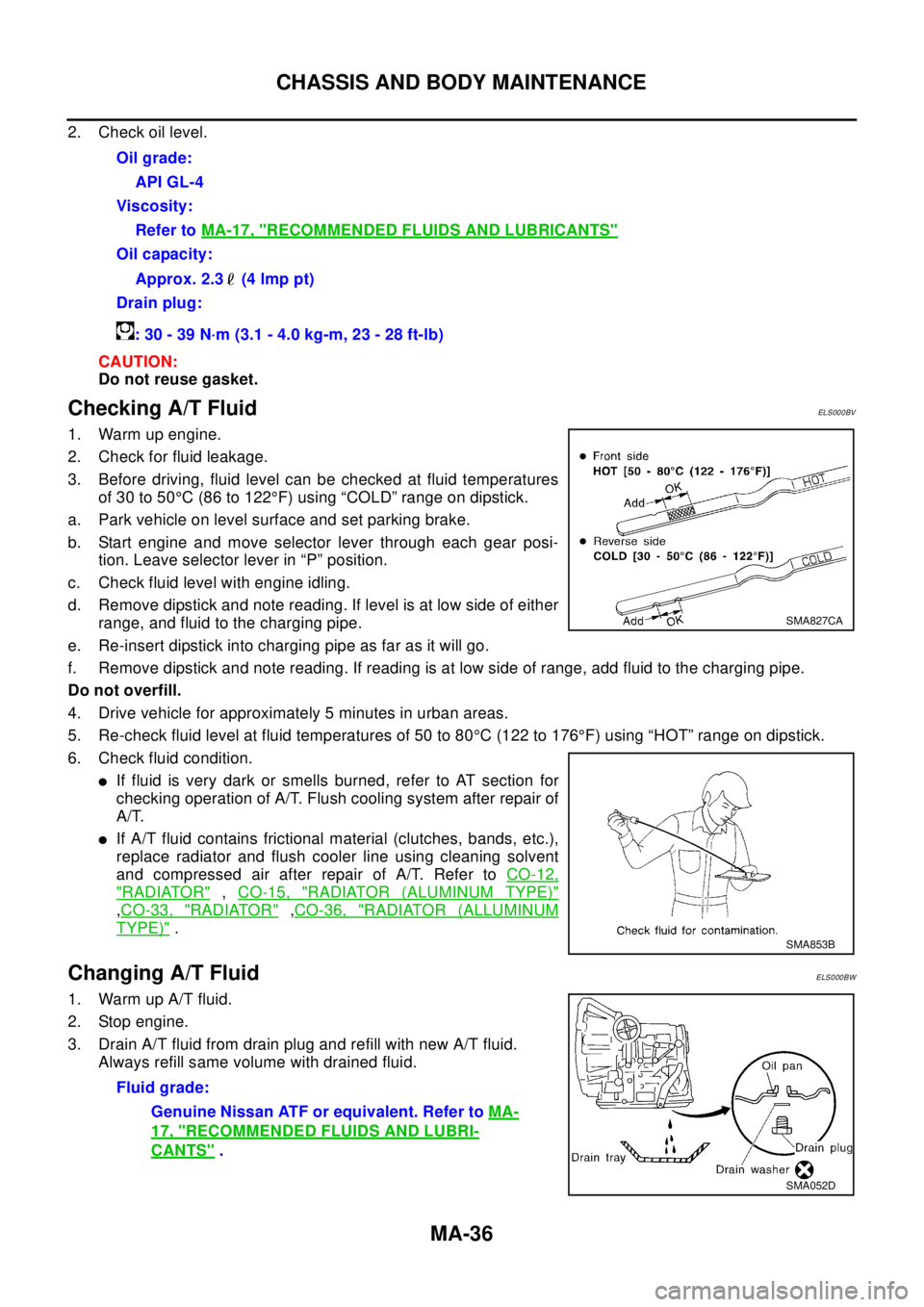

Checking A/T FluidELS000BV

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of either

range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

lIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-12,

"RADIATOR",CO-15, "RADIATOR (ALUMINUM TYPE)"

,CO-33, "RADIATOR",CO-36, "RADIATOR (ALLUMINUM

TYPE)".

Changing A/T FluidELS000BW

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.Oil grade:

API GL-4

Viscosity:

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRICANTS"

Oil capacity:

Approx. 2.3 (4 lmp pt)

Drain plug:

: 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

SMA827CA

SMA853B

Fluid grade:

Genuine Nissan ATF or equivalent. Refer toMA-

17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

SMA052D

Page 2654 of 3066

MTC-18

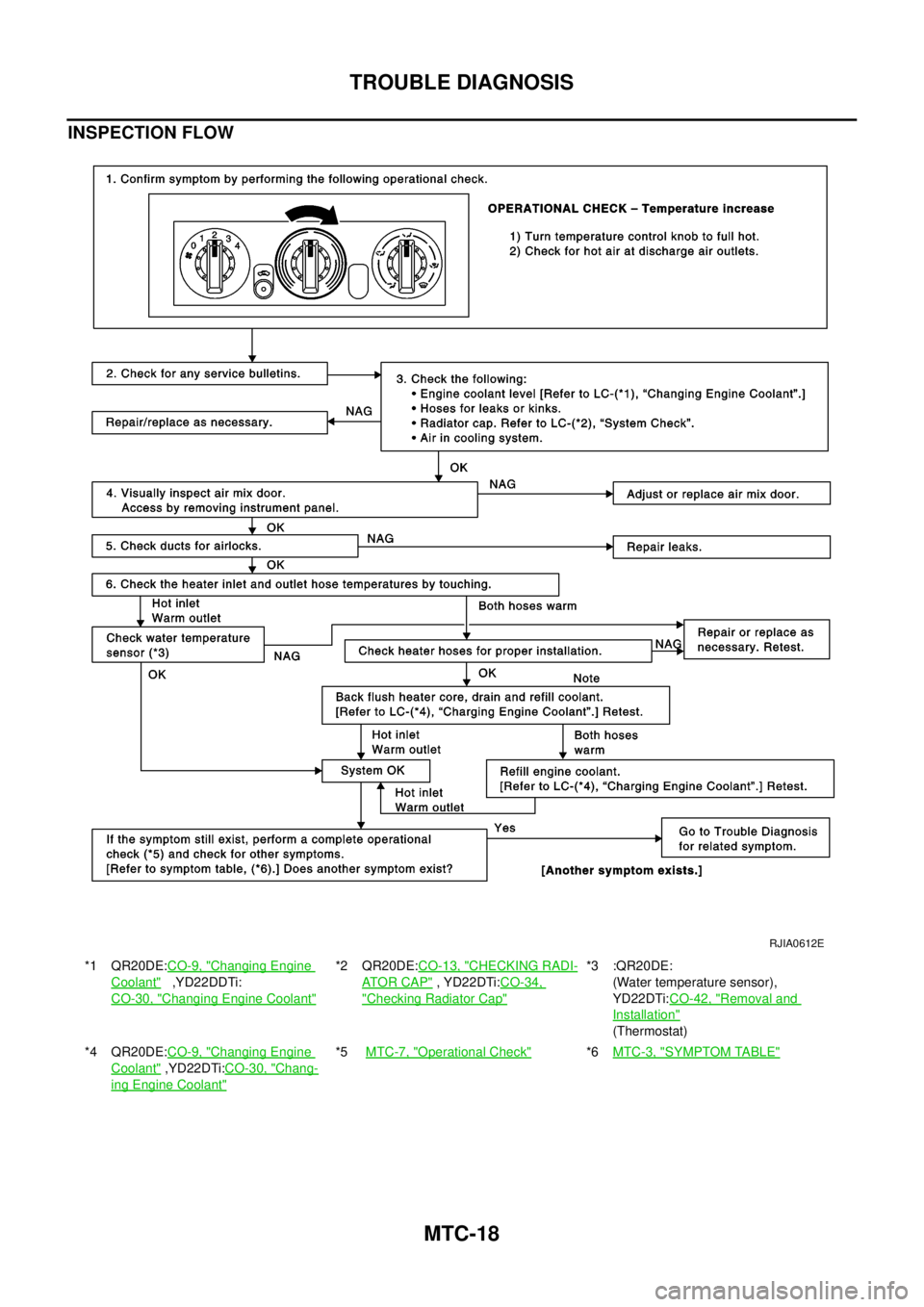

TROUBLE DIAGNOSIS

INSPECTION FLOW

*1 QR20DE:CO-9, "Changing Engine

Coolant",YD22DDTi:

CO-30, "

Changing Engine Coolant"

*2 QR20DE:CO-13, "CHECKING RADI-

AT O R C A P", YD22DTi:CO-34,

"Checking Radiator Cap"

*3 :QR20DE:

(Water temperature sensor),

YD22DTi:CO-42, "

Removal and

Installation"

(Thermostat)

*4 QR20DE:CO-9, "

Changing Engine

Coolant",YD22DTi:CO-30, "Chang-

ing Engine Coolant"

*5MTC-7, "Operational Check"*6MTC-3, "SYMPTOM TABLE"

RJIA0612E